Page 1

for

This

relay

INSTRUCTIONS

supplement

model

12IAC8OL(-)A.

TIME

in

conjunction

OVERCURRENT

TYPE

MODEL

TAC

12IAC8OL(-)A

INTRODUCTION

with

RELAY

GEH—1788

forms

Insert

the

Booklet-

instructions

GEH-1788

unit

relay

in

GEH-1788

Relay

with

is

1)

2)

The

model

a

seal—in

similar

The

internal

supplement.

The

induction

provide

3

and

4)

ment

in

is

completed,

the

unit

is

open,

tap

value.

time

current

for

model

12IAC8OL(-)A

unit

model

mounted

121AC53A(-)A

to

connections

unit

torque

must

flux

control.

be

to

completed

rotate

torque

will

operate

the

unit

will

curves,

121AC53A(-)A.

DESCRIPTION

consists

in

are

uses

wound

This

the

can

be

on

overcurrent.

not

burdens

of

a

small

described

as

shading

control

in

order

disk.

developed

operate

and

a

single

single

shown

that

When

at

ratings

in

in

figure

coils

circuit

there

the

on

the

When

current

of

IAC

type

ended

GEK-1788

1

on

the

(connected

be

shading

induction

the

shading

levels

this

relay

time

(Si)

except:

of

U-magnet

a

phase

coil

case.

this

up

circuit

disk

coil

to

are

overcurrent

This

to

to

studs

displace

and

circuit

20

times

as

given

Those

nor

to

operation

probls

matter

Instructions

provide

or

arise

should

do

every

are

not

possible

Should

not

to

SYSTEMS

for

.aintenanc..

which

referred

be

POWER

GENERAL•

purport

covered

the

General

to

cover

contingency

further

•ufficiently

MANAGEMENT

all

to

information

Liectric

detafle

be

for

Company.

or

met

be

the

variation.

in

connection

desired

purchaser’s

DEPARTMENT

or

should

ELECTRIC

in

with

puro.ea,

equip..nt

inatal3atioq,

particular

the

Page 2

GEK-

27870

SEAL—IN

CONTROL

WINDINGS

8-70

FIG.

1

GENERAL

=

*

(0226A7211-0)

ELECTRIC

SHORT

INTERNAL

CO..

POWER

1

2

FINGERS

COKNECTIONS

SYSTEMS

3

DIAGRAM

MANAGEMENT

FOR

BUSINESS

4

THE

IACBOL(-)A

DEPT.,

C)

6

RELAY

MALVERN,

(FRONT

PA.

19355

VIEW)

Page 3

INSTRUCTIONS

TIME

OVERCURRENT

RELAYS

GEH-1

788L

IAC53A

IAC53B

IAC53C

TYPES

IA

C5

3

IAC54A

IAC54B

R

GENERAL

ELECTRIC

Page 4

GEH-1788

Tvne

Time

IAC

TOP

TAP

SEAL-IN

UNIT

HOLDING

(0I

SEAL-

TARGET

SEAL-IN

UNIT

STATIONARY

CONTACT,

S[AL

UNIT

STATIONARY

CO

RIGHT

SEAL

MOVING

CON

AC

PIVOT

PLUG

L

IN

FT

N

TA

(.T

N

IN

TACT

3EMBLY

Overcurrent

--

Relay

(ii

‘4

BLOCK

TAP

DIAL

--TIMF

SHAFT

DISK

MAIN

MOVING

CONTACT

M

A

N

IDNARY

STA’

AND

ROUGH

CONTACT

ASS

Si,p,

—

-‘p

MAGNET

0151<

Y

MB

C

L

c’1

Fiq.

I

DISK

AND

SHAFT

JEWEL

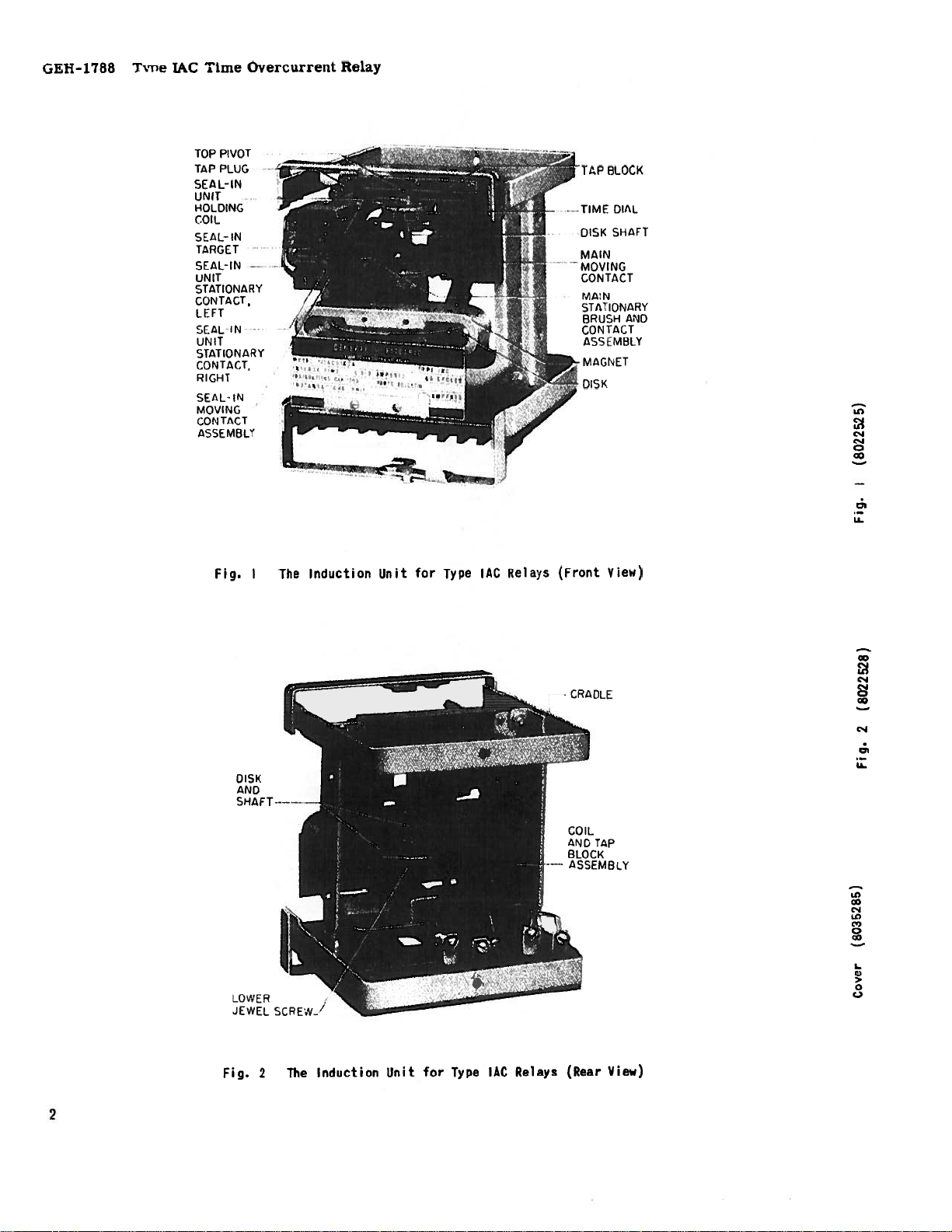

The

SCREW

Induction

—

Unit

for

Type

IAC

Relays

(Front

View)

c..J

c..1

Di

LL

cS-i

LC)

C’,

0

>

0

C-,

View)

Fin.

for

Induction

The

2

Unit

Type

IAC

Relays

(Rear

2

Page 5

TIME

OVERCURRENT

RELAYS

IAC53A(-)A

IAC53B(-)A

IAC53C(-)A

iAC53R(-)A

IAC54A(-)A

1AC54B(-)A

The

overcurrent

acteristic.

overcurrent

The

various

differ

in

the

instantaneous

included.

These

induction

T

Types

on

relays

number

relays

unit

ype

1AC53

relays

They

single-phase

unit

with

with

are

employed

described

of

circuits

and/or

consist

instantaneous

an

Contact

Circuits

One

One

One

One

Two

Two

and

1AC54

very-inverse

a

and

an

of

to

poly-phase

in

this

they

a-c

an

induction

TYPE

INTRODUCTION

Instan.

Unit

No

Yes

No

Yes

No

Yes

relays

time

protect

instruction

close,

tripping

unit

which

are

against

circuits.

and

unit

unit

time

char

book

if

or

per-

A-C

an

is

an

IAC

Trip

Unit

No

No

Yes

Yes

No

No

mits

instantaneous

rents,

use

where

preferred.

composed

is,

the

a-c

tripping

ed

separately

indicates

the

internal

diagrams.

Induc.

One

One

On

One

One

One

or

an

d-c

of

induction

the

Unit

tripping

induction

power

Since

practically

various

unit,

unit),

they

in

the

units

comprising

connections

Outline

D.

&P.

Fig.

20

Fig.

20

Fin.

20

Fig.

20

Fig.

20

‘Fig.

20

for

unitwithana-c

is

unavailable

combinations

the

instantaneous

are,

for

following

and

outline

Conn.

Fig.

Fig.

Fig.

Fig.

Fig.

Fig.

exteremely

tripping

or

all

Type

of

convenience,

text.

each

The

type

andpanel

mt.

a-c

IAC

the

and

12

13

14

15

16

17

high

tripping

relays

above

unit

describ

above

also

cur

unit

(that

and

table

lists

drilling

for

is

are

the

TAC

mounted

tion-disk

current

disk

the

alarm

ary

by

a

current

magnet

delay.

the

left

and

such

unit

picks

up

and

button

a

n’Jer

rurt;2-O-

the

pur.:lianer

but

no

The

relays.

shaft

contact

spiral

acting

There

of

its

contacts

that

picks

up,

remains

Shove

posszble

information

To

Civ

such

INTRODUCTION

induction

Figs.

in

the

construction

operating

carries

or

trip

or

spring

and

its

is

a

the

shaft.

when

up

and

it

raises

beneath

instructions

contingency

‘s

Cxtent

ssura.nce

unit

cradle.

coil

the

circuit

contacts.

to

motion

on

the

seal-in

in

parallel

the

main

seals

a

exposed

the

he

purposes,

requlred

is

and

1

These

type.

on

moving

give

disk

unit

This

target

lower

do

des;rcd

is

qiven

the

basic

2

show

units

Thediskisactuatedby

a

laminated

contact

when

The

the

is

it

disk

proper

retarded

to

give

touches

shaft

mounted

unit

has

with

the

contacts-close

in.

When

into

left

the

released

corner

purport

be

or

matter

products

with

view

met

should

until

not

to

the

INDUCTION

unit

in

all

the

induction

are

of

U-magnet.

which

the

is

contact-closing

by

a

the

correct

on

the

its

coil

main

the

the

seal-in

which

by

of

to

in

connect

particular

should

described

respect

Type

the

induc

completes

station

restrained

permanent

time

front

in

series

contacts

seal-in

unit

latches

pressing

the

cover.

cover

al.!

ion

be

referred

to

local

unit

The

a

to

details

with

problems

herein

codes

UNIT

The

IAC

relays,

characteristics

tripping

cause

closing

to

time

the

rent

four

bination

amperes;

0.5,

0.12,

installation,

to

meet

the

it

to

OPERATING

The

induction

contacts

the

pick-up

delay

setting

characteristics

The

induction

operating

of

0.6,

0.16,

or

variations

arise

the

General

applicable

and

ordinances

APPLICATION

induction

supplying

of

breakers

close

its

which

value

in

closing

of

the

time

coils,

taps

1.5,2.0,

0.8,

0.2,

which

as

2.5,

1.0,

0.24,

in

operation

are

Electric

ANSI,

because

unit

is

the

main

unit

inverse

soundingan

currents

the

the

relay

for

very

and

overload

contacts.

CHARACTERISTICS

unit

are

may

close

as

the

dial

have

set

contacts

(Fig.

shown

one

the

as

current

on

the

tap

is

1).

in

Fig.

RATINGS

unit

is

each

follows,

3.0,

1.2,

0.3

and

equipment

or

not

Company.

IEEE

designed

having

4.0,

1.5

0.4

rrintenance.

covered

and

they

to

a

4,5,6,7,8,10,12,

5.0

and

and

2.0

amperes.

nor

to

sufficiently

NEMA

vary

greatly.

in

all

time

alarm

or

two

increases

block.

determined

The

time-cur

3.

use

any

different

6.0

amperes;

amperes;

provide

Should

standards;

Type

delay

which

circuit-

The

one

com

and

for

for

or

by

of

16

0.1,

3

Page 6

GEH-1788

:

“I

7W

II,

be

I,.

Type

:.;.;;

liii—

I

TIN

P

U

API

HIlt

0.5-4.0

1.5—12.0

2-16

H

::

--

[AC

S

C,

—

Overcurrent

Time

4

4

$

I

UNIT

lIST

I

I

0

5-4

0.

2—16

0-ITO

20-ISO

ia

Relay

1I!11

I

ADJ

INST.

AUJU

17111

I

TI

I

US

UNIT

NUOLISLY

TI

tO

S

I

ENPS

IJI

I

NI

eu

‘I’

P

‘44

I..

‘7

II

N

I.

Ii

441,44744411!

5,2.0,2.5,3.

$7

1F11Ii1II_

I

I

EXTQE[

TIIIE

0,5.0,

r’(E

061

S.O6

(ECO

TAPS

.0,7.0,6.0,

I_L

r[p’)

III

I

7

I

C.5,O.6,O.7,0.8,I.O,I.2,I.S,2.O,2..,3.0,4.0

I.

2.O,2.5,3.0,4.05.0,6.O,7,O,80.,IO.0,I2,I6

•

1IIII1

I

0,

12

I

I

J

CON

:

-

—

4

III

—

——-

I

-

fiiiij

I

I

I

I

.4

.4

.1

.4

3

.2

.1

44

44

17

U

-

13

74fl

.1

5

——

.E

-

4;

—

-

JA

—

.-

——-

I..

44

MULTIPLES

W7IWW

N

$

RELAY

OF

TAP

£

SETTING

.5

I

S

Figure

3

(0888e0270

[3])

Time-Current

Very-Inverse-Time

Curves

for

Characteristics

Type

IAC

Relays

with

4

Page 7

1•C’4

C.,’

cc

c..J

C.,’

cc

U-

Type

IAC

Time

Overcurrent

CALIBRATION

PLATE

ADJUSTABLE

I-.----

POLE

PIECE

TA

N

TA

N

MS

[

UNIT

OPERATING

COIL

TARGET

STATIONARY

CONTACTS

MOVING

CONTACT

ASSEMBLY

0,

LL

EDUS

CONTACTS

SHORTING

COIL

MAIN

COIL

A

-C

TRIPPING

UNIT

Relay

GEH-1788

Fig.

The

30

amperes

The

current-carrying

selection

as

indicated

Function

Tripping

Carry

Operating

Resistance

Impedance

If

aaxiliary

such

that

the

contacts

protective

L

Type

current-closing

for

of

the

in

Duty

Continuously

Range

at

60

the

tripping

relay

tripping

the

or

relay.

AC

voltages

tap

the

cy

should

the

Relay

(Front

ratings

on

following

2-Amp

current

be

current

target

with

View)

rating

not

the

target

table:

Amperes,

30

3

2-30

0.13

0.53

exceeds

used,

does

and

an

Instantaneous

of

the

exceeding

affected

are

and

a-c

Tap

seal-in

or

0.2

contacts

250

Amp

d-c

volts.

by

Tap

Unit

is

the

coil

5

0.3

0.2-2

7

52

the

connections

not

seal-in

30

pass

amperes

coils

being

through

of

an

the

INSTANTANEOUS

Fig.

Burdens

following

five

amperes

Volt-ampere

of

the

of

current,

Coil

Amps

4-16

1.5-6

0.5-2

0.1-0.4

5

table.

three

Freq.

60

50

25

60

50

25

60

50

25

60

5tJ

UNIT

Type

for

coils

up

IAC

(Rear

BURDENS

the

These

based

burdens

can

20

to

Tap

4

4

4 5

1.5

1.5

1.5

0.5

0.5

0.5

0.1

0.1

Relay

standard

are

on

burden

be

times

Amps

5

5

5

5

5

5

5

5

5

5

with

an

View)

coils

calculated

for

the

determined

tap

setting,

Volt Imp.

I

Amps

2.0

1.7

1.3

14.5

12.0

9.0

105.0

86.0

82.0

3050

2546

A—C

are

of

lowest

Ohms

0.08

0.07

0.05

0.58

0.48

0.36

4.20

3.45

3.28

Trip

given

burdens

minimum

tap

for

any

from

122

102

Unit

PF

0.50

0.50

0.61

0.42

0.42

0.55

0.35

0.34

0.55

in

on

value

Fig.

0.38

0.36

the

at

tap.

any

6.

The

hinge-type

front

side

contacts

the

contacts

in

series

INTRODUCTION

instantaneous

unit

which

of

are

of

with

induction

the

normally

the

the

operating

main

unit

may

connected

unit.

is

be

a

small

mounted

unit

Its

coil

instantaneous

(See

in

parallel

coil

is connected

of

the

on

Fig.

the

main

4).

right

with

unit.

Its

value,

contact

The

released

left-hand

When

the

target

the

instantaneous

circuit

latches

by

pressing

corner

and

of

current

raising

in

the

the

unit

the

relay

reaches

operates,

its

exposed

button

cover.

a

predetermined

target

position

beneath

closing

into

the

the

view.

until

lower

5

Page 8

GEH-1788

26

24

Type

IAC

Time

Overcurrent

Relay

22

z

20

V

6

0r.,

TA

P

RANGE

0.5—2.0

AMPS.

V

5Q,,,

16

V

14

0

;

L

T

12

A

G

E

10

8

6

/Ez

25.

6O

50

TAP

RANGE

1.5—6.0

AMPS.

V..

C

C

0

‘a

-

4

—--

-

-

25

50.-s.,

20

IAC

25

Re’ays

2

0

6

iEEEEz

—--------

0

Fig.

2

6

4

MULTIPLES

SATURATION

INDUCTION

Saturation

6

TYPE

Curves

Lowest

10

FOR

ON

RELAYS

Taps

8

OF

MINIMUM

CURVES

UNITS

IAC

for

Very—Inverse-Time

12

14

PIC1(—UP

LOWEST

VERY

of

INVERSE

Induction

tre

Character

16

CURRENT

TAPS

i

OF

Unit

stics

18

of

Type

TAP

.RANGE

4—16

AMPS.

with

U-

Page 9

Type

IAC

Time

Overcurrent

Relay

(JEH-1788

Fig.

c)

LI

Cr,

LI

L)

0

0.030

0.025

20

0.

0.015

010

0.

0.005

7A

0

0

(K-6306872

—

&

—

1

2

3

M.JLTIPLES

Time-Current

[5).

Characteristics

OPERATING

c—

PICKUP

4

OF

RANGE

5

PICK—UP

TIME

FOR

ANY

SETTING

6

for

7

Original

—

8

Instantaneous

9

10

Unit

Fig.

7B

(0208A869

5-1)

Time-Current

$I94C

RATD

,I

TMTIRJS

OF

aILTIPiF

Characteristics

IJIT

PICOOP

for

the

Hi-G”

Unit

.7

Page 10

GEH-1788

Type

IAC

Time

Overcurrent

Relay

rhe

IAC

relay

for

current

OPERATING

*

The

scale

for

1977

range

the

it

“Hi—C”

the

7B.

to—one

a

Time—current

7A

In

make

instantaneous

ing

above

characteristic

Fig.

APPLICATION

instantaneous

models

exceeding

instantaneous

mounted

the

have

and

beside

characteristics

instantaneous

instantaneous

higher

a

unit

moulded

target

for

to

is

unit

provide

a

predetermined

instantaneous

used

on

CHARACTERISTICS

unit

the

seismic

be

the

“Hi—C”

operates

calibration

adjustable

unit

unit

identified

front

are

used

rating.

The

unit

shown

was

moulding

has

can

into

windows.

the

its

certain

tripping

value.

over

a

stamped

pole

in

before

modified

The

the

by

time—current

is

shown

Type

four—

piece.

1977.

mark

Fig.

just

on

new

RATINGS

use

is

unit

Volt-

the

coils

Coil

The

listed

Freq

instantaneous

below;

Amp

Amp

-

0.5-2

1-4

2—8

60

60

60

25

4-16

60

50

40

25

to

7—28

10-40

60

60

5

5

5

5

5

5

5

5

50

25

in

20-80

60

50

I

25

360

90

22.5

8.0

5.63

4.77

3.93

2.37

1.88

0.83

5

0.80

5

0.68

5

0.20

5

0.20

5

0.18

designed

Imp.

Ohms

14.4

3.6

0.90

0.32

0.225

0.191

0.157

0.095

0.067

0.033

0.032

0.027

0.008

0.008

0.007

to

P.F.

0.74

0.77

0.83

0.83

0.87

0.87

0.88

0.88

0.88

0.95

0.95

0.98

0.95

0.95

0.98

The

designed

from

operation

transfers

current

current

the

The

frame

duction

is

illustrated

8

a-c

to

its

associated

of

the

transformer

from

tripping

opposite

unit

*

Indicates

INTRODUCTION

unit

tripping

energize

the

main

current

the

(see

in

the

unit

tapped

Fig.

FIg.

revision

circuit-breaker

a

current

of

unit

from

into

trip

coilwhen

mounted

is

5).

11.

isaType

the

operating

The

transformer

Type

the

secondary

the

coil

trip

the

on

operation

The

secondary

A-C

REA

TAC

and

breaker

the

coil

TRIPPING

unit

relay

trip

coil

the

upon

relay.

of

the

removes

trips.

the

of

rear

of

of

the

this

current

in

unit

It

circulates

the

main

returning

rent

transformer.

by

ated

upper

armature

the

of

REA

Type

this

in

tribution

REA

Type

contacts

trip

the

UNIT

through

coil

through

the

limb

firmly

induction

unit

coil

flux

of

contacts.

causes

coil

the

of

main

the

of

against

unit

is

by

transformer

which

the

which

Induction

the

Type

REA

REA

Type

the

Normally,

REA

Type

magnetic

this

close,

short-circuited

actuates

opening

The

secondary

the

trips

unit

auxiliary

contacts

most

coil

structure

limb.

the

action,

the

current

breaker.

current

the

of

passes

When

shorting

and

causing

armature

of

tripping

to

flux

through

and

the

current

the

flow

to

coil

the

holds

contacts

coil

a

Type

through

unit,

cur

gener

of

flows

redis

and

REA

and

the

the

the

the

Page 11

Type

IAC

Time

Overcurrent

Relay

GEH-1788

Figure

Three

Phase

8

Type

and

(K-6315667

IAC53A

Ground

3

[2])

Relays

Overcurrent

3-Phase

External

Used

Circuit

Connections

for

Phase-to-

Protection

of

Device

External

50

J

51

51N

52

SI

TC

A

Function

Diagrams

Instantaneous

Overcurrent

Ground

Power

Seal-in

Trip

Overcurrent

Circuit

Unit,

Coil

Auxiliary

when

breaker

Numbers

Unit

Relay,

Breaker

with

Contact,

closes

for

Type

Relay,

Target

closed

Use

IAC

with

Type

ALL

IAC

of

a

Figure

Three

with

9.

Type

Tripping

(K6375668-1)

IAC53A

Relays

Reactors

External

used

for Protection

Circuit

Connections

in

Conjunction

of

a

3-Phase

of

Figure

Three

(K-6375669-6)

10.

Type

IAC53R

Circuit

Relays

Protection

External

Used

Connections

For

3-Phase

POC

of

9

Page 12

GH-11

where

not

from

Type

a-c

The

reliable

a

available

current-transformer

the

‘time

TAC

APPLICATION

tripping

and

unit

direct-current

is

necessary

it

Overcurrent

used

is

secondary.

Type

in

tripping

trip

to

Relay

[AC

the

relays

source

breaker

is

IL

The

five

amperes

3.5

of

ampere

transfer

100

to

ondary

REA11B

peres,

overcurrent

mounted

Burdens

following

Frequency

60

50

25

These

control

protect

receipt

sustained

from

once

at

notify

Office.

Reasonable

tripping

a-c

but

will

amperes.

coils.

trip

current-transformer

amperes.

be

exceeds

which

used

current

relay,

can

relays.

inside

the

the

of

table:

Amps

5

5

5

relays,

them

of

in

nearest

will

against

relay,

a

transit.

handling

transportation

the

panel

rough

with

the

care

RATINGS

unit

operate

It

The

should

contacts

on

a

be

continuous

a

has

secondary

applications

For

Type

has

in

conjunction

The

IAC

100

contacts

Type

case.

amperes,

SURDENS

unit

REA

Type

Impedance

Ohms

in

0.49

0.33

0.23

RECEIVING,

included

not

when

shipped

be

damage.

examine

If

is

General

should

injury

evident,

Electric

in

or

company

exercised

be

minimum

used

these

of

where

rated

with

REA11B

are

PF

0.80

0.80

0.62

as

cartons

Immediately

for

it

damage

damage

a

file

Apparatus

rating

of

current

three-

with

current

given

units

the

the

200

Type

is

will

sec

Type

am

IAC

in

up

not

the

Amperes

12.2

8.3

5.8

HANDLING

of

part

a

designed

any

resulting

andpromptly

unpack-

in

a

to

upon

damage

claim

Sales

Fig.

ing

injured

iately,

tons

and

the

when

the

II

lAG

AND

relay

the

or

the

If

they

a

in

metallic

outside

the

operation

Diagram

Relays

having

STORAGE

order

in

adjustments

the

relays

should

of

of

that

chips.

the

is

the

place

cover

Illustrating

an

that

not

are

stored

be

is

Foreign

case

removed

relay.

Tripping

A—C

none

disturbed.

be

to

in

from

free

may

and

Operation

of

installed

their

matter

find

cause

AC

NOPI.’ALLY

CLOCE

CONTACJ

AC

SNORTING

COIL

of

Unit

parts

the

original

moisture,

collected

way

its

trouble

TRIP

[)

TRIP

TRIP

AC

EAIN

Type

immed

inside

UNIt

S

COIL

are

car

dust

UNIT

UNI

on

in

(‘J

LS)

I

C

The

dust

facilitate

*

surface.

Fig.

in

The

10

and

The

*

location

excessive

inspection

reLay

The

20.

internal

Indicates

LOCATION

clean

should

be

vibration,

testing.

and

MOUNTiNG

mounted

should

outline

and

be

panel

CONNECTIONS

connection

Revision

diagrams

and

and

iNSTALLATION

from

free

dry,

well

on

diagram

for

lighted

a

the

vertical

shown

is

various

to

types

relay

Typical

inclusive.

10

One

permanently

12

No.

At

inspected

be

other

or

should

it

under

MAINTENANCE.

are

wiring

the

of

grounded

S

&

B

time

the

f6r

imperfections.

corrected

be

Figs.

shown

diagrams

mounting

gage

in

by

copper

are

studs

a

INSPECTION

installation,

of

tarnished

in

12

given

or

conductor

wire

contacts,

any

If

the

to

screws

its

or

the

trouble

manner

inclusive.

17

Figs.

in

should

not

equivalent.

relay

loose

desctibed

less

screws,

is

8

be

than

should

found,

to

Page 13

c•4

a.

U-

Type

IAC

Time

Overcurrent

C

U,

0’

0

‘C

SEAL—IN

I

NOUCT

UNIT

ON

IN5TAN

I

UN

I

Relay

GEH-1788

/11

SEAL—

N

UN

I

0

‘C

0’

0

1’

Fig.

SEA

UNIT

Li

12

N

1

Internal

Relay

Connections

(Front

View)

for

5

Type

6

ZSHORT

IAC53A

FINGER

INDUCT

UN

T

I

INDUCTION

UN

Fig.

13

13

2

Internal

Relay

Connections

(Front

5

View)

6

for

SHORT

Type

FINGER

1AC538

I

iRI

A—C

I

UN

NSTANT

I

T

a.

a.

3

6

L1

,

Fig.

*

1ndicatts

(K-6209660-7)

Type

IAC53C

Revision

Relay

Internal

(Front

Connections

View)

For

*

Fig.

15

Internal

Relay

Connections

(Front

for

View)

Type

IAC5

11

Page 14

GEH-l,

TAG

Time

NUIJCI

UN

‘rype

N

—

I

AL

SI

Overcurrent

a

Melay

ION

6

SH(IQI

=

FINGEA

SEAL—IN

1

UN

I

NSTANT.

II

IN

=

9

SHORT

10

FINGER

-Ti

-‘-a

a.

r.j

aD

0’

0’

C-i

CD

-n

a.

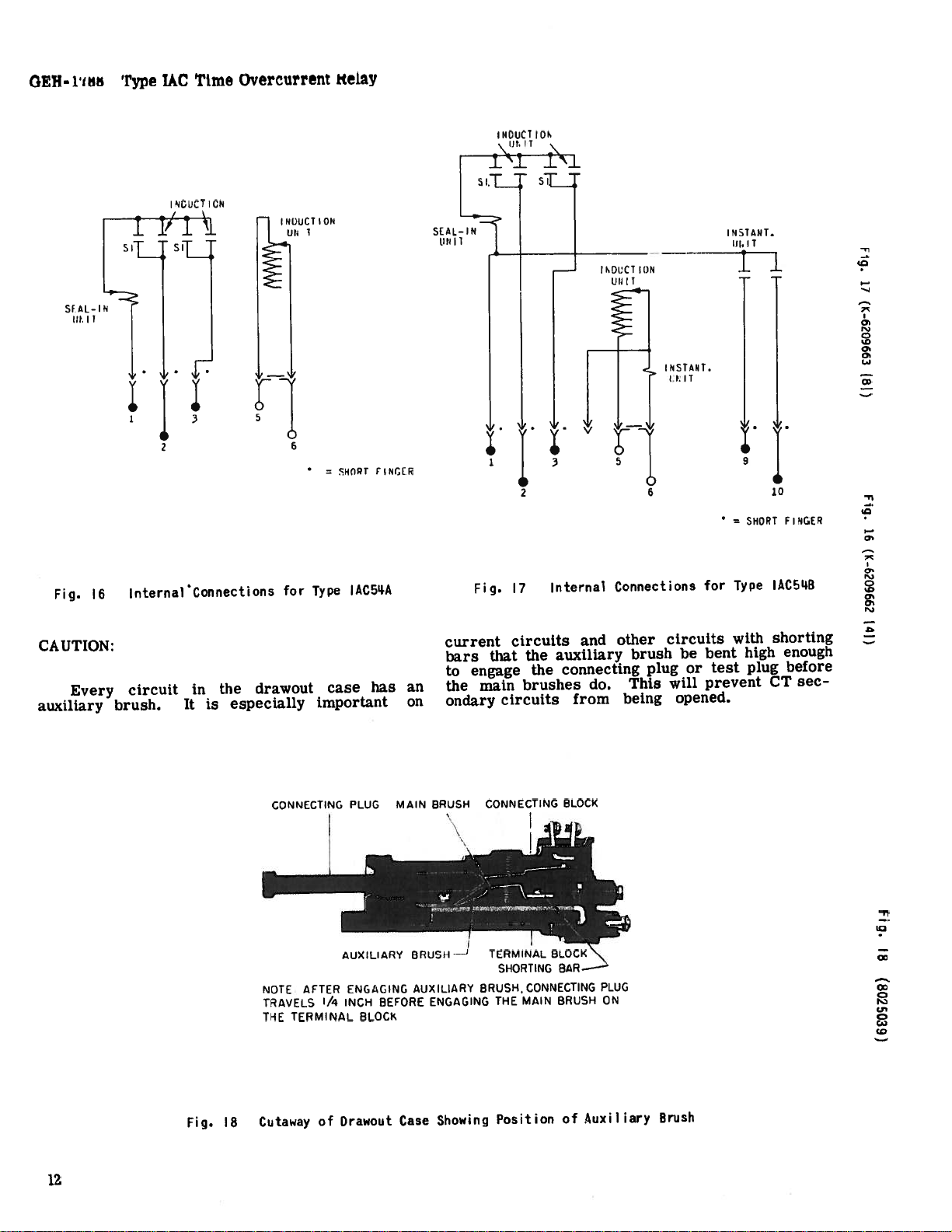

Fig.

16

CAUTION:

Every

auxiliary

InternalConnections

circuit

brush.

in

It

the

is

drawout

especially

CONNECTING

NOTE

TRAVELS

THE

for

Type

important

AFTER

TERMINAL

IACSLIA

case

PLUG

AUXILIARY

ENGAGING

)/4

INCH

has

BEFORE

BLOCK

an

on

MAIN

BRUSH---

AUXILIARY

ENGAGING

current

bars

to

the

ondary

BRUSH

17

Fig.

circuits

that

engage

main

circuits

CONNECTING

TERMINAL

SHORTING

BRUSH,

THE

Internal

auxiliary

the

connecting

the

brushes

BLOCK

.i1

BLOCK\

BAR—

CONNECTING

MAIN

BRUSH

and

from

Connections

other

do.

PLUG

ON

brush

This

being

plug

circuits

be

or

will

opened.

for

Type

with

bent

test

prevent

high

plug

IAC5L4B

shorting

enough

before

sec

CT

!•1

L0

CD

CD

U,

Ci)

CD

12

Fig.

18

Cutaway

of

Drawout

Case

Showing

Position

of

Auxiliary

Brush

Page 15

Type

ADJUSTMENTS

JAC

Time

Overcurrent

Relay

GEH-

1788

TARGET

For

from

voltage,

the

0.2-ampere

from

voltage

hand

change

plug.

stationary

Next,

place

necessary

contact

should

0.2

For

2

place

The

stationary

the

Then,

remove

it

in

from

not

trip

to

set

trip

to

tap

contact

the

30

tap

to

INDUCTION

CURRENT

The

be

changed

in

the

tap

plug

current

When

remove

current-transformer

screw

current

The

adjusted

ring

may

around

current

with

the

this

adjustment

also

permits

tween

unit

is

from

within

unit

resets

value.

TIME

The

length

tacts

value.

is

set

must

current

tap

block

firmly

(below

changing

the

the

tap

and

pickup

by

be

the

of

tap

the

various

adjusted

any

time-dial

five

SETTING

setting

of

time

when

The

on

0.

travel

SETTING

by

then

means

turned

edge.

the

per

at

the

contacts

AND

coils

amperes

2.0

the

target

tap.

coils

amperes

the

tap

screw

contact

setting,

take

and

the

left-hand

prevent

getting

in

be

at

changing

at

into

which

connecting

plug

replace

of

by

By

unit

setting

has

any

desired

tap

at

cent

90

per

of

the

current

When

the

maximum

operating

and

operating

screw

is

the

first

a

screw

place

screw

contact.

the

out

both

which

the

the

top

the

tap

the

the

current

plug

secondary

into

tap

the

the

unit

of

a

spring-adjusting

inserting

turning

may

be

employed,

been

disturbed.

settings

the

factory

position

of

the

cent

the

time

unit

requires

reaches

are

just

the

dial

SEAL-IN

on

at

the

seal-in

on

at

the

in

screw

of

the

remove

from

it

in

from

right-hand

of

adjustment.

taps

at

UNIT

the

contacts

position

of

the

marked

unit

is

setting

to

marked

connecting

for

any

a

ring,

the

brought

if

setting

to

to

at

a

tap

of

the

dial

the

closed

is

set

amount

currents

minimum

tap

currents

minimum

the

2-ampere

holding

seal-in

the

the

the

desired

the

other

This

procedure

the

operate

of

the

relay.

for

not

to

short-circuit

circuit.

for

the

plug.

current

tool

in

the

into

for

some

This

intermediate

be

obtained.

close

its

minimum

plug

setting.

minimum

determines

to

close

predetermined

when

on

10,

to

UNIT

ranging

control

screw

ranging

control

the

right-

unit.

connecting

left-hand

tap

stationary

Screws

same

time.

tap

Screw

the

desired

operate).

of

the

unit,

Next,

desired

tap

ring.

the

notches

operating

agreement

reason,

adjustment

contacts

current

closing

its

con

the

the

disk

close

tap.

tap.

and

may

plug

The

be

The

The

the

dial

the

in

To

is

the

the

is

contacts

Imum

The

ation

dial.

moving

shelf;

the

unit

increases

If

required,

circuit

value

insure

several

made

after

unless

accuracy,

whose

EXAMPLE

current

time

required

time-dial

number

to

shown

proper

the

lustrates

where

current

breaker

current

current

minimum

transformer

equals

tap,

time-dial

3750

ratio.

which

ferring

will

current

is

of

of

obtained.

second

secure

set

The

an

the

for

the

The

value

proper

Assume

The

the

amperes,

be

on

accurate

and

time

setting.

primary

of

the

However,

the

permanent

moving

decreases

the

selective

determine

current

for

each

the

proper

circuit

the

relay

circuit

the

there

(at

operation

OF

time

unit can

for

setting

of

times

any

in

Fig.

tap

the

the

circuit

of

approximately

should

of

3750

transformers

current

primary

7.5

amperes.

8-ampere

setting

This

is

7.8

to

the

seen

gives

the

No.

above

dial

therefore

adjustment

unit

further

the

time.

action

of

relay

breakers.

time

contacts

should

the

maximum

is

SETTING

and

be

shown

the

contacts

when

the

of

the

3,

insert

receptacle

position.

procedure

Type

a

breaker

trip

amperes.

tap

ratio.

to

divide

gives

times

time

that

7.8

1.0-second

6

time-dial

results

timing

can

be

is

made

magnet

magnet

the

the

the

line

sequence

involved

time

to

be

current

made

in

the

current-tap

particular

and

The

[AC

in

1.0

setting

tripping

In

this

Since

tap

is

give

62.5

the

current

times

should

device.

made

this

setting

adjustment

toward

time,

of

two

maximum

and

that

differs

in

in

close.

operation

of

dhfference

be

a

current)

selective.

settings

easily

Fig.

to

close

current

the

removable

adjust

following

in

making

relay

should

450

second

of

60/1

is

current

case,

there

used.

1.0-second

3750

amperes

8-ampere

the

time

setting.

until

gives

for

the

by

means

along

the

while

3

Assume

be

moving

or

more

possible

then

the

operation

Allowance

opening

For

between

and

indicates

with

Isaprescribed

setting.

time-current

the

a

is

used

trip

amperes;

on

a

ratio

found

by

by

450

is

To

find

by

the

secondary

petting.

curves

minimum

delay

when

checked

Slight

the

desired

the

time

of

of

the

is

obtained

its

supporting

main

shaft

It

relays

choose

sufficiently

must

each

breaker

this

reason,

is

known

of

about

of

the

quickly.

the

particular

a

In

settings

plug

time-dial

example

relay

setting:

in

circuit

a

on

sustained

a

also,

short-circuit

further

are

dividing

the

current

divided

no

7.5

ampere

the

time

readjustment

proper

delay

transformer

current

By

(Fig.

operating

the

by

means

time

max

oper

time

away

short-

time

a

of

with

relays

over-

Each

time

order

in

that

used.

by

re

3),

relay

by

of

is

to

the

be

0.5

the

to

Il

the

the

60

at

it

is

13

Page 16

GEH-1788

Aid

settings

est

Sales

Select

have

adjustable

head

scale.

locknut

position.

The

about

inch

1/8

loosening

moving

and

IAC

Type

in

may

Office

making

be

the

obtained

the

of

INSTANTANEOUS

current

the

instantaneous

the

is

the

even

To

and

contacts

pole

raise

same

wipe.

the

the

with

turn

screws

piece

lower

or

it

should

time

This

contacts

the

up

Time

General

so

or

and

adjustment

holding

up

Overcurrent

proper

application

on

above

operate

unit

the

that

desired

pole

the

down

be

to

the

down

or

selection

Electric

which

top

calibration

piece,

and

adjusted

have

stationary

Relay

of

the

to

Company.

UNIT

desired

is

and

its

of

loosen

tighten

then

make

to

approximately

made

be

can

as

contacts

required.

relay

near

the

set

hexagon

the

on

the

to

in

at

by

-

-

IIA:3

)

wtN

ç

TE1T

NUICAI

VAN

FLI.G

iTCNG

51

IN’

1_IGIlT

Pri’up

10

INDICATING

CHECKING

SlANT

PICKUP

ANELIL5

LIGHT

o;

IT

UN

N

‘0

The

attention

may

However,

be

tacts.

it

CONTACT

With

should

tension

lie

to

movable

this

Also

pound

ture.

to

bushing

The

allow

open.

adjusted

to

just

armature

of

1/32

the

supporting

edge

ly

contact

ARMATURE

Loosen

assembly

bracket

the

armature

the

core.

about

core.

leaf

1/32

Next,

spring

TRIPPING

A-C

tripping

a-c

other

than

restored

ADJUSTMENT

unit

the

against

always

contact

contact

supported

brass

1/16-inch

a

compound

The

allow

to

touch

the

operates

compound

from

inch

ADJUSTMENT

two

the

bracket

or

in

just

position,

this

In

inch

slide

assumes

unit

occasional

adjustment

the

if

follows:

as

de-energized,

stationary

the

insure

brush

brush

a

should

should

backing

contact

bushing

back

the

brass

open

to

bushing

inner

the

post.

screws

bottom

the

to

whichever

out,

touches

the

the

bracket

from

a

should

good

from

strip

of

backing

the

which

the

the

vertical

cleaning

the

contact

closed

be

the

gap

the

contacts.

should

edge

pole

armature

pole

in

UNIT

not

movable

free

not

top

should

with

support

movable

be

of

hold

of

the

is

face

face

until

require

of

should

with

circuit.

any

of

touch

the

of

be

the

should

when

strip

The

approximate

stationary-

the

armature-

the

frame.

necessary,

of

should

of

the

position

any

the

con

lost,

be

contact

enough

The

kinks.

com

the

arma

adjusted

contacts

contact

outer

Slide

until

upper

the

the

lower

armature

and

be

the

be

is

RFCWU[NDED

L’IN.

RATED

A!

120

FigJ9

spaced

bracket.

the

of

flush

be

should

always

lower

core

alignment

armature

operates

unit

tarily,

breaker

momentary

shock

pole

of

face

cessive

bracket

high

a

during

screws

obtained.

been

I

FR[UENCY

Test

clear

against

enough

put

return

after

is

and

dropping

reclosed.

is

opening

the

when

pressure

being

pickup

operation

securely

10

TM[P

“START”

VOLTS,

Connections

both

of

With

the

flush

it

each

important

pole

may

the

armature

the

pushed

chattering

or

of

after

JAC

of

armature

this

pole

pressure

face

cause

relay

of

lower

the

on

in

the

TO

ACCURATELY

RELAY

ALL

MADE

for

Testing

Relays

setting,

face

against

operation

as

of

the

contacts

target

Under

the

being

coil

armature,

too

unit.

the

and

the

on

the

slight

lower

SHOULD

RELAY

Pickup

armature

both

of

the

pole

of

to

R{PROWCE

IN

the

the

core

open

CHARACTERISTICS

T[STS

WITH

a

when

pulled

is

conditions,

is

in

energized.

these

contacts

caused

will

far,

of

the

movable

Tighten

proper

adjustment

BE

CASE.

Time

&

vertical

cores,

armature

face

unit.

between

gap

after

momen

the

due

against

result

the

Curve

should

and

of

This

circuit

to

Ex

by

in

contact

bracket

tip

to

the

the

the

the

the

the

too

has

The

or

more

one

for

Recommended

are

test

14

pick-up

of

more

or

shown

the

taps

dial

in

current

and

settings.

test

Fig.

should

the

connections

19.

time

be

should

OPERATION

one

be

the

on

checked

above’

checked

for

given

ments

will

factory.

order

Before

a

have

be

to

check

set

It

open

the

is

relay

to

not

zero

at

necessary

the

is

determine

been

relay

into

put

disturbed.

before

to

contacts.

service

that

the

change

factory

The

relay

this

it

leaves

should

adjust-

time

setting

be

dial

the

in

Page 17

Type

MAiNTENANCE

IAC

Time

Overcurrent

Relay

GEH-1788

exploring

The

centered

locked

for

this

burnishing

flexible

surface,

polishing

left,

A.

MAIN

Pickup

Set

minimum

19

the

of

±5%

Time

Set

minimum

19,

and

should

pickup

7.21

seconds

applied

±

7%.

The

jewel

For

yet

tap

Test

operate

current

in

purpose.

strip

resembling

corroded

the

main

the

applying

the

DISK

lower

its

should

in

this

jewel

surface

the

position

AND

air

may

with

be

gaps,

CONTACT

cleaning

tool

action

should

of

is

fine

metal

in

so

delicate

material

ELECTRICAL

UNIT

relay

tap,

value

relay

tap.

operating

unit

Using

at

applied

±7%.

at

Using

should

current.

at

5

1.31

the

the

the

the

times

the

With

time

BEARINGS

be

tested

the

by

point

up

after

the

turned

CLEANING

silver

be

with

effect

5.0

test

seconds

10

used.

a

that

will

0.5

time

test

connections

close

time

connections

pickup

operating

times

should

contacts,

an

be

±7%.

for

cracks

of

a

fine

the

it

should

provided

a

consists

roughened

file.

needle.

disk

flexible

of

The

are

rapidly

until

which

set

screw

This

etched

superfine

no

removed

scratches

ACCEPTANCE

dial

its

contacts

dial

current,

time

pickup

be

position

position

of

the

With

should

0.72

of

Figure

within

Figure

2

times

current

seconds

and

and

relay

be

by

is

be

a

and

thoroughly.

the

cleaning

Fine

knives,

files

deterioration

may

material

standard

checked

may

The

It

files,

leave

is

at

TESTS

B.

INSTANTANEOUS

Pickup

With

pickup

should

pickup

after

C.

Pickup

tap

Dropout

should

of

each

TARGET

The

value

Open

tap

value;

at

be

checks.

unit

remain

of

the

silver

leave

in

burnishing

relay

or

of

minute

the

tool

contacts

abrasive

scratches

the

contacts

PERIODIC

recommended

least

once

gradually

of

±10%

no

more

SEAL

should

the

picked

the

Be

main

unit

test.

with

the

The

actual

contacts.

particles

tool

kit

applied

the

than

sure

IN

pickup

main

unit

should

flexibility

described

obtainable

that

every

UNIT

minimum

UNIT

unit

contacts,

up.

points

should

paper

which

Abrasive

of

and

thus

TESTING

pickup

six

months.

current

variation

±5%

the

target

between

contacts

Reduce

drop

of

the

of

contact.

not

be

or

cloth.

increase

paper

insulating

prevent

is

included

from

of

the

calibration.

has

75

closed.

the

the

current

out.

tool

cleaned

Knives

arcing

abrasive

the

au

unit

on

repeated

been

and

seal

insures

or

cloth

closing.

in

factory.

units

should

There

reset

100%

in

to

with

or

and

the

be

of

unit

25%

renewal

prompt

or

damaged.

It

is

replacement

recommended

parts

be

carried

of

that

any

sufficient

in

stock

that

RENEWAL

quantities

to

are

enable

worn,

broken,

the

PARTS

of

nearest

pany,

the

Parts

When

parts

Sales

specify

by

Bulletin

ordering

Office

the

catalogue

No.

renewal

of

quantity

GEF-3883.

the

numbers

parts,

General

required

as

Electric

and

shown

address

describing

in

the

Com

Renewal

15

Page 18

GEH-l7B

Type

IAC

Time

Overcurrent

Relay

:1/4

4

DRILL

HOLES

1,125

29MM

PANEL

SEMI-FLUSH

MTG.

4)

MTG.

4

406

12MM

LOCATION

10-32

SCREWS

6.187

157MM

SURFACE

MTG.

—

3/9

X

DRILL

5/8

HOLES

2

l5Mi

(2)

FUR

0—32

1

STUDS

-

5/16—18

SURFACE

75

MM

CUTOUT

DRILLED

STUDS

MTG.

NUMBER

97531

00000

00000

8

10

BACK

MAY

156

1.

29MM

STUD

I

‘

6

VIEW

REPLACE

HOLES

NG

2

218.

5MM

FUR

TYPiCAL

INCHES

MM

Fig.

--;---

CUTLUT

•i

5,

14

PANEL

SEMI-FLUSH

DIM.

20

DRILLING

FRONT

(K-6209271

843

72MM

1

687

4MM

MOUNTING

VIEW

181)

VIEW

FUR

Outline

I—

8.812

223MM

CASE

SHOWING

SURFACE

Panel

and

3.0

76MM

ASSEMBLY

MTG.

Drilling

ON

Dimensions

3/4

10

OF

STEEL

5

133MM

DRILL

HOLES

19MM

5/16-18

HARDWARE

PANELS

Relay

for

25

FUR

STUD

Types

PANEL

SURFACE

FRONT

(TYPICAL)

DRILLANG

VIEW

Relays

IAC

.500

12MM

MOUNTING

(11/91)

(200)

GENERAL

ELECTRIC

CO.,

POWER

SYSTEMS

MANAGEMENT

BUSINESS

DEPT..

MALVERN,

PA.

19355

Loading...

Loading...