Page 1

INSTRUCTIONS

GEK—

36767

INSTANTANEOUS

MODEL

D.C.

UNDERVOLTAGE

TYPE

PJV

12PJV11BK(-)E

RELAY

GENERAL

ELECTRIC

Page 2

DESCRIPTION

APPLICATION

RATINGS

TABLE

COIL

TABLE

CHARACTERISTICS

TABLE

CONSTRUCTION

OUTLINE

RECEIVING,

ACCEPTANCE

INSTALLATION

LOCATION

MOUNTING

CONNECTIONS

ADJUSTMENTS

PERIODIC

SERVICING

RENEWAL

AND

BURDENS

CONTACT

1

CIRCUIT

2

OPERATING

PICKUP

RELAY

PICKUP

3

DROPOUT

PLUNGER

CASE

VISUAL

MECHANICAL

ELECTRICAL

MECHANICAL

ELECTRICAL

PARTS

RATINGS

RATINGS

AND

CALIBRATION

VOLTAGE

TIME

UNIT

DIAGRAM

HANDLING

TESTS

INSPECTION

PROCEDURE

CHECKS

AND

PRINCIPLES

DROPOUT

AND

INTERNAL

AND

STORAGE

INSPECTION

TESTS

AND

ROUTINE

CHECKS

CHECKS

GEK-36767

CONTENTS

BURDENS

DEFINITIONS

CONNECTIONS

MAINTENANCE

DIAGRAM

PAGE

3

3

3

3

3

3

4

4

4

4

4

4

5

5

5

5

5

5

6

6

6

6

7

7

7

7

7

7

7

7

8

8

8

2

Page 3

for

application

out

setting

plug

outline

that

shown

coil

circuit

regard

applying

voltage

The

is

is

in

The

to

PJV11BK

on

available

and

mounting

required

Figure

PJV11BK

polarity.

this

when

of

relay,

it

on

the

2.

this

is

relay

D.C.

relay.

which

and

relay

set

is

a

systems

The

permits

dimensions

furnished

is

designed

relay

should

The

contacts

Table

3

to

drop

operated

DC

to

PJV11BK

disconnection

for

with

be

should

should

out

detect

the

the

to

connected

be

at

the

single

short

relay

relay

relay

provide

be

used

consulted

desired

GEK-

36767

DESCRIPTION

unit

instantaneous

circuits

comes

in

the

given

given

an

contact

in

of

are

is

APPLICATION

high

speed

to

the

portion

to

initiate

to

insure

value.

that

reduce

SI-E

non-drawout

circuits

Figure

in

Figure

undervoltage

of

the

that

undervoltage

3.

8.

the

D.C.

desired

the

relay

the

from

The

The

detection

system

case.

the

outline

internal

system

action

will

device.

voltage

However,

front

for

connection

on

being

on

low

pick-up

of

the

D.C.

monitored

voltage.

for

It

below

the

the

relay.

external

systems.

normal

is

intended

the

standard

diagram

drop

The

resistor

is

The

without

When

system

CONTACT

The

interrupting

RATINGS

contacts

ratings

are

are

rated

given

at

5

amperes

in

Table

AC

VOLTS

115

230

460

DC

VOLTS

125

250

48

24

RATINGS

for

continuous

1.

TABLE

INTERRUPTING

TNDUCTIVE

0.5

INDUCTIVE

1.0

0.5

0.3

0.15

AND

2

1

BURDENS

duty

1

RATINGS

AMPS

AMPS

and

at

30

amperes

NON-INDUCTIVE

5

2

1

NON-INDUCTIVE

5

2

1

0.3

for

tripping

duty.

The

operating

the

external

resistor

These

resistance,

cuil.

relays

resistor.

every

further

the

but

are

Ratings

These

possi

information

purchaser’s

ic

the

no

such

supplied

and

nsttuCtiOfls

Pie

Cxtient

assurance

and

Table

operating

caltinyency

purposes,

aequu

with

burdens

2

gives

do

be

dosirod

ted

given

is

COIL

CIRCUIT

external

an

given

for

the

be

putt

purport

or

products

vi

riot

tier

ti

continuous

resistance

to

in

connection

should

particu

should

,ies,.

respect

coil

nOt

to

the

the

cover

this

be

r

to

resistor

referred

be,!

lal

RATINGS

relay

voltage

for

these

all

duta:ls

with

p’binru

Ir

herOun

c-r,des

ncra,

tic

AND

which

are

or

thiS’S,

usret

an,!

BURDENS

is

for

the

rating,

relays.

v,’’.jtcs,’

,‘..t,.

In.

rise

w:

ri

.ippf

-jhic

c

ird,

‘cances

to

be

operating

calibrating

:0

pr:

ar.’

h

,rie,

‘,!iJI,

tu’,Oau$C

it0

t

yr

r.

wired

a::im

Cr

:.

Comj’accy

tPEP

v

the:,

in

coil

.

nor

eu:nt,-’rc.cn,,.

ci

-

nd

vary

series

range,

to

Sut

fi:c’ntli

NFL

grett4%.

wired

;rcv:dr

ut

,aodards;

with

in

burden,

for

Sbouad

for

the

series

external

with

3

Page 4

GEK-36767

TABLE

2

OPERATING

These

opened

or

An

coil.

type

effect

of

This

circuit

on

temperature

PICKUP

AND

Pickup

increasing

contacts

pickup

A

RELAY

voltage.

normally

CALIBRATION

These

for

the

by

various

adjusting

calibrations

tube.

PRINCIPLES

plunger

closed

external

external

prevents

relay

operating

insignificant

DROPOUT

voltage

voltage

will

close

open

contact

relays

operating

the

vertical

appear

relays

by

armature

an

resistor

resistor

DEFINITIONS

is

defined

is

applied

when

Reset

voltage

defined

are

calibrated

on

the

RATING

VOLTS

operate

is

self

voltage.

in

the

applied

coil

position

top

700

which

included

has

heating

terms

as

to

is

as

—

external

of

DC

on

a

of

the

the

the

a

at

of’

the

resistance

The

CAL.

RANGE

DROPOUT

280

-

the

principle

is

drawn

as

part

and

variations

high

the

total

voltage

relay.

voltage

voltage

contact

the

factory

resistor

the

armature

nameplate

VOLTS

580

AT

RATED

67

CHARACTERISTICS

BURDEN

of

electromagnetic

vertically

up

of

these

is

which

is

dropout

relays

much

in

ambient

value

resistance.

the

voltage

the

open

makes

decreased

relay

when

that

resistor

circuit

at

Dropout

is

gradually

which

at

which

for

combinations

on

the

and

plunger

correspond

WATTS

VOLTS

into

to

higher

temperature

normally

s

the

will

the

volts.

used

to

COIL

OHMS

solenoid.

a

be

connected

than

changes

open

voltage

from

assume

relay

Table

in

rod.

the

scrihed

RESISTOR

345

attraction.

that

in

contacts

some

is

2

these

The

four

EXTERNAL

OHMS

7000

The

in

series

of

the

from

operating

having

operating

will

at

which

level

its

of

de—energized

completely

shows

the

relays.

factory

marks

on

1

contacts

with

an

appreciable

coil

close

the

normally

voltage

de—energized.

calibrating

Dropout

dropout

the

calibrating

are

the

coil.

resistance

when

above

position.

is

set

voltage

operating

This

with

gadually

closed

ranges

To

should

plunger

coil)

corresponds

dropout

gradually

is

When

That

is,

which

at

PICKUP

Dropout

percentage

wEth

two

voltage

Tnis

set

the

be

set

so

in

its

calibrations

reduced.

these

with

applied

the

normally

VOLTAGE

voltage

of

dropout

normally

is

which

percentage

relay

to

that

its

de-energized

to

the

are

relays

voltage

open

and

voltage

open

or

less

than

will

bottom

lowest

the

are

pickup

one

dropout

position.

voltage

properly

gradually

contacts

that

normally

145

cecrease

at

edge

dropout

voltage

percent

one

t5

adjusted,

open.

is

a

as

of

just

The

voltage

percent

reduced,

are

function

open

of

the

the

lines

scribed

not

and

set

dropout

factory

with

mark

calibration

which

at

they

the

independently

of

one

dropout

voltage

calibrated

the

highest

will

relay

the

dropout

normally

voltage.

corresponding

on

listed

the

relay

dropout

will

reset

adjustable.

voltage

closed

setting

voltages,

the

on

will

in

one

contact,

is

scribed

calibrating

the

nameplate

dropout

smooth

within

setting.

increased

the

two

The

pickup

adjustable

marking

when

motion

percent

relays

For

as

tube

and

the

D.C.

will

shown

to

will

with

(closest

so

on.

applied

the

of

the

pickup

operated

occur

in

table

armature

the

relay

to

The

voltage

reset

voltage

at

the

factory

position.

at

relays

some

3.

a

4

Page 5

GEK-36767

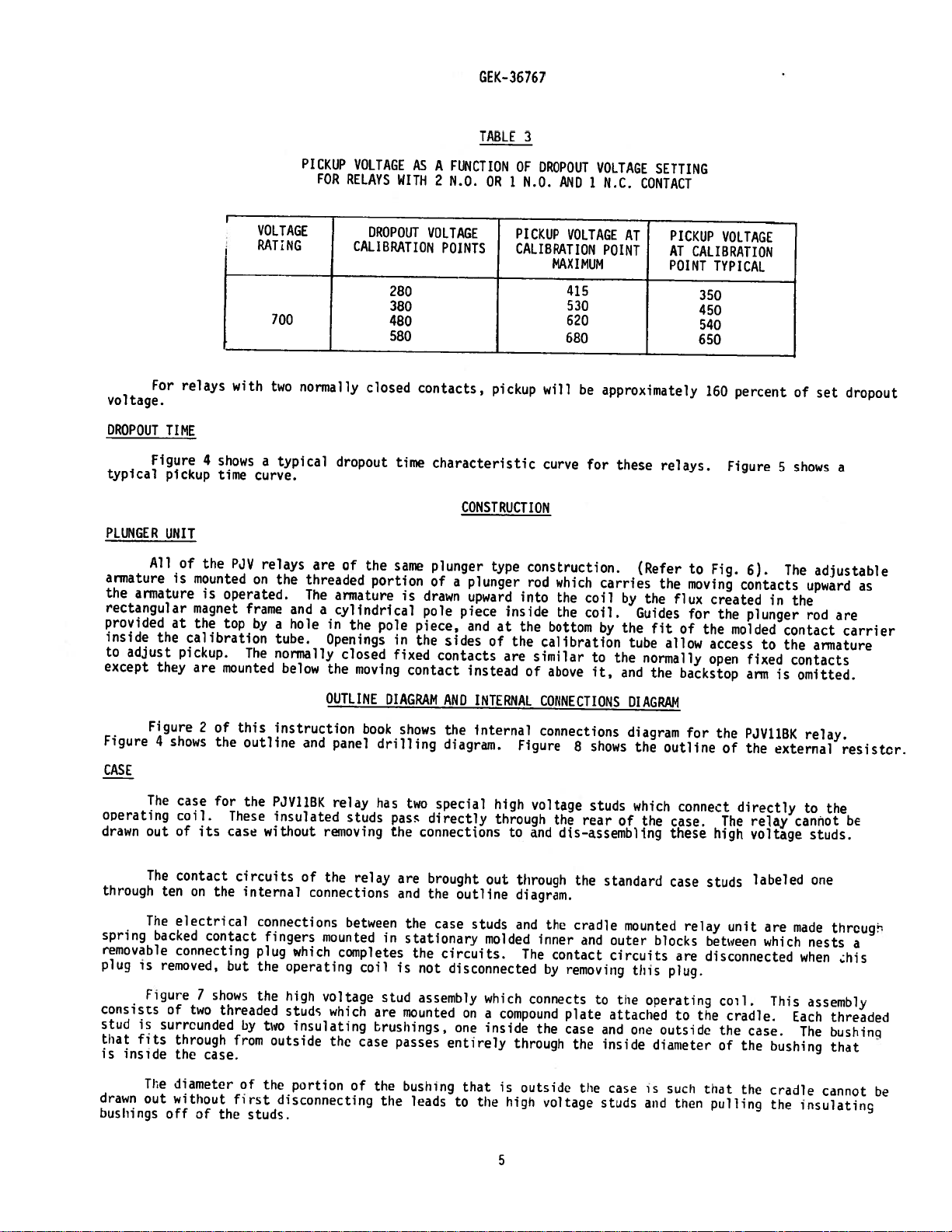

TABLE

3

For

voltage.

DROPOUT

Figure

typical

PLUNGER

All

armature

armature

the

rectangular

provided

inside

to

adjust

except

Figure

Figure

4

CASE

TIME

pickup

UNIT

is

at

the

they

shows

relays

4

the

of

mounted

is

magnet

the

calibration

pickup.

are

of

2

the

with

shows

time

PJV

on

operated.

frame

top

by

The

mounted

this

outline

PICKUP

VOLTAGE

RATING

700

two

normally

a

typical

curve.

relays

the

threaded

The

and

a

hole

tube.

normally

below

instruction

and

VOLTAGE

FOR

RELAYS

CALIBRATION

dropout

are

of

armature

a

cylindrical

in

the

Openings

closed

the

OUTLINE

panel

DROPOUT

280

380

480

580

closed

the

same

portion

pole

in

fixed

moving

DIAGRAM

book

drilling

AS

WITH

contacts,

time

is

piece,

the

contact

shows

VOLTAGE

drawn

pole

A

FUNCTION

N.O.

2

OR

POINTS

pickup

characteristic

CONSTRUCTION

plunger

type

ofaplunger

upward

piece

and

sides

at

of

contacts

instead

AND

INTERNAL

the

internal

diagram.

OF

DROPOUT

M.D.

1

PICKUP

AND

VOLTAGE

CALIBRATION

MAXIMUM

415

530

620

680

will

curve

construction.

rod

which

into

the

the

of

the

the

bottom

calibration

similar

above

inside

are

CONNECTIONS

connections

Figure

8

VOLTAGE

1

N.C.

AT

POINT

approximately

be

for

these

carries

coil

by

coil.

by

the

the

to

it,

and

shows

SETTING

CONTACT

PICKUP

AT

POINT

relays.

(Refer

the

the

flux

Guides

fit

tube

allow

normally

the

OIAGRAM

diagram

the

outline

VOLTAGE

CALIBRATION

TYPICAL

350

450

540

650

160

percent

Figure

to

Fig.

moving

6).

contacts

created

for

the

the

plunger

molded

of

access

open

the

of

fixed

arm

PJVI1BK

the

backstop

for

5

in

to

is

external

of

shows

The

upward

the

rod

contact

the

contacts

omitted.

relay.

set

dropout

a

adjustable

are

carrier

armature

resistor.

as

operating

drawn

through

spring

removable

plug

is

consists

stud

is

that

fits

inside

is

The

drawn

out

bushings

The

case

coil.

of

out

The

contact

ten

Tne

electrical

backed

connecting

removed,

Figure

of

surrcunded

through

the

diameter

without

off

its

on

7

two

case.

of

for

These

case

the

contact

but

shows

threaded

first

the

the

without

circuits

internal

connections

fingers

plug

the

the

by

two

froii

of

the

studs.

PJV11BK

insulated

removing

of

the

connections

mounted

which

operating

high

voltage

studs

insulating

outside

portion

disconnecting

relay

studs

relay

between

completes

coil

which

the

case

of

has

two

pass

connections

the

are

and

the

in

stationary

the

is

not

stud

assembly

are

mounted

brushings,

passes

the

hushing

the

leads

special

directly

brought

the

outline

case

circuits.

disconnected

on

one

entirely

that

to

out

studs

molded

which

a

inside

the

high

voltage

through

to

and

through

diagram.

and

inner

The

connects

compound

the

througn

is

outside

high

S

studs

the

rear

dis—assembling

the

standard

the

cradle

and

contact

by

removing

to

plate

case

and

the

inside

the

voltage

studs

which

of

the

mounted

outer

circuits

this

the

attached

one

case

connect

case.

these

case

blocks

are

plug.

ooerating

to

outside

diameter

su’i

is

tnen

and

The

high

studs

relay

betwrcn

disconnected

col.

tne

the

of

that

pulling

directly

relay

voltage

labeled

unit

cradle.

case.

trio

trio

are

which

This

bushing

cradle

the

to

the

cannot

studs.

one

made

nests

when

assemb1

Each

bushinq

The

cannot

insulating

bc

thrcug

a

his

threaded

that

be

Page 6

cradle

of

the

upside

blocks

by

thumbscrews,

external

pulled

been

released.

bushings

unit

with

is

provided

sealing

The

relay

held

is

case.

down.

of

the

To

draw

connections

off

have

the

The

case

wire.

the

for

mechanism

firmly

The

cases

The

connecting

cradle

holds

out

rear

To

been

external

is

suitable

either

in

and

the

the

relay

to

of

the

replace

replaced

connections

mounting.

is

the

and

cradles

case,

connecting

the

high

studs.

the

on

for

mounted

case

plug,

also

unit

voltage

relay

the

either

The

with

are

besides

locks

the

The

high

intact.

in

a

plug

cover

relay

unit,

surface

cover

steel

a

latch

so

constructed

making

the

in

studs

the

voltage

GEK—JbJbi

framework

at

latch

place.

is

first

are

unit

reverse

studs.

or

attaches

the

top

that

the

electrical

in

place.

removed,

then

can

then

order

semi-flush

to

called

and

the

the

relay

The

and

disconnected

be

easily

is

These

followed

bushings

panel

the

case.

the

cradle

bottom

cannot

connections

cover,

the

connecting

and

drawn

do

mounting

Each

cover

and

and

which

the

out

making

not

and

is

by

a

guide

be

inserted

between

is

plug

insulating

after

certain

allow

an

assortment

screw

complete

a

the

fastened

drawn

the

the

has

pinat

in

the

respective

to

out.

bushings

latches

that

the

removal

of

provision

cnit.

the

case

the

are

have

insulating

of

hardware

back

case

The

the

for

This

then

relay

a

These

to

protect

substained

claim

at

once

Apparatus

Reasonable

injured

cartons

on

the

If

outside

or

the

in

operation

Immediately

that

no

damage

VISUAL

INSPECTION

Check

the

relay

received

Examine

signs

tact

MECHANICAL

of

leads

physical

extend

INSPECTION

relays,

them

in

Sales

the

a

of

that

against

transit.

with

Office.

care

adjustments

relays

place

of

the

has

the

the

when

the

should

are

that

the

relay.

upon

been

nameplate

agree

relay

damage,

striaght

not

included

damage.

If

injury

transportation

be

disturbed.

not

to

is

free

case

may

receipt

sustained

with

the

by

visual

and

that

back

tmmediately

or

exercised

be

installed

from

find

of

relay

a

in

stamping

requisition.

inspection

all

from

RECEIV1NG

as

a

part

damage

company

in

unpacking

immediately,

moisture,

its

way

inside

ACCEPTANCE

inspection

an

shipment

to

insure

that

screws

the

contacts

HANDLING

of

a

upon

receipt

resulting

and

promptly

dust

when

and

that

that

there

are

tight.

and

AND

control

from

the

and

TESTS

and

the

the

are

have

STORAGE

panel,

of

rough

notify

relay

they

met3llic

the

cover

acceptance

relay

moael

no

Also

not

a

relay,

handling

in

should

chins.

calibrations

number,

broken

check

been

will

examine

the

nearest

order

be

stored

is

removed

test

or

to

see

deformed.

be

shipped

is

that

Foreign

should

rating

cracked

that

it

evident,

General

none

in

matter

and

have

and

molded

the

in

for

any

of

their

cause

be

made

not

calibration

flexible

cartons

damage

file

Electric

the

parts

original

collected

trouble

to

been

parts

designed

damage

a

are

in

insure

disturbed.

range

or

other

moving

the

of

con

It

1.

2.

is

recommended

Operate

from

friction

just

making

me

wipe

normally

either

The

gap

armature

the

on

open

contact

between

reset.

that

plunger

or

there

a

normally

contact

arrangement.

the

the

binds.

is

following

on

each

less

open

gap

backstop

If

than

with

unit

two

nomally

1/64

or

closed

the

Backstops

and

contact

mechanical

by

hand

inch

contact

armature

should

adjustments

and

open

gap

fully

brush

6

allow

contacts

on

should

be

at

the

reset

present

the

it

other

to

are

be

tip

be

chccked:

reset

to

i:resent,

contact.

approximately

should

above

should

be

all

insure

observe

3/64

approximately

normally

be

approximately

that

that

mci.

open

the

unit

with

The

3/32

contacts

1/16

one

inch

is

with

free

contact

for

only.

the

Page 7

GEK-36

767

ELECTRICAL

DROPOUT

1.

aligned

point

given

this

setting.

test

To

external

normally

indicates

resistor

open

drop-out

visually.

To

simply

connected

directly

Check

The

location

facilitate

The

Figure

relay

3.

TESTS

AND

PICKUP

with

on

the

contact

check

smooth

for

inspection

should

outline

The

the

relay

to

top

the

a

will

when

for

the

to

should

and

-

The

mark

nameplate.

proper

for

variable

indicate

voltage

the

operation

relay

operation

be

testing.

mounted

be

diagram

units

on

clean

for

are

the

It

operation,

D.C.

on

but

without

of

plunger

and

on

the

normally

calibration

should

supply.

pick-up.

lowered

s

not

the

dry,

a

vertical

external

supplied

tube.

be

sufficient

preferable

it

is

A

contact

Similarly,

the

from

for

calibration,

resistor.

operating

when

INSTALLATION

LOCATION

free

from

dust

MOUNT

IN

surface.

resistor

CONNECTIONS

from

This

the

corresponds

to

check

to

indicating

indication

an

picked-up

a

D.C.

the

relay.

PROCEDURE

excessive

and

C

The

outline

is

s,own

factory

dropout

connect

light

condition.

supply

end

in

Figure

with

to

the

and

relay

the

or

ohmmeter

on

a

Reset

of

not

vibration,

panel

8.

the

bottom

minimum

pickup

in

dropout

of

series

conncted

normally-closed

must

be

over

35

and

well

diagram

is

of

each

checked

volts

shown

the

calibration

unit

with

to

contact

can

lighted

armature

at

the

a

be

to

in

Internal

One

12

not

B&S

The

binding.

is

It

case

it

will

The

knurled

If

dropout

turn

view

in

of

gage

plunger

required

With

decrease

the

the

No.

and

in

its

which

of

the

setting.

Gradually

high,

increasing

oacteristics

C

thataperiodic

it

is

recommended

MECHANICAL

CHECKS

connection

the

mounting

‘opper

desirable

mounted

and

used.

be

armature

a

variable

is

armature

applied

section.

of

the

test

unit

dropout

the

too

vital

program

that

wire

should

that

in

to

applied

low,

to

voltage

the

diagram

studs

or

be

the

its

voltage

the

approximate

source

voltage

turn

ride

with

role

be

following

is

shown

or

screws

equivalent.

its

manually

final

setting

permanent

may

of

D.C.

the

lower.

the

PERIODIC

of

protective

followed.

points

should

operated

location

be

set

position

voltage

and

note

armature

Once

unit

CHECKS

Unless

in

of

as

dropout

dropped

relays

be

Figure

be

(JSTMENTS

ADJ

the

iid

follows.

apply

the

ride

to

AND

otherwise

cheked

2.

permanently

make

to

required

with

on

the

sufficient

voltag2

lower

voltage

out.

ROUTINE

in

the

at

an

grounded

that

sure

dropout

the

With

tube

th.

voltage

relay

wired

the

relay

corresponding

voltage

at

which

the

in

th.

set,

:‘librating

check

votage

is

Pickup

MAINTENANCE

a.cn

ope

dictatoi

by

interval

of

unusual

of

by

assembly

rlay

a

from

a

conductor

is

be

performed

to

the

external

de-energized

the

to

to

the

relay

L,35

tube,

pickup

should

power

voltage

be

sy;te,

environeental

to

one

working

turn

desired

out.

if

described

as

two

not

with

resistor

to

pick

dropout

by

t

years.

less

smoothly

the

the

bottom

dropout

it

gradually

is

important

conditions,

than

is

in

relay

with

up.

too

the

excessive

Manually

friction

operate

or

the

voltage

tendency

unit

to

armature

bind.

and

allow

it

to

reset

to

make

sure

that

no

a

7

Page 8

Check

gap

is

open

approximately

contact

Examine

cleaned

with

surface.

factory.

ELECTRICAL

Check

It

are

is

noted,

that

differences

1.

Friction

armature

leads

between

2.

Moving

centrally

follows:

to

see

ar

the

a

burnishing

Burnishing

Do

not

CHECKS

the

dropout

not

recormiended

as

in

test

If

does

to

the

the

armature

Contact

located.

that

the

3/32

approximately

contact

tools

use

knives,

and

long

as

equipment

there

is

not

have

moving

contacts

and

Leads

-

If

contacts

inch

surfaces

tool,

designed

files

pickup

that

the

or

any

a

tendency

calibrating

The

these

with

the

1/16

for

which

especially

or

voltage

the

relay

by

human

tendency

are

flexible

moving

have

inch

signs

consists

abrasive

relay

is

to

not

still

to

moving

contact

approximately

armature

above

the

of

of

for

paper

of

the

be

readjusted

within

error.

SERVICING

bind

rotate

formed

tube.

contact

GEK—36767

reset.

stationary

tarnishing

flexible

a

cleaning

or

relay

limits.

or

excessive

and

bind

properly.

leads

leads

have

3/64

Check

cloth

as

when

as

inch

to

contact

or

corrosion.

strip

relay

of

described

minor

Such

friction

the

relay

Also

check

should

been

deformed,

wipe

see

of

contacts

any

setting

deviation

be

and

that

tips.

metal,

kind

in

the

is

present,

operates.

that

formed

that

the

Silver

with

can

to

clean

installation

variations

can

no

foreign

to

they

the

back

contacts

an

be

obtained

be

check

If

keep

should

normally

Stops

etched,

relay

from

introduced

to

it

does,

matter

the

be

open

on

the

should

roughened

from

contacts.

section.

the

see

the

is

moving

reshaped

contacr.

normally

be

the

previous

by

that

flexible

present

assembly

as

the

The

bend

closed

The

the

moving

3.

See

wipes

4.

Fixed

The

is

This

If

only

grams.

For

It

prompt

When

specify

number.

furnished.

lead

should

should

contact.

whole

lead

leads

are

parts.

the

acceptance

are

adjusted

Contact

stationary

the

face

face

may

contacts

one

normally

In

all

cther

is

recomended

replacement

ordering

quantity

If

possible,

be

Initial

applied

be

are

this

contact

required,

have

vertical

The

should

formed

tests

by

contact

to

measured

replaced

closed

arrangement

that

of

any

renewal

give

right

a

with

lead

should

lie

in

correctly

and

forming

Tension

normally

the

with

or

contact

codes,

sufficient

that

parts,

name

the

angle

the

a

installation

or

contact

readjusted

the

all

are

worn,

address

of

part

General

bend

lead

then

vertical

providing

bending

rests

tip

a

gram

is

used,

normally

contacts

quantities

wanted,

Electric

when

going

down

flow

in

plane

the

sections

the

onamember

which

gauge.

for

wipe

the

open

should

RENEWAL

broken

the

or

nearest

and

Company

it

leaves

foranormally

a

smooth

and

not

relay

is

for

stationary

called

necessary

is

or

gap,

initial

contact

have

PARTS

of

renewal

damaged.

Sales

give

requisition

the

arc

blow

not

contact

contacts.

the

initial

tension

should

about

parts

Office

complete

tail

to

out

binding

contact

to

part

on

have

five

nameplate

of

the

open

the

contact

terminal

horizontally.

due

gap

and

stop

the

tension

this

about

grams

be

carried

of

the

number

moving

to

foreign

wipe

contact

should

contact

five

initial

General

data,

on

which

contact

and

screw

Binding

adjustments.

arm.

from

be

should

grams

tension.

in

stock

Electric

including

the

up

on

matter

Initial

checked.

initial

for

the

its

to

relay

button,

a

molded

will

or

tension

stop

be

about

enable

Company,

serial

normal]”

stop

bent

Gaps

arm.

When

tension.

was

this

base.

when

and

14

the

8

Page 9

GFK—35757

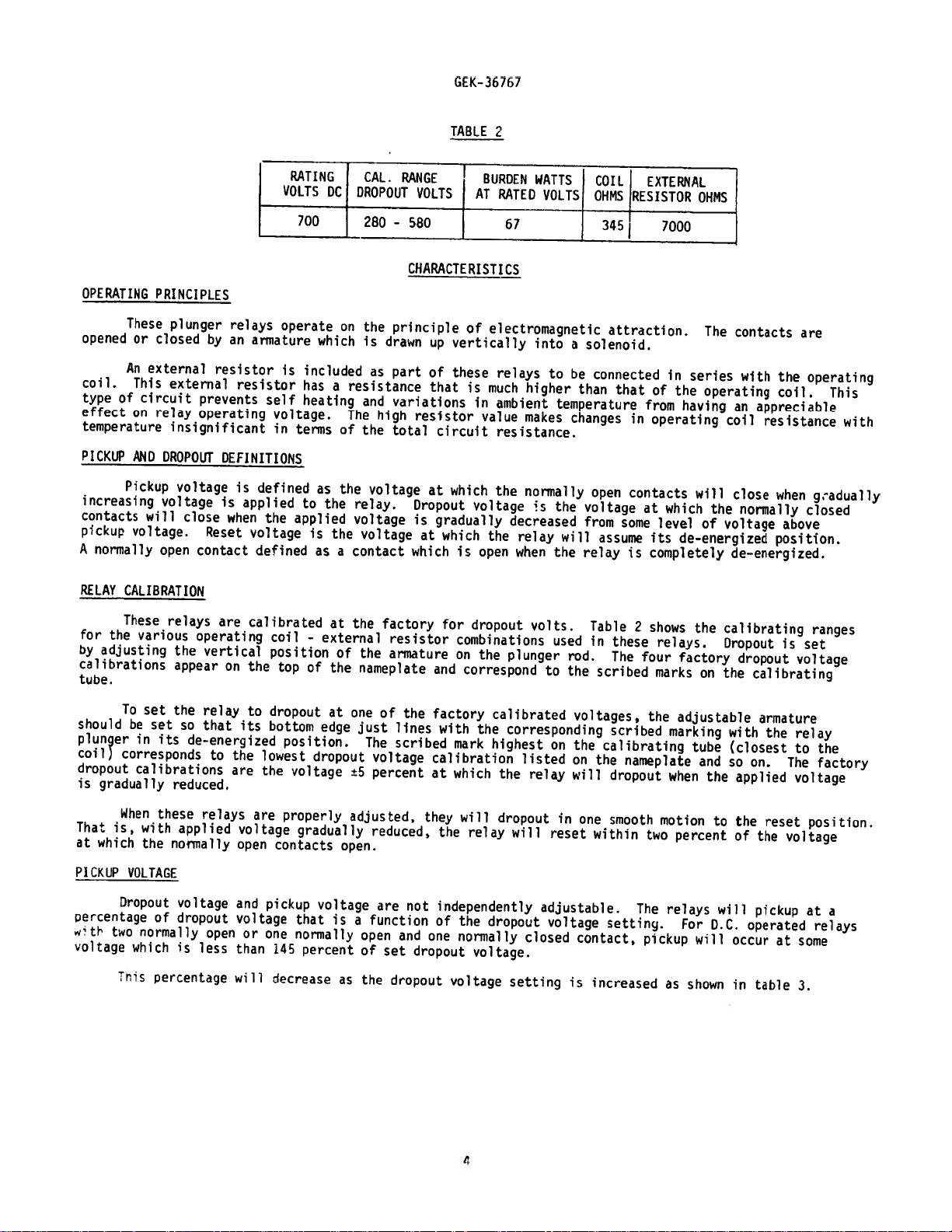

FIG.

1

(Photo

Not

Available)

Type

PJV1IBK(-)E

9

Relay

Out

Of

Case-Front

View

Page 10

20

LLL

TTT

GEK—36767

COCE

NI’MPFP

02

2!

22

-----EZTh---

EXTEP’AL

RESI

‘\1

MA(E

7

CC*’NFCTIOt1S

/‘

2

DOTtED

!HORTING

ARE

PEUIRED

IF

FARS

n

e

STOP

IC

*

S!OPT

FI3C-EPS

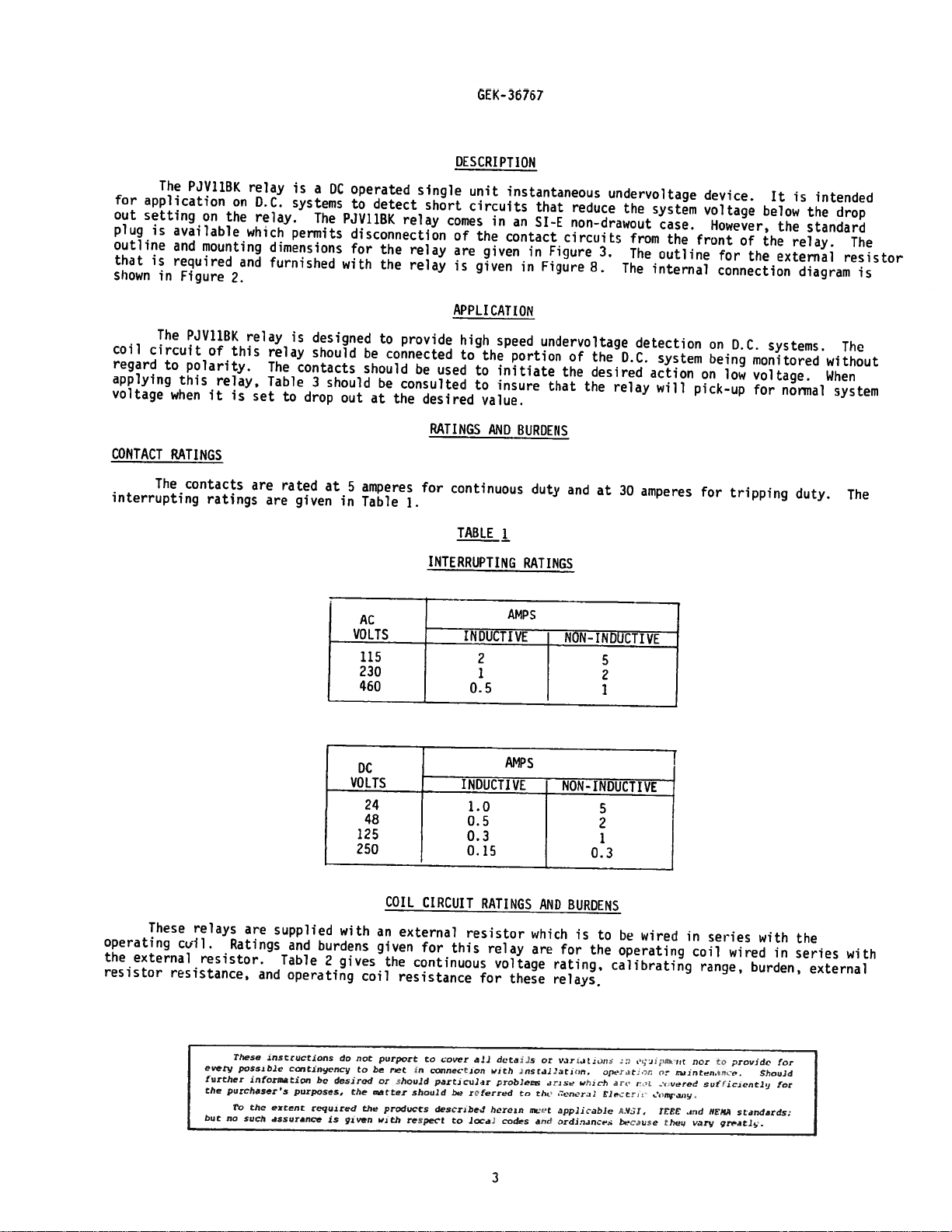

FIG.

2

(0245A3667—1)

NOTE:

Internal

141G[1

VftTAGE

THROUGH

ftSHINGS

REFORE

Connections

10

SThDS

REAP

CF

VST

CRADLE

Diagram

CASE.

RFHOVED

FE

Cfl

FE

For

Model

(2!

&

22)

LEADS

FRO!A

W:THDPM.

PJV11BK(—

PROJECT

A’D

ThESE

SIUDS

Page 11

LLJ

CD

a

Wa

-a

I

a

a

0

‘-a

has

I-.

a

.,

.,

—

.,

—

I.

I

%ID

4

a

a

—

‘-a

-C

-

-

LU

C

a

I

_____

4

4—fr

C’

‘CL

F

C-

-

a

0

I

C’

LU,

a,

-

a

or

a

a

0

LU.

La)

-j

I

Las

—

I

—

In

cL’1

CD

(C)

cC’

CD

-

C’”’

t

—

,-

-r

0

t

_

C’

F

C

C)

a-’

a.,

F

C’

C

C

‘

-n

‘C

,

,_,

-,

La

-C

CD

C)

0

CD

C,)

C’

L

a

0

C

0

a

CL.

c)

‘a

LU

Page 12

GEK-36

767

PLV

RELAY

DROPOUT

30

26

0

z

22

0

‘3

-J

----—-

E

r

iN

L.a

10

PICRUP

INITIAL

VOLTAGE

A—CTOPER

100

VOLTAGE

IS

DECREASED

CENT

.—----

VOLTS

—

115

OF

......

C

Los

A—C

VOLTS

SUODEMIT

PICKuP

I

MG

TINE

CURVE

A—C

FROM

VOLTAGE

-—--

fF_bCONTAc_._

4

_L

115

SNOIN

VOLTS

8ELC.

—

I

-,

-

—

CYCLE

(60

CYCLE

;:::7’

NASE

ONE

6

2

.0

10

‘

20 30

FINAL

OPENING

VOLTAGE

tIw(

.1

NO

VALUE

OF

—

PERCENT

a’

CONTACT

o

OF

60

PICKUP

70

VOLTAGE

eo

90

100

4

(y.379..1)

Typiciil

Dropout

Tiuie

Ch1rdc1r

i.,t

r

Ic

PV11I(—)[

1?

Page 13

GE

(-36767

70

I

60

N

I

I

30

S

E

C

20

0

N

0

S

0

(—(3

,-1)

1

VOLTAGE

Tyoic,i

cIuL

2

IN

U1TIPLES

Tu;Ie—Voltdge

OF

PICN—UP

Chdracteristic

3

For

PJVIIBK(-)E

13

Page 14

GEK—36767

MAGNET

CALIBRATING

TUBE

FAC

I

t

I

ft...

ABLE

MOVING

CONTACT

FIG.

(8009444)

6

•1

Typical

Plunger

r

Voltage

14

Unit

Used

STATIONARY

CONTACT

CONTACT

CARRIER

ASSEMBLY

In

These

Relays

Page 15

G[K-36757

C

(

RELAY

CASE

OF

B

,jJ

FIG.

7

(0257A3242_o)

Diagram

Of

High

Voltage

Stud

Assembly

FIG.

(403A119-1)

8

Outline

For

External

Resistor

BARE

HOLE

STRIP

Page 16

GE

Power

Management

Anderson

215

Markham,

Canada

Tel:

Fax:

www.gecomIindsysIpm

L6E

(905)

(905)

Avenue

Ontario

1B3

294-6222

201-2098

Loading...

Loading...