Page 1

4.0 OPERATING INSTRUCTIONS

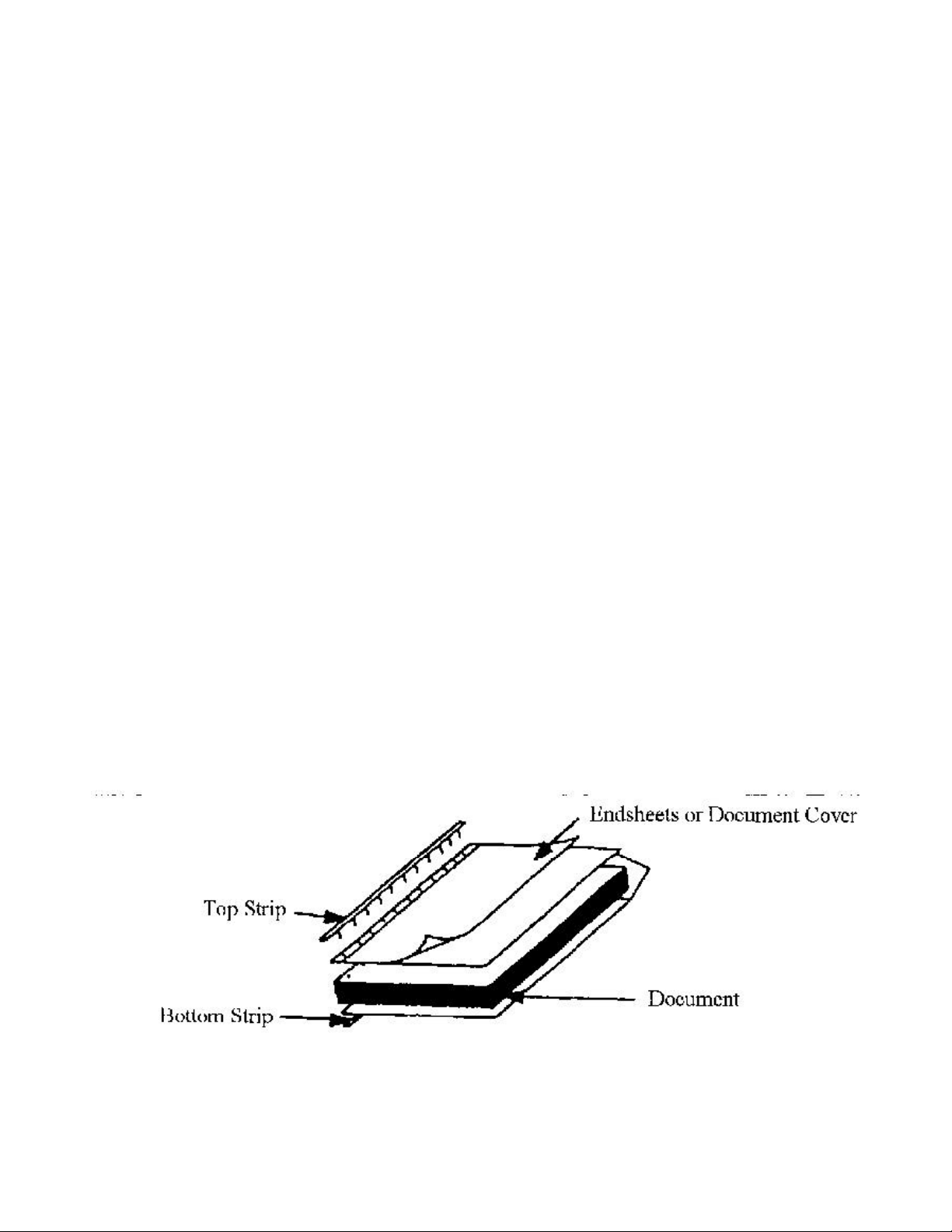

4.1 Document Assembly

1. Check the bind edge guide alignment by inserting a receiving strip in the strip

recess area. Lay a sheet of correctly aligned punched paper on the strip,

matching up the holes and the strip so that the strip is not showing at the top or

bottom of the paper. Ad just the bind edge guide if necessary by loosening the

screw and sliding the guide to the edge of the paper.

2. Place the back cover (face down), the punched sheets (last page on the bottom),

and front cover (face up) on top of the receiving strip.

3. Place the receiving strip (bottom binding strip with holes), textured side down

in the strip recess, located in front of the backstop. Be sure the small hole in

the receiving strip is over the locating pin. The locating pin is on the left

hand side of the strip recess area in front of the backstop. The locating pin

fits into the small hole in the plastic strip. The strip is positioned correctly

over the locating pin when it is difficult to slide the strip to the right.

Failure to properly align the strip can cause machine damage.

4. Now determine the correct size of the pin strip. Use the scale on the backstop to

determine the thickness of the document and the size of the pins required. 1

inch (25 mm) on the scale requires a 1 inch (25 mm) pin. Anything over 1 inch

(25 mm) requires a 2 inch (51 mm) pin. Anything over 2 inches (51 mm)

requires a 3 inch (75 mm) pin. The pins should extend all the way through the

document but not more than 1 inch (25 mm) beyond. Insert the strip through the

document's hole s and the receiving strip.

Figure 4-1

4-1

Page 2

4.0 OPERATING INSTRUCTIONS

4.2 Binding

1. Turn the machine on, and the "Wait" light will be on. The machine takes about

45 seconds to warm up, and the "Wait" light to go off.

2. Use the selector button to identify whether the document is less than or greater

than 1 inch (25 mm). The machine will automatically vary the binding speed to

make the most secure bind.

3. Begin the binding process by pulling the pressure bar toward you and lowering

it on top of the document. To prevent jamming problems, lower the bar onto the

document rather than "drop" it.

4. The binding cycle will start automatically, and the pressure bar will return to its

original position when the cycle is complete.

5. Remove the bound document.

4-2

Page 3

OPERATING INSTRUCTIONS

4.3 Debinding

1. Place document to be debound as follows: bound edge against the backstop,

small hole in bottom strip over locating pin, edge of document next to bind edge

guide.

2 Once the document to be debound is properly located, depress the Bind/Debind

selector to place machine in debind mode.

3 Lower the pressure bar onto document, and the machine will go through the

debinding cycle.

5. Immediately after pressure bar raises (approximately 12 seconds), remove the

document and peel the top strip off.*

*NOTE: If you do not perform this step quickly enough, it will be too difficult

to remove the strip. Put the document through the debind process again and

remove the strip faster this time.

Figure 4-2

4-3

Loading...

Loading...