Page 1

Refrigerators

Top-Freezer

ge.com

197D5226P003 49-60419 11-05 JR

Safety Instructions . . . . . . . . . .2–3

Operating Instructions

Automatic Icemaker . . . . . . . . . . .8

Care and Cleaning . . . . . . . . . 9, 10

Shelves . . . . . . . . . . . . . . . . . . . .5, 6

Storage Drawers . . . . . . . . . . . . .6, 7

Temperature Controls . . . . . . . . . .4

Installation Instructions

Preparing to Install

the Refrigerator . . . . . . . . . . . . . 11

Reversing the Door Swing . . 16–21

Water Line Installation . . . . . 12–16

Troubleshooting Tips

Before You Call For Service . .22, 23

Normal Operating Sounds . . . . .22

Consumer Support

Consumer Support . . . . Back Cover

Product Registration

(Canadian) . . . . . . . . . . . . . . 25, 26

Product Registration (U.S.) . 27, 28

Warranty for

Canadian Customers . . . . . . . . . 24

Warranty for U.S. Customers . . . 29

Write the model and serial

numbers here:

Model # __________________

Serial # __________________

You can find them on a label on

the upper left side of the fresh food

compartment.

Réfrigérateurs

Congélateur supérieur

Models 16, 17, 18

Manuel d’utilisation

et d’installation

Owner’s Manual and

Installation Instructions

La section française commence à la page 30

Refrigeradores

Congelador superior

Manual del propietario

e instalación

La sección en español empieza en la página 60

Page 2

2

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

Use this appliance only for its intended purpose as described in this Owner’s Manual.

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

■

■ This refrigerator must be properly installed

and located in accordance with the Installation

Instructions before it is used.

■

■ Do not allow children to climb, stand or hang

on the shelves in the refrigerator. They could

damage the refrigerator and seriously injure

themselves.

■

■ Do not touch the cold surfaces in the freezer

compartment when hands are damp or wet.

Skin may stick to these extremely cold surfaces.

■

■ Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

■

■ In refrigerators with automatic icemakers,

avoid contact with the moving parts of the

ejector mechanism, or with the heating element

located on the bottom of the icemaker. Do not

place fingers or hands on the automatic

icemaking mechanism while the refrigerator is

plugged in.

■

■ Keep fingers out of the “pinch point” areas;

clearances between the doors and between

the doors and cabinet are necessarily small.

Be careful closing doors when children are

in the area.

■

■ Unplug the refrigerator before cleaning and

making repairs.

NOTE: We strongly recommend that any servicing be

performed by a qualified individual.

■

■ Turning the control to the 0 position does

not remove power to the light circuit.

■

■ Do not refreeze frozen foods which have

thawed completely.

DANGER! RISK OF CHILD ENTRAPMENT

PROPER DISPOSAL OF THE REFRIGERATOR

Child entrapment and suffocation are not

problems of the past. Junked or abandoned

refrigerators are still dangerous…even if they will

sit for “just a few days.” If you are getting rid of

your old refrigerator, please follow the instructions

below to help prevent accidents.

Before You Throw Away Your Old

Refrigerator or Freezer:

■ Take off the doors.

■ Leave the shelves in place so that children may

not easily climb inside.

Refrigerants

All refrigeration products contain refrigerants,

which under federal law must be removed prior

to product disposal. If you are getting rid of an

old refrigeration product, check with the company

handling the disposal about what to do.

Page 3

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

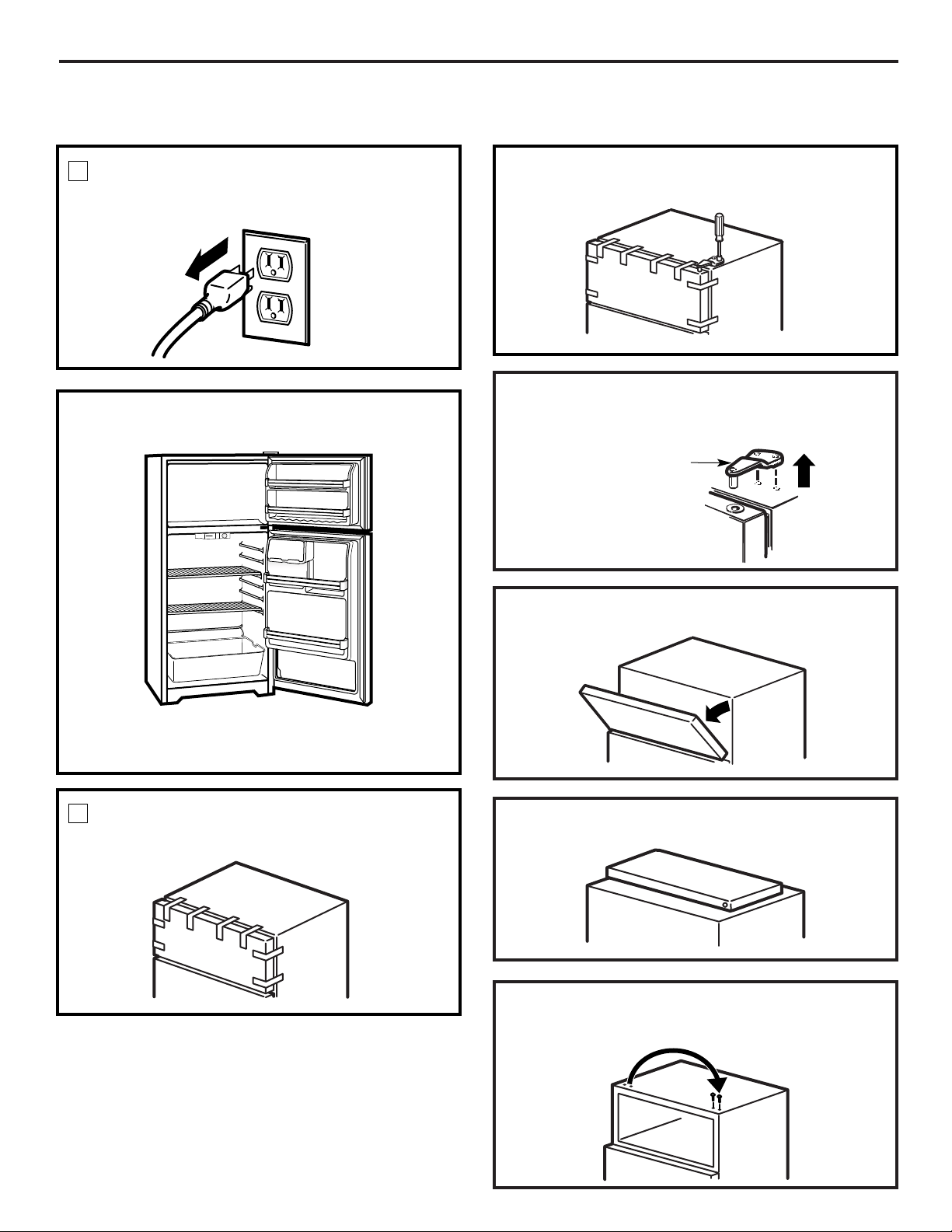

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped with

a 3-prong (grounding) plug which mates with a

standard 3-prong (grounding) wall outlet to

minimize the possibility of electric shock hazard

from this appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall outlet is

encountered, it is your personal responsibility and

obligation to have it replaced with a properly

grounded 3-prong wall outlet.

The refrigerator should always be plugged into its

own individual electrical outlet which has a voltage

rating that matches the rating plate.

This provides the best performance and also

prevents overloading house wiring circuits which

could cause a fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the

power cord. Always grip plug firmly and pull

straight out from the outlet.

Repair or replace immediately all power cords that

have become frayed or otherwise damaged. Do not

use a cord that shows cracks or abrasion damage

along its length or at either end.

When moving the refrigerator away from the

wall, be careful not to roll over or damage the

power cord.

3

Consumer Support

Troubleshooting TipsOperating InstructionsSafety Instructions Installation Instructions

USE OF EXTENSION CORDS

Because of potential safety hazards under certain conditions, we strongly recommend against

the use of an extension cord.

However, if you must use an extension cord, it is absolutely necessary that it be a UL-listed (in the United

States) or a CSA-listed (in Canada), 3-wire grounding type appliance extension cord having a grounding

type plug and outlet and that the electrical rating of the cord be 15 amperes (minimum) and 120 volts.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

Page 4

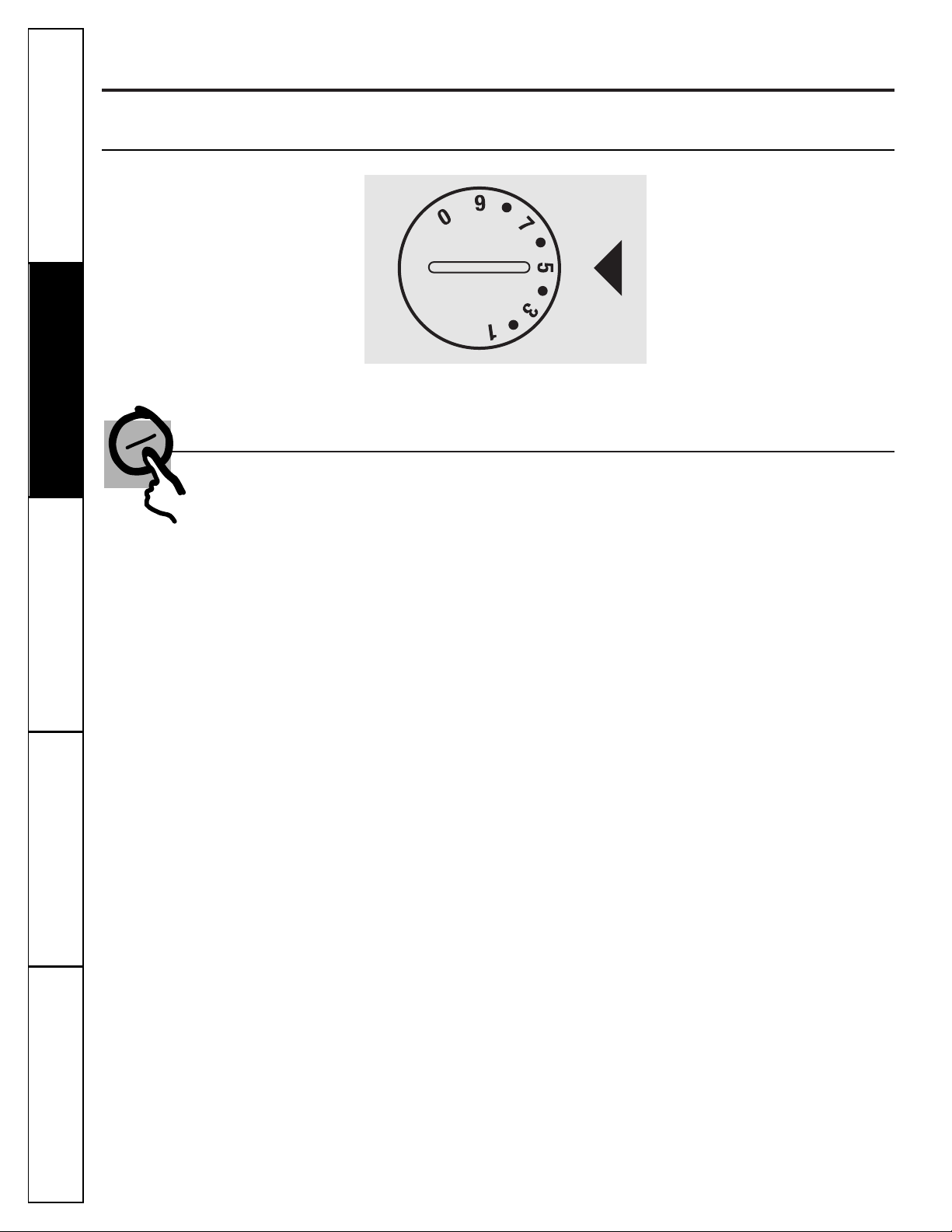

About the temperature control dial.

Control Settings

Temperature Control Dial

The temperature control dial has nine settings plus 0. 1 is the warmest. 9 is the coldest.

At first, set the dial at 5.

After using the refrigerator, adjust the dial if necessary.

Insert a coin into the slot in the middle of the dial and you can turn the dial to the setting

that is best suited to your needs.

Allow 24 hours for the refrigerator to get cold.

Turning the dial to 0 stops cooling in both compartments—fresh food and freezer. It does not shut off power to

the refrigerator.

4

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Troubleshooting Tips

Installation Instructions Safety InstructionsOperating Instructions

Page 5

Consumer Support

Troubleshooting TipsOperating InstructionsSafety Instructions Installation Instructions

5

About the fresh food compartment shelves.

Shelf supports at various levels allow you to custom-space your shelves. Not all features are on all models.

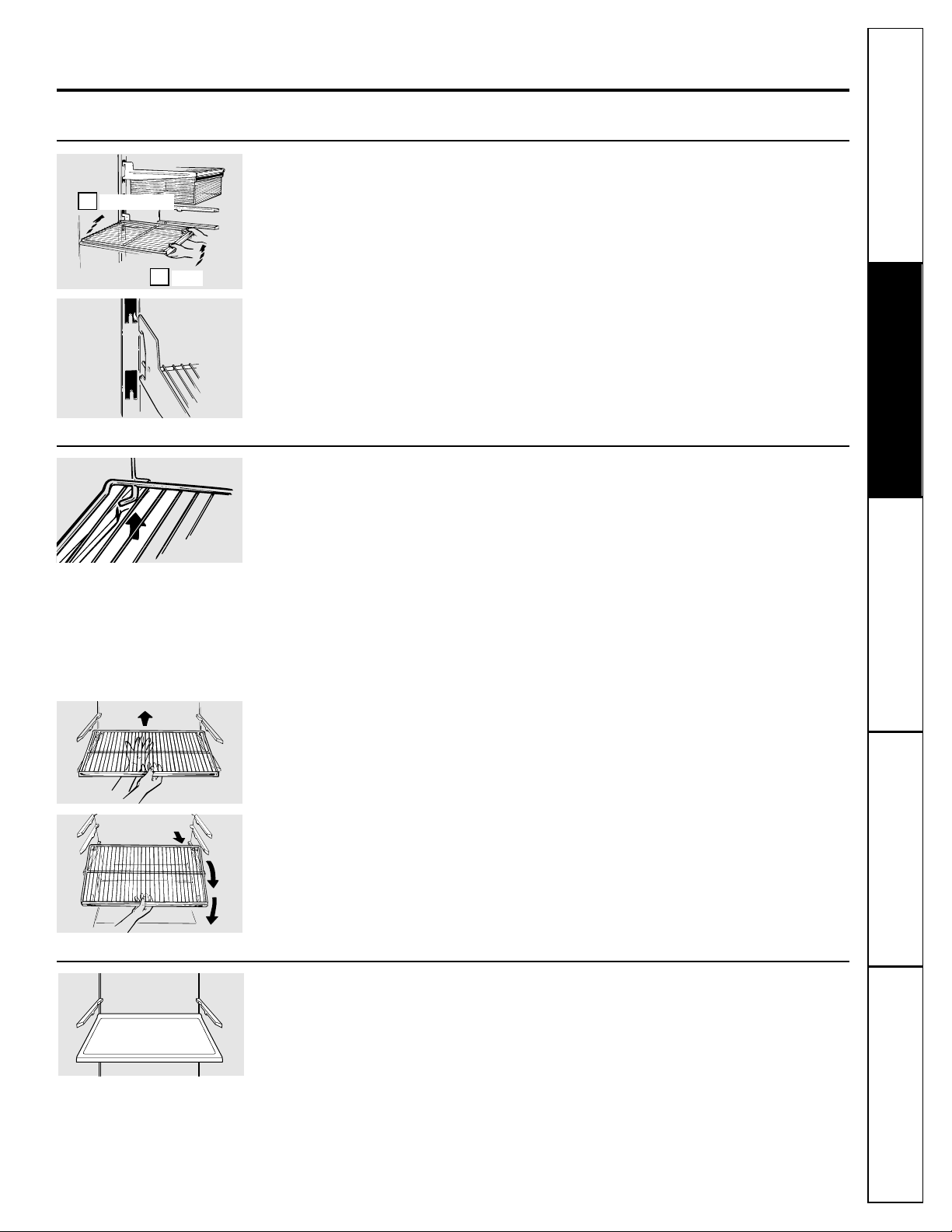

Full-Width Shelves

Some models have a steel wire sliding

shelf, a stationary tempered glass shelf or

two steel wire stationary shelves. These

shelves can be moved to another place

in the fresh food compartment.

The full-width sliding shelf has stop-locks.

When placed correctly on the shelf

supports, the shelf will stop before coming

completely out of the refrigerator and will

not tilt when you place food on it or

remove food from it.

To remove the full-width shelves, lift the

rear of the shelf and pull forward.

To remove a full-width shelf when the fresh

food compartment door cannot be opened

fully, lift the rear of the shelf, pull

forward and down, tilt the shelf and

take it out.

Half-Width Shelves

One end of the shelf rests on a molded

side-wall support; a bracket on the other

end hooks into a track on the rear

cabinet wall.

To remove, lift the shelf up at front, then

off the support and out of the track.

To replace, select desired shelf height.

With shelf front raised slightly, hook the

bracket’s top lug into the track, then

lower the shelf onto the support.

NOTE: The shelf to the right of the track is

designed to hook into the right-hand slot;

the shelf to the left is designed to hook

into the left-hand slot.

2

Lift up and out

1

Tilt up

Spillproof Shelves (on some models)

Spillproof shelves have special edges

to help prevent spills from dripping

to lower shelves. To remove or replace

the shelves, see the above instructions.

Page 6

About the freezer compartment shelves.

Some models have an ice-tray shelf and some have a full-width step shelf.

Ice-Tray Shelf

To remove the ice-tray shelf, lift the left

side of the shelf off its supports, then

pull the shelf to the left to free it of the

plug supports. Pull the shelf to the right

to free the pins from the holes in the

cabinet wall.

Step Shelf

To remove the step shelf:

Lift left side of shelf slightly.

Move shelf to the left to free its right

ends from holes in the cabinet wall.

Lower right side of shelf, move shelf to

the right and take it out.

To replace the step shelf:

With shelf tilted as shown, fit left ends

of shelf into holes in cabinet wall.

Lift left side of shelf slightly, swing shelf

up, fit right ends of shelf into holes in

cabinet wall, and lower shelf into place.

2

1

3

2

1

Plug Supports

About the storage drawers.

Not all features are on all models.

Fruit and Vegetable Drawers

Excess water that may accumulate in the

bottom of the drawers should be emptied

and the drawers wiped dry.

Snacks Drawer

The snacks drawer can be moved to the

most useful location for your family’s

needs.

6

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Page 7

7

Consumer Support

Troubleshooting TipsOperating InstructionsSafety Instructions Installation Instructions

About storage drawer and cover removal.

Not all features are on all models.

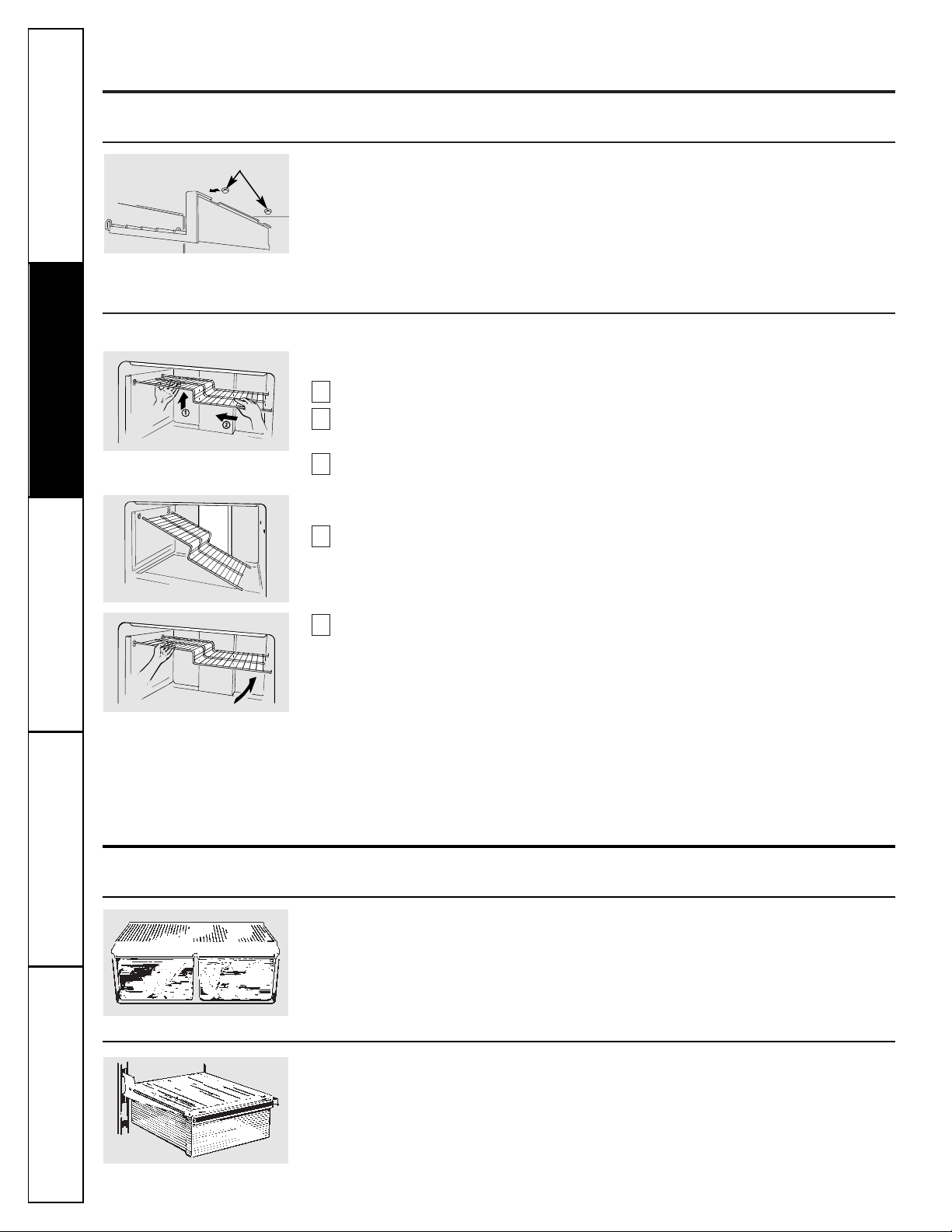

Drawer and Cover Removal

Drawers can be removed easily by grasping

the sides and lifting up slightly while

pulling drawers past the stop location.

Full-Width Drawer with Plastic Cover

To remove the cover, lift it off its supports,

pull it forward, tilt it and take it out.

Twin Drawers with Glass Cover

To remove:

Remove the drawers.

Reach in, push the front of glass

cover up, and at the same time,

pull it forward as far as it will come.

Tilt it and take it out. Avoid cleaning the

cold glass cover with hot water because

the extreme temperature difference may

cause it to break.

Remove the drawer frame. (Always

remove the glass cover before you

take out the drawer frame.)

Lift the frame off the supports at each

side and back, pull it forward, tilt it and

take it out.

To replace:

Lower the frame until it rests on the

supports at each side and back.

Replace the glass cover, pushing its

rear edge firmly into the rear frame

channel and gently lowering the front

into place.

Replace the drawers.

3

2

1

3

2

1

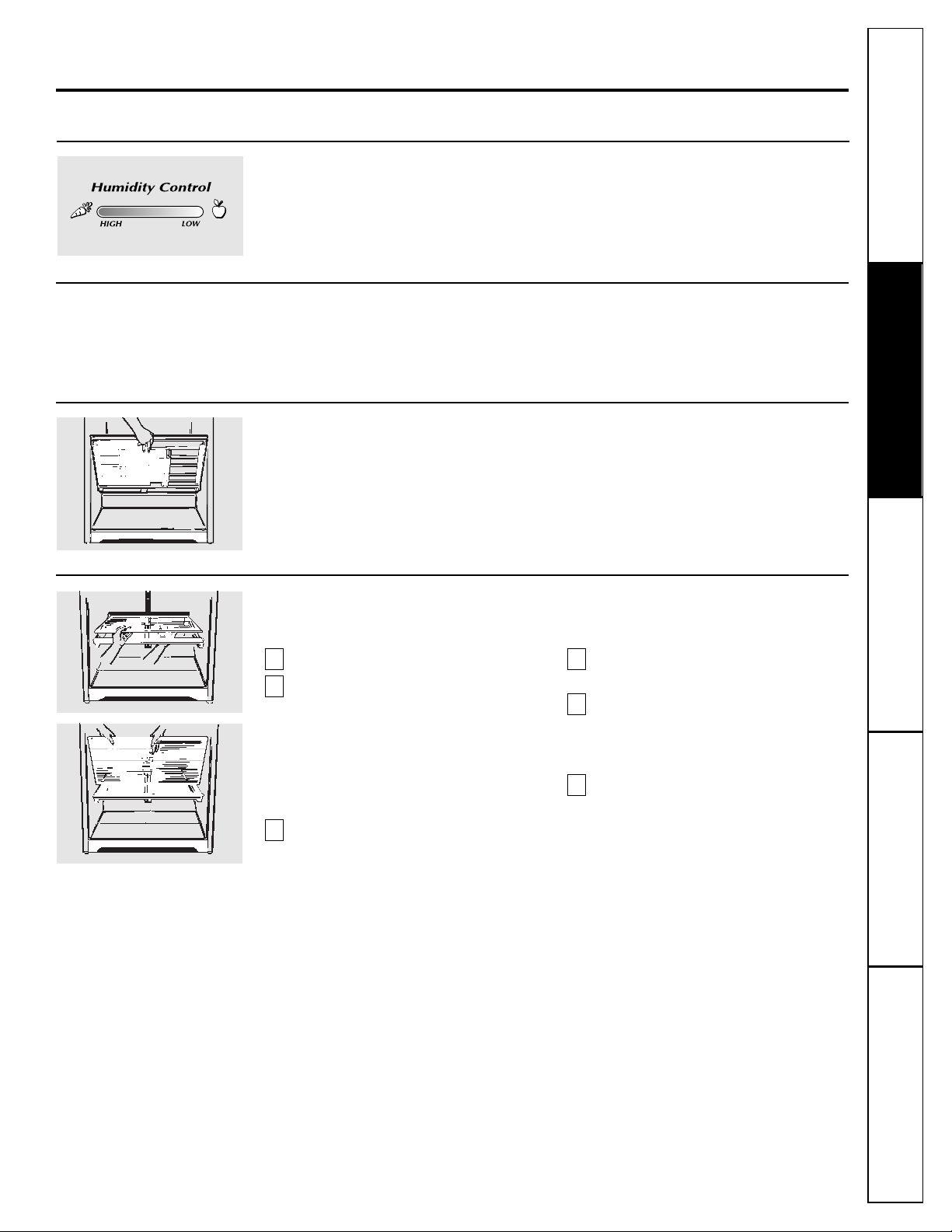

Adjustable Humidity Drawer (on some models)

Slide the control all the way to the

HIGH setting to provide high humidity

recommended for most vegetables.

Slide the control all the way to the LOW

setting to provide lower humidity levels

recommended for most fruits.

Page 8

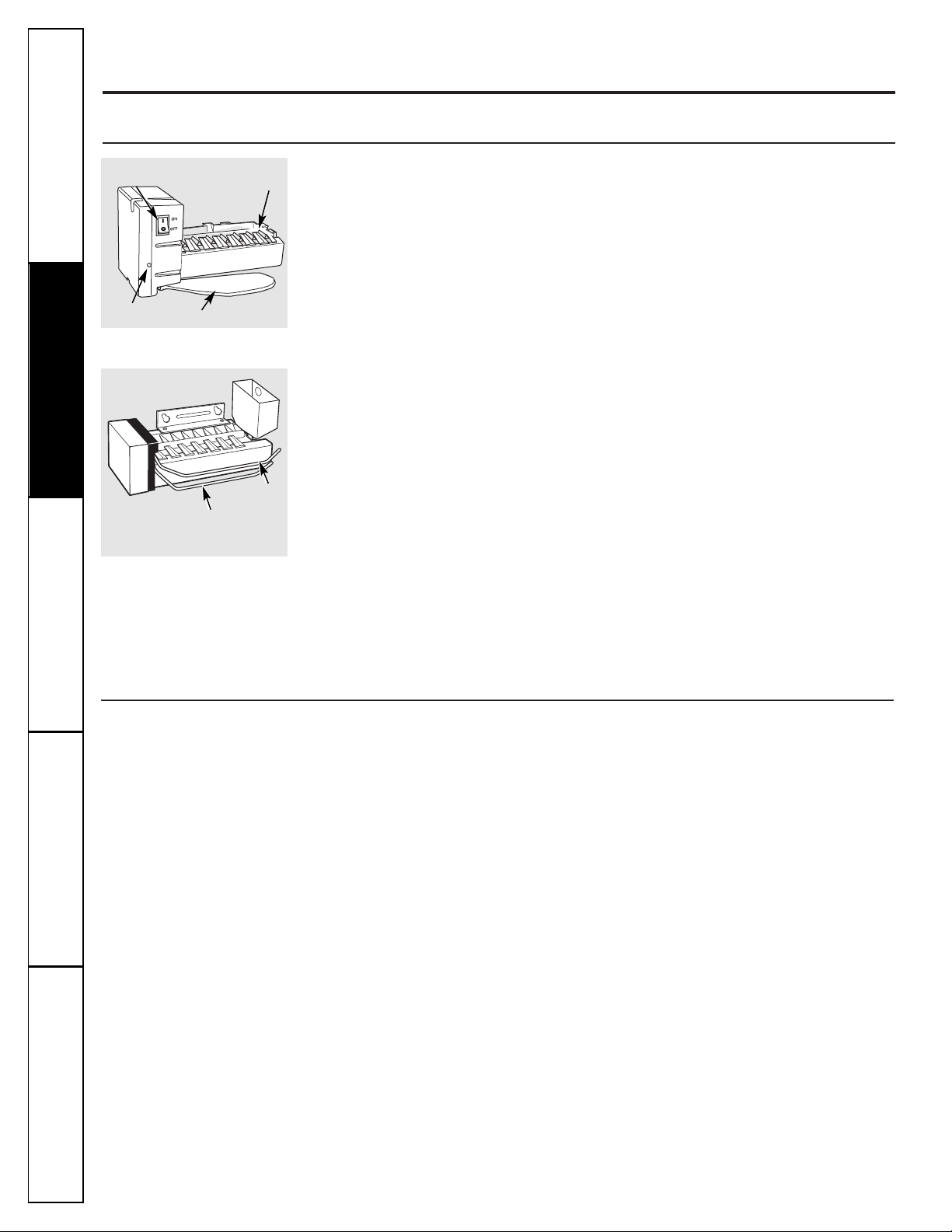

About the automatic icemaker.

A newly-installed refrigerator may take 12 to 24 hours to begin making ice.

Icemaker Accessory Kit

If your refrigerator did not already come

equipped with an automatic icemaker,

an icemaker accessory kit is available at

extra cost.

Check the back of the refrigerator for

the specific icemaker kit needed for your

model.

8

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

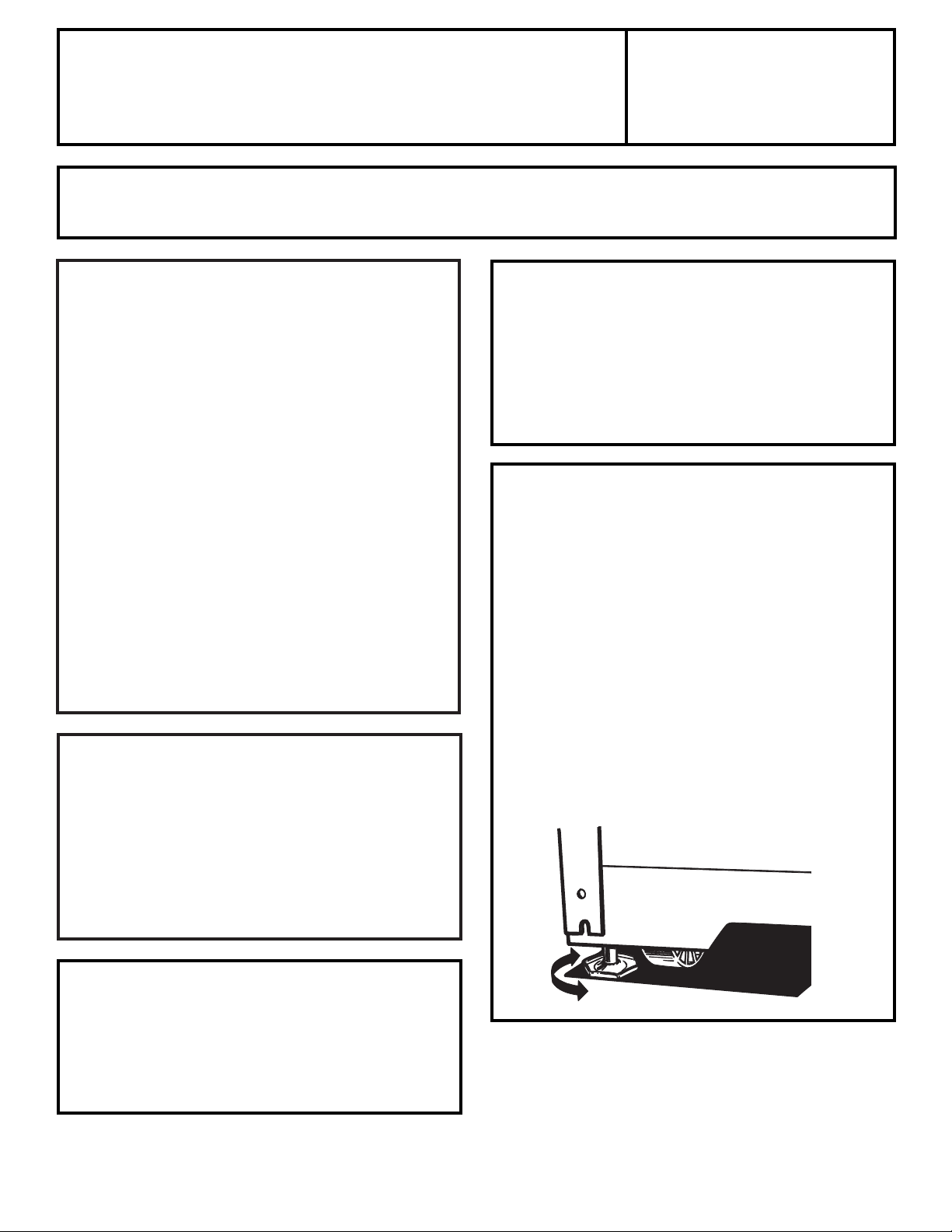

Icemaker

Feeler Arm

Power

Switch

Green

Power Light

Automatic Icemaker (on some models)

The icemaker will produce approximately

100–130 cubes in a 24-hour period,

depending on the freezer compartment

temperature, room temperature, number

of door openings and other use conditions.

There are two types of icemakers: power

switch models and feeler arm models.

If the refrigerator is operated before the

water connection is made to the icemaker,

set the power switch to O (off) or move the

feeler arm to the STOP (up) position.

When the refrigerator has been connected

to the water supply, set the power switch to

the I (on) position or move the feeler arm to

the ON (down) position. On power switch

models, the green light will come on.

You will hear a buzzing sound each time

the icemaker fills with water.

The icemaker will fill with water when it

cools to 15°F. A newly-installed refrigerator

may take 12 to 24 hours to begin making

ice cubes.

Throw away the first few batches of ice to

allow the water line to clear.

Be sure nothing interferes with the sweep

of the feeler arm.

When the bin fills to the level of the feeler

arm, the icemaker will stop producing ice.

It is normal for several cubes to be joined

together.

If ice is not used frequently, old ice cubes

will become cloudy, taste stale and shrink.

On power switch models, the green power

light will blink if ice cubes get stuck in the

icemaker. To correct this, set the power

switch to O (off) and remove the cubes. Set

the power switch to I (on) to restart the

icemaker. After the icemaker has been

turned on again, there will be a delay of

about 45 minutes before the icemaker

resumes operation.

NOTE: In homes with lower-than-average water

pressure, you may hear the icemaker cycle multiple

times when making one batch of ice.

Feeler Arm in

the STOP

(up) position

Feeler Arm in

the ON (down)

position

Feeler arm model

Power switch model

Page 9

Consumer Support

Troubleshooting TipsOperating InstructionsSafety Instructions Installation Instructions

9

Care and cleaning of the refrigerator.

Cleaning the Outside

The door handles and trim (on some

models). Clean with a cloth dampened

with soapy water. Dry with a soft cloth.

Keep the outside clean. Wipe with a clean

cloth lightly dampened with kitchen

appliance wax or mild liquid dish

detergent. Dry and polish with a clean,

soft cloth.

The stainless steel panels and door handles

(on some models) can be cleaned with

a commercially available stainless steel

cleaner. Do not use appliance wax or

polish on the stainless steel.

Do not wipe the refrigerator with a soiled dish

cloth or wet towel. These may leave a residue

that can erode the paint. Do not use scouring

pads, powdered cleaners, bleach or cleaners

containing bleach because these products can

scratch and weaken the paint finish.

Cleaning the Inside

To help prevent odors, leave an open box

of baking soda in the fresh food and

freezer compartments.

Unplug the refrigerator before cleaning.

If this is not practical, wring excess

moisture out of sponge or cloth when

cleaning around switches, lights or

controls.

Use warm water and baking soda solution–

about a tablespoon (15 ml) of baking soda

to a quart (1 liter) of water. This both

cleans and neutralizes odors. Rinse and

wipe dry.

After cleaning the door gaskets, apply a

thin layer of petroleum jelly to the door

gaskets at the hinge side. This helps keep

the gaskets from sticking and bending

out of shape.

Avoid cleaning cold glass shelves (on some

models) with hot water because the extreme

temperature difference may cause them to

break. Handle glass shelves carefully. Bumping

tempered glass can cause it to shatter.

Do not wash any plastic refrigerator parts in

the dishwasher.

Condenser

There is no need for routine condenser

cleaning in normal home operating

environments. However, in environments

that may be particularly dusty or greasy,

the condenser should be cleaned

periodically for efficient refrigerator

operation.

To clean the condenser, turn the

temperature control dial to 0. Sweep

away or vacuum up dust.

For best results, use a brush specially

designed for this purpose. It is available

at most appliance parts stores.

Cleaning the condenser coils.

Page 10

Care and cleaning of the refrigerator.

Behind the Refrigerator

Be careful when moving the refrigerator

away from the wall. All types of floor

coverings can be damaged, particularly

cushioned coverings and those with

embossed surfaces.

Turn the leveling legs at each front corner

of the refrigerator counterclockwise until

the rollers support the refrigerator. Pull the

refrigerator straight out and return it to

position by pushing it straight in. Moving

the refrigerator in a side direction may

result in damage to the floor covering or

refrigerator.

When pushing the refrigerator back, make sure

you don’t roll over the power cord or icemaker

supply line (on some models).

After rolling the refrigerator back into

place, turn the legs clockwise until the

legs again bear the weight of the

refrigerator.

Light Bulb Replacement

To replace a burned-out bulb, unplug

the refrigerator from its electrical outlet,

unscrew the bulb when cool and replace

it with an appliance bulb of the same or

lower wattage.

Turning the control to the 0 position does not

remove power to the light circuit.

Preparing for Vacation

For long vacations or absences, remove

food and unplug the refrigerator. Move

the temperature control dial to the 0

position, and clean the interior with a

baking soda solution of one tablespoon

(15 ml) of baking soda to one quart

(1 liter) of water. Leave the doors open.

Set the icemaker power switch to the

O(off)position or move the feeler arm to

the STOP (up) position (depending on

model) and shut off the water supply to

the refrigerator.

If the temperature can drop below

freezing, have a qualified servicer drain

the water supply system (on some

models) to prevent serious property

damage due to flooding.

Preparing to Move

Secure all loose items such as grille,

shelves and drawers by taping them

securely in place to prevent damage.

Be sure the refrigerator stays in an upright

position during moving.

10

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Page 11

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these

instructions for local inspector’s use.

•

IMPORTANT – Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this appliance requires

basic mechanical skills.

• Completion time – Refrigerator Installation

15 minutes

Reversing the Door Swing

1 hour

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Do not install the refrigerator where the temperature

will go below 60°F (16°C) because it will not run often

enough to maintain proper temperatures.

• Install it on a floor strong enough to support it fully

loaded.

REFRIGERATOR LOCATION

Installation

Refrigerator

Instructions

Models 16, 17, 18

Allow the following clearances for ease of installation,

proper air circulation and plumbing and electrical

connections.

• Sides 3/4″ (19 mm)

• Top 1″ (25 mm)

• Back 1″ (25 mm)

CLEARANCES

Leveling legs near each front corner of the refrigerator

are adjustable. They firmly position the refrigerator

and prevent it from moving when the doors are

opened. Leveling legs should be set so the front of the

refrigerator is raised just enough that the doors close

easily when opened about halfway.

Turn the leveling legs clockwise to raise the

refrigerator, counterclockwise to lower it.

Rollers next to the leveling legs allow you to move the

refrigerator away from the wall for cleaning.

Turn the legs counterclockwise until the weight of the

refrigerator is transferred from them to the rollers.

After rolling the refrigerator back into place, turn the

legs clockwise until the legs again bear the weight of

the refrigerator.

ROLLERS AND LEVELING LEGS

If the refrigerator has an icemaker, it will have to be

connected to a cold water line. A water supply kit

(containing copper tubing, shutoff valve, fittings and

instructions) is available at extra cost from your dealer,

by visiting our Website at ge.com (in Canada at

www.geappliances.ca) or from Parts and Accessories,

800.626.2002 (in Canada 1.888.261.3055).

WATER SUPPLY TO THE ICEMAKER

(on some models

)

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: ge.com

In Canada, call 1.800.361.3400

or Visit our Website at: www.geappliances.ca

11

Page 12

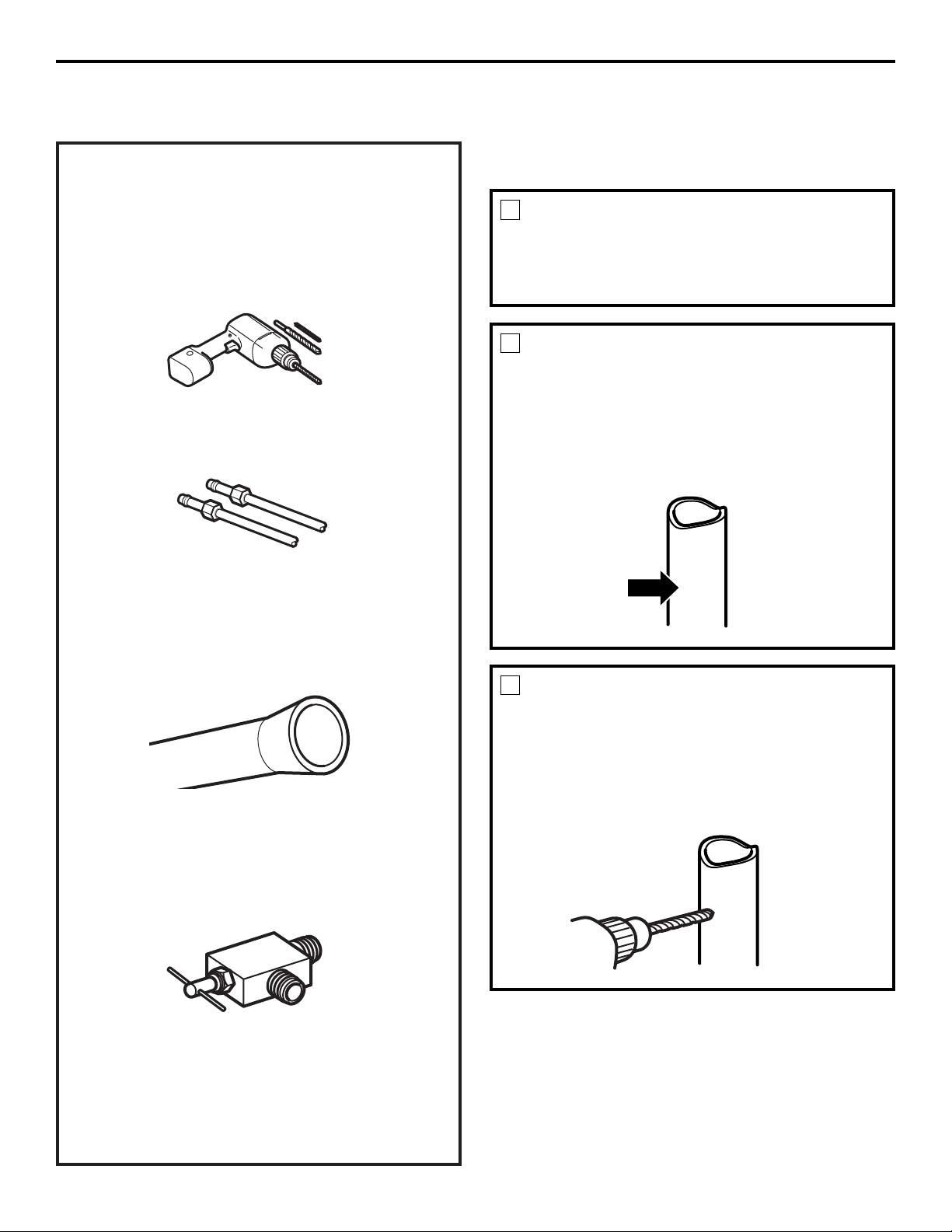

WHAT YOU WILL NEED

• Copper or GE SmartConnect™Refrigerator Tubing

kit, 1/4″ outer diameter to connect the refrigerator

to the water supply. If using copper, be sure both

ends of the tubing are cut square.

To determine how much tubing you need: measure

the distance from the water valve on the back of the

refrigerator to the water supply pipe. Then add 8′

(2.4 m). Be sure there is sufficient extra tubing

(about 8′ [2.4 m] coiled into 3 turns of about 10″

[25 cm] diameter) to allow the refrigerator to move

out from the wall after installation.

GE SmartConnect™Refrigerator Tubing Kits are

available in the following lengths:

2′ (0.6 m) – WX08X10002

6′ (1.8 m) – WX08X10006

15′ (4.6 m) – WX08X10015

25′ (7.6 m) – WX08X10025

Be sure that the kit you select allows at least 8′ (2.4 m)

as described above.

NOTE: The only GE approved plastic tubing is that

supplied in GE SmartConnect™Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Certain

types of plastic will crack or rupture with age and

cause water damage to your home.

INSTALLING THE WATER LINE (ON SOME MODELS)

Installation Instructions

BEFORE YOU BEGIN

Recommended copper water supply kits are WX8X2,

WX8X3 or WX8X4, depending on the amount of

tubing you need. Approved plastic water supply lines

are GE SmartConnect™Refrigerator Tubing

(WX08X10002, WX08X10006, WX08X10015 and

WX08X10025).

When connecting your refrigerator to a GE Reverse

Osmosis Water System, the only approved installation

is with a GE RVKit. For other reverse osmosis water

systems, follow the manufacturer’s recommendations.

This water line installation is not warranted by the

refrigerator or icemaker manufacturer. Follow these

instructions carefully to minimize the risk of expensive

water damage.

Water hammer (water banging in the pipes) in house

plumbing can cause damage to refrigerator parts and

lead to water leakage or flooding. Call a qualified

plumber to correct water hammer before installing

the water supply line to the refrigerator.

To prevent burns and product damage, do not hook

up the water line to the hot water line.

If you use your refrigerator before connecting the

water line, make sure the icemaker power switch is

in the O (off) position (on power switch models) or

the feeler arm is in the STOP (up) position (on feeler

arm models).

Do not install the icemaker tubing in areas where

temperatures fall below freezing.

When using any electrical device (such as a power

drill) during installation, be sure the device is double

insulated or grounded in a manner to prevent the

hazard of electric shock, or is battery powered.

All installations must be in accordance with local

plumbing code requirements.

1

12

Page 13

WHAT YOU WILL NEED (CONT.)

• A GE water supply kit (containing tubing, shutoff

valve and fittings listed below) is available at extra

cost from your dealer or from Parts and Accessories,

800.626.2002.

• A cold water supply. The water pressure must be

between 20 and 120 p.s.i. (1.4–8.1 bar).

• Power drill.

• 1/2″ or adjustable wrench.

• Straight and Phillips blade screwdriver.

• Two 1/4″ outer diameter compression nuts and

2 ferrules (sleeves)—to connect the copper tubing

to the shutoff valve and the refrigerator water valve.

OR

• If you are using a GE SmartConnect™Refrigerator

Tubing kit, the necessary fittings are preassembled

to the tubing.

• If your existing copper water line has a flared fitting

at the end, you will need an adapter (available at

plumbing supply stores) to connect the water line to

the refrigerator OR you can cut off the flared fitting

with a tube cutter and then use a compression

fitting. Do not cut formed end from GE

SmartConnect™Refrigerator tubing.

• Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with a

minimum inside diameter of 5/32″ at the point of

connection to the COLD WATER LINE. Saddle-type

shutoff valves are included in many water supply kits.

Before purchasing, make sure a saddle-type valve

complies with your local plumbing codes.

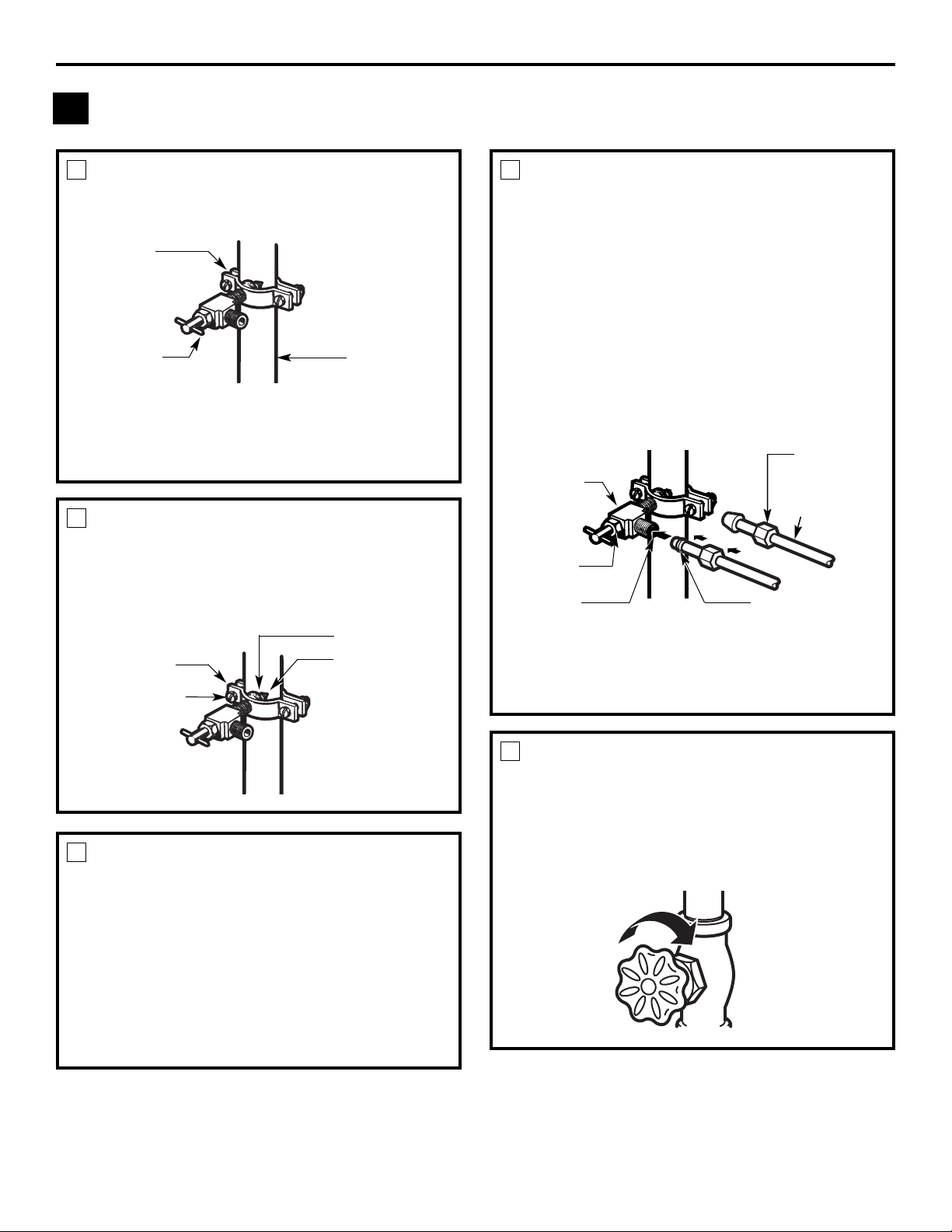

DRILL THE HOLE FOR THE VALVE

Drill a 1/4″ hole in the water pipe (even if using

a self-piercing valve) using a sharp bit. Remove any

burrs resulting from drilling the hole in the pipe.

Take care not to allow water to drain into the drill.

Failure to drill a 1/4″ hole may result in reduced

ice production or smaller cubes.

3

CHOOSE THE VALVE LOCATION

Choose a location for the valve that is easily

accessible. It is best to connect into the side of

a vertical water pipe. When it is necessary to

connect into a horizontal water pipe, make the

connection to the top or side, rather than at the

bottom, to avoid drawing off any sediment from

the water pipe.

2

Installation Instructions

Install the shutoff valve on the nearest frequently used

drinking water line.

SHUT OFF THE MAIN WATER

SUPPLY

Turn on the nearest faucet long enough to clear

the line of water.

1

13

Page 14

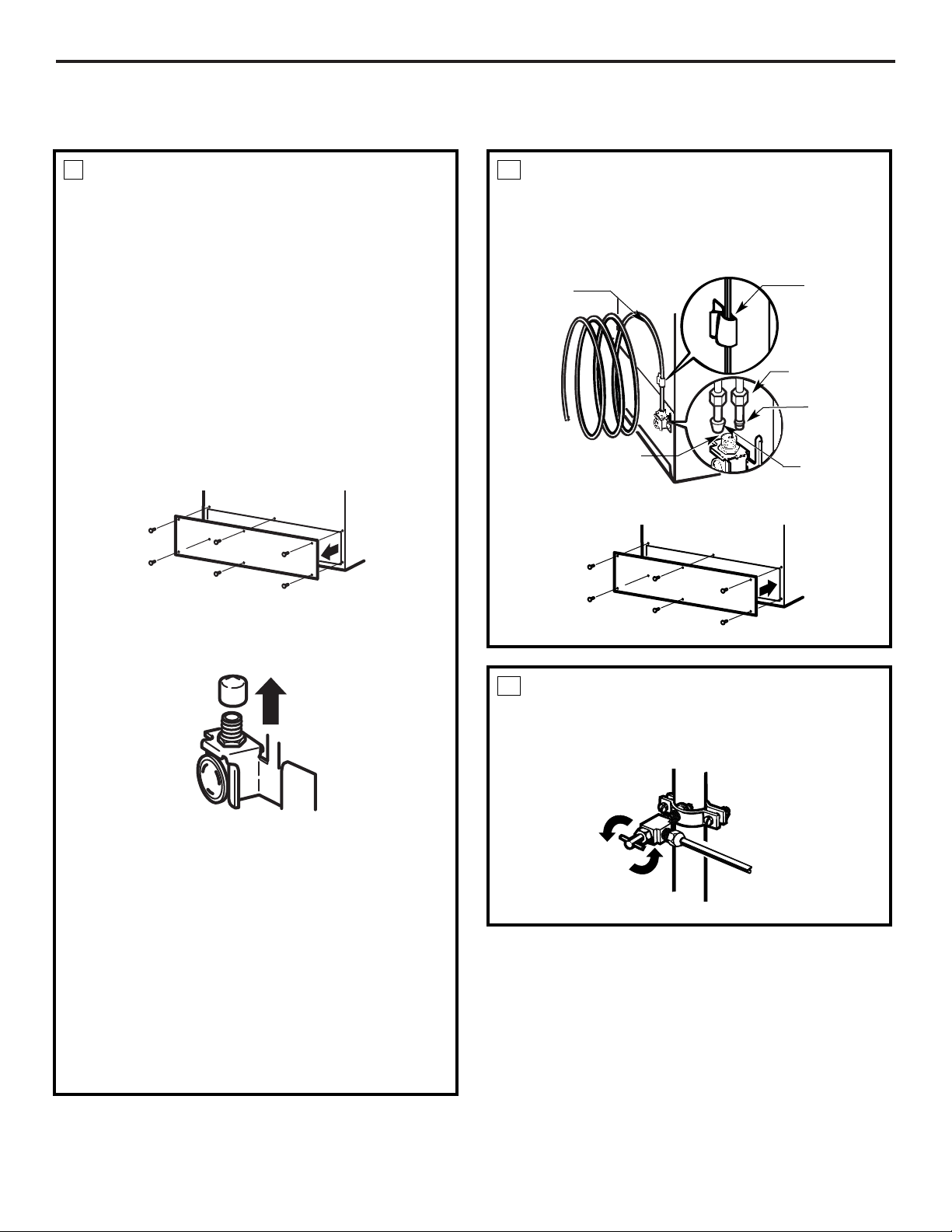

FLUSH OUT THE TUBING

Turn the main water supply on and flush out the

tubing until the water is clear.

Shut the water off at the water valve after about

one quart (1 liter) of water has been flushed

through the tubing.

8

CONNECT THE TUBING

TO THE VALVE

Place the compression nut and ferrule (sleeve)

for copper tubing onto the end of the tubing and

connect it to the shutoff valve.

Make sure the tubing is fully inserted into the

valve. Tighten the compression nut securely.

For plastic tubing from a GE SmartConnect

™

Refrigerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then tighten

one additional turn with a wrench. Overtightening

may cause leaks.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

7

Installation Instructions

Saddle-Type

Shutoff Valve

Compression

Nut

SmartConnect

™

Tubing

Packing Nut

Outlet Valve

Ferrule (sleeve)

FASTEN THE SHUTOFF VALVE

Fasten the shutoff valve to the cold water pipe with

the pipe clamp.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

4

Vertical Cold

Water Pipe

Saddle-Type

Shutoff Valve

Pipe Clamp

TIGHTEN THE PIPE CLAMP

Tighten the clamp screws until the sealing washer

begins to swell.

NOTE: Do not overtighten or you may crush the

tubing.

5

Washer

Inlet End

Pipe Clamp

Clamp Screw

ROUTE THE TUBING

Route the tubing between the cold water line and

the refrigerator.

Route the tubing through a hole drilled in the wall

or floor (behind the refrigerator or adjacent base

cabinet) as close to the wall as possible.

NOTE: Be sure there is sufficient extra tubing

(about 8 feet [244 cm] coiled into 3 turns of about

10″ [25 cm] diameter) to allow the refrigerator to

move out from the wall after installation.

6

14

INSTALLING THE WATER LINE (CONT.)

1

Page 15

Installation Instructions

CONNECT THE TUBING TO THE

REFRIGERATOR

NOTES:

• Before making the connection to the refrigerator,

be sure the refrigerator power cord is not plugged

into the wall outlet.

• We recommend installing a water filter if your

water supply has sand or particles that could clog

the screen of the refrigerator’s water valve. Install

it in the water line near the refrigerator. If using

GE SmartConnect™Refrigerator Tubing kit,

you will need an additional tube (WX08X10002)

to connect the filter. Do not cut plastic tube to

install filter.

Remove the access cover.

Remove the plastic flexible cap from the water

valve (refrigerator connection).

Place the compression nut and ferrule (sleeve)

onto the end of the tubing as shown. On GE

SmartConnect

™

Refrigerator Tubing kit,

the nuts are already assembled to the tubing.

Insert the end of the tubing into the water valve

connection as far as possible. While holding the

tubing, tighten the fitting.

For plastic tubing from a GE SmartConnect

™

Refrigerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then

tighten one additional turn with a wrench.

Overtightening may cause leaks.

9

TURN THE WATER ON AT THE

SHUTOFF VALVE

Tighten any connections that leak.

10

CONNECT THE TUBING TO THE

REFRIGERATOR

(CONT.)

Fasten the tubing into the clamp provided to

hold it in a vertical position. You may need to

pry open the clamp.

Reattach the access cover.

9

Tubing Clamp

1/4″ Compression

Nut

Ferrule

(sleeve)

SmartConnect

™

Tubing

Refrigerator

Connection

1/4″ Copper

Tubing

15

Page 16

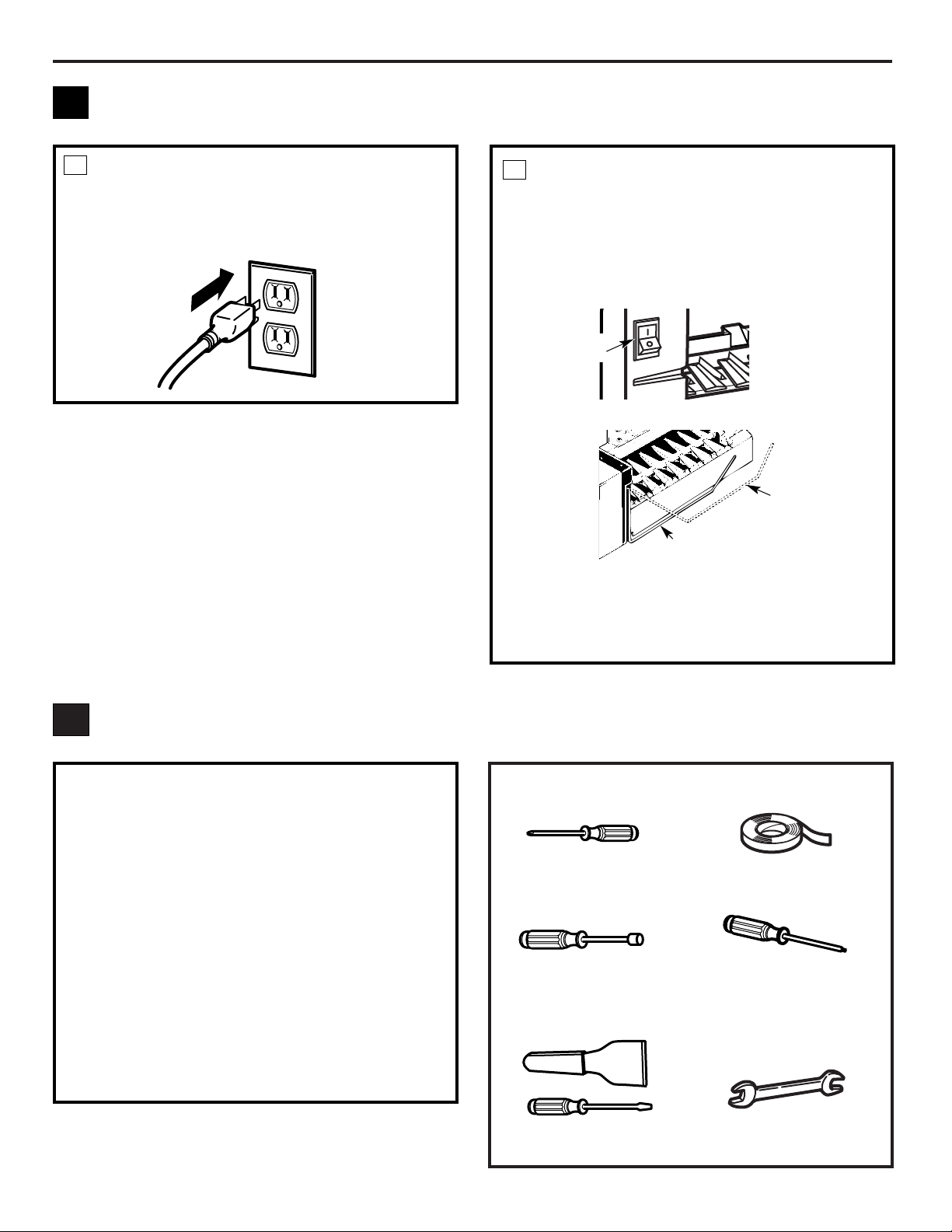

Installation Instructions

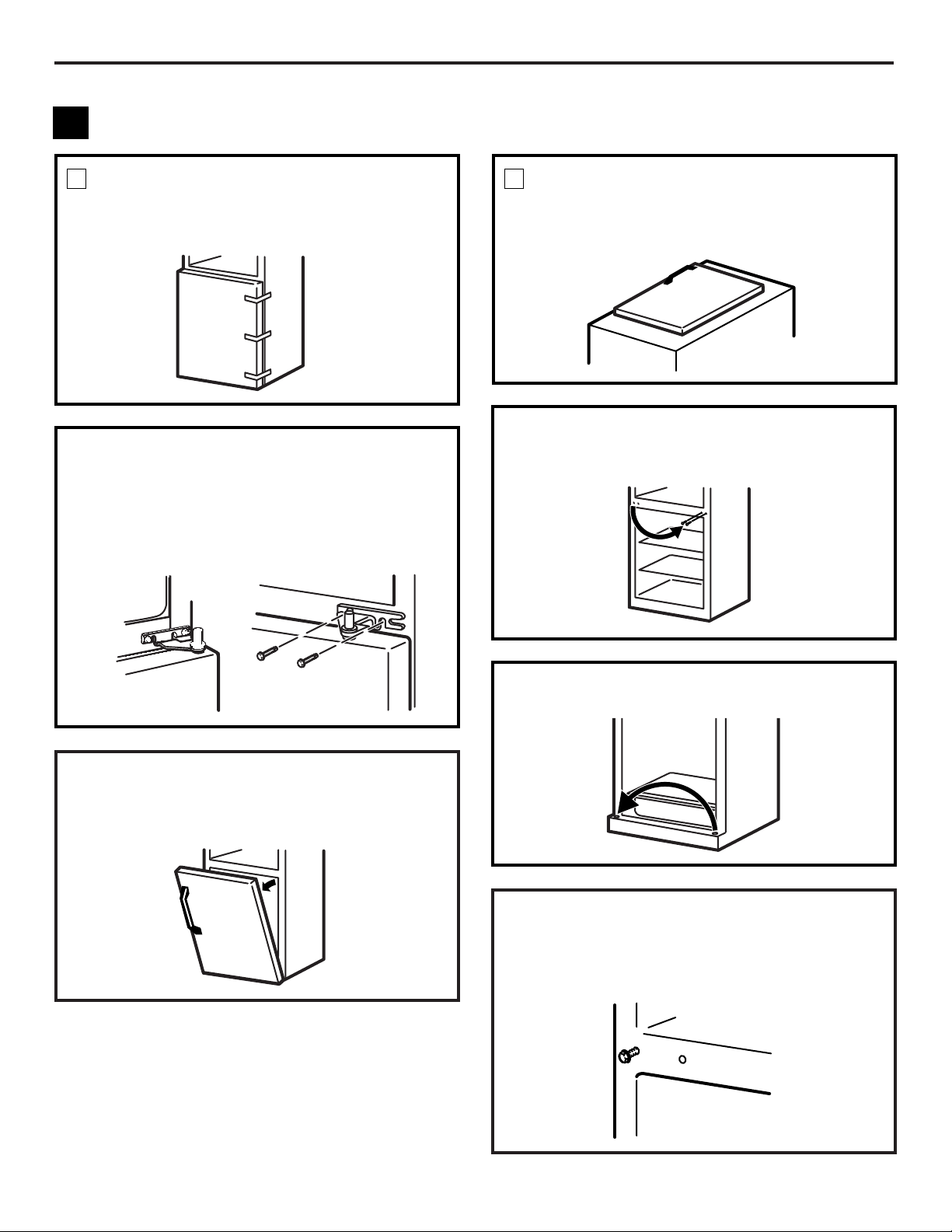

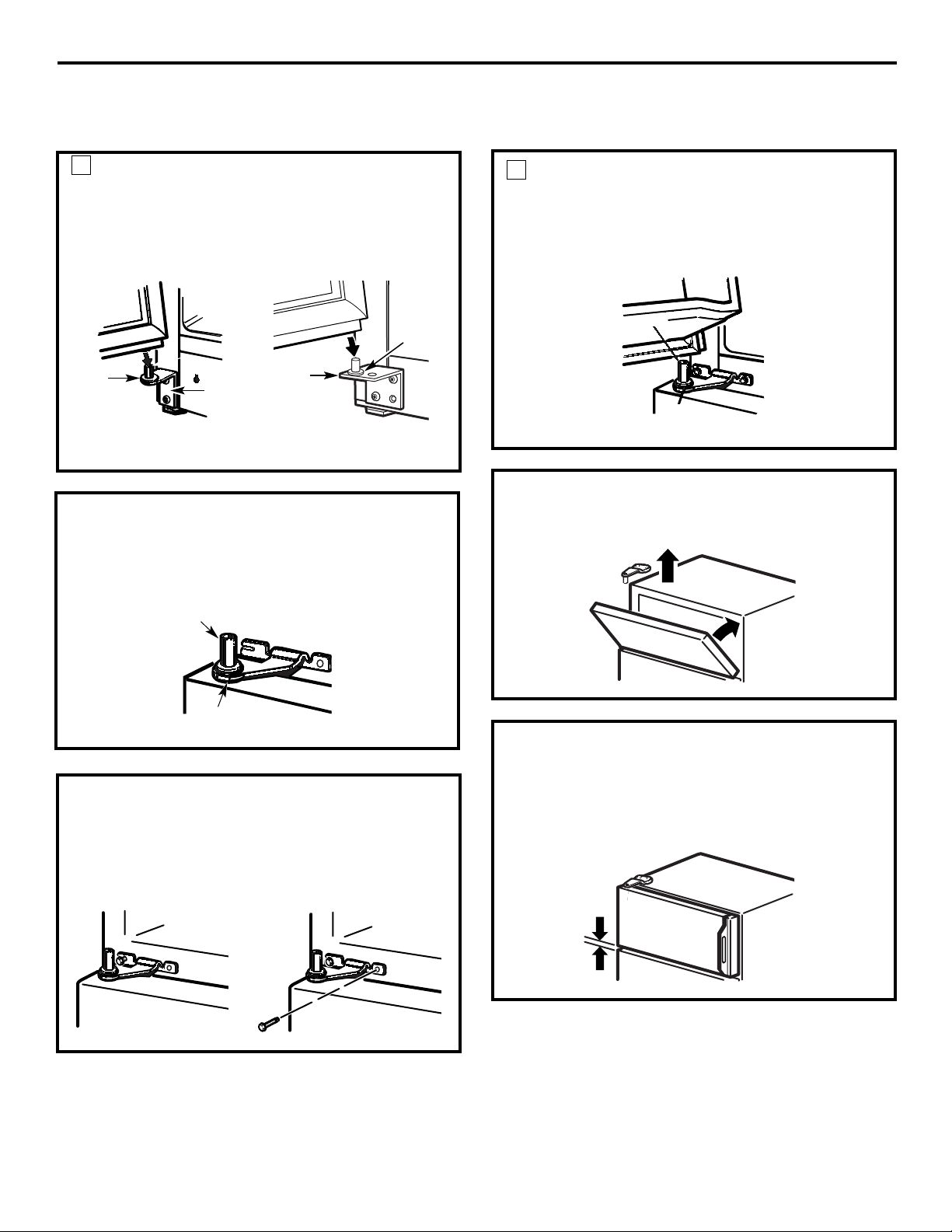

REVERSING THE DOOR SWING

2

When reversing the door swing:

• Read the instructions all the way through before

starting.

• Handle parts carefully to avoid scratching paint.

• Set screws down by their related parts to avoid using

them in the wrong places.

• Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is completed.

These instructions are for changing the hinges from

the right side to the left side—if you ever want to change

the hinges back to the right side, follow these same

instructions and reverse all references to left and right.

IMPORTANT NOTES

Phillips screwdriver

TOOLS REQUIRED

Masking tape

T20 or T25 Torxdriver,

(needed for some

models)

5/16″ hex-head

socket driver

5/16″ open-end

wrench

Putty knife or thin-blade

screwdriver

PLUG IN THE REFRIGERATOR

Arrange the coil of tubing so that it does not vibrate

against the back of the refrigerator or against the

wall. Push the refrigerator back to the wall.

11

16

On power switch models, set the icemaker power

switch to the l (on) position. On feeler arm models,

move the feeler arm to the ON (down) position. The

icemaker will not begin to operate until it reaches

its operating temperature of 15°F (–9°C) or below.

It will then begin operation automatically.

NOTE: In lower water pressure conditions, the

water valve may turn on up to 3 times to deliver

enough water to the icemaker.

START THE ICEMAKER

Power

switch

Power switch model

Feeler Arm in the

STOP (up) position

Feeler Arm in

the ON (down) position

Feeler arm model

12

INSTALLING THE WATER LINE (CONT.)

1

Page 17

Installation Instructions

2.1 Tape the door shut with masking tape.

REMOVE THE FREEZER DOOR

2

2.2 With a 5/16″ hex-head socket driver, remove the

screws that hold the top hinge to the cabinet.

2.3 Lift the hinge (and the shim glued to it) straight

up to free the hinge pin from the socket in

the top of the door and set it aside, along with

its screws.

Top Hinge

2.6 Transfer the 2 screws from the opposite side of

the cabinet to the screw holes vacated by the

top hinge removal.

2.5 Set the door on a non-scratching surface with

the outside up.

2.4 Remove the tape and tilt the door away from the

cabinet. Lift it off the center hinge pin.

1.1 Unplug the refrigerator from its electrical

outlet.

BEFORE YOU START

1

1.2 Empty all door shelves, including the dairy

compartment.

CAUTION: Do not let either door drop to the

floor. To do so could damage the door stop.

17

Page 18

Installation Instructions

3.1 Tape the door shut with masking tape.

REMOVE THE FRESH FOOD

DOOR

3

3.4 Set the door outside-up on a non-scratching

surface.

REMOVE THE FRESH FOOD

DOOR

(CONT.)

3

3.3 Remove the tape and tilt the door away from the

cabinet. Lift the door from the pin in the bottom

hinge bracket. (If the plastic washer sticks to the

door bottom, put it back on the hinge.)

3.2 Using a 5/16″ hex-head socket screwdriver and

a 5/16″ open-end wrench, remove the two

screws holding the center hinge (and the shim

glued to it) to the cabinet. Lift the center hinge

to free its pin from the socket in the top of the

door, and set hinge and screws aside. Be careful

not to lose the center hinge spacer and washer.

3.7 Take one of the screws removed in step 2 and start

it in the outermost screw hole on the opposite side.

Do not drive it all the way down—leave enough

space under the screw head for thickness of shim

and bracket.

3.6 Transfer the washer (if your model has one) to the

opposite side.

3.5 Transfer the two screws from the opposite side of

the cabinet to the screw holes vacated by the center

hinge removal.

18

REVERSING THE DOOR SWING (CONT.)

2

Page 19

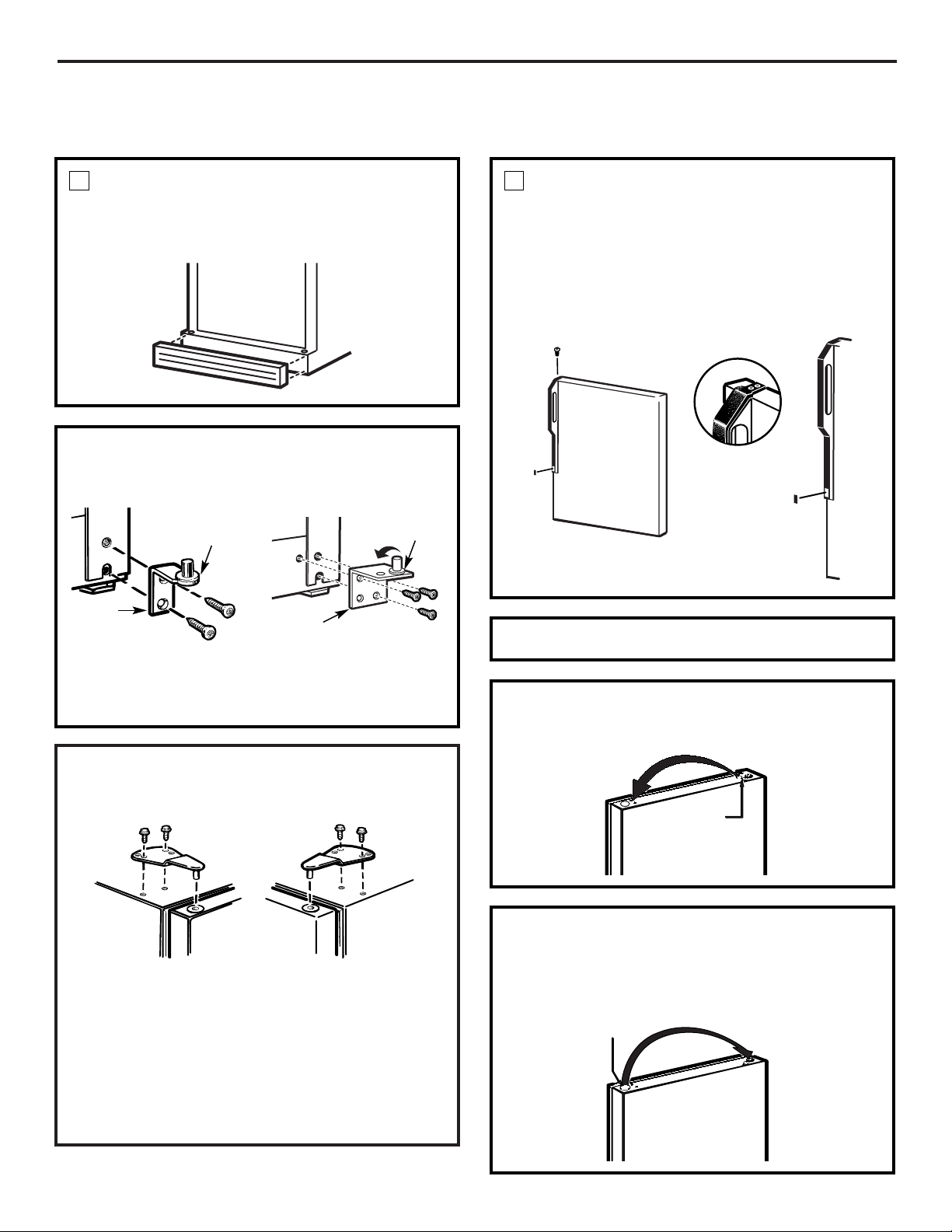

Installation Instructions

REVERSING THE HARDWARE

4

4.1 Remove the base grille (if your refrigerator has

one) by pulling it straight out.

4.3 Interchange hinge (and the shim glued to it) and

screws at top right with screws at top left of cabinet.

Do not tighten screws on hinge side at this time.

NOTES:

• Some hinges have four holes. Which holes you

use for installing the hinge depends on which

side you install the hinge.

• The outer edge of the hinge should be parallel

to the edge of the case for correct installation.

Installing the hinge on the left.

Installing the hinge on the right.

REVERSING THE DOOR HANDLES

5

5.1 Transfer fresh food door handle

5.1.1 Remove the handle plug using a

tape-tipped putty knife under the edge,

and remove the screw underneath.

Remove the two screws holding the

handle to the top of the door.

5.1.2 Remove the handle.

5.1.3 Remove the screws from the right edge of the

door top and insert them into the handle screw

holes on the opposite side.

Top

Screws

for Handle

Holes

5.1.4 With tape-tipped putty knife or thin-blade

screwdriver, pry out the plug button from the

hinge hole on the left side of the door and

insert it into the hole on the opposite side that

was vacated by removal of the top hinge.

Plug Button

Plug

19

4.2 Move the bottom hinge bracket (and shim glued

to it) and plastic washer from the right side to the

left side.

Plastic

Washer

Hinge

Bracket

Models with a hinge bracket

that has 2 screw holes.

Models with a hinge bracket

that has 4 screw holes.

Switch the hinge pin to the

opposite side of the bracket.

Plastic

Washer

Hinge

Bracket

Page 20

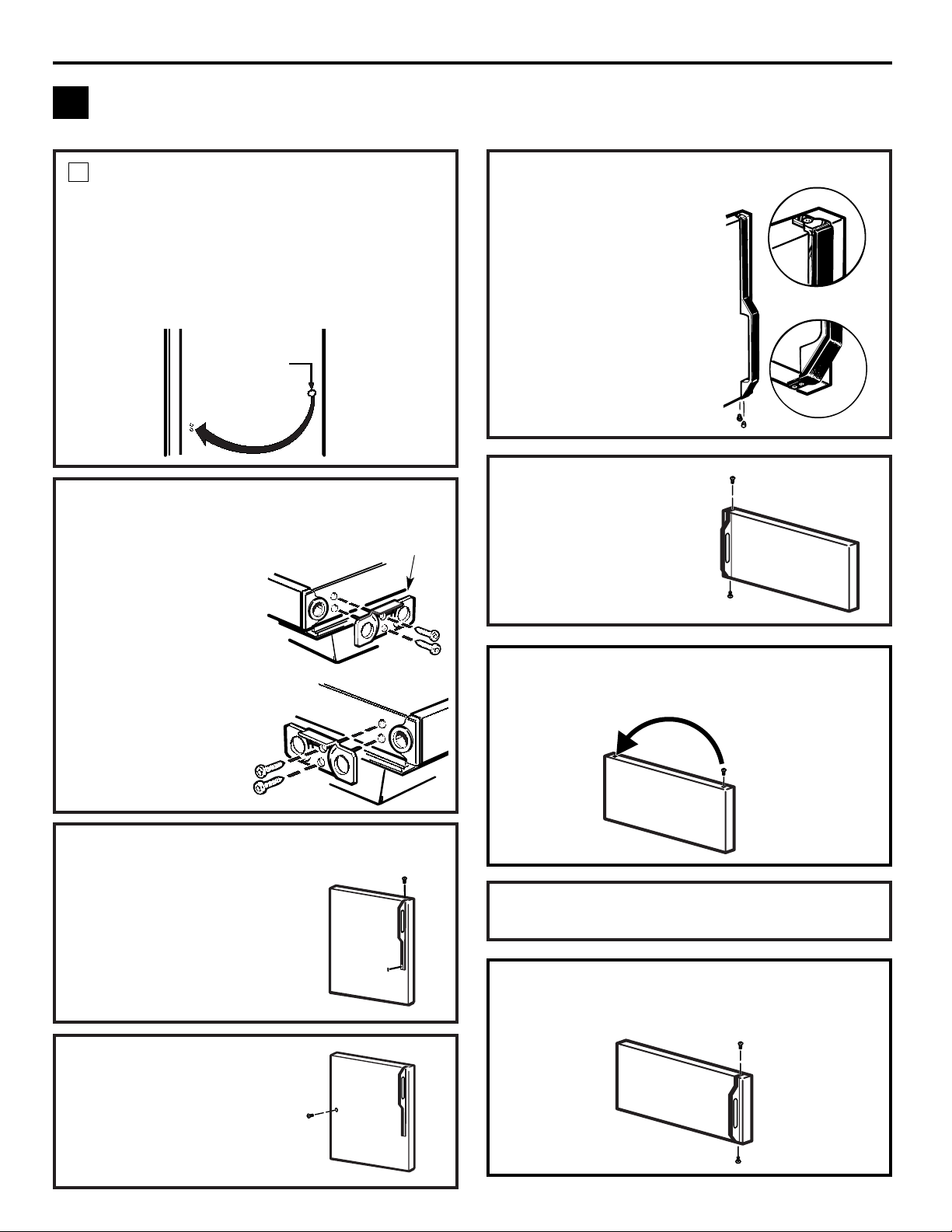

5.1 Transfer fresh food door handle

(cont.)

5.1.5 Pull the plug button from the front

of the door and transfer it to the

opposite side.

5.2 Transfer door stop

5.2.1 Move the metal door stop

from the right end to the

left end.

Installation Instructions

To reattach the

handle on the

opposite side.

Plug Button

5.2.2 Move any

screws from

the left end to

the right end.

Door Stop

Left Side

Right Side

5.3 Reinstalling the Fresh Food Door

Handle

5.3.1 Attach the handle to

the right side of the

door with screws at

the top and under

the handle plug.

5.3.2 Reinstall the handle plug.

5.4.2 Remove the handle.

5.4.3 Remove the screw from the right top edge of the

door and insert it into the handle screw hole on

the left side.

5.4.4 Transfer the door stop as shown on the

preceding page.

5.4.5 Attach the handle to the right edge of the door

with screws at top and bottom, using bottom

holes vacated by removal of the door stop screws.

TOP

BOTTOM

REVERSING THE DOOR HANDLES

(CONT.)

5

Top

Bottom

5.4 Transfer Freezer Door Handle

5.4.1 Remove the screw

holding the handle

to the top of the

door and the two

screws holding the

handle to the bottom

of the door.

20

REVERSING THE DOOR SWING (CONT.)

2

Page 21

Installation Instructions

6.1.2 Insert the pin on the center hinge into the

socket in the top of the door. Place the spacer,

then the washer, on the hinge pin.

NOTE: The center hinge must be turned over

as shown when mounted on the left side.

Plastic Washer

and Spacer

Hinge Pin

6.2 Rehang the freezer door

6.2.1 Lower the freezer door onto the center

hinge pin. Be sure the washer and

spacer are in place on the pin.

REHANGING THE DOORS (CONT.)

6

Center Hinge Pin

Plastic Washer

and Spacer

6.2.2 Tilt the door toward the cabinet, lifting the top

hinge so the pin fits into the socket on the top

of the door.

6.2.3. Make sure the door is slightly above the top of

the cabinet and the gap between the doors is

even across the front. Tighten the top hinge

screws. Do not overtighten these screws–tighten

them until they are just snug, then turn them

another one-half turn.

21

6.1.3 Tilt the door toward the cabinet. As the door is

brought into position, slide the hinge under the

head of the screw which earlier had been partly

driven into the outermost hole. Insert the

remaining screw, then tighten both screws

securely.

6.1 Rehang the fresh food door

6.1.1 Lower the fresh food door onto the

bottom hinge pin. Be sure the washer

is in place on the pin.

REHANGING THE DOORS

6

Hinge

Bracket

Plastic

Washer

Plastic

Washer

Hinge

Bracket

Models with a hinge bracket

that has 2 screw holes.

Models with a hinge bracket

that has 4 screw holes.

Page 22

■

The new high efficiency

compressor may run

faster and longer than

your old refrigerator

and you may hear a high-pitched hum or pulsating

sound while it is operating.

■

You may hear a whooshing sound when the doors close.

This is due to pressure equalizing within the refrigerator.

Normal operating sounds.

Newer refrigerators sound different from older refrigerators. Modern refrigerators have more features

and use newer technology.

■

You may hear the fans spinning at

high speeds.

This happens when the refrigerator

is first plugged in, when the doors

are opened frequently or when

a large amount of food is added to the refrigerator or

freezer compartments. The fans are helping to

maintain the correct temperatures.

CLICKS, POPS,

CRACKS and CHIRPS

■

You may hear cracking or popping sounds when the

refrigerator is first plugged in. This happens as the

refrigerator cools to the correct temperature.

■

The compressor may cause a clicking or chirping sound

when attempting to restart (this could take

up to 5 minutes).

■

Expansion and contraction of cooling coils during and

after defrost can cause a cracking or popping sound.

■

On models with an icemaker, after an icemaking cycle, you

may hear the ice cubes dropping into the ice bucket.

WATER SOUNDS

■

The flow of refrigerant through the freezer cooling coils

may make a gurgling noise like boiling water.

■

Water dropping on the defrost heater can cause a sizzling,

popping or buzzing sound during the defrost cycle.

■

A water dripping noise may occur during the defrost cycle as

ice melts from the evaporator and flows into the drain pan.

■

Closing the door may cause a gurgling sound due to

pressure equalization.

Do you hear what I hear? These sounds are normal.

For additional information on normal

icemaker operating sounds, see the

About the automatic icemaker section.

22

Consumer Support

Troubleshooting Tips

Operating Instructions Safety InstructionsInstallation Instructions

Before you call for service…

Troubleshooting Tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

Problem Possible Causes What To Do

Refrigerator does not Refrigerator in defrost cycle. • Wait about 30 minutes for defrost cycle to end.

operate

Temperature control dial • Move the temperature control dial to a temperature

in 0 position. setting.

Refrigerator is unplugged. • Push the plug completely into the outlet.

The fuse is blown/circuit • Replace fuse or reset the breaker.

breaker is tripped.

Vibration or rattling (slight Roller screws or leveling legs • See Rollers and Leveling Legs.

vibration is normal) need adjusting.

Fresh food or freezer Temperature control dial • See About the temperature control dial.

compartment too warm not set cold enough.

Warm weather or frequent • Set the temperature control dial one step colder.

door openings. See About the temperature control dial.

Door left open. • Check to see if package is holding door open.

Package blocking air duct in • Check to see if package is blocking air duct in freezer

freezer compartment. compartment.

HUMMM...

WHOOSH...

Page 23

Consumer Support

Troubleshooting TipsOperating InstructionsSafety Instructions Installation Instructions

23

Problem Possible Causes What To Do

Normal when refrigerator • Wait 24 hours for the refrigerator to completely

is first plugged in. cool down.

Often occurs when large • This is normal.

amounts of food are

placed in refrigerator.

Door left open. • Check to see if package is holding door open.

Hot weather or frequent • This is normal.

door openings.

Temperature control dial • See About the temperature control dial.

set at the coldest setting.

Grille and condenser • See Care and cleaning.

need cleaning.

Frost or ice crystals Door left open. • Check to see if package is holding door open.

on frozen food

Too frequent or too long

(frost within package

door openings.

is normal)

Automatic icemaker Icemaker power switch • On power switch models, set the power switch to the

does not work is not on. I (on) position. On feeler arm models, move the feeler

(on some models) arm to the ON (down) position.

Water supply turned off or • See Installing the water line.

not connected.

Freezer compartment • Wait 24 hours for the refrigerator to completely

too warm. cool down.

Piled up cubes in the storage • Level cubes by hand.

bin cause the icemaker

to shut off.

Frequent “buzzing” sound Icemaker is on but the water • Turn the icemaker off. On power switch models, set the

supply to the refrigerator has power switch to the O (off) position. On feeler arm

not been connected. models, move the feeler arm to the STOP (up) position.

Keeping it on will damage the water valve.

Cubes too small Water shutoff valve connecting • Call the plumber to clear the valve.

refrigerator to water line may

be clogged.

Slow ice cube freezing Door left open. • Check to see if package is holding door open.

Temperature control dial • See About the temperature control dial.

not set cold enough.

Ice cubes have Ice storage bin needs cleaning. • Empty and wash bin. Discard old cubes.

odor/taste

Food transmitting odor/taste • Wrap foods well.

to ice cubes.

Interior of refrigerator • See Care and cleaning.

needs cleaning.

Moisture forms on Not unusual during • Wipe surface dry and reset temperature control dial

cabinet surface periods of high humidity. one setting colder.

between the doors

Moisture collects inside Too frequent or too

(in humid weather, air long door openings.

carries moisture into

refrigerator when doors

are opened)

Refrigerator has odor Foods transmitting • Foods with strong odors should be tightly wrapped.

odor to refrigerator.

• Keep an open box of baking soda in the refrigerator;

replace every three months.

Interior needs cleaning. • See Care and cleaning.

Motor operates for long

periods or cycles on and

off frequently. (Modern

refrigerators with more

storage space and a larger

space and a larger freezer

require more operating

time. They start and stop

often to maintain even

temperatures.)

Page 24

24

TERMS AND CONDITIONS:

This warranty applies only for single family domestic use in

Canada when the Refrigerator has been properly installed

according to the instructions supplied by Camco and is

connected to an adequate and proper utility service.

Damage due to abuse, accident, commercial use, and alteration

or defacing of the serial plate cancels all obligations of this

warranty.

Service during this warranty period must be performed by an

Authorized Camco Service Agent.

Neither Camco nor the Dealer is liable for any claims or

damages resulting from failure of the Refrigerator or from

service delays beyond their reasonable control.

To obtain warranty service, purchaser must present the original

Bill of Sale. Components repaired or replaced are warranted

through the remainder of the original warranty period only.

This warranty is extended to the original purchaser and any

succeeding owner for products purchased for home use within

Canada. In home warranty service will be provided in areas

where it is available and deemed reasonable by Camco to

provide.

This warranty is in addition to any statutory warranty.

WHAT IS NOT COVERED:

• Owner is responsible to pay for service calls related to

product installation and/or teaching how to use the product.

• Damage to finish must be reported within 48 hours following

the delivery of the appliance.

• Damage to finish after delivery.

• Improper installation—proper installation includes adequate

air circulation to the refrigeration system, adequate electrical,

plumbing and other connecting facilities.

• Replacement of house fuses or resetting of circuit breakers.

• Replacement of light bulbs.

• Damage to product caused by accident, fire, floods or acts

of God.

• Loss of food due to spoilage.

• Proper use and care of product as listed in the owner’s

manual, proper setting of controls.

• Product not accessible to provide required service.

• WARRANTOR IS NOT RESPONSIBLE FOR CONSEQUENTIAL

DAMAGES.

IMPORTANT

Keep this warranty and your bill of sale as proof of original purchase and purchase date.

Please have serial number and model number available when calling for service.

Camco Service is available coast to coast. If further help is

needed concerning this warranty, contact:

Manager, Consumer Relations

Camco Inc., Consumer Service

1 Factory Lane, Suite 310

Moncton, New Brunswick E1C 9M3

1.800.361.3400

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

What is covered How Long Warranted Parts Labour

(From Date of Sale) Repair or Replace

at Camco’s Option

Compressor GE Profile: Ten (10) Years GE Profile: Ten (10) Years GE Profile: Five (5) Years

GE and All Other GE and All Other GE and All Other

Brands: One (1) Year Brands: One (1) Year Brands: One (1) Year

Sealed System (including GE Profile: Five (5) Years GE Profile: Five (5) Years GE Profile: Five (5) Years

evaporator, condenser GE and All Other GE and All Other GE and All Other

tubing and refrigerant) Brands: One (1) Year Brands: One (1) Year Brands: One (1) Year

All Other Parts One (1) Year One (1) Year One (1) Year

CUSTOMER WARRANTY

(for customers in Canada)

Your refrigerator is warranted to be free of defects in material and workmanship.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular purpose,

are limited to one year or the shortest period allowed by law.

Page 25

25

Please place in envelope and mail to:

Veuillez mettre dans une enveloppe et envoyez à :

OWNERSHIP REGISTRATION

P.O. BOX 1780

MISSISSAUGA, ONTARIO

L4Y 4G1

(FOR CANADIAN CONSUMERS ONLY)

Page 26

26

Page 27

General Electric Company

Warranty Registration Department

P.O. Box 32150

Louisville, KY 40232-2150

GE Service Protection Plus

™

GE, a name recognized worldwide for quality and dependability, offers you

Service Protection Plus

™

—comprehensive protection on all your appliances—

No Matter What Brand!

Benefits Include:

• Backed by GE

• All brands covered

• Unlimited service calls

• All parts and labor costs included

• No out-of-pocket expenses

• No hidden deductibles

• One 800 number to call

You will be completely satisfied with our service protection or you may request your money back

on the remaining value of your contract. No questions asked. It’s that simple.

Protect your refrigerator, dishwasher, washer and dryer, range, TV, VCR and much more—any brand!

Plus there’s no extra charge for emergency service and low monthly financing is available. Even icemaker

coverage and food spoilage protection is offered. You can rest easy, knowing that all your valuable

household products are protected against expensive repairs.

Place your confidence in GE and call us in the U.S. toll-free at 800.626.2224

for more information.

*All brands covered, up to 20 years old, in the continental U.S.

We’ll Cover Any Appliance.

Anywhere. Anytime.*

Please place in envelope and mail to:

✁

Cut here

27

Page 28

Consumer Product Ownership Registration

Im

p

o

rta

n

t

M

a

il

T

o

d

a

y!

First

Name

Mr. ■■ Ms. ■■ Mrs. ■■ Miss ■■

Street

Address

City

State

Date Placed

In Use

Month

Day

Year

Zip

Code

Apt. #

Last

Name

Phone

Number

_

_

Consumer Product Ownership Registration

Dear Customer:

Thank you for purchasing our product and thank you for placing your confidence in us.

We are proud to have you as a customer!

Follow these three steps to protect your new appliance investment:

Important: If you did not get a registration card with your

product, detach and return the form below to

ensure that your product is registered, or register

online at ge.com.

1

23

Model Number Serial Number

✁

Cut here

Complete and mail

your Consumer

Product Ownership

Registration today.

Have the peace of

mind of knowing we

can contact you in

the unlikely event of

a safety modification.

After mailing the

registration below,

store this document

in a safe place. It

contains information

you will need should

you require service.

Our service number

in the USA is:

800 GE CARES

(800.432.2737). In

Canada: 1.888.880.3030.

Read your Owner’s

Manual carefully.

It will help you

operate your new

appliance properly.

Model Number Serial Number

E-mail Address*

28

* Please provide your e-mail address to receive, via e-mail, discounts, special offers and

other important communications from GE Appliances (GEA).

■■ Check here if you do not want to receive communications from GEA’s carefully

selected partners.

FAILURE TO COMPLETE AND RETURN THIS CARD DOES NOT DIMINISH YOUR

WARRANTY RIGHTS.

For information about GEA’s privacy and data usage policy, go to ge.com and click on

“Privacy Policy” or call 800.626.2224.

GE Consumer & Industrial

Appliances

General Electric Company

Louisville, KY 40225

ge.com

Page 29

Refrigerator Warranty. (For customers in the United States)

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule service,

on-line, 24 hours a day, visit us at ge.com, or call 800.GE.CARES

(800.432.2737). Please have serial number and model number

available when calling for service.

For The Period Of: GE Will Replace:

GE and GE PROFILE MODELS:

One Year Any part of the refrigerator which fails due to a defect in materials or workmanship.

From the date of the During this limited one-year warranty, GE will also provide, free of charge, all labor and

original purchase related service to replace the defective part.

Thirty Days Any part of the water filter cartridge which fails due to a defect in materials or workmanship.

(Water filter, if included) During this limited thirty-day warranty, GE will also provide, free of charge, a replacement water

From the original filter cartridge.

purchase date of

the refrigerator

GE PROFILE MODELS ONLY:

Five Years Any part of the sealed refrigerating system (the compressor, condenser, evaporator

(GE Profile models only) and all connecting tubing) which fails due to a defect in materials or workmanship.

From the date of the During this limited five-year sealed refrigerating system warranty, GE will also provide,

original purchase free of charge, all labor and related service to replace the defective part in the sealed

refrigerating system.

■ Service trips to your home to teach you how to use

the product.

■ Improper installation, delivery or maintenance.

■ Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

■ Loss of food due to spoilage.

■ Replacement of house fuses or resetting of circuit

breakers.

■ Damage caused after delivery.

■ Replacement of the water filter cartridge, if included,

due to water pressure that is outside the specified

operating range or due to excessive sediment in the

water supply.

■ Replacement of the light bulbs, if included, or water filter

cartridge, if included, other than as noted above.

■ Damage to the product caused by accident, fire, floods

or acts of God.

■ Incidental or consequential damage caused by possible

defects with this appliance.

■ Product not accessible to provide required service.

What GE Will Not Cover:

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. If the product is located in an area where service by a GE Authorized Servicer is not available,

you may be responsible for a trip charge or you may be required to bring the product to an Authorized GE Service

location for service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this

Limited Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a

particular purpose, are limited to one year or the shortest period allowed by law.

29

Consumer Support

Troubleshooting TipsOperating InstructionsSafety Instructions Installation Instructions

Page 30

Mesures de sécurité . . . . . . . . . .31–33

Instructions de fonctionnement

Bacs de rangement . . . . . . . . . . .36, 37

Clayettes . . . . . . . . . . . . . . . . . . .35, 36

Commandes de la température . . . .34

Entretien et nettoyage . . . . . . . .39, 40

Machine à glaçons automatique . . . .38

Instructions d’installation

Installation de la

conduite d’eau . . . . . . . . . . . . . .42–46

Inversion de

l’ouverture des portes . . . . . . . . .47–52

Préparation à l’installation

du réfrigérateur . . . . . . . . . . . . .41, 42

En cas de panne

Avant d’appeler un réparateur . . .54, 55

Bruits normaux

de fonctionnement . . . . . . . . . . . . . .53

Soutien au consommateur

Garantie . . . . . . . . . . . . . . . . . . . . . .56

Soutien au consommateur . . . . . . . .59

Écrivez ici le numéro de modèle et le

numéro de série :

Modèle #__________________________

Série # __________________________

Vous les trouvez sur une étiquette

dans le coin supérieur gauche du

compartiment réfrigérateur.

30

Soutien au

consommateur

Conseils de dépannage

Fonctionnement Mesures de sécuritéInstallation

Page 31

31

Soutien au

consommateur

Conseils de dépannageFonctionnementMesures de sécurité Installation

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ.

LISEZ TOUTES LES INSTRUCTIONS AVANT

D’UTILISER VOTRE RÉFRIGÉRATEUR.

www.electromenagersge.ca

AVERTISSEMENT!

N’utilisez cet appareil qu’aux fins prévues dans le présent Manuel du propriétaire.

MESURES DE SÉCURITÉ

Pour utiliser un appareil électroménager électrique, vous devez prendre des mesures de sécurité,

en particulier :

■

■ Vous devez bien installer et placer votre

réfrigérateur, conformément aux Instructions

d’installation avant de l’utiliser.

■

■ Ne permettez jamais aux enfants de grimper, de

monter, de se tenir ou de se pendre aux étagères

de votre réfrigérateur. Ils peuvent endommager

le réfrigérateur et se blesser sérieusement.

■

■ Ne touchez jamais les surfaces froides dans le

compartiment congélation quand vos mains sont

humides ou mouillées. Votre peau peut coller à

ces surfaces extrêmement froides.

■

■ Ne conservez jamais ou n’utilisez jamais

d’essence ou d’autres liquides ou gaz

inflammables à proximité de votre réfrigérateur

ou de tout autre appareil électroménager.

■

■ Dans les réfrigérateurs qui ont des machines à

glaçons, évitez tout contact avec les éléments

mobiles du mécanisme d’éjection ou avec

l’élément chauffant situé à la partie inférieure de

la machine à glaçons. Ne mettez jamais vos doigts

ou vos mains sur le mécanisme de fabrication

automatique de glaçons quand le réfrigérateur

est branché.

■

■ Ne laissez jamais vos doigts dans des endroits où

ils risquent d’être pincés. L’écartement entre les

portes et l’armoire est nécessairement petit. Faites

attention de fermer les portes quand des enfants

se trouvent à proximité.

■

■ Débranchez votre réfrigérateur avant de le

nettoyer et de le réparer.

NOTE : Nous vous recommandons fortement de faire

accomplir tout service par un technicien qualifié.

■

■ Lorsque vous réglez la commande sur 0 (arrêt),

l’alimentation électrique de l’ampoule n’est pas

coupée.

■

■ Ne recongelez jamais des aliments congelés qui

ont complètement dégelé.

Page 32

UTILISATION DE RALLONGES ÉLECTRIQUES

Nous vous recommandons fortement de ne pas utiliser de rallonge électrique, à cause d’un danger de

risques possibles de sécurité dans certaines conditions.

Cependant, si vous devez absolument utiliser un cordon rallonge électrique, il est absolument requis que

vous utilisiez un cordon rallonge trifilaire, avec mise à la terre, certifié UL (aux États-Unis) ou ACNOR

(au Canada), avec prise et fiche à trois conducteurs, et à notation électrique de 15 ampères (minimum)

et 120 volts.

DANGER! RISQUE DE PRISE AU PIÈGE D’ENFANT

BONNE MISE AU REBUT DE VOTRE RÉFRIGÉRATEUR

L’enfermement et l’asphyxie des enfants ne sont

pas des histoires du passé. Les réfrigérateurs jetés

ou abandonnés sont toujours dangereux... même

s’ils ne doivent rester là que «quelques jours». Si

vous vous débarrassez de votre vieux réfrigérateur,

suivez les instructions suivantes pour prévenir tout

accident.

Avant de jeter votre vieux réfrigérateur ou

congélateur :

■ Enlevez les portes.

■ Laissez les clayettes en place, pour éviter que

des enfants puissent facilement grimper

et se tenir dans votre réfrigérateur.

Réfrigérants

Tous les appareils de réfrigération contiennent

des réfrigérants qui, conformément aux lois

fédérales, doivent être enlevés avant toute

élimination de l’appareil. Si vous vous

débarrassez de vieux appareils de réfrigération,

vérifiez, auprès de la société qui s’occupe de

leur élimination, ce que vous devez faire.

32

Soutien au

consommateur

Conseils de dépannage

Fonctionnement Mesures de sécuritéInstallation

INSTRUCTIONS IMPORTANTES DE SÉCURITÉ.

LISEZ TOUTES LES INSTRUCTIONS AVANT

D’UTILISER VOTRE RÉFRIGÉRATEUR.

Page 33

33

Soutien au

consommateur

Conseils de dépannageFonctionnementMesures de sécurité Installation

BRANCHEMENT ÉLECTRIQUE

Ne coupez ou n’enlevez jamais, en n’importe quelles conditions, la troisième broche (mise à la terre)

de votre cordon d’alimentation. Pour votre sécurité personnelle, vous devez bien mettre à la terre cet

appareil électroménager.

Le cordon d’alimentation de cet appareil est muni

d’une fiche à trois broches (bipolaire avec terre)

qui se met dans une prise murale à trois trous

(bipolaire avec terre), pour réduire le risque de

secousse électrique occasionné par cet appareil.

Faites vérifier la prise murale et le circuit électrique

par un électricien qualifié pour vous assurer que

la prise murale est bien mise à la terre.

Si vous avez une prise murale à deux broches

seulement (sans terre), vous êtes personnellement

responsable et obligé de la faire remplacer par une

bonne prise murale avec terre, bien mise à la terre.

Vous devez toujours brancher votre réfrigérateur à

sa propre prise électrique, qui doit avoir un voltage

correspondant à celui de la plaque signalétique de

votre réfrigérateur.

Le rendement de votre réfrigérateur sera meilleur

et vous éviterez ainsi de surcharger les circuits

électriques et de surchauffer le câblage de votre

maison, et éviterez ainsi tout risque d’incendie

provoqué par des câbles surchauffés.

Ne débranchez jamais votre réfrigérateur en

tirant sur le cordon d’alimentation. Tenez toujours

la fiche fermement et enlevez-la de la prise en

tirant droit.

Réparez ou remplacez immédiatement tout cordon

d’alimentation usé ou endommagé. N’utilisez

jamais de cordon fissuré ou usé sur sa longueur

ou à l’une de ses extrémités.

Pour écarter votre réfrigérateur du mur, faites

attention de ne pas écraser ou d’endommager

le cordon d’alimentation.

LISEZ ET SUIVEZ SOIGNEUSEMENT CES MESURES DE SÉCURITÉ.

CONSERVEZ CES INSTRUCTIONS

www.electromenagersge.ca

AVERTISSEMENT!

Page 34

34

Soutien au

consommateur

Conseils de dépannage

Installation Mesures de sécuritéFonctionnement

Bouton de commande de la température.

Réglages de la commande

Bouton de commande de la température

Le bouton de commande de la température possède neuf positions plus la position 0. 1 est la

température la plus élevée, 9 la plus basse. Au départ, réglez le bouton de commande à la position 5.

Après avoir utilisé le réfrigérateur quelque temps, réglez le bouton de commande si nécessaire.

Insérez une pièce de monnaie dans l’encoche au milieu du bouton de commande pour pouvoir

tourner celui-ci à la position qui convient le mieux à vos besoins.

24 heures sont nécessaires pour refroidir le réfrigérateur.

Tournez le bouton à la position 0 pour arrêter le refroidissement dans les deux compartiments réfrigérateur et

congélateur, mais cela ne coupe pas l’alimentation du réfrigérateur.

Page 35

Soutien au

consommateur

Conseils de dépannageFonctionnement

Mesures de sécurité

Installation

Clayettes du compartiment réfrigérateur.

www.electromenagersge.ca

Les clayettes se placent à différents niveaux vous permettant de personnaliser l’espace de rangement.

Toutes les caractéristiques ne sont pas disponibles sur tous les modèles.

Clayettes pleine largeur

Certains modèles possèdent une clayette

coulissante métallique, une clayette en

verre trempée fixe ou deux clayettes fixes

métalliques. Vous pouvez déplacer ces

clayettes à un autre endroit du

compartiment réfrigérateur.

La clayette coulissante pleine largeur

possède des butées. Lorsqu’elle est placée

correctement sur ses supports, la clayette

s’arrêtera aux butées et ne sortira pas

complètement du réfrigérateur, et ne

s’inclinera pas si vous y placez ou enlevez

de la nourriture.

Pour enlever les clayettes pleine largeur,

relevez l’arrière de la clayette et tirez-la

vers l’avant.

Pour enlever une clayette pleine largeur

lorsque la porte du compartiment

réfrigérateur ne peut pas s’ouvrir

complètement, relevez l’arrière de la

clayette, tirez-la vers l’avant et vers le bas,

inclinez la clayette pour la retirer.

Clayettes demi-largeur

Un côté de la clayette repose sur le

support moulé dans la cloison latérale;

un support de l’autre côté permet

d’accrocher la clayette dans un rail

de la cloison arrière.

Pour enlever la clayette, relevez-la à

l’avant et retirez-la du support et du rail.

Pour remettre la clayette, sélectionnez la

hauteur désirée. Relevez légèrement la

clayette à l’avant, fixez le crochet

supérieur dans le rail, puis abaissez

la clayette sur le support.

REMARQUE : La clayette à droite du rail est

conçue pour s’accrocher dans l’encoche de

droite; la clayette à gauche du rail est conçue

pour s’accrocher dans l’encoche de gauche.

2

Soulevez pour dégager

1

Relevez

Clayettes anti-déversement (sur certains modèles)

Les clayettes anti-déversement ont des

bords spéciaux pour empêcher tout

déversement aux clayettes inférieures. Pour

enlever ou remettre en place ces clayettes,

consultez les instructions ci-dessus.

35

Page 36

36

Soutien au

consommateur

Conseils de dépannage

Installation Mesures de sécuritéFonctionnement

Clayettes du compartiment congélateur.

Certains modèles possèdent une clayette pour moule à glaçons et certains modèles, une clayette étagée

pleine largeur.

Clayette pour moule à glaçons

Pour enlever la clayette pour moule à

glaçons, relevez le côté gauche de la

clayette de ses supports. Tirez ensuite la

clayette vers la gauche pour la libérer des

capuchons de support. Tirez la clayette

vers la droite pour libérer les tenons des

trous de la cloison de la caisse.

Clayette étagée

Pour enlever la clayette étagée :

Relevez légèrement le côté gauche de

la clayette.

Déplacez la clayette vers la gauche pour

libérer son côté droit des trous de la

cloison de la caisse.

Abaissez le côté droit de la clayette,

déplacez-la vers la droite pour l’enlever.

Pour remettre la clayette étagée :

La clayette étant inclinée comme il

est illustré sur la figure, insérez les

extrémités gauches de la clayette dans

les trous de la cloison de la caisse.

Relevez légèrement le côté gauche

de la clayette, relevez-la et insérez les

extrémités droites de la clayette dans

les trous de la cloison de la caisse.

Abaissez la clayette pour la mettre

en place.

2

1

3

2

1

Capuchons de support

Bacs de rangement.

Toutes les caractéristiques ne sont pas disponibles sur tous les modèles.

Bacs à légumes et à fruits

Lorsque l’eau s’accumule au fond des

bacs, videz-les et essuyez-les.

Bac à collation

Le bac à collation peut être placé à

l’emplacement qui convient le mieux

aux besoins de votre famille.

Page 37

37

Soutien au

consommateur

Conseils de dépannageFonctionnementMesures de sécurité Installation

Enlèvement du bac de rangement et du couvercle.

www.electromenagersge.ca

Toutes les caractéristiques ne sont pas disponibles sur tous les modèles.

Enlèvement du bac de rangement et du couvercle

Vous pouvez enlever facilement les bacs

en relevant légèrement les côtés lorsque

le bac dépasse la position de butée stop.

Bac pleine largeur avec couvercle en plastique

Pour enlever le couvercle, soulevez-le de

ses supports, tirez-le vers l’avant, inclinezle pour l’enlever.

Bacs doubles avec couvercle en verre

Pour enlever les bacs :

Enlevez les deux bacs.

Relevez l’avant du couvercle en verre

par-dessous et en même temps, tirezle vers l’avant aussi loin que possible.

Inclinez-le et enlevez-le. Évitez de

nettoyer le couvercle en verre froid avec

de l’eau chaude, car la grande différence

de température peut le briser.

Enlevez le cadre du bac (enlevez

toujours le couvercle en verre avant

d’enlever le cadre).

Soulevez le cadre des supports de chaque

côté et derrière, tirez-le vers l’avant.

Inclinez-le pour le retirer.

Pour remettre les bacs :

Placez le cadre pour qu’il repose sur

les supports de chaque côté et

derrière.

Remettez le couvercle en verre,

appuyez fermement le bord arrière

dans la rainure arrière du cadre et

abaissez doucement le devant du

couvercle pour le mettre en place.

Replacez les bacs.

3

2

1

3

2

1

Bac à légume à humidité réglable (sur certains modèles)

Faites glisser le réglage en position HIGH

(élevée) pour obtenir l’humidité maximum

qui est recommandée pour la plupart

des légumes.

Faites glisser le réglage en position LOW

(basse) pour obtenir l’humidité minimum

qui est recommandée pour la plupart

des fruits.

Page 38

Machine à glaçons automatique

(sur certains modèles)

La machine à glaçons produit sept glaçons

par cycle, environ 100 à 130 glaçons par

24 heures, selon la température du

compartiment congélation, la température de

la pièce, le nombre de fois que la porte est

ouverte et les autres conditions d’utilisation.

Il y a deux catégories de machine à glaçons :

le modèle à commutateur de marche et le

modèle à bras palpeur.

Si vous faites fonctionner le réfrigérateur

avant de raccorder l’eau à la machine à

glaçons, mettez le commutateur de marche

en position O (arrêt) ou amenez le bras