Page 1

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these

instructions for local inspector’s use.

•

IMPORTANT – Observe all

governing codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this appliance requires

basic mechanical skills.

• Completion time – Refrigerator Installation

15 minutes

Reversing the Door Swing

1 hour

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is not

covered under the Warranty.

• Do not install the refrigerator where the temperature

will go below 60°F (16°C) because it will not run often

enough to maintain proper temperatures.

• Install it on a floor strong enough to support it fully

loaded.

REFRIGERATOR LOCATION

Installation

Refrigerator

Instructions

Models 15, 16, 17, 18

Allow the following clearances for ease of installation,

proper air circulation and plumbing and electrical

connections.

• Sides 3/4″ (19 mm)

• Top 1″ (25 mm)

• Back 1″ (25 mm)

CLEARANCES

Leveling legs near each front corner of the refrigerator

are adjustable. They firmly position the refrigerator

and prevent it from moving when the doors are

opened. Leveling legs should be set so the front of the

refrigerator is raised just enough that the doors close

easily when opened about halfway.

Turn the leveling legs clockwise to raise the

refrigerator, counterclockwise to lower it.

Rollers next to the leveling legs allow you to move the

refrigerator away from the wall for cleaning.

Turn the legs counterclockwise until the weight of the

refrigerator is transferred from them to the rollers.

After rolling the refrigerator back into place, turn the

legs clockwise until the legs again bear the weight of

the refrigerator.

ROLLERS AND LEVELING LEGS

If the refrigerator has an icemaker, it will have to be

connected to a cold water line. A water supply kit

(containing copper tubing, shutoff valve, fittings and

instructions) is available at extra cost from your dealer,

by visiting our Website at www.GEAppliances.com (in

Canada at www.geappliances.ca) or from Parts and

Accessories, 800.626.2002 (in Canada 1.888.261.3055).

WATER SUPPLY TO THE ICEMAKER

(on some models)

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: www.GEAppliances.com

In Canada, call 1.800.361.3400

or Visit our Website at: www.geappliances.ca

12

Page 2

WHAT YOU WILL NEED

• Copper or GE SmartConnect™Refrigerator Tubing

kit, 1/4″ outer diameter to connect the refrigerator

to the water supply. If using copper, be sure both

ends of the tubing are cut square.

To determine how much tubing you need: measure

the distance from the water valve on the back of the

refrigerator to the water supply pipe. Then add 8′

(2.4 m). Be sure there is sufficient extra tubing

(about 8′ [2.4 m] coiled into 3 turns of about 10″

[25 cm] diameter) to allow the refrigerator to move

out from the wall after installation.

GE SmartConnect™Refrigerator Tubing Kits are

available in the following lengths:

2′ (0.6 m) – WX08X10002

6′ (1.8 m) – WX08X10006

15′ (4.6 m) – WX08X10015

25′ (7.6 m) – WX08X10025

Be sure that the kit you select allows at least 8′ (2.4 m)

as described above.

NOTE: The only GE approved plastic tubing is that

supplied in GE SmartConnect™Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Certain

types of plastic will crack or rupture with age and

cause water damage to your home.

INSTALLING THE WATER LINE (ON SOME MODELS)

Installation Instructions

BEFORE YOU BEGIN

Recommended copper water supply kits are WX8X2,

WX8X3 or WX8X4, depending on the amount of

tubing you need. Approved plastic water supply lines

are GE SmartConnect™Refrigerator Tubing

(WX08X10002, WX08X10006, WX08X10015 and

WX08X10025).

When connecting your refrigerator to a GE Reverse

Osmosis Water System, the only approved installation

is with a GE RVKit. For other reverse osmosis water

systems, follow the manufacturer’s recommendations.

This water line installation is not warranted by the

refrigerator or icemaker manufacturer. Follow these

instructions carefully to minimize the risk of expensive

water damage.

Water hammer (water banging in the pipes) in house

plumbing can cause damage to refrigerator parts and

lead to water leakage or flooding. Call a qualified

plumber to correct water hammer before installing

the water supply line to the refrigerator.

To prevent burns and product damage, do not hook

up the water line to the hot water line.

If you use your refrigerator before connecting the

water line, make sure the icemaker power switch is

in the O (off) position (on power switch models) or

the feeler arm is in the STOP (up) position (on feeler

arm models).

Do not install the icemaker tubing in areas where

temperatures fall below freezing.

When using any electrical device (such as a power

drill) during installation, be sure the device is double

insulated or grounded in a manner to prevent the

hazard of electric shock, or is battery powered.

All installations must be in accordance with local

plumbing code requirements.

1

13

Page 3

WHAT YOU WILL NEED (CONT.)

• A GE water supply kit (containing tubing, shutoff

valve and fittings listed below) is available at extra

cost from your dealer or from Parts and Accessories,

800.626.2002.

• A cold water supply. The water pressure must be

between 20 and 120 p.s.i. (1.4–8.1 bar).

• Power drill.

• 1/2″ or adjustable wrench.

• Straight and Phillips blade screwdriver.

• Two 1/4″ outer diameter compression nuts and

2 ferrules (sleeves)—to connect the copper tubing

to the shutoff valve and the refrigerator water valve.

OR

• If you are using a GE SmartConnect™Refrigerator

Tubing kit, the necessary fittings are preassembled

to the tubing.

• If your existing copper water line has a flared fitting

at the end, you will need an adapter (available at

plumbing supply stores) to connect the water line to

the refrigerator OR you can cut off the flared fitting

with a tube cutter and then use a compression

fitting. Do not cut formed end from GE

SmartConnect™Refrigerator tubing.

• Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with a

minimum inside diameter of 5/32″ at the point of

connection to the COLD WATER LINE. Saddle-type

shutoff valves are included in many water supply kits.

Before purchasing, make sure a saddle-type valve

complies with your local plumbing codes.

DRILL THE HOLE FOR THE VALVE

Drill a 1/4″ hole in the water pipe (even if using

a self-piercing valve) using a sharp bit. Remove any

burrs resulting from drilling the hole in the pipe.

Take care not to allow water to drain into the drill.

Failure to drill a 1/4″ hole may result in reduced

ice production or smaller cubes.

3

CHOOSE THE VALVE LOCATION

Choose a location for the valve that is easily

accessible. It is best to connect into the side of

a vertical water pipe. When it is necessary to

connect into a horizontal water pipe, make the

connection to the top or side, rather than at the

bottom, to avoid drawing off any sediment from

the water pipe.

2

Installation Instructions

Install the shutoff valve on the nearest frequently used

drinking water line.

SHUT OFF THE MAIN WATER

SUPPLY

Turn on the nearest faucet long enough to clear

the line of water.

1

INSTALLING THE WATER LINE (CONT.)

1

14

Page 4

FLUSH OUT THE TUBING

Turn the main water supply on and flush out the

tubing until the water is clear.

Shut the water off at the water valve after about

one quart (1 liter) of water has been flushed

through the tubing.

8

CONNECT THE TUBING

TO THE VALVE

Place the compression nut and ferrule (sleeve)

for copper tubing onto the end of the tubing and

connect it to the shutoff valve.

Make sure the tubing is fully inserted into the

valve. Tighten the compression nut securely.

For plastic tubing from a GE SmartConnect

™

Refrigerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then tighten

one additional turn with a wrench. Overtightening

may cause leaks.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

7

Installation Instructions

Saddle-Type

Shutoff Valve

Compression

Nut

SmartConnect

™

Tubing

Packing Nut

Outlet Valve

Ferrule (sleeve)

FASTEN THE SHUTOFF VALVE

Fasten the shutoff valve to the cold water pipe with

the pipe clamp.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

4

Vertical Cold

Water Pipe

Saddle-Type

Shutoff Valve

Pipe Clamp

TIGHTEN THE PIPE CLAMP

Tighten the clamp screws until the sealing washer

begins to swell.

NOTE: Do not overtighten or you may crush the

tubing.

5

Washer

Inlet End

Pipe Clamp

Clamp Screw

ROUTE THE TUBING

Route the tubing between the cold water line and

the refrigerator.

Route the tubing through a hole drilled in the wall

or floor (behind the refrigerator or adjacent base

cabinet) as close to the wall as possible.

NOTE: Be sure there is sufficient extra tubing

(about 8 feet [244 cm] coiled into 3 turns of about

10″ [25 cm] diameter) to allow the refrigerator to

move out from the wall after installation.

6

15

Page 5

Installation Instructions

CONNECT THE TUBING TO THE

REFRIGERATOR

NOTES:

• Before making the connection to the refrigerator,

be sure the refrigerator power cord is not plugged

into the wall outlet.

• We recommend installing a water filter if your

water supply has sand or particles that could clog

the screen of the refrigerator’s water valve. Install

it in the water line near the refrigerator. If using

GE SmartConnect™Refrigerator Tubing kit,

you will need an additional tube (WX08X10002)

to connect the filter. Do not cut plastic tube to

install filter.

Remove the access cover.

Remove the plastic flexible cap from the water

valve (refrigerator connection).

Place the compression nut and ferrule (sleeve)

onto the end of the tubing as shown. On GE

SmartConnect

™

Refrigerator Tubing kit,

the nuts are already assembled to the tubing.

Insert the end of the tubing into the water valve

connection as far as possible. While holding the

tubing, tighten the fitting.

For plastic tubing from a GE SmartConnect

™

Refrigerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then

tighten one additional turn with a wrench.

Overtightening may cause leaks.

9

TURN THE WATER ON AT THE

SHUTOFF VALVE

Tighten any connections that leak.

10

CONNECT THE TUBING TO THE

REFRIGERATOR

(CONT.)

Fasten the tubing into the clamp provided to

hold it in a vertical position. You may need to

pry open the clamp.

Reattach the access cover.

9

Tubing Clamp

1/4″ Compression

Nut

Ferrule

(sleeve)

SmartConnect

™

Tubing

Refrigerator

Connection

1/4″ Copper

Tubing

INSTALLING THE WATER LINE

(CONT.)

1

16

Page 6

Installation Instructions

REVERSING THE DOOR SWING

2

When reversing the door swing:

• Read the instructions all the way through before

starting.

• Handle parts carefully to avoid scratching paint.

• Set screws down by their related parts to avoid using

them in the wrong places.

• Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is completed.

These instructions are for changing the hinges from

the right side to the left side—if you ever want to change

the hinges back to the right side, follow these same

instructions and reverse all references to left and right.

IMPORTANT NOTES

Phillips screwdriver

TOOLS REQUIRED

Masking tape

T20 or T25 Torxdriver,

whichever your model

requires

5/16″ hex-head

socket driver

5/16″ open-end

wrench

Putty knife or thin-blade

screwdriver

PLUG IN THE REFRIGERATOR

Arrange the coil of tubing so that it does not vibrate

against the back of the refrigerator or against the

wall. Push the refrigerator back to the wall.

11

17

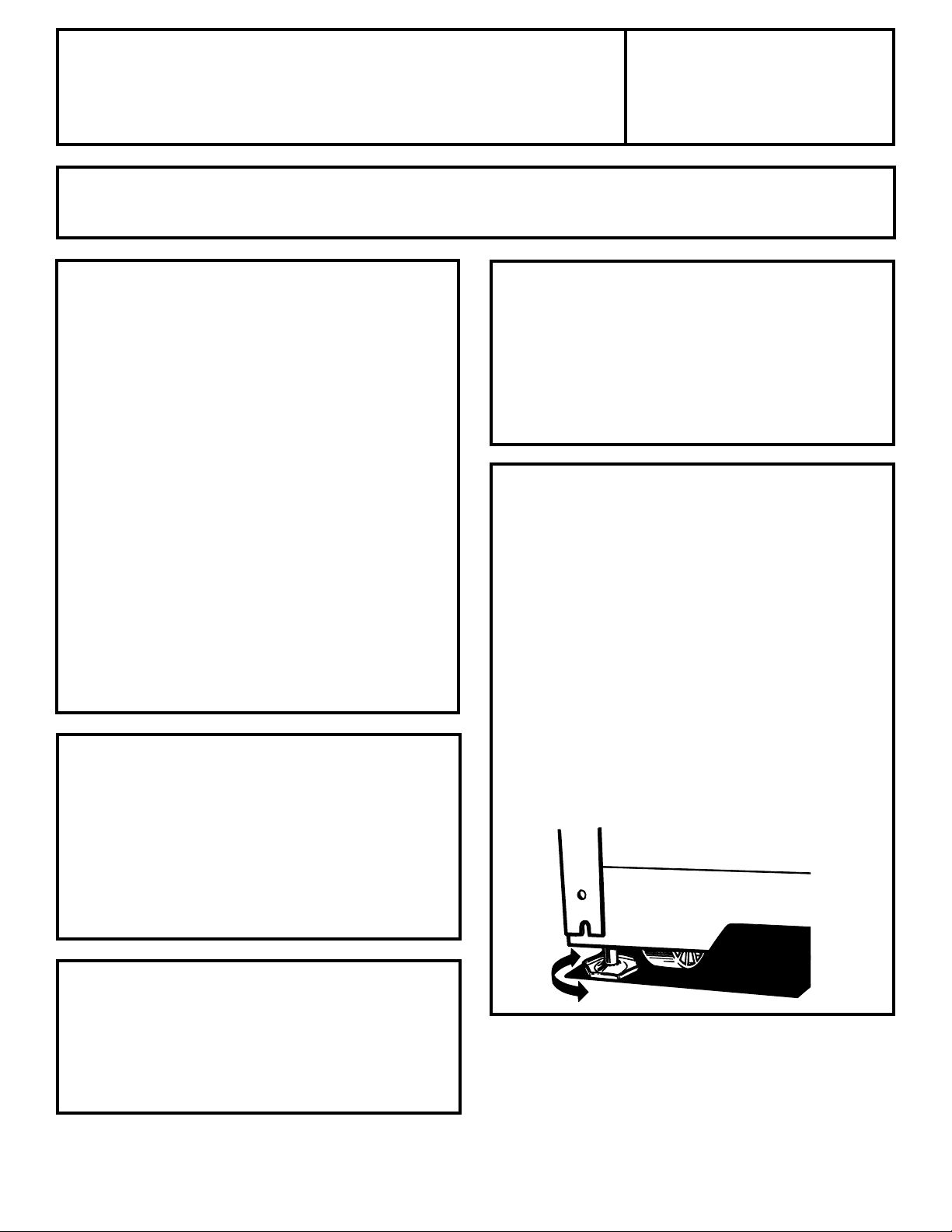

On power switch models, set the icemaker power

switch to the l (on) position. On feeler arm models,

move the feeler arm to the ON (down) position. The

icemaker will not begin to operate until it reaches

its operating temperature of 15°F (–9°C) or below.

It will then begin operation automatically.

NOTE: In lower water pressure conditions, the

water valve may turn on up to 3 times to deliver

enough water to the icemaker.

START THE ICEMAKER

Power

switch

Power switch model

Feeler Arm in the

STOP (up) position

Feeler Arm in

the ON (down) position

Feeler arm model

12

Loading...

Loading...