Page 1

STL1000 OPERATING

INSTRUCTIONS

GBC IS AN ACCO BRANDS COMPANY

Page 2

1

GENERAL BINDING

CORPORATION

AUTOMATED FINISHING

DIVISION

STL-1000 SEMI-AUTOMATIC TWIN

LOOP BINDER

60 Hz. SERVICE MANUAL REV 1.0

Section: pg.

Table of contents………………………………..………………………..……..…..…1

1. Installation and setup preparation………………..…………..…………..…2

2. About this Manual……………….………………………………………………,,,,4

3. Specifications…………………………………………………………………......5

4. Theory of Operations…………………………………………………………….8

5. Operating instructions for keypad……………………..……………….……11

6. Spool and Supply Chute Loading the Spool……………………………….14

7. Spool and Supply Chute Adjusting the Supply Chute………………...…16

8. Feed and cut Feed Wheel Guide Adjustment…………………………..….17

9. Feed and Cut Height and Width Adjustment of Guides……………..…..18

10. Loading Area…………………………………………………………………..…19

11. Book Transport Area……………………………………………………….…..20

12. Closing Area…………………………………………………………………...…21

13. Closing Height Adjustment……………………………………….……….…..23

14. Loading the Book…………………………………………………..………...…24

15. Air Solenoid Explanation……………………………………….…………..…26

16 Troubleshooting Guide…………………………………………..……….……27

17. Maintenance Requirements…………………………………….……….……33

18 Exploded Assembly and Parts List………………………………….….…..36

Page 3

2

19 Exploded Assembly and parts list conveyor………………..……….……63

20. STL- 1000 Field Problem Report Form……………………………..……… 69

21. Electrical Diagram………………………………………………………………70

22 Electrical Parts Layout…………………………………………………..….…72

NOTES………………………………………………………………………….…75

FOR YOUR SAFETY

Your safety as well as the safety of others is

important to us at GBC. In this Service Manual and on

the STL1000 itself are important safety messages.

Please read these message carefully.

The Safety Alert symbol precedes each

safety message in thi s manual. This symbol

indicates a potential safety hazard that

could injure you or others, as well as cause

product or property damage.

This safety message means that you could be

seriously hurt or killed if you open the electrical

enclosure and ex pose yourself to hazardous voltage:

This safety message means that your hands could be

crushed and cut if you place your hands in the area of

moving parts:

The following ISO and IEC symbols appear on this

product.. Their meaning is:

“I” means Power On

“O” means Power Off

“ ! “ means emergency stop

“ o “ means dereel

Do not connect electrical power to the STL1000 or

attempt to operate it before reading this Operators

Manual or you have been fully trained as an operator.

Save the operator’s manual for future

use and referral.

Keep hands, long hair, neckties, and loose

articles away from moving parts.

Never override or attempt to defeat electrical or

mechanical interlock devices

Never insert objects or spill liquids into the

STL1000. They may contact dangerous voltage

or short out components, resulting in fire or

dangerous shock.

Connect the STL1000 only to the electrical

supply shown in the machine specification

section of this manual and the Serial/Rating label

on the equipment. Connect to a power outlet

installed near the equipment and easily

accessible.

Connect the plug only to a matching receptacle,

contact a qualified electrician to have one

installed.

Turn the STL1000 power “Off” (O) at the end of

each day.

Do not attempt to service the STL1000. Contact

an authorized GBC service representative if any

of the conditions listed below are encountered:

Marty Moore

Page 4

3

?? Liquid has been spilled into the STL1000 has

been exposed to rain or water.

?? STL1000.

?? The STL1000 has been dropped, bumped, or

dented.

?? The product does not operate normally when

following the operating instructions.

WARNING:

SUPERVISORS PLEASE NOTE:

THESE PRECAUTIONS MUST BE FOLLOWED

WHEN OPERATING OR SERVICING THIS MACHINE.

?? ALL OPERATORS MUST BE PROPERLY TRAINED

PRIOR TO USING THIS EQUIPMENT.

?? READ INSTRUCTION MANUAL BEFORE OPERATING

OR SERVICING THIS MACHINCE.

?? ONLY A TRAINED, QUALIFIED TECHNICIAN SHOULD

SERVICE THIS MACHINE.

?? DO NOT ATTEMPT SET-UP CHANGES UNLESS

FULLY TRAINED.

?? FOLLOW ALL STATE, LOCAL AND FEDERAL POWER

LOCKOUT / TAGOUT STANDARDS WHEN SERVICING

THIS EQUPIMENT.

?? HAVING MACHINE UNDER POWER WHILE MAKING

ALTERATIONS CAN RESULT IN SERIOUS BODILY INJURY.

ALWAYS DISCONNECT ELECTRICAL POWER AND AIR

SUPPLY BEFORE MAKING ALTERATIONS.

?? NEVER OPERATE MACHINE WITHOUT ALL GUARDS

IN OPERATING POSITION.

?? SAFETY GLASSES SHOULD BE WORN AT ALL TIMES WHEN

OPERATING THIS MACHINE OR MANUALLY CLIPPING WIRE.

Page 5

4

. KEEP HANDS AND LOOSE CLOTHING AWAY FROM ALL MOVING PARTS.

1. Installation and setup Preparation

Use this section to properly unpack ,set into place, and setup the STL1000.

1.1 Inspect the shipping container for any visible damage while the trucking company is still

th ere . If you see any damage, file a damage claim with that trucking company immediately .

Otherwise you may be responsible for any needed repairs.

1.2 Remove the cardboard slip cover and dispose of in accordance with local regulations.

1.3 Cut the banding material securing the output conveyor to the shipping skid. Remove

conveyor from shipping skid and move to the location where the STL1000 is to be located

in your facility .

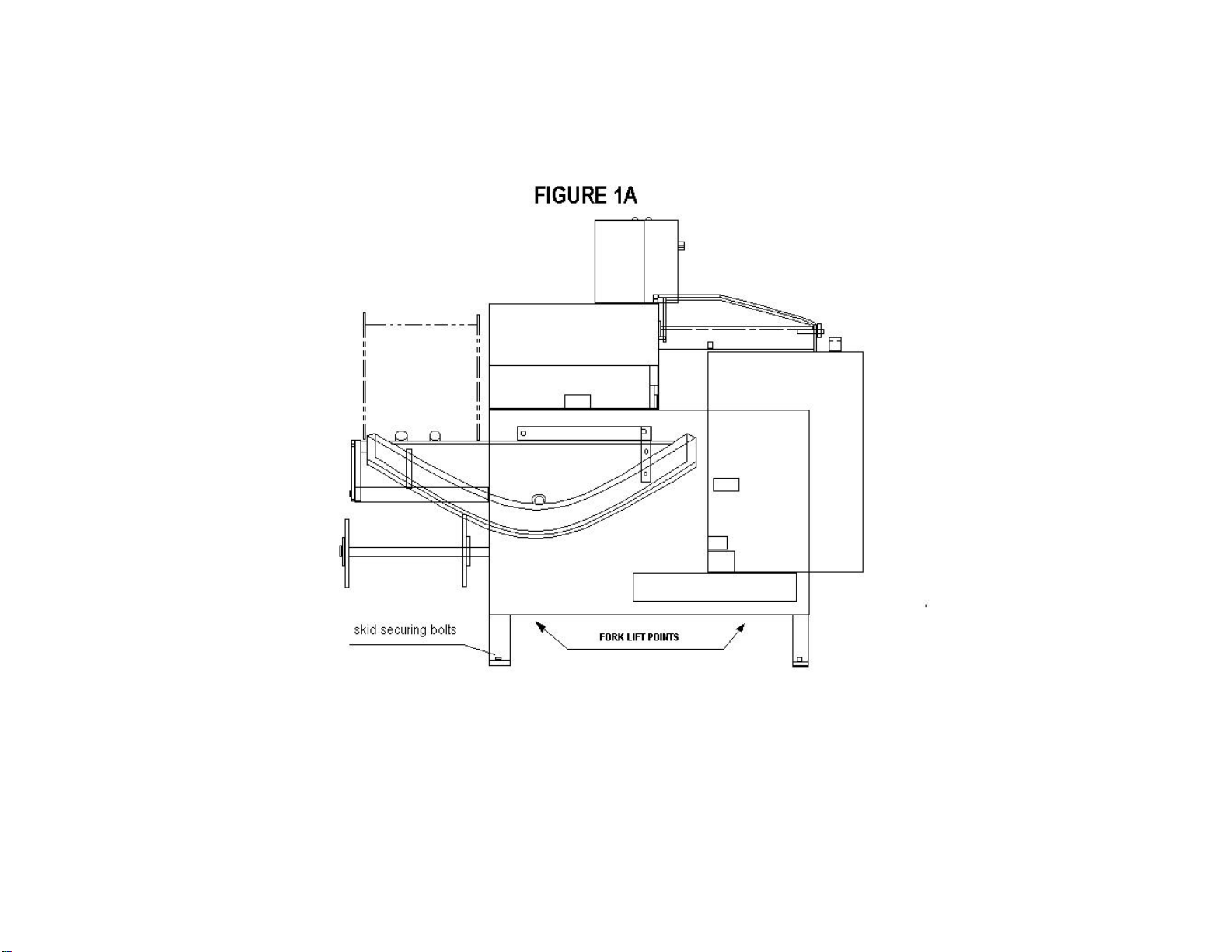

1.4 There are four bolts securing the STL1000 to the shipping skid (REF. FIG. 1A). These

bolts are located one in each foot pad of the STL1000. Use a ¼” Allen wrench to remove

these bolts and discard.

1.5 Locate the orange colored foot pedal secured to the shipping skid. Remove the fasteners

that secure the foot pedal to the skid and discard fasteners. Place foot pedal on the table

top of the STL1000 . CAUTION: Make sure the foot pedal will not fall off the table

top. It may damaged by falling.

1.6 Refer to fig._1A_ for fork lift points of the STL1000. Using a fork lift with a lift capacity of

700kg/2000lbs. , lift the STL1000 from the shipping skid and transport it to the operating

location.

1.7 Have your electrician hook up the appropriate power requirements. Refer to section 3 of

this manual to find the right requirements for your machine CAUTION DO NOT

APPLY POWER TO THE STL1000 !! A GBC technician will check to insure proper

power is present when installation is scheduled . YOU WILL VOID YOUR

WARRANTY IF YOU APPLY POWER.

1.8 You will need to supply compressed air to the STL1 000. Refer to section 3 of this manual

for minimum air requirements . A quick connect is supplied on the air regulator located on

the rear of the machine..

1.9 Be sure that you have TWIN LOOP WIRE and enough prepunched books to run your

machine for at least one hour . Please contact your sales representative if you have any

supply needs.

1.10 Contact GBC National service to schedule a technician to complete your installation.

Page 6

5

Page 7

6

Page 8

7

2. About this Manual REV. 1

2.1 General

This manual is intended as a training and reference document for persons

responsible for installation, service and maintenance of the STL-1000 binder. It is

assumed the reader has basic mechanical and electrical troubleshooting abilities.

This Service Manual, revision ( A ), covers 220 Volt, 3 Phase, 60 Hz STL-1000,

version _1 system.

2.2 Document Control

It is intended that future revisions of this document will be published, please refer

to the revision number on the top of this page to determine the most recent.

2.3 Problem Solving

The path for solving problems with the STL-1000 should proceed in the following

sequence:

1) Find the description of the problem in the table in section 16

2) Evaluate the list of possible causes for the probable one.

3) Proceed to the referenced section (see 4 ) for further diagnosis. Part

replacement instructions (section 18 or 19) or adjustment instructions

(section 6 thru 14 ).

4) If problem is not properly described in the problem column of the

troubleshooting tables of section 16, reread the Theory of Operation

(section 4 ) for insight.

5) If the problem is unsolved call for support with a clear description of the

problem and the results of any unsuccessful solution you have tried.

6) Fill out and Fax the Problem Report Form (section 20 ) after solving

the problem. A strong feedback loop from service personnel is the best

way to improve the design and manufacturing of our products.

Page 9

8

3. Specifications

Use this section to determine proper installation requirements as well as the capabilities

of the STL-1000.

3.1 Purpose

The STL-1000 is designed to automatically supply spool fed Twin Loop elements cut to a

specified length and is automatically staged for the next book to be bound.

Operator hung pre-punched documents are transported to the closing area, bound and are

transported from the bind area to a stacking conveyor.

3.1.1 Dimensions

Machine only: 85” L x 56” W x 50” H (2.16M x 1.42M x 1.27M ).

Smallest doorway machine will fit through 40” (1.016M) wide (with the removal of the

spool holder assembly). NOTE: This unit should only be removed by a GBC service

tech.

Recommended work area: 10 ft. x 10 ft. (3.05M x 3.05M).

Shipping: 65” x 91” x 60” high (1.65M x 2.31M x 1.52M).

3.2.2 Weight

Weight (machine only): 1200 lbs. (545.6Kgms.)

Shipping weight: 1350 lbs. (613.6Kgms.)

3.3 Electrical Power

2.3.1 Voltage 2.3.2 PHASE 2.3.3 Current 2.3.3 Short circuit interrupt

220 VAC, 60Hz 3 15 amps capacity: 2000 A

Page 10

9

3.4 Compressed Air

8 cfm at 80 psi ( 227L/min @ 522K Pa )

3.5 Environment

Ambient air temperatures, 41 degrees F to 104 degrees F. ( 5 degrees C to 40

degrees C.)

Altitude rating, up to 3280 feet ( 1000 meters ).

3.6 Noise Generation

TBD

3.7 Initial Year of Manufacturing: 1999

3.8 Productivity

3.8.1 Cycle Time

The time the system takes to bind a placed document until it is ready to accept the

next document, independent of the operator, is dependent on the specified length

of the Twin Loop element.

The STL-1000 is capable of up to 1,000 books per hour.

3.8.2 Throughput

The number of documents produced in a given time period depends on element

length, document punching quality, but most importantly operator proficiency.

3.9 Book Thickness

3.9.1

Page 11

10

The STL-1000 can successfully bind documents within the capacity of each given

Twin Loop element size. Use the element size chart supplied by your Twin Loop sales

representative to determine the appropriate element for the book to be bound. If book

size is at the maximum for a given size use the next larger size to insure quality closure of

the bound book.

3.9.2 Bind Length

The STL-1000 is capable of a book bind length of a minimum of 3 inches (76mm ) and

with a maximum of 13 inches (330.2mm ).

3.9.3 Book Width

The STL-1000 is capable of transporting books with the unbound edge width of 3 ½’

(85.75mm )to 12’ (304.2mm ).

3.9.4 Hole Quality

The holes must be pre-punched in the paper and be of 2 to 1 or 3 to 1 punch pattern.

The quality of the holes has a direct relationship on the success of the operators ability to load

books on to waiting Twin Loop elements. Cleaner , crisp holes that align well from

one page to the next will speed up the process of loading books on to the STL-1000.

Page 12

11

4. Theory of Operation of the STL-1000

Conditions at Power up of the STL-1000

1. Closing guard must be closed to actuate the closing guard interlock switch IS-1. IS-1 has

two switches in one housing.

A. One side of the IS-1 breaks main power to the E-stop.

B. The other side of IS-1 is used to monitor 24 volts to the P.L.C. at X7

Which shouldn’t be illuminated.

2. P.L.C. is in ready condition should have at least X0, X13 and Y12, or Y13.

Conditions After Power up of the STL-1000

1. Series of events after the depression of the foot switch (FS).

A. X6 on the P.L.C. will illuminate.

B. Y2 to energize Sol-2 (pusher) to advance book to closing area.

C. Y6 to energize 1CR to turn on 1M (feed motor) to feed element to be cut.

D. Y10 to energize 3CR to turn on 3M (belt) to advance element is cut.

2. During element feed cycle:

A. Either the signal from X4 (count prox 2:1) or X10 (count prox. 3:1) will be used

to count the number of element legs to the number entered into the keypad.

Page 13

12

B. Once the entered number is reached Y6 (feed 1M) is turned off.

C. Y4 energized Sol-4 (cut) which charges the air cylinder to swing the knife and

drop the pawl into the element stop gear to stop rotation of the element feed shaft.

At this point the feed shaft should be stopped so the knife can cut a stationary

element. Through P.L.C. timer Sol-4 is deenergized through Y4 to release the

knife and pawl.

Conditions After Power up of the STL-1000 (Continued)

3. Series of events during the book transport and closing cycle:

A. After pusher has advanced LS-2 (forward 1) will close and illuminate X1 on the

P.L.C.

B. Y5 will energize Sol 1 (door) closing doors on the closing area guard. This will

also open IS-2 at X13 and close IS-2 at Y3. (NOTE: IS-2 has two sets of

switches in one housing).

C. Y3 energizes to fire Sol-3, which charges the closing air cylinder to actuate the

closing ram to full down stroke.

D. When the ram reaches its full down stroke LS-3 (close) actuates and illuminates

X2 on the P.L.C. and releases Sol-3 through Y3 to let the ram return to its home

position. NOTE: Home position is fully up.

E. Sol -1 is deenergized through Y5, which opens the guard doors.

F. Sol -2 is deenergized through Y2. The pusher returns home and actuates LS-1,

which illuminates X0 on the P.L.C.

G. Y11 energized 4CR (conveyor 4M) to advance conveyor to a predetermined

distance through an entry from the keypad.

Conditions on a Need Basis

1. Dereel Unit

Page 14

13

A. When dereel switch is on auto, spool prox X3 illuminates when no element is

present Y7 illuminates to fire 2CR which turns on 2M (dereel).

B. When dereel switch is on manually pressing the green button will illuminate X15

then Y7 on the P.L.C. to turn on 2CR (dereel) which turns on 2M.

2. Pitch Selection

A. When pressing 2:1 on the keypad Y12 on the P.L.C. will illuminate and fire Sol-5

to change the air cylinder to shift the feed sprocket. At this time X4 on the P.L.C.

is being used to count 2:1 by prox switch.

Conditions on a Need Basis (Continued)

B. When pressing 3:1 on the keypad Y13 will illuminate on the P.L.C. and fire Sol-6

to charge the air cylinder to shift the feed sprocket. At this time X10 is being used

to count 3:1 by prox switch.

Page 15

14

5. STL-1000 OPERATING INSTRUCTIONS FOR KEYPAD

MAIN MENU

When you first power up the machine you should see the following two lines on the Keypad.

B.COUNTER 0 ( any number may appear)

SETUP MENU 0

Line 1: “B. COUNTER:” = Batch Counter. This counter will count the number of books, which are

bound on the STL1000 and display a running total.

To reset this counter, use the ? arrow key to move the cursor over. When blinking, key in “0” from the

numeric section of the keypad then press “ENTERS”. The value “0” will be displayed.

Li ne 2: SETUP MENU:” The Setup Menu will allow you to make other adjustments to control the

STL1000. Use the ? arrow key to move the cursor over to the ? arrow. Press the “ENTER” key to

get into the Setup menu.

Line 3: “ SERVICE MENU:” The Service Menu will allow our service Technicians to monitor the

STL1000 when making service calls. There is no useful information in this menu for the operator or

setup person. You can get into the Service Menu in the same manner as the Setup Menu.

SETUP MENU

Line 1: “NO. OF LOOPS:”= Number of Loops required to bind your book.

Page 16

15

Use the numeric keypad to key in the number of desired loops and press “Enter”.

The range of amount of loops is limited from five (5) through forty-two (42).

Line 2: “CONVEYOR STEP:” = The amount of travel desired on the Output conveyor. Use the

numeric keypad to key in the amount of desired travel and press “ ENTER”. The range of travel is

limited to one (1) through six (6) inches.

Line 3: “GOTO MAIN MENU:” = This will bring you back to the Main Menu so the operator can

view the batch count as they run the STL1000.

Press the “ENTER” key to return to the main menu.

Line 4: “SERVICE MENU:” = The Service Menu will allow our Service Technicians to monitor the

STL1000 when making service calls. There is no useful information in this menu for the operator or

setup person. You can get into the Service Menu in the same manner as the Setup Menu.

FUNCTION KEYS (fig. 1 Section 5)

There are six “Function Keys” on the keypad, which will allow you to activate certain functions of the

STL1000 during the setup process.

PUSHER ADVANCE / HOME: This key will allow you to transport a prehung book into the closing

area or to discharge a bound book onto the conveyor. Press this key again to return the Pushers back

to the home position. NOTE: A red light will illuminate above the PUSHER key and the message

“AUTOMATIC CYCLE IS NOT READY!!! “ will appear on the display on the keypad Make sure

the pushers are in the home position and the display doesn’t read “AUTOMA TIC CYCLE IS NOT

READY “ to run in automatic mode.

RAM DOWN / UP: This key will allow you close the element of the book in the closing area. Press

this key again to return the Ram to the up position.

NOTE: A red light will illuminate above the RAM DOWN / UP key, also the message “

AUTOMATIC CYCLE IS NOT READY “ will appear on the display on the keypad when the RAM

is in the down position.

3:1 This key will shift a gear in the feed area so you can run with 3:1 pitch elements.

2:1 This key will shift a gear in the feed area so you can run with 2:1 pitch elements.

FEED ELEMENT: This key will feed and cut an element to the desired length.

CUT ELEMENT: This key will cycle the cut unit, can be used to test knife block height setting or if an

element didn’t cut in the auto cycle mode.

Page 17

16

Page 18

17

Page 19

18

6. Spool and Supply Chute Loading the Spool

When viewing from the back of the machine, the spool of Twin Loop wire will rotate in a

clockwise direction (See figure 6-1). For loading a new spool, the following steps are

recommended:

1. Place the spool onto the two rollers with the wire unspooling from the top of the spool.

2. Make sure the end boards of the spool are riding between the flanges of the idler roller (See Figure

6-2). This will place the end boards on the knurled portion of the drive rollers.

3. Unspool approximately 5 feet of wire from the top of the spool. Place the wire over the top of the

cross bar and between the two side guides (See Figure).

Note:

To unspool the wire, twist the collar on the despool button located on the top of the control box to

manual, then push the green button until the desired length has been acquired.

IMPORTANT: Be sure to return the selector collar to auto on the despool button to feed wire

automatically.

Page 20

19

SPOOL AND SUPPLY CHUTE LOADING THE SPOOL

(CONTINUED)

4. Lay the wire inside the storage chute and thread the scrap paper between both drive rollers and

wind it up on the scrap take-up spool in a counter-clockwise direction (See Figure 6-3).

Notes:

1. The scrap paper should be wound taunt to prevent it from breaking when the spool drive starts up.

2. The storage chute has a sensor at the bottom to control the spool drive. The sensor will start and

stop the spool drive on demand to replenish the supply of wire to the storage chute.

Page 21

20

7. Spool and Supply Chute Adjusting the Supply Chute

The supply chute is designed to be used in three different positions (see figure 7-1). The upper position

is for larger size wire -1” and 1 ¼”. The middle position is for medium sizes 9/16” through 7/8’. The

lower position is for the small size wire - ¼” through ½”. The smaller sizes need more weight inside the

supply chute to prevent the wire from unspooling on the bottom side of the spool. On the other hand,

the larger and medium sizes will stretch too much, causing misfeeds in the feed area if left in the lower

position.

For the Small and Medium Sizes:

1. Loosen the handle and slide the storage chute to the required position.

2. Tighten the handle to secure the storage chute.

For the Larger Sizes:

1. Remove the right and left -hand supply chute brackets and replace them with brackets

#4270035 and #4270036, which are, include with the machine.

2. Fasten the right hand bracket to the upper mounting hole (see figure 7-1).

3. On the left side, swing the supply chute adjustment bracket over and fasten the left bracket as

shown in figure 7-1.

Page 22

21

8. Feed and Cut Feed Wheel Guide Adjustment

The outboard guide on the feed wheel (see Figure 8-1) should be adjusted so that there is

approximately 1/16” (.06) clearance for the wire. Make sure the outboard guide does not rub against

the feed wheel. See figure 8-1 for the correct orientation of the wire.

Page 23

22

up

9. Feed and Cut Height and Width Adjustment of Guides

The upper and side guides should be adjusted so that the Twin Loop wire will travel back and forth

freely (see Figure 9-1) but without too much room to move around. The following steps are

recommended:

1. Cut a 12” long piece of Twin Loop wire element from the supply chute and use it as a set-

Sample.

2. Loosen the two adjustable handles for the upper guide and the side guides (see Figure 9-1).

3. Insert the 12” long sample as shown in Figure 9-1.

4. To set the .01 clearance, use three sheets of 20# bond paper as a gauge. Hold the open side of the

wire up against the sideplate of the feed assembly. Insert the three sheets of paper and slide the side

guide up against the paper. Tighten the handles to secure the guide and remove the paper.

5. Repeat step 4 for the upper guide.

Page 24

23

FEED AND CUT HEIGHT ADJUSTMENT OF CUTTING BLOCK

Using a 5/32 hex key, loosen the two (2) screws which secure the cutting block (see Figure 9-1).

Adjust the height of the cutting block to allow the Twin Loop wire to pass freely under it.

Tighten the screws to secure the cutting block. Note: The height of the cutting block must be adjusted

for each wire size.

The set-up of the feed area is now complete. To double check, insert the 12” long sample piece again,

into the guides. Slide the sample forward until the feed sprocket stops it. Now rotate the handwheel

(see Figure 9-1) in the clockwise direction and continue feeding the sample all the way through and past

the cutting block. If the element does not go through freely, repeat step #4 in the “ Height and Width

Adjustment of Guides” section or repeat the above step.

10. Loading Area

Before you load a book for binding, you need to make a few adjustments to the loading area.

The following steps are recommended:

Select either the large or small wire holder, the small wire holder should be used for element size no

larger than 5/16. Use the large wire holder for all other sizes. Part number for the large support guide is

460003900, and the part number for the small support-guide is 0460004000.

Adjusting the wire holder: using your 12” long sample piece of wire feed it through the feed assembly by

turning the hand wheel (see figure 9-1) right up to the loading area. Adjust the height of the wire holder

(see 10-1) by loosening the two adjusting knobs located on the backside of the machine which hold the

holder in place. Slide the holder up or down to allow for free movement of the wire. Enough room

should be provided so the wire sits back on a 15-degree angle as shown in figure 10-1. This angle will

Page 25

24

make it easier to load the book. Tighten the two adjusting knobs to secure the wire holder. Load book

onto element and adjust rear rail in the book loading area. To adjust, loosen adjusting screws and slide

up to book loosely.

Tighten adjusting screws.

11. Book Transport Area

At this time, check to see if the pusher will hit the rear rail or be pushed down because of rear rail

interference (see figure 11-1). To prevent the interference, push the pusher foot down below the table

top and tighten the set screw located on the top of the pusher foot (see figure 11-2) to lock in place.

Note: If you lock down one of the pusher feet, you must lock down the foot directly in front of it or it

will crash into the closing rail.

Page 26

25

12. Closing Area

Adjusting the closing rail (For the following see figure 12-1).

1. Open closing guard and prop open with prop rod.

2. Loosen the adjusting screws, which secure the closing rail located in front of the closing area

And slide toward the front of the machine.

Page 27

26

3. Close the closing guard.

4. Twist the red emergency stop button located on the front of the machine to supply power to

the machine.

5. Using the hand wheel on the upper right hand side of the closing head, turn hand wheel until

the indicator points the proper wire size to be closed.

6. Push the pusher advance/home button on the control panel and advance the book under

Closing ram (a red light will illuminate above button).

7. Open closing guard.

8. Adjust the closing rail forward so the open side of the wire element is up against the back of

the closing area. Do not apply pressure to the book. Tighten the adjusting screws to lock the

Closing rail into position.

9. Close closing guard.

10. Press ram down/up button and close wire. Press ram down/up button to release the closed

wire. Adjust wire closure with hand wheel and reclose wire until proper closure is attained.

11.Press pusher advance/home button to return pushers to their home position.

Figure 12-1

Page 28

27

13. CLOSING HEIGHT ADJUSTMENT

To adjust height of the closing ram, the following steps are recommended:

1. The pointer for the Twin Loop Size Gauge (see Figure 13-1) will move up or down. A hand wheel

is provided on the right side of the closing area. This hand wheel is to be used to adjust the height.

Page 29

28

2. The size gauge is used to accurately adjust the closing height. After closing a sample book, you may

need to make further fine adjustments to get the proper closing of the wire. See figure 13-2 for

proper closing of Twin Loop elements.

3. Never cycle the closing ram under power without checking the size gauge first.

FIGURE 13-1 FIGURE 13-2

14. Loading the Book

Books with 2-Piece Flush Cut Covers:

Stack the books with the front covers up; rotate the back cover to the top (see Figure 14-1). This

ensures that the wire loop closure will be inside and in the back of the book.

Page 30

29

FIGURE 14-1

Pick up the two covers and the body of the book; jog it on the side with the binding edge down. The

back page (not the back cover) should face the operator (see figure 14-2).

Align the holes with the Twin Loop tines and lay the book toward you (see figure 14-3) and press the

foot pedal to cycle the STL1000.

FIGURE 14-3

Loading The Book (continued)

Books With Oversized or Wrap-Around Covers:

Due to its design, the STL-1000 is well suited for non -standard cover styles.

Page 31

30

Load the body of the book (front) onto the Twin Loop tines, then load the covers (folded back to

back) on the tines and push the foot pedal.

15. Air Solenoid Explanation

This write up is to understand the location and function of the five air solenoids (see fig 15-1) on the

STL1000.

Page 32

31

To get to the solenoids to either replace or adjust, the rear panel must be removed. Once the panel is

removed, the air solenoids will be before you, working left to right.

Solenoid # 1 Guard Solenoid is responsible for opening for opening and closing guard doors to

allow entrance and exit of books into the closing area .

Solenoid # 2 Pusher is responsible for the transporting the book from loading station to closing area

and to the conveyor.

Solenoid # 3 Closing Head Solenoid is responsible for the actuation of the closing ram.

Solenoid # 4 Cutter Solenoid is responsible for the actuation of the element cutting knife.

Solenoid #5&6 Feed Sprocket Selection is responsible for the selection of 2:1 to 3:1 feed sprocket.

Solenoid #5 for 2:1, solenoid #6 for 3:1. This solenoid is different from solenoid #1

through 4 because it is a dual circuit solenoid to prevent crushing of the element on

power down.

Controlling actuation speed adjusts consist of regulating air being discharged through adjusting screws

on the exhaust mufflers (see figure 15-2). To slow down actuation, loosen jam nut on muffler and screw

in setscrew. To speed up action, back setscrew out . Once desired actuation speed has been achieved,

tighten jam nut.

16. Trouble Shooting Guide

Page 33

32

PROBLEM PROBABLE CAUSE SOLUTION

Dereel unit won’t run.

Dereel unit runs on.

Wire tangled with scrap paper. Adjust supply chute height to

Check height of spool prox

Faulty spool prox switch. Replace prox switch.

Wire stretching or

sagging on the bottom

Dereel switch on manual. Turn collar of dereel switch to

auto.

Wire not properly routed along

supply shoot.

Route wire from top of spool to

supply chute and up to wire

cutting unit. Make sure wire is

routed to pass in front of prox

switch located on the supply

chute.

prevent wire from tangling with

scrap paper.

The face of the prox switch

switch.

should be flush or slightly

protruding on the supply chute.

Supply chute. Adjust supply chute height to

accommodate wire size.

of spool.

Wire not traveling

Wire guides too tight. Check width of feed wheel

smoothly through wire

feed and cutting unit.

PROBLEM PROBABLE CAUSE SOLUTION

guide.

Check side and upper guides,

also knife cutting block height.

Page 34

33

Feed sprocket not

turning.

Scrap paper tearing.

Scrap paper not being

Worm gear clutch pad. Needs

adjustment or clutch pads need

cleaning.

Lockout pawl too low. With the air on, adjust height of

Scrap paper take up spool. Adjust tension spring behind

Scrap paper take up spool. Adjust tension spring behind

spooled.

Improper number of

Air pressure. Make sure a constant air supply

loops.

Water separator Empty water separator.

Airline oiler Check airline oiler.

Locking pawl. Check height of locking pawl.

Make sure the air regulator on

PROBLEM PROBABLE CAUSE SOLUTION

Remove collar, spring, pressure

collar, key and worm gear.

Clean all parts with alcohol and

reassemble. Adjust tension

spring to full compression.

lockout pawl and adjust with

height adjustment nut to just

clear lockout gear.

panel in line with paper take up

spool. Adjust to have slight

pressure.

panel in line with paper take up

spool. Adjust to have slight

pressure.

is maintained at 100

PSI.

the STL-1000 is set at 80 psi.

Should just clear the locking

gear.

Page 35

34

Improper number of

proper count has been achieved.

Locking gear. Check screws in locking gear for

loops. (continued)

Cut length’s tails

Counting gear. Loosen setscrew on counting

Counting prox sensor. Rotate counting gear and check

Locking pawl. Disconnect air. With wire in

uneven.

PROBLEM PROBABLE CAUSE SOLUTION

tightness.

gear and slightly advance

clockwise and test. Repeat until

NOTE: Disregard first element

after each adjustment

for flashing light on the PLC.

Inside the control box. Check

x4 for 2:1 and x10 for 3:1. If

not flashing, prox switch should

be replaced.

machine, seat locking pawl into

lockout gear. Check position of

wire in relation to the cutting

block to cut in the center of the

wide leg of the element. If

adjustment is needed, loosen

screw on the side of locking

pawl. Push pawl into locking

gear and rotate until ideal

position has been acquired.

Tighten screw. NOTE: Screw

can be accessed through side

plate.

Page 36

35

Uneven wire closure.

Anvil adjustment. Loosen two socket head screws

at the back of the anvil. Adjust

anvil with the two hex head bolts

underneath the anvil to achieve

even end to end closure.

NOTE: Tighten socket head

screws after each adjustment to

insure accurate closure. Also

tighten jam nuts on the hex head

after final adjustment.

Wire closing with an

over or under bite.

Table straps. Utilize one of two table straps to

control over or under bite.

There are two sizes of table

straps and two different

locations to mount them.

Experiment with the different

straps and locating positions.

The straps elevate the binding

edge of the book to control the

books influence in proper

closure of wire elements.

Pushers won’t advance

when foot switch is

depressed.

Mai n power. Check main power switch

located on the main power box

is in the ON position.

E-STOP or Interlock switches. Check E-STOP to insure it is in

the ON position and also check

all guards to be sure that they

are in their full closed position.

Main air supply. Check airline connections.

Check air regulator is set at 80

psi.

PROBLEM PROBABLE CAUSE SOLUTION

Page 37

36

Pushers won’t advance

when foot switch is

depressed. (continued)

Pushers advance then

LS1 home switch. Remove center panel on the

LS2 needs to be adjusted. Remove center panel on

stop.

Pushers advance, safety

Door switch IS2. Check closing doors for any

doors close, cycle stops.

PROBLEM PROBABLE CAUSE SOLUTION

tabletop (section 18 drawing 2

detail #23). Located LS1 on the

left side of the air cylinder

Loosen the clamp, which

secures LS1 to the air cylinder.

Slide LS1 to the left or right until

the LED on LS1 illuminates.

Tighten clamp to secure to air

cylinder. Depress foot switch

and test for a completed cycle.

Replace tabletop.

tabletop (section 18 drawing 2

of 3 detail #23). Locate LS2 on

the right side of the air cylinder).

Loosen the clamp, which

secures LS2 to the air cylinder.

Close safety hood, turn power

on, press pusher advance key on

the keypad. This will advance

the pushers to the right. Slide

LS2 to the right or left until the

LED on LS2 illuminates.

Tighten clamp to secure LS2 to

the air cylinder. Depress pusher

key to return the pushers to their

home position. Depress foot

switch and test for a complete

cycle. Replace tabletop.

obstruction.

Page 38

37

Pushers advance, safety

doors close, cycle stops

(continued)

Pushers advance, safety

doors close, closing

head comes down and

machine cycle stops.

Door switch IS2. This adjusting screw located on

the exit door is used to set IS2,

which completes the circuit for

PLC numbers, X13 and Y3.

X13 must be illuminated before

Y3 circuit can be completed.

Book thickness. Failure to adjust closing unit

height. Book is too thick and

not letting the closing ram make

LS3.

LS3 needs adjustment. Remove rear cover on closing

area.

Locate the air cylinder).

Mounted on the air cylinder is

LS3.

Turn power on.

Depress the ram down key on

the keypad.

Loosen the clamp that secures

LS3 to the air cylinder and slide

LS3 to the right or to the left

until the LED illuminates.

Tighten clamp.

NOTE: There shouldn’t be any

books or wire under closing ram

during this adjustment.

Depress ram up key and test

cycle.

17. MAINTENANCE REQUIREMENTS

FOR THE STL1000

Page 39

38

1. EMPTY WATER SEPARATOR DAILY

A. To empty water separator, loosen bleeder valve located on the bottom of the water

separator.

2. CHECK AIR LINE OILER WEEKLY

A. Fill only with a good quality air tool oil.

B. To fill with air tool oil:

1) Disconnect air supply.

2) Remove oil reservoir cup by turning a 1/4 turn, and then pull cup downward.

3) Fill reservoir with good quality air tool oil to max line.

4) Install oil reservoir.

5) Connect air supply.

3. OIL PUSHER AXLES BI-WEEKLY

A. To oil pusher axles:

1) Remove center tabletop by removing two end screws.

2) Locate pusher axles.

3) Apply two or three drops of 3&1 oil the length of each axle.

4) Return center table and tighten in place.

WARNING: DO NOT APPLY GREASE OR HEAVY OIL. THIS WILL

DESTROY THE LINAR BEARINGS!!!

FILTER/REGULATOR/LUBICATOR (FRL)

The filter portion (see Figure 17-1) of the FRL is used to remove moisture from the compressed air

supply. Before the water level reaches the “MAX LEVEL” line (see figure 17-1), you should drain the

water. How often you have to drain depends on the amount of humidity in the air. To drain the filter,

turn the knob on the bottom of the filter in the “O” (open) direction. Turn the knob in the “S” (shut)

Page 40

39

direction after all of the water has drained. NOTE: a ¼ inch soft nylon tube can be attached to the end

of the drain so that the water can be emptied into a container.

The regulator portion (see figure 17-1) of the FRL is used to regulate the air pressure being supplied to

the machine. The proper setting is 80 PSI. To adjust the pressure, pull the regulator knob down and

turn clockwise to reduce the pressure and turn counter-clockwise to increase the pressure. Push the

knob back up to lock it into position.

WORN PARTS

FEED AND CUT AREA

Page 41

40

The only wear item in the feed area is the knife blade (see figure 17-2). If the wire has a burr on it after

cutting, or, if a groove has worn into the cutting edge of the knife, it is time to rotate the blade. The knife

blade has four cutting edges on it. To switch to a new cutting edge, the following steps are

recommended:

A. Disconnect air and electrical power from the machine.

B. Remove feed cover.

C. Using a 5/32” hex key, loosen and remove the two screws, which secure the cutting block.

D. Loosen the jam nut and remove the pivot screw.

E. Flip the blade over to a new cutting edge.

F. Apply grease to the pivot screw and the mating surfaces of the cutting block and the knife blade.

G. Install the knife blade by tightening the pivot screw enough so the blade pivots freely with zero

clearance to the cutting block.

H. Tighten the jam nut to secure the pivot screw.

I. Apply grease to the pin for the upper pivot joint and attach the knife blade

USE CAUTION! KNIFE BLADE IS VERY SHARP!!

J. Mount the cutting block.

Page 42

41

18.

Exploded

Assembly

And

Parts

List

Page 43

42

Loading...

Loading...