Page 1

Provided By

http://www.MyBinding.com

http://www.MyBindingBlog.com

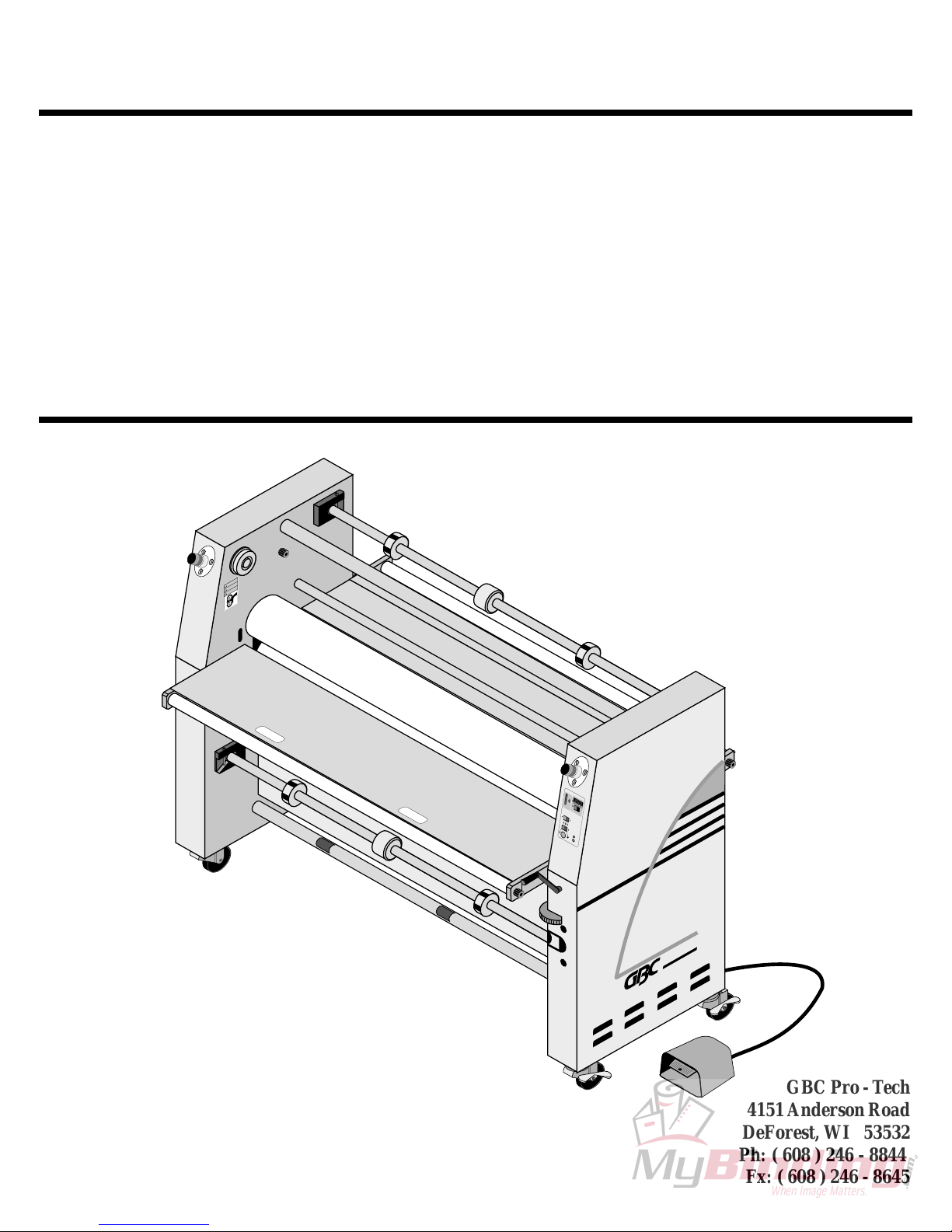

GBC F-60H

Roll Laminator

Instruction Manual

Page 2

FALCON 60 H

OPERATION & MAINTENANCE

MANUAL

© APRIL 2001 GENERAL BINDING CORPORA TION. ALL RIGHTS RESERVED.

Do not duplicate without written permission.

ARNNG

W

HTUN

R

AC

A

N

S

M

F-60 H

PRO-TECH

GBC Pro - T ech

4151 Anderson Road

DeForest, WI 53532

Revision : A Ph: ( 608 ) 246 - 8844

Part number : 930 - 063

Fx: ( 608 ) 246 - 8645

Page 3

Read me fileF 60 H Operation and Maintenance Manual

Read Me File . . . . . . . . .

The information in this publication is provided for reference and is believed to be accurate and complete. General Binding Corporation is not liable for errors in this publication or for

incidental or consequential damage in connection with the furnishing or use of the information

in this publication, including, but not limited to, any implied warranty of fitness or merchantability for any particular use.

General Binding Corporation reserves the right to make changes to this publication and

to the products described in it without notice. All specifications and information concerning

products are subject to change without notice.

Reference in this publication to information or products protected by copyright or patent

does not convey any license under the rights of General Binding Corporation or others. General

Binding Corporation assumes no liability arising from infringements of patents or any other

rights of third parties.

This publication is copyrighted © 2001 by General Binding Corporation. All rights reserved. The information contained in this publication is proprietary and may not be reproduced, stored, transmitted, or transferred, in whole or in part, in any form without the prior and

express written permission of the Genral Binding Corporation.

The following information will explain how to move around within the electronic version

of this publication. The hand will change to a pointer finger identifying hyperlinked areas. When

moving from page to page, use

PAGE, use

from view to view, use

VIEW.

Should you find an error within this publication or would like to make a suggestion,

please utilize the fax correspondence sheet following this read me file and fax it to the number

provided. Your comments and help will ensure up to date information. Thank you.

to go back one PAGE and use to advance one PAGE. When moving

to return to a previous VIEW and use to advance to the next

to return to the first PAGE, use to advance to the last

© April 2001 General Binding Corporation

Page 4

Read me file F 60 H Operation and Maintenance Manual

This page intentionally left blank.

© April 2001 General Binding Corporation

Page 5

Fax Correspondence

Fax number : ( 608 ) 246 - 8645 Date :

To : Technical Coordinator at GBC Protech

4151 Anderson Road

DeForest, WI 53532

From :

Company :

Address :

Phone number : ( ) Fax number : ( )

Read me fileF 60 H Operation and Maintenance Manual

Re : F 60 H Operations and Maintenance Manual ( 930063A )

Section #: Page #:

Correction (s):

Additional comments:

© April 2001 General Binding Corporation

Page 6

Read me file F 60 H Operation and Maintenance Manual

This page intentionally left blank.

© April 2001 General Binding Corporation

Page 7

1.0 Safety

1.1 Symbols .......................................................................................................1 - 1

1.2 Safety precautions ......................................................................................1 - 2

1.3 Safety features ............................................................................................1 - 3

1.4 Installation ..................................................................................................1 - 4

T able of ContentsF 60 H Operation and Maintenance Manual

Table of Contents

1.5 Operations ..................................................................................................1 - 7

1.6 Applications ................................................................................................1 - 9

1.7 Troubleshooting .........................................................................................1 - 10

1.8 Maintenance ...............................................................................................1 - 10

1.9 Decal explanation .......................................................................................1 - 12

Figure 1.9.1 Safety label locations ............................................1 - 14

2.0 Warranty

2.1 Limited warranty information ....................................................................2 - 1

2.2 Exclusions to the warranty ........................................................................2 - 1

© April 2001 General Binding Corporation

Page I

Page 8

T able of Contents F 60 H Operation and Maintenance Manual

3.0 Specifications

3.1 General .......................................................................................................3 -1

3.2 Consumables ...............................................................................................3 - 2

3.3 Function ......................................................................................................3 - 3

3.4 Electrical ....................................................................................................3 - 4

3.5 Dimensions ................................................................................................3 - 5

Figure 3.5.1 Dimensions ...............................................................3 - 6

4.0 Installation

4.1 Pre-installation check list ...........................................................................4 - 1

Figure 4.1.1 Suggested floor layout .............................................4 - 3

4.2 Know your machine ...................................................................................4 - 4

4.3 Unpacking ..................................................................................................4 - 5

4.4 Shrink wrapped .........................................................................................4 - 5

4.5 Crated .........................................................................................................4 - 6

4.6 Accessory pack content ............................................................................4 - 8

Page II

© April 2001 General Binding Corporation

Page 9

4.7 Installing levelers .......................................................................................4 - 9

4.8 Leveling ......................................................................................................4 - 9

4.9 Connecting power ......................................................................................4 - 11

4.10 Safety check ............................................................................................4 - 13

5.0 Operations

5.1 Power ON/ OFF .........................................................................................5 - 2

T able of ContentsF 60 H Operation and Maintenance Manual

5.2 Control panel ..............................................................................................5 - 3

Figure 5.2.1 Front control panel ...................................................5 - 4

5.3 Set temperature ..........................................................................................5 - 5

5.4 Load/ unload film ........................................................................................5 - 6

5.5 Unwind brake tension .................................................................................5 - 9

5.6 Rewind brake tension .................................................................................5 - 9

5.7 Setting the nip ...........................................................................................5 - 10

5.8 Footswitch ..................................................................................................5 - 12

© April 2001 General Binding Corporation

Page III

Page 10

T able of Contents F 60 H Operation and Maintenance Manual

6.0 Applications

6.1 Helpful hints ...............................................................................................6 - 1

6.2 Temperature conversion chart ...................................................................6 - 3

6.3 Charts and diagrams ..................................................................................6 - 5

Blank chart .......................................................................................................6 - 6

Blank diagram ..................................................................................................6 - 7

Blank diagram w/ roll to roll option ................................................................6 - 9

Chart - Pre-coating substrates ........................................................................6 - 10

Diagram - Pre-coating substrates ...................................................................6 - 11

Chart - Mounting an image ............................................................................6 - 12

Diagram - Mounting an image .......................................................................6 - 13

Chart - PSA decaling ......................................................................................6 - 14

Diagram - PSA decaling .................................................................................6 - 15

Diagram - PSA decaling w/ roll to roll options ..............................................6 - 17

Chart - Lo-Melt decaling ................................................................................6 - 18

Page IV

© April 2001 General Binding Corporation

Page 11

T able of ContentsF 60 H Operation and Maintenance Manual

Diagram - Lo-Melt decaling ...........................................................................6 - 19

Diagram - Lo-Melt decaling w/ roll to roll options .........................................6 - 21

Chart - Mounting a decal ...............................................................................6 - 22

Diagram - Mounting a decal ..........................................................................6 - 23

Chart - PSA single sided lamination ( sled ) ...................................................6 - 24

Diagram - PSA single sided lamination ( sled ) ...............................................6 - 25

Chart - PSA single sided lamination ( craft paper ).........................................6 - 26

Diagram - PSA single sided lamination ( craft paper ) ...................................6 - 27

Diagram - PSA single sided lamination ( craft paper ) w/ roll to roll option ...6 - 29

Chart - PSA over-lamination of a mounted image .........................................6 - 30

Diagram - PSA over-lamination of a mounted image ....................................6 - 31

Chart - Lo-Melt over-lamination of a mounted image ...................................6 - 32

Diagram - Lo-Melt over-lamination of a mounted image ...............................6 - 33

© April 2001 General Binding Corporation

Page V

Page 12

T able of Contents F 60 H Operation and Maintenance Manual

7.0 Troubleshooting

7.1 Wave problems ..........................................................................................7 - 1

7.2 Film problems .............................................................................................7 - 3

7.3 Machine problems ......................................................................................7 - 4

7.4 Glossary .....................................................................................................7 - 5

8.0 Maintenance

8.1 Maintenance schedule ................................................................................8 - 1

8.2 Cleaning the rollers ...................................................................................8 - 2

8.3 Clean cabinets and covers ..........................................................................8 - 4

8.4 Clean the control panel ..............................................................................8 - 4

8.5 Chain tensioning .........................................................................................8 - 5

Page VI

© April 2001 General Binding Corporation

Page 13

F 60 H Operation and Maintenance Manual

Safety

1.0 Safety

CAUTIO N

Do n o t attempt to o p era te y ou r

Fa lco n 6 0 H lam in a tor u n til yo u

ha v e rea d th is s ectio n ca r efu lly !

Your safety, as well as the safety of others, is

important to GBC Films Group. This section contains

important safety information.

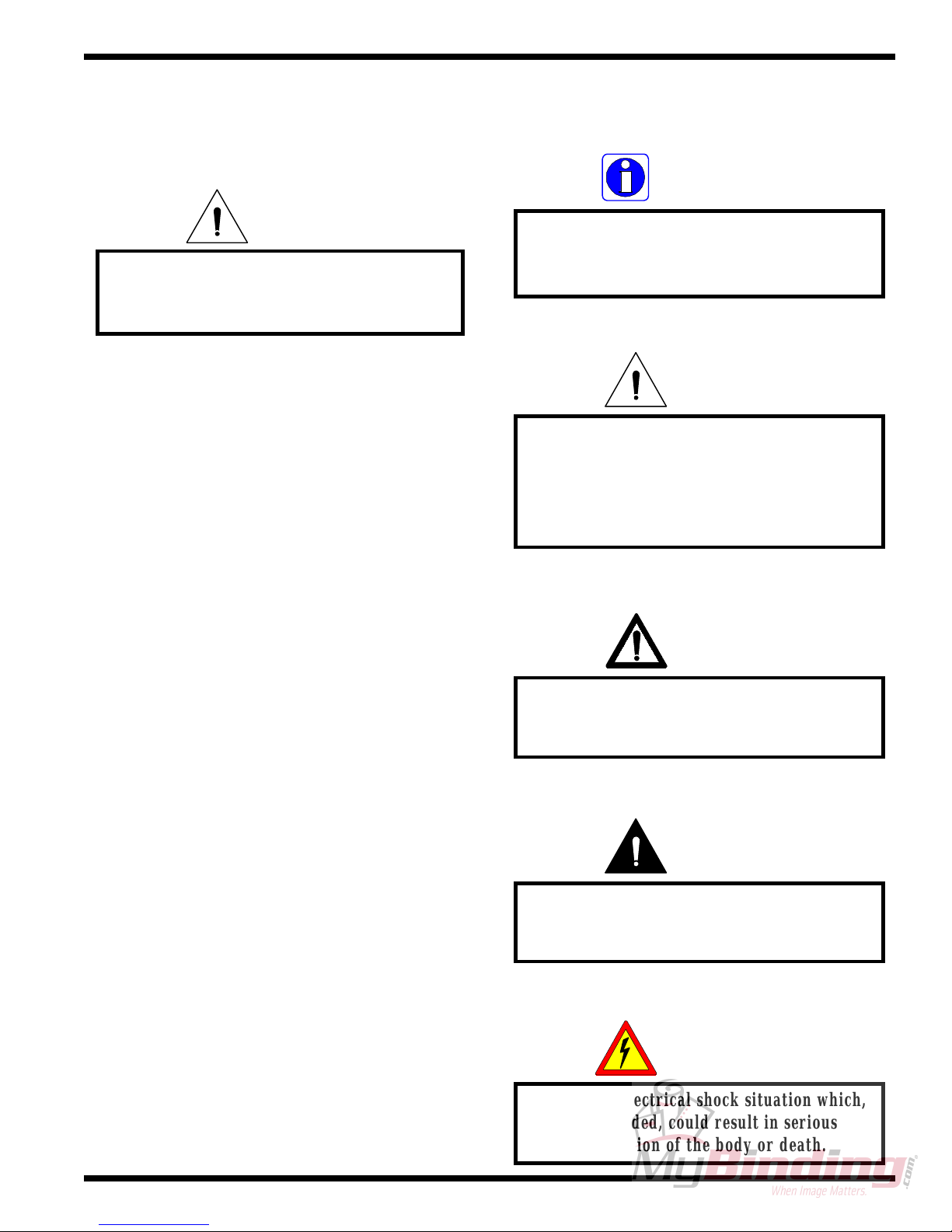

1.1 Symbols

INFORMATION

Indicates helpful information that should be

considered before, during, or after an

action, step or procedure is given.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, could result in minor

or moderate injury, or alerts against unsafe

practices or alerts against actions which

could damage the product.

The following symbols are used throughout this

manual to indicate Information, Caution, Warning,

Danger and Electrical Shock conditions.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in serious

injury.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, could result in death

or serious injury.

ELECTRICAL

SHOCK

© April 2001 General Binding Corporation

Indicates an electrical shock situation which,

if not avoided, could result in serious

paralyzation of the body or death.

Page 1 - 1

Page 14

Safety F 60 H Operation and Maintenance Manual

1.2 Safety precautions

DANGER

At these temperatures there is a danger of

severe burn if the rolls are touched during

The Falcon 60 H laminator has been designed

with safety as a primary consideration; however, you must

become thoroughly familiar with the controls, proper

operation, proper service procedures and safety features

of the laminator before using or servicing the unit.

The manual main roller lift mechanism used to

provide downward pressure on the upper main roller is

capable of producing forces greater than 400 pounds.

This force is applied to any object presented in the opening

( called the nip ) between the two rollers.

The word qualified is defined below;

Qualified;

setup, operation or servicing.

Use care in lowering the upper laminating roller

and know how to react quickly in an emergency. The

main laminator roll up / down control is located on the

right side of the machine within the front. Before turning

the crank handle to set the GAP down, ensure that nothing

is in the nip area.

WARNING

Keep h an d s an d fingers clear of the

laminator roller nip when adjusting nip.

You can be CRUSHED or BURNED!

• Any engineer that has experience with electrical

and mechanical design of lamination equipment. The

engineers should be fully aware of all aspects of safety

with regards to lamination equipment.

• Any commissioning or service engineer must be

of competent nature, trained and qualified to GBC Films

Group standards to fulfill that job. This person will have

completed and passed the full service training course from

GBC Pro-T ech.

• Any GBC T echnician, GBC Specialist, and / or

GBC Films Group T echnician that has been through the

GBC Pro-T ech service training course.

In addition, the main laminating rollers of the

Falcon 60 H can reach temperatures up to 200oF (100oC).

Page 1 - 2

© April 2001 General Binding Corporation

Page 15

F 60 H Operation and Maintenance Manual

1

/

4

t

u

r

n

POWER

Reset

ROT CH

F 60 H

PHOTO-EYE

Safety

1.3 Safety features

The laminator is equipped with four emergency

stops ( E-STOP ). Two are located at the front of the

cabinets and two are at the rear of the cabinets.

E-STOP

E-STOP

T o continue operation, all E-STOPs must be in

the unlatched position. T o reset, twist the E-STOP 1/4

turn counter clockwise.

Press RESET located on the control side cabinet

at the rear of the machine just above the main power on/

off.

T o engage an E-STOP, press down on any of the

four . Any E-STOP, when engaged, removes power to

the laminator .

INFORMATION

The machine will only operate if all four

E-STOPS are in the unlatched position.

© April 2001 General Binding Corporation

The nip area is protected by a electric photo-eye

which shoots a beam in front of the nip across the width

of the rollers. When this beam is broken, power to the

drive motor is removed. The objetc must be removed to

clear the photo-eye. The motor engage switch must be

pressed again to continue motor operation.

Page 1 - 3

Page 16

Safety F 60 H Operation and Maintenance Manual

1.4 Installation

WARNING

The Fa lcon 60 H L am inator is a large and

The following symbols are positioned at various

points in Section 4 Installation.

CAUTION

Failure to follow the pre-installation check

list can result in damage to the laminator.

heavy piece of equipment. It is necessary to

employ LICENSED RIGGERS ONLY to

move the lam inator. The lam inator is not

de sig n e d to b e tip p e d u p or sidew a y s in a n y

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requ ires extensive realignm en t. You can

be crushed or seriously injured.

INFORMATION

ALL SHIPMENTS ARE EX-WORKS.

dock, title passes to the buyer. Please review

WARNING

The operating environment must be free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors.

WARNING

Vapor build up or stored flammable

liquids can cause a fire. Excessive

dust can damage the laminator.

At our

your insurance coverage prior to shipment,

as you are responsible for all subsequent

freight charges and risks.

INFORMATION

Before signing the Bill of Lading, you

should be sure to inspect the crate

and / or pallet for signs of damage or

missing items; if applicable, make

note of this on the Bill of Lading.

CAUTIO N

Do n ot locate the Falcon 60 H w h ere air is

blowing directly on the machine. Th e air

flow can co ol the rolls un ev en ly an d resu lt

in poor output quality.

Page 1 - 4

WARNING

The unpacking process requires at least two

people. You can be severely injured, crushed

or cause damage to the laminator.

© April 2001 General Binding Corporation

Page 17

F 60 H Operation and Maintenance Manual

INFORMATION

Depending on the destination and customer

preference, your machine may be shipped in

various ways. The laminator may arrive

shrink wrapped or in a plywood crate on a

skid. Please follow the unpacking procedure

that pertains to your method of shipment.

Safety

CAUTION

Do not allow the top to fall into the crate. It

can damage the laminator.

INFORMATION

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

WARNING

Do not attempt to move the laminator across

anything other than a flat level surface

without trained and qualified riggers. You

can be crushed or seriously injured.

Do not put packing screws on the floor.

They can cause problems when trying to roll

the laminator into position or you can

become injured if stepped on.

CAUTION

A second person must support the side

labeled 5 in Figure 4.5.1 It can fall and

damage the laminator or cause harm to you

and others.

INFORMATION

GBC Film Group's warranty does not

cover malfunction of the equipment due to

mishandling and / or tipping. GBC Films

Group bears no responsibility for personal

injury or damage due to moving the

laminator improperly.

© April 2001 General Binding Corporation

WARNING

Do not attempt to use the ramps if they are

not secured to the pallet. Ensure the pallet is

on a flat even surface before attempting to

roll the machine off.

Page 1 - 5

Page 18

Safety F 60 H Operation and Maintenance Manual

IN F O RM A T ION

Ab out recycling: The crate compon ents can

be reused for shipping the laminator again

or can be disassembled and the wood and

screws recycled. Th e sh rink wrap is not

recyclable, so it must be d iscarded.

CAUTION

Do n o t m ove th e leveling nu t when securin g

the inside nut to the cabinet.

WARNING

Follow the correct wiring diagram when

supplying power to the laminator. If

improperly connected, you can be seriously

injured or cause damage to the laminator.

WARNING

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

IN F OR MAT ION

Yo u will ne ed the con tr o l sid e ca b in e t co v e r

off to conn ect the electrical power.

ELECTRICAL

SHOCK

Only a qualified electrician should connect

power to the laminator. You can be severely

shocked, electrocuted or cause a fire if

power is improperly applied.

WARNING

If a safety feature is not working

properly, contact your local service

representative immediately.

CAUTIO N

Do not use a hard substrate or a substrate

with sharp edges. You may cause damage to

the lam inating rollers!

Page 1 - 6

© April 2001 General Binding Corporation

Page 19

F 60 H Operation and Maintenance Manual

1.5 Operations

The following symbols are positioned at various

points in Section 5 Operations.

WARNING

Do not w ear ties, loose fit clothing or

dangling jewelry while operating or

servicing the lam in ator. Th ese item s can g et

caught in the nip and choke you or you can

be crushed or burned.

Safety

WARNING

W h en the lam in ator ro llers are in

motion, keep hands and fingers

away from the nip of the rollers.

You may be CRUSHED or BURNED!

WARNING

When o p e ra tin g th e la minato r u sing the

footsw itch, keep h an d s an d fin gers

away from the nip of the rollers.

You may be CRUSHED or BURNED!

IN F OR MAT ION

The m ac h in e will only o p e ra te if a ll

four emergency stop s are u n latched an d

RESET has been pressed.

WARNING

It is u n sa fe to sh e et f eed with o u t the

pressu re plate pro p erly placed o n

the fron t feed tab le.

WARNING

Do n o t opera te the lam ina tor, except

during web set up, without the front

and rear feed tables in position.

CAUTIO N

En su re the roll of lam in ate is loaded

properly on the unwind shaft.

Exposed adhesive should be facing

away from the rollers.

Th is will pre v ent hou r s o f ro ll cle a n in g !

WARNING

Keep h an d s and fin gers clear of th e

lamina tor roller nip when ch an gin g G A P .

You can be CRUSHED or BURNED!

© April 2001 General Binding Corporation

IN F OR MAT ION

Th e P o ly -in / P o ly-o u t diagra ms refe r to th e

upper rolls of film only. The mount adhesive

and craft p ap ers are fo r referen ce on ly.

Page 1 - 7

Page 20

Safety F 60 H Operation and Maintenance Manual

WARNING

Never leave the unw ind shaft out of the

unwind support saddle unless loading

or unloading film.

CAUTIO N

W h en u sing tw o rolls on th e m ach ine,

ensur e the film w idth s are id entical.

Exposed adhesive can cause complications.

CAUTIO N

CAUTIO N

Excess pressure can damage the laminating

rollers. Alway s u se the m in imu m roll

pressure n ecessa ry to co m p lete the task.

CAUTIO N

Objects other than m edia, film or approved

substrates, will cause irreparable damage

to the rollers if caugh t in the n ip.

CAUTIO N

Never use an open blade near the laminating

rollers. You may cut the rollers or yo ur self.

IN F OR MAT ION

Always use the minimum amount

of bra ke fo r the job .

IN F OR MAT ION

If mo re bra ke is need ed, ad d an O-ring

to the brake side of the rewind.

Sharp edges on a substrate

should be filed smooth.

Sha rp edg es can C U T th e rollers!

IN F OR MAT ION

Ex c es siv e pressu r e will cause the

substrate to bow or flatten.

IN F OR MAT ION

De n s ity o f the substrate w ill determine th e

amoun t of pressure you may use.

Page 1 - 8

© April 2001 General Binding Corporation

Page 21

F 60 H Operation and Maintenance Manual

1.6 Applications

The following symbols are positioned at various

points in Section 6 Applications.

Safety

IN F OR MAT ION

Ex c es siv e pressu r e will cause the

substrate to bow or flatten.

WARNING

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

IN F OR MAT ION

Use film brake tension to control the

separa tion po int of the r elease liner.

IN F OR MAT ION

Excessive brake tension may cause the

imag e to curl. A lw ays u se the minimum

amoun t of brake for the job.

CAUTIO N

Excess pressure can damage the laminating

rollers. Alway s u se the m in imu m roll

pressure n ecessa ry to co m p lete the task.

IN F OR MAT ION

Sp ee d s and tempera tu r es will affe ct th e

bond strength of Lo-Melt adhesives.

IN F OR MAT ION

Th e m o un t ad h esive m u st no t exceed 1 in.

the w idth of the substrate. If it does, you

w ill e xp e rie n ce c omplications with th is

application.

© April 2001 General Binding Corporation

IN F OR MAT ION

Never stop the lam inator when an im age is

within the n ip of th e rollers.

IN F OR MAT ION

Lam inates and papers should always be

stored in a co n trolled env irom en t.

Page 1 - 9

Page 22

Safety F 60 H Operation and Maintenance Manual

1.7 Troubleshooting

The following symbols are positioned at various

points in Section 7 T roubleshooting.

WARNING

Do not wear ties, loose fitting clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

1.8 Maintenance

The following symbols are positioned at various

points in Section 8 Maintenance.

WARNING

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

INFORMATION

For optimal temperature settings of

various laminates, contact your

supplier or sales representative.

INFORMATION

Improper maintenance, can

result in poor output quality.

ELECTRICAL

SHOCK

Remove power from the laminator before

servicing. You can be severely shocked,

electrocuted or cause a fire.

IN F O RM A T ION

Page 1 - 10

Below is a recommended maintenance

schedule. Before performing any of the steps

listed, read through the procedures first.

Please follow the instructions pertaining to

the step you are perform ing.

© April 2001 General Binding Corporation

Page 23

F 60 H Operation and Maintenance Manual

CAUTION

Safety

ELECTRICAL

SHOCK

Excessive pressure can destroy the silicone

layer by pressing to hard or scrubbing

too long in one spot.

CAUTION

Exercise care when cleaning the laminating

rollers with 80% isopropyl alcohol:

Use only in a well ventilated area

Wear rubber gloves

Use only on cool rolls

CLEANING HEATED ROLLERS CAN

IGNITE THE FUMES!

Remove power from the laminator before

cleaning. You can be severely shocked,

electrocuted or cause a fire.

ELECTRICAL

SHOCK

Do not use liquid or aerosol cleaners on the

laminator. Do not spill liquid of any kind on

the laminator. You can be severely shocked,

electrocuted or cause a fire. Use only a damp

cloth for cleaning unless other wise

specified.

WARNING

CAUTION

Do NOT pick or pull heat activated adhesive

off the rolls when they are cold. You can

cause irreparable damage to the

laminating rolls.

Always practice lock out/ tag out procedures

WARNING

W h en op erating the laminator using the

footswitch, keep hands and fingers

away from the nip of the rollers.

You may be CRUSHED or BURNED!

Rem o ve ALL p ow er to th e lam in ator b efo re

remo ving an y ca bin et covers.

You may be shocked or electrocuted!

WARNING

wh en p erforming any ty pe o f service or

main tena nce work on the machine.

IN F OR MAT ION

Th e m o tor con trols the tension of th e bo th

cha ins. If on e c h ain is still too lo o se ,

a half link may be removed.

© April 2001 General Binding Corporation

Page 1 - 11

Page 24

Safety F 60 H Operation and Maintenance Manual

y

g

g

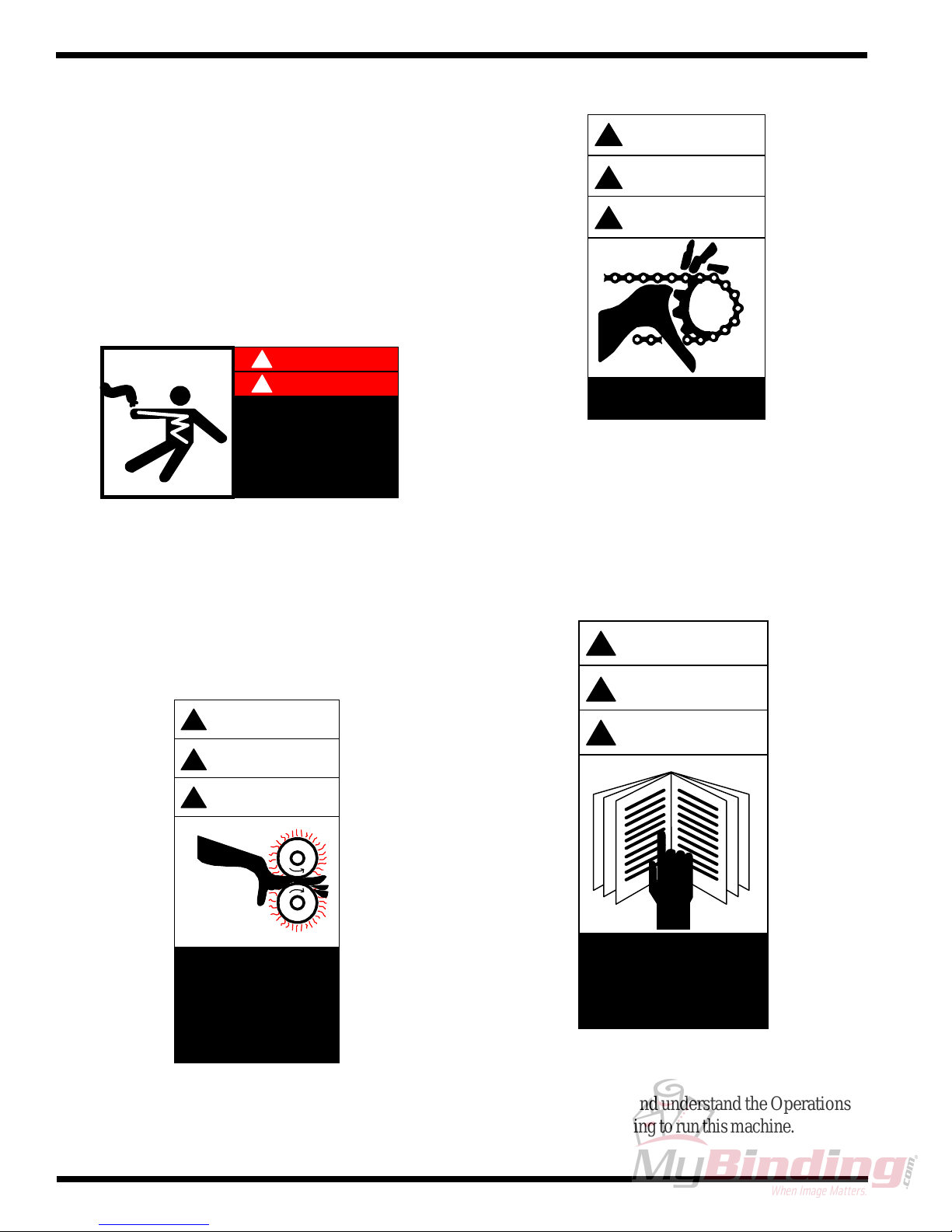

1.9 Label locations

WARNING

!

ACHT UNG

Posted at various locations on the Falcon 60 H

Laminator are important safety labels. Pay careful

attention to these labels at all times! Figure 1.12.1

illustrates the location of each of these labels.

!

DANGER

!

GEFAHR

HAZARDOUS

VOLTAGE

To be serviced only

by trained and

authorized personnel.

Lockout power b efore

servicing

Moving Parts: Keep hands and fingers away . Y ou

may be crushed and/ or cut.

!

M ISE EN GARDE

!

Moving parts can

crush and cut.

Hazardous V oltage: Do not open these cabinets. This

machine is to be serviced only by trained and authorized

personnel.

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Crush and burn

hazard. Sta

of movin

Stop m achine and

raise roll before

cleanin

clear

rollers.

.

WARNING

!

ACHTUNG

!

M ISE EN G ARDE

!

Carefully read Operator's

Manual before handling

this machine. Observe

instructions and safety

rules when operating.

Roller Pinch Point: Keep hands and fingers away.

Y ou may be crushed and/ or burned.

Page 1 - 12

Read Manual: Read and understand the Operations

Manual before attempting to run this machine.

© April 2001 General Binding Corporation

Page 25

F 60 H Operation and Maintenance Manual

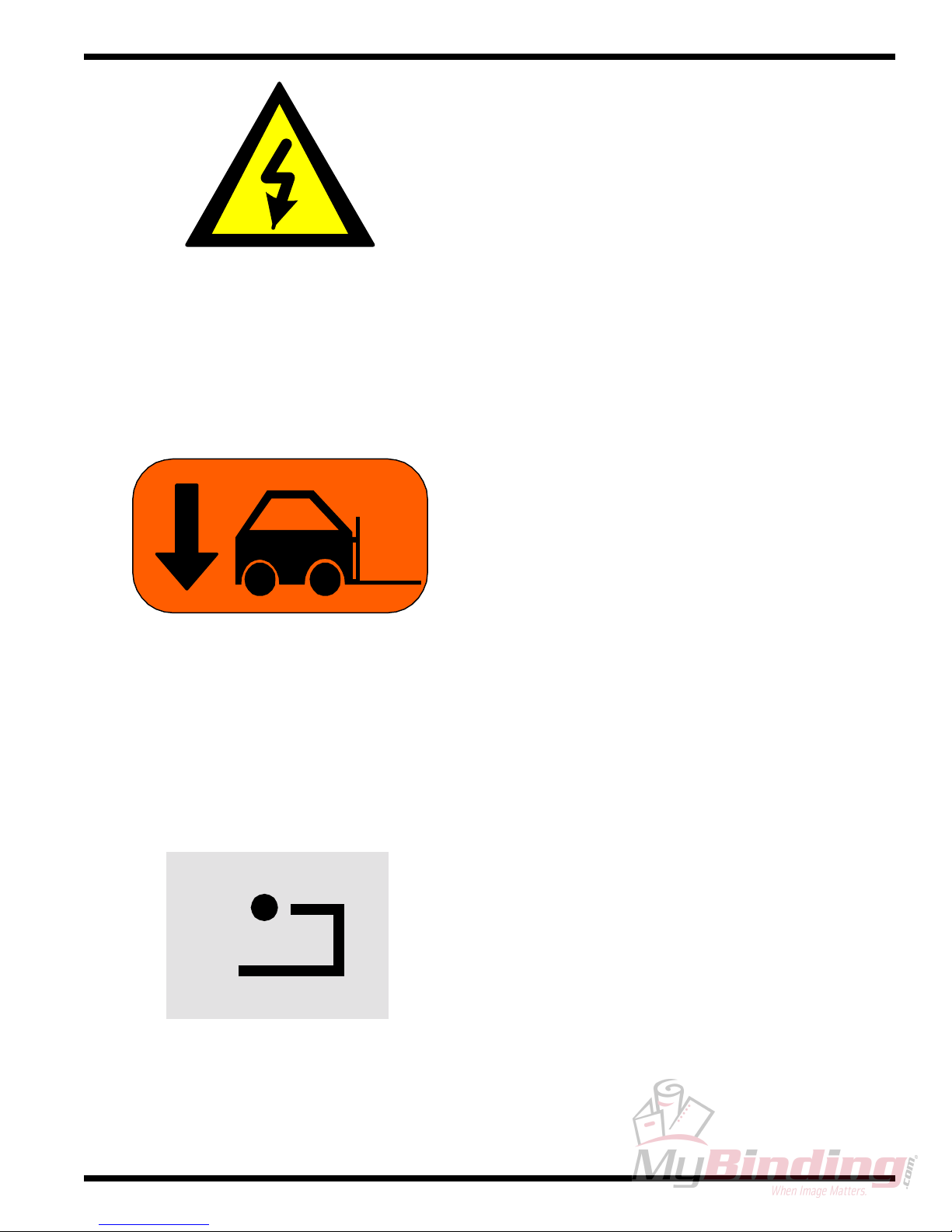

Electrical Shock: Live voltage present. Exercise

extreme caution. Y ou may be electrocuted!

Safety

Refer to Figure 1.9.1 Label Placement illustrates

the location of each of these labels.

Lift Here: This point may be used as a lifting point. If

ignored, damage will occur to the laminator.

Reset: Machine reset. Press after initiating power to the

laminator or after an E-STOP or E-CABLE has been

engaged then reset.

© April 2001 General Binding Corporation

Page 1 - 13

Page 26

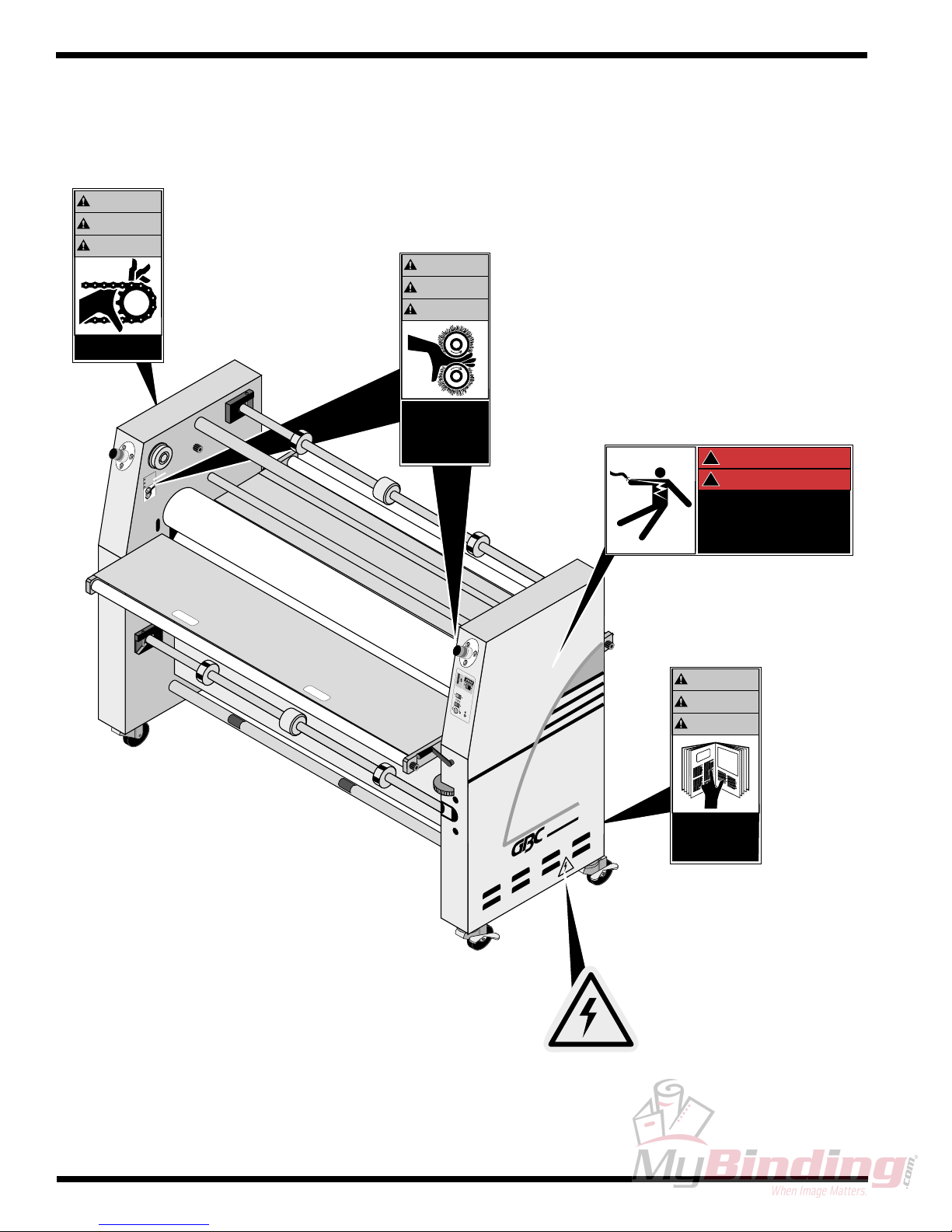

Safety F 60 H Operation and Maintenance Manual

Figure 1.9.1 Safety label locations

(Inside cabinet)

WARNING

ACHTUNG

MISE EN GARDE

WARNING

ACHTUNG

MISE EN GARDE

Moving parts can

cruch and cut.

Crush and burn

hazard. Stay clear

of moving rollers.

Stop machine and

raise roll before

cleaning.

ARNN

A HU

N

S

M

(Inside cabinet)

!

DANGER

!

GEFAHR

HAZARDOUS

VOLTAGE

To be serviced only

by trained and

authorized personnel.

Lockout power before

servicing

F-60 H

PRO-TECH

WARNING

ACHTUNG

MISE EN GARDE

Carefully read operator's

Manual before handling

this machine. Observe

instructions and safety

rules when operating.

Page 1 - 14

© April 2001 General Binding Corporation

Page 27

WarrantyF 60 H Operation and Maintenance Manual

2.0 Warranty

GBC Films Group warrants the equipment sold

is free from defects in material and workmanship for a

period of one ( 1 ) year parts ( excludes normal wear

items ) and 90 days labor from the date of installation.

This warranty is the only warranty made by GBC Films

Group and cannot be modified or amended.

GBC Films Group’s sole and exclusive

liability and the customer’s sole and exclusive

remedy under this warranty shall be, at GBC Films

Group’s option, to repair or replace any such

defective part or product. These remedies are only

available if GBC Films Group’s examination of the

product discloses to GBC Films Group’ s satisfaction

that such defects actually exist and were not caused

by misuse, neglect, attempt to repair , unauthorized

alteration or modification, incorrect line voltage, fire,

accident, flood, or other hazard.

THE WARRANTY MADE HEREIN IS IN

LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING

ANY WARRANTY OR

MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. GBC

FILMS GROUP WILL NOT BE LIABLE

FOR PROPERTY DAMAGE OR

PERSONAL INJURY ( UNLESS

PRIMARILY CAUSED BY ITS

NEGLIGENCE ), LOSS OF PROFIT OR

OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES

ARISING OUT OF THE USE OR

INABILITY TO USE THE EQUIPMENT.

2.2 Exclusions to the

2.1 Limited Warranty

This warranty specifically does not cover damage

to the laminating rollers caused by knives, razor blades,

other sharp objects, failure caused by adhesives or

improper use of the machine. Warranty repair or

replacement does not extend the warranty beyond the

initial one year period from the date of delivery .

CAUTION

Warranty

This warranty specifically does not

cover;

1. Damage to the laminating rollers caused by knives,

razor blades, other sharp objects or failure caused

by adhesives.

2. Damage to the machine caused by lifting, tilting and /

or any attempt to position the machine other than

rolling on the installed castors on even surfaces.

3. Improper use of the machine.

Unauthorized customer alterations will

void this warranty.

© April 2001 General Binding Corporation

4. Damage due from unqualified person(s) servicing the

machine.

Page 2 - 1

Page 28

Warranty F 60 H Operation and Maintenance Manual

Qualified

• Any engineer that has experience with electrical

and mechanical design of lamination equipment. The

engineers should be fully aware of all aspects of safety

with regards to lamination equipment.

• Any commissioning or service engineer must be

of competent nature, trained and qualified to GBC Films

Group standards to fulfill that job. This person will have

completed and passed the full service training course from

GBC Pro-T ech.

• Any GBC T echnician, GBC Specialist, and / or

GBC Films Group T echnician that has been through the

GBC Pro-T ech service training course.

Page 2 - 2

© April 2001 General Binding Corporation

Page 29

3.0 Specifications

Specifications provide all of the technical data for

the Falcon 60 H Laminator.

3.1 General

SpecificationsF 60 H Operation and Maintenance Manual

Description:

Features:

• Cost efficient, wide format color finisher for the sheet

fed ink jet market. The Falcon 60 H is a self standing,

bi-directional cold mounter and laminator with the abilty

to run Lo-Melt overlaminate.

• T wo unwinds ( 1 upper, 1 center/ front )

• One rewind ( upper front )

• Infeed and oufeed tables

• Footswitch

• Front and rear table idlers

• Bi-directional system

• Four E-STOPs

• Photo-eye nip protection

• Roll to roll capability ( option)

Applications:

© April 2001 General Binding Corporation

• Single sided lamination

• Mounting

• Decaling

• Low melt film

Page 3 - 1

Page 30

Specifications F 60 H Operation and Maintenance Manual

3.2 Consumable

Film types:

Film diameters:

Core size:

• Pressure sensitive laminates

• Pressure sensitive adhesives

• Low melt laminates

• Up to a 8 in. roll diameter ( 20.3 cm )

• 3 in. core standard ( 7.62 cm )

• 2-1/4 in. optional ( must have optional core adapters )

( 5.72 cm )

Film widths:

Paper widths:

Mounting thickness:

Safety:

• 62 in. Pressure sensitive ( 162.6 cm )

• 60 in. Low Melt ( 157.8 cm )

• 62 in. maximum paper width ( 157.8 cm )

• Up to 1 in. thick ( 2.54 cm ) either direction

• Designed to UL safety standards

Page 3 - 2

© April 2001 General Binding Corporation

Page 31

3.3 Function

SpecificationsF 60 H Operation and Maintenance Manual

Speed:

Motor:

Heating capabilities:

Controls:

• 0 - 16 ft / min ( 0 - 4.6 m / min )

• 2-1/4 horse power drive motor

• Bi-directional D.C. motor

o

• 68

F - 200oF ( 20oC - 93oC )

• Front control panel

• Footswitch

Roll design:

© April 2001 General Binding Corporation

• High release silicone rollers

Page 3 - 3

Page 32

Specifications F 60 H Operation and Maintenance Manual

3.4 Electrical

United Statesand Canada:

B.T .U. output:

Heater wattages:

Amperage draw:

• 230 ~ 240 VAC, 50/60 Hz, single phase, 40 amps

• 18,520 B.T.U. / hour

• 5429 watts per heater @ 240 vac

• No heat, motor only : 1 - 3 amps

• T op heat and motor : 25 - 30 amps

D/C voltage used:

A/C voltage used:

Page 3 - 4

• 24 vdc

• 230~ 240 vac ( minimum )

© April 2001 General Binding Corporation

Page 33

3.5 Dimensions

W eight:

SpecificationsF 60 H Operation and Maintenance Manual

Uncrated:

Crated:

Dimensions

Uncrated:

Crated

• 1350 lbs. ( 612 kg. )

• 1625 lbs. ( 737 kg. )

• 80 in. (L) x 38.5 in. (W) x 57 in. (H)

( 203 cm (H) x 98 cm (W) x 145 cm (L) )

Refer to Figure 3.5.1 Dimensions

• 90 in. (L) x 44 in. (W) x 68 in. (H)

( 229 cm (H) x 112 cm (W) x 173 cm (L) )

Nip Height:

© April 2001 General Binding Corporation

• 38 in. ( 96.5 cm )

Page 3 - 5

Page 34

Specifications F 60 H Operation and Maintenance Manual

Figure 3.5.1 Dimensions

80 in.

( 203 cm )

ARNING

W

HTUNG

AC

MS N AR

57 in.

( 145 cm )

F-60 H

PRO-TECH

38.5 in.

( 98 cm )

Page 3 - 6

© April 2001 General Binding Corporation

Page 35

InstallationF 60 H Operation and Maintenance Manual

4.0 Installation

GBC Films Group is committed to a program of

ongoing product improvement. As a result, we are

providing these instructions so you can insure that your

new Falcon 60 H Laminator is properly and securely

unpacked, moved, and installed. Installation should be

performed by a qualified technician.

Before a Falcon 60 H Laminator can be installed,

there are a few requirements that must be met. Make

certain that each of the requirements listed in the following

pre-installation checklist are met before beginning

installation.

CAUTION

Is the environment appropriate for the laminator?

The laminator requires a clean, dust and vapor

free environment to operate properly. Do not

locate it where there is air blowing directly on the

machine.

Have you contacted a certified electrician to both

wire the laminator and ensure that adequate power

is being supplied, having the appropriate capacity ,

over current protection and safety lockouts are

available?

WARNING

The operating environment must be free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors.

Failure to follow the pre-installation check

list can result in damage to the laminator.

4.1 Pre-installation

Are doorways and hallways wide enough for the

laminator to be moved to the installation site?

Is there ample room for the laminator?

A work area must be established that allows for

operation in both the front and rear of the

laminator and provides space for efficient material

flow. Figur e 4.1.1 illustrates a typical machine

area layout.

WARNING

Vapor build up or stored flammable

liquids can cause a fire. Excessive

dust can damage the laminator.

CAUTIO N

Do n ot locate the Falcon 60 H w h ere air is

blowing directly on the machine. Th e air

flow can co ol the rolls un ev en ly an d resu lt

in poor output quality.

© April 2001 General Binding Corporation

Page 4 - 1

Page 36

Installation F 60 H Operation and Maintenance Manual

The Falcon 60 H requires single phase, 230 to

240 vac, 50/ 60 Hz, 40 amp service. No other

type of connection is permitted.

WARNING

The Fa lcon 60 H L am inator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED RIGGERS ONLY to

move the lam inator. The lam inator is not

de sig n e d to b e tip p e d u p or sidew a y s in a n y

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requ ires extensive realignm en t. You can

be crushed or seriously injured.

For instructions on how to connect power,

proceed to 4.9 Connecting power in this section.

Page 4 - 2

© April 2001 General Binding Corporation

Page 37

Figure 4.1.1 Suggested Floor Layout

4 ft. x 6 ft. (1.22 m x 2 m )

Work table on wheels

InstallationF 60 H Operation and Maintenance Manual

20 ft.

( 6 m )

8.2 ft.

( 2.57 m )

38.5"

( .98 m )

Table height

37-3/4 in. (.95 - .96 m)

78 in.

( 2 m )

Electrical

supply

3 ft. ( 1 m )

Front operating position

8.2 ft.

( 2.57m )

© April 2001 General Binding Corporation

4 ft. x 6 ft. (1.22 m x 2 m )

Work table on wheels

Table height

37-3/4 in. (.95 - .96 m)

13' ( 4 m)

Page 4 - 3

Page 38

Installation F 60 H Operation and Maintenance Manual

4.2 Know your machine

Before performing any procedure within this

manual, it is recommended that you take time to know

the parts of your new machine.

Figure 4.2.1 The laminator

Drive side

( Left )

Rear

Figure 4.2.3 Idlers and unwinds

Upper unwind

Web idler

Rear table idler

Tie bars

F-60 H

Lower Unwind

PRO TECH

Front table idler

Figure 4.2.4 Misc.

Front

F-60 H

Control side

PRO TECH

( Right )

Figure 4.2.2 Safety and controls

Rewind drive

Main roller lift

Core grip

E-stop

Upper unwind brake

Photo-eye

Unwind saddle

Front table

Figure 4.2.5 Power

Run/ Stop

Main rollers

Rear table

F-60 H

PR -TECH

Castors

Core support

F-60 H

Foot switch

Lower unwind brake

Control panel

Page 4 - 4

POWER

H

C

-TE

O

R

P

On/ Off

© April 2001 General Binding Corporation

Reset

Page 39

InstallationF 60 H Operation and Maintenance Manual

4.3 Unpacking

INFORMATION

ALL SHIPMENTS ARE EX-WORKS.

dock, title passes to the buyer. Please review

your insurance coverage prior to shipment,

as you are responsible for all subsequent

freight charges and risks.

INFORMATION

Before signing the Bill of Lading, you

should be sure to inspect the crate

and / or pallet for signs of damage or

missing items; if applicable, make

note of this on the Bill of Lading.

At our

With regards to your shipping methods, use one

of the following procedure described to safely and

properly unwrap / uncrate your laminator .

4.4 Shrink Wrapped

a) Inspect the machine for any obvious shipping

damages upon receipt. Report any damage to

your carrier .

b) Carefully unwrap the shrink wrap from around

the laminator .

INFORMATION

Depending on the destination and customer

preference, your machine may be shipped in

various ways. The laminator may arrive

shrink wrapped or in a plywood crate on a

skid. Please follow the unpacking procedure

that pertains to your method of shipment.

WARNING

The unpacking process requires at least two

people. You can be severely injured, crushed

or cause damage to the laminator.

Do not attempt to move the laminator across

without trained and qualified riggers. You

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

c) Carefully wheel your Falcon 60 H Laminator

with a second person to the installation site.

WARNING

anything other than a flat level surface

can be crushed or seriously injured.

© April 2001 General Binding Corporation

Page 4 - 5

Page 40

Installation F 60 H Operation and Maintenance Manual

4.5 Crated

WARNING

The Fa lcon 60 H L am inator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED RIGGERS ONLY to

move the lam inator. The lam inator is not

de sig n e d to b e tip p e d u p or sidew a y s in a n y

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requ ires extensive realignm en t. You can

be crushed or seriously injured.

To uncrate the laminator

a) Remove the top of the crate and then the sides

in the order shown in Figure 4.5.1

CAUTION

Do not allow the top to fall into the crate. It

can damage the laminator.

INFORMATION

GBC Film Group's warranty does not

cover malfunction of the equipment due to

mishandling and / or tipping. GBC Films

Group bears no responsibility for personal

injury or damage due to moving the

laminator improperly.

Tools required

• # 2 Phillips head screwdriver

• 7/8” open end wrench or adjustable wrench

• Crow bar

• A second person

INFORMATION

Do not put packing screws on the floor.

They can cause problems when trying to roll

the laminator into position or you can

become injured if stepped on.

CAUTION

A second person must support the side

labeled 5 in Figure 4.5.1 It can fall and

damage the laminator or cause harm to you

and others.

Page 4 - 6

© April 2001 General Binding Corporation

Page 41

InstallationF 60 H Operation and Maintenance Manual

Figure 4.5.1 Disassembling of the crate

3

A

U

A

1

5

4

F-60 H

R E

2

Removing the shrink wrap

Moving the laminator

a) Have the laminator rolled off the skid and placed

on the floor by licensed riggers. The ramps

included with the laminator can be secured utilizing

screws removed from the disassembled crate.

Figure 4.5.2 illustrates positioning of the ramps.

WARNING

Do not attempt to use the ramps if they are

not secured to the pallet. Ensure the pallet is

on a flat even surface before attempting to

roll the machine off.

a) Gently unwrap the shrink wrap from around the

laminator.

Figure 4.5.2 Positioning of the ramps

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

b) Move all packing materials to a safe distance.

b) Remove any plastic strapping and/or packing

paper taped to the rollers.

© April 2001 General Binding Corporation

Page 4 - 7

Page 42

Installation F 60 H Operation and Maintenance Manual

4.6 Accessory pack

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

unpacked and moved into final position, open the accessory

pack and verify the contents.

Once the Falcon 60 H Laminator has been

c) Remove all packing materials to a safe distance

from the laminator and dispose of properly .

d) Use two people to carefully roll the laminator to

the desired location.

INFORMATION

About recycling: The crate components can

be reused for shipping the laminator again

or can be disassembled and the wood and

screws recycled. The shrink wrap is not

recyclable, so it must be discarded.

contact your local service technician or sales

representative.

Accessory Pack contents

• One Fuse, 250 V, 20 amp ( 186 - 135 )

• T wo Fuses, 2,5 amp ( 186 - 220 )

• One fuse, 0.5 amp ( 186-016 )

• One Operators Manual ( 930 - 063 )

• One T owel ( 475 - 950 )

• One Zippy knife ( 475 - 620 )

• One strain relief for main power ( 175-201 )

• One rubber cement pad ( 930320 )

• One crank handle ( 629-018 )

• One O-ring ( 480 - 005 )

• Four leveling pads ( 470 - 101 )

• One T-handle, 1/4 in. ( 475 - 210 )

• One roll of masking tape ( 475 - 000 )

• One crank handle ( ??? - ??? )

• One BHCS ( floor stock item )

If you are missing any of the items listed above,

Page 4 - 8

Contacts:

GBC Parts ( 800 ) 790 - 7787

GBC Europe parts 33 - 45 - 535 - 7676

© April 2001 General Binding Corporation

Page 43

InstallationF 60 H Operation and Maintenance Manual

4.7 Installing levelers

Leveling of the machine is a customer option. If

you choose not to level the laminator and you encounter

output problems, please level the machine and try your

application again before calling for technical support.

Tools required

• ( 2 ) 3/4” open end wrenches

• Four leveling pads

( from the accessory pack )

4.8 Leveling

Leveling of the laminator is very important in the

way the machine performs. Leveling is crucial to the tram

( tracking ) of the materials through the machine.

Tools required

• ( 2 ) 3/4 in. open end wrenches

• 1/8 in. allen wrench

• Level

• A second person

a) V erify that the laminator has sufficient room

around it to load film, walk around and to be

serviced if necessary .

b) Place one leveling pad on each of the four

leveling bolts on the laminator.

Jam n uts

Leveling pads

a) W ith a 1/8 in. allen wrench, remove the drive

side and control side cabinet covers by;

1) Loosen the three screws along the

bottom.

2) Remove the seven screws along the

top and sides of the cover.

2

F-60 H

c) Use a 3/4 in. open end wrench to secure the

jam nut against the leveling pad.

© April 2001 General Binding Corporation

PRO-TECH

1

Page 4 - 9

Page 44

Installation F 60 H Operation and Maintenance Manual

b) Loosen the nut on the inside of both cabinets

securing the leveling bolt with a 3/4 in. wrench.

Inside nuts

c) Position the level on the top of the control side

cabinet.

e) Position the level on the top of the drive side

cabinet.

A

F-60 H

PRO-TECH

f) Level the drive side from front to back by

turning the leveling nut clockwise to raise or

counter clockwise to lower .

F-60 H

PRO TECH

d) Level the control side from front to back by

turning the leveling nut clockwise to raise or

counter clockwise to lower.

9

Leveling nuts

g) Position the level center of the upper tie bar.

F-60 H

PRO TECH

h) Level the laminator from drive side to control

side by turning the leveling nut clockwise to

raise or counter clockwise to lower.

Page 4 - 10

© April 2001 General Binding Corporation

Page 45

InstallationF 60 H Operation and Maintenance Manual

i) Verify that all three points are still leveled.

j) Hold the leveling nut in place with a 3/4 in. open

end wrench while you secure the inside nut to

the cabinet. Do this for both sides.

9

Inside nuts

4.9 Connecting power

ELECTRICAL

SHOCK

Only a qualified electrician should connect

power to the laminator. You can be severely

shocked, electrocuted or cause a fire if

power is improperly applied.

Tools required

CAUTIO N

Do n o t m ove th e leveling n ut when securin g

the inside nut to the cabinet.

k) Replace the drive side cabinet cover at this time.

IN F OR MAT ION

• 1/8 in. allen wrench

• # 2 phillips head screw driver

• Multi meter

a) Ensure the power at the junction box is in the

OFF position.

b) Feed the power cable through the main power

strain relief from the accessory pack, then

through the hole provided below the circuit

breaker on/ off.

Line Terminal Block

Yo u will ne ed the con tr o l sid e ca b in e t co v e r

off to conn ect the electrical power.

© April 2001 General Binding Corporation

Stra in r elie f

Power cable

Page 4 - 11

Page 46

Installation F 60 H Operation and Maintenance Manual

c) Connect the wires to the Line T erminal Block

(L TB) as illustrated below .

red wires blue wires

1

3

5

2

4

6

f) Verify line voltage with regards to the type of

power being supplied to the laminator at the line

terminal block.

1

3

5

2

4

6

hot leg

(A)

hot leg

(B)

ground

(C)

• (A) - (B) = 230 ~ 240 VAC

hot leg hot leg ground

WARNING

Follow the correct wiring diagram when

supplying power to the laminator. If

improperly connected, you can be seriously

injured or cause damage to the laminator.

d) Secure the main power strain relief to the

cabinet.

• (A) - (C) = 115 ~ 120 VAC

• (B) - (C) = 115 ~ 120 VAC

g) Replace the control side cabinet cover.

h) Turn the On/ Off to the “ON” position by

flipping the handle to the up position and press

reset.

Reset

POWER

e) Turn the junction box power to the ON

position.

Page 4 - 12

On/ Off

© April 2001 General Binding Corporation

Page 47

InstallationF 60 H Operation and Maintenance Manual

4.10 Safety check

The safety check will ensure that all safety devices

and interlocks are functioning properly .

This procedure describes how to check one

E-STOP and the PHOTO-EYE. Repeat the steps for

the remaining three E-STOPS. ALL SAFETY

FEA TURES MUST BE CHECKED!

WARNING

E-STOPs

a) Turn MAIN POWER to ON .

POWER

On

Off

b) Press RESET. The power indicator on the front

control panel will be illuminated.

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

WARNING

If a safety feature is not working

properly, contact your local service

representative immediately.

Reset

POWER

c) Press the motor direction to FORWARD.

Contacts:

GBC National Service: ( 800 ) 790 - 7787

My service rep:_____________________

© April 2001 General Binding Corporation

(reverse) (forward)

Page 4 - 13

Page 48

Installation F 60 H Operation and Maintenance Manual

1

/

4

t

u

r

n

d) Rotate the speed dial to a setting greater than 1.

56

4

3

2

1

7

8

9

10

e) Press the motor engage/ disengage to ENGAGE.

(disengage) (engage)

h) The bottom main roller stops turning, the power

indicator light goes out, the display on the

temperature controller unit goes out.

i) T urn the E-STOP 1/4 turn counter clockwise to

unlatch.

f) Press the temperature on/off to ON.

(off) (on)

g) Press one of the four E-STOPs.

j) Repeat steps b) through i) for the remaining

three E-STOPs.

PHOTO-EYE

a) Cut a piece of 1/2 inch ( 1.3 cm ) thick foam

board to 4 inches x 6 inches. ( 10 cm x 15 cm )

This piece will be referred to as the “finger board”.

CAUTIO N

Page 4 - 14

Do not use a hard substrate or a substrate

with sharp edges. You may cause damge to

the lam inating ro llers.

© April 2001 General Binding Corporation

Page 49

InstallationF 60 H Operation and Maintenance Manual

b) Ensure all E-STOPs are in the unlatched position

and remove the pressure plate from the front feed

table.

c) If the power indicator on the control panel is not

illuminated, press Reset.

Reset

POWER

f) Press the motor engage/ disengage to ENGAGE.

(disengage) (engage)

g) Slide the “finger board” on the front feed table

towards the nip about 10 in. ( 25 cm ) from the

control side.

d) Set the motor direction to FWD.

(reverse) (forward)

e) Lower the main roller to initial contact ( one bar

on the pressure display is illuminated ).

finger board

h) The rollers should stop just before the finger

board can enter the roller nip.

i) Slide the finger board back away from the rollers

nip. Press the motor engage/ disengage to

ENGAGE.

© April 2001 General Binding Corporation

(disengage) (engage)

Page 4 - 15

Page 50

Installation F 60 H Operation and Maintenance Manual

j) If the finger board comes in contact with the

rollers while they are turning, contact your

service representative to adjust the PHOTO-

EYEs.

k) Slide the “finger board” towards the roller nip

about center of the front feed table.

finger board

o) Slide the “finger board” on the front feed table

towards the nip about ten in. ( 25 cm ) from the

control side.

finger board

p) The rollers should stop just before the finger

board can enter the roller nip.

l) The rollers should stop just before the finger

board can enter the roller nip.

m) Slide the finger board back away from the rollers

nip. Press the motor engage/ disengage to

ENGAGE.

(disengage) (engage)

q) Slide the finger board back away from the

rollers nip.

r) If the finger board comes in contact with the

rollers while they are turning, contact your

service representative to adjust the PHOTO-

EYEs.

s) Raise the main roller .

n) If the finger board comes in contact with the

rollers while they are turning, contact your

service representative to adjust the PHOTO-

EYEs.

Page 4 - 16

© April 2001 General Binding Corporation

Page 51

F 60 H Operation and Maintenance Manual

5.0 Operations

In this section you will find information on how to

properly turn your Falcon 60 H Laminator on, learn

functions of the control panel, increase and decrease

temperature, properly load and unload film, use of the

unwind brake tensioning system, rewind brake tensioning,

how to manually set the nip for mounting, and foot switch

function.

The following general rules should always be

adhered while operating this machine.

Operations

WARNING

W h en the lam in ator ro llers are in

motion, keep hands and fingers

away from the nip of the rollers.

You may be CRUSHED or BURNED!

WARNING

WARNING

Do not w ear ties, loose fit clothing or

dangling jewelry while operating or

servicing the lam in ator. Th ese item s can g et

caught in the nip and choke you or you can

be crushed or burned.

IN F OR MAT ION

The m ac h in e will only o p e ra te if a ll

four emergency stop s are u n latched an d

RESET has been pressed.

Keep h an d s an d fin gers clear o f the

lamina tor roller nip when cha n ging G A P .

You can be CRUSHED or BURNED!

WARNING

When o p e ra tin g th e la minato r u sing the

footsw itch, keep h an d s an d fin gers a w a y

from th e n ip o f the rollers.

You may be CRUSHED or BURNED!

WARNING

It is u n sa fe to sh e et f eed with o u t the

pressu re plate pro p erly placed o n

the fron t feed tab le.

© April 2001 General Binding Corporation

WARNING

Do n o t opera te the lam ina tor, except

during web set up, without the front

and rear feed tables in position.

Page 5 - 1

Page 52

Operations F 60 H Operation and Maintenance Manual

5.1 Power On/ Off

Power on

a) Ensure the laminator is plugged in and that all E-

STOPs are in the unlatched position.

1

/

4

t

u

r

n

d) Power indicator on the control panel should be

illuminated at this time.

00

4 7

2

9

Power indicator light

Power off

b) T urn the MAIN POWER to the up position.

POWER

On

Off

c) Press RESET located above the main power

on/off.

Reset

POWER

a) Ensure the rollers are in the up position.

b) T urn the MAIN POWER to the down position.

POWER

On

Page 5 - 2

Off

© April 2001 General Binding Corporation

Page 53

F 60 H Operation and Maintenance Manual

Operations

5.2 Control panel

The operator control panel for the Falcon 60 H

Laminator is located to the right of the front operating

position. For an illustration of the complete front control

panel, please refer to Figure 5.2.1 Falcon 60 H. The

names and functions of these controls are as follows:

( 1 ) NIP PRESSURE DISPLAY: When pressure at

the nip of the rollers is applied, bars on the nip pressure

display are illuminated in increments of 5% up to 100%.

( 3 ) FWD / REV : When pressed to the right, the motor

turns in a forward direction as illustrated by the image

above the switch. When pressed to the left, the motor

turns in a reverse direction.

(reverse) (forward)

( 4 ) SPEED DIAL: When turned clockwise, increases

the speed of the motor. T urning it counter clockwise will

decrease motor speed.

( 2 ) MOTOR ENGAGE/ DISENGAGE: When

pressed to the right, power to the motor is supplied and

the rollers will begin to turn. When pressed to the left,

power to the motor is removed and the rollers stop turning.

56

4

3

2

1

7

8

9

10

( 5 ) TEMP ON/ OFF: When pressed to the right,

supplies power to the temperature controller unit located

just above it. When pressed to the left, removes power to

the temperature controller unit.

(disengage) (engage)

© April 2001 General Binding Corporation

(off) (on)

Page 5 - 3

Page 54

Operations F 60 H Operation and Maintenance Manual

( 6 ) TEMPERATURE CONTROLLER UNIT :

Displays the current temperature of the upper roller . Allows

the operator to control the operating temperature of the

upper roller. T o set temperature refer to Section 5.3.

CAL 3200

Figure 5.2.1 Front control panel

( 7 ) POWER INDICATOR: When illuminated

represents power to the laminator is supplied. If not

illuminated, power to the laminator has been removed via

an E-STOP , no RESET , circuit breaker is the off position

or line voltage has been removed.

6

CAL 3200

1

5

2

3

56

4

3

4

2

1

7

8

9

10

7

Page 5 - 4

© April 2001 General Binding Corporation

Page 55

F 60 H Operation and Maintenance Manual

Operations

5.3 Set Temperature

The Falcon 60 H has upper roller heating

capabilities which enables the machine to run Lo-Melt

film. You can set a desired temperature from 32 OF

O

( 0

C ) up to 200 OF ( 93 OC ).

When power to the temperature controller unit is

supplied, the display indicates the current temperature of

the upper roller.

Increase set point

a) Press and hold ✽ key while pressing ▲ key to

increase the set point temperature. Single presses

of the ▲ key increases the set point by increments

of one while holding the key down will increase

by increments of ones then tens.

CAL 3 0

CAL 3200

(72 is an example of room temperature )

To display the current set point value of the

temperature controller unit, press and hold the star key

located just to the left just below the temperature display .

When the star key is released, the temperature display

reverts to the current temperature of the upper roller .

b) Release the ✽ key and ▲ key once desired set

point has been obtained.

Decrease set point

a) Press and hold ✽ key while pressing ▼ key to

decrease the set point temperature. The same

increments apply.

CAL 3

CAL 3

© April 2001 General Binding Corporation

b) Release the ✽ key and ▼ key once desired set

point has been obtained.

Page 5 - 5

Page 56

Operations F 60 H Operation and Maintenance Manual

5.4 Load/ Unload film

CAUTIO N

En su re the roll of lam in ate is loaded

properly on the unwind shaft.

Exposed adhesive should be facing

away from the rollers.

Th is will pre v ent hou r s o f ro ll cle a n in g !

Figure 5.4.1 Lo-Melt Poly-in/ Poly-out

The film supply shafts, commonly known as unwind

shafts, pivot out for ease of loading and unloading of film.

Always pay particular attention to which side is the

adhesive side and which side is the carrier side. The

adhesive side will always face away from the rollers. Refer

to Figure 5.4.1 and Figure 5.4.2.

IN F OR MAT ION

Th e P o ly -in / P o ly-o u t diagra ms refe r to th e

upper rolls of film only. The mount adhesive

and craft p ap ers are fo r referen ce on ly.

Figure 5.4.2 PSA Poly-in/ Poly-out

Craft

paper

Lo-Melt

Po ly - in

Lo-Melt

film

Lo-Melt

Lo-Melt

Po ly - o u t

film

Craft

paper

PSA

Po ly - in

PSA

film

PSA

Po ly - o u t

PSA

film

Mount

adhesive

Page 5 - 6

Mount

adhesive

© April 2001 General Binding Corporation

Page 57

F 60 H Operation and Maintenance Manual

Load film

a) Adjust the core grips so they are close to the edge

of the roll of film being used but remain inside the

core when the roll of film is positioned on the

unwind shaft.

Operations

WARNING

Never leave the unw ind shaft out of the

unwind support saddle unless loading

or unloading film.

Ro ll of film

Core chuck Core chuckCore support

b) Lift up on the clevis pin to the unwind shaft located

in the unwind support saddle.

Clevis pin

Unwind support saddle

d) Swing the unwind shaft completely back into the

unwind support saddle and push the clevis pin

down.

Clevis pin

Unwind support saddle

e) If using the lower unwind, center the upper roll of

film on the laminating rollers.

( A )

( C )

( B )

( C )

c) Swing the unwind shaft out far enough to slide the

roll of film completely on.

© April 2001 General Binding Corporation

( A ) - ( B ) / 2 = ( C )

CAUTIO N

W h en u sing tw o rolls on th e m ach ine,

ensur e the film w idth s are id entical.

Exposed adhesive can cause complications.

f) Repeat steps a) through c) to load film on the

lower unwind shaft.

Page 5 - 7

Page 58

Operations F 60 H Operation and Maintenance Manual

g) Measure the distance from the side frame to the

edge of the upper roll of film. Use this

measurement to evenly align the roll of mount

adhesive or craft paper.

Align

Center

b) Lift up on the clevis pin to the unwind shaft located

in the unwind support saddle.

Clevis pin

Unwind support saddle

c) Swing the unwind shaft out far enough to slide the

roll of film completely off.

Unload film

a) Cut the roll of film from the web using an enclosed

blade.

CAUTIO N

Never use an open blade near the laminating

rollers. You may cut the rollers or yo ur self.

Page 5 - 8

CAUTIO N

W h en u sing tw o rolls on th e m ach ine,

ensur e the film w idth s are id entical.

Exposed adhesive can cause complications.

d) Swing the unwind shaft completely back into the

unwind support saddle and push the clevis pin

down.

Clevis pin

Unwind support saddle

© April 2001 General Binding Corporation

Page 59

F 60 H Operation and Maintenance Manual

Operations

5.5 Unwind brake tension

The unwind brakes are uniquely designed to allow

you to change rolls of film without changing your current

brake setting. Brake tension may vary from roll to roll so

some adjustments may be required for optimal output.

IN F OR MAT ION

Always use the minimum amount

of bra ke fo r the job .

5.6 Rewind brake tension

The rewind brake controls the tension of the

rewind tubes. Rewind brakes along with the unwind brakes

allow for precise control of the release liner in PSA films.

If your Falcon 60 H is equipped with the roll to roll option,

the rewind brakes are helpful as the finished product

rewind becomes heavier by adding more friction to the

rewind tube.

a) Turn the brake dial counter clockwise to

increase rewind brake tension.

a) Turn the upper black brake knob ( shown below)

or the lower gray brake disc ( not shown )

clockwise to increase unwind brake tension.

Increase decrease

IN F OR MAT ION

If mo re bra ke is need ed, ad d an O-ring

to the brake side of the rewind.

Increase Decrease

b) Turn the upper black brake knob ( shown above)

or the lower gray brake disc ( not shown )

counter clockwise to decrease unwind brake

tension.

© April 2001 General Binding Corporation

b) Turn the brake dial clockwise to decrease

rewind brake tension.

Page 5 - 9

Page 60

Operations F 60 H Operation and Maintenance Manual

5.7 Setting the nip

Setting the nip is made easy when it comes to

performing a mounting application. Pressure will vary with

regards to the types of substrate being used. An incorrect

nip setting can cause complications with output quality .

For safe nip setting, always adhere to the following

rules listed below .

WARNING

a) Ensure all E-STOPs are unlatched, power is on

and RESET has been pressed.

Reset

1

/

4

t

u

r

n

POWER

On

b) Set the motor direction to REV.

Keep h an d s an d fingers clear of the

laminator roller nip when adjusting nip.

You can be CRUSHED or BURNED!

CAUTIO N

Excess pressure can damage the laminating

rollers. Alway s u se the m in imu m roll

pressure n ecessa ry to co m p lete the task.

CAUTIO N

Objects other than m edia, film or approved

substrates, will cause irreparable damage

to the rollers if caugh t in the n ip.

(reverse) (forward)

c) Set a comfortable speed for the application you

are performing.

56

4

3

2

1

7

8

9

10

Page 5 - 10

© April 2001 General Binding Corporation

Page 61

F 60 H Operation and Maintenance Manual

(disengage) engage)

Operations

CAUTIO N

Sharp edges on a substrate

should be filed smooth.

Sha rp edg es can C U T th e rollers!

d) Position the substrate center of the feed table

between the two rollers.

IN F OR MAT ION

Ex c es siv e pressu r e will cause the

substrate to bow or flatten.

Sufficient Excessive

IN F OR MAT ION

F-60 H

substrate

PR -TECH

e) Lower the upper main roller until it makes

contact with the substrate. Lower enough to

apply sufficient pressure without crushing the

substrate.

De n s ity o f the substrate w ill determine th e

amoun t of pressure you may use.

f) Press the motor engage/ disengage to engage or

step on the footswitch to back the board out

from the nip.

© April 2001 General Binding Corporation

f) The nip is now set for the substrate being used.

Remember to set the motor direction to FWD.

Page 5 - 11

Page 62

Operations F 60 H Operation and Maintenance Manual

5.8 Footswitch

WARNING

Th e va riable sp eed fo otswitch over-rides

WARNING

W h en op erating the lam in ator u sing th e

footswitch, keep hands and fingers

away from the nip of the rollers.

You may be CRUSHED or BURNED!

The footswitch operates differently based on the

motor direction setting.

the PH OTO -E YE safety circuit !

c) When the footswitch is pressed, roller speed is

dependent on what you have selected on the

speed dial.

d) You may adjust speed while the footswitch is

depressed.

Forward

a) Press the motor direction to FWD.

(reverse) (forward)

b) Set your speed dial to a comfortable operating

speed.

Reverse

a) Press the motor direction to REV.

56

4

3

2

1

7

8

9

10

Page 5 - 12

b) Press on the footswitch. The footswitch speed is

limited to 1 foot per minute ( 30 cm/ minute )

regardless of motor speed dial setting..

© April 2001 General Binding Corporation

Page 63

ApplicationsF 60 H Operation and Maintenance Manual

6.0 Applications