Page 1

GBC FOTON 30

AUTOMATED LAMINATOR

INSTALLATION & OPERATION MANUAL

Document Number: CBT10000 Rev B

Do not duplicate without written

Brands

permission

from ACCO

Page 2

ACCO Brands reserves the right to make changes to this publication and to the products described in it without notice. All

specifications and information concerning products are subject to change without notice. Reference in this publication to

information or products protected by copyright or patent does not convey any license under the rights of ACCO Brands or

others. ACCO Brands assumes no liability arising from infringements of patents or any other rights of third parties.

This publication is copyrighted © 2018 by ACCO Brands. All rights reserved.

Page 3

1. Safety

YOUR SAFETY, AS WELL AS THE SAFETY OF OTHERS IS

IMPORTANT TO ACCO. IN THIS INSTRUCTION

MANUAL AND ON THE PRODUCT ARE IMPORTANT

SAFETY MESSAGES. BEFORE YOU INSTALL OR USE

THE MACHINE, READ AND FOLLOW ALL THE SAFETY

NOTICES CAREFULLY IN THIS CHAPTER.

Observe all the safety information provided.

Observe all safety warnings. Never remove safety

warnings or other information from the equipment.

Read all of the instructions and save these

instructions for further use.

The safety alert symbol precedes each safety

notice in this manual. The symbol indicates a

potential personal safety hazard to you or others, as

well as cause product damage or property damage.

This safety alert symbol indicates a potential

electrical shock. It warns you not to open the

laminator and expose yourself to hazardous voltage.

DO NOT OPEN. NO USER SERVICABLE PARTS INSIDES.

REFER SERVICING TO QUALITFIED SERVICE PERSONAL.

THE FOLLOWING WARNINGS ARE FOUND ON THE

FOTON 30 AUTOMATED LAMINATOR.

CAUTION Hot Surface: Laminator rollers can

be in excess of 260° F/ 126.7° C. Please use caution

and do not touch the rollers.

WARNING: Do not attempt to service or

repair the laminator.

WARNING: do not connect the

laminator to an electrical supply or attempt to

operate the laminator until you have completely

read these instructions. Maintain these

instructions in a convenient location for future

reference.

General safeguards

• Use this laminator only for its intended

purposes as according to the

specifications outlined in the operating

instructions.

• Keep hands, long hair, loose clothing and

articles such as necklaces or ties away

from the front of the feed rollers to

avoid entanglement and entrapment.

• When opening the top door of the

laminator, avoid contact with the

internal rollers when laminator is

powered on or shortly after the

laminator has been turned off. The

rollers can reach temperatures in excess

of 260º F / 126.7° C.

• Keep hands and fingers away from the

path of the sharp film cutter blade

located at the film exit.

Do not place the laminator on an

unstable cart, stand or table. An

unstable surface may cause the

laminator to fall resulting in serious

bodily injury. Avoid quick stops,

excessive force and uneven floor

surfaces when moving the laminator on

a cart or stand.

• Do not defeat or remove electrical and

mechanical safety equipment such as

interlocks, shields and guards.

• Do not insert objects unsuitable for

lamination.

• Do not expose laminator to liquids.

Page 4

Electrical Safeguards

• The equipment should be connected to an

easily accessible and grounded (3-pin)

receptacle (socket outlet) near the

equipment.

• This laminator must be connected to a supply

voltage corresponding to the electrical rating

as indicated on the serial plate located on the

rear of the machine.

• Unplug the laminator before moving it, or

when it is not in use for an extended period

of time.

• Do not operate the laminator with a damaged

power supply cord or plug.

• Do not overload electrical outlets as this can

result in fire or shock.

• Do not alter the attachment plug. This plug is

configured for the appropriate electrical

supply.

• The unit is intended for indoor use only.

• Disconnect the attachment plug from the

receptacle to which it is connected and keep

the power supply cord in your possession

while moving the laminator.

• Do not operate the laminator with a damaged

power supply cord or attachment plug, upon

occurrence of a malfunction, or after

laminator has been damaged. Contact an

authorized GBC service representative for

assistance.

CAUTION: The receptacle must be located

near the equipment and easily accessible. Do not

use an extension cord.

GBC Technical Service

To order replacement accessories, service, parts,

or an Equipment Maintenance Agreement, please

contact GBC Technical Service and Support at:

United States

ACCO Brands GBC Technical Service and Support

4 Corporate Drive Lake Zurich, IL 60047-8997

www.gbcconnect.com

1-800-723-4000

Canada

Ontario and Quebec – 1-800-268-3310

All other Provinces – 1-800-268-3447

Local 905-595-3100

Callcentre@GBCCanada.com

Mexico

(55) 1500 5778

Lada SIN costo: 01 800 759 6825

serviciotecnico@acco.com.mx

Page 5

2. Warranty

Limited 2 year/5000 Laminates Warranty; USA,

Mexico, and Canada

ACCO Brands USA LLC, ACCO Brands, 4 Corporate

Drive, Lake Zurich, IL 60047 (in Mexico, ACCO Brands

Mexicana, Neptuno 43, Fraccionamiento Nueva

Industrial Vallejo México 07700 D.F. México), (in

Canada, ACCO Brands Canada Inc., 7381 Bramalea

Road, Mississauga ON L5S1C4) (each, respectively,

“ACCO Brands”) warrants to the original purchaser

that this ACCO Brands product is free from defects in

workmanship and material under normal use and

service for a period of: two (2) years or 5000

laminates whichever comes first for parts.

ACCO Brands’ obligation under this warranty is limited

to replacement or repair, at ACCO Brands’ option, of

any warranted part found defective by ACCO Brands

without charge for material or labor. Any replacement,

at ACCO Brands’ option, may be the same product or a

substantially similar product that may contain

remanufactured or refurbished parts. This warranty

shall be void in the following circumstances:

(i) if the product has been improperly installed or

misused,

(ii) if the product has been damaged by negligence or

accident, or

(iii) if the product has been altered by anyone other

than ACCO Brands or ACCO Brands’ authorized agents.

Without limiting the generality of the previous

paragraph, ACCO Brands’ obligation under this limited

warranty does not include:

(iiii) damage caused to the rollers by knives, razors, or

other sharp tools; by any foreign objects falling into

the working area of the laminator; or by cleaning the

laminator with solutions or materials that harm its

surfaces;

For warranty execution, please contact ACCO Brands

at: 800-723-4000 or www.gbcconnect.com in the USA

800-263-1063 or www.gbccanada.com in Canada (55)

1500 5578 or www.accomexico.mx in Mexico

TO THE EXTENT ALLOWED BY APPLICABLE LAW,

THIS WARRANTY IS IN LIEU OF ALL OTHER

EXPRESSED WARRANTIES. REPRESENTATIONS OR

PROMISES INCONSISTENT WITH OR IN ADDITION

TO THIS WARRANTY ARE UNAUTHORIZED AND

SHALL NOT BE BINDING ON ACCO BRANDS. TO

THE EXTENT PERMITTED BY APPLICABLE LAWS,

ANY IMPLIED WARRANTIES (IF APPLICABLE) ARE

LIMITED IN DURATION TO THE DURATION OF

THIS WARRANTY. SOME STATES AND

JURISDICTIONS DO NOT ALLOW LIMITATIONS ON

HOW LONG AN IMPLIED WARRANTY LASTS, SO

THE ABOVE LIMITATION MAY NOT APPLY TO

YOU. TO THE EXTENT PERMITTED BY APPLICABLE

LAW, IN NO EVENT SHALL ACCO BRANDS BE

LIABLE FOR ANY SPECIAL, INCIDENTAL, PUNITIVE,

EXEMPLARY, CONSEQUENTIAL OR SIMILAR

DAMAGES, WHETHER OR NOT FORESEEABLE.

SOME STATES AND JURISDICTIONS DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF

SPECIAL, INCIDENTAL, PUNITIVE, EXEMPLARY,

CONSEQUENTIAL, OR SIMILAR DAMAGES, SO THE

ABOVE EXCLUSION OR LIMITATION MAY NOT

APPLY TO YOU.

FOR CONSUMERS WHO HAVE THE BENEFIT OF

CONSUMER PROTECTION LAWS OR

REGULATIONS IN THEIR JURISDICTION OF

PURCHASE OR, IF DIFFERENT, IN THEIR

JURISDICTION OF RESIDENCE, THE BENEFITS

CONFERRED BY THIS WARRANTY ARE IN

ADDITION TO ALL RIGHTS AND REMEDIES

CONVEYED BY SUCH CONSUMER PROTECTION

LAWS AND REGULATIONS.

To the extent permitted by law, this warranty is

not transferable and will automatically terminate

if the original product purchaser sells or

otherwise disposes of the product.

This warranty gives you specific legal rights. Other

rights, which vary from jurisdiction to jurisdiction,

may exist. In addition some jurisdictions do not

allow (i) the exclusion of certain warranties, (ii)

limitations on how long an implied warranty lasts

and/or (iii) the exclusion or limitation of certain

types of costs and/ or damages, so the above

limitations may not apply.

Page 6

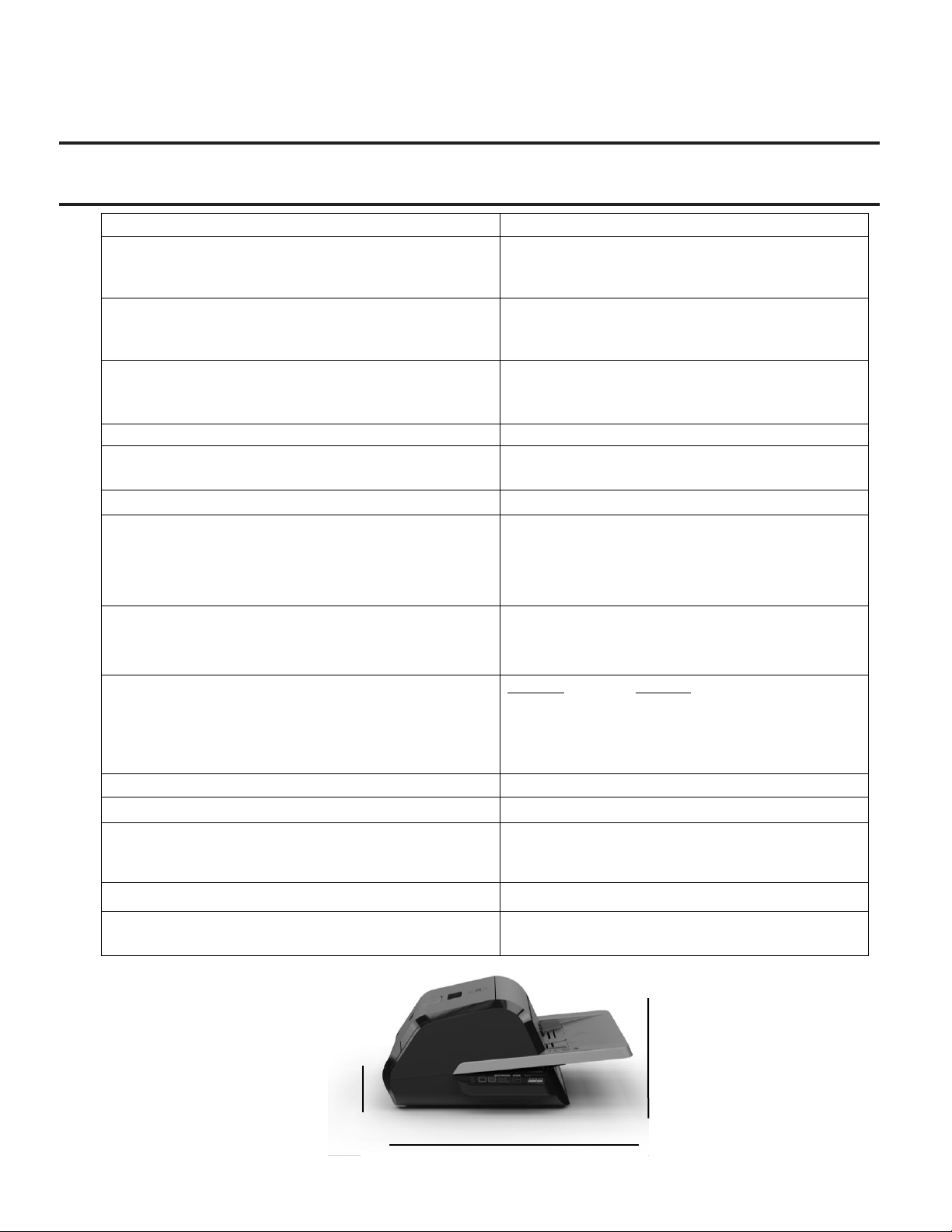

Model

FOTON 30 Automated Laminator

Operating Speed

3mil (75mic) 29.1"/min (700mm)

4mil (100mic) 25.6"/min (670mm)

5mil (125mic) 23.6"/min (650mm)

Operation Modes

Auto Feed / Auto Cut

Manual Feed / Auto Cut

Manual Feed / Manual Cut

Warm-up Time

3.5 min.

75mic/3mil

3.5 min. 100mic/4mil

4 min.

125mic/5mil

30 Sheets 75gsm paper

Maximum Film Width

12.01” (306mm) – Rest of World

11.5” (292mm) – North America

Maximum Document Thickness

250gsm Manually Fed

Document Lengths Supported

Document Widths Supported

Minimum 6” (152mm)

Maximum 17” (432mm)

Minimum 5” (127 mm)

Maximum 11.69” (297mm)

Auto Feeder Media Weight

Manual Feed Media Weight

High Reliability: 64 – 120 gsm

Variable Reliability: 121 – 220 gsm

64 – 250 gsm

Dimensions:

Width

Height

Depth

Weight

Machine: Shipping:

22.7” (57.7 cm) 27” (68.6 cm)

9.6” (24.5 cm) 15” (38.1 cm)

18.8” (47.8 cm) 22.7” (57.8 cm)

21lbs (9.5kgs) 32.8lbs (14.9kg)

Auto Shut Off

15 minutes of inactivity

Duty Cycle

80 documents per week

Electrical Requirements

Voltage

Receptacle

120V, 60Hz

NEMA 5-15P

Fuse

Yes (internal & non-replaceable)

Operating Environment

41 – 95 (F) / 5 – 35 (C)

Maximum Altitude of 2,000m

Height

Width

Depth

Figure 1. Foton 30 Dimensions

3. Specifications

Page 7

FCC Class B Notice

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

This device may not cause harmful

interference.

This device must accept any interference

received, including interference that may

cause undesired operation.

NOTE: This equipment has been tested and found

to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference in a residential

installation. This equipment generates, uses, and

can radiate radio frequency energy and, if not

installed and used in accordance with the

instructions, may cause harmful interference to

radio communications. However, there is no

guarantee that interference will not occur in a

particular installation. If this equipment does cause

harmful interference to radio or television reception,

which can be determined by turning the equipment

off and on, the user is encouraged to try to correct

the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the

equipment and receiver.

- Connect the equipment into an outlet on a

circuit different from that to which the

receiver is connected.

- Consult the dealer or an experienced

radio/TV technician for help.

Canada Class B Notice - Avis

Canada, Class B

This Class B digital apparatus complies with

Canadian ICES-003.

Modifications

Any modifications made to this device that are

not approved by ACCO Brands may void the

authority granted to the user by the FCC and/or

by Industry Canada to operate this equipment.

Page 8

4. Installation

Service

WARNING:

the laminator.

result in

Disconnect the plug from the receptacle and contact

Customer Service when one or more of the following

has occurred.

severe

•

The

power supply cord or attachment plug is

damaged.

• Liquid has been spilled into the laminator.

• The laminator is m

mishandled.

• The laminator does not operate as described in

these instructio

Installation

• Shipping damage should be brought to the

immediate attention of the delivering carrier.

• Place the laminator on a stable flat surface

capable of supporting 50 lbs.

• The surface should be at least 30” high to

assure comfortable positioning during

operation. All four rubber feet should be on the

supporting surface.

• Connect power cord to an appropriate power

source. Avoid connecting other equipment to

the same branch circuit to which the laminator

is connected as this may cause nuisance

tripping of the circuit breaker or blown fuses.

• The laminator should be positioned to allow

exiting film to drop freely to a flat surface.

Accumulation of laminated documents as they

exit the laminator may cause a jam.

• Avoid placing laminator near sources of heat or

cold. Avoid locating the laminator in the direct

path of forced, heated or cooled air.

Caring for Foton 30

The only maintenance required by the operator is to

periodically clean the rollers. Keeping the rollers clean

ensures that your finished items will not be damaged by

dirt and adhesive build-ups.

Do not attempt to service or repair

Failure

to observe this warning could

personal injury or death.

alfunctioning after being

ns.

CAUTION: the following procedure is performed

while the laminator is hot. Use extreme caution.

WARNING: Do not apply cleaning fluids or

solvents to the rollers.

WARNING: Do not attempt to laminate

adhesives marked ‘Flammable’.

WARNING: Do not expose laminator to liquids.

1. Power the machine on, wait for it to completely

warm up.

2. Open the laminator door using the silver latch.

3. Clean the top rollers with a clean, damp lint-free

cloth. If there are any adhesive build-ups, you

may use isopropyl alcohol instead of water.

4. Lift leading film edge up to the handle of the

cartridge.

5. Clean the bottom rollers with a clean, damp lint-

free cloth. If there are any adhesive build-ups,

you may use isopropyl alcohol instead of water.

6. Place the leading film edge into proper position

and close the door.

7. Press and hold the RUN/STOP button for 5-7

seconds to manually advance the rollers.

8. Open the laminator door using the silver latch.

9. Repeat steps 4 – 6.

Note: Do not use metal scouring pads to clean the heat

rollers!

WARNING: Do not laminate glitter and/or

metallic items. Damage to the rollers may result.

The side covers and feed table can be cleaned with a

lint-free cloth and a mild detergent.

Page 9

Page 10

Page 11

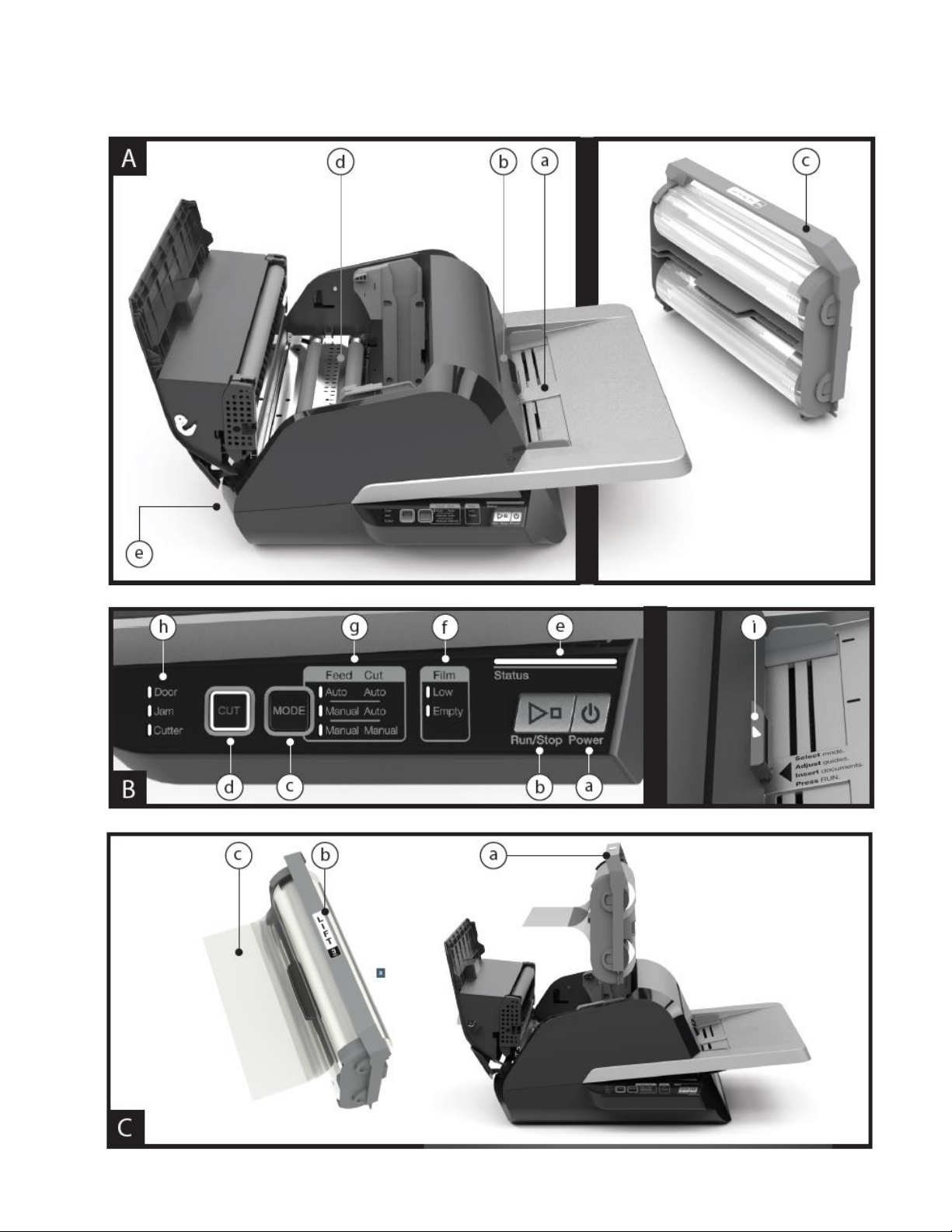

5. Feature Guide

A. GETTING TO KNOW YOUR LAMINATOR:

(Shown in image A above)

a. FEED TRAY & SIDE GUIDES:

i. Place document(s) to be

laminated and use the slide guides

to minimize skew. Flip out

extension for larger documents.

b. FEEDER/FEEDER DOOR:

i. Feeds document into laminator. A

red light on the door will indicate

that a mis-feed has occurred.

Open the door to clear any misfeeds.

c. LAMINATOR DOOR:

i. Door that gives access to the inner

parts of the laminator: rollers, film

cartridge, etc.

ii. To Open: pull on the silver latch,

and lift up

iii. To Close: gently lower using the

silver latch, and push latch closed.

DO NOT push down on the

laminator door to close.

d. FILM CARTRIDGE:

i. Replace the film cartridge when

empty or when a different

thickness is required. See

CARTRIDGE FILM LOADING for

details.

e. LAMINATORS ROLLERS:

i. Rollers heat-up to activate the

adhesive on the film and apply the

pressure to ensure the film sticks

to the document.

f. AUTO TRIMMER:

i. When in Auto Cut modes, the

trimmer finds the leading and

trailing edge of the document and

cuts the film. In Manual Cut

mode, it will cut the film when the

CUT button is pressed.

B. CONTROL PANEL: (Shown in image B above)

BUTTONS

a. POWER – turns the machine on/off. After

15 minutes of no use, the machine will

automatically turn off.

b. RUN/STOP – used to start and stop the

laminator.

i. Dual Function – Manual Advance:

Continuously hold the button to

manually advance the laminator

rollers. This can be used to clear

jams and debris for cleaning.

c. MODE – allows users to toggle through

three modes of operation.

i. Auto Feed / Auto Cut – best for

standard paper sizes printed on

20-32lb bond paper.

ii. Manual Feed / Auto Cut – best for

standard paper sizes on heavy

paper stocks that won’t Auto

Feed.

iii. Manual Feed / Manual Cut – best

for odd shaped and nonrectangular documents.

d. CUT – pressing this button will cycle the

trimmer to cut the film one time. This

button is primarily used in Manual Cut

mode.

INDICATORS

e. STATUS – communicates the status of the

machine:

i. Solid Green = ready to use

ii. Green Blinking Sequence =

running

iii. Solid Amber = warming up

iv. Amber Blinking Sequence =

warming up and RUN command

accepted. Will begin laminating

once ready.

v. Solid Red = error status

f. FILM – LED light will indicate when film is

low (approx. 30% remaining) or is empty.

i. Low = Amber LED light

ii. Empty = Red LED light

g. MODE – green LED light identifies what

mode of operation the machine is in.

h. ERROR MESSAGE – communicates error

messages that need to be resolved.

i. DOOR: one or both doors are

open

ii. JAM: the machine may encounter

two types of jams:

1. Laminator jam: push and

hold the RUN button to

manually advance the

rollers to clear itself.

2. Feeder jam: open the

feeder door and remove

the paper.

iii. CUTTER: trimmer cannot

complete full cut cycle

Page 12

i. MANUAL FEED INDICATOR – Located on

the Feeder Door, Illuminates GREEN when

the laminator is ready for a document to

be manually fed.

C. FILM CARTRIDGE: (Shown in image C above)

a. CARTRIDGE – inserts into the laminator.

b. CARTRIDGE LABEL – indicates film

thickness. Located on top of handle.

a. FILM LEADER – the first 3-4” (75-100mm)

of sealed laminating film provided on the

film cartridge. The film leader must be

placed facing the exit of the machine.

Page 13

6. Operation

OPERATION MODES:

AUTO FEED / AUTO CUT

Note: Best for standard paper sizes printed

on 20-32lb bond (75-120 gsm) paper.

1. Press the POWER button to turn the machine ON.

The machine will automatically start in Auto Feed

/ Auto Cut mode.

2. Place your document(s) in the FEED TRAY.

3. Slide the Side Guides to fit your document(s) to

minimize skew during lamination.

4. Press the RUN button:

Note: If RUN is pressed before the machine

has completely warmed up, the status bar

will be AMBER blinking in a sequence. The

laminator has accepted the command and

will start automatically when machine

reaches proper temperature.

5. Document(s) will be automatically laminated and

automatically trimmed as they exit the machine.

Note: If you hit stop while the document is

still feeding through the laminator, the

machine will finish laminating the document

before stopping.

MANUAL FEED / AUTO CUT

Note: Best for standard rectangular paper

sizes on heavy paper stocks that won’t Auto

Feed.

1. Press the POWER button to turn the machine ON.

2. Select the Manual Feed / Auto Cut mode by

pressing the Mode button.

3. Wait for the machine to reach proper

temperature: solid green STATUS light.

4. Place only the first document in the FEED TRAY.

The document must be placed in the center of the

Feed Tray and far enough into the feeder to grab

your document.

5. Press the RUN button. The document will begin to

feed into the laminator.

6. After your first document begins laminating, wait

for the MANUAL FEED indicator to illuminate

green. Once illuminated, the machine can be

manually fed the next document. Repeat this

process one sheet at a time until the job is

complete.

7. Documents will be manually laminated and

automatically trimmed as they exit the machine.

8. After the final document has been cut and exits

the machine will automatically stop.

MANUAL FEED / MANUAL CUT

Note: This mode is best used for odd-shaped

or non-rectangular documents that won’t

Auto Feed.

1. Press the POWER button to turn the machine

ON.

2. Select the Manual Feed / Manual Cut mode by

pressing the Mode button.

3. Wait for the machine to reach proper

temperature: solid green STATUS light.

4. Place only the first document in the FEED TRAY.

The document must be placed in the center of

the Feed Tray and far enough into the feeder to

grab your document.

5. Press the RUN button. The document will begin

to feed into the laminator.

6. After your first document begins laminating,

wait for the MANUAL FEED indicator to

illuminate green. Once illuminated, the

machine can be manually fed the next

document. Repeat this process one sheet at a

time until the job is complete.

7. Press the CUT button to cycle the trimmer

anytime you want to cut the film.

Note: It is recommended to press the CUT

button after you see the entire document

exit the machine to avoid cutting the

document.

8. After the final document has exited the

machine, press the STOP button to stop the

lamination process.

9. Once lamination has stopped, press CUT to cut

the remaining film that has exited the machine.

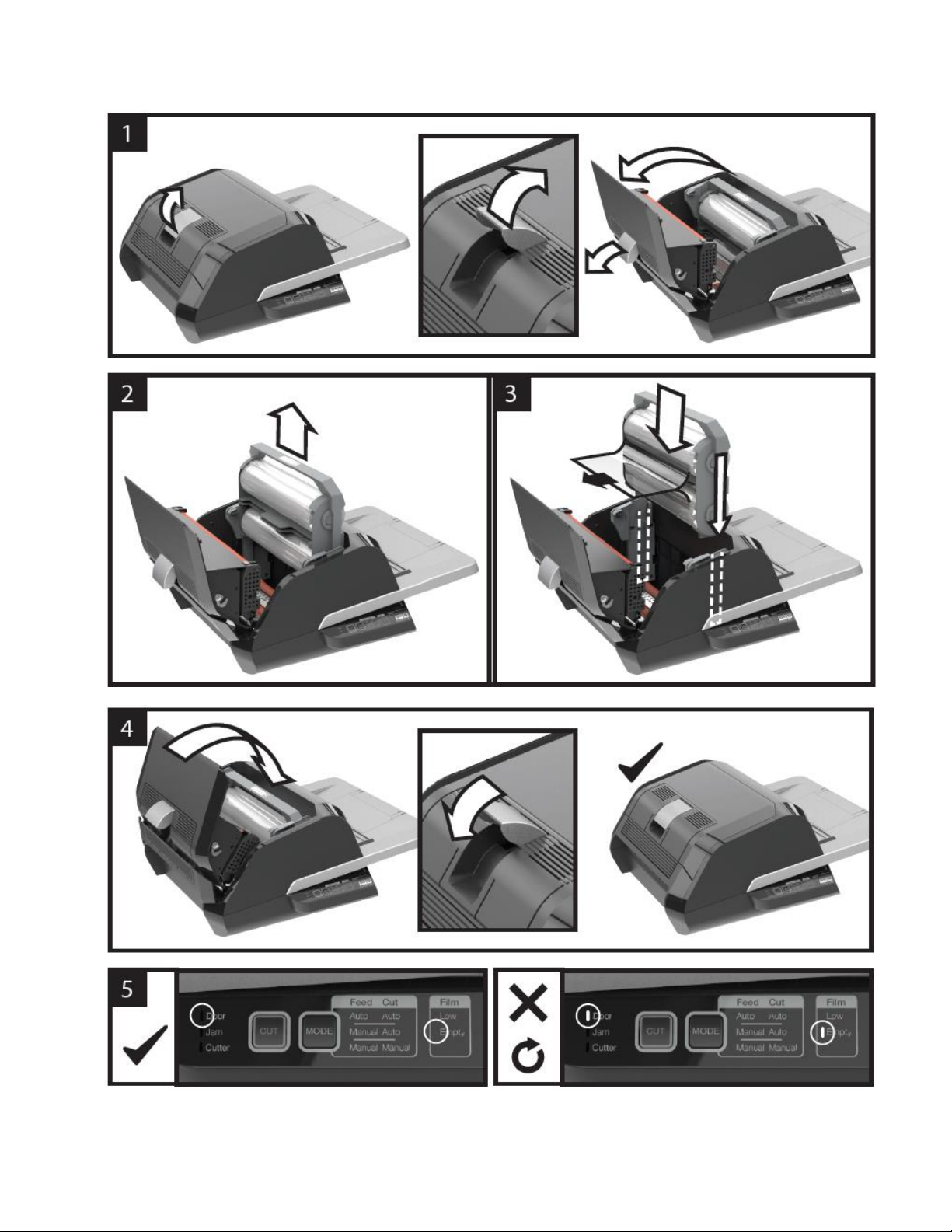

CARTRIDGE FILM LOADING

(Reference Images 1-4 to demonstrate process)

CAUTION: the following procedure might be

performed while the laminator is hot. Use extreme

caution.

Note: The film cartridges have an End of Roll sticker

which the laminator will automatically detect. Once

detected, the laminator will stop feeding any

remaining documents in the feed tray. The

laminator continue to laminate in the laminator.

The sticker may appear on the last document but

can be removed from the laminate.

1. Open Laminator Door: Open the laminator

door by fully raising the silver latch on the

top of the machine and pull up until door

fully opens.

Page 14

2. Remove Cartridge: Lift upward on the

cartridge handle to remove the installed

cartridge.

Caution: full cartridges tend to be

heavy

3. Insert Cartridge: Insert replacement

cartridge by aligning edges of cartridge over

grey channel guide in laminator and lowering.

Note: Film leader should be inserted

away from the feeder, facing

towards the exit of the machine.

4. Close Laminator Door: Close the laminator

door by gently lowering the door and fully

close the silver hatch on top. DO NOT push

down on the laminator door to close; use

the latch.

5. Ensure Cartridge is Fully Inserted: Film

6. Empty indicator will be illuminated when

no cartridge is installed or if the cartridge is

not fully seated on the bottom.

7. Automatically Thread: When the laminator

reaches proper temperature, the machine

will finish threading film and feed

approximately 9” (22.9 cm) of film to

eliminate potential wrinkles in the film.

Page 15

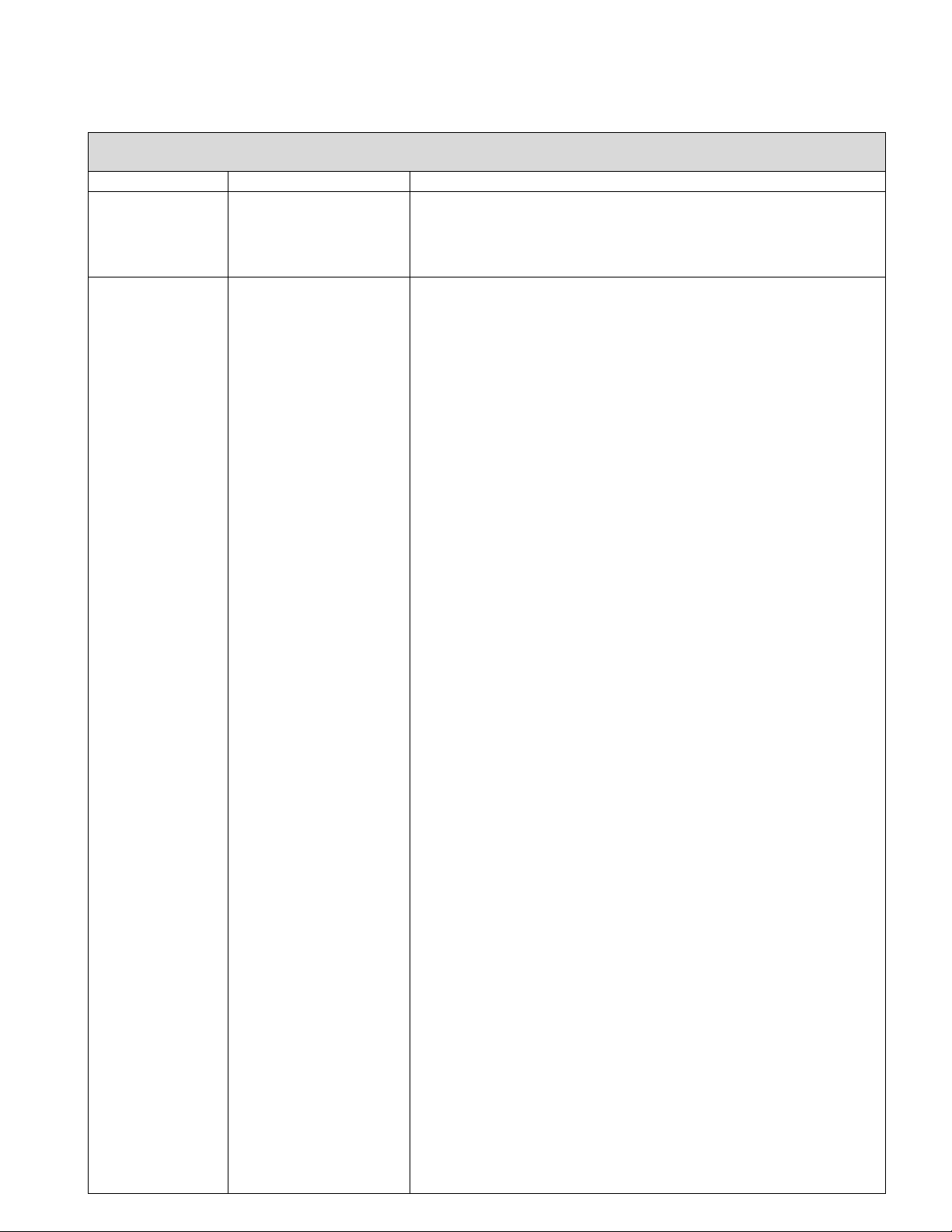

TROUBLE SHOOTING

SYMPTON

POSSIBLE CAUSE

CORRECTIVE ACTION

Pressing the Power

button does not

turn the machine

ON

The power cord may not

be inserted all the way

into outlet

Fully Insert plug into outlet

Make sure the outlet has power

Status Indicator

Red:

Door Error Indicator Red:

Paper Jam Error Indicator

Red:

Film Empty Indicator Red:

Cutter Error Indicator Red

Remove any paper from the feeder tray. Open and Close both the

laminator door and the feeder door. Ensure they are fully closed

Open the feeder door, and remove any paper from the feeder tray.

Close the feeder door.

If the above does not clear the error, press and hold the RUN button for

10 seconds to manually feed film. Film should begin to exit the machine

and Jam should clear.

If Jam error remains, open laminator door and look to see if film leader

is caught on an obstacle or the rollers. DO NOT CUT the film. Lift-up the

film leader and replace it in proper position. Shut Laminator door and

hold the run button for 10 Seconds.

Cartridge End of Roll label has been detected. Replace the film cartridge

with new cartridge and shut the laminator door.

The cutter could not initiate a cut, or did not finish a cut.

Press the manual cut button one time to try and activate the cutter. Not

resolved, try the following:

Observe the film at the exit of the laminator to see if the film is not cut

or partially cut.

Film is not cut:

Press and hold the RUN button for about 10-20 seconds to

manually advance the film. If there is laminated media in the

exit of the laminator, hold the RUN button until the media has

fully exited the laminator. Now press the manual cut button to

see if the cutter is activated.

Film is Partially Cut:

Open the laminator door and look to see if you can see the

trimmer blade. It will be near the back of the laminator

partway through the film. Using scissors cut the film hanging

out the exit of the laminator. Then using caution not to put

your fingers near the trimmer knife, carefully remove the

cartridge. Close the laminator door and try to manually cycle

the cutter. If the cutter works Re-insert your cartridge. Might

need to trim off the leading edge of film where the cutter

jammed. If you need to trim the film leave 4 inches (100mm)

of sealed film as the cartridge leader. Re-insert the cartridge.

The machine once warmed-up will automatically thread the

film and activate the trimmer.

If the cutter does not work after the above steps contact your service

provider.

Page 16

Film Wrinkles on

output

Film Misaligned

Press and hold the RUN button to manually advance the film. After 5 –

20 inches (125 – 500mm) of film has been advanced the wrinkle should

work themselves out. If wrinkle clear press the manual cut button and

you are ready to begin.

If wrinkles still present, open the laminator door. Grasp the film exiting

the laminator and hold it Taut while closing the laminator door. Repeat

above step and wrinkles should disappear.

Film Edges are not

evenly aligned.

Top and bottom rolls of

film are not matched

properly.

Press and hold the RUN button to manually advance the film. After 5

inches (125 mm). Grasp the film exiting the laminator and hold it Taut

while closing the laminator door.

Documents are

skewed in the film

when exiting

Documents fed in skewed

Before loading paper, try tapping the leading edge of the paper on a flat

surface and then repeat with the bottom or top edge to get your paper

properly squared.

Insert your media in the auto feeder and slide the edge guide up to edge

of your media.

Experiencing

frequent double

feeds

Paper has heavy static

Try fanning the media or placing in a paper jogger prior to feeding it. If

issues persist use the Manual Feed / Auto Cut mode.

Experiencing

frequent mis-feeds

Rollers are slipping on

media and do not feed

sheets

Try fanning the media or placing in a paper jogger prior to feeding it. If

issues persist use the Manual Feed / Auto Cut mode.

If mis-feeds continue use the Manual Feed / Auto Cut operation mode

and manual feed the media one sheet at a time

Page 17

Contre-colleuse sans pochette

GBC FOTON 30

MANUEL D’INSTALLATION ET D’UTILISATION

Numéro de document : CBT10000 Rév. B

Ne pas reproduire sans la permission écrite d'ACCO Brands.

Page 18

ACCO Brands se réserve le droit de modifier cette publication et les produits décrits dans les présentes sans préavis.

Toutes les spécifications et tous les renseignements concernant les produits peuvent être modifiés sans préavis. Dans cette

publication, toute référence à des renseignements ou des produits protégés par des droits d'auteur ou des brevets ne

confère aucune licence au titre des droits d'ACCO Brands ou des autres. ACCO Brands n’assume aucune responsabilité

découlant de toute violation aux brevets ou de tout autre droit de tiers.

Cette publication est protégée par des droits d’auteur © 2018 par ACCO Brands. Tous droits réservés.

Page 19

1. Sécurité

ACCO PREND TRÈS AU SÉRIEUX VOTRE SÉCURITÉ ET

CELLE DES AUTRES. D’IMPORTANTS MESSAGES DE

SÉCURITÉ SE TROUVENT DANS CE MANUEL

D’UTILISATION ET SUR LE PRODUIT. AVANT D’INSTALLER

OU D’UTILISER LA MACHINE, VEUILLEZ LIRE ET SUIVRE

ATTENTIVEMENT TOUTES LES CONSIGNES DE SÉCURITÉ

FIGURANT DANS CE CHAPITRE.

Respectez toutes les consignes de sécurité fournies.

Respectez tous les avertissements de sécurité. Ne

retirez pas les avertissements de sécurité ou les

autres renseignements de l’équipement.

Lisez toutes les directives et conservez-les

pour référence ultérieure.

Dans ce manuel le symbole d’alerte de

sécurité précède chaque consigne de sécurité.

Le symbole indique un risque éventuel pour votre

sécurité personnelle ou celle des autres, et la

possibilité de causer des dommages matériels.

Ce symbole d’alerte de sécurité indique le

risque d’un choc électrique. Il vous recommande de

ne pas ouvrir la contre-colleuse et de ne pas vous

exposer à des tensions dangereuses.

LES AVERTISSEMENTS SUIVANTS SE TROUVENT SUR LA

CONTRE-COLLEUSE SKYWARP.

NE L’OUVREZ PAS. IL NE CONTIENT AUCUNE PIÈCE QUI

PEUT ÊTRE RÉPARÉE PAR L’UTILISATEUR. TOUTE

RÉPARATION DOIT ÊTRE EFFECTUÉE PAR LE

PERSONNEL DE SERVICE QUALIFIÉ.

MISE EN GARDE surface chaude : La

température des rouleaux de la contre-colleuse peut

dépasser 126,7°C (260 °F). Soyez prudent et ne

touchez aux rouleaux.

AVERTISSEMENT : Ne tentez pas de

réparer la contre-colleuse.

AVERTISSEMENT : Ne reliez pas la

contre-colleuse à une alimentation électrique et

ne tentez pas d’utiliser la contre-colleuse avant

d’avoir complètement lu ces directives.

Conservez ces directives dans un endroit

pratique pour référence ultérieure.

Protections générales

• N'utilisez cette contre-colleuse que pour

son usage prévu et conformément aux

spécifications décrites dans les directives

d'utilisation.

• Gardez les mains, les cheveux longs, les

vêtements amples et les articles comme

les colliers ou les cravates loin des

rouleaux d’alimentation pour éviter tout

enchevêtrement et blocage.

• Lorsque vous ouvrez la porte de la

contre-colleuse, évitez tout contact avec

les rouleaux internes lorsque la contrecolleuse est sous tension ou peu après

qu'elle ait été mise hors tension. La

température des rouleaux peut

atteindre 126,7°C (260 °F).

• Gardez les mains et les doigts loin de la

lame tranchante du massicot de pellicule

située à la sortie de la pellicule.

Ne placez pas la contre-colleuse sur un

chariot, un support ou une table

instables. Une surface instable peut

provoquer la chute de la contre-colleuse

et causer des blessures graves. Évitez les

arrêts rapides, une force excessive et

des planchers à surface irrégulière

lorsque vous devez déplacer la contrecolleuse sur un chariot ou un support.

• Ne déjouez pas et ne retirez pas

l’équipement de sécurité électrique et

mécanique, comme les dispositifs de

verrouillage, les écrans et les éléments

de protection.

• N’insérez pas des objets qui ne doivent

pas être plastifiés.

• N’exposez pas la contre-colleuse à des

liquides.

Page 20

Protections électriques

• L’équipement doit être relié à une prise

facilement accessible et mise à la terre (trois

broches) près de celui-ci.

• Cette contre-colleuse doit être reliée à une

tension d’alimentation correspondant à la

puissance électrique indiquée sur la plaque

signalétique située à l’arrière de la machine.

• Débranchez la contre-colleuse avant de la

déplacer ou lorsqu’elle ne sera pas utilisée

pendant de longues périodes.

• N’utilisez pas contre-colleuse si le cordon

d’alimentation ou la fiche sont endommagés.

• Ne surchargez pas les prises électriques pour

éviter tout risque d'incendie ou de choc

électrique.

• Ne modifiez pas la fiche. Cette fiche est

configurée pour l’alimentation électrique

appropriée.

• L’unité est conçue pour être utilisée à

l’intérieur seulement.

• Débranchez la fiche de la prise dans laquelle

elle est insérée et gardez le cordon

d’alimentation en votre possession lorsque

vous déplacez la contre-colleuse.

• N’utilisez pas la contre-colleuse si le cordon

d’alimentation ou la fiche sont endommagés,

en cas de mauvais fonctionnement ou si elle a

été endommagée. Communiquez avec un

représentant de service GBC autorisé pour

obtenir de l’aide.

MISE EN GARDE : La prise doit être située

près de l’équipement et être facilement

accessible. N’utilisez pas de rallonge.

AVERTISSEMENT : Ne reliez pas la contrecolleuse à une alimentation électrique et ne tentez

pas d’utiliser la contre-colleuse avant d’avoir

complètement lu ces directives. Conservez ces

directives dans un endroit pratique pour référence

ultérieure.

AVERTISSEMENT: Cet appareil n'est pas

conçu pour être utilisé dans le champ de vision direct

des postes de travail à affichage visuel. Pour éviter

les réflexions gênantes sur les lieux de travail avec

écrans de visualisation, cet appareil ne doit pas être

placé dans le champ de vision directe.

Service technique GBC

Pour commander des accessoires de rechange,

des pièces, obtenir du service ou un contrat

d’entretien d’équipement, communiquez avec le

service technique et d’assistance GBC :

États-Unis

ACCO Brands GBC Technical Service and Support

4 Corporate Drive Lake Zurich, IL 60047-8997

www.gbcconnect.com

1-800-723-4000

Canada

Ontario et Québec – 1-800-268-3310

Toutes les autres provinces – 1-800-268-3447

Localement – 905-595-3100

Callcentre@GBCCanada.com

Mexique

(55) 1500 5778

Lada SIN costo: 01 800 759 6825

serviciotecnico@acco.com.mx

Page 21

2. Garantie

Garantie limitée de deux ans/ 5 000 laminages;

É.-U., Mexique et Canada

ACCO Brands USA LLC, ACCO Brands, 4 Corporate

Drive, Lake Zurich, IL 60047 É.-U. (au Mexique, ACCO

Brands Mexicana, Neptuno 43, Fraccionamiento

Nueva Industrial Vallejo México 07700 D.F. México),

(au Canada, ACCO Brands Canada Inc., 7381 Bramalea

Road, Mississauga ON L5S1C4) (chacune,

respectivement, « ACCO Brands ») garantit à

l’acheteur original que ce produit ACCO Brands sera

exempt de défauts de fabrication et de matériau s’il

est utilisé et entretenu normalement pendant une

période de deux (2) ans/5 000 laminages pour les

pièces de rechange.

L’obligation d'ACCO Brands en vertu de cette garantie

se limite au remplacement ou à la réparation, à la

discrétion d'ACCO Brands, de toute pièce garantie

jugée défectueuse par ACCO Brands, et ce, sans frais

pour les matériaux et la main d'œuvre. Tout

remplacement, à la discrétion d'ACCO Brands, sera

effectué au moyen du même produit ou d’un produit

substantiellement similaire qui peut contenir des

pièces reconstruites ou remises à neuf. Cette garantie

sera annulée dans les circonstances suivantes :

(i) le produit a été mal installé ou mal utilisé;

(ii) le produit a été endommagé par négligence ou par

accident; ou

(iii) le produit a été modifié par une personne autre

que ACCO Brands ou ses agents autorisés.

Sans limiter la généralité du paragraphe précédent,

l’obligation d'ACCO Brands au titre de cette garantie

ne comprend pas :

(iiii) les dommages causés aux rouleaux par des

couteaux, des rasoirs ou d’autres outils tranchants; par

tout corps étranger se trouvant dans la zone de travail

de la contre-colleuse; ou par le nettoyage de la contrecolleuse avec des solutions ou des matériaux

susceptibles d'endommager ses surfaces.

Pour l’exécution de la garantie, veuillez communiquer

avec ACCO Brands à : 800-723-4000 ou

www.gbcconnect.com aux É.-U;

800-263-1063 ou www.gbccanada.com au Canada;

(55) 1500 5578 ou www.accomexico.mx au Mexique

DANS LA MESURE PERMISE PAR LA LOI EN

VIGUEUR, CETTE GARANTIE REMPLACE TOUTES

LES AUTRES GARANTIES EXPRESSES.

LES REPRÉSENTATIONS OU PROMESSES

INCOMPATIBLES AVEC LA PRÉSENTE GARANTIE

S'Y AJOUTANT NE SONT PAS AUTORISÉES ET

N'ENGAGENT PAS ACCO BRANDS. DANS LA

MESURE PERMISE PAR LES LOIS EN VIGUEUR,

TOUTES LES GARANTIES IMPLICITES (LE CAS

ÉCHÉANT) SE LIMITENT EN DURÉE À LA DURÉE DE

CETTE GARANTIE. CERTAINES PROVINCES ET

JURIDICTIONS NE PERMETTENT PAS LES LIMITES

SUR LA DURÉE D’UNE GARANTIE IMPLICITE, PAR

CONSÉQUENT, LA LIMITE PRÉCÉDENTE PEUT NE

PAS S’APPLIQUER À VOTRE CAS. DANS LA

MESURE PERMISE PAR LA LOI EN VIGUEUR, ACCO

BRANDS NE SERA DANS AUCUN CAS TENUE

RESPONSABLE DES DOMMAGES SPÉCIAUX,

CONSÉCUTIFS, PUNITIFS, EXEMPLAIRES,

INDIRECTS OU SIMILAIRES, QU’ILS SOIENT

PRÉVISIBLES OU NON. CERTAINES PROVINCES ET

JURIDICTIONS NE PERMETTENT PAS L’EXCLUSION

OU LA LIMITE DES DOMMAGES SPÉCIAUX,

CONSÉCUTIFS, PUNITIFS, EXEMPLAIRES,

CONSÉCUTIFS OU SIMILAIRES, PAR CONSÉQUENT,

L’EXCLUSION OU LA LIMITE PRÉCÉDENTE PEUT NE

PAS S’APPLIQUER À VOTRE CAS.

POUR LES CONSOMMATEURS QUI BÉNÉFICIENT DE

LOIS OU DE RÈGLEMENTS SUR LA PROTECTION DU

CONSOMMATEUR DANS LEUR JURIDICTION

D’ACHAT, OU SI DIFFÉRENTE, DANS LEUR

JURIDICTION DE RÉSIDENCE, LES AVANTAGES

CONFÉRÉS PAR CETTE GARANTIE S’AJOUTENT À

TOUS LES DROITS OU RECOURS CONFÉRÉS PAR DE

TELLES LOIS ET DE TELS RÈGLEMENTS SUR LA

PROTECTION DU CONSOMMATEUR.

Dans la mesure permise par la loi, cette garantie

ne peut pas être transférée et prendra fin

automatiquement si l’acheteur initial du produit

vend ou dispose autrement du produit.

Cette garantie vous donne des droits juridiques

précis. Vous pouvez bénéficier d’autres droits,

qui varient d’une juridiction à l’autre. De plus,

certaines juridictions ne permettent pas (i)

l’exclusion de certaines garanties, (ii) les limites

sur la durée des garanties implicites; et/ou (iii)

l’exclusion ou la limite de certains types de coûts

et dommages; par conséquent, les limites ci-

dessus peuvent ne pas s’appliquer à votre cas.

Page 22

Modèle

Contre-colleuse sans pochette

FOTON 30

Vitesse de fonctionnement

3 mil (75 mic) 29,1 po/min (700 mm)

4 mil (100 mic) 25,6 po/min (670 mm)

5 mil (125 mic) 23,6 po/min (650 mm)

Modes de fonctionnement

Alimentation automatique/coupe automatique

Alimentation manuelle/coupe automatique

Alimentation manuelle/coupe manuelle

Durée du réchauffement

3 min 75 mic/3 mil

3,5 min 100 mic/4 mil

4 min 125 mic/3 mil

30 feuilles papier de 75 g/m²

Largeur maximale de la pellicule

12,01 po (306 mm) – reste du monde

11,5 po (292 mm) – Amérique du Nord

Épaisseur maximale du document

250 g/m² pour l’alimentation manuelle

Longueurs de document prises en charge

Largeurs de document prises en charge

Minimum 6 po (152 mm)

Maximum 17 po (432 mm)

Minimum 5 po (127 mm)

Maximum 11,69 po (297 mm)

Poids du support pour l’alimentation automatique

Poids du support pour l’alimentation manuelle

Fiabilité élevée : 64 – 120

g/m²

Fiabilité variable : 121 à 220 g/m²

64 à 250 g/m²

Dimensions :

Largeur

Hauteur

Profondeur

Poids

Machine : Expédition :

22,7 po (57,7 cm) 27,0 po (68,6 cm)

9,6 po (24,5 cm) 15,0 po (38,1 cm)

18,8 po (47,8 cm) 22,7 po (57,8 cm)

21 lb (9,5 kg) 32.8 lb (14,9 kg)

Arrêt automatique

15 minutes d’inactivité

Cycle de fonctionnement

80 documents par semaine

Exigences électriques

Tension

Prise

120 volts, 60 Hz

NEMA 5-15P

Fusible

Oui (interne et non remplaçable)

Environnement opérationnel

5 à 35 °C (41 à 95 °F)

Altitude maximale de 2 000 m

Hauteur

Largeur

Profondeur

Figure 1. Dimensions du Foton 30

3. Spécifications

Page 23

Avis de classe B de la FCC

Ce dispositif est conforme à la l'article 15 des

règlements de la FCC. Le fonctionnement est assujetti

aux deux conditions suivantes :

Ce dispositif ne doit pas causer d'interférences

nuisibles

Ce dispositif doit accepter toute interférence

reçue, y compris les interférences susceptibles

de provoquer un fonctionnement non désiré.

REMARQUE : Cet équipement a été testé et déclaré

conforme aux limites d'un appareil numérique de classe

B, conformément à l'article 15 des règlements de la

FCC. Ces limites sont conçues pour fournir une

protection raisonnable contre les interférences nuisibles

dans une installation résidentielle. Cet équipement

génère, utilise et peut émettre de l’énergie

radiofréquence et, s’il n’est pas installé et utilisé

conformément aux directives, peut causer de

l’interférence nuisible aux communications radio.

Cependant, il n'y a aucune garantie que des

interférences ne se produiront pas dans une installation

particulière. Si cet équipement cause des interférences

nuisibles à la réception radio ou télévisée, ce qui peut

être déterminé en allumant et en éteignant

l’équipement, l’utilisateur est encouragé à tenter de

corriger ces interférences en prenant une ou plusieurs

des mesures suivantes :

- Réorienter ou déplacer l’antenne de réception.

- Augmenter la distance entre l’équipement et le

récepteur.

- Brancher l'équipement à une prise de courant

sur un circuit différent de celui auquel le

récepteur est branché.

- Consulter le concessionnaire ou un technicien

radio/télé expérimenté pour obtenir de l’aide.

Avis de classe B du Canada

Classe B, Canada

Cet appareil numérique de classe B est conforme à la

norme canadienne ICES-003.

Modifications

Toute modification apportée à cet appareil qui n’est

pas approuvée par ACCO Brands peut annuler

l'autorité accordée à l'utilisateur par la FCC et/ou

Industrie Canada à utiliser cet équipement.

Page 24

4. Installation

Service

AVERTISSEMENT : Ne tentez pas de réparer la

contre-colleuse. Le non-respect de cet avertissement

pourrait entraîner des blessures graves ou la mort.

Débranchez la fiche de la prise et communiquez avec le

service à la clientèle dans l’un ou l’autre des cas suivants.

• Le cordon d’alimentation ou la fiche sont

endommagés.

• Du liquide a été renversé dans la contre-

colleuse.

• La contre-colleuse ne fonctionne pas

correctement après une mauvaise

manipulation.

• La contre-colleuse ne fonctionne pas comme il

est décrit dans ces directives.

Installation

• Tout dommage survenu durant l’expédition

doit être signalé immédiatement au

transporteur.

• Placez la contre-colleuse sur une surface plate

et stable pouvant soutenir une charge de 23 kg

(50 lb).

• La surface doit se trouver à une hauteur d’au

moins 76 cm (30 po) pour obtenir une position

confortable durant le fonctionnement. Les

quatre pieds en caoutchouc doivent se trouver

sur la surface portante.

• Reliez le cordon d’alimentation à une source

d’alimentation appropriée. Évitez de relier

d’autres équipements sur le circuit sur lequel la

contre-colleuse est branchée puisque cela peut

causer des déclenchements intempestifs du

disjoncteur ou le grillage des fusibles.

• La contre-colleuse doit être placée de manière

à permettre à la pellicule sortante de tomber

librement sur une surface plate. L’accumulation

de documents plastifiés à la sortie de la contrecolleuse peut provoquer un blocage.

• Évitez de placer la contre-colleuse près d’une

source de chaleur ou de froid. Évitez de placer

la contre-colleuse dans la voie directe de l’air

pulsé, chauffé ou refroidi.

Entretien du Foton 30

Le seul entretien devant être effectué par l’opérateur

consiste à nettoyer périodiquement les rouleaux. En

gardant les rouleaux propres, vous vous assurez que vos

produits finis ne seront pas endommagés par de la

saleté et l'accumulation d’adhésif.

MISE EN GARDE : Effectuez la procédure

suivante lorsque la contre-colleuse est chaude. Faites

preuve d'extrême prudence.

AVERTISSEMENT : N’appliquez pas des liquides

de nettoyage ou des solvants sur les rouleaux.

AVERTISSEMENT : Ne tentez pas de plastifier

des adhésifs portant la mention « Inflammable ».

AVERTISSEMENT : N’exposez pas la contre-

colleuse à des liquides.

1. Mettez la machine en marche et attendez qu’elle

se réchauffe.

2. Ouvrez la porte de la contre-colleuse au moyen

du loquet argenté.

3. Nettoyez les rouleaux supérieurs avec un chiffon

propre, humide et non pelucheux. En cas

d'accumulation d’adhésif, utilisez de l’alcool

isopropylique à la place de l’eau.

4. Soulevez le rebord avant de la pellicule jusqu’à la

poignée de la cartouche.

5. Nettoyez les rouleaux inférieurs à l'aide d'un

chiffon propre, humide et non pelucheux. En cas

d'accumulation d’adhésif, utilisez de l’alcool

isopropylique à la place de l’eau.

6. Placez le rebord avant de la pellicule dans la

position appropriée et fermez la porte.

7. Appuyez et maintenez le bouton RUN/STOP

(avancer/arrêter) enfoncé pendant cinq à sept

secondes pour faire avancer manuellement les

rouleaux.

8. Ouvrez la porte de la contre-colleuse au moyen

du loquet argenté.

9. Répétez les étapes 4 à 6.

Remarque : N’utilisez pas de tampons à récurer

métalliques pour nettoyer les rouleaux chauffants!

AVERTISSEMENT : Ne plastifiez pas des articles

métalliques et/ou à paillettes. Cela risque

d’endommager les rouleaux.

Les couvercles latéraux et la table d’alimentation

peuvent être nettoyés à l'aide d'un chiffon non

pelucheux et un détergent doux.

Page 25

Page 26

Page 27

5. Guide des caractéristiques

A. APPRENDRE À CONNAÎTRE VOTRE CONTRE-

COLLEUSE :

(illustrée dans la photo A ci-dessus)

a. BAC D’ALIMENTATION ET GUIDES

LATÉRAUX :

i. Placez le(s) document(s) à

plastifier et utilisez les guides

coulissants pour minimiser toute

déviation. Ouvrez l’extension pour

les documents plus longs.

b. ALIMENTATION/PORTE

D’ALIMENTATION :

i. Alimente le document dans la

contre-colleuse. Un voyant rouge

sur la porte indique que le

document n’a pas été inséré

correctement. Ouvrez la porte

pour éliminer tout problème

d'alimentation.

c. PORTE DE LA CONTRE-COLLEUSE :

i. Porte donnant accès aux pièces

internes de la contre-colleuse :

rouleaux, cartouche de pellicule, etc.

ii. Pour ouvrir : Tirez sur le loquet

argenté et soulevez.

iii. Pour fermer : Abaissez

doucement en utilisant le loquet

argenté et poussez-le pour le

fermer. NE poussez PAS sur la

porte de la contre-colleuse pour

la fermer.

d. CARTOUCHE DE PELLICULE :

i. Remplacez la cartouche de

pellicule lorsqu’elle est vide ou

lorsque vous avez besoin d’une

épaisseur différente. Reportezvous à CHARGEMENT DE LA

CARTOUCHE DE PELLICULE pour

de plus amples détails.

e. ROULEAUX DE LA CONTRE-COLLEUSE :

i. Les rouleaux se réchauffent pour

activer l’adhésif se trouvant sur la

pellicule tout en exerçant une

pression pour s’assurer que la

pellicule adhère au document.

f. MASSICOT AUTOMATIQUE :

i. En mode Auto Cut (coupe

automatique), le massicot trouve le

rebord avant et arrière du document

et coupe la pellicule. En mode

Manual Cut (coupe manuelle), il

coupe la pellicule lorsque le bouton

CUT (couper) est enfoncé.

B. PANNEAU DE COMMANDE : (illustré dans la photo

B ci-dessus)

BOUTONS

a. POWER – permet d’allumer ou d’éteindre

la machine. Après 15 minutes de non

utilisation, la machine s’éteint

automatiquement.

b. RUN/STOP – utilisé pour démarrer ou

arrêter la contre-colleuse.

i. Fonction double – avancée

manuelle : Gardez le bouton

enfoncé en continu pour faire

avancer manuellement les

rouleaux de la contre-colleuse.

Ce bouton peut être utilisé pour

éliminer les blocages et les débris

pour le nettoyage.

c. MODE – permet aux utilisateurs de

basculer entre les trois modes de

fonctionnement.

i. Auto Feed/Auto Cut (alimentation

et coupe automatiques) – idéal

pour les formats de papier bond

de 20 à 32 lb de taille standard.

ii. Manual Feed/Auto Cut

(alimentation manuelle/coupe

auto) – idéal pour les formats de

papier standard sur les papiers

épais qui ne s'alimentent pas

automatiquement.

iii. Manual Feed/Manual Cut

(alimentation et coupe manuelles)

– idéal pour les documents de

forme irrégulière et non

rectangulaires.

d. CUT (couper) – en appuyant sur ce bouton,

le massicot coupe une seule fois la

pellicule. Ce bouton est surtout utilisé en

mode de coupe manuelle.

INDICATEURS

e. STATUS (statut) – communique le statut de

la machine :

i. Vert fixe = prête à utiliser

ii. Vert clignotant =

en fonctionnement

iii. Orange fixe = réchauffement

iv. Orange clignotant =

réchauffement et commande RUN

(avancer) acceptée. Commencera

à plastifier dès qu’elle sera prête.

v. Rouge fixe = erreur

Page 28

f. FILM (pellicule) – le voyant à DEL indique

lorsque la cartouche est vide ou presque

vide (environ 30 % de la cartouche).

i. Low (presque vide) = voyant à

DEL orange

ii. Empty (vide) = voyant à DEL rouge

g. MODE – le voyant à DEL vert indique le

mode de fonctionnement de la machine.

h. ERROR MESSAGE (message d’erreur) –

communique les messages d’erreur qui

doivent être corrigés.

i. DOOR (porte) : une porte ou les

deux portes sont ouvertes

ii. JAM (blocage) : deux types de

blocage peuvent se produire :

1. Blocage de la contre-

colleuse : Enfoncez et

maintenez enfoncé le

bouton RUN (avancer)

pour faire avancer

manuellement les

rouleaux et éliminer le

blocage.

2. Blocage d’alimentation :

Ouvrez la porte

d’alimentation et retirez

le papier.

iii. CUTTER (massicot) : Le massicot

n'est pas en mesure d'effectuer

un cycle complet de coupe

i. MANUAL FEED INDICATOR (indicateur

d'alimentation manuelle) – Siuté sur la

Porte d'alimentation, indique que la

contre-colleuse est prête en s'allumant en

VERT pour charger le prochain document à

alimentation manuelle.

C. CARTOUCHE DE PELLICULE : (illustrée dans la photo

C ci-dessus)

a. CARTOUCHE – elle s’insère dans la contre-

colleuse.

b. ÉTIQUETTE DE CARTOUCHE – indique

l’épaisseur de la pellicule. Située sur le

dessus de la poignée.

a. AMORCE DE PELLICULE – les premiers 75 à

100 mm (3 à 4 pouces) de pellicule scellée

se trouvant sur la cartouche de pellicule.

Cette amorce doit être orientée vers la

sortie de la machine.

Page 29

6. Fonctionnement

MODES DE FONCTIONNEMENT :

AUTO FEED/AUTO CUT

(alimentation et coupe automatiques)

Remarque : Idéal pour les papiers bond

imprimés de 20 à 32 lb (75 à 120 g/m²) de

taille standard.

1. Enfoncez le bouton POWER (marche-arrêt) pour

mettre la machine en marche. La machine se met

en marche automatiquement en mode

d’alimentation et de coupe automatiques.

2. Placez votre (vos) document(s) dans le BAC

D’ALIMENTATION.

3. Glissez les guides latéraux pour qu'ils s'adaptent à

vos documents pour minimiser la déviation

durant le laminage.

4. Enfoncez le bouton RUN (avancer).

Remarque : Si le bouton RUN (avancer) est

enfoncé avant que la machine n’ait terminé son

réchauffement, la barre de statut clignotera en

ORANGE. La contre-colleuse a accepté la

commande et démarre automatiquement

lorsqu’elle a atteint la température appropriée.

5. Le document sera automatiquement plastifié et

découpé à sa sortie de la machine.

Remarque : Si vous enfoncez le bouton Stop

(arrêt) pendant que le document avance dans

la contre-colleuse, la machine terminera le

laminage avant de s’arrêter.

MANUAL FEED/AUTO CUT

(alimentation manuelle et coupe automatique)

Remarque : Idéal pour les papiers imprimés

épais de tailles rectangulaires standards qui

ne s’alimenteront pas automatiquement.

1. Enfoncez le bouton POWER (marche-arrêt) pour

mettre la machine en marche.

2. Sélectionnez le mode Manual Feed/Auto Cut

(alimentation manuelle et coupe automatique) en

enfonçant le bouton Mode.

3. Attendez que la machine ait atteint la

température appropriée, indiquée par le voyant

de statut en vert fixe.

4. Ne placez que le premier document dans le BAC

D’ALIMENTATION. Le document doit être placé au

centre du bac d’alimentation et suffisamment loin

dans le bac pour saisir votre document.

5. Enfoncez le bouton RUN (avancer). Le document

commencera à avancer dans la contre-colleuse.

6. Après avoir plastifié votre premier document,

attendez que l’indicateur MANUAL FEED

(alimentation manuelle) s’allume en vert. Une fois

allumé, la machine peut alors accepter le

prochain document à plastifier. Répétez cette

procédure une feuille à la fois jusqu’à ce que la

tâche soit terminée.

7. Les documents seront plastifiés manuellement

et taillés automatiquement à leur sortie de la

machine.

8. Lorsque le dernier document a été coupé et

expulsé de la machine, cette dernière s’arrête

automatiquement.

MANUAL FEED/MANUAL CUT

(alimentation et coupe manuelles)

Remarque : Ce mode est idéal pour les

documents de forme irrégulière ou non

rectangulaire qui ne peuvent pas être

alimentés automatiquement.

1. Enfoncez le bouton POWER (marche-arrêt)

pour mettre la machine en marche.

2. Appuyez sur le bouton Mode pour sélectionner

le mode Manual Feed/Manual Cut

(alimentation et coupe manuelles).

3. Attendez que la machine ait atteint la

température appropriée, indiquée par le

voyant de statut en vert fixe.

4. Ne placez que le premier document dans le

BAC D’ALIMENTATION. Le document doit être

placé au centre du bac d’alimentation et

suffisamment loin dans le bac pour saisir

votre document.

5. Enfoncez le bouton RUN (avancer). Le

document commencera à avancer dans la

contre-colleuse.

6. Après avoir plastifié votre premier document,

attendez que l’indicateur MANUAL FEED

(alimentation manuelle) s’allume en vert. Une

fois allumé, la machine peut alors accepter le

prochain document à plastifier. Répétez cette

procédure une feuille à la fois jusqu’à ce que la

tâche soit terminée.

7. Appuyez sur le bouton CUT (couper) pour

activer le massicot chaque fois que vous

souhaitez couper la pellicule.

Remarque : Il est recommandé d’enfoncer

le bouton CUT (couper) lorsque le

document complet est sorti de la machine

pour éviter de le couper.

8. Lorsque le dernier document est sorti de la

machine, enfoncez le bouton Stop (arrêter)

pour arrêter le processus de laminage.

9. Une fois le laminage arrêté, enfoncez le bouton

CUT (couper) pour couper le reste de la

pellicule qui est sorti de la machine.

Page 30

CHARGEMENT DE LA CARTOUCHE DE PELLICULE

(Reportez-vous aux photos 1 à 4 qui décrivent le

processus)

MISE EN GARDE : La procédure suivante peut être

effectuée lorsque la contre-colleuse est chaude. Faites

preuve d'extrême prudence.

Remarque : Les cartouches de pellicule sont munies

d’un autocollant portant la mention « fin de rouleau »

qui sera automatiquement détecté par la contrecolleuse. Une fois l'autocollant détecté, la contre-

colleuse cessera d’alimenter les autres documents

dans le bac d’alimentation. La contre-colleuse

continue à plastifier les documents. L’autocollant peut

apparaître sur le dernier document, mais il peut être

retiré du laminage.

1. Ouvrez la porte de la contre-colleuse :

Ouvrez la porte en relevant complètement le

loquet argenté situé sur le dessus de la

machine et soulevez jusqu’à ce que la porte

soit entièrement ouverte.

2. Retirez la cartouche : Soulevez la poignée de

la cartouche pour retirez la cartouche

installée.

Mise en garde : Les cartouches

pleines ont tendance à être lourdes.

3. Insérez la cartouche : Insérez une nouvelle

cartouche en alignant ses rebords sur le

profilé de guidage gris de la contre-colleuse

et en l’abaissant.

Remarque : L’amorce de la

pellicule doit être insérée du côté

opposé à l’alimentation, faisant

face à la sortie de la machine.

4. Fermez la porte de la contre-colleuse :

Fermez la porte de la contre-colleuse en

abaissant doucement la porte et en

fermant complètement le loquet argenté

qui se trouve sur le dessus. NE poussez PAS

la porte de la contre-colleuse vers le bas

pour la fermer; utilisez le loquet.

5. Vérifiez que la cartouche est bien insérée :

L’indicateur de pellicule vide s’allume

lorsqu’il n’y a pas de cartouche ou si cette

dernière n’est pas correctement enfoncée.

6. Enfilage automatique : Lorsque la contre-

colleuse atteint la température appropriée,

elle termine l'enfilage de la pellicule et

charge environ 23 cm (9 po) de pellicule

pour en éliminer les plis éventuels.

Page 31

DÉPANNAGE

SYMPTÔME

CAUSE POSSIBLE

ACTION CORRECTRICE

Le bouton Power

(marche-arrêt) est

enfoncé, mais la

machine ne se met

pas en marche

Le cordon d’alimentation

peut ne pas être

entièrement inséré dans

la prise

Insérez la fiche complètement dans la prise

Assurez-vous que la prise est sous tension

Indicateur de

statut rouge :

Indicateur d’erreur de

porte rouge :

Indicateur d’erreur de

blocage de papier rouge :

Indicateur de cartouche

de pellicule vide rouge :

Indicateur d’erreur de

coupe rouge :

Retirez tout papier se trouvant dans le bac d’alimentation. Ouvrez et

fermez la porte de la contre-colleuse et la porte d’alimentation. Vérifiez

qu’elles sont bien fermées.

Ouvrez la porte d’alimentation et retirez tout papier du bac

d’alimentation. Fermez la porte d’alimentation.

Si les mesures précédentes ne corrigent pas l’erreur, enfoncez et

maintenez enfoncé le bouton RUN (avancer) pendant 10 secondes pour

charger manuellement la pellicule. La pellicule devrait commencer à

sortir de la machine et le blocage devrait se dégager.

Si l’erreur de blocage persiste, ouvrez la porte de la contre-colleuse et

regardez si l’amorce de la pellicule est bloquée par un obstacle ou les

rouleaux. NE COUPEZ PAS la pellicule. Soulevez l’amorce de la pellicule

et replacez-la en bonne position. Fermez la porte de la contre-colleuse

et maintenez le bouton RUN (avancer) enfoncé pendant 10 secondes.

Une étiquette de fin de cartouche a été détectée. Remplacez la

cartouche de pellicule par une nouvelle cartouche et fermez la porte de

la contre-colleuse.

Le massicot n'a pas pu amorcer une coupe ou terminer la coupe.

Enfoncez le bouton Manual Cut (coupe manuelle) une fois pour tenter

d'activer le massicot. Si cela ne résout pas le problème, essayez les

mesures suivantes :

Observez la pellicule à sa sortie de la contre-colleuse pour voir si elle est

complètement ou partiellement coupée.

La pellicule n'est pas coupée :

Enfoncez et tenez le bouton RUN (avancer) pendant 10 à

20 secondes pour faire avancer manuellement la pellicule. S’il y a

un support plastifié à la sortie de la contre-colleuse, enfoncez le

bouton RUN (avancer) jusqu’à ce que le média soit complètement

sorti de la contre-colleuse. Enfoncez maintenant le bouton Manual

Cut (coupe manuelle) pour voir si le massicot s’active.

La pellicule est partiellement coupée :

Ouvrez la porte de la contre-colleuse et vérifiez que vous

pouvez voir la lame du massicot. Celle-ci devrait se trouver près

de l’arrière de la contre-colleuse, à mi-chemin de la pellicule.

Au moyen de ciseaux, coupez la pellicule qui se trouve à la

sortie de la contre-colleuse. Ensuite, en prenant soin de ne pas

mettre vos doigts près de la lame du massicot, retirez

soigneusement la cartouche. Fermez la porte de la contre-

Page 32

Indicateur de

statut rouge

(suite) :

Indicateur d’erreur de

coupe rouge (suite) :

colleuse et tentez d’activer manuellement le massicot. Si le

massicot fonctionne, réinsérez votre cartouche. Vous devrez

peut-être tailler le rebord avant de la pellicule à l’endroit où le

massicot s’est coincé. Si vous devez tailler la pellicule, laissez

une longueur de 100 mm (4 pouces) de pellicule scellée en

guise d'amorce de cartouche. Réinsérez la cartouche. Une fois

réchauffée, la machine enfilera automatiquement la pellicule et

activera le massicot.

Si, après avoir effectué les étapes précédentes, le massicot ne

fonctionne pas, communiquez avec votre fournisseur de service.

Plis sur la pellicule

à la sortie

La pellicule n'est pas

correctement alignée

Enfoncez et tenez le bouton RUN (avancer) pour faire avancer

manuellement la pellicule. Après avoir fait avancer 125 à 500 mm (5 à

20 pouces) de pellicule, les plis devraient disparaître. Si les plis sont

éliminés, enfoncez la bouton Manual Cut (coupe manuelle) pour

démarrer.

Si vous observez encore des plis, ouvrez la porte de la contre-colleuse.

saisissez la pellicule sortant de la contre-colleuse et tenez la bien tendue

tout en fermant la porte. Répétez l’étape ci-dessus et les plis devraient

disparaître.

Les rebords de la

pellicule ne sont

pas alignés

uniformément

Les rouleaux supérieur et

inférieur de pellicule ne

sont pas alignés

correctement

Enfoncez et tenez le bouton RUN (avancer) pour faire avancer

manuellement la pellicule. Après avoir avancé 125 mm (5 pouces) de

pellicule, saisissez la pellicule sortant de la contre-colleuse et tenez la

bien tendue tout en fermant la porte.

Les documents

sont décalés dans

la pellicule

lorsqu’ils sortent

Les documents ont été

mal insérés

Avant de charger le papier, tentez de tapoter son rebord avant sur une

surface plate, puis répétez avec le bas ou le rebord inférieur pour bien

centrer le papier.

Insérez votre support dans l’alimentation automatique et glissez le

guide latéral jusqu’à l’arête de votre support.

Deux documents

sont souvent

alimentés

ensemble

Le papier est chargé

d’électricité statique

Essayez de ventiler le support ou de placer une taqueuse avant de le

charger. Si les problèmes persistent, utilisez le mode Manual Feed/Auto

Cut (alimentation manuelle/coupe automatique).

Fréquentes

anomalies

d'alimentation

Les rouleaux glissent sur

le support et les feuilles

n’avancent pas

Page 33

GBC FOTON 30

Laminadora sin bolsa

MANUAL DE INSTALACIÓN Y OPERACIÓN

Número de documento: CBT10000 Rev B

No duplicar sin el permiso escrito de ACCO Brands.

Page 34

ACCO Brands se reserva el derecho de realizar cambios en esta publicación y en los productos descritos en ella sin previo

aviso. Todas las especificaciones e información sobre los productos están sujetas a cambios sin previo aviso. La referencia en

esta publicación a información o productos protegidos por derechos de autor o patentes no supone ninguna licencia bajo los

derechos de ACCO Brands u otros. Acco Brands no asume ninguna responsabilidad derivada de la infracción de patentes o

de cualquier otro derecho de terceros.

Esta publicación está protegida por los derechos de autor © 2018 de ACCO Brands. Todos los derechos reservados.

Page 35

1. Seguridad

PARA ACCO SU SEGURIDAD Y LA SEGURIDAD DE LOS

DEMÁS ES MUY IMPORTANTE. EN ESTE MANUAL DE

INSTRUCCIONES Y EN EL PRODUCTO, HAY MENSAJES

DE SEGURIDAD IMPORTANTES. ANTES DE INSTALAR

O UTILIZAR LA MÁQUINA, LEA Y SIGA ATENTAMENTE

TODAS LAS INDICACIONES DE SEGURIDAD DE ESTE

CAPÍTULO.

Respete toda la información de seguridad que se

brinda. Respete todas las advertencias de seguridad.

Nunca quite las advertencias de seguridad ni otro

tipo de información del equipo.

Lea todas las instrucciones y guárdelas para

uso posterior.

El símbolo de alerta de seguridad precede a

cada nota de seguridad de este manual. El símbolo

indica un riesgo potencial para su seguridad personal

o la de los demás, así como para el producto o la

propiedad.

Este símbolo de alerta de seguridad indica

una posible descarga eléctrica. Le advierte que no

abra la laminadora a fin de no exponerse a una

tensión peligrosa.

LAS SIGUIENTES ADVERTENCIAS SE ENCUENTRAN EN LA

LAMINADORA SKYWARP.

NO ABRIR NO HAY PARTES INTERNAS QUE PUEDA

REPARAR EL USUARIO. DERIVE EL SERVICIO A

PERSONAL CALIFICADO.

PRECAUCIÓN superficie caliente: Los rodillos

de la laminadora pueden tener más de 260 °F/126.7 °C

de temperatura. Tenga cuidado y no los toque.

ADVERTENCIA: No intente reparar ni

realizar mantenimiento a la laminadora.

ADVERTENCIA: No conecte la laminadora

a una fuente de alimentación eléctrica ni intente

utilizarla hasta que haya leído completamente

estas instrucciones. Mantenga estas instrucciones

en un lugar práctico para futuras consultas.

Garantías generales

• Utilice esta laminadora solo para los

fines previstos de acuerdo con las

especificaciones indicadas en el manual

de instrucciones.

• Mantenga las manos, el cabello largo, la

ropa holgada y artículos como collares o

corbatas lejos de la parte delantera de

los rodillos de alimentación para evitar

enredos y atrapamientos.

• Cuando abra la puerta superior de la

laminadora, evite el contacto con los

rodillos internos cuando esta esté

encendida o poco después de que se

haya apagado. Los rodillos pueden

alcanzar temperaturas superiores a los

260 °F/126.7 °C.

• Mantenga las manos y los dedos

alejados del trayecto de la hoja de corte

afilada situada en la salida del carrete

No coloque la laminadora sobre un carro,

soporte o mesa inestables. Una superficie

inestable puede causar que la laminadora

se caiga, lo cual puede provocar lesiones

graves. Evite paradas rápidas, fuerza

excesiva y superficies de piso irregulares

cuando mueva la laminadora sobre un

carro o soporte.

• No anule ni retire los equipos de

Protecciones eléctricas

seguridad eléctricos y mecánicos, como

enclavamientos, escudos y protecciones.

• No inserte objetos que no sean aptos

para la laminación.

• No exponga la laminadora a líquidos.

• El equipo debe estar conectado a un

receptáculo (tomacorriente) de fácil acceso y

con conexión a tierra (de 3 clavijas) cerca del

equipo.

Page 36

• Esta laminadora debe estar conectada a la

tensión de alimentación correspondiente a la

potencia eléctrica indicada en la placa de serie

situada en la parte posterior de la máquina.

• Desenchufe la laminadora antes de moverla o

cuando no esté en uso por un período

prolongado.

• No opere la laminadora con un cable de

alimentación o enchufe dañado.

• No sobrecargue los tomacorrientes, ya que

esto puede provocar incendios o descargas

eléctricas.

• No modifique el enchufe de conexión. Este

enchufe está configurado para la

alimentación eléctrica correspondiente.

• La unidad está diseñada para uso exclusivo en

interiores.

• Desconecte el enchufe del tomacorriente al

que está conectado y sostenga el cable de

alimentación mientras mueve la laminadora.

• No opere la laminadora con un cable de

alimentación o enchufe de conexión dañados

ante el mal funcionamiento ni después de

que la laminadora se haya dañado. Póngase

en contacto con un representante de servicio

autorizado de GBC para obtener ayuda.

PRECAUCIÓN: El receptáculo debe estar

situado cerca del equipo y debe ser de fácil

acceso. No utilice un cable prolongador.

ADVERTENCIA: No conecte la laminadora

a una fuente de alimentación eléctrica ni intente

utilizarla hasta que haya leído completamente

estas instrucciones. Mantenga estas instrucciones

en un lugar práctico para futuras consultas.

ADVERTENCIA: este dispositivo no está

diseñado para su uso en el campo de visión

directo en los lugares de trabajo de visualización.

Para evitar reflexiones incómodas en los lugares

de trabajo de pantallas visuales, este dispositivo

no debe colocarse en el campo de visión directa

Servicio técnico de GBC

Para solicitar accesorios de repuesto, servicio de

mantenimiento, piezas o un contrato de

mantenimiento de equipos, póngase en contacto

con el servicio de asistencia técnica y soporte

técnico de GBC en:

Estados Unidos

ACCO Brands GBC Technical Service and Support

4 Corporate Drive Lake Zurich, IL 60047-8997

www.gbcconnect.com

1-800-723-4000

Canadá

Ontario y Quebec: 1-800-268-3310

Todas las demás provincias: 1-800-268-3447

Local: 905-595-3100

Callcentre@GBCCanada.com

México

(55) 1500 5778

Lada SIN costo: 01 800 759 6825

serviciotecnico@acco.com.mx

Page 37

2. Garantía

Garantía limitada de 2 años/5000 laminados; EE. UU.,

México y Canadá.

ACCO Brands USA LLC, ACCO Brands, 4 Corporate Drive,

Lake Zurich, IL 60047 (en México, ACCO Brands

Mexicana, Neptuno 43, Fraccionamiento Nueva Industrial

Vallejo México 07700 D.F. México), (en Canadá, ACCO

Brands Canada Inc., 7381 Bramalea Road, Mississauga

ON L5S1C4) (cada uno, respectivamente, “ACCO Brands”)

garantiza al comprador original que este producto de

ACCO Brands no presenta defectos de mano de obra ni

materiales, en condiciones de uso habitual y

mantenimiento, por un período de: dos (2)

años/5000 laminados para piezas.

La obligación de ACCO Brands en virtud de esta

garantía se limita a la sustitución o reparación, a

elección de ACCO Brands, de cualquier pieza en

garantía que ACCO Brands encuentre defectuosa, sin

cargo por materiales ni mano de obra. El reemplazo, a

elección de ACCO Brands, puede ser el mismo

producto o un producto sustancialmente similar que

pueda contener piezas refabricadas o

reacondicionadas. Esta garantía quedará anulada en

las siguientes circunstancias:

(i) Si el producto se ha instalado o utilizado

incorrectamente.

(ii) Si el producto ha sido dañado por negligencia o

accidente.

(iii) Si el producto ha sido alterado por cualquier otra

persona que no sea ACCO Brands ni los agentes

autorizados de ACCO Brands

Sin limitar la generalidad del párrafo anterior, la

obligación de ACCO Brands bajo esta garantía limitada

no incluye:

(iiii) daños causados a los rodillos por cuchillos, navajas

de afeitar u otras herramientas filosas; por cualquier

objeto extraño que caiga en el área de trabajo de la

laminadora; o por la limpieza de la laminadora con

soluciones o materiales que dañen sus superficies.

Para la ejecución de la garantía, póngase en contacto

con ACCO Brands a: 800-723-4000 o

www.gbcconnect.com en los Estados Unidos;

800-263-1063 o www.gbccanada.com en Canadá;

(55) 1500 5578 o www.accomexico.mx en México.

EN LA MEDIDA EN QUE LO PERMITA LA LEY

APLICABLE, ESTA GARANTÍA SUSTITUYE A TODAS

LAS DEMÁS GARANTÍAS EXPRESAS. LAS

REPRESENTACIONES O PROMESAS

INCONSISTENTES CON ESTA GARANTÍA O APARTE

DE ESTA NO ESTÁN AUTORIZADAS Y NO SERÁN

VINCULANTES PARA ACCO BRANDS. EN LA

MEDIDA EN QUE LO PERMITAN LAS LEYES

APLICABLES, CUALQUIER GARANTÍA IMPLÍCITA (SI

CORRESPONDIERA) ESTÁ LIMITADA EN

DURACIÓN A LA DE ESTA GARANTÍA. ALGUNOS

ESTADOS Y JURISDICCIONES NO PERMITEN

LIMITACIONES EN CUANTO A LA DURACIÓN DE

UNA GARANTÍA IMPLÍCITA, POR LO QUE ES

POSIBLE QUE LA LIMITACIÓN ANTERIOR NO SE

APLIQUE EN SU CASO. EN LA MEDIDA EN QUE LO

PERMITA LA LEY APLICABLE, EN NINGÚN CASO

ACCO BRANDS SERÁ RESPONSABLE DE NINGÚN

DAÑO ESPECIAL, INCIDENTAL, PUNITIVO,

EJEMPLAR, CONSECUENTE O SIMILAR, SEA O NO

PREVISIBLE. ALGUNOS ESTADOS Y

JURISDICCIONES NO PERMITEN LA EXCLUSIÓN O