Page 1

Coin- Operated Commercial Dryer

Installation Instructions and

Use and Care Guide

Machine À Laver Par Culbutage Commerciale

à encaissement automatique

Instructions d’installation et

Guide d’utilisation et d’entretien

P/N 134996600B (0711) www.GEAppliances.ca

Page 2

Contents

SUBJECT PAGE

Pre-Installation Requirements.................................3

Electrical Requirements..........................................3

Exhaust System Requirements............................3-4

Gas Supply Requirements.......................................4

Rough-In Dimensions..............................................5

Unpacking................................................................5

Reversing Door Swing.............................................5

Location of Your Dryer.............................................6

Electrical Installation...............................................7

Grounding Requirements........................................7

Electrical Connections—3-wire..............................8

Electrical Connections—4-wire..............................8

Installation................................................................9

Lint Blade Retaining Pin Location...........................9

Meter case instructions......................................9-12

Replacement Parts.................................................12

Parts lists.........................................................13-15

Consumer support.............................................16-17

Français.............................................................18-32

For GE warranty information or to contact a GE Service

Center, call:

1-800-GE CARES or www.GEAppliances.com.

In Canada call:

1-800-561-3344 or www.geappliances.ca.

If you need SERVICE or PARTS for your GE coinoperated dryer: be ready to give the model number,

serial number and date of purchase. Record below.

Model number__________________________________

Serial number___________________________________

Purchase date___________________________________

Record Coin Box

Key Number__________________________

Key number is on key and/or coin box.

Product Record

DRYER SAFETY

Clothes dryer installation and service must be performed by a qualified installer, service agency or the

gas supplier. Install the clothes dryer according to the manufacturer's instructions and local codes.

Before beginning installation, carefully read these instructions. This will simplify the installation and

ensure the dryer is installed correctly and safely. Leave these instructions near the Dryer after

installation for future reference.

NOTE: The electrical service to the Dryer must conform with local codes and ordinances and the latest

edition of the National Electrical Code, ANSI/NFPA 70.

NOTE: The gas service to the Dryer must conform with local codes and ordinances and the latest edition

of the National Fuel Gas Code ANSI Z223.1.

NOTE: The Dryer is designed under ANSI Z 21.5.1 - for HOME USE only. This Dryer is not recommended for

commercial applications such as restaurants or beauty salons, etc.

Your safety and the safety of others is very important. We have provided many important safety messages in the

Installation Instructions / Use & Care Guide and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to hazards that can kill or hurt you or others. All safety

messages will be preceded by the safety alert symbol and the word "DANGER" or "WARNING". These words

mean:

DANGER

All safety messages will identify the hazard, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

fire or explosion or to prevent property damage, personal injury or loss of life. SAVE THESE INSTRUCTIONS.

- Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

· Do not try to light any appliance.

· Do not touch any electrical switch; do not use any phone in your building.

· Clear the room, building or area of all occupants.

· Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier's instructions.

· If you cannot reach your gas supplier, call the fire department.

Installations must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the state, province, or region where this appliance is being installed.

You can be killed or seriously injured if you don't immediately follow instructions.

You

can be killed or seriously injured if you don't follow instructions.

Risk OF FIRE.

For your safety the information in this manual must be followed to minimize the risk of

2

Page 3

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver.

2. Channel-lock adjustable pliers.

3. Carpenter's level.

4. Flat or straight blade screwdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.2 cm) duct.

7. Vent hood.

8. Pipe thread sealer (Gas).

9. Plastic knife.

ELECTRICAL REQUIREMENTS

ELECTRIC Dryer

CIRCUIT - Individual 30 amp. branch circuit fused with 30 amp.

time delay fuses or circuit breakers.

Use separately fused circuits for washers and dryers, and DO

NOT operate a washer and a dryer on the same circuit.

POWER SUPPLY - 3 wire, 240 volt, single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD KIT - The dryer MUST employ a 3conductor power supply cord NEMA 10-30 type SRDT rated at

240 volt AC minimum, 30 amp., with 3 open end spade lug

connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. If being installed in a new

branch circuit installation, manufactured (mobile) home,

recreational vehicle or area which prohibits grounding through

the neutral conductor, the dryer MUST employ a 4-conductor

power supply cord NEMA 14-30 type SRDT or ST (as required)

rated at 240 volt AC minimum, 30 amp., with 4 open end spade

lug connectors with upturned ends or closed loop connectors and

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONS FOR A 4-WIRE SYSTEM.

OUTLET RECEPTACLE - NEMA 10-30R or 14-30R receptacle to

be located so the power supply cord is accessible when the dryer

is in the installed position.

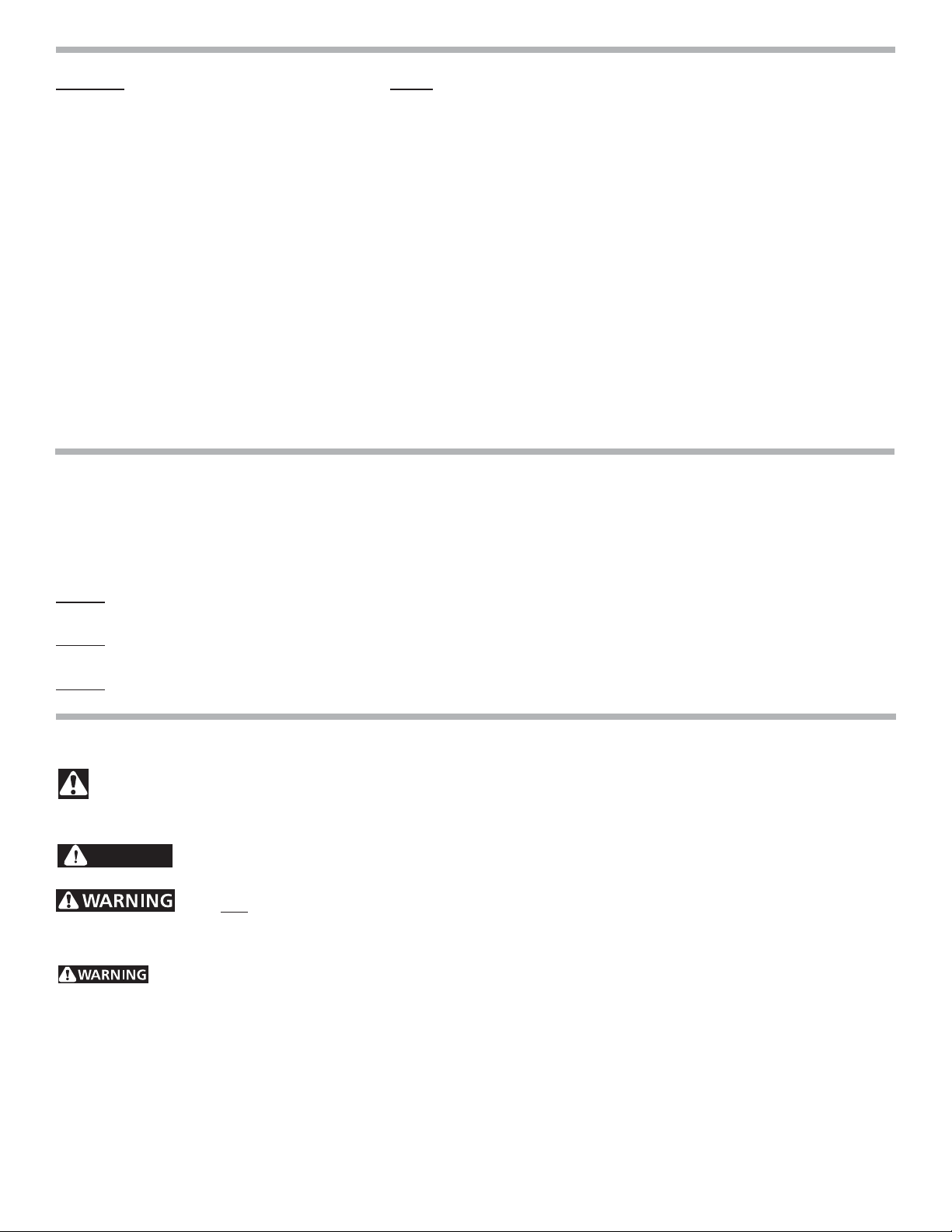

Typical 3-wire installation

POWER SUPPLY

3 WIRE GROUNDED NEUTRAL

120-240 VOLT 60 CYCLE

MAIN FUSE BOX

30 AMP DELAYED ACTION

FUSES

OR CIRCUIT BREAKER

NEUTRAL WIRE

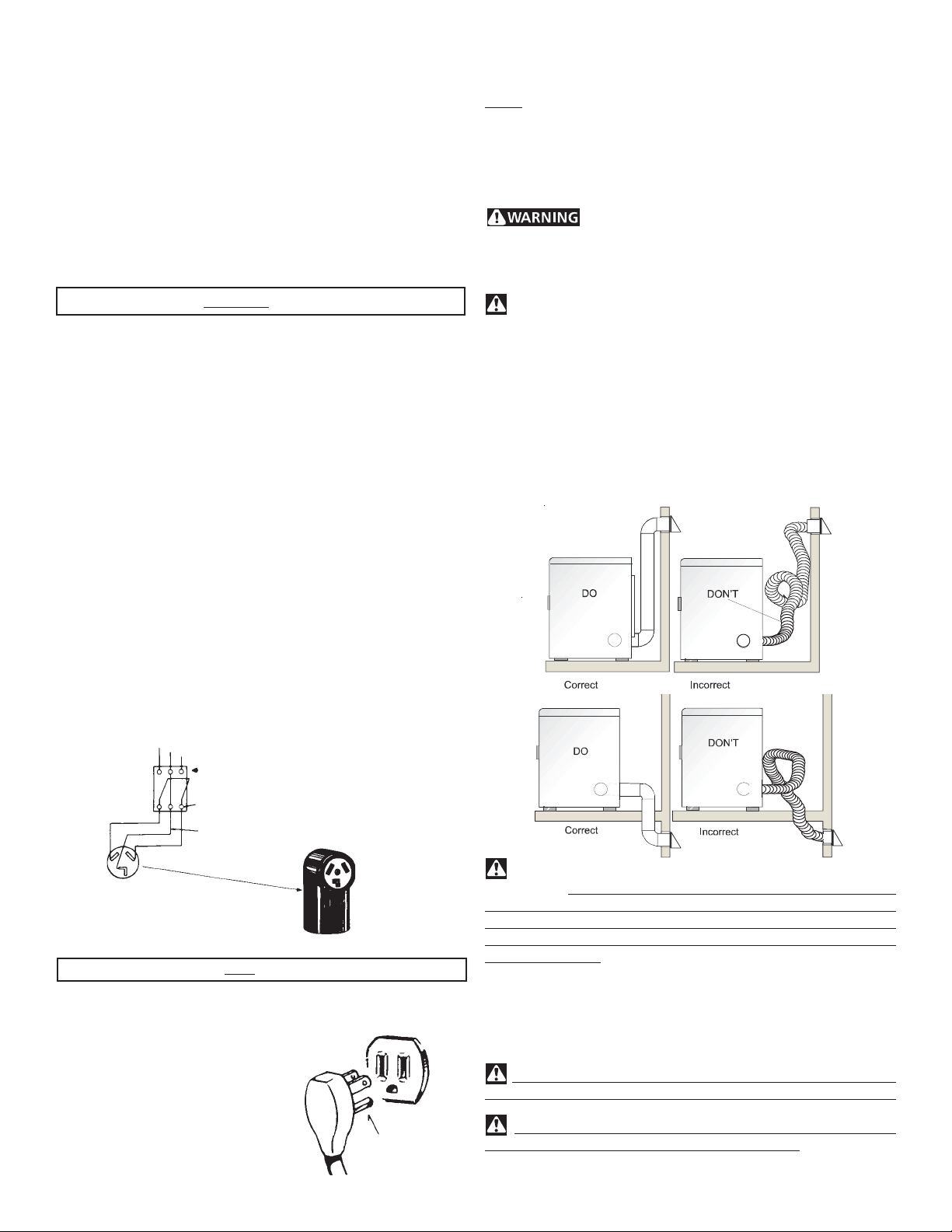

EXHAUST SYSTEM REQUIREMENTS

Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that open when the dryer is in operation. When the

dryer stops, the dampers automatically close to prevent drafts

and the entrance of insects and rodents. To avoid restricting the

outlet, maintain a minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or any other obstruction.

The following are specific requirements for

proper and safe operation of your dryer. Failure to follow

these instructions can create excessive drying times and

fire hazards.

Do not install a clothes dryer with flexible plastic

venting materials. If your present system is made up of plastic

duct or metal foil duct, replace it with a rigid or flexible metal

duct. In Canada and the United States if metal (foil type) duct is

installed, it must be of a specific type identified by the appliance

manufacturer as suitable for use with clothes dryers and in the

United States must also comply with the Outline for Clothes

Dryer Transition Duct, UL standard 2158A. Flexible venting

materials are known to collapse, be easily crushed and trap lint.

These conditions will obstruct clothes dryer airflow and increase

the risk of fire. Ensure the present duct is free of any lint

prior to installing dryer duct.

OUTLET

RECEPTACLE

(COPPER)

SUBJECT TO LOCAL REGULATIONS

NEMA 10-30R (COPPER)

GAS Dryer

CIRCUIT - Individual 15 amp. branch circuit fused with a 15 amp.

maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD - The dryer is

equipped with a 120 volt 3-wire

power cord.

NOTE: Do not under

any circumstances

remove grounding

prong from plug.

GROUNDING

PRONG

- Risk of Fire - A clothes dryer must be exhausted

outdoors. Do not exhaust dryer into a chimney, a wall, a

ceiling, an attic, a crawl space or any concealed space of a

building. A clothes dryer produces combustible lint. If the dryer

is not exhausted outdoors, some fine lint will be expelled into

the laundry area. An accumulation of lint in any area of the

home can create a health and fire hazard. The dryer must be

connected to an exhaust outdoors. Regularly inspect the

outdoor exhaust opening and remove any accumulation of lint

around the outdoor exhaust opening and in the surrounding

area.

Do not allow combustible materials (for example: clothing,

draperies/curtains, paper) to come in contact with exhaust system.

Exceeding the length of duct pipe or number of elbows

allowed in the "MAXIMUM LENGTH" charts can cause an

accumulation of lint in the exhaust system. Plugging the system

could create a fire hazard, as well as increase drying times.

3

Page 4

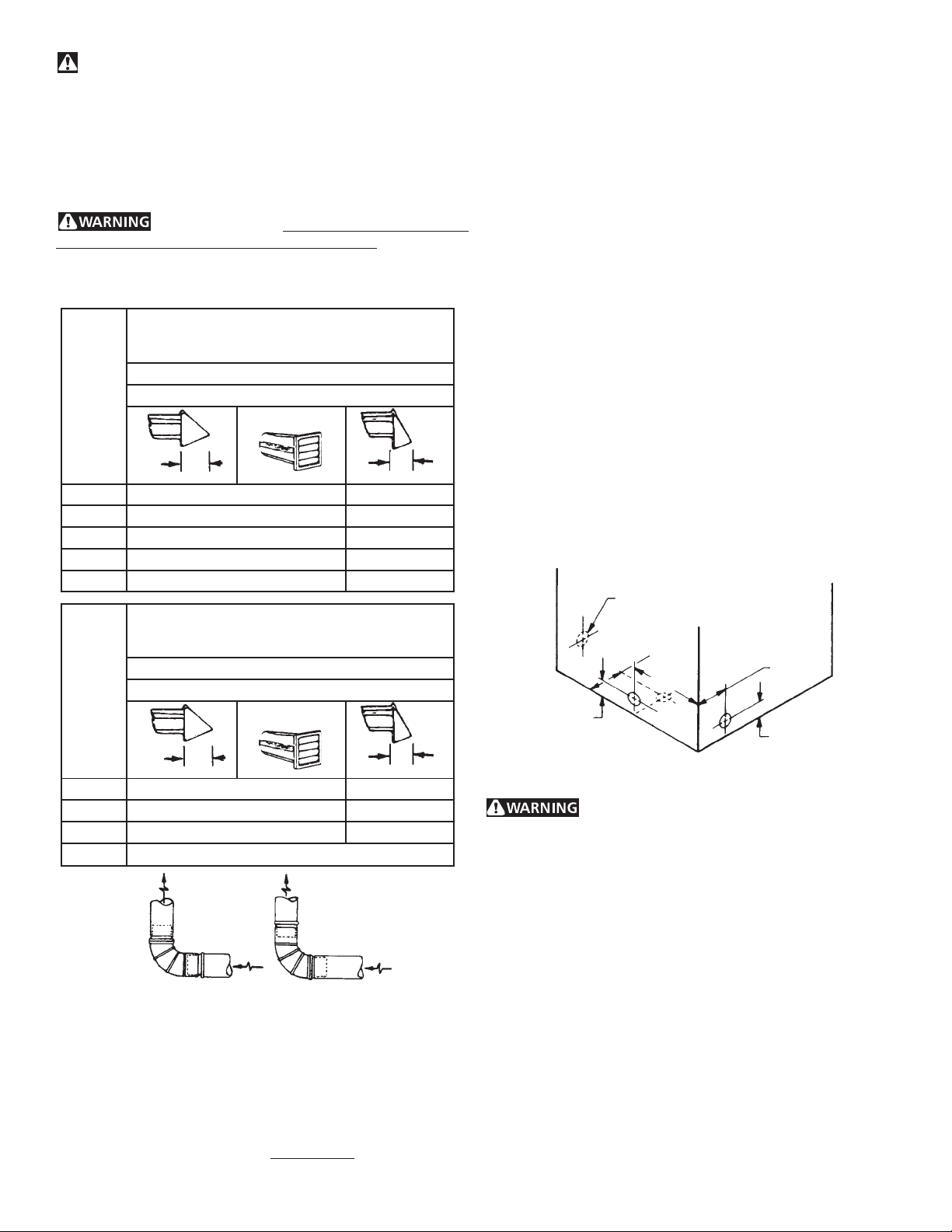

Do not screen the exhaust ends of the vent system,

nor use any screws, rivets or other fastening means that

extend into the duct and catch lint to assemble the exhaust

system. Lint can become caught in the screen, on the screws or

rivets, clogging the duct work and creating a fire hazard as well

as increasing drying times. Use an approved vent hood to

terminate the duct outdoors, and seal all joints with duct tape.

All male duct pipe fittings MUST be installed downstream with

the flow of air.

Explosion hazard. Do not install the dryer where

gasoline or other flammables are kept or stored. If the dryer is

installed in a garage, it must be a minimum of 18 inches (45.7

cm) above the floor. Failure to do so can result in death, explosion,

fire or burns.

MAXIMUM LENGTH

of 4” (10.2 cm) Dia. Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

Number

of

90°

Turns

0 60 ft. (18.28 m) 48 ft.(14.63 m)

1 52 ft. (15.84 m) 40 ft.(12.19 m)

2 44 ft. (13.41 m) 32 ft. (9.75 m)

3 32 ft. (9.75 m) 24 ft. (7.31 m)

4 28 ft. (8.53 m) 16 ft. (4.87 m)

4”

(10.2 cm)

Louvered

2½"

(6.35 cm)

MAXIMUM LENGTH

of 4” (10.2 cm) Dia. Flexible Metal Duct

VENT HOOD TYPE

(Preferred)

Number

of

90°

Turns

0 30 ft. (9.14 m) 18 ft. (5.49 m)

1 22 ft. (6.71 m) 14 ft. (4.27 m)

2 14 ft. (4.27 m) 10 ft. (3.05 m)

3 NOT RECOMMENDED

INSTALL MALE FITTINGS IN CORRECT DIRECTION

4”

(10.2 cm)

CORRECTCORRECT

CORRECT

CORRECTCORRECT

In installations where the exhaust system is not described in the

charts, the following method must be used to determine if the

exhaust system is acceptable:

1. Connect an inclined or digital manometer between the

dryer and the point the exhaust connects to the dryer.

2. Set the dryer timer and temperature to air fluff (cool

down) and start the dryer.

3. Read the measurement on the manometer.

4. The system back pressure MUST NOT be higher than

0.75 inches of water column.

Louvered

(6.35 cm)

INCORRECTINCORRECT

INCORRECT

INCORRECTINCORRECT

2½"

If the system back pressure is less than 0.75 inches of water

column, the system is acceptable. If the manometer reading is

higher than 0.75 inches of water column, the system is too

restrictive and the installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, certain extenuating circumstances could affect the

performance of the dryer:

• Only the rigid metal duct work should be used.

• Venting vertical through a roof may expose the exhaust

system to down drafts causing an increase in vent

restriction.

• Running the exhaust system through an uninsulated area

may cause condensation and faster accumulation of lint.

• Compression or crimping of the exhaust system will cause

an increase in vent restriction.

The exhaust system should be inspected and cleaned a

minimum of every 6 months with normal usage. The more the

dryer is used, the more often you should check the

exhaust system and vent hood for proper operation.

EXHAUST DIRECTION

All dryers shipped from the factory are set up for rear exhausting.

However, on electric dryers, exhausting can be to the right or left

side of the cabinet or the bottom of the dryer. On gas dryers

exhausting can be to the right side of the cabinet or the bottom

of the dryer. Directional exhausting can be accomplished by

installing Exhaust Kit, P/N 131456800, available through your

parts distributor. Follow the instructions supplied with the kit.

EXHAUST DUCT LOCATING DIMENSIONS

SAME AS OTHER SIDESAME AS OTHER SIDE

SAME AS OTHER SIDE

SAME AS OTHER SIDESAME AS OTHER SIDE

5 7/8"5 7/8"

5 7/8"

5 7/8"5 7/8"

(15 cm)(15 cm)

(15 cm)

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

(15 cm)(15 cm)

13 1/2"13 1/2"

13 1/2"

13 1/2"13 1/2"

(34 cm)(34 cm)

(34 cm)

(34 cm)(34 cm)

4 3/8"4 3/8"

4 3/8"

4 3/8"4 3/8"

(11 cm)(11 cm)

(11 cm)

(11 cm)(11 cm)

3 3/4"3 3/4"

3 3/4"

3 3/4"3 3/4"

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

(9.5 cm)(9.5 cm)

(9.5 cm)

(9.5 cm)(9.5 cm)

GAS SUPPLY REQUIREMENTS

Replace copper connecting pipe that is not

plastic-coated. Stainless steel or plastic-coated brass MUST

be used.

Note: See rough-in dimensions on the following page

(Figure 1).

1. Installation MUST conform with local codes, or in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1

(latest edition).

2. The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3. If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

4. The gas supply line MUST have an individual shutoff valve.

5. A 1/8 inch (0.32 cm) N.P.T. plugged tapping, accessible for

test gauge connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

6. The dryer MUST be disconnected from the gas supply piping

system during any pressure testing of the gas supply piping

system at test pressures in excess of 1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the gas supply piping system

during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psig (3.45 kPa).

4

Page 5

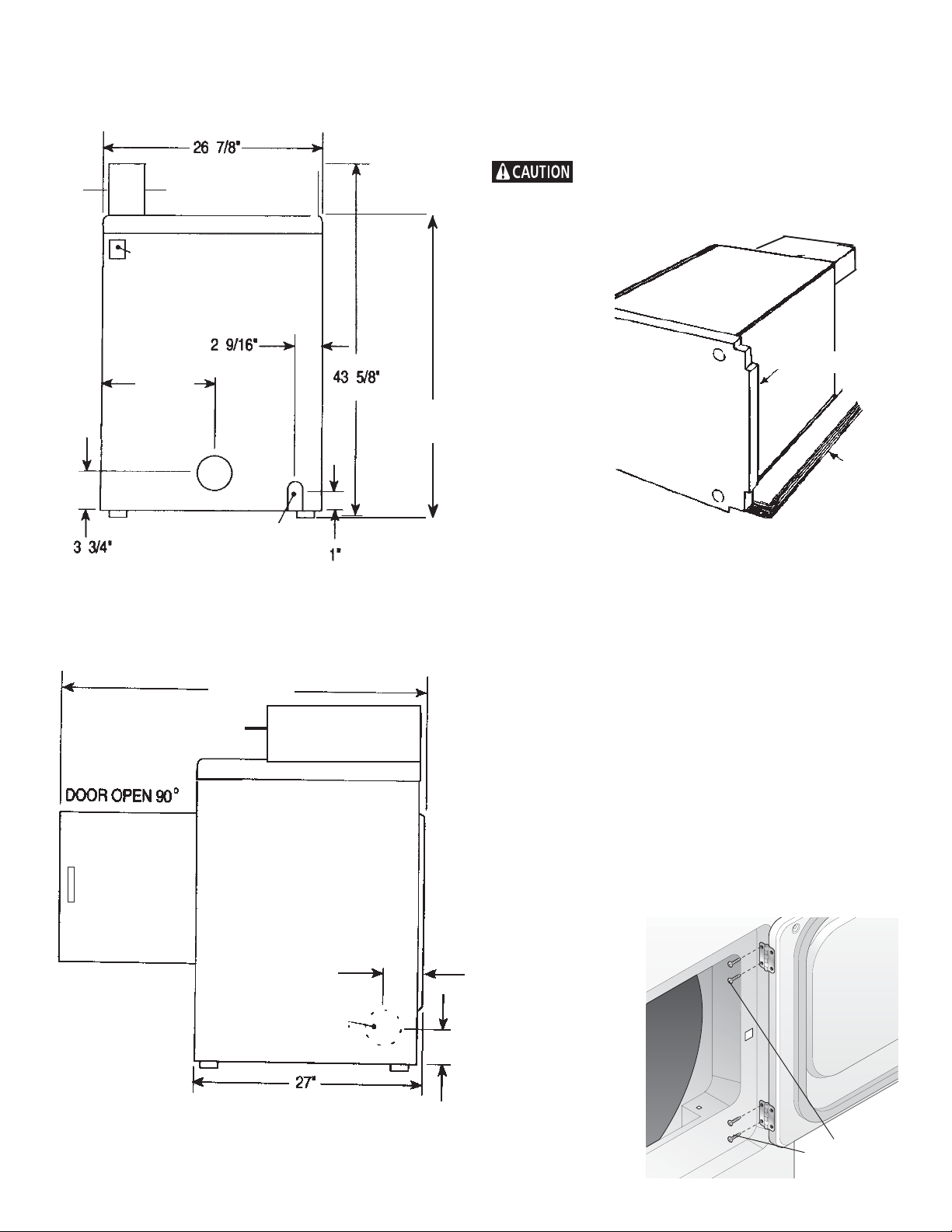

ROUGH-IN DIMENSIONS

UNPACKING

1. Using the four shipping carton corner posts (two on each

side), carefully lay the dryer on its left side and remove foam

shipping base.

(9.5 cm)

(68.3 cm)

43/8"

(11.2cm)

ELECTRIC CONNECTION

REAR VIEWREAR VIEW

REAR VIEW

REAR VIEWREAR VIEW

(6.5 cm)

13 1/2"

3/8" (0.96 cm) DIA. GAS

(110.7 cm)

(2.54 cm)

36"

To prevent damage, do not use the control panel

or coin meter housing as a means to pick up or move the dryer.

2. Return the dryer to an upright position.

FOAM

SHIPPING

PAD

PACKING

REVERSING DOOR SWING

Your dryer is designed so the door swing may be reversed at any

time without additional parts. Conversion is accomplished by

transferring hinges to the opposite side of the cabinet.

To change the direction of the door opening:

47 1/2"

(120.7 cm)

SIDE VIEWSIDE VIEW

SIDE VIEW

SIDE VIEWSIDE VIEW

(11.1 cm)(11.1 cm)

(11.1 cm)

(11.1 cm)(11.1 cm)

OPTIONALOPTIONAL

OPTIONAL

OPTIONALOPTIONAL

VENT VENT

VENT

VENT VENT

(68.6 cm)

4 3/8"4 3/8"

4 3/8"

4 3/8"4 3/8"

KNOCKOUTKNOCKOUT

KNOCKOUT

KNOCKOUTKNOCKOUT

1. Open the dryer door. Remove the four hinge hole plugs from

the left side of the door opening. Place nearby for future

installation.

NOTE: You may need a plastic knife to help pull out the plugs.

Be careful not to scratch the paint.

2. Remove the four screws that secure the door hinges to the

dryer front panel (see below). NOTE: Remove one screw from

each of the two hinges first. Hold the door firmly before

removing the last two screws.

3. Rotate the door 180° and reinstall the door hinges to the dryer

front panel with the four screws.

4. Install the four

hinge hole plugs

in the open

screw holes on

the right side of

the door

opening.

3 3/4"

(9.5 cm)

(Figure 1)

REMOVE 4 SCREWS

(ONE FROM EACH

HINGE FIRST)

5

Page 6

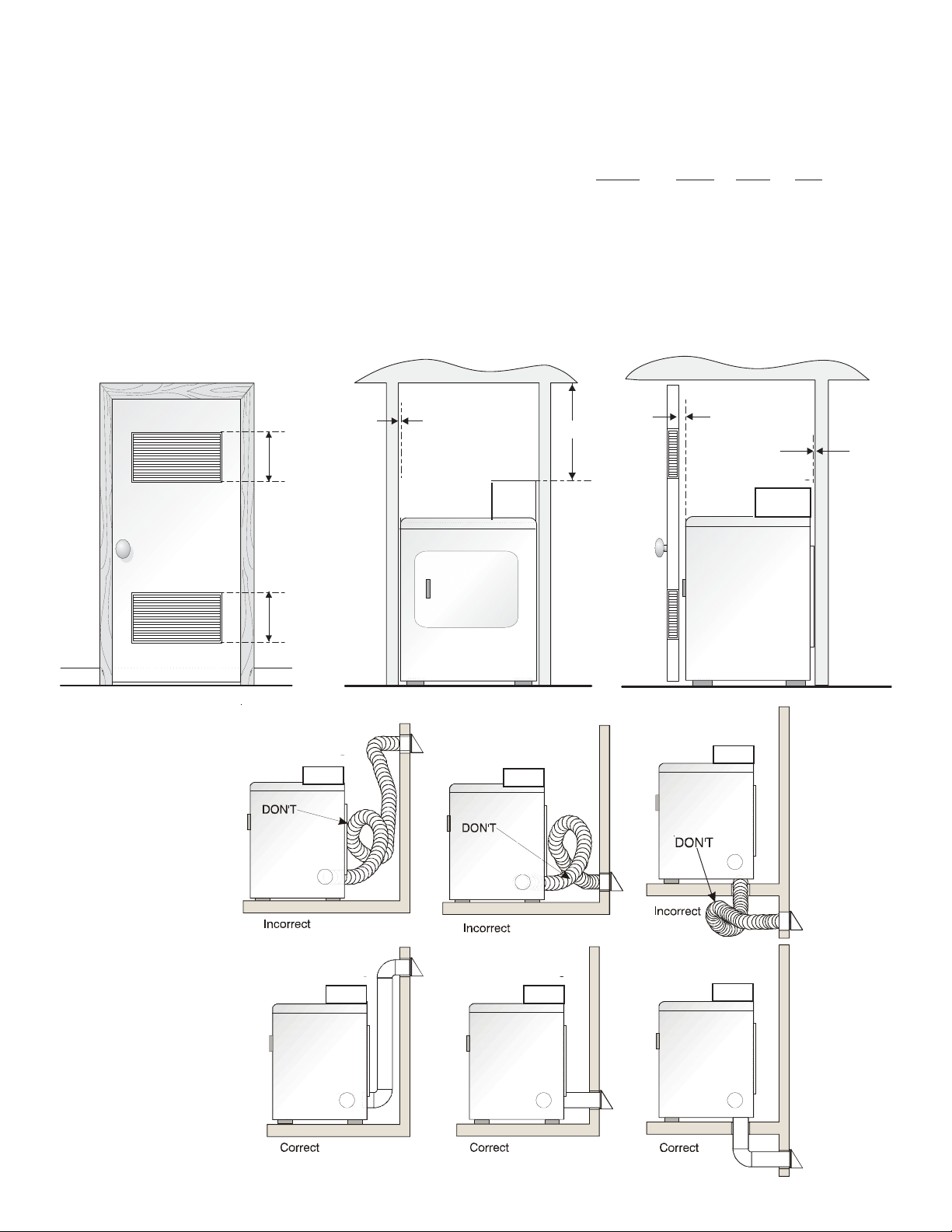

DO NOT INSTALL YOUR DRYER:

1. In an area exposed to dripping water or outside weather

conditions.

2. In an area where it will come in contact with curtains, drapes,

or anything that will obstruct the flow of combustion and

ventilation air.

3. On carpet. Floor MUST be solid with a maximum slope of 1

inch (2.54 cm).

INSTALLATION IN RECESS OR CLOSET

1. A dryer installed in a bedroom, bathroom, recess or closet,

MUST be exhausted outdoors.

2. No other fuel burning appliance shall be installed in the

same closet as the Gas dryer.

3. Your dryer needs the space around it for proper ventilation.

DO NOT INSTALL YOUR DRYER IN A CLOSET WITH A

SOLID DOOR.

0" (0 cm)0" (0 cm)

0" (0 cm)

0" (0 cm)0" (0 cm)

60 SQ. IN.60 SQ. IN.

60 SQ. IN.

60 SQ. IN.60 SQ. IN.

(387.1 SQ. CM)(387.1 SQ. CM)

(387.1 SQ. CM)

(387.1 SQ. CM)(387.1 SQ. CM)

4. A minimum of 120 square inches (774.2 square cm) of

opening, equally divided at the top and bottom of the door,

is required. Air openings are required to be unobstructed

when a door is installed. A louvered door with equivalent

air openings for the full length of the door is acceptable.

MINIMUM INSTALLATION CLEARANCES (Inches)

FRONT SIDES REAR TOP

Alcove 0 (0 cm) 0 (0 cm) 0 (0 cm) 15 (38.1 cm)

Closet 1 (2.54 cm) 0 (0 cm) 0 (0 cm) 15 (38.1 cm)

Closet door ventilation required: 2 louvered openings each 60

square inches (387 square centimeters) — 3 inches (7.6 cm)

from bottom and top of door.

THIS DRYER MUST BE EXHAUSTED OUTDOORS.

5. The following illustrations show minimum clearance

dimensions for proper operation in a recess or closet

installation.

1" (2.54 cm)1" (2.54 cm)

1" (2.54 cm)

15" (38.1 cm)15" (38.1 cm)

15" (38.1 cm)

15" (38.1 cm)15" (38.1 cm)

1" (2.54 cm)1" (2.54 cm)

0" (0 cm)0" (0 cm)

0" (0 cm)

0" (0 cm)0" (0 cm)

CLOSET DOOR

60 SQ. IN.60 SQ. IN.

60 SQ. IN.

60 SQ. IN.60 SQ. IN.

(387.1 SQ. CM)(387.1 SQ. CM)

(387.1 SQ. CM)

(387.1 SQ. CM)(387.1 SQ. CM)

Rigid

Metal

Only

Rigid

Metal

Only

Rigid

Metal

Only

6

Page 7

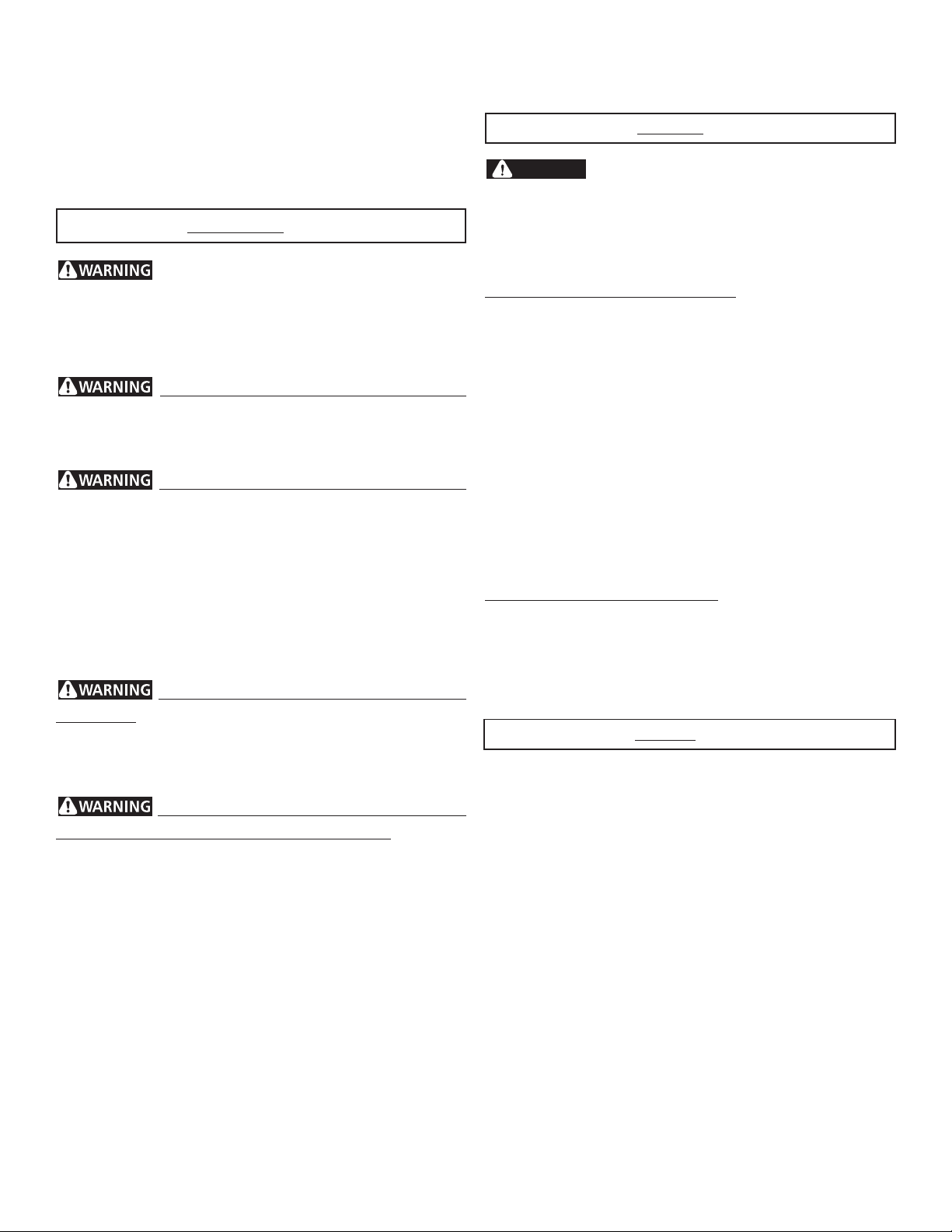

ELECTRICAL INSTALLATION

GROUNDING REQUIREMENTS

Before proceeding with electrical installation, install the

dryer's coin-metering system (when used) in accordance

with the separate instructions provided with the meter.

ALL ELECTRIC Dryers

The following are specific requirements for

proper and safe electrical installation of your dryer. Failure

to follow these instructions can create electrical shock and/

or a fire hazard.

This appliance MUST be properly grounded.

Electrical shock can result if the dryer is not properly grounded.

Follow the instructions in this manual for proper grounding.

Do not use an extension cord with this dryer.

Some extension cords are not designed to withstand the amounts

of electrical current this dryer utilizes and can melt, creating

electrical shock and/or fire hazard. Locate the dryer within reach

of the receptacle for the length power cord to be purchased,

allowing some slack in the cord. Refer to the pre-installation

requirements in this manual for the proper power cord to be

purchased.

A U.L. listed strain relief must be installed onto

power cord. If the strain relief is not attached, the cord can be

pulled out of the dryer and can be cut by any movement of the

cord, resulting in electrical shock.

Do not use an aluminum wired receptacle with

a copper wired power cord and plug (or vice versa). A chemical

reaction occurs between copper and aluminum and can cause

electrical shorts. The proper wiring and receptacle is a copper

wired power cord with a copper wired receptacle.

ELECTRIC Dryer

DANGER

grounding conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to whether the

appliance is properly grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by a path of least resistance for electrical current.

2. If your dryer is equipped with a power supply cord having an

equipment-grounding conductor and a grounding plug, the

plug MUST be plugged into an appropriate, copper wired

receptacle that is properly installed and grounded in

accordance with all local codes and ordinances. If in doubt,

call a licensed electrician. Do not modify plug provided

with the appliance.

For a permanently connected dryer:

1. The dryer MUST be connected to a grounded metal,

permanent wiring system; or an equipment grounding conductor must be run with the circuit conductors and connected

to the equipment-grounding terminal or lead on the appliance.

Improper connection of the equipment

ALL GAS Dryers

This dryer is equipped with a three-prong (grounding) plug for

your protection against shock hazard and should be plugged

directly into a properly grounded three-prong receptacle. Do not

cut or remove the grounding prong from this plug.

NOTE: Dryers operating on 208 volt power supply will have

longer drying times than operating on 240 volt power supply.

7

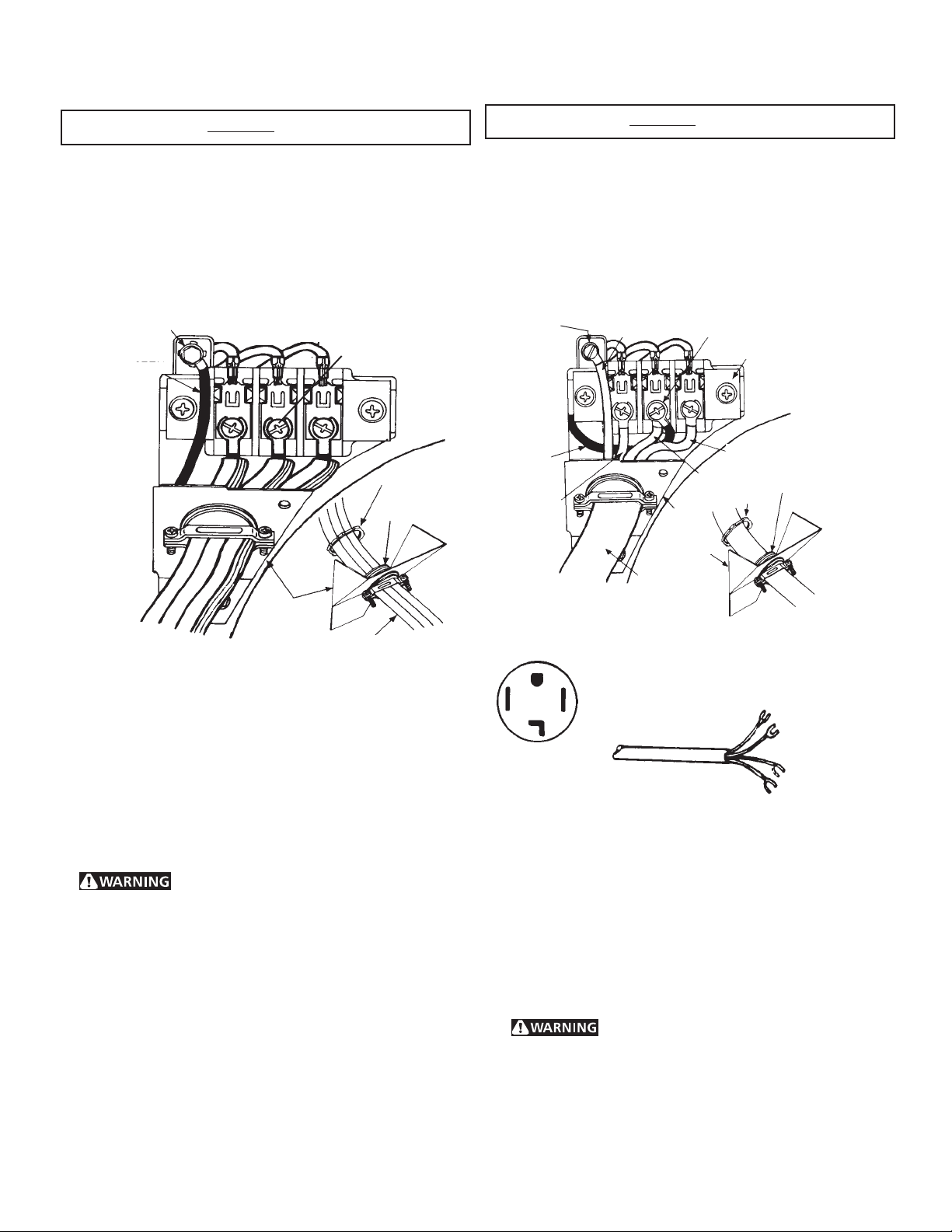

Page 8

ELECTRICAL CONNECTIONS

FOR 3-WIRE SYSTEM

ELECTRICAL CONNECTIONS

FOR 4-WIRE SYSTEM

ELECTRIC Dryer

1. Remove the screws securing the terminal block access cover

and the strain relief mounting bracket located on the back of

the dryer upper corner.

2. Install a U.L. listed strain relief into the power cord entry hole

of the mounting bracket. Finger tighten the nut only at this

time.

GREEN GROUND

SCREW

NEUTRAL

GROUND

WIRE

SILVER TERMINAL

NUT

TIGHTEN NUT

TO THESE

THREADS

ELECTRIC Dryer

1. Remove the screws securing the terminal block access cover

and the strain relief mounting bracket located on the back of

the dryer upper corner.

2. Install a U.L. listed strain relief in the entry hole of the mounting

bracket. Finger tighten the nut only at this time.

3. Remove the ground wire from the green ground screw located

above the terminal block.

GREEN POWER CORD

GREEN

GROUND

SCREW

NEUTRAL

GROUND

WIRE

RED

GROUND WIRE

STRAIN

RELIEF

MOUNTING

BRACKET

SILVER TERMINAL

TERMINAL

BLOCK

BLACK

WHITE

NUT

TIGHTEN NUT

TO THESE

THREADS

STRAIN

RELIEF

MOUNTING

BRACKET

POWER CORD

3. Thread a U.L. listed 30 amp. power cord, NEMA 10-30 Type

SRDT, through the strain relief.

4. Attach the power cord neutral (center wire) conductor to the

silver colored center terminal on the terminal block. Tighten

the screw securely.

5. Attach the remaining two power cord outer conductors to

the outer brass colored terminals on the terminal block. Tighten

both screws securely.

Do not make a sharp bend or crimp wiring/

conductor at connections.

6. Reattach the strain relief mounting bracket to the back of

the dryer with two screws. Tighten screws securely.

7. Tighten the screws securing the cord restraint firmly against

the power cord.

8. Tighten the strain relief nut securely so that the strain relief

does not turn.

9. Reinstall the terminal block cover.

POWER

CORD

4. Thread a U.L. listed 30 amp power cord, NEMA 14-30 type

ST or SRDT through the strain relief.

TYPICAL 4

CONDUCTOR

RECEPTACLE

TYPICAL 4

CONDUCTOR CORD

30 AMP NEMA 14-30 TYPE SRDT OR ST30 AMP NEMA 14-30 TYPE SRDT OR ST

30 AMP NEMA 14-30 TYPE SRDT OR ST

30 AMP NEMA 14-30 TYPE SRDT OR ST30 AMP NEMA 14-30 TYPE SRDT OR ST

BLACK 240V

WHITE NEUTRAL

RED 240V

GREEN GROUND

5. Attach the green power cord ground wire to the cabinet with

the green ground screw.

6. Attach the white (neutral) power cord conductor from the

power cord and the neutral ground wire from the dryer harness

(removed from the ground screw in step 3) to the silver-colored

center terminal on the terminal block. Tighten the screw

securely.

7. Attach the red and black power cord conductors to the outer

brass colored terminals on the terminal block.

Do not make a sharp bend or crimp wiring/

conductor at the connections.

8. Tighten the screws securing the cord restraint firmly against

the power cord.

9. Tighten the strain relief nut securely so the strain relief does

not turn.

10.Reinstall the terminal block access cover.

8

Page 9

INSTALLATION

1. GAS CONNECTION (Gas dryers only)

a. Remove the shipping cap from gas pipe at the rear of the

dryer.

NOTE: DO NOT connect the dryer to L.P. gas service without

converting the gas valve. An L.P. conversion kit must

be installed by a qualified gas technician.

b. Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or approved

pipe from gas supply line to the 3/8 inch (0.96 cm) pipe

located on the back of the dryer. Use a 1/2 inch to 3/8

inch (1.27 cm to 0.96 cm) reducer for a connection. Apply

an approved thread sealer that is resistant to the corrosive

action of liquefied gases on all pipe connections.

Lint Blade Retaining Pin Location and Orientation

c. Open the shutoff valve in the gas supply line.

d. Test all connections by brushing on a soapy water solution.

NEVER TEST FOR GAS LEAKS WITH AN OPEN FLAME.

2. Connect the exhaust duct to outside exhaust system. Use

duct tape to seal all joints.

3. With the dryer in its final position, adjust one or more of the

legs until the dryer is resting solid on all four legs. Place a

level on top of the dryer. THE DRYER MUST BE LEVEL AND

RESTING SOLID ON ALL FOUR LEGS.

4. Plug the power cord into a grounded outlet. NOTE: Check

to ensure the power is off at circuit breaker/fuse box before

plugging the power cord into the outlet.

5. Turn on the power at the circuit breaker/fuse box.

Before operating the dryer, make sure the

dryer area is clear and free from combustible materials,

gasoline, and other flammable vapors. Also see that nothing

(such as boxes, clothing, etc.) obstructs the flow of combustion

and ventilation air.

6. Run the dryer through a cycle check for proper operation.

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If the burner does

not light within 45 seconds the first time the dryer is turned

on, the safety switch will shut the burner off. If this happens,

turn the timer to "OFF" and wait 5 minutes before making

another attempt to light.

Install the pins after the lint blade is installed.

METER CASE INSRUCTIONS

COIN BOX ADJUSTMENT

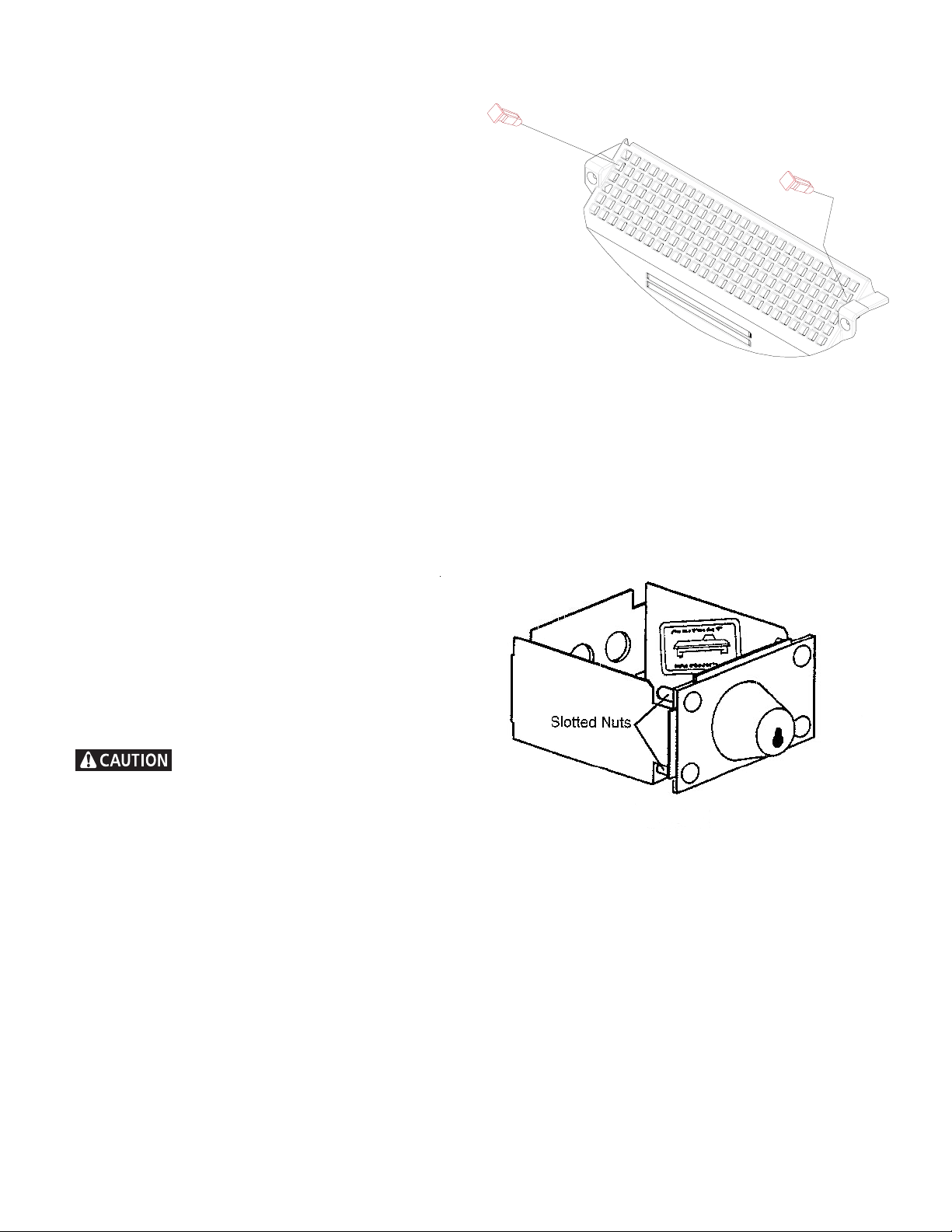

The tight fit of the money box is set at the factory. Customer

may loosen fit as desired by loosening the slotted nuts. See

FIG.1.

FIGURE 1

Keep A record of all coin-box key numbers. A lost key can

only be replaced by ordering the key numbers from the place

were the unit was purchased. The key number is located both

on the key and behind the end panel of the coin box. If the key

number is not available, the lock must be drilled out to remove

the coin box.

7. Place these instructions in a location near the dryer for future

reference.

NOTE: A wiring diagram is located inside the dryer.

9

Page 10

REPLACING NYLON TIMING CAMS ON ACCUMULATOR

MECHANISM

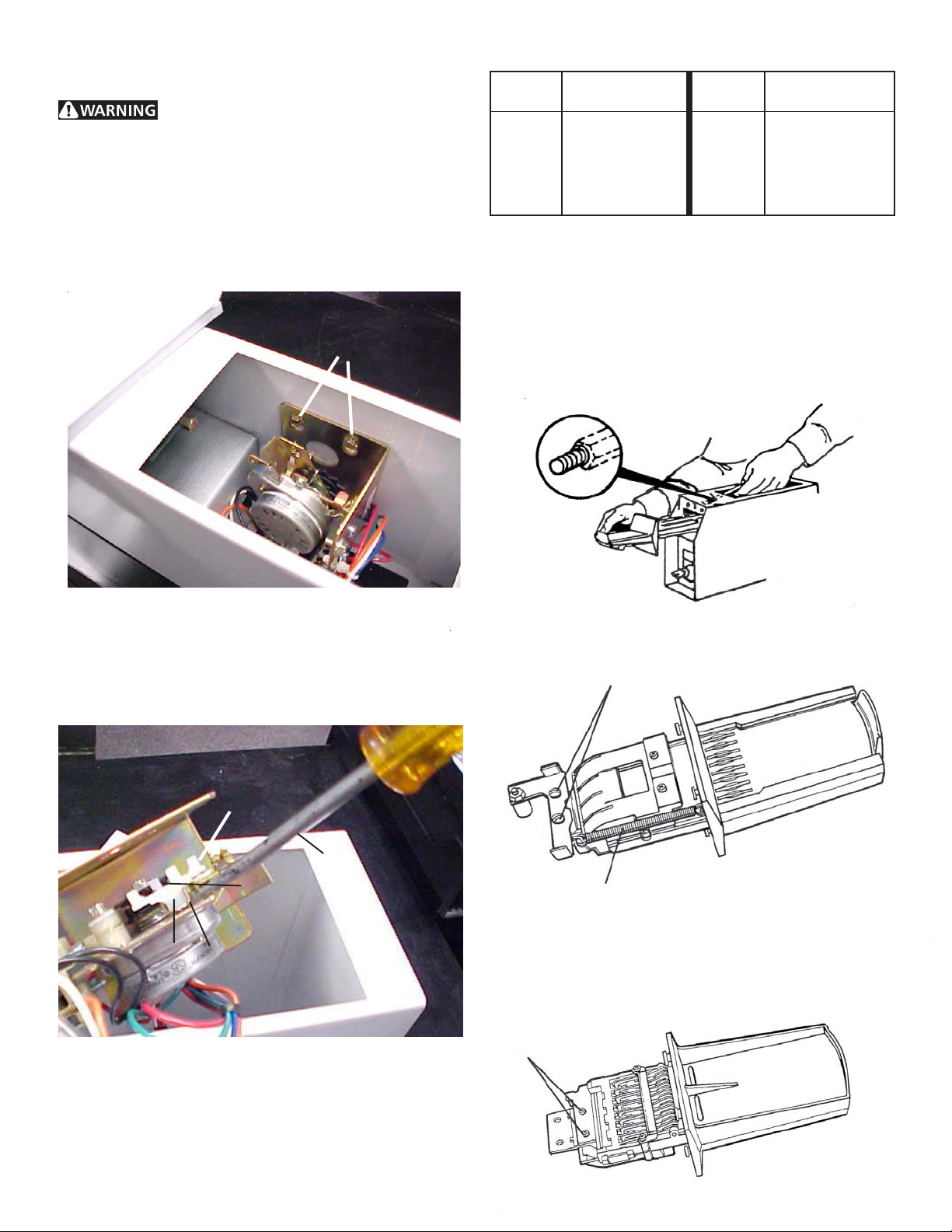

Electrical Shock Hazard

• Disconnect both power supply cords from the electric

power supply before making these changes.

• Change timing cams before completing electrical

connection. Failure to do so could result in electrical

shock or personal injury.

A. Remove meter-case service door:

1. Loosen two screws securing timer bracket to meter case

and lift timer assembly out. See FIG. 2

Screws (2)

FIGURE 2

Timing Cam Pin Chart

NUMBER

OF PINS

1

2

3

4

5

6

TIME PER

COIN INSERTED

180 minutes

90

60

45

36

30

NUMBER

OF PINS

7

8

9

10

11

12

TIME PER

COIN INSERTED

25.7

22.5

20

18

16.3

15

INSTRUCTIONS FOR CHANGING VEND PRICE

TOOLS NEEDED

• Medium sized slotted screwdriver

• Small slotted Phillips screwdriver

Place all screws and other items removed from coin slide assembly

on a cloth so they will not get lost.

STEP 1

Remove slide mechanism from meter case

(see FUGURE 1).

B. Remove nylon timing cam:

1. Rotate cam by hand until "V" notch lines up underneath

the ratchet tooth. See FIG. 3.

2. Insert narrow screwdriver under nylon cam close to the

timer shaft. Lift cam gently off shaft. Make sure that

pressure is directed upward and the "V" notch clears

the ratchet tooth.

Timing

Cam

Lift

Gently

with

Narrow

Blade

Hub

Down

Drive

Lug

Line Up

Notch

to Clear

Ratchet

T ooth

FIGURE 3

C. Replace new timing cam:

1. Be sure drive lug is in place. Place cam (hub down) over

timer shaft, lining up flat on shaft with flat of drive lug

hole.

2. Rotate cam until "V" notch lines up with ratchet tooth.

3. Press down to seat cam on timer shaft. make sure that

"V" notch freely clears ratchet tooth.

FIGURE 1

STEP 2

Remove the coin slide extension from coin slide by removing

two mounting screws and spacers

(see FIGURE 2).

(2) Mounting Screws

and Spacers

FIGURE 2

Slide Return Spring

STEP 3

Remove coin slide from coin chute:

• Unhook and remove the coin slide return spring

(see FIGURE 2).

• Turn coin slide mechanism upside down.

• Remove coin slide stop by taking out two screws to the chute

bottom (see FIGURE 3).

(2) Slide Stop Screws

FIGURE 3

10

10

Page 11

• Pull coin slide out of coin chute (see FIGURE 4).

FIGURE 4

STEP 4

Turn coin slide upside down and remove screw that holds coin receiver block

(see FIGURE 5).

(1) Receiver

Block Screw

FIGURE 5

Spare Parts

Compartment

and Screw

STEP 5

Remove coin receiver block from coin slide

(see FIGURE 6):

• Turn coin slide right side up. Keep coin receiver block in place with your fingers.

• Carefully lift coin slide from coin receiver block. If necessary, shake coin slide gently

to loosen block.

STEP 6

Set new vend price by adding or

removing the appropriate block-out

keys and/or dime inserts according

to th Table of Vend Prices

(see FIGURE 7).

NOTE: Black colored slots are

closed off by block-out key.

FIGURE 7

TABLE OF VEND PRICE

VEND

PRICE

0

$.10

$.20

$.25

$.35

$.45

$.50

$.60

$.70

$.75

$.85

$.95

$1.00

$1.10

$1.20

$1.25

$1.35

$1.45

$1.50

$1.60

$1.70

$1.75

$1.85

$2.00

COIN SLOTS

1 2 3 4 5 6 7 8

Coin Receiver

Block

FIGURE 6

11

Page 12

To remove block-out keys, pull straight up.

NOTE: Be sure block-out keys and /or dime inserts are seated

properly and ratchet dog is in place with irs spring connected

(see FIGURE 8).

Be sure the proper coin sizing block is in place.

STEP 7

Replace coin receiver block into slide:

• Hold coin receiver right side up in the palm of one hand.

• Lower coin slide until coin receiver block fits into the coin

slide cavity. CAUTION: Do not dislodge ratchet dog and

spring.

Ratchet

Dog and

Spring

Block-Out

Keys

FIGURE 8

Change coin sizing block:

• Remove two screws that hold upper coin chute cover.

Remove cover (see FIGURE 9).

Anti-Cheat

(2) Upper Coin

Chute Cover

Screws

(2) Coin Sizing

Block Screws

FIGURE 9

Gate

• Hold coin receiver block in place with your fingers and turn

slide upside down.

• Insert and tighten screw.

STEP 8

Install slide into coin chute. Slide can only be pushed in if the

anti-cheat gate in flange is pushed to the left. (see FIGURE 9).

STEP 9

Replace coin slide stop with two screws. Replace coin slide

return spring. Replace coin slide extension with two screws (be

sure spacers are in place).

STEP 10

Replace coin slide mechanism in meter case. Replace and tighten

coin slide mounting bolt.

NOTE: It may be easier to insert coin slide mounting bolt if you

remove the timer from the mounting screws temporarily.

REPLACEMENT PARTS

If replacement parts are needed for your dryer, contact the source

where you purchased your dryer, or call 1-800-GE CARES for

the GE Authorized Parts Distributor nearest you.. For coin box

parts, call 1-800-221-0982, Greenwald Industries.

FIGURE 10

Coin Sizing

Block

• Remove two screws that hold coin sizing block to upper coin

chute cover cover (see FIGURE 10).

• Put new coin sizing block in place. Reinsert and tighten

mounting screws.

• Replace coin chute cover. Reinsert and tighten screws.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

Destroy the carton and plastic bags after the

dryer is unpacked. Children might use them for play. Cartons

covered with rugs, bedspreads, or plastic sheets can become

airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

The instructions in this manual and all other

literature included with this dryer are not meant to cover every

possible condition and situation that may occur. Good safe

practice and caution MUST be applied when installing, operating

and maintaining any appliance.

12

Page 13

Meter Case Parts List

Parts List For Greenwald Dryer Timers

Timer Assembly

Model 50-1232-9

ITEM P ART NUMBER DESCRIPTION

1

2

3

*Additional

cams that

are available.

Cams pull

off and push

on for

replacement.

50-61-13-2 Timing motor, 115VAC, 1/180RPM

51-161-4 Timing cam, 4-PIN (45 Minutes)*

00-6164 Switch

51-161-1 Timing cam,1-PIN (180 Minutes)

51-161-2 Timing cam,2-PIN (90 Minutes)

51-161-3 Timing cam,3-PIN (60 Minutes)

51-161-5 Timing cam,5-PIN (36 Minutes)

51-161-6 Timing cam,6-PIN (30 Minutes)

51-161-7 Timing cam,7-PIN (25.7 Minutes)

51-161-8 Timing cam,8-PIN (22.5 Minutes)

51-161-9 Timing cam,9-PIN (20 Minutes)

51-161-10 T iming cam,10-PIN (18 Minutes)

51-161-1 1 T iming cam,11-PIN (16.3 Minutes)

51-161-12 T iming cam,12-PIN (15 Minutes)

Timer Assembly

Model 50-1223-10

13

Page 14

V8 Coin Chute Parts List

V8 Parts List

DESCRIPTION REQ. 20-3020 20-3000

————————————————————————————

1 SCREW (METRIC) 2 00-9724 00-7924

————————————————————————————

2 SCREW (METRIC) 2 00-7938 00-7938

————————————————————————————

3 TOP HOUSING 1 20-3019 20-3002

————————————————————————————

4 SHIM 2 20-2042 ----------————————————————————————————

5 COIN SIZING BLOCK 1 20-3006 20-3006

————————————————————————————

6 GATE COVER 1 20-2043 20-2006

————————————————————————————

7 GATE 1 20-2035 20-2000

————————————————————————————

8 SLIDE STOP DOG 8 20-201 1 20-2011

————————————————————————————

9 DOG SHAFT 1 20-4004 20-4000

————————————————————————————

10 DECAL,CASTING 1 00-9905 00-9905

————————————————————————————

11 BODY CASTING 1 20-3020 20-3000

————————————————————————————

12 COIN SLIDE 1 20-3021 -----------————————————————————————————

13 DECAL, SLIDE 1 00-9104 00-9104

————————————————————————————

14 CHUTE LOCATING SCREW 4 00-7483 61-55

————————————————————————————

15 SLIDE RETURN SPRING 1 00-8148 00-8148

————————————————————————————

DESCRIPTION REQ. 20-3020 20-3000

————————————————————————————

16 SPRING 1 20-2040 20-2001

————————————————————————————

17 SPRING PROTECTOR 1 20-2038 20-2007

————————————————————————————

18 RACK 1 20-2023 20-2005

————————————————————————————

19 SCREW (METRIC) 2 00-7931 00-7931

————————————————————————————

20 10¢ INSERT varies 20-3023 20-5001

————————————————————————————

21 SCREW (METRIC) 2 00-7923 00-7929

————————————————————————————

22 SLIDE STOP 1 20-2039 20-2004

————————————————————————————

23 RATCHET DOG SPRING 1 00-8123 00-8123

————————————————————————————

24 BLOCKOUT KEY varies 20-5002 20-2010

————————————————————————————

25 SLIDE RATCHET DOG 1 20-2041 20-2008

————————————————————————————

26 STORAGE COMP . COVER 20-2037 20-2003

————————————————————————————

27 SCREW (METRIC) 2 00-7935 ----------————————————————————————————

28 BUFFER 1 20-2034 ---------————————————————————————————

29 RATCHET DOG POST 1 20-4005 ----------————————————————————————————

30 COIN RETAINER optional Opt. 00-8168 -----------————————————————————————————

14

20-3020

DESCRIPTION REQ. 20-3020 20-3000

————————————————————————————

31 COIN SIZING BLOCK varies 20-3007 20-3007

————————————————————————————

32 PRESSURE SPRING ASMY Opt. 20-1012 20-1012

————————————————————————————

33 MAGNET Opt. 00-9256 00-9256

————————————————————————————

34 SHIELD Opt. 20-2045 20-2045

————————————————————————————

35 COIN RECEIVER BLOCK 1 --------- 20-2003

————————————————————————————

37 LOCK WASHER 1 --------- 00-7934

————————————————————————————

38 SCREW (METRIC) 1 --------- 00-7933

————————————————————————————

39 SCREW (METRIC) 1 --------- 00-7932

————————————————————————————

40 SCREW 00-7541 00-7541

————————————————————————————

41 TOP HOUSING ASMY 20-1103-1 20-1104-1

————————————————————————————

20-3000

Page 15

NEW VEND PRICE

____________________________________________________________

Order Form

T o change vend price, detach and mail the lower portion to:

Customer Service Department

Greenwald Industries Inc.

212 Middlesex Ave.

Chester, CT 06412

____________________________________________________

The coin chute has been pre-set at the factory .

When increasing in $.25 pricing

Follow product information instructions; no extra parts required.

When decreasing in $.25 pricing - or - changing to

$.10 pricing.

(Coin sizing block required; see "Changing Vend Price"

section.)

Notes

Order required parts using this tear-off. Block-out keys will be

shipped to you at no charge. Follow product information

instructions.

Quantity____________________________________________________

Existing Vend Price_________________________________________

Name_____________________________________________________

Company_________________________________________________

Address__________________________________________________

City_______________________________________________________

State/Zip__________________________________________________

Daytime phone_____________________________________________

Purchase date_____________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

____________________________________________________________________________________________________________________________

______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

__________________________________________________________________

__________________________________________________________________

________________________________________________________________

_________________________________________________________________

Questions about your product? Contact us at

www.GEAppliances.com

15

Page 16

Consumer Support.

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day,

any day of the year! For greater convenience and faster service, you can now download Owner’s Manuals,

order parts or even schedule service on-line.

ge.com

Schedule Service ge.com

Expert GE repair service is only one step away from your door. Get on-line and schedule your service at your

convenience 24 hours any day of the year! Or call 800.GE.CARES (800.432.2737) during normal business hours.

Real Life Design Studio ge.com

GE supports the Universal Design concept—products, services and environments that can be used by people of all

ages, sizes and capabilities. We recognize the need to design for a wide range of physical and mental abilities and

impairments. For details of GE’s Universal Design applications, including kitchen design ideas for people with

disabilities, check out our Website today. For the hearing impaired, please call 800.TDD.GEAC (800.833.4322).

Extended Warranties ge.com

Purchase a GE extended warranty and learn about special discounts that are available while your warranty is still

in effect. You can purchase it on-line anytime, or call 800.626.2224 during normal business hours. GE Consumer

Home Services will still be there after your warranty expires.

Parts and Accessories ge.com

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today, 24 hours every day or by phone at

800.626.2002 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing generally should be

referred to qualified service personnel. Caution must be exercised since improper servicing may cause unsafe operation.

Contact Us ge.com

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details

including your phone number, or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

Register Your Appliance ge.com

Register your new appliance on-line—at your convenience! Timely product registration will allow for enhanced

communication and prompt service under the terms of your warranty, should the need arise. You may also

mail in the pre-printed registration card included in the packing material.

Page 17

Consumer Support.

GE

Appliances Website GEAppliances.ca

GE supports the Universal Design concept---products, services and environments that can be used by people of all

ages,

sizes and capabilities. We recognize the need to design for a wide range of physical and mental abilities and

impairments.

For details of GE’s Universal Design applications, including kitchen design ideas for people with

disabilities,

check out our Website today.

In Canada, contact: Manager, Consumer Relations, Camco, Inc.

Suite

310, 1 Factory Lane

Moncton,

N.B. E1C 9M3

Extended Warranties 1.888.261.2133 or GEAppliances.ca

Purchase a GE extended warranty and learn about special discounts that are available while your warranty is still

in

effect. You can purchase it on-line anytime, or call 1.888.261.2133 during normal business hours. GE Consumer

Home

Services will still be there after your warranty expires.

Parts and Accessories 1.800.661.1616 or GEAppliances.ca

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA,

MasterCard and Discover cards are accepted). Order on-line today, 24 hours every day or by phone at

1.800.661.1616

during normal business hours.

Instructions

contained in this manual cover procedures to be performed by any user. Other servicing generally should be

referred

to qualified service personnel. Caution must be exercised, since improper servicing may cause unsafe operation.

Contact Us

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details

including

your phone number, or write to:

Director, Consumer Relations, Camco, Inc.

Suite

310, 1 Factory Lane

Moncton,

N.B. E1C 9M3

Register Your Appliance GEAppliances.ca

Register your new appliance on-line----at your convenience! Timely product registration will allow for

enhanced

communication and prompt service under the terms of your warranty, should the need arise.

You may also mail in the pre-printed registration card included in the packing material.

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day,

any

day of the year! For greater convenience and faster service, you can now download Owner’s Manuals,

order

parts, catalogs, or even schedule service on-line. You can also “Ask Our Team of Experts™” your questions,

and

so much more...

Schedule Service 1.800.561.3344 or GEAppliances.ca

Expert GE repair service is only one step away from your door. Get on-line and schedule your service at your

convenience 24 hours any day of the year! Call 1.800.561.3344 during normal business hours.

Real Life Design Studio

GEAppliances.ca

Page 18

Contents

Avant l’installation.....................................................19

Installation électrique....................................................19

Évacuation de l’air...................................................19-20

Alimentation en gaz......................................................20

Emplacement de la sécheuse......................................21

Dimensions de l’emplacement...................................22

Déballage........................................................................22

Porte Réversible............................................................22

Installation électrique....................................................23

Mise à la terre................................................................23

Branchement électrique - 3 fils....................................24

Branchement électrique - 4 fils......................................24

Installation........................................................................25

Mécanisme de monnaie..........................................25-27

Instructions et liste de pièces

pour le boîtier du compteur....................................28-31

Soutenir un client...........................................................32

Pour des informations sur la garantie de GE ou pour

communiquer avec le Centre de service GE, appelez

1-800-561-3344 o www.electromenagersge.ca.

Aux États-Unis veuillez composer 1-800-GE CARES

ou site Web www.GEAppliances.com.

Pour tout service ou pièce pour la machine à secheuse

à encaissement automatique Frigidaire, ayez à portée

de la main le numéro du modèle, le numéro de série et

la date d’achat. Enregistrez ces informations

ci-dessous :

N° de modèle_________________________________

N° de série___________________________________

Date de l’achat_______________________________

Enregistrez la boîte à monnaie

Numéro de la clé ____________________________

Le numéro de la clé est situé sur la clé et/ou sur la

boîte à monnaie.

Enregistrement du produit

SÉCURITÉ RELATIVE À UNE SÉCHEUSE

L’installation et le service de la Sécheuse de vêtements doivent être effectués par un installateur

qualifié, l’agence de service ou le fournisseur de gaz. Installez la Sécheuse de vêtement selon les

instructions du fabricant et les codes locaux.

Avant de commencer, lire attentivement le présent document. Cela simplifiera l’installation et assurera

la pose correcte et sécuritaire de la sécheuse. Après l’installation, laisser ce document à proximité de

la sécheuse pour référence future.

REMARQUE : L ’alimentation électrique de la sécheuse doit respecter les codes et ordonnances locaux ainsi que

l’édition la plus récente du Code ANSI/NFP A 70, ou au Canada, le Code canadien d'électricité, ACNOR C22.1, partie1.

REMARQUE : L’alimentation en gaz de la sécheuse doit respecter les codes et ordonnances locaux ainsi que l’édition

la plus récente du Code ANSI Z223.1, ou au Canada, le code CAN/ACG B149.1-2000.

REMARQUE : La sécheuse est conçue conformément au code ANSI Z 21.5.1 ou ANSI/UL 2158 - CAN/ACG C22.2

No. 1 12 (l’édition la plus récente).

La sécurité de l’utilisateur et celle des autres sont très importantes.

Le guide de l’utilisateur, les consignes d’utilisation et les directives d’installation contiennent de nombreuses

consignes de sécurité importantes. Toujours lire et respecter toutes les consignes de sécurité.

Voici le symbole de mise en garde. Ce symbole met en garde contre les risques pouvant entraîner le

décès ou des blessures à soi ou aux autres. Tous les messages relatifs à la sécurité sont précédés du

symbole de mise en garde et du terme « DANGER » ou « AVERTISSEMENT ». Ces termes signifient :

DANGER

Tous les messages relatifs à la sécurité indiquent le risque, comment réduire le risque de blessure et

ce qui peut survenir si on ne suit pas les directives.

pour minimiser les risques d’incendie, d’explosion, de dommages matériels, de blessures et de mort.

- Ne pas entreposer ni utiliser d’essence ou d’autres vapeurs ou liquides inflammables à proximité de cette sécheuse

ou de tout autre appareil électroménager.

- QUE FAIRE S’IL Y A UNE ODEUR DE GAZ

• N’allumer aucun appareil électrique.

• Ne toucher aucun commutateur électrique; ne pas utiliser le téléphone dans l’immeuble.

• Faire sortir tous les occupants de la pièce, de l’immeuble ou de la zone avoisinante.

• Appeler la compagnie de gaz immédiatement en utilisant le téléphone d’un voisin. Suivre les instructions de la

compagnie de gaz.

• S’il est impossible de joindre la compagnie de gaz, appeler les pompiers.

L’inst allation et les réparations doivent être effectuées par un installateur ou un technicien qualifié ou par la compagnie

de gaz.

L’utilisateur sera tué ou gravement blessé s’il ne suit pas ces directives.

L’utilisateur peut être tué ou gravement blessé s’il ne suit pas ces directives.

RISQUE D’INCENDIE. Pour votre sécurité, suivre les directives données dans le présent guide

GARDEZ CES INSTRUCTIONS.

18

Page 19

AVANT L’INSTALLATION

Outils et matériel requis pour l’installation :

1. Tournevis à pointe cruciforme

2. Pinces multiprise

3. Niveau de menuisier

4. Tournevis à pointe plate ou à lame droite

5. Ruban adhésif pour conduites

6. Conduite en métal rigide ou flexible de 10,2 cm (4 po)

7. Grille de sortie

8. Pâte à joint pour conduites (modèle à gaz)

9. Couteau à mastic en plastique

INSTALLATION ÉLECTRIQUE

Sécheuses ÉLECTRIQUES

CIRCUIT - Dérivation distincte de 30 A avec fusibles à retardement

ou disjoncteurs d’au 30 A.

Utilisez des circuits avec un disjoncteur ou fusible séparé pour les

machines à laver et sécheuses, et NE PAS faire fonctionner une

machine à laver et une sécheuse sur un même circuit.

ALIMENTATION ÉLECTRIQUE - 3 fils, 240 volts, une phase, 60 Hz,

courant alternatif. (Canada - 240 volts, une phase, 60 Hz, courant

alternatif.)

CORDON D’ALIMENTATION ÉLECTRIQUE - La sécheuse DOIT

être reliée à un cordon d’alimentation électrique à 3 conducteurs

NEMA 10-30 de type SRDT d’une capacité minimale de 240 volts,

courant alternatif, 30 A, avec fiche en L à 3 broches pleines ou

repliées conçue pour le branchement d’une sécheuse. Si étant

installé dans une nouvelle installation de circuit de branche,

manufacturée (mobile) à la maison, véhicule la récréationnel ou

secteur qui interdisent fondre par le conducteur neutre, elle DOIT

être reliée à un cordon d’alimentation électrique à 4 conducteurs

NEMA 14-30 de type SRDT ou ST (au besoin) d’une capacité

minimale de 240 volts, courant alternatif, 30 A, avec fiche en L à

4 broches pleines ou repliées conçue pour le branchement d’une

sécheuse. Se reporter à la section BRANCHEMENT ÉLECTRIQUE

D’UNE INSTALLATION À 4 FILS.

Canada - Cordon d'alimentation à 4 fils branché à la sécheuse.

PRISE - Prise NEMA 10-30R située de façon à ce que le cordon

d’alimentation électrique soit accessible une fois la sécheuse en

place. (Canada - prise NEMA de 14-30R.)

ALIMENTATION

ÉLECTRIQUE

PRISE MURALE (CUIVRE)

SOUS RÉSERVE DES EXIGENCES

LOCALES

CIRCUIT - Dérivation distincte de 15 A avec fusible à retardement

ou disjoncteur d’au plus 15 A.

ALIMENTATION ÉLECTRIQUE - 3 fils, 120 volts, une phase, 60

Hz, courant alternatif.

CORDON D’ALIMENTATION ÉLECTRIQUE La sécheuse est pourvue

d’un cordon d’alimentation

électrique à 3 fils de

120 volts.

BOÎTE À FUSIBLES PRINCIPALE

NEUTRE À 3 FILS 120-240 VOLTS 60 CYCLES

FUSIBLES À RETARDEMENT OU

DISJONCTEUR DE 30 A

FIL NEUTRE

NEMA 10-30R (CUIVRE)

Sécheuses à GAZ

REMARQUE : Il ne

faut en aucun cas

retirer la broche

de mise à la terre

de la fiche.

BROCHE

DE MISE À

LA TERRE

ÉVACUATION DE L’AIR

Utiliser uniquement une conduite en métal rigide ou flexible de

10,2 cm (4 po) de diamètre (minimum) ainsi qu’une grille de sortie

approuvée pourvue de clapets qui s’ouvrent lorsque la sécheuse

fonctionne. Quand la sécheuse s’arrête, les clapets se ferment

automatiquement pour éviter les courants d’air et l’entrée

d’insectes ou de rongeurs. Afin de ne pas obstruer l’évacuation

de l’air, laisser une distance minimum de 30,5 cm (12 po) entre

la grille de sortie et le sol ou tout autre obstacle.

Les mises en garde qui suivent se

rapportent directement au fonctionnement correct et

sécuritaire de la sécheuse. Toute dérogation à ces mises en

garde pourrait ralentir le séchage et entraîner des risques

d’incendie.

N’installez pas la Sécheuse avec des

matériels de ventilation en matières plastiques flexibles.

Si la conduite existante est en plastique ou en papier métallique,

la remplacer par une conduite en métal rigide ou flexible. Au

Canada et aux Etats-Unis si le conduit est de métal (type feuille

d’aluminium), celui-ci doit être d’un type spécifique identifié par

le fabricant, recommandé pour l’utilisation avec des Sécheuses ;

et aux Etats-Unis il doit en outre remplir la norme UL 215Å. Les

matériaux de ventilation flexibles peuvent s’abimer facilement

et recueillir du duvet. Ces conditions obstrueront la circulation d’air

de la Sécheuse de vêtements et augmenteront le risque

d’incendie. S’assurer qu’il n’y a pas de charpie dans la

conduite existante avant d’installer la conduite de la

sécheuse.

OUI NON

CORRECT

– Risque d’incendie – une Sécheuse de

vêtement doit être aéré à l’air libre. N’aérez pas la Sécheuse

dans une cheminée, une paroi, un plafond, un espace fermé ou

aucun espace caché du bâtiment. Une sécheuse à linge produit

de la charpie combustible. Si l’air n’était pas repoussé à l’extérieur

de la maison, de petites particules de charpie se retrouveraient

dans la pièce où est installée la sécheuse. Toute accumulation de

charpie dans la maison peut présenter des risques pour la santé

et des risques d’incendie. La sécheuse doit être connectée à

une bouche d’évacuation vers l’extérieur du bâtiment ou

de l’immeuble. Vous devez inspecter régulièrement l’évent

extérieur et enlever toute accumulation de charpie autour de

l’évent et dans la cavité du conduit d’évacuation.

Ne laisser aucun matériau inflammable

(comme des vêtements, des tentures, des rideaux ou du papier)

entrer en contact avec les conduits d’évacuation.

Augmenter la longueur du conduit rigide

ou le nombre de coudes permis au tableau «LONGUEUR

MAXIMUM» risque de réduire la capacité d'évacuation du circuit.

Obturer le circuit peut créer un risque d'incendie et augmenter le

temps de séchage.

N’obstruez pas les extrémités du tube de

ventilation, ni utilisez des vis, rivets ou autres moyens de fixation

qui peuvent obstruer le conduit et recueillir du duvet.

19

INCORRECT

Page 20

De la charpie pourrait s’emprisonner dans le grillage ou sur les vis

ou les rivets et ainsi engorger la conduite d’évacuation en plus de

présenter un risque d’incendie et de ralentir le séchage. Utiliser une

grille de sortie approuvée pour fermer l’ouverture extérieure et

sceller tous les joints à l’aide d’un ruban adhésif pour conduites.

L’extrémité mâle de chaque composante de la conduite DOIT être

installée en aval par rapport à la circulation de l’air.

Risques d'explosion. Ne pas installer la

sécheuse à un endroit où l'on garde de la gazoline ou tout autre

produit inflammable. Si la sécheuse est installée dans un garage,

elle doit être à un minimum de 45,7 cm (18 po) au-dessus du

plancher. Toute dérogation pourrait provoquer la mort, l'explosion,

l'encendie ou les brûlures.

LONGUEUR MAXIMUM

d’une conduite en métal rigide de

10,16 cm (4 po) de diam.

TYPE DE GRILLE DE SORTIE

(Recommandé)

Nombre de

coudes à

90°

10,210,2

10,2

10,210,2

cmcm

cm

cmcm

(4 po)(4 po)

(4 po)

(4 po)(4 po)

0 18,28 m (60 po) 14,63 m (48po)

1 15,84 m (52 po) 12,19 m (40 po)

2 13,41 m (44 po) 9,75 m (32 po)

3 9,75 m (32 po) 7,31 m (24 po)

4 8,53 m (28 po) 4,87 m (16 po)

à volet

6,35 6,35

6,35

6,35 6,35

cmcm

cm

cmcm

(2 1/2 po)(2 1/2 po)

(2 1/2 po)

(2 1/2 po)(2 1/2 po)

LONGUEUR MAXIMUM

d’une conduite en métal flexible de

10,16 cm (4 po) de diam.

TYPE DE GRILLE DE SORTIE

(Recommandé)

Nombre de

coudes à

90°

10,210,2

10,2

10,210,2

cmcm

cm

cmcm

(4 po)(4 po)

(4 po)

(4 po)(4 po)

0 9,14 m (30 po) 5,49 m (18po)

1 6,71 m (22 po) 4,27 m (14 po)

2 4,27 m (14 po) 3,05 m (10 po)

3 NON RECOMMANDÉ

CORRECTCORRECT

CORRECT

CORRECTCORRECT

POSER LES RACCORDS MÂLES DANS LA BONNE DIRECTION

Pour les installations dont le circuit d'évacuation n'est pas décrit

dans les tableaux, il faut utiliser la méthode suivante si le circuit

d'évacuation n'est pas acceptable:

1. Brancher un manomètre digital ou à tube incliné entre la

sécheuse et le raccord d'évacuation de la sécheuse.

2. Régler la minuterie de la sécheuse et la température à air froid

(refroidissement) et démarrez la sécheuse.

3. Lire la mesure indiquée au manomètre.

4. La basse pression ne doit pas être supérieure à 0,75 pouce de

colonne d'eau. Si la basse pression est inférieure à 0,75 pouce

de colonne d'eau, le circuit est acceptable. Si la lecture indique

une pression supérieure à 0,75 pouce de colonne d'eau, la

capacité du circuit est insuffisante et l'installation inacceptable.

à volet

INCORRECTINCORRECT

INCORRECT

INCORRECTINCORRECT

6,35 6,35

6,35

6,35 6,35

cmcm

cm

cmcm

(2 1/2 po)(2 1/2 po)

(2 1/2 po)

(2 1/2 po)(2 1/2 po)

Bien qu'un circuit vertical soit acceptable, certaines circonstances

atténuantes peuvent influencer la performance de la sécheuse.

• Il faut utiliser uniquement des conduits rigides en métal.

• Une sortie sur un toit d'un circuit vertical peut exposer celui-ci

à un contre-tirage et ainsi réduire sa capacité d'évacuation.

• L'isolant que doit traverser un tel circuit peut causer de la

condensation et ainsi réduire la capacité d'évacuation du

circuit.

• Un circuit d'évacuation comprimé ou ondulant peut voir sa

capacité d'évacuation réduite.

Il faut inspecter le circuit d'évacuation et le nettoyer au moins à

tous les 18 mois d'utilisation normale. Plus la sécheuse est

utilisée, plus il faut procéder souvent à une vérification du bon

fonctionnement du circuit d'évacuation et du couvercle du registre

ou de l'évent.

DIRECTION DE L’ÉVACUATION D’AIR

Toutes les sécheuses empaquetées par l’usine sont conçues de

façon à ce que l’évacuation d’air se fasse à l’arrière. Toutefois,

dans le cas des sécheuses électriques, l’évacuation d’air peut se

faire sur la droite ou sur la gauche du boîtier ou encore, sous la

sécheuse. Dans le cas des sécheuses à gaz, l’évacuation d’air peut

se faire sur la droite du boîtier ou sous la sécheuse. On peut donc

modifier l’orientation de l’évacuation d’air en installant un

ensemble d'évacuation d'air n° de pièce 131456800 disponible

chez d’un fournisseur de pièces agréé. Suivre les directives qui

accompagnent cet ensemble.

EMPLACEMENT DES BOUCHES D’ÉVACUATION

COMME SUR L’AUTRE CÔTÉ

15 cm

9,7cm9,7cm

9,7cm

9,7cm9,7cm

(5 7/8 po)

11 cm

(4 3/8 po)

(6,0 cm)(6,0 cm)

(6,0 cm)

(6,0 cm)(6,0 cm)

9,5 cm

(3 3/4 po)

(9,5 cm)(9,5 cm)

(9,5 cm)

(9,5 cm)(9,5 cm)

9,5 cm

(3 3/4 po)

(9,5 cm)(9,5 cm)

(9,5 cm)

(9,5 cm)(9,5 cm)

34 cm

(33,3 cm)(33,3 cm)

(33,3 cm)

(33,3 cm)(33,3 cm)

(13 1/2 po)

ALIMENTATION EN GAZ

cuivre non recouvert de plastique. Il FAUT utiliser du laiton

inoxydable ou recouvert de plastique.

1. L’installation DOIT respecter les codes locaux, ou s’il n’existe

pas de codes locaux, le code ANSI Z223.1 (l’édition la plus

récente) ou au Canada, le Code actuel CAN/CGA B149.

2. La conduite d’alimentation en gaz doit mesurer 1,27 cm (1/

2 po).

3. Si les codes le permettent, un tuyau en métal flexible peut être

utilisé pour connecter la sécheuse à l’alimentation en gaz. Le

tuyau DOIT être fabriqué en acier inoxydable ou en cuivre avec

un revêtement de plastique.

4. La conduite d’alimentation en gaz DOIT comporter un robinet

d’arrêt distinct.

5. Une prise de 0,32 cm (1/8 po) NPT accessible pour le

branchement d’un manomètre DOIT être installée tout juste

en amont du branchement de la conduite d’alimentation en

gaz sur la sécheuse.

6. La sécheuse DOIT être débranchée de la canalisation de gaz

pendant toute vérification de pression de l’alimentation en gaz

à des pressions qui dépassent 3,45 kPa (1/2 lb/po²).

7. La sécheuse DOIT être isolée de la canalisation de gaz pendant

toute vérification de pression de l’alimentation en gaz à des

pressions égales ou inférieures à 3,45 kPa (1/2 lb/po²).

20

Remplacer le tuyau de raccordement en

Page 21

EMPLACEMENT DE LA SÉCHEUSE

NE PAS INSTALLER LA SÉCHEUSE :

1. Dans un endroit exposé à un écoulement d’eau ou aux

conditions atmosphériques.

2. Dans un endroit où elle serait en contact avec des rideaux,

draperies ou tout ce qui obstruera le flux d'air de combustion

et de ventilation.

3. Sur un tapis. Le plancher DOIT être ferme et présenter une

pente de 2,54 cm (1 po) au maximum.

INSTALLATION DANS UNE ALCÔVE OU UN PLACARD

1. Toute sécheuse installée dans une chambre à coucher, une

salle de bain, une alcôve ou un placard DOIT être reliée à

une conduite d’évacuation d’air se terminant à l’extérieur de

la maison.

2. Aucun autre appareil brûlant du combustible ne doit être

installé dans le même placard que la sécheuse au Gaz.

3. La sécheuse a besoin d’un dégagement suffisant pour

permettre la circulation de l’air.

0 cm (0 po)0 cm (0 po)

0 cm (0 po)

0 cm (0 po)0 cm (0 po)

387,1 cm387,1 cm

²²

387,1 cm

²

387,1 cm387,1 cm

²²

(60 po(60 po

²²

))

(60 po

²

)

(60 po(60 po

²²

))

NE PAS INSTALLER LA SÉCHEUSE DANS UN PLACARD

POURVU

D’UNEPORTE PLEINE.

4. Une ouverture minimum de 774,2 cm² (120 po²) répartie

également entre le haut et le bas de la porte est requise. Cette

ouverture ne doit pas être obstruée lorsque la porte est en

place. Une porte à volets dont les ouvertures totalisent la

norme décrite ci-dessus est acceptable.

DÉGAGEMENTS MINIMAUX POUR L'INSTALLATION

en po (cm)

D'AVANT CÔTÉS ARRIÈRE DESSUS

Alcôve ou sous un

comptoir 0 (0) 0 (0) 0 (0) 15 (38,1)

Armoire 1 (2,54) 0 (0) 0 (0) 15 (38,1)

Aération nécessaire dans la porte de l'armoire: 2 ouvertures à

persiennes de 60 pouces carrés (387 cm carrés) chacun - à 3

pouces (7,6 cm) du bas et du haut de la porte.

L'AÉRATION DE CETTE SÉCHEUSE SE FAIT VERS L'EXTERIEUR.

5. Les illustrations qui suivent donnent le dégagement minimum

pour une installation dans une alcôve ou un placard.

2,54 cm2,54 cm

2,54 cm

38,1 cm (15 po)38,1 cm (15 po)

38,1 cm (15 po)

38,1 cm (15 po)38,1 cm (15 po)

2,54 cm2,54 cm

(1 po)(1 po)

(1 po)

(1 po)(1 po)

0 cm (0 po)0 cm (0 po)

0 cm (0 po)

0 cm (0 po)0 cm (0 po)

PORTE DU PLACARDPORTE DU PLACARD

PORTE DU PLACARD

PORTE DU PLACARDPORTE DU PLACARD

NON

OUI

387,1 cm387,1 cm

387,1 cm

387,1 cm387,1 cm

(60 po(60 po

²²

(60 po

²

(60 po(60 po

²²

²²

²

²²

))

)

))

NON

OUI

NON

OUI

21

Page 22

MODELES AUTONOMES AVEC CONSOLE

SUPÉRIEURE

DIMENSIONS DE L'EMPLACEMENT

68,3 cm

(26 7/8 po)

43/8"

(11.2)

BRANCHEMENT

ÉLECTRIQUE

87,9 cm87,9 cm

87,9 cm

87,9 cm87,9 cm

DÉBALLAGE

1. À l’aide des quatre coins de protection de l’emballage (deux

sur chaque côté), déposer délicatement la sécheuse sur son

côté gauche et retirer le morceau de mousse placé sous la

sécheuse pour l’expédition.

Pour ne pas endommager la sécheuse, ne

pas prendre prise sur le panneau de commande pour soulever

ou déplacer la sécheuse.

REMARQUE : Si la sécheuse doit être installée sous un comptoir,

le panneau du dessus peut être démonté pour l’installation.

2. Remettre la sécheuse à la verticale.

9,5 cm

(3 3/4 po)

inch(cm)

OUVERTURE

DE LA PORTE

90°

34,4 cm

(13 1/2 po)

BRANCHEMENT DU

TUYAU DE GAZ

0,96 cm (3/8 po)

DE DIAMÈTRE

6,5 cm

(2 9/16 po)

VUE ARRIÈRE

120,7 cm

(47 1/2 po)

(122,2 cm)(122,2 cm)

(122,2 cm)

(122,2 cm)(122,2 cm)

110,7 cm

(43 5/8 po)

91,5 cm

(91,5 cm)(91,5 cm)

(91,5 cm)

(91,5 cm)(91,5 cm)

(36 po)

2,54 cm (1 po)

17"

(43.2)

8"

(20.4)

MORCEAU

DE MOUSSE

EMBALLAGE

PORTE RÉVERSIBLE

La sécheuse est conçue de façon à ce que l’ouverture de la

porte puisse être inversée en tout temps sans que des pièces

additionnelles ne soient requises. L’inversion de la porte requiert

le transfert des charnières au côté opposé du boîtier.

Pour inverser l’ouverture de la porte:

1. Ouvrir la porte de la sécheuse. Retirer les quatre bouchons

de trous de vis du côté gauche de la porte. Les laisser à

proximité pour installation future. NOTA : Un couteau à mastic en plastique peut s’avérer nécessaire pour retirer les

bouchons de trous de vis. Veiller à ne pas égratigner la

peinture.

2. Retirer les quatre vis fixant les charnières de la porte au

panneau avant de la sécheuse (voir ci-dessous). NOTA :

Retirer d’abord une vis dans chacune des deux charnières.

Tenir la porte fermement avant de dévisser les deux dernières

vis.

3. Tourner la porte à un angle de 180° et reposer les charnières

de porte au panneau avant de la sécheuse avec les quatre

vis.

4. Poser les quatre bouchons de trous de vis du côté droit de la

porte.

inch(cm)

11,1 cm

(4 3/8 po)

TROU DE

VENTILATION À

PERFORER

FACULTATIF

68,6 cm

(27 po)

VUE LATÉRALE

9,5 cm

(3 3/4 po)

DÉPOSER LES 4 VIS

(UNE DE CHAQUE

CHARNIÈRE D’ABORD)

22

Page 23

DANGER

INSTALLATION ÉLECTRIQUE

TOUTES les sécheuses ÉLECTRIQUES

Les mises en garde qui suivent se rapportent

directement au branchement électrique correct et

sécuritaire de la sécheuse. Toute dérogation à ces mises

en garde pourrait entraîner des risques choc électrique et

d’incendie.

Cet appareil DOIT être convenablement mis à la terre. La

sécheuse présenterait des risques choc électrique si elle n’était

pas convenablement mise à la terre. Respecter les directives de

mise à la terre contenues dans cette notice pour une mise à la

terre correcte.

Pour brancher la sécheuse en permanence :

1. La sécheuse DOIT être branchée à une installation métallique

mise à la terre en permanence; sinon, un conducteur de mise

à la terre de l’appareil doit suivre les conducteurs du circuit

et être branché à la borne ou à la connexion de mise à la

terre de l’appareil.

Sécheuses ÉLECTRIQUES Canadiennes

Le branchement inadéquat du conducteur de mise

à la terre pourrait présenter un risque choc électrique. En cas de

doute quant à la mise à la terre adéquate de l’appareil, contacter

un électricien agréé.

Ne pas utiliser de cordon de rallonge avec cette sécheuse.

Certains cordons de rallonge ne sont pas conçus pour supporter

l’intensité du courant qu’utilise cette sécheuse; ils peuvent fondre

et présenter un risque choc électrique ou d’incendie. Placer la

sécheuse à portée de la prise murale afin de déterminer la

longueur du cordon à acheter et prévoir un certain jeu dans la

longueur du cordon. Se reporter à la section «Avant l’installation»

de cette notice pour savoir quel type de cordon acheter.

Un détendeur approuvé par U.L. doit être fixé au cordon

d’alimentation. Si le détendeur n’était pas présent, le cordon

pourrait être arraché de la sécheuse ou coupé par tout type de

mouvement, ce qui présenterait un risque choc électrique.

Ne pas utiliser une prise à conducteurs en aluminium avec un

cordon ou une prise à conducteurs en cuivre (ni l’inverse). Une

réaction chimique se produit entre le cuivre et l’aluminium qui

pourrait causer un court-circuit. Il faut utiliser un cordon

d’alimentation à conducteurs en cuivre avec une prise à

conducteurs en cuivre.

REMARQUE : Les sécheuses qui fonctionnent avec une

alimentation de 208 volts auront un temps de séchage plus

long que celles qui utilisent une alimentation de 240 volts.

MISE À LA TERRE

Pour brancher et mettre à la terre la sécheuse à l’aide d’un cordon

d’alimentation :

1. La sécheuse doit être mise à la terre. En cas de mauvais

fonctionnement ou de panne, la mise à la terre réduit les

risques choc électrique en offrant un parcours de moindre

résistance au courant.

2. Puisque la sécheuse est pourvue d’un cordon d’alimentation

électrique comportant un conducteur et une fiche de terre, la

fiche doit être branchée dans une prise murale à conducteur

en cuivre convenablement raccordée au réseau et mise à la

terre conformément à tous les codes et ordonnances locaux.

En cas de doute, contacter un électricien agréé. Ne modifiez

pas la prise équipée d’appareil.

TOUTES les sécheuses à GAZ

Pour votre protection contre les chocs électriques, la sécheuse

est équipée d'une fiche à trois bornes (mise à la terre) et doit être

branchée directement dans une prise à 3 bornes correctement

mise à la terre. Ne pas couper ni enlever la fiche de mise à la

terre de cette prise.

Sécheuses ÉLECTRIQUES non-Canadiennes

DANGER

à la terre pourrait présenter un risque choc électrique. En cas de

doute quant à la mise à la terre adéquate de l’appareil, contacter

un électricien agréé.

Pour brancher et mettre à la terre la sécheuse à l’aide d’un cordon

d’alimentation :

1. La sécheuse DOIT être mise à la terre. En cas de mauvais

fonctionnement ou de panne, la mise à la terre réduit les

risques choc électrique en offrant un parcours de moindre

résistance au courant.

2. Si la sécheuse est pourvue d’un cordon d’alimentation

électrique comportant un conducteur et une fiche de terre, la

fiche DOIT être branchée dans une prise murale à conducteur

en cuivre convenablement raccordée au réseau et mise à la