Page 1

INSTALLATION, MAINTENANCE AND USE

INSTRUCTIONS FOR

FREE-STANDING COOKERS

60x60 cm (type M6)

READ THE INSTRUCTION BOOKLET BEFORE INSTALLING AND USING

THE APPLIANCE.

The manufacturer will not be responsible for any damage to property or to persons

caused by incorrect installation or improper use of the appliance.

The manufacturer is not responsible for any inaccuracies, due to printing or transcription

errors, contained in this booklet. In addition, the appearance of the figures reported is also

purely indicative.

The manufacturer reserves the right to make changes to its products when considered

necessary and useful, without affecting the essential safety and operating characteristics.

Page 2

CONTENTS:

INSTALLER TECHNICAL MANUAL ............................................................................................................... pg. 2

Installing the cooker - Installation information ................................................................................................. pg. 2

Backguard installation instruct ........................................................................................................................ pg. 3

Electric connection .......................................................................................................................................... pg. 3

APPLIANCE MAINTENANCE - Replacing parts ............................................................................................. pg. 4

USE AND MAINTENANCE MANUAL ............................................................................................................. pg. 4

Description of control panel and control types ................................................................................................. pg. 4

Using the induction hob ………………………………………………………………………………………………. pg. 5

Hob control knob ………………………………………………………………………………………………………. pg. 5

Type of pan ………………………………………………………………………………………………………. pg. 6

Using the electric thermostat ........................................................................................................................... pg. 7

Using the 9+0 switch ....................................................................................................................................... pg. 7

Using the natural conventional electric oven .................................................................................................. pg. 8

Using the ventilated electric oven .................................................................................................................... pg. 8-9

Using the electric grill - ventilated electric grill ................................................................................................. pg. 9

Using the self cleaning oven .......................................................................................................................... pg. 9

Cleaning the appliance .................................................................................................................................... pg. 10

After-sales technical service and spare parts .................................................................................................. pg. 10

THIS APPLIANCE HAS BEEN DESIGNED FOR NON-PROFESSIONAL DOMESTIC USE.

This appliance is marked according to the European directive 2002/95/EC

INSTALLER TECHNICAL MANUAL

This appliance is marked according to the European directive 2002/96/EC on Waste

Electrical and Electronic Equipment (WEEE).

This guideline is the frame of a European-wide validity of return and recycling on

Waste Electrical and Electronic Equipment.

INSTALLER INFORMATION

The installation, all adjustments, transformations and maintenance listed in this part of the manual must be

carried out only by skilled personnel.

Improper installation may cause damage to persons, animals or property, for which the manufacture will not be

held responsible.

The appliance safety or automatic adjustment devices may be changed during the service life of the system only

by the manufacturer or by the duly authorised supplier.

INSTALLING THE COOKER

After having removed the various loose parts from the internal and external packing, make sure that the cooker is not

damaged. In case of doubt, do not use the appliance and contact skilled personnel.

Keep all the dangerous packing parts (polystyrene foam, bags, cardboard, staples, etc.) away from children.

The appliance can be installed as a freestanding unit, next to a wall or inserted between two walls (Fig.1). A single

sidewall that exceeds the height of the work surface is possible. This must be at a minimum distance of 70 mm from the

edge of the cooker (Fig. 1 I)

Any walls of the adjacent furniture pieces and the wall behind the cooker must be made with heat-resistant material that

can withstand a minimum overtemperature of 65 K.

WARNING: the connection to the gas network must only use metal flexible pipes that conform with the national

standards in force.

IMPORTANT INFORMATION FOR INSTALLING THE APPLIANCE

The cooker can be installed separately, as a freestanding unit, or between kitchen units or between a kitchen

unit and the wall. The device must be installed in accordance with the regulations stated in UNI 7129 and UNI

7131 standards.

This appliance is not connected to devices which exhaust combustion products.

Special attention must be focused on the prescriptions described below regarding room aeration and

ventilation. Any hanging cabinets installed above the work surface must be located at a distance of no less than

700 mm.

2

Page 3

BACKGUARD INSTALLATION INSTRUCTION

1) Remove n°2 screws fixing worktop as shown in fig.4

2) Place front part of the backguard and attach it from bottom side with the two removed screws (point 2) as shown in

fig .5

3) Fix the front part of the backguard with the screws supplied with the backguard kit (fig.6)

4) Assemble back part with front part of the backguard and fix them with a screws supplied with the backguard kit

(fig.7)

APPLIANCE ELECTRIC CONNECTION:

The electric connection must comply with the current legal standards and regulations.

Before making the connection, check that:

- The system electrical rating and the current outlets are adequate for the maximum power output of the appliance (see

the label applied to the bottom of the casing).

- The outlet or the system is equipped with an efficient ground connection in accordance with the current legal standards

and regulations. The company will not be responsible for the non-compliance with these instructions.

When the connection to the power supply network is made using an outlet:

- If the power cord is supplied without a plug, apply a standard plug that is suitable for the load indicated on the label.

Connect the wires according to the diagram shown in FIG.8 and check that:

letter L (phase) = brown wire;

letter N (neutral) = blue wire;

ground symbol

- The power cord must be positioned so that an overtemperature of 75 K will not be reached at any point.

- Do not use reductions, adapters or splitters since they might cause false contacts and lead to dangerous overheating.

When the connection is made directly to the electric network:

- Use a device that ensures disconnection from the mains in which the contacts are opened to a distance that permits

complete disconnection according to the conditions for over-voltage category III.

- Remember that the ground wire must not be interrupted by the circuit-breaker.

- As an alternative, the electric connection can also be protected by a high-sensitivity residual current circuit-breaker.

- It is highly recommended to attach the special green-yellow ground wire to an efficient ground system.

WARNING: If the power cord is replaced, the ground wire (yellow-green) connected to the terminal, should be

longer than the other wires by about 2 cm.

= green-yellow wire;

TYPES OF POWER CORDS

The appliance is equipped with a terminal for the electric connection placed behind, which is accessible removing the

posterior casing (Fig.9)

The cable of alimentation can be :

Operation at 220-240V~ : use a H05BB-F three-wire cable (cable 3x4 mm²)

Operation at 380-415V2N~ : use a H05RR-F o H07RN-F four-wire cable (cable 4x4 mm²)

Operation at 380-415V3N~ : use a H05RR-F o H07RN-F five-wire cable (cable 5x1,5 mm²)

Fig.10

The power supply cable is suitable for appliance operating on 220-240 V~

ATTENTION: The appliance conforms with the regulations of directives 2009/142/CE(ex 90/396/EC) (Gas

Directive) regarding gas appliances for domestic use and the like, 2006/95/CE (Low Voltage Directive) regarding

electrical safety and 2004/108/CE, (EMC Directive) regarding electromagnetic compatibility.

Electrical requirements

220-240V~ - 10000W( induction 7100W) (45 A max)

380-415V2N~ 10000W( induction 7100W) (32 A max/phase).

380-415V3N~ 10000W( induction 7100W) (16 A max/phase).

3

Page 4

APPLIANCE MAINTENANCE

ATTENTION: IMPORTANT WARNINGS

For cookers resting on a base

ATTENTION: If the cooker rests on a base, take the measures necessary to prevent the cooker from sliding along the

support base.

For cookers with glass covers

ATTENTION: Before opening the appliance’s glass cover, carefully remove all liquid residues from the top of it.

ATTENTION: Before closing the appliance’s glass cover, make sure that the work surface has cooled.

For cookers with electric ovens

The unit becomes hot during use. Do not touch the heating elements inside the oven.

For cookers with electric ovens

ATTENTION: The accessible parts can become hot during use. Keep children away from the appliance.

For the food warmer compartment (or drop leaf in our case)

ATTENTION: The internal parts of the food warmer can become hot during use.

For glass doors

Do not use abrasive cleaning products or metal spatulas with sharp edges to clean the oven door’s glass since this could

scratch the surface and the glass could break.

Do not use steam cleaners to clean the appliance.

REPLACING PARTS

Before performing any maintenance operation, disconnect the appliance from the gas supply and electricity

network.

To replace parts such as knobs and burners, just remove them from the seats without disassembling any part of the

cooker.

To replace parts such as nozzle supports, valves and electric components follow the procedure described in the burner

adjustment paragraph. To replace the valve or the gas thermostat, it is also necessary to disassemble the two rear gas

train brackets, loosening the 4 screws (2 per bracket) that attach it to the rest of the cooker and, unscrew the nuts that

attach the front burner valves to the control support, after removing all the knobs. To replace the gas or electric

thermostat, also disassemble the rear cooker guard, loosening the relative screws, to be able to pull out and reposition

the thermostat bulb.

To replace the oven bulb, just unscrew the protection cap that projects out inside the oven. (Fig.11)

WARNING: Before replacing the bulb, disconnect the appliance from the electric power supply.

WARNING: The power cord supplied with the appliance is connected to that appliance with an X type connection (in

compliance with standards EN 60335-1, EN 60335-2-6 and subsequent amendments) for which it can be installed

without the use of special tools, with the same type of cord as the one installed.

If the power cord becomes worn or damaged, replace it based on the information reported in table 3 .

WARNING: If the power cord is replaced, the installer shall ensure that the ground cable is longer than the

phase cables and also shall comply with the warnings regarding the electric connection.

To replace the power cable, lift the terminal board’s cover and replace the cable. To access the terminal board in cookers

with a 3x2.5mm² cable, the back panel on the rear of the appliance must be removed.

CONTROL PANEL DESCRIPTION

On the control panel, small symbols show the function of each knob or key. Here as follows are the several controls that

a cooker can have:

USE AND MAINTENANCE MANUAL

the symbol shows the disposition of induction zone on the worktop, the full dot identifies the zone in object (in

this case the central zone).

the symbol

shows the running of any left oven ( 9 positions switch)

the symbol

shows the electric thermostat for electric left oven

4

Page 5

USING THE INDUCTION HOB

HOB CONTROL KNOB

These knobs provide control of the ceramic hob's cooking zones.

The zone it controls is shown above eachknob. Turn the knob to the right to set the zone's operating power; the settings

range from a minimum of 1 to a maximum of 9. (fig.12)

The working power is shown by a display on the hob.

Heating accelerator

Each cooking zone is equipped with a heating accelerator.

This system allows the zone to be operated at peak power for a time proportional to the heating power selected.

To start the heating accelerator, turn the knob to the left, select setting "A" and then release. The letter "A" will appear on

the display on the hob.

You now have 3 seconds to select the heating setting of your choice. Once a setting between 1 and 9 has been selected,

"A" and the chosen setting will flash in alternation on the display. '

While the heating accelerator is in operation, the heating level can be increased at any time. The "full power" time will be

modified accordingly. If the power is reduced by turning the knob anticlockwise, option "A" is automatically deactivated.

Power Function

The power function allows the user to operate each heating zone continuously at the maximum power for a time of no

more than 10 minutes. This function can be used, for example, to bring a large amount of water to the boil in a hurry, or

to turn up the heat under meat.

Turn the knob clockwise and set heating level 9, then use the knob to set the "P" position and release il. "P" appears on

the corresponding zone display.

After 10 minutes, the power is reduced automatically, the knob returns to the 9 setting and the "P" disappears.

However, the power function can be turned ott at any time by reducing the heating level. .

When the power function is selected for one heating zone (e.g. the left front zone), the power absorbed by the second

zone (Ieft rear zone) might be reduced to supply the maximum available energy to the first zone.

Consequently, the power function takes priority over the heating accelerator.

If a pan is removed from the cooking zone while the power function is on, the function is switched off.

Holding Function

The holding function keeps the temperature of the bottoms of pans at about 42°C or 70°C . This allows foods to be kept

hot with optimal energy consumption and to be heated gently. The holding function can be kept in operation for up to 2

hours.

The holding function is

Bridge Function

This function allows to use the 2 cooking zones at the right at same time with the same features as a single cooking

zone. Booster function isn’t allowed.

1 – rotate both knobs, rear right and front right, at the same time in the P position and keep the knobs in that position.

2 – we see that the ∏ symbol blinks in the display, then after a few seconds the ∏ symbol appears on the rear right

display and the front right display shows the power level.

3 – to control the bridge power level use the knob 4 (front right zone). If you turn the knob 3 (rear right zone) the display

shows a horizontal segment and the bridge function ends.

and is indicated by the relevant symbols on the cooking zones.

HOB

ATTENTION:

Metal items such as cutlery or lids must never be placed on the surface of the hob since they may become hot.

Cooking zones (fig.13)

The appliance is equipped with 4 cooking zones having different diameters and powers. Their positions are clearly

marked by rings, while the heating power is only released in the area shown on the ceramic hob. The 4 cooking zones

are of HIGH-LlGHT type and start to heat up a few seconds after they are switched on. The heat level of each zone can

be regulated from the minimum to the maximum setting using the knobs on the front panel.

Underneath each cooking zone there is a coil called an inductor, supplied with power by an electronic system, which

generates a variable magnetic field. When a pan is placed inside this magnetic field, the highfrequency currents

concentrate directly on the bottom of the pan and produce the heat needed to cook the foods.

The 4 lights between the cooking zones come on when the temperature of one or more cooking zones exceeds 60° C..

The lights go out when the temperature drops to below about 60° C.

5

Page 6

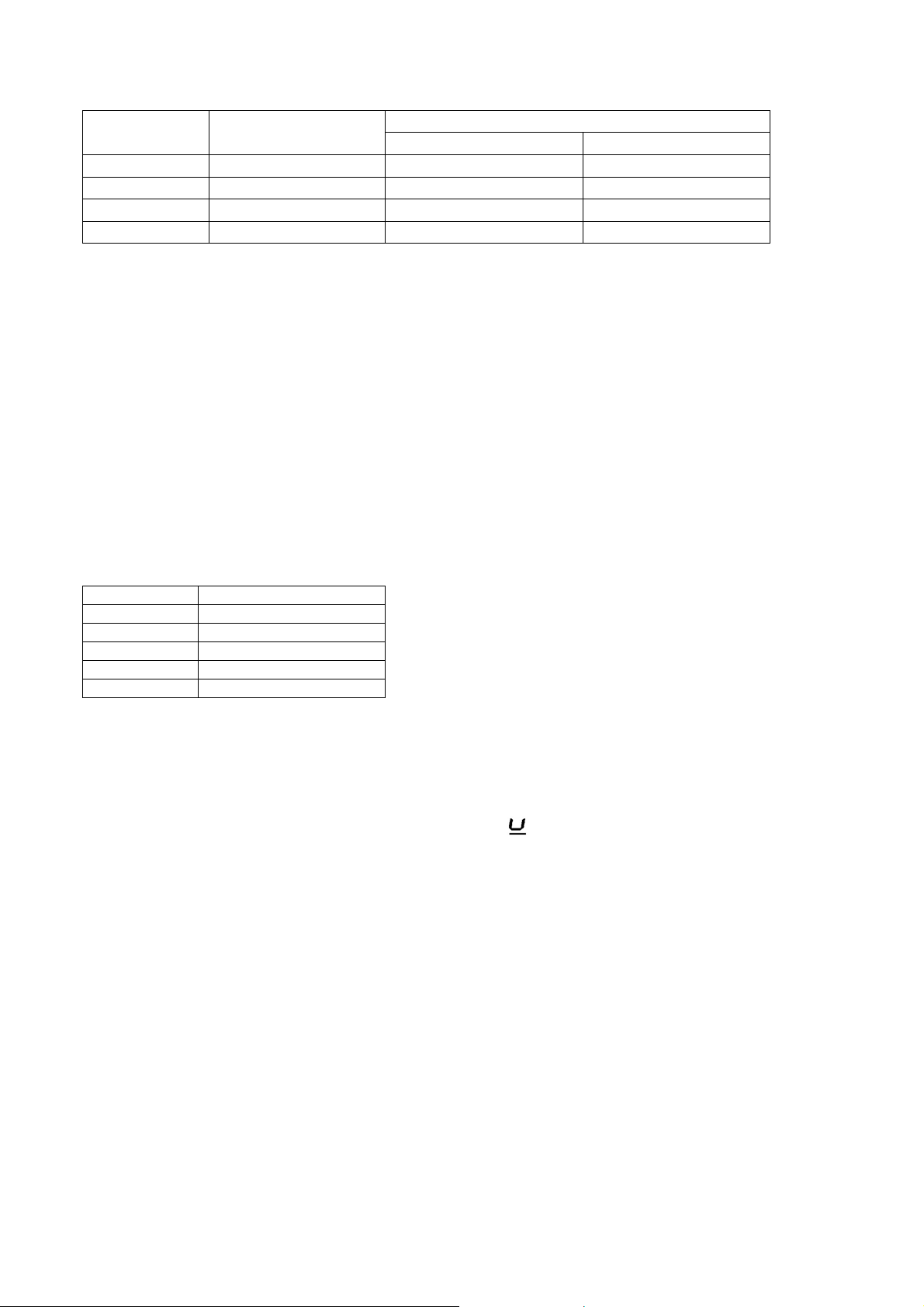

Zone number: Zone diameter: Power absorption

Normal operation: With power function:

1 210 mm 2300W 3700W

2 180 mm 1850W 3000W

3 180 mm 1850W 3000W

4 180 mm 1850W 3000W

When the hob is used for the first time, it should be heated to its maximum temperature for long enough to bum off

any oily residues left by the manufacturing process, which might contaminate foods with unpleasant smells.

TYPES OF PANS

This type of appliance can only operate with pans of special kinds.

The bottom of the pan must be iron or steel/iron to generate the magnetic field necessary for the heating processo

Vessels made from the following materials are not suitable:

glass;

porcelain;

pottery;

steel, aluminium or copper without magnetic bottom;

To check that a pan is suitable, simply piace a magnet close to its bottom:

if the magnet is attracted, the pan is suitable for induction cooking. If no magnet is to hand, put a little water in the pan,

piace it on a cooking zone and switch it on. If the symbol appears on the display instead of the power, the pan is not

suitable.

The pans used for cooking must have certain minimum diameters to ensure satisfactory operation.

Pans larger than the cooking zones can also be used, but it is important to ensure that the bottom of the pan does not

touch other cooking zones, and that it is always centred over the perimeter of the cooking zone.(fig.14-15)

Zone number Pan minimum diameter

1 90 mm

2 140 mm

3 110 mm

4 140 mm

5 90 mm

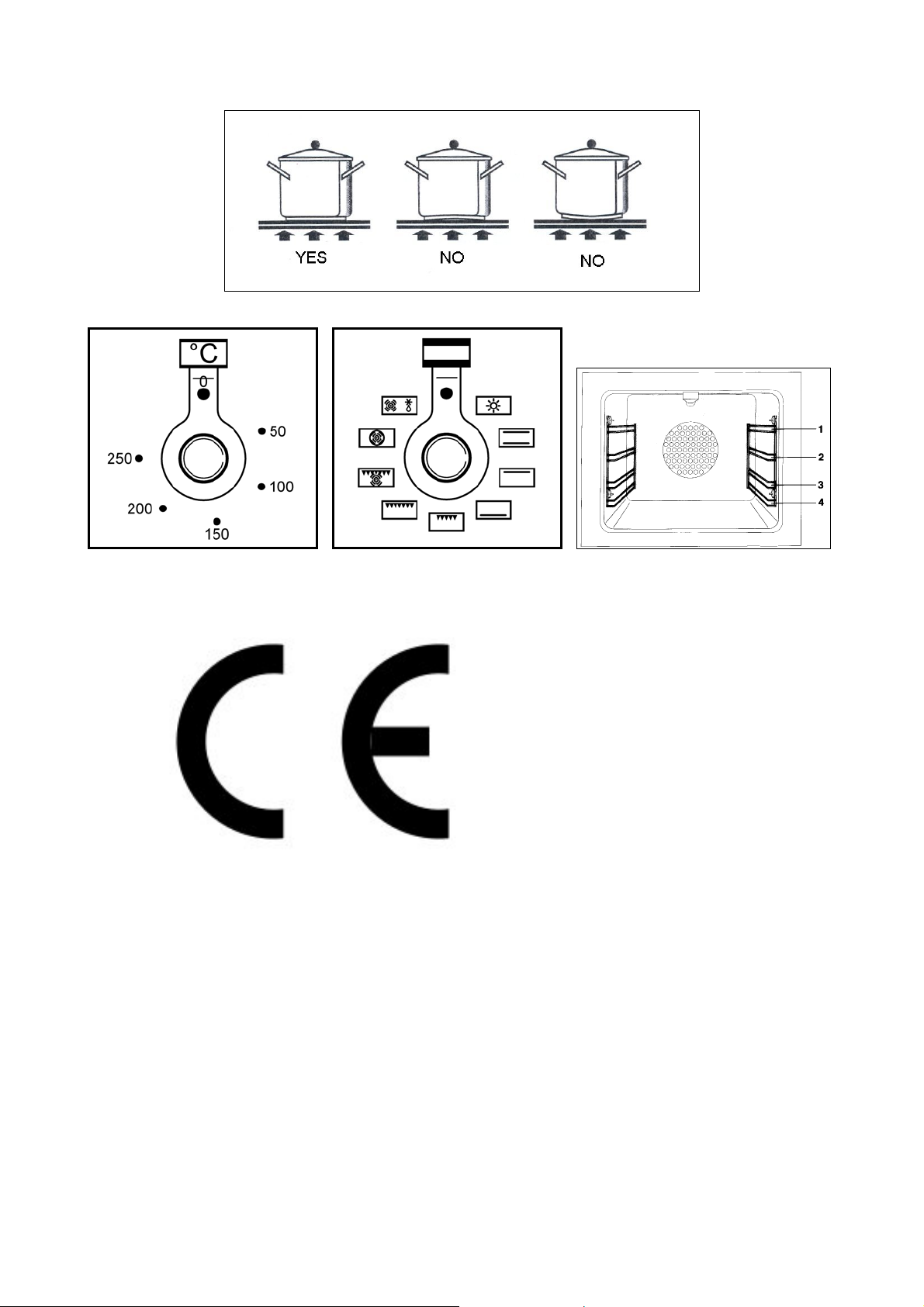

Use only vessels specially designed for induction cooking, with thick, completely flat bottom; if these are not available,

the pans used must not have crowned (concave or convex) bottom. (fig.16)

Pan present device

Each cooking zone is equipped with a "pan present" device, which ensures that cooking cannot start unless a suitable

pan is present on the cooking zone and properly positioned.

If the user attempts to switch on the cooking zone with the pan not positioned properly or with a pan which is not of

suitable material, a few seconds after the zone is switched on the

has been made.

Residual heat

Each cooking zone is equipped with a device which warns of residual heat. After any cooking zone is switched off, a

flashing ‘H’ may appear on the display. This warns that the cooking zone concerned is stili very hot. Cooking can be

restarted while the ‘H’ is flashing; proceed as described in point "3".

Locking-out the hob

When not in use, the hob can be "locked out" to prevent children from accidentally switching it on.

With the cooking zones off, turn the knobs of zones 1 and 2 to the left simultaneously until ‘’L’’ appear on the power

display and then release the knobs.

To deactivate it, repeat the same procedure: the cooking zone displays will stop displaying the ‘’L’’, indicating that the

cooking zone lock-out function has been deactivated.

Attention:

Take care not to spill sugar or sweet mixtures onto the hob during cooking, or to piace materials or substances which

might melt (plastic or aluminium foil) on it; if this should occur, to avoid damage to the surface, tum the heating off

immediately and clean with the scraper supplied while the cooking zone is stili warm. If the ceramic hob is not cleaned

immediately, residues may form which cannot be removed once the hob has cooled.

Important!

Keep a close eye on children because they are unlikely to see the residual heat waming lights. The cooking zones are

stili very hot for some time after use, even if they are switched off. Make sure that children never touch them.

symbol will appear to warn the user that an error

6

Page 7

WARNING: Under no circumstance use aluminium foil or plastic containers to hold the food while cooking on a glassceramic hob.

WARNING: Do not touch the cooking area as long as the light indicating residual heat on the glass-ceramic hob, is “on”;

this indicates that the temperature in the relative area is still high.

WARNING: Never place pan with bottoms which are not perfectly flat and smooth on the hob

WARNING: If you notice a crack in the ceramic hob, disconnect the appliance from the elettricity supply and contact a

service centre

WARNING: Your glass-ceramic hob is thermal shock resistant and resistant to both heat and cold.

If you drop a heavy pot on your hob it will not break.

On the contrary, if a hard object, such as the salt shaker or the spice bottle strikes the edge or the corner of the hob, the

hob may break.

WARNING: never use the glass-ceramic hob as support surface.

USING THE ELECTRIC THERMOSTAT

The thermostat supplied with the relative models maintains a constant temperature inside the oven at a specific

temperature setting ranging from 50°C to 250°C.(fig.17)

Turn the knob clockwise and align the selected temperature indicated on the ring with the index etched on the control

panel. Thermostat operation is indicated by an orange light which will turn off when the temperature inside the oven is

10°C greater than the temperature setting, and will turn on when the oven is 10°C less than the temperature setting. The

thermostat can control the oven elements only if the relative switch is in one of the possible oven element operating

modes: if the switch is in position 0, the thermostat has not effect on the oven elements, which remain off.

USING THE 9 + 0 SWITCH

The 9 + 0 switch installed in the multifunction oven models is used, along with the thermostat, to control the electric fan

and the oven elements since they can be turned on by turning the 9 + 0 switch knob and the thermostat knob. Turning

just one of the two knobs will not have any effect on the oven except to turn on the oven light or the electric fan when

inserted. The electric oven is heated by 4 elements: one on the bottom, two on the top or one circular; turning the switch

knob (fig.18) turns on the element relative to the symbol indicated on the ring but to be activated the thermostat knob

must be turned until the orange light turns on indicating that the element has been turned on. Placing the switch knob on

any of the nine operating modes turns on the oven light, together with the relative element. Once the temperature and

the elements to be used have been set, the oven elements are turned on and off by the thermostat; therefore, it is normal

for the orange light to turn on and off while the oven is working.

To turn off the electric oven set the switch knob to position 0 to prevent the thermostat from controlling the elements.

Setting the thermostat knob to position 0 turns off the elements but it is still possible, using the switch, to turn on the

electric fan and the oven light.

The switch has 9 different fixed positions corresponding to 9 different types of oven operation:

- the symbol indicates that only the oven light is turned on;

- the symbol

on;

- the symbol

- the symbol indicates the only the bottom element (1300W) has been turned on;

- the symbol indicates that only the grill element (2000W) has been turned on;

- the symbol

- the symbol

been turned on;

- the symbol indicates that the circular element (2400W) and the electric fan have been turned on;

- the symbol

When the knob is set to one of these nine positions, the oven light is always on, thus indicating that the oven is being

energised.

indicates that the bottom element (1300W) and the top external element (900W) have been turned

indicates that only the top external element (900W) has been turned on;

indicates that the top external element (900W) and the grill element (2000W) have been turned on;

indicates that the top external element (900W), the grill element (2000W) and the electric fan have

indicates that only the electric fan has been turned on.

7

Page 8

USING THE NATURAL CONVENTIONAL ELECTRIC OVEN

When using the oven for the first time it should be operated for a maximum of 30 minutes at a temperature of about 250°

to eliminate any odours generated by the internal insulation. During normal oven use, select the desired cooking

temperature using the thermostat knob and wait until the orange light turns off before putting in any food. The oven is

equipped with 4 guides at different heights (fig.19) which can be used to insert shelves or the tray. To keep the oven as

clean as possible it is recommended to cook meat on the tray or on the shelf that has been inserted inside the tray. Table

below lists the cooking times and the position of the tray for different types of foods. Personal experience will help to

determine any variations in the values reported in the table. In any case, it is recommended to follow the instructions of

the specific recipe being used.

NATURAL CONVENTIONAL ELECTRIC OVEN COOKING TABLE

MEAT

PORK ROAST

BEEF ROAST (YOUNG STEER)

BEEF ROAST

VEAL ROAST

LAMB ROAST

ROAST BEEF

ROAST HARE

ROAST RABBIT

ROAST TURKEY

ROAST GOOSE

ROAST DUCK

ROAST CHICKEN

FISH

PASTRY

FRUIT PIE

TEA CAKE

BRIOCHES

SPONGE CAKE

RING CAKE

SWEET PUFF PASTRIES

RAISIN LOAF

STRUDEL

SAVOIA COOKIES

APPLE FRITTERS

SAZOIARDI SANDWICH

TOAST SANDWICH

BREAD

PIZZA

TEMP °C HEIGHT MINUTES

225 3/4 60-80

225 3/4 60-80

250 3/4 50-60

225 3/4 60-80

225 3 40-50

230 3/4 50-60

250 3/4 40-50

250 3 60-80

250 3 50-60

225 3 60-70

250 3/4 45-60

250 3/4 40-45

200-225 2 15-25

225 2 35-40

175-200 2 50-55

175-200 2 25-30

220-250 2 20-30

180-200 2 30-40

200-220 2 15-20

250 2 25-35

180 2 20-30

180-200 2 40-50

200-220 2 15-20

200-220 2 20-30

250 3 5

220 3 30

220 2 20

USING THE VENTILATED ELECTRIC OVEN

When using the oven for the first time it should be operated for a maximum of 30 minutes at a temperature of about 250°

to eliminate any odours generated by the internal insulation.

Before cooking, allow the oven to reach the desired temperature setting waiting for the orange light to turn off. This type

of oven is equipped with a circular element around which a fan has been installed that creates forced-air circulation in the

horizontal direction. Thanks to this type of operation, the ventilated oven can be used for different types of cooking at the

same time, without changing the taste of each food. Only some models are equipped with a removable metallic filter

applied to the rear screen which collects the fat while a roast is cooking. Therefore, it is recommended to remove this fat

periodically, washing the screen with soapy water and rinsing thoroughly. To remove the metallic filter just apply slight

pressure toward the top on the tab indicated by the arrow. Hot-air circulation guarantees a uniform distribution of heat.

Pre-heating the oven is not necessary, but for very delicate pastries, it is recommended to heat the oven before inserting

the trays.

The ventilated conventional system partially changes the various notions about traditional cooking. Meat no longer needs

to be turned while it is cooking and the rotisserie is no longer needed to cook a roast on the spit. Just put the meat

directly on the shelf.

8

Page 9

VENTILATED ELECTRIC OVEN COOKING TABLE

MEAT

PORK ROAST

BEEF ROAST (YOUNG STEER)

BEEF ROAST

VEAL ROAST

LAMB ROAST

ROAST BEEF

ROAST HARE

ROAST RABBIT

ROAST TURKEY

ROAST GOOSE

ROAST DUCK

ROAST CHICKEN

FISH

PASTRY

FRUIT PIE

TEA CAKE

BRIOCHES

SPONGE CAKE

RING CAKE

SWEET PUFF PASTRIES

RAISIN LOAF

STRUDEL

SAVOIA COOKIES

APPLE FRITTERS

SAZOIARDI SANDWICH

TOAST SANDWICH

BREAD

PIZZA

TEMP °C HEIGHT MINUTES

160-170 2 70-100

170-180 2 65-90

170-190 2 40-60

160-180 2 65-90

140-160 2 100-130

180-190 2 40-45

170-180 2 30-50

160-170 3 80-100

160-170 3 160-240

160-180 3 120-160

170-180 2 100-160

180 2 70-90

160-180 2-3

180-200 2 40-50

200-220 2 40-45

170-180 2 40-60

200-230 2 25-35

160-180 2 35-45

180-200 2 20-30

230-250 2 30-40

160 2 25-35

150-180 2 50-60

180-200 2 18-25

170-180 2 30-40

230-250 3 7

200-220 3 40

200-220 2 20

USING THE CONVENTIONAL ELECTRIC GRILL

The electric grill can also be combined with the gas oven or electric oven.

In both cases, the grill is controlled using the oven’s temperature knob (see also, Using the gas or electric oven). Like

the gas grill, the electric grill can be used for grilling on the oven’s grill. The static electric grill must be used with the door

closed. The temperature set on the thermostat (when present) must not exceed 150°C.

Grilling on the shelf: In this case, the shelf supplied is placed on level 1 or 2 and the foods to be grilled are placed on

top, while the tray is inserted on the lower levels to collect the cooking juices. Then turn on the grill element switching the

thermostat to the relative position (electric oven version).

WARNING: the accessible parts may become very hot while grilling. Keep children away from the appliance

while cooking.

USING THE VENTILATED ELECTRIC GRILL

The ventilated electric grill is a special function equipped only on the multifunction oven. Set the 9 + 0 switch to the

relative position to activate the grill element and the electric fan. Generally, to ensure excellent grilling, place the oven

shelf in the middle position while the oven tray should be inserted at the bottom.

IMPORTANT: When using the ventilated electric grill, set the thermostat knob no higher than 175 °C, which is

between the 150 °C and 200 °C setting, to avoid overheating the front of the appliance. In fact, ventilated grilling

must be carried out with the door closed.

Note:

The cooker is equipped with the cooling fan that starts operation each time the oven knob is on a position different from 0

(zero). The fan circulates the air between the control panel and the oven door and also allows the control panel and the

oven door stay at a warm temperature during the appliance operation in any condition.

USING THE SELF-CLEANING OVEN

In the cookers where this feature is foreseen , the self-cleaning oven differs from the standard one for the fact that its

internal surfaces are enamelled with a special microporous material which absorbs and eliminates the greasy particles

during the cooking. In case of spillage of greasy liquids, the self-cleaning action becomes not efficient, therefore it will be

necessary to clean the oven properly. Proceed in the following way: (a) wipe a humid sponge on the grease stains; (b)

heat up the oven to the maximum temperature; (c) wait 5 minutes and then switch off the oven; (d) wait until the oven

gets cool again; (e) wipe again the humid sponge on all the surface. Do not use detergent in any case.

9

Page 10

CLEANING THE APPLIANCE

Before cleaning the appliance, it should be disconnected from the power supply and turn off the main gas

feeder valve.

Cleaning the work surface:

Periodically clean the burner heads, the enamelled steel grids, the enamelled covers and the flame caps using warm

soapy water. Then those parts should be rinsed and thoroughly dried.

Any liquid that overflows from pots must always be removed using a rag.

If it becomes difficult to open or close a valve, do not force it, but immediately request the assistance of the

technical service personnel.

Cleaning the ceramic hob:

Sefore carrying out any operations, disconnect the appliance from the electricity supply.

The ceramic hob must be cleaned regularly, preferably atter each use, when the residual heat waming lights have gone

out.

Any marks left by the use of pans with aluminium bottoms can be wiped off with a cloth dipped in vinegar.

If burnt residues are left after cooking, remove them with the scraper provided, rinse with water and dry thoroughly with a

clean cloth. Regular use of the scraper considerably reduces the use of chemicals for daily cleaning of the hob.

In any case, abrasive or corrosive cleaners (e.g. powder products, ovencleaner sprays, stain removers and metal

scouring pads) must never be used.

Cleaning the enamelled parts:

To maintain the original features of the enamelled parts they should be cleaned frequently with soapy water. Never use

abrasive powders. Do not leave acidic or alkaline substances on the enamelled parts (vinegar, lemon juice, salt, tomato

sauce, etc.) and do not wash the enamelled parts while they are still hot.

Cleaning the STAINLESS steel parts:

Clean the parts with soapy water and then dry them with a soft cloth. The shine is maintained by periodically using

special products that generally are found in the market. Never use abrasive powders.

Cleaning the burner flame caps:

Since the flame caps are resting on the burner, to clean them just remove them from their seat and wash them with

soapy water. After they have been thoroughly dried and having checked that the holes are not clogged, they can be

replaced in their proper position.

Cleaning the inner glass door: Clean the glass with warm soapy water using a sponge. A spatula can be used to

remove burner fat if used gently.

ATTENTION: while cleaning the door make sure to avoid any spillage in the venting holes on the top part of the door. To

clean inside the door it is necessary to disassemble the door through a service engineer.

ATTENTION: for further details about cleaning of the appliance, please contact your applliance retailer.

AFTER-SALES TECHNICAL SERVICE AND SPARE PARTS

Before leaving the factory, this appliance was tested and calibrated by skilled and qualified personnel.

Any repairs or calibration that may become necessary after leaving the factory should be performed by skilled personnel.

For this reason we advise the customer to contact the Dealer that sold the appliance or the nearest Service Centre,

providing them with information about the type of appliance and the type of problem that has occurred. If defective parts

must be replaced, it is recommended to replace them with original spare parts that are available only in our technical

Service Centres and authorised dealers.

10

Page 11

Fig. 1

Fig. 4 Fig. 5

11

Page 12

Fig. 6 Fig. 7

Fig. 8 Fig.9

Fig.10

12

Page 13

Fig.11 Fig.12

Fig.13

Fig.14 Fig.15

13

Page 14

Fig.16

Fig.17 Fig.18 Fig.19

14

Page 15

15

Page 16

310692

16

Loading...

Loading...