GC EUROPE Fujivest Super User Manual

Focus Edition from GC

Phosphate

Bonded

Investments

for C&B techniques

Table of contents

Introduction 3

Guidelines for optimal use of phosphate bonded investments for Crown & Bridge techniques 5

1

Preparation before investing

2 Expansion and investing 12

3 Heating up / Burnout procedures 18

4 Casting 23

5 Effects of the main factors influencing the casting results 25

6 The GC Europe range of Phosphate bonded investments for C&B techniques 26

7 Related products 27

Troubleshooting Phosphate Bonded Investments for C&B techniques 29

1 Investment sets too quickly 30

2 Investment sets too slow 31

3 Differences in Investment texture (too thin or too thick, not consistent) 31

6

4 Rough casting surfaces (pits, nodules and porosities) 32

5 Investment cracking (fins on the castings, miscasting ….) 34

6 Incomplete castings & rounded cervical edges 36

7 Inaccurate fit of casting objects 37

Instructions for use for implantology 39

Optimal fit, a simple step by step procedure 49

Clinical Cases 59

2

Focus Edition from GC

Introduction

Dear Customer,

Thank you very much for selecting GC Europe’s

Phosphate Bonded Investment material for your

crown and bridge technique. You have purchased

high quality products which have been specifically

designed to produce consistently accurate

castings and meet the production requirements

of the modern dental laboratory.

For more information on GC products please

visit our website www.gceurope.com

The construction of high quality crown and

bridge restorations is dependant both on precise

workmanship and a clear understanding of the

processing instructions of the various materials

involved in the dental casting process.

The aim of this document is to help you understand

our products in more detail and provide useful

information that will help you to avoid mistakes

and potential problems in the future, by

identifying the optimal techniques for their use

and by analysing the various problems that can

occur if ‘best practice’ is not followed.

Whilst we have tried to be as comprehensive as

possible no guide can cover every eventuality,

so should you require further any assistance

please do not hesitate to contact your local GC

representative.

3

4

Guidelines for

optimal use

of phosphate bonded investments for

Focus Edition from GC

Crown & Bridge techniques

This chapter will help you understand

our Phosphate Bonded Investments

for C&B techniques in more detail and

provide useful information that will help

you to avoid mistakes and potential

problems in the future, by identifying

the optimal techniques for their use

and by analysing the various problems

that can occur if ‘best practice’ is not

followed.

5

1 Preparation before investing

1.1 Instruction for Use

When working with our investments it is imperative

that the ‘Instructions For Use’ are consulted from

the outset as they offer you a clear summary of

each working stage, based both on the results

of comprehensive laboratory testing, carried out

by the GC Europe Research and Development

Department in combination with an extensive

range of casting trials.

Each investment type has its own specific

characteristics that should be taken into account

to guarantee consistently accurate results.

However because the working methods and

equipment can differ between individual dental

laboratories (e.g. waxes, resins, casting liner,

mixing equipment, etc.) it is possible that differing

end-results may be obtained.

Each package of GC

investment contains

multilingual ‘Instructions

for Use’ and it is important that you use the

latest version included

with your material

as this information is

under a process of

continual review.

6

The latest instructions for use are always available

at the download section of our website

www.gceurope.com.

1.2 Storage

When used on a regular basis the powder and

liquid may be stored at normal room temperature

(21-23°C), this is also the optimal working

temperature. However for longer term or bulk

storage a slightly lower temperature is preferable

(please also see point 2.3).

The storage environment must be dry to avoid

the risk of exposing the powder to humidity (this

is particularly important once a package has

been opened) which will cause it to react in an

unpredictably fast manner.

It is important that the liquid is never stored below

5˚C as once it has frozen it can no longer be used

and must be discarded. Pay particular attention to

winter deliveries, if debris or crystals are present in

the liquid, it must never be used!

The bottles should always be kept tightly sealed

and away from direct sunlight to avoid problems

caused by evaporation.

Focus Edition from GC

1.3 Working temperature

The working temperature of the investment powder

and liquid are critical factors in determining the

setting time, expansion, surface roughness and

consequently the final fit of the castings.

The optimal working temperature of both powder

& liquid is 21-23°C, this must be considered if

either the room temperature is lower than this

or the materials have been stored at a lower

temperature.

If the ambient working temperature is below

20°C, the following problems can occur:

- A delay in setting time

- Uncontrollable expansion values

- A reduced surface quality, meaning a rougher

surface of the casting object

- A higher risk of crack formation leading to

possible miscasting

Likewise if the ambient working temperature is

higher than 21-23°C the following factors must be

considered:

- An increase in temperature of liquid and/or

powder decreases the working time and

accelerates setting

- The working time at 23°C is approximately

9 min, whilst at 24°C it will be approximately

8 min as for each 1°C increase in working

temperature the working time decreases by

+/- 1 min

- If the temperature of the powder and liquid

cannot be optimised a slight reduction in the

mixing time may help increase the working

time

The use of a temperature controlled refrigerator

set at 21-23°C is highly recommended for the

storage of the investment powder, liquid and

mixing vessels, as this completely eliminates the

risk of seasonal temperature differences.

1.4 Preparations before investing

1.4.1 Modeling

- Die Separator

Use a high quality type 4 dental stone such as

GC Fujirock EP for optimal accuracy and wear

resistance. GC Multi Sep is an ideal wax separator,

leaving no oily residue on the die stone surface.

- Modeling materials

The correct positioning of the wax/resin patterns is

important in order to ensure sufficient thickness of

investment material around the objects to withstand

the casting forces and provide sufficient expansion.

The highest point of the pattern structure should

be 5-10 mm lower than top of the ring and at least

5 mm away from the axial wall of investment ring.

7

- Resin modeling materials

1.4.2 Ring sizes

GC Pattern Resin LS makes an excellent choice,

offering a high degree of accuracy in combination

with optimal burnout properties which leave no

residues.

It is always advisable to cover the pattern resin with

a layer of wax to allow for its expansion during the

burnout process.

For single crowns, the investing and burnout

procedures can be performed in the usual

manner, however for larger amounts of pattern

resin it is advisable to hold the temperature at

250°C (482°F) for 1 hour, before rising to the final

burn out temperature or follow the step heating

schedule according to the ‘Instructions for Use.’

The rigid nature of the pattern resin material means

that the initial setting expansion can be restricted,

which may result in a tight casting. This problem

can be solved by the adoption of a slightly higher

ratio of investment liquid/distilled water.

The majority of GC Europe investment materials

can be utilised for both the ring and ringless

techniques, using either the quick or step heating

technique as detailed in the particular

‘Instructions for Use.’

In most instances GC Europe investments can

be used with all ring sizes from X1 to X9 for the

casting ring technique (metal ring with liner) and

sizes from X1 to X6 for the ringless technique.

The choice of ring size depends on the size and

type of work, however to get consistently accurate

casting results it is advisable to take a uniform

approach. This is best achieved by always selecting

the same size/type of investment ring for the same

size/type of work. In general terms ring sizes X3 &

X6 provide consistently accurate and reproducible

results due to the optimal volume of investment

material that is used.

When using the X1 type ring tighter castings may

be produced, this is caused by the smaller amount

of material producing a smaller setting expansion;

this is related to the exothermic reaction during

setting. Conversely ring sizes above X6 tend to

produce a less stable expansion values and an

increased risk of cracking.

1.4.3 Ring types

Various sizes and types of casting ring are available,

all created with the same goal of producing a

refractory investment mould which can be heated

to eliminate the pattern material and filled with

molten alloy.

88

Focus Edition from GC

When using the metal

casting ring technique

it is advisable to use a

high quality casting

liner such as GC New

Casting Liner. This

enables the investment

material to expand

during setting and

provide the optimal

buffer to achieve

consistently accurate castings and reduce any risk

of cracking (please see section 1.4.4).

When using the ringless technique, it is best to

use a soft type of silicone ring former to allow the

optimal setting reaction and expansion to occur.

This type of ring former also has the advantage

of being sufficiently flexible to be easily removed

from the investment material after the initial set

without the need for excessive or damaging

removal forces.

Using the more rigid type of plastic ring former

can impede the setting reaction as they tend to

be poor insulators, allowing the heat from the

exothermic reaction to be dissipated far too

quickly.

The rigidity of the plastic also means that these

formers need to be removed very quickly after the

initial set, as they allow for very little expansion.

This creates the further problem that ‘weak’

investment may be placed under too much stress

if this is done at a too early stage, resulting in

cracks or distortion.

1.4.4 Liner for metal ring types

When using a metal casting ring type, it is

advisable to use a high quality casting ring

liner such as GC New Casting Liner which is

approximately 1 mm thick. This enables the

investment material to expand during setting and

provides the optimal buffer to achieve accurate

castings and reduce the risk of cracking.

9

The borders of the liner should be sealed with

a thin layer of petroleum jelly. GC New Casting

Liner is impervious to the absorption of liquid and

should not be immersed in or moistened with

water. If the border is not sealed, a wet liner used

or an absorbent dry liner there is a risk that the

powder/ liquid ratio of the mixture will be altered

and consequently alter the expansion.

Be sure that the entire inner surface of the metal

ring is evenly covered with casting liner and that the

liner is flush with the upper rim of the metal ring, so

that there is no direct contact between investment

and metal ring. A badly fitting ring liner leads to an

uneven expansion and the risk of crack formation.

We therefore recommend the use of GC New Casting

Liner, a dry casting liner made of ceramic fibers

For X3 ring size = Use 1 layer of

GC New Casting Liner

For X6 ring size = Use 2 layers of

GC New Casting Liner

For X9 ring size = Use 2 layers of

GC New Casting Liner

As a liner needs to provide an optimal buffer to

achieve accurate castings and reduce the risk of

cracking it is important that it is of the correct

thickness and does not absorb any water from

the investment. Liners that absorb water are

best avoided as they can remove moisture from

the investment mixture whilst setting, thus

compromising the final result by either causing

cracking or expansion in an unpredictable manner.

Conversely if the liner is soaked there is a similar

risk, but this time the problem is the dilution of

the investment mixture.

Dry GC New Casting Liner & Competitor product

Competitor product

GC New Casting Liner

Competitor product, GC New Casting Liner

liner absorbing water a dry casting liner

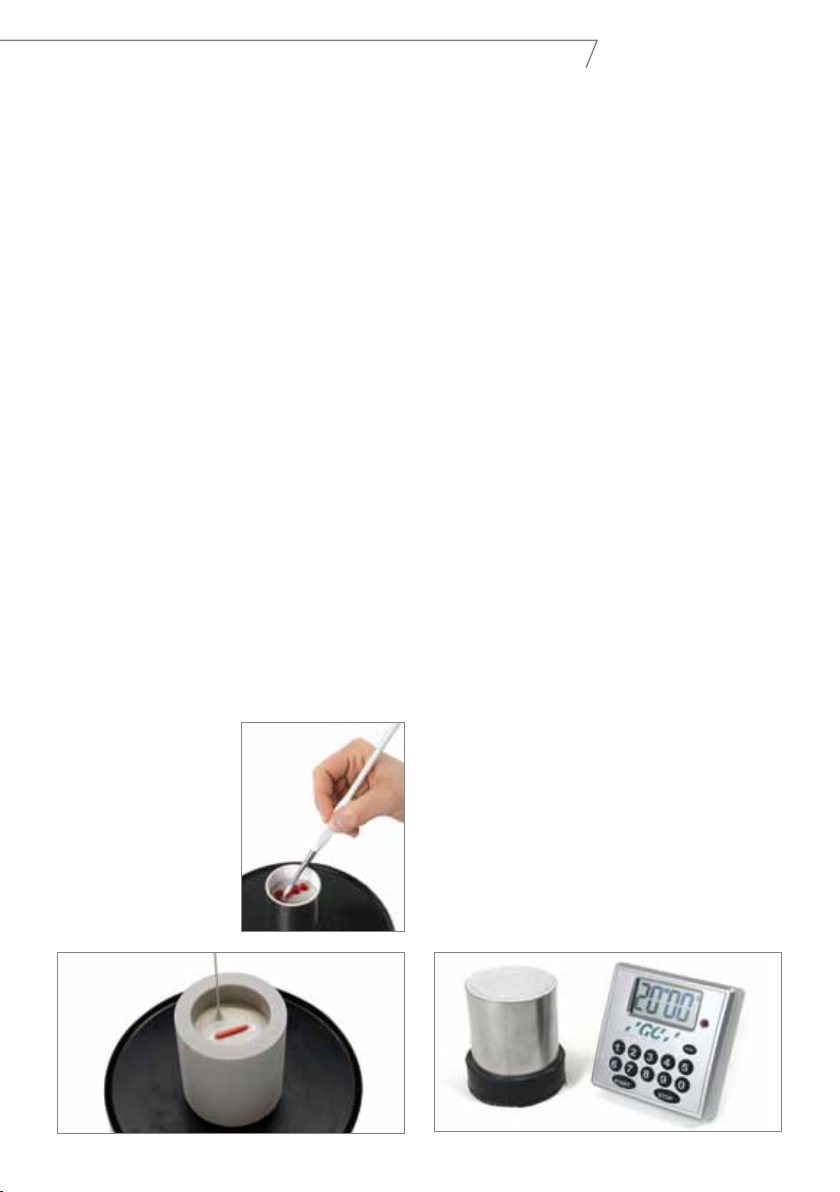

1.4.5 Wetting agents

A surface tension reducing agent is designed

to allow the investment to flow uniformly and

smoothly over all areas of the pattern helping to

eliminate casting bubbles; however please bear

in mind the following:

- All GC investment materials have the optimal

fluidity and smooth consistency which eliminates

the need for these agents.

- If these agents

are used, it is very

important to check

that they are fully dry

before pouring in the

investment material

as a wet residue of

these agents may

adversely react with the

investment material,

creating a rough

mould and casting

surface together with

an increased risk of

fracture.

10

Focus Edition from GC

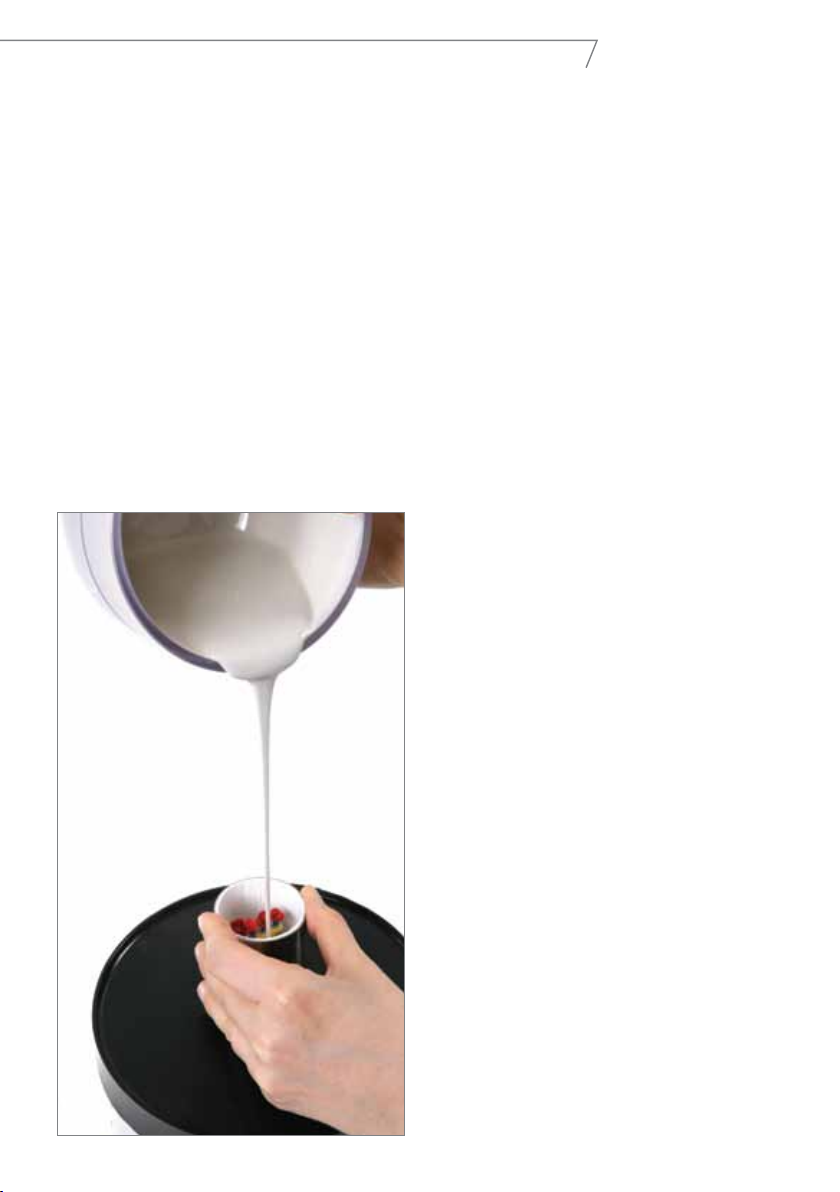

1.5 Powder / Liquid ratio

All of the phosphate bonded investment materials

manufactured by GC Europe for the Crown and

Bridgework technique share a common Powder/

Liquid ratio of 100 g to 22 ml (with the exception

of GC Vest-G, please consult the ‘Instructions for

Use’).

In order to obtain consistently accurate castings

the correct powder/liquid ratio must be used, as

this ratio is the result of comprehensive laboratory

development and batch testing.

Any alteration of the ratio is likely to result in less

predictable expansion properties, inferior casting

surface and an increased risk of mould fracture.

The use of an accurate electronic balance for

weighing the powder together with a measuring

cylinder or pipette for the liquid is highly

recommended. It is also suggested that only

distilled water is used when diluting the

investment liquid.

Ringsize Powder Liquid

X1 60 g 13,2 ml

X3 150 g 33,0 ml

X6 300 g 66,0 ml

X9 420 g 92,4 ml

1.5.1 Atomized measuring equipment for

investments

Whilst as previously discussed in sections 1.3 &

1.5 the use of accurate measuring equipment and

a temperature controlled refrigerator should

guarantee consistent results, an alternative method

exists in the form of atomized measuring

equipment. This combines an integrated cooling

system with precise measuring technology to

produce a consistently accurate temperature

controlled ratio of water, investment liquid

and investment powder to produce highly

accurate mixing results and subsequent castings.

These devices need to be programmed with

correct ratio and it should be noted that as the

measuring of the liquids is done by weight for

increased accuracy the precise input of the liquid

density is a critical factor. The correct densities

for GC Europe phosphate bonded investment

liquids are listed in the table below.

Liquid Density

3

)

(g/cm

GC Fujivest II Liquid 1,25

GC Fujivest II Low Expansion Liquid 1,15

GC Fujivest Super Liquid 1,14

GC Fujivest Super High Expansion Liquid

GC Fujivest Platinum 1,14

GC Vest-G 1,19

GC Stellavest 1,23

GC Fujivest Premium 1,25

1,23

11

2 Expansion and investing

2.1.1 General rules about expansion levels

The expansion rate of phosphate bonded

investment material may be adjusted by altering

the ratio of expansion liquid to water, we can

therefore state that:

- Pure liquid gives the maximum setting expansion,

meaning the largest casting.

- Diluting the liquid with water will result in the

reduction of the setting expansion resulting in

smaller castings.

Use only distilled water to dilute the expansion

liquid and use only the correct expansion liquid

designed for the investment powder that you are

using, do not use other liquids.

2.1.2 Why is expansion needed?

Wax Modellation

invested

Setting Expansion

in Furnace

Thermal Expan-

sion in Furnace

The required concentration of the expansion

liquid depends on various factors:

- Type of alloy

- Type of work (e.g. posts & inlays require less

expansion)

- The fit required

- Type of pattern material (see 1.4)

Comprehensive guidance is given in the “liquid

dilution chart” in the ‘Instructions for Use’, which

should enable you to find the optimal expansion

values for your individual requirement (see 2.1.4).

It should also be noted that the expansion value is

also influenced by the following factors:

- Storage & working temperature of the investment

materials (see 1.2 & 1.3)

- Mixing time & paddle speed (see 2.2)

Investment with

total Expansion

Casting

Cold Casting after

cooling down

Total expansion is needed to compensate for metal shrinkage during the cooling phase.

12

Focus Edition from GC

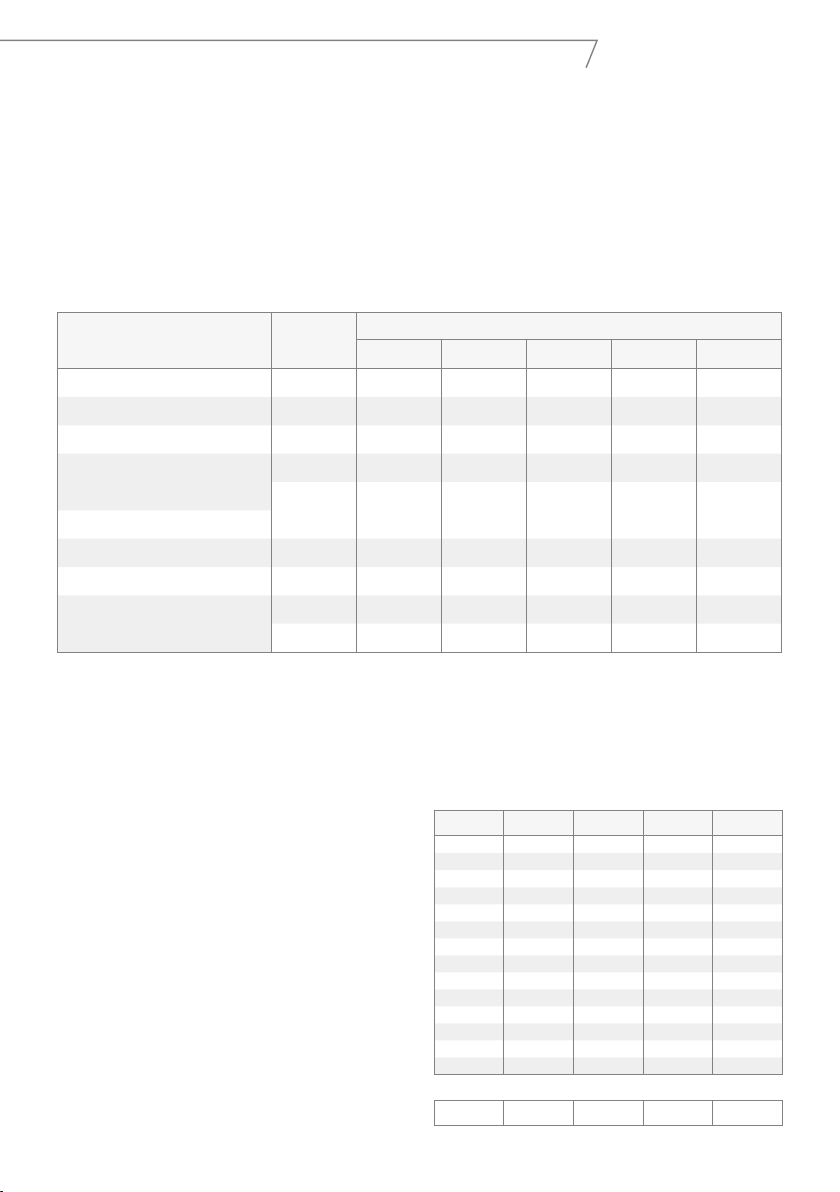

2.1.3 Liquid dilution chart

The liquid dilution chart is designed to help produce the optimal expansion value for your individual

castings and is based upon the type of alloy and size of ring used. This information is contained within

the ‘Instructions for Use’ and is based on extensive laboratory testing in combination with a complete

series of casting trials.For example here is the liquid dilution chart for GC Fujivest Premium.

Type of Alloy

High Precious > 70% Au

Semi Precious < 55% Au

Pd-base

Non-precious alloy

High Precious ceramic alloy

Semi Precious ceramic alloy

Pd-base ceramic alloy

Non-precious ceramic alloy

Liquid / Wa-

ter ratio %

50/50 6.6 ml/6.6 ml 9.9 ml/9.9 ml 16.5 ml/16.5 ml 33 ml/33 ml 42.2 ml/42.2 ml

60/40 8 ml/5.2 ml 11.8 ml/8 ml 20 ml/13 ml 40 ml/26 ml 55.4 ml/37 ml

60/40 8 ml/5.2 ml 11.8 ml/8 ml 20 ml/13 ml 40 ml/26 ml 55.4 ml/37 ml

NiCr 75/25 10 ml/3.2 ml 15 ml/4.8 ml 25 ml/8 ml 50 ml/16 ml 55.4 ml/37 ml

CoCr 100% 13.2 ml 19.8 ml 33 ml 66 ml 92.4 ml

55/45 7.3 ml/5.9 ml 11.8 ml/8 ml 18 ml/15 ml 36 ml/30 ml 55.4 ml/37 ml

55/45 7.3 ml/5.9 ml 11.8 ml/8 ml 18 ml/15 ml 36 ml/30 ml 55.4 ml/37 ml

60/40 8 ml/5.2 ml 11.8 ml/8 ml 20 ml/13 ml 40 ml/26 ml 55.4 ml/37 ml

NiCr 72/25 10 ml/3.2 ml 15 ml/4.8 ml 25 ml/8 ml 50 ml/16 ml 69,4 ml/23 ml

CoCr 100% 13.2 ml 19.8 ml 33 ml 66 ml 92.4 ml

X1 / 60 g 90 g X3 / 150 g X6 / 300 g X9 / 420 g

Ring size: Liquid / Water

However because the working methods and equipment can differ between individual dental laboratories

(e.g. waxes, resins, casting liner, mixing equipment, etc.) it is possible that differing end-results may be

obtained requiring slight changes to the stated ratios (see 2.1.4).

All of the fit tests have been carried out on castings using the quick heating method (20 min setting) and

it should be noted that a longer setting time would increase the expansion.

2.1.4 Individual liquid dilution chart

Name

dental alloy

Ring type X1 Ring type X3 Ring type X6 Ring type X9

When trying new alloys, alloy manufacturers or

investment materials we suggest that initially you

use the correct ratio as stated in our ‘Instructions

for Use’. It is then possible for you to judge whether

this provides the correct expansion for your needs

or a slight alteration of the dilution is needed.

We also provide a chart that can be used to

indicate the alloy type, type of work and your

personal choice of dilution ratio obtained

following your personal casting experiences.

Here it is very important to consider the information

given in sections 1.5 & 2.1.1.

Example :

Dental alloy

XYZ

6,6 ml Exp.Liq

6,6 ml H2O

16,5 ml Exp.Liq

16,5 ml H2O

33 ml Exp.Liq

33 ml H2O

46,2 ml Exp.Liq

46,2 ml H2O

13

2.2 Mixing of the investment

Tips for mixing:

In order to obtain a complete chemical reaction

between the powder and the liquid, it is important

to ensure that the components are mixed to a

homogeneous consistency.

- Pre-mix powder and liquid thoroughly by hand

with a spatula.

Be sure that all of the powder is completely

wetted by the liquid to produce a uniform

mixture.

- Mix for 60 sec under vacuum (320-420 rpm).

Always use a clean mixing bowl and check

the vacuum level. An inadequate vacuum

level leads to an inconsistent fit and casting

bubbles.

Insufficient mixing produces rougher casting

surfaces.

Faster mixing (and or longer mixing) accelerates

the set and decreases the working time and may

also result in lower expansion values.

Always check if the mixture is homogenous and

smooth with no dry ‘lumps’ before pouring the

investment.

Over time it is possible for a residue of investment

material to build up on the inner surfaces of the

mixing bowl and this can reduce the expansion, so

when switching to a new mixing bowl an increased

expansion may sometimes be noticed.

- Use different mixing bowls for gypsum and for

phosphate-bonded investments!

Gypsum contamination interferes with setting

of phosphate-bonded investments.

- For efficient, homogeneous mixing, mix for only

one ring at a time.

- Check the mixing and vacuum efficiency.

Do not rely on the indicated vacuum levels on

the mixing devises.

- Use calibrated equipment.

- Change worn paddles or mixing bowls.

- To keep the mixing bowl, mixing paddle and

instruments clean:

14

Always clean them

immediately after use

eliminating all residues

of investment material

and store them in a clean

plastic container (the GC

Fujirock container makes

an excellent choice)

filled with water to help

reduce the risk of a build

up of sediment.

Focus Edition from GC

2.3 Investing

2.3.1 Working time (see 1.3)

The working and pouring time for each investment

material is stated in their individual ‘Instructions

for Use,’ however it must be understood that

this is calculated for material stored and used

at normal room temperature of 21 - 23°C.

Temperature variations will result in a longer

(if cooler) or shorter (if warmer) working times.

2.3.2 Investing , filling the moulds

Invest using a thin stream of material and low

frequency (gentle) vibration, once the ring is filled

stop the vibration immediately and do not touch

the investment until set. The optimised consistency

of GC Europe’s phosphate bonded investments

means that they possess excellent flow properties

rendering strong vibration unnecessary.

2.3.3 Investing under pressure

We do not recommend high pressure investing

as this may lead to a

delayed setting

(especially when

the compressed air

temperature is low)

which can result in a

rough casting surface

and increased risk

of fining on the cast

objects.

2.4 Setting

2.4.1 Setting time

The optimal setting time prior to insertion in

the furnace is normally 20 min, however please

always check the most recent ‘Instructions for

Use.’ The setting time is based on the material

being stored and used at a room temperature

of 21 - 23˚C, as said previously variations in this

temperature may affect the setting time and

expansion.

Best results are then normally obtained by placing

the casting ring immediately into a preheated

burnout furnace. Prior to putting the investment

into the burnout furnace it is essential to make

sure that it has fully set, as unset investment

material is likely to cause casting defects such as

distortion and/or rough surfaces.

Lengthening the setting time before putting the

mould into the furnace is a technique often used

when a lot of investing is done late in the day and

the casting is to be undertaken the next morning,

this is the so called “over night” burn-out technique.

This longer setting period will usually work but can

result in an over expansion, a reduction of surface

smoothness and increased risk of cracking.

If the filled investment ring does need to be

left for an extended period prior to burnout it is

better to put it into a plastic container or

bag which will help retain humidity within the

investment material, it can be inserted into

the burnout furnace and processed with the

conventional step heating method.

15

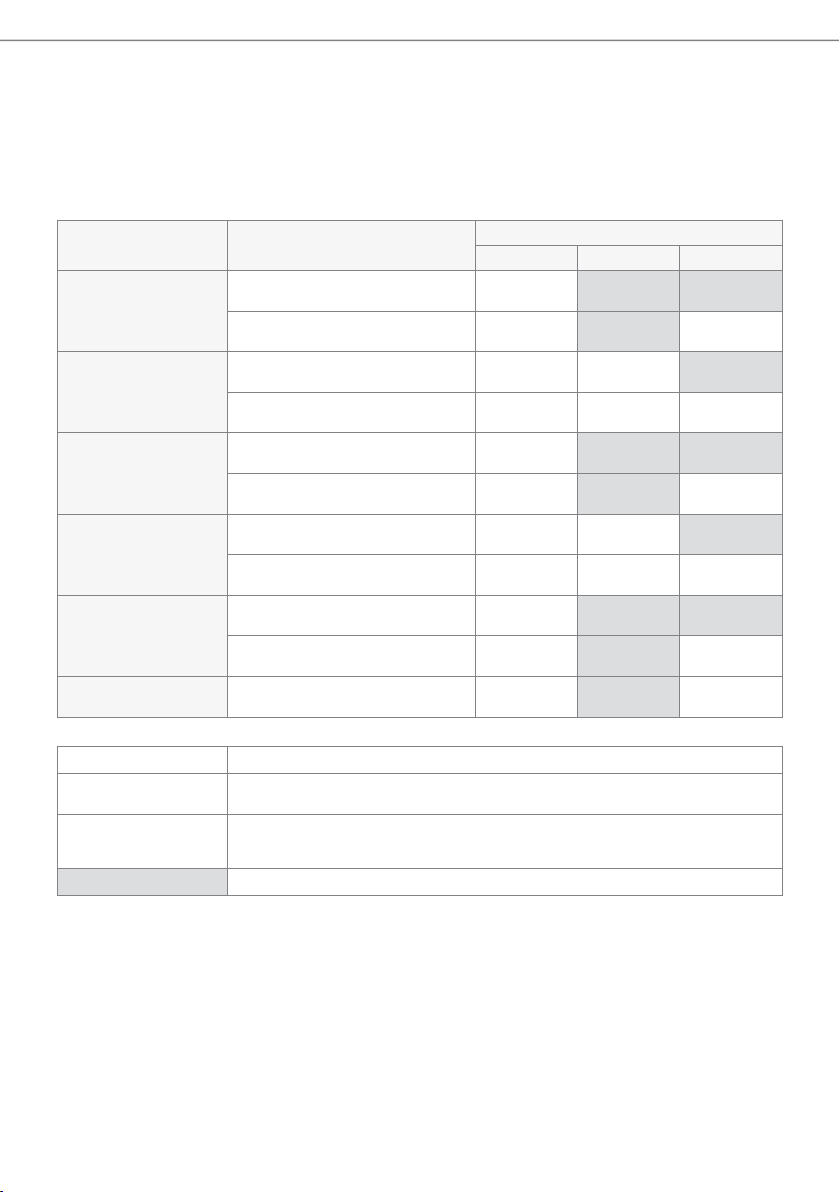

2.4.2 Advise on variations in setting time

Setting times

Product Heating up schedule

Speed technique

GC Fujivest Platinum

GC Fujivest Premium

GC Fujivest Super

GC Fujivest II

GC Stellavest

GC Vest-G

Furnace at end temperature

Step heating technique

Furnace in steps to end temperature

Speed technique

Furnace at end temperature

Step heating technique

Furnace in steps to end temperature

Speed technique

Furnace at end temperature

Step heating technique

Furnace in steps to end temperature

Speed technique

Furnace at end temperature

Step heating technique

Furnace in steps to end temperature

Speed technique

Furnace at end temperature

Step heating technique

Furnace in steps to end temperature

Step heating technique

Furnace in steps to end temperature

X Recommended

X* Can be used. A longer setting time can result in a somewhat looser fit. An increased

Remark In the case that investment has to be left overnight, put it in a container which can reatin

risk of cracks and reduction of the surface quality can be observed.

its humidity, prior to placing in burnout furnace and heat it up with conventional step

heating.

Not recommended , increased risk on crack formation and miscastings.

20 ‘ setting 120’ setting “Overnight”

X

X X*

X X*

X X* X*

X

X X*

X X*

X X* X*

X

X X*

X X*

16

Focus Edition from GC

2.4.3 Preparation prior to burnout

The investment material at the top of the investment ring will normally have a smooth ‘glazed’

appearance; this must be scraped with a sharp knife to create a slightly roughened porous surface.

This allows for an easier escape of gases during both the burnout and casting procedures. Failure to

undertake this procedure may cause cracking due to a build up of pressure and lead to miscasting.

The use of a model trimmer for this process is to be discouraged as the quartz and cristobalite particles

within the investment will cause rapid wear of the diamond disc.

17

3 Heating up / Burnout procedures

3.1 Schedule in Instruction for Use

The majority of GC Europe investment materials can be used with either the quick or step heating

technique, however as each investment has its own heating schedule the corresponding ‘Instructions

for Use’ must be consulted. For example here is the heating schedule for GC Fujivest Premium.

Quick heating Conventional Step heating

Insertion

temperature

Step 1

Step 2

Step 3

Step 4

Step 5

Holding time

800°-850°C/1470-1560°F for Ceramic alloys

Pre-heated furnace at

700°-750°C/1290-1380°F for Au - alloys

900°C/1650°F for Non-precious alloys

Room temperature (23°) to 260°C/500°F

Holding time at 260°C/500°F 40-90 min

Rise temperature from 260°C/500°F to 580°C/1076°F

Holding time at 580°C/1076°F 20-50 min

Rise temperature from 580°C/1076°F to 750°C/1380°F

Rise temperature from 580°C/1076°F to

800-850°C/1470-1560°F for Ceramic Alloys

Rise temperature from 580°C/1076°F to 900°C/1650°F

X1 40 min at end temperature X1 30 min at end temperature

X3 50 min at end temperature X3 40 min at end temperature

X6 60 min at end temperature X6 50 min at end temperature

X9 90 min at end temperature X9 60 min at end temperature

Room temperature

Heat rate 3°C/37° F per min

Heat rate 6°C/43° F per min

for Au-Alloys

for Non-precious Alloys

Heat rate 9°C/48°F per min

- Due to aggressive burning out, do not open the furnace during heating-up. In case of vacuum

pressure casting, raise the end temperature by 50°C/122°F.

- When several investment rings are put into the furnace at the same time, prolong the heating period

by 10 min per investment ring.

- Best results are obtained by putting immediately into a preheated furnace after 20 min, i.e. the Quick

heating method.

18

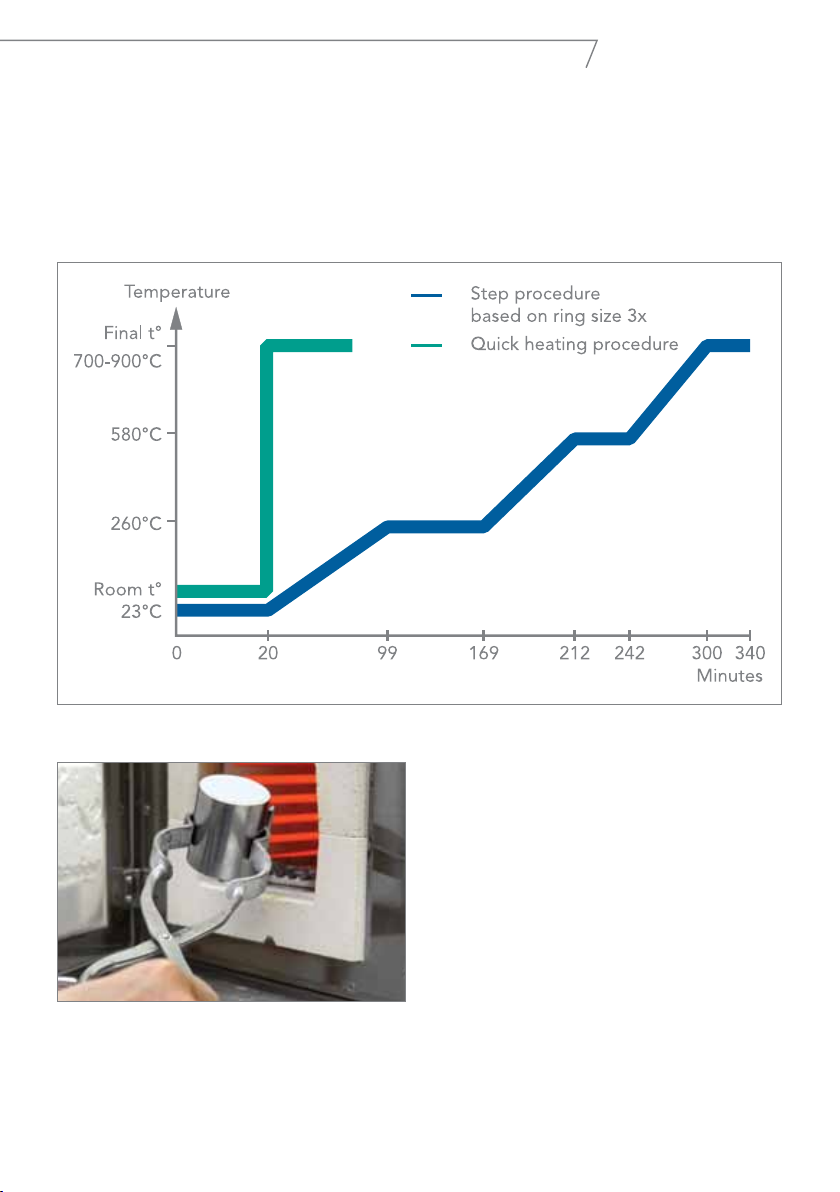

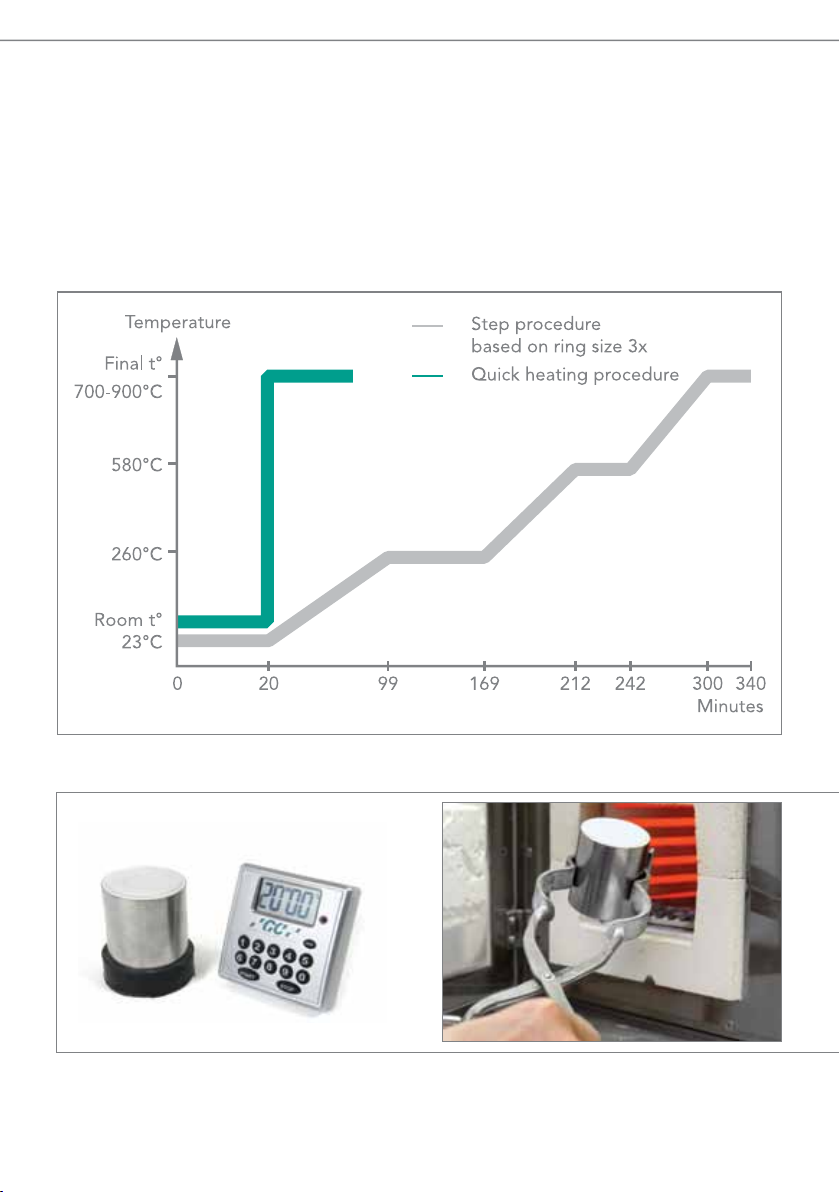

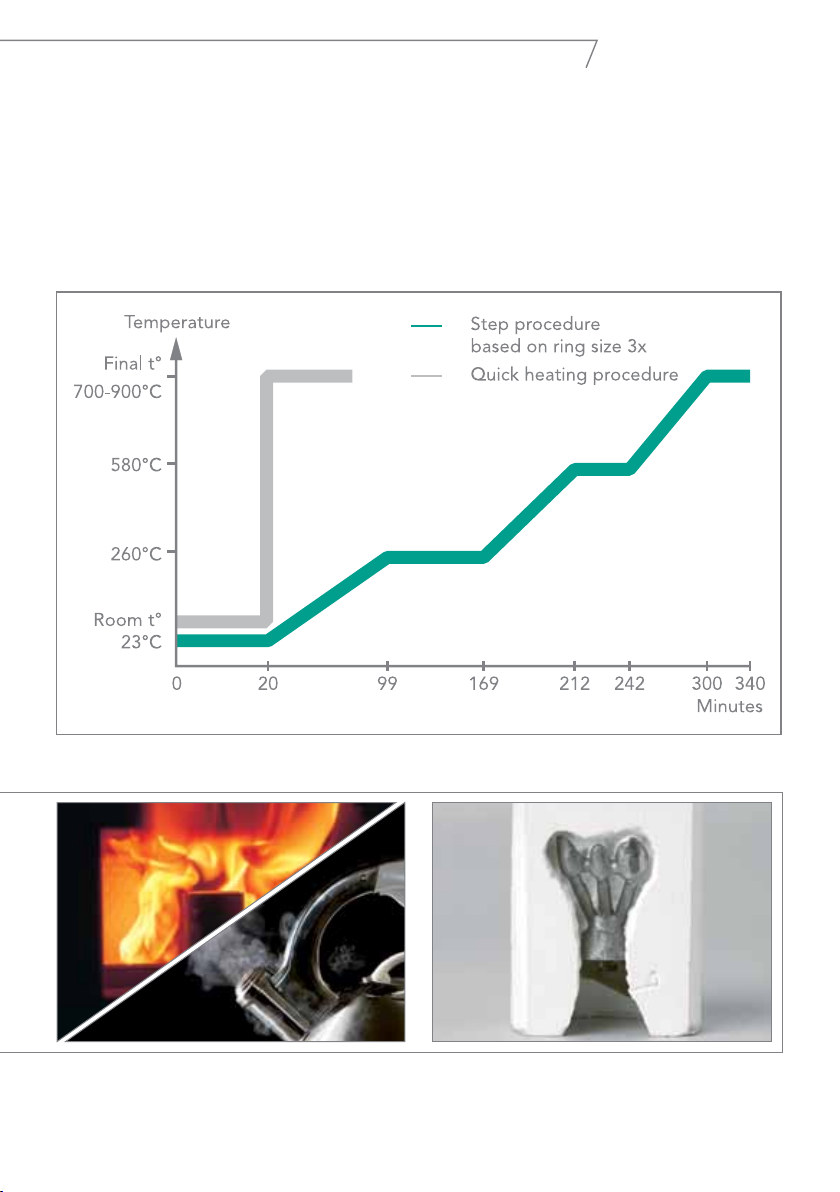

3.2 “Quick heating” versus conventional “step heating”

Schematic time/temperature chart

Focus Edition from GC

Heating-up schedules

19

3.2.1 Process of a Quick Heating schedule (Speed technique) QH

The investment is allowed to set for 20 min and then placed in the burnout furnace at the end temperature,

it is then allowed to heat soak at this temperature for a period as stated in the ‘Instructions for Use’ prior

to casting.

Heating-up schedules

20 min setting starting from mixing

20

+ >

QH Into furnace at end temperature between

700-900°C

SLH Into furnace at room temperature.

Start heating schedule immediately!

Focus Edition from GC

3.2.2 Process of a Step- Heating schedule (Conventional technique) SLH

The investment material is allowed to set for 20 min and then placed in the burnout furnace at room

temperature; it is then heated up in a series of temperature steps, before being heat soaked at the final

end temperature for a period as indicated in the ‘Instructions for Use’ prior to being cast.

Heating-up schedules

> >

High temperatures assuring a complete burnout

of all pattern materials, extra stimulated by a

“steam” effect

Perfectly cast objects

21

Loading...

Loading...