Page 1

F - 160 CE OPERATION AND

MAINTENANCE MANUAL

© April 2000 GBC Films Group

Do not duplicate without written permission.

GBC Films Group

4151 Anderson Road

DeForest, WI 53532

Revision : Ph: ( 608 ) 246 - 8844

Part number : 930 - 065

Fx: ( 608 ) 246 - 8645

Page 2

Section 1: Safety

1.1 Symbols .......................................................................................................1 - 1

1.2 Safety features ............................................................................................1 - 2

1.3 Safety shield ...............................................................................................1 - 3

1.4 Emergency stop ...........................................................................................1 - 4

T able of ContentsF - 160 CE Operation and Maintenance Manual

Table of Contents

1.5 Emergency cable .........................................................................................1 - 5

1.6 Front feed table ..........................................................................................1 - 6

1.7 Decal locations ............................................................................................1 - 7

Figure 1.7.1 Decal location - front ................................................1 - 9

Figure 1.7.2 Decal location - rear ..............................................1 - 10

Section 2: Warranty

2.1 Limited warranty information ....................................................................2 - 1

2.2 Exclusions to the warranty ........................................................................2 - 1

© GBC Films Group April 2000

Page I

Page 3

T able of Contents F - 160 CE Operation and Maintenance Manual

Section 3: Specifications

3.1 General .......................................................................................................3 -1

3.2 Consumables ...............................................................................................3 - 1

3.3 Function ......................................................................................................3 - 2

3.4 Electrical ....................................................................................................3 - 3

3.5 Dimensions ................................................................................................3 - 4

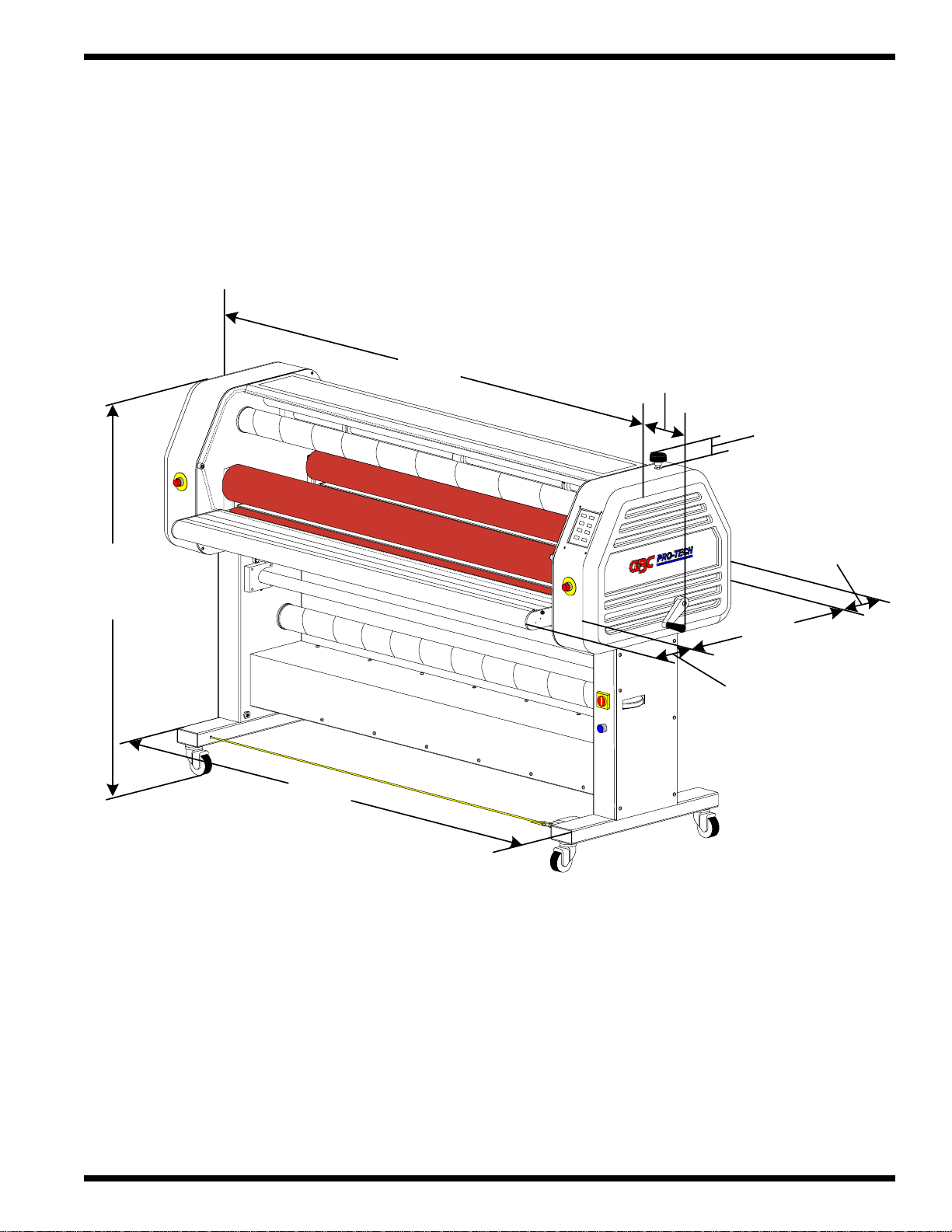

Figure 3.5.1 Dimensions ...............................................................3 - 5

Section 4: Installation

4.1 Preinstallation check list ...........................................................................4 - 1

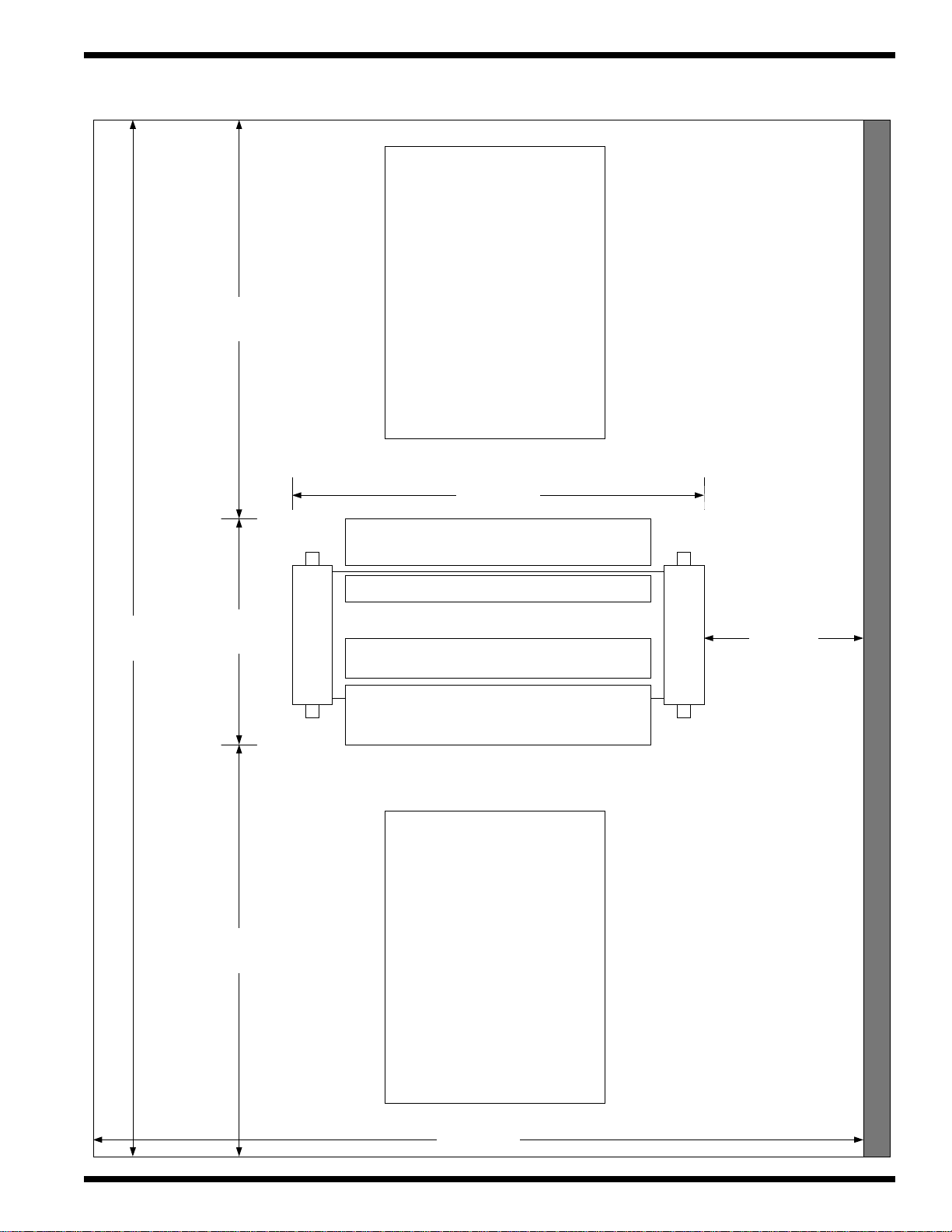

Figure 4.1.1 Suggested floor layout .............................................4 - 3

4.2 Know your machine ...................................................................................4 - 4

4.3 Unpacking ..................................................................................................4 - 5

Page II

4.4 Shrink wrapped .........................................................................................4 - 5

4.5 Crated .........................................................................................................4 - 6

4.6 Accessory pack content ............................................................................4 - 8

© GBC Films Group April 2000

Page 4

T able of ContentsF - 160 CE Operation and Maintenance Manual

4.7 Installing levelers .......................................................................................4 - 9

4.8 Leveling .....................................................................................................4 - 11

4.9 Connecting power ....................................................................................4 - 15

Figure 4.9.1 Single phase ( U.S. & Canada ) ..............................4 - 17

Figure 4.9.2 Three phase ( Europe ) ...........................................4 - 17

4.10 Safety check ............................................................................................4 - 18

4.10.1 Front feed table ...................................................................................4 - 18

4.10.2 Safety shield ..........................................................................................4 - 20

4.10.3 E-STOP ...............................................................................................4 - 21

4.10.4 E-CABLE .............................................................................................4 - 22

4.11 Function check ........................................................................................4 - 23

4.11.1 Control panel .......................................................................................4 - 23

Figure 4.11.1 Default settings ......................................................4 - 27

4.11.2 Variable speed footswitch ....................................................................4 - 27

4.11.3 Unwind shafts and unwind brakes ......................................................4 - 28

© GBC Films Group April 2000

Page III

Page 5

T able of Contents F - 160 CE Operation and Maintenance Manual

Section 5: Operations

5.1 Control panel ..............................................................................................5 - 1

Figure 5.1.1 Front control panel .................................................5 - 9

5.2 Emergency ................................................................................................5 - 10

5.2.1 In an emergency .....................................................................................5 - 10

5.2.2 Resume operation ...................................................................................5 - 11

5.3 Set up .........................................................................................................5 - 12

5.3.1 Power ......................................................................................................5 - 12

5.3.2 Film loading ..........................................................................................5 - 12

Chart 5.3.1 Measurement chart ..................................................5 - 14

5.3.5 Heating ...................................................................................................5 - 14

5.4 Job programming ....................................................................................5 - 16

Chart 5.4.1 Job save chart .........................................................5 - 17

Page IV

5.5 Manual nip adjustment ............................................................................5 - 18

5.5.1 Main roller manual nip adjustment ......................................................5 - 18

© GBC Films Group April 2000

Page 6

5.5.2 Pull roller manual nip adjustment .........................................................5 - 21

5.6 Front feed table .........................................................................................5 - 24

5.6.1 Removing the table ...............................................................................5 - 24

5.6.2 Replacing the table ................................................................................5 - 24

Section 6: Applications

T able of ContentsF - 160 CE Operation and Maintenance Manual

6.1 Parameter charts and diagrams

Chart 6.1.1 Temperature conversion chart ...................6 - 3

Blank chart .......................................................................................................6 - 4

Blank diagram ..................................................................................................6 - 5

Chart 1 - Precoating substrates ........................................................................6 - 6

Diagram 1 - Precoating subtrates ....................................................................6 - 7

Chart 2 - Mounting only ....................................................................................6 - 8

Diagram 2 - Mounting only ..............................................................................6 - 9

Chart 3 - Single sided ( Sled ) .........................................................................6 - 10

© GBC Films Group April 2000

Page V

Page 7

T able of Contents F - 160 CE Operation and Maintenance Manual

Diagram 3 - Single sided ( Sled ) .....................................................................6 - 11

Chart 4 - Single sided ( Craft paper ) ..............................................................6 - 12

Diagram 4 - Single sided ( Craft paper ) ........................................................6 - 13

Chart 5 - Decal and mount ( Decal ) ..............................................................6 - 14

Diagram 5 - Decal and mount ( Decal ) .........................................................6 - 15

Chart 6 - Decal and mount ( Mount ) ............................................................6 - 16

Diagram 6 - Decal and mount ( Mount ) .......................................................6 - 17

Chart 7 - Precoating subtrates .......................................................................6 - 18

Diagram 7 - Precoating subtrates ...................................................................6 - 19

Chart 8 - One pass mount ...............................................................................6 - 20

Diagram 8 - One pass mount ..........................................................................6 - 21

Chart 9 - Thermal decal and mount ( Decal ) ................................................6 - 22

Diagram 9 - Thermal decal and mount ( Decal ) ...........................................6 - 23

Page VI

Chart 10 - Thermal decal and mount ( Mount ) .............................................6 - 24

Diagram 10 - Thermal decal and mount ( Mount ) ........................................6 - 25

© GBC Films Group April 2000

Page 8

Chart 11 - Encapsulation ...............................................................................6 - 26

Diagram 11 - Encapsulation ..........................................................................6 - 27

Section 7: Troubleshooting

7.1 Wave problems ..........................................................................................7 - 1

7.2 Film problems ............................................................................................7 - 3

T able of ContentsF - 160 CE Operation and Maintenance Manual

7.2.1 Thermal laminates ..................................................................................7 - 3

7.2.2 Pressure senstive .....................................................................................7 - 3

7.3 Machine problems ......................................................................................7 - 4

7.4 Glossary .....................................................................................................7 - 5

Section 8: Maintenance

8.1 Maintenance schedule ................................................................................8 - 1

8.2 Cleaning the rollers ...................................................................................8 - 2

8.2.1 Cabinets and covers ................................................................................8 - 7

8.2.2 Touch screen control panel .....................................................................8 - 7

© GBC Films Group April 2000

Page VII

Page 9

T able of Contents F - 160 CE Operation and Maintenance Manual

This page intentionally left blank.

Page VIII

© GBC Films Group April 2000

Page 10

F - 160 CE Operation and Maintenance Manual

Section 1 Safety

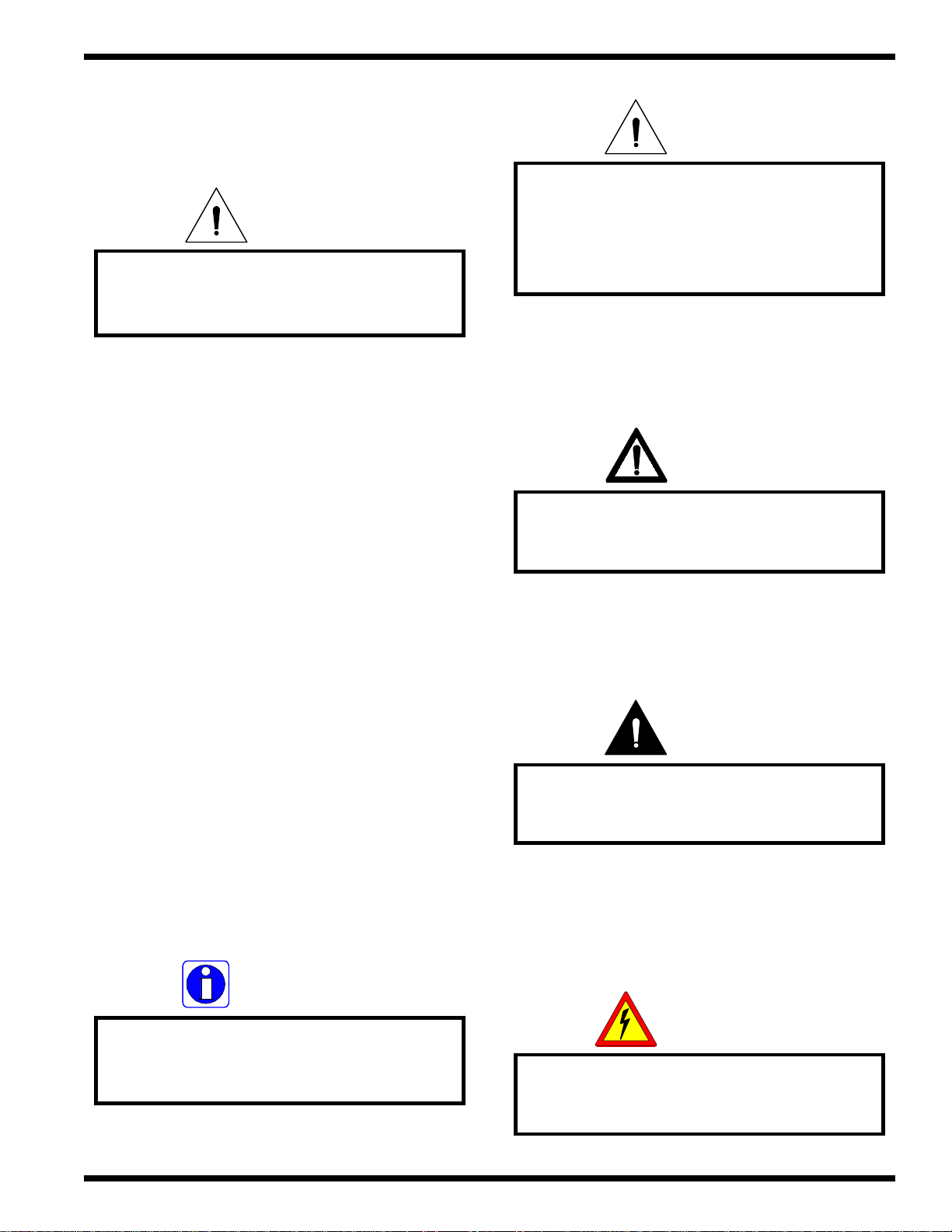

CAUTION

Do not attempt to operate your Falcon 160

CE laminator until you have read this

section carefully!

Safety

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, could result in minor

or moderate injury, or alerts against unsafe

practices or alerts against actions which

could damage the product.

Your safety, as well as the safety of others, is

important to GBC Films Group. This section contains

important safety information.

The following symbols are used throughout this

manual to indicate Information, Caution, Warning,

Danger and Electrical Shock conditions.

1.1 Symbols

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in serious

injury.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, could result in death

or serious injury.

INFORMATION

Indicates helpful information that should be

considered before, during, or after an

action, step or procedure is given.

© GBC Films Group April 2000

ELECTRICAL

SHOCK

Indicates an electrical shock situation which,

if not avoided, could result in serious

paralyzation of the body or death.

Page 1 - 1

Page 11

Safety F - 160CE Operation and Maintenance Manual

1.2 Safety features

DANGER

At these temperatures there is a danger of

severe burn if the rolls are touched during

The F-160 CE laminator has been designed

with safety as a primary consideration; however, you

must become thoroughly familiar with the controls,

proper operation, proper service procedures and safety

features of the laminator before using or servicing the

unit.

Only a qualified service technician should

GBC Films Group laminators are powerful

machines that are designed to mount, laminate, and

encapsulate. The forces required to accomplish these tasks

can vary from negligible to very large.

setup, operation or servicing.

INFORMATION

perform any procedure in Part B of this

manual.

The motorized main roller lift mechanism used to

provide downward pressure on the upper main roller is

capable of producing forces greater than 400 pounds.

This force is applied to any object presented in the opening

( called the nip ) between the two rollers.

Use care in lowering the upper laminating roller

and know how to react quickly in an emergency. The

main laminator roll up / down control is located on the

right side of the machine within the front control panel.

The GAP up / down arrows control the motion of the

upper laminating roller. Before pressing GAP down arrow ,

ensure that nothing is in the nip area.

In addition, the main laminating rollers of the F160CE can reach temperatures of over 200

o

F ( 100oC ).

The word qualified is defined below;

Qualified ;

• Any engineer that has experience with electrical

and mechanical design of lamination equipment.The

engineers should be fully aware of all aspects of safety

with regards to lamination equipment.

• Any commissioning or service engineer must be

of competent nature, trained and qualified to GBC Films

Group standards to fulfill that job. This person will have

completed and passed the full service training course from

GBC Pro-T ech.

Page 1 - 2

© GBC Films Group April 2000

Page 12

F - 160 CE Operation and Maintenance Manual

Safety

• Any GBC T echnician, GBC Specialist, and / or

GBC Films Group T echnician that has been through the

GBC Pro-T ech service training course.

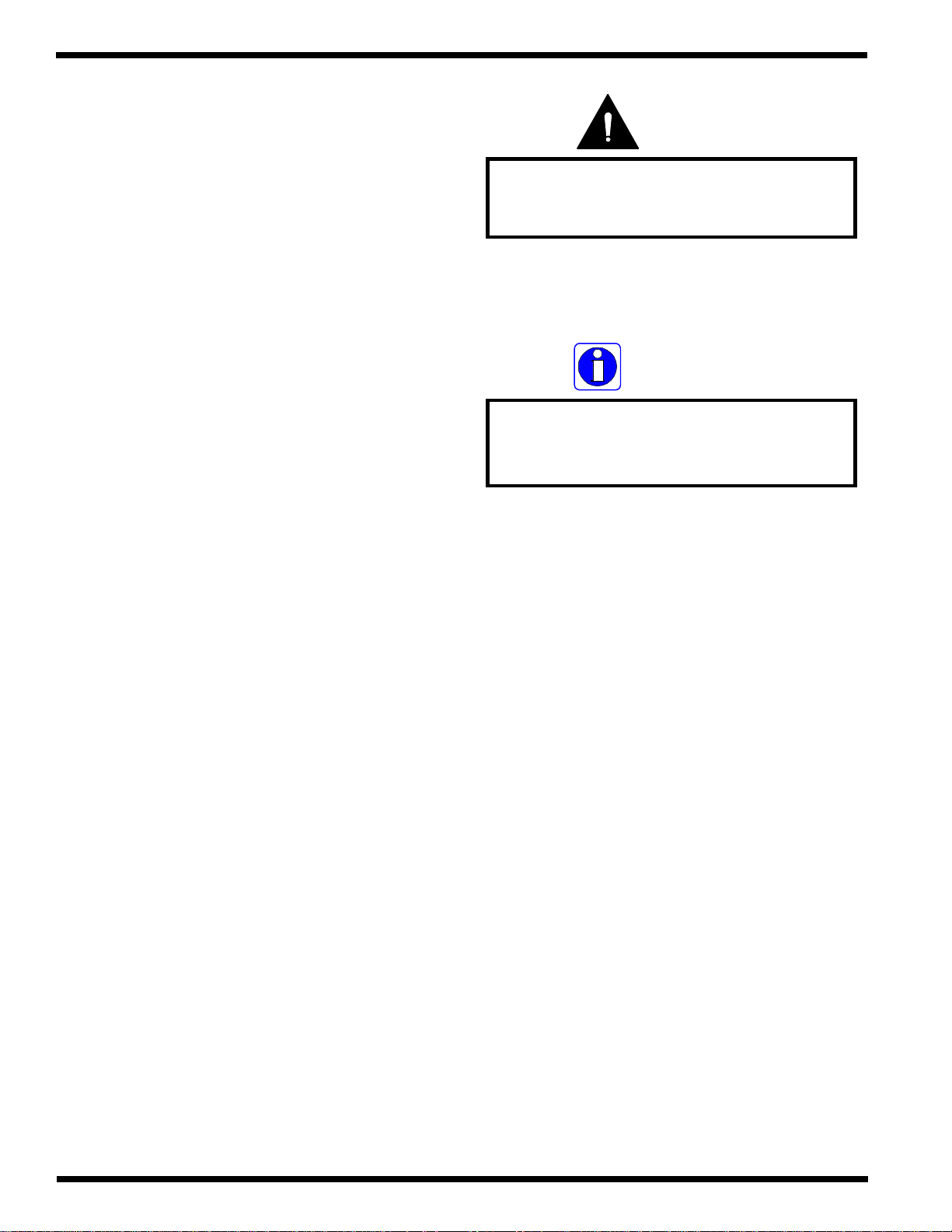

The F-160CE laminator has cabinets and

panels that are bolted close to isolate the electrical and

drive system components for the safety of the operator.

Figure 1.2.1 illustrates placement of the cabinets and

covers.

Figure 1.2.1 Cabinets and covers

1.3 Safety shield

An important feature of the F-160 CE laminator

is the safety shields, when raised, the auto run is disabled

and drive control is transferred to the footswitch.Refer to

Figure 1.3.1 Safety shield raised.

WARNING

Caution should always be exercised

when using the laminator with

the safety shields raised.

You can be seriously HURT or INJURED!

Covers

Cabinets

Figure 1.3.1 Safety shields raised

© GBC Films Group April 2000

Page 1 - 3

Page 13

Safety F - 160CE Operation and Maintenance Manual

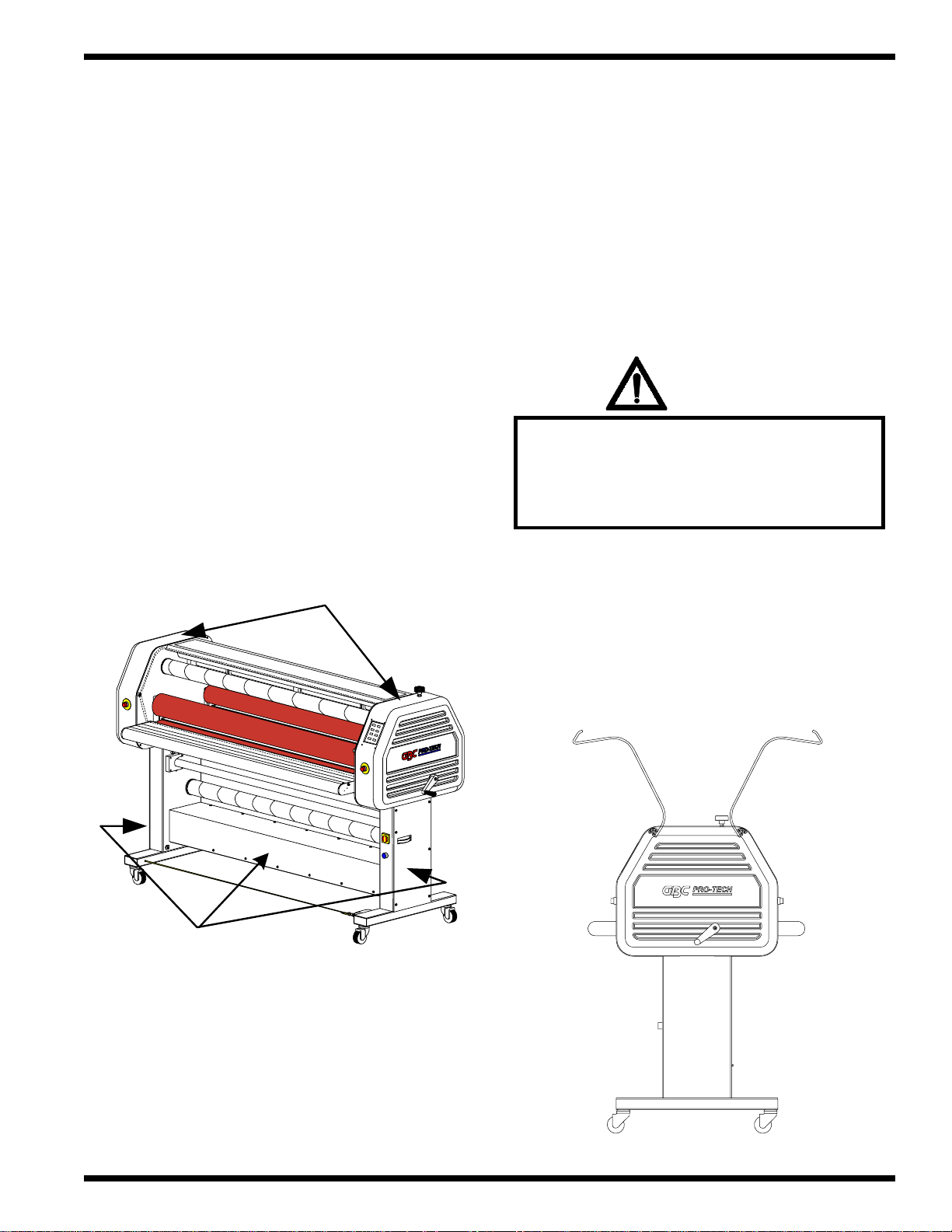

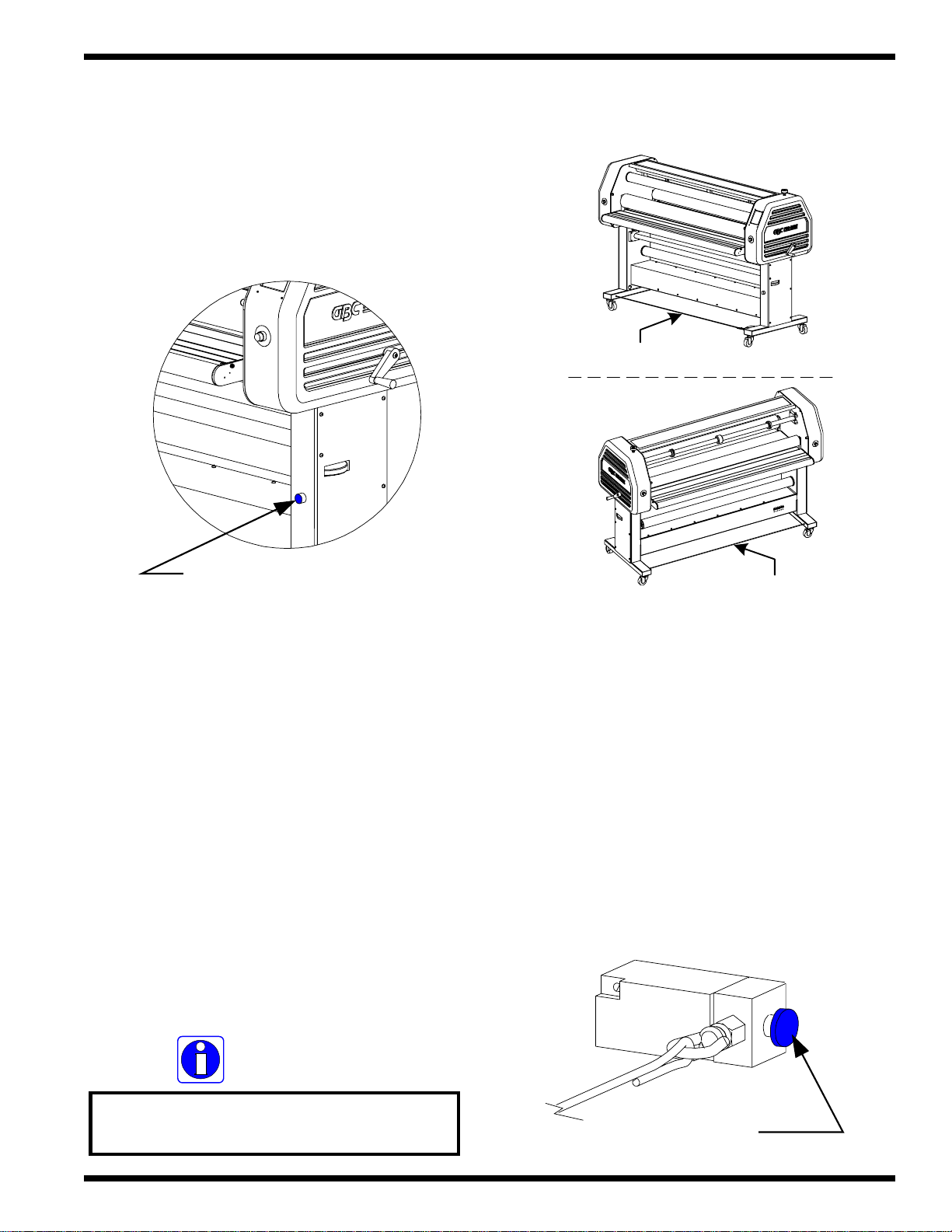

1.4 Emergency stop

The laminator is equipped with four emergency

stops ( E-STOP ) located at the front of the cabinets and

the rear of the cabinets. Refer to Figure 1.4.1 Emergency

stops.

Figure 1.4.1 Emergency stops

T o engage an E-STOP, press down on any of the

four . Any E-STOP, when engaged, removes power to

the laminator. Refer to Figure 1.4.2 Engage an E-STOP.

Figure 1.4.2 Engage an E-STOP

Push

Emergency stops

Rear

INFORMATION

Front

The machine will only operate if all four

E-STOPS are in the unlatched position.

T o continue operation, all E-STOPs must be in

the unlatched position. T o reset, twist the E-STOP 1/4

turn clockwise. Refer to Figure 1.4.3 Reset the E-

STOP.

Figure 1.4.3 Reset the E-STOP

Page 1 - 4

Unlatch

Emergency stops

© GBC Films Group April 2000

Page 14

F - 160 CE Operation and Maintenance Manual

Safety

Press RESET located on the right leg at the front

of the machine. Refer to Figure 1.4.4 Machine reset.

Figure 1.4.4 Machine rest

Figure 1.5.1 Emergency cable

Front

Emergency cable

Rear

Machine reset

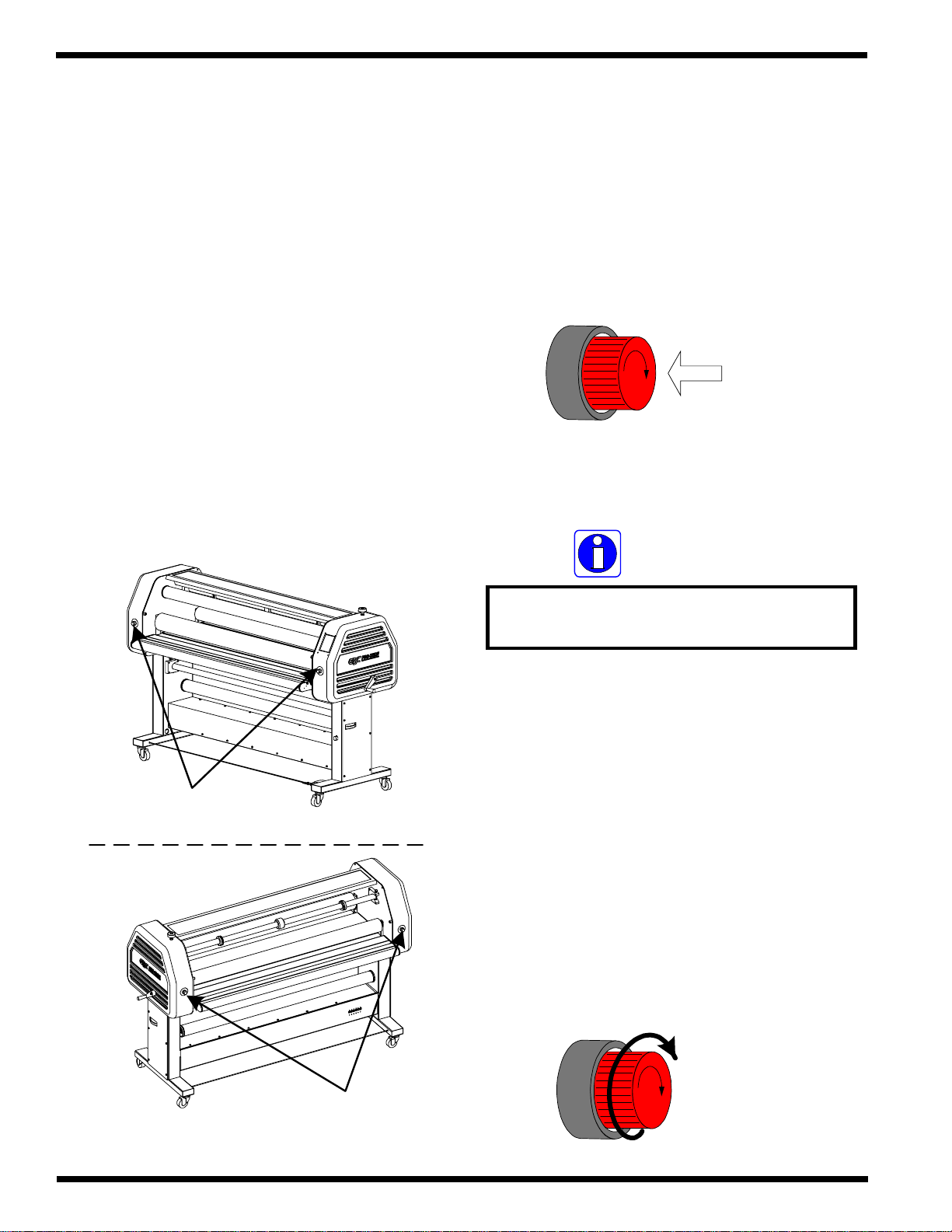

1.5 Emergency cable

In the event an E-STOP is not reachable, use

your foot to activate an emergency cable ( E-CABLE )

located at the base of the stand from the front or rear of

the machine. Refer to Figure 1.5.1 Emergency cable.

Emergency cable

T o continue operation, press in on the cable reset

located on the right leg of the front operating position.

Refer to Figure 1.5.2 Reset the E-CABLE.

Figure 1.5.2 Reset the E-CABLE

INFORMATION

The machine will only operate if the

E-CABLE is in the unlatched position.

© GBC Films Group April 2000

Push in

Page 1 - 5

Page 15

Safety F - 160CE Operation and Maintenance Manual

Press RESET located on the right leg at the front

of the machine. Refer to Figure 1.5.3 Machine reset.

Figure 1.5.3 Machine rest

Figure 1.6.1 Front feed table

Machine reset

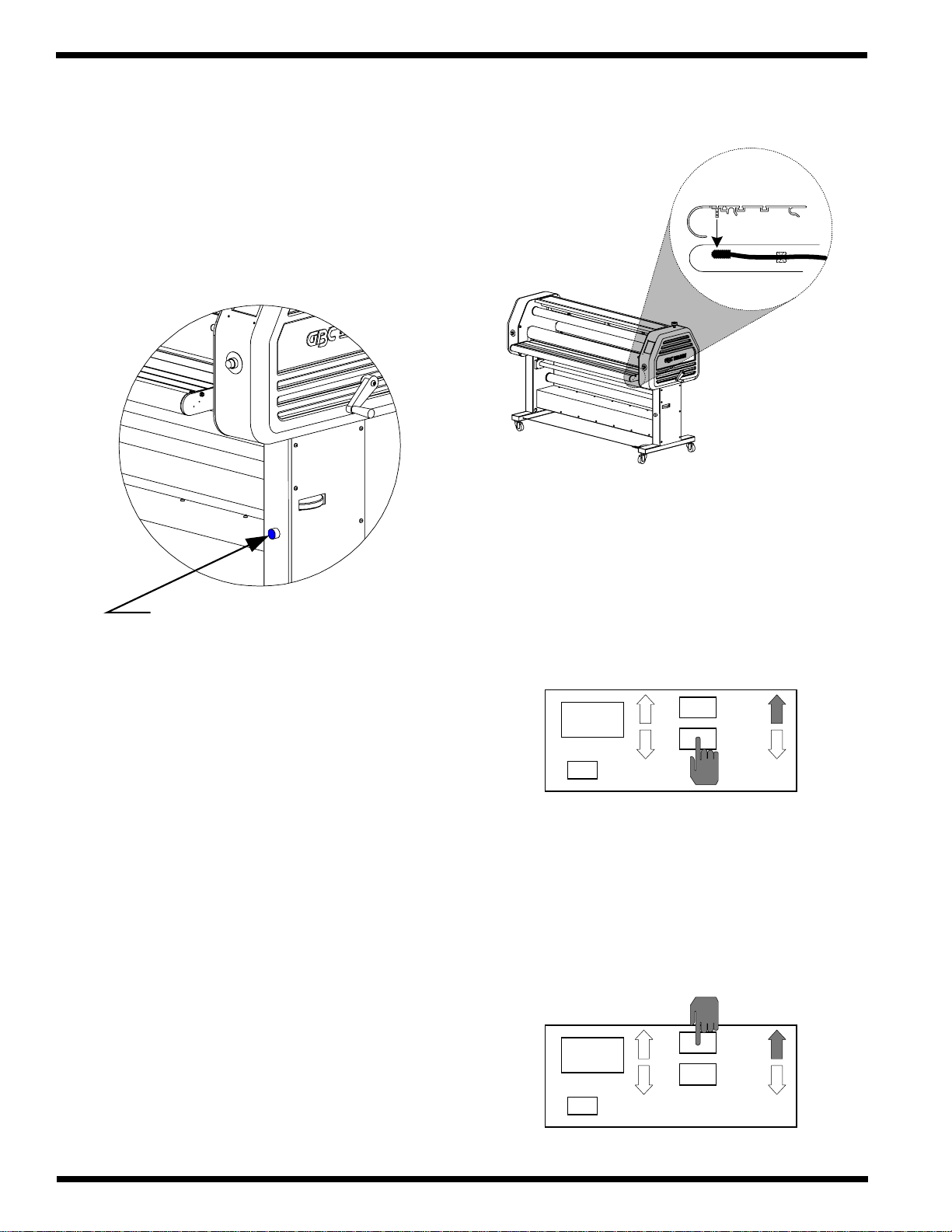

1.6 Front feed table

The front feed table must be in proper position

for the laminator to operate in auto run. Refer to Figure

1.6.1 Front feed table.

When the key is removed from the interlock, the

laminator will stop. With the table removed, the laminator

will operate using the variable speed footswitch.

T o continue operation, press STOP.

5.0

SPEED

SAFETY

GO

STOP

FWD

REV

Then press GO.

5.0

SPEED

SAFETY

GO

STOP

FWD

REV

Page 1 - 6

© GBC Films Group April 2000

Page 16

F - 160 CE Operation and Maintenance Manual

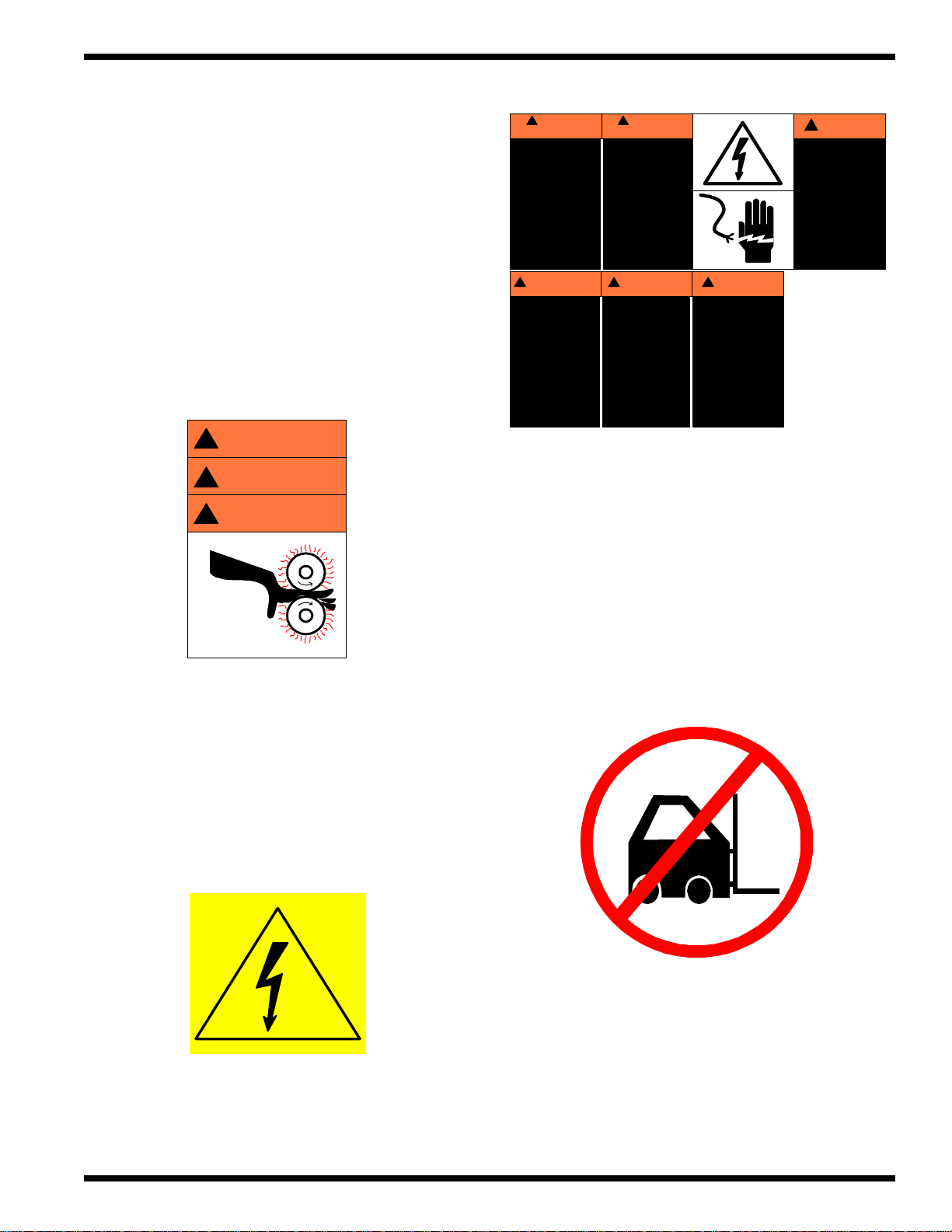

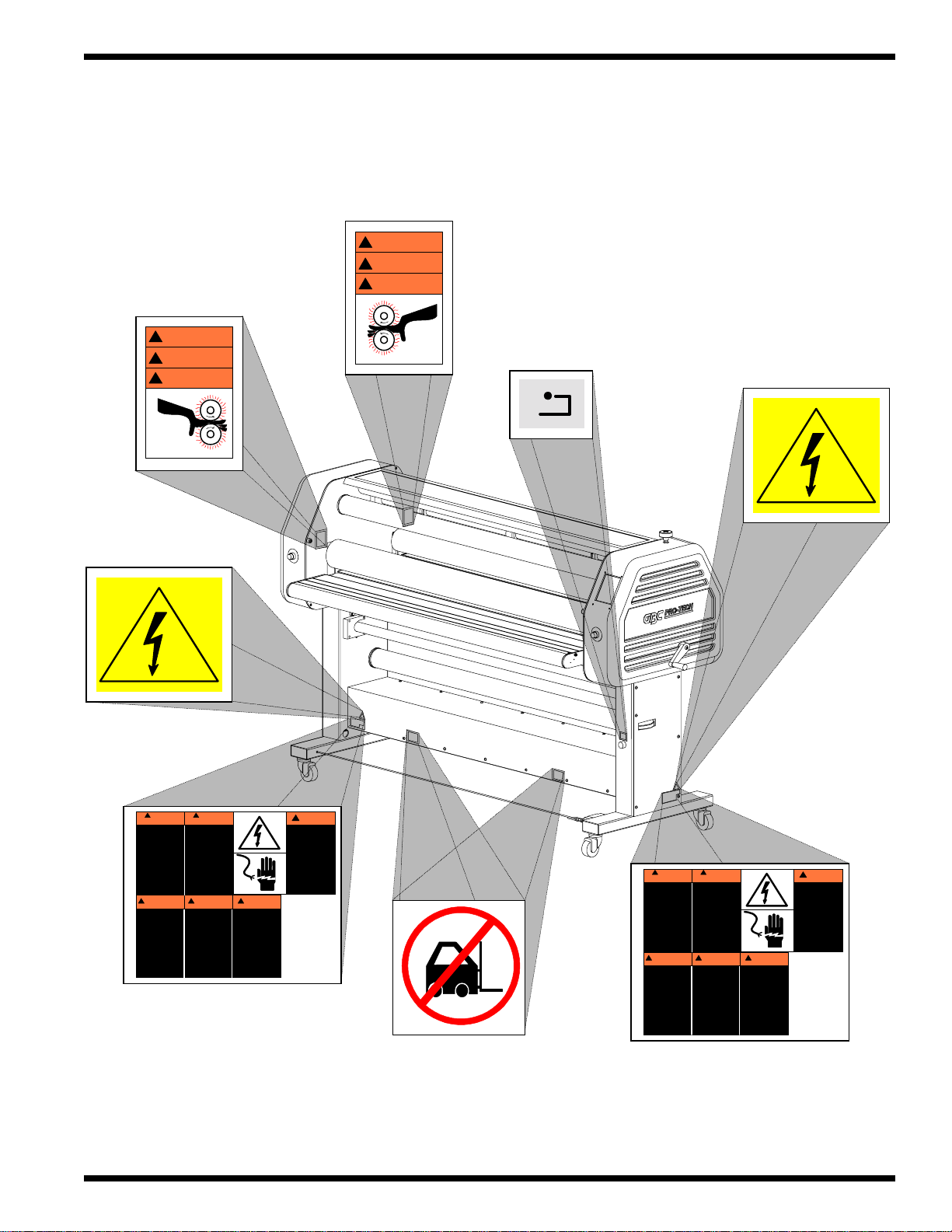

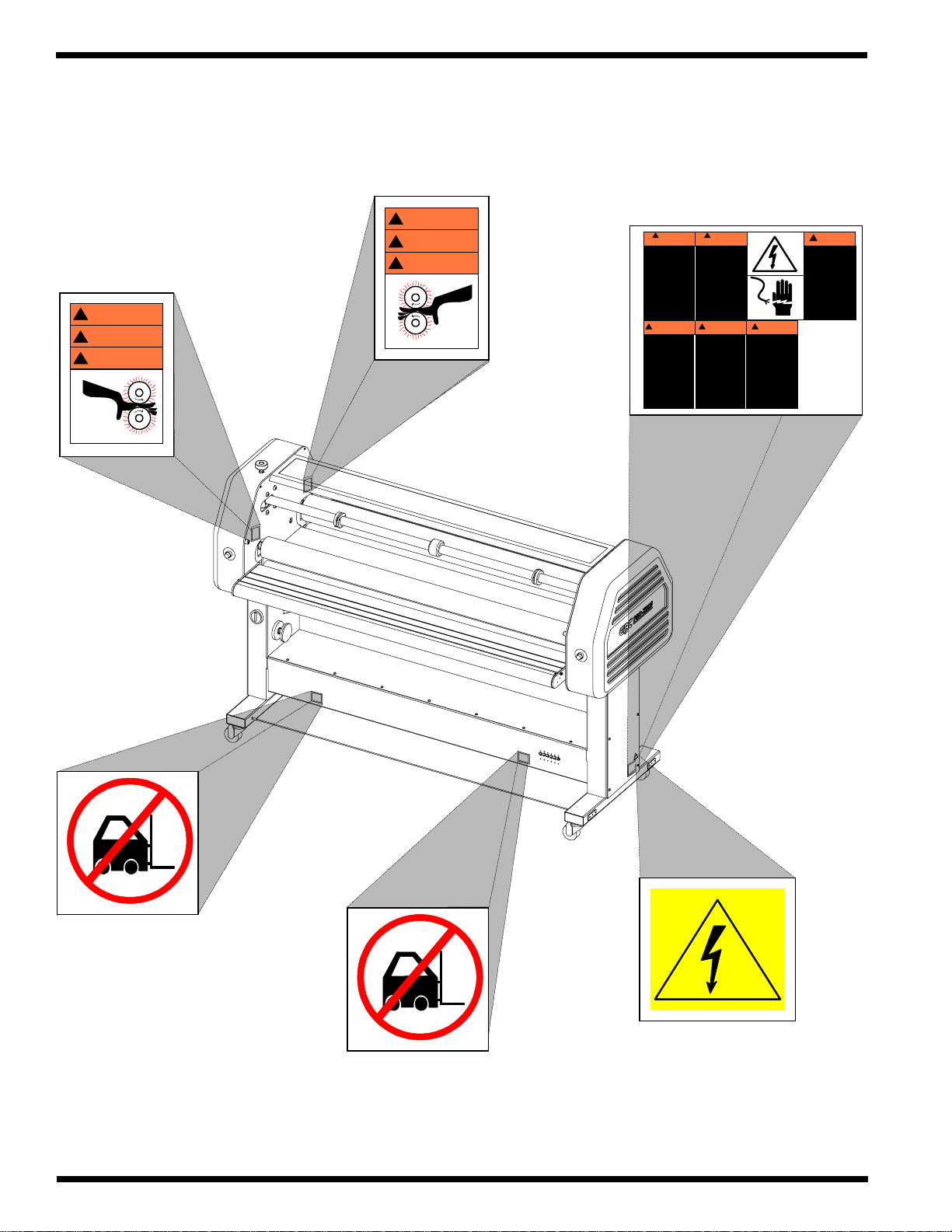

1.7 Label locations

Posted at various locations on the Falcon 160

Laminator are important safety labels. Pay careful

attention to these labels at all times! Figure 1.7.1

and Figure 1.7.2 illustrates the location of each of these

labels.

!

WARNING

ACHTUNG

!

!

MUCHO

CUIDADO

Riesgo de

choque

electrico

No abra

Adentro, no hay

piezas

reparables

para el usuario.

Mantenimiento

solamente para

personal

calificado

WAARSCHUWING!ATTENZIONE

Kans op

elektrische

schok.

Niet openen

Bevatgeen door

gebruik te

repareren

onderdelen.

Door bevoegd

service

personeel

laten repareren

!

MUCHO

CUIDADO

Risque de

secousse

electrique.

Ne pas ouvrir.

Pas de pieces

reparables par

l'utilisateur.

Entretien par

personnel

qualifie.

!

Pericolo di

scarica

elettrica.

Nessuna parte

riparabile

dall' utente.

Chiamare un

servizio

di riparazioni

qualificato.

!

WARNUNG

SpannungsfUhrend

e

Teile.

Nicht offnen.

Enthalt keine vom

Enduerbraucher zu

wartende Teile.

Fur service bitte an

qualifiziertes

Service-Personal

wenden.

Safety

!

WARNING

Electrical shock

hazard.

Do not open.

No user

serviceable

parts inside.

Refer servicing to

qualified service

personnel.

MISE EN GARDE

!

Roller Pinch Point: Keep hands and fingers away.

Y ou may be crushed and/ or burned.

Danger V oltage: High voltage wires behind this panel.

Do not remove cover. You may be shocked, electrocuted,

paralyzed or die!

Electrical Shock: Live voltage present. Exercise

extreme caution. Y ou may be electrocuted!

© GBC Films Group April 2000

Do not Lift: This point can not be used as a lifting

point. If ignored, damage will occur to the laminator .

Page 1 - 7

Page 17

Safety F - 160CE Operation and Maintenance Manual

Reset: Machine reset. Press after iniating power to the

laminator or after an E-STOP or E-CABLE has been

engaged then resetted.

Page 1 - 8

© GBC Films Group April 2000

Page 18

F - 160 CE Operation and Maintenance Manual

g

g

g

q

q

q

y

q

q

g

q

g

g

g

q

q

q

y

q

q

g

q

Figure 1.7.1 Label locations - Front

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Safety

!

Riesgo de

cho

electrico

No abra

Adentro, no ha

piezas

reparables

para el usuario.

Mantenimiento

solamente para

personal

calificado

WAARSCHUWING!ATTENZIONE!WARNUNG

Kans op

elektrische

schok.

Niet openen

Bevat

ebruik te

repareren

onderdelen.

Door bevoe

service

personeel

laten repareren

© GBC Films Group April 2000

MUCHO

CUIDADO

ue

een door

!

MUCHO

CUIDADO

Risque de

secousse

electri

ue.

Ne pas ouvrir.

Pas de pieces

reparables par

l'utilisateur.

Entretien par

personnel

ualifie.

!

ualificato.

SpannungsfUhrend

e

Teile.

Nicht offnen.

Enthalt keine vom

Enduerbraucher zu

wartende Teile.

Fur service bitte an

ualifiziertes

Service-Personal

wenden.

Pericolo di

scarica

elettrica.

Nessuna parte

riparabile

dall' utente.

Chiamare un

servizio

d

di riparazioni

!

WARNING

Electrical shock

hazard.

Do not open.

No user

serviceable

parts inside.

Refer servicin

ualified service

personnel.

to

!

Riesgo de

cho

electrico

No abra

Adentro, no ha

piezas

reparables

para el usuario.

Mantenimiento

solamente para

personal

calificado

WAARSCHUWING!ATTENZIONE!WARNUNG

Kans op

elektrische

schok.

Niet openen

Bevat

ebruik te

repareren

onderdelen.

Door bevoe

service

personeel

laten repareren

MUCHO

CUIDADO

ue

een door

!

MUCHO

CUIDADO

Risque de

secousse

electri

ue.

Ne pas ouvrir.

Pas de pieces

reparables par

l'utilisateur.

Entretien par

personnel

ualifie.

!

ualificato.

SpannungsfUhrend

e

Teile.

Nicht offnen.

Enthalt keine vom

Enduerbraucher zu

wartende Teile.

Fur service bitte an

ualifiziertes

Service-Personal

wenden.

Pericolo di

scarica

elettrica.

Nessuna parte

riparabile

dall' utente.

Chiamare un

servizio

d

di riparazioni

!

WARNING

Electrical shock

hazard.

Do not open.

No user

serviceable

parts inside.

Refer servicin

ualified service

personnel.

to

Page 1 - 9

Page 19

Safety F - 160CE Operation and Maintenance Manual

Figure 1.7.2 Label locations - Rear

!

!

WARNING

ACHTUNG

!

MISE EN GARDE

!

WARNING

ACHTUNG

!

MISE EN GARDE

!

!

CUIDADO

Riesgo de

choque

electrico

No abra

Adentro, no hay

piezas

reparables

para el usuario.

Mantenimiento

solamente para

personal

calificado

WAARSCHUWING!ATTENZIONE!WARNUNG

Kans op

elektrische

schok.

Niet openen

Bevatgeen door

gebruik te

repareren

onderdelen.

Door bevoegd

service

personeel

laten repareren

MUCHO

!

MUCHO

CUIDADO

Risque de

secousse

electrique.

Ne pas ouvrir.

Pas de pieces

reparables par

l'utilisateur.

Entretien par

personnel

qualifie.

Pericolo di

scarica

elettrica.

Nessuna parte

riparabile

dall' utente.

Chiamare un

servizio

di riparazioni

qualificato.

!

SpannungsfUhrend

e

Teile.

Nicht offnen.

Enthalt keine vom

Enduerbraucher zu

wartende Teile.

Fur service bitte an

qualifiziertes

Service-Personal

wenden.

!

WARNING

Electrical shock

hazard.

Do not open.

No user

serviceable

parts inside.

Refer servicing to

qualified service

personnel.

Page 1 - 10

© GBC Films Group April 2000

Page 20

WarrantyF - 160 CE Operation and Maintenance Manual

Section 2 Warranty

GBC Films Group warrants the equipment sold

is free from defects in material and workmanship for a

period of one ( 1 ) year parts and 90 days labor from

the date of installation. This warranty is the only warranty

made by GBC Films Group and connot be modified or

amended.

GBC Films Group’s sole and exclusive

liability and the customer’s sole and exclusive

remedy under this warranty shall be, at GBC Films

Group’s option, to repair or replace any such

defective part or product. These remedies are only

available if GBC Films Group’s examination of the

product discloses to GBC Films Group’ s satisfaction

that such defects actually exist and were not caused

by misuse, neglect, attempt to repair , unauthorized

alteration or modification, incorrect line voltage, fire,

accident, flood, or other hazard.

THE WARRANTY MADE HEREIN IS IN

LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING

ANY WARRANTY OR

MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. GBC

FILMS GROUP WILL NOT BE LIABLE

FOR PROPERTY DAMAGE OR

PERSONAL INJURY ( UNLESS

PRIMARILY CAUSED BY ITS

NEGLIGENCE ), LOSS OF PROFIT OR

OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES

ARISING OUT OF THE USE OR

INABILITY TO USE THE EQUIPMENT.

2.2 Exclusions to the

2.1 Limited Warranty

This warranty specifically does not cover damage

to the laminating rollers caused by knives, razor blades,

other sharp objects, failure caused by adhesives or

improper use of the machine. Warranty repair or

replacement does not extend the warranty beyond the

initial one year period from the date of delivery .

CAUTION

Warranty

This warranty specifically does not

cover;

1. Damage to the laminating rollers caused by knives,

razor blades, other sharp objects or failure caused

by adhesives.

2. Damage to the machine caused by lifting, tilting and /

or any attempt to position the machine other than

rolling on the installed castors on even surfaces.

3. Improper use of the machine.

Unauthorized customer alterations will

void this warranty.

© GBC Films Group April 2000

4. Damage due from unqualified person(s) servicing the

machine.

Page 2 - 1

Page 21

Warranty F - 160 CE Operation and Maintenance Manual

Qualified

• Any engineer that has experience with electrical

and mechanical design of lamination equipment.The

engineers should be fully aware of all aspects of safety

with regards to lamination equipment.

• Any commissioning or service engineer must be

of competent nature, trained and qualified to GBC Films

Group standards to fulfill that job. This person will have

completed and passed the full service training course from

GBC Pro-T ech.

• Any GBC T echnician, GBC Specialist, and / or

GBC Films Group T echnician that has been through the

Page 2 - 2

© GBC Films Group April 2000

Page 22

Section 3: Specifications

Specifications provide all of the technical data for

the Falcon 160 CE Laminator.

Section 3.1 General

SpecificationsF - 160 CE Operation and Maintenance Manual

Description:

Features:

Applications:

• Mid level, wide format color finisher for the sheet fed

ink jet market. The Falcon 160 CE is a self standing,

bi-directional laminator ..

• T wo unwinds ( 1 upper, 1 lower )

• T wo rewinds ( 1 upper front, 1 lower center )

• Safety shielded

• Infeed and oufeed tables

• Accelerator footswitch

• Job programmable

• Bi-directional system

• Four E-STOPs

• Front and rear E-Cable

• Single sided lamination

• Encapsulation

• Mounting

• Decaling

Section 3.2 Consumable

Film types:

© GBC Films Group April 2000

• Pressure sensitive laminates

• Pressure sensitive adhesives

• Low melt laminates

• Thermal laminates

• Thermal adhesives

Page 3 - 1

Page 23

Specifications F - 160CE Operation and Maintenance Manual

Film diameters:

Core size:

Film widths:

Paper widths:

Mounting thickness:

• Up to a 8” roll diameter ( 20.3 cm )

• 3” core standard ( 7.62 cm )

• 2-1/4” optional ( must have optional core adapters )

( 5.72 cm )

• 64” Pressure sensitive ( 162.6 cm )

• 62” Thermal ( 157.8 cm )

• 62” maximum paper width ( 157.8 cm )

• Up to 1” inch thick ( 2.54 cm ) either direction

Safety:

Section 3.3 Function

Speed:

Motor:

Heating capabilities:

Designed to UL / CSA / CE safety standards

• 0 - 15 ft / min ( 0 - 4.6 m / min )

• 2-1/4 horse power drive motor

• Bi-directional D.C. motor

• 68oF - 290oF ( 20oC - 143oC )

Controls:

Page 3 - 2

• Front control panel

• V ariable speed footswitch

© GBC Films Group April 2000

Page 24

SpecificationsF - 160 CE Operation and Maintenance Manual

Job save:

Roll design:

Section 3.4 Electrical

United Statesand Canada:

Europe:

• Save up to 9 job parameters

• High release silicone rolls

• 230 - 240 V AC, 50/60 Hz, single phase, 55 amps.

• 230 - 240 VAC, Wye 3 phase, 32 amps/ phase

B.T .U. output:

Heater wattages:

Amperage draw:

D/C voltage used:

A/C voltage used:

• 31,732 B.T .U. / hour

• 5600 watts per heater

• No heat, motor only : 1 - 3 amps

• T op heat and motor : 20 - 23 amps

• Both heat and motor : 40 - 43 amps

• 24 vdc

• 12 vdc isolated x 2

• 24 vdc isolated

• 230 vac ( minimum )

© GBC Films Group April 2000

Page 3 - 3

Page 25

Specifications F - 160CE Operation and Maintenance Manual

Section 3.5 Dimensions

W eight:

Crated:

Uncrated:

Dimensions

Crated:

Uncrated

Nip Height:

• 1568 lbs. ( 711 kg. )

• 1200 lbs. ( 544 kg. )

• 90 in. (H) x 46 in. (W) x 72 in. (L)

( 229 cm (H) x 117 cm (W) x 183 cm (L) )

• 54 in. (H) x 38 in. (W) x 82.5 in. (L)

( 137 cm (H) x 96 cm (W) x 209 cm (L) )

Refer to Figure 3.5.1

• 37 3/16 in. ( 95 cm )

Safety Shield Raised Height:

Page 3 - 4

• 66 5/8 in. ( 169 cm)

© GBC Films Group April 2000

Page 26

Figure 3.5.1 Dimensions

SpecificationsF - 160 CE Operation and Maintenance Manual

53 in.

(135 cm)

76 in.

(193 cm)

82.5 in.

(210 cm)

3.63 in.

(9 cm)

1.38 in.

(3.5 cm)

4.75 in.

(12 cm)

28 in.

(71 cm)

4.875 in.

(12 cm)

© GBC Films Group April 2000

Page 3 - 5

Page 27

Specifications F - 160CE Operation and Maintenance Manual

This page intentionally left blank.

Page 3 - 6

© GBC Films Group April 2000

Page 28

InstallationF - 160 CE Operation and Maintenance Manual

Section 4 Installation

GBC Films Group is committed to a program of

ongoing product improvement. As a result, we are

providing these instructions so you can insure that your

new Falcon 160 CE Laminator is properly and securely

unpacked, moved, and installed.

Before a Falcon 160 CE Laminator can be

installed, there are a few requirements that must be met.

Make certain that each of the requirements listed in the

following pre-installation checklist are met before beginning

installation.

CAUTION

Is the environment appropriate for the laminator?

The laminator requires a clean, dust and vapor

free environment to operate properly . It must not

be located where there is air blowing directly on

the machine

Have you contacted a certified electrician to both

wire the laminator and ensure that adequate power

is being supplied, having the appropriate capacity ,

over current protection and safety lockouts are

available?

WARNING

The operating environment must be free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors.

Failure to follow the pre-installation check

list can result in damage to the laminator.

4.1 Pre-installation

Are doorways and hallways wide enough for the

laminator to be moved to the installation site?

Is there ample room for the laminator?

A work area must be established that allows for

operation in both the front and rear of the

laminator and provides space for efficient material

flow. Figur e 4.1.1 illustrates a typical machine

area layout.

WARNING

Vapor build up or stored flammable

liquids can cause a fire. Excessive

dust can damage the laminator.

CAUTION

Do not locate the laminator where air is

blowing directly on the machine. The air

flow can cool the rolls unevenly and result

in poor output quality.

© GBC Films Group April 2000

Page 4 - 1

Page 29

Installation F - 160 CE Operation and Maintenance Manual

The laminator requires 230 to 240 vac, 50/ 60

Hz, 55 amps. Or, in Europe only, 3-N phase,

240 vac, 32 amps/ phase.

WARNING

The Falcon 160 CE Laminator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED RIGGERS ONLY to

move the laminator. The laminator is not

designed to be tipped up or sideways in any

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requires extensive realignment. You can

be crushed or seriously injured.

For instructions on how to connect power,

proceed to 4.9 Connecting power in this section.

Page 4 - 2

© GBC Films Group April 2000

Page 30

Figure 4.1.1 Suggested Floor Layout

g

4' x 6' ( 1.22 m x 2m )

Work table on wheels

8.4'

( 2.57 m )

35-3/4" ( .94 - .95m )

InstallationF - 160 CE Operation and Maintenance Manual

Table height

82.5"

( 209 cm )

20'

( 6 m )

38"

( 96 cm )

8.4'

( 2.57m )

4' x 6' ( 1.22 m x 2m )

Work table on wheels

Table hei

35-3/4" ( .94 - .95m )

ht

3' ( 1 m)

© GBC Films Group April 2000

13' ( 4 m)

Page 4 - 3

Page 31

Installation F - 160 CE Operation and Maintenance Manual

pp

pp

4.2 Know your machine

Before performing any procedure within this

manual, it is recommended that you take time to know

the parts of your new machine.

Figure 4.2.1 The laminator

Drive

side

Rear side

Figure 4.2.3 Front view

Upper

rewind

Front

feed

table

Lower

unwind

shaft

Castors

Main

rollers

Control

panel

Upper

unwind

brake

Lower

rewind

Pull roll

lift handle

Lower

unwind

brake

Drive

side leg

Electrical

bridge

Front side

Figure 4.2.2 Safety features

E-STOP

Rear safety shield

Control

side

Control

side leg

Figure 4.2.4 Rear view

Core

ort

su

Core

chuck

Power

ON/OFF

E-CABLE

Core

chuck

U

unwind

shaft

Pull rollers

Rear

feed

table

Circuit

breaker

er

Front safety

shield

E-CABLE

Page 4 - 4

E-CABLE reset

Figure 4.2.5 Footswitch

E-STOP

ATTUNG

WARNING

ADVERTENCIA

Machine reset

© GBC Films Group April 2000

Page 32

InstallationF - 160 CE Operation and Maintenance Manual

4.3 Unpacking

INFORMATION

ALL SHIPMENTS ARE EX-WORKS.

dock, title passes to the buyer. Please review

your insurance coverage prior to shipment,

as you are responsible for all subsequent

freight charges and risks.

INFORMATION

Before signing the Bill of Lading, you

should be sure to inspect the crate

and / or pallet for signs of damage or

missing items; if applicable, make

note of this on the Bill of Lading.

At our

With regards to your shipping methods, use one

of the following procedure described to safely and

properly unwrap / uncrate your laminator .

4.4 Shrink Wrapped

a) Inspect the machine for any obvious shipping

damages upon receipt.

b) Carefully unwrap the shrink wrap from around

the laminator .

CAUTION

INFORMATION

Depending on the destination and customer

preference, your machine may be shipped in

various ways. The laminator may arrive

shrink wrapped or in a plywood crate on a

skid. Please follow the unpacking procedure

that pertains to your method of shipment.

WARNING

Do not attempt to move the laminator across

The unpacking process requires at least two

people. You can be severely injured, crushed

or cause damage to the laminator.

without trained and qualified riggers. You

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

c) With another person, carefully wheel your

F - 160 CE Laminator to the installation site.

WARNING

anything other than a flat level surface

can be crushed or seriously injured.

© GBC Films Group April 2000

Page 4 - 5

Page 33

Installation F - 160 CE Operation and Maintenance Manual

4.5 Crated

WARNING

The Falcon 160 CE Laminator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED RIGGERS ONLY to

move the laminator. The laminator is not

designed to be tipped up or sideways in any

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requires extensive realignment. You can

be crushed or seriously injured.

To uncrate the laminator

a) Remove the top of the crate and then the sides

in the order shown in Figure 4.5.1

CAUTION

Do not allow the top to fall into the crate. It

can damage the laminator.

INFORMATION

GBC Film Group's warranty does not

cover malfunction of the equipment due to

mishandling and / or tipping. GBC Films

Group bears no responsibility for personal

injury or damage due to moving the

laminator improperly.

Tools required

• # 2 Phillips head screwdriver

• 7/8” open end wrench or adjustable wrench

• Crow bar

• A second person

INFORMATION

Do not put packing screws on the floor.

They can cause problems when trying to roll

the laminator into position or you can

become injured if stepped on.

CAUTION

A second person must support the side

labeled 5 in Figure 4.5.1 It can fall and

damage the laminator or cause harm to you

and others.

Page 4 - 6

© GBC Films Group April 2000

Page 34

InstallationF - 160 CE Operation and Maintenance Manual

Figure 4.5.1 Disassembling of the crate

1

P

l

a

n

e

3

4

P

l

a

n

e

4

P

l

a

n

e

4

4

2

5

b) Move all packing materials to a safe distance.

Moving the laminator

a) Have the laminator rolled off the skid and

placed on the floor by licensed riggers. The ramps

included with the laminator can be secured utilizing

screws removed from the disassembled crate.

Figure 4.5.2 illustrates positioning of the ramps.

Removing the shrink wrap

a) Gently unwrap the shrink wrap from around the

laminator.

CAUTION

WARNING

Do not attempt to use the ramps if they are

not secured to the pallet. Ensure the pallet is

on a flat even surface before attempting to

roll the machine off.

Figure 4.5.2 Positioning of the ramps

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

© GBC Films Group April 2000

Page 4 - 7

Page 35

Installation F - 160 CE Operation and Maintenance Manual

b) Remove any plastic strapping and/or packing

paper taped to the rollers.

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

c) Remove all packing materials to a safe distance

from the laminator and dispose of properly .

d) Use two people to carefully roll the laminator to

the desired location.

4.6 Accessory pack

unpacked and moved into final position, open the accessory

pack and verify the contents.

Once the Falcon 160 CE Laminator has been

Accessory Pack contents

• One T-handle allen wrench ( 475-200 )

• One Zippy knife ( 475-620 )

• One T erry clothe towel ( 475-950 )

• One Operators manual ( 930-045 rev . A )

• One roll masking tape ( 475-000 )

• T wo Polyurethane O-rings ( 480-005 )

• One strain relief for main power ( 175-201 )

• One rubber cement pad ( 930320 )

• One crankhandle ( 629-018 )

• One fuse, 0.5A ( 186-022 )

• T wo fuses, 2.5A ( 186-220 )

• Four leveling bolts ( 645-011 )

• T welve 3/4 - 10 nuts ( No P/N )

INFORMATION

About recycling: The crate components can

be reused for shipping the laminator again

or can be disassembled and the wood and

screws recycled. The shrink wrap is not

recyclable, so it must be discarded.

Page 4 - 8

If you are missing any of the itemslisted above,

contact your local service technician or sales

representative.

Contacts:

GBC Parts ( 800 ) 790 - 7787

GBC Europe parts 33 - 45 - 535 - 7676

© GBC Films Group April 2000

Page 36

InstallationF - 160 CE Operation and Maintenance Manual

4.7 Installing levelers

Leveling of the machine is a customer option. If

you choose not to level the laminator and you encounter

output problems, please level the machine and try your

application again before calling for technical support.

Before leveling can be performed, the castors

must be replaced with leveling bolts and leveling pads.

b) Lock the castors on the drive side leg.

CAUTION

Do not lift the machine where NO LIFT

warnings are located. You can cause

damage to the electrical bridge.

c) Slide the floor jack under the control side leg.

Tools required

• T orpedo level

• ( 2 ) 3/4” open end wrenches

• Four leveling pads

( from the accessory pack )

• Four Leveling bolts

( from the accessory pack )

• T welve 3/4 - 10 nuts

( from the accessory pack )

• Floor jack

( 600 pound rating )

• Second person

Control side

a) V erify that the laminator has sufficient room

around it to load film, walk around and to be

serviced if necessary .

Center of the leg

d) Raise the control side approximately 4 in. from

the bottom of the castor to the floor. (10 cm)

Must have eneough clearance to remove the

castors

© GBC Films Group April 2000

Page 4 - 9

Page 37

Installation F - 160 CE Operation and Maintenance Manual

e) Remove the front control side castor by turning

the nut securing the castor in the leg.

Nut

Castor

f) Slide one of the leveling bolts where the castor

was removed and along with a 3/4-10 nut

inside the leg.

Figure 4.7.1 Leveling pad installed

Nut

Nut

Jam nut

Leveling pad

Nut

Bolt

g) Place two more 3/4-10 nuts on the leveling bolt

under the leg. Refer to Figure 4.7.1 Leveling

pad installed.

h) Attach the leveling pad to the bottom of the

leveling bolt and secure with wrenches. Refer to

Figure 4.7.1 Leveling pad installed.

i) T ighten the jam nut against the leveling pad.

Refer to Figure 4.7.1 Leveling pad installed.

j) Perform steps e through “ i ” for the rear control

side castor and leveling pad.

Drive side

a) Perform steps “ a ” through “ j ” from the

Control side.

Page 4 - 10

© GBC Films Group April 2000

Page 38

InstallationF - 160 CE Operation and Maintenance Manual

4.8 Leveling

Leveling of the laminator is very important in the

way the machine performs. Leveling is crucial to the tram

( tracking ) of the materials through the machine.

a) Position the level on the top of the control side

frame. Not on the cabinet. Refer to Figure

4.8.1 Front to back control side

4.8.1 Front to back control side

b) Level the control side from front to back by

holding the nut inside the leg and turning the nut

below the leg with the wrench.

INFORMATION

A second person can read the level while you

make the appropriate adjustments.

- T o raise; raise the nut inside the leg and turn

the nut below the leg clockwise.

Level

INFORMATION

The side frame provides a more accurate

reading than the cabinet.

Raise

Turn clockwise

- T o lower; turn the nut below the leg counter

clockwise.

Lowering

limit

Turn counter

clockwise

© GBC Films Group April 2000

Page 4 - 11

Page 39

Installation F - 160 CE Operation and Maintenance Manual

INFORMATION

Lowering is limited to the amount of

height within the inside of the leg.

c) Position the level on the top of the drive side

frame. Not on the cabinet. Refer to Figure

4.8.2 Front to back drive side

Figure 4.8.2 Front to back drive side

INFORMATION

A second person can read the level while you

make the appropriate adjustments.

- T o raise; raise the nut inside the leg and turn

the nut below the leg clockwise.

Raise

Level

d) Level the control side from front to back by

holding the nut inside the leg and turning the nut

below the leg with the wrench.

Turn clockwise

- T o lower; turn the nut below the leg counter

clockwise.

Lowering

limit

Turn counter

clockwise

e) Confirm that power is supplied to the

laminator.

Page 4 - 12

© GBC Films Group April 2000

Page 40

InstallationF - 160 CE Operation and Maintenance Manual

f) Flip the circuit breaker on the laminator to the up

position.

= ON

= OFF

h) Press RESET. The front control panel should

be illuminated at this point.

Machine reset

g) Turn MAIN POWER to “ I ” position.

Power

ON/OFF

WARNING

Caution should always be exercised

when using the laminator with

the safety shields raised.

You can be seriously HURT or INJURED!

i) Raise the front safety shield. The SAFETY

indicator will begin flashing.

INFORMATION

Ensure all E-STOPS are unlatched and

the E-CABLE is reset before turning

power on to the laminator.

© GBC Films Group April 2000

00.0

SPEED

SAFETY

GO

STOP

= Flashing

FWD

REV

Page 4 - 13

Page 41

Installation F - 160 CE Operation and Maintenance Manual

l) Level the laminator from drive side to control

side by adjusting the two front leveling pads.

WARNING

Keep hands and fingers clear of the

laminator roller nip when changing GAP.

You can be CRUSHED or BURNED!

- T o raise; raise the nut inside the leg and turn

the nut below the leg clockwise.

j) Press PRESSURE ▼ to illuminate 3 bars in

the pressure dsiplay .

GAP

PRESSURE

0

k) Place the level across the top of the upper main

roller in the center. Refer to Figur e 4.8.3

Drive to control side front

Raise

Turn clockwise

- T o lower; turn the nut below the leg counter

clockwise.

Lowering

limit

Figure 4.8.3 Drive to control side front

Level

Page 4 - 14

n) Press GAP

GAP

1

© GBC Films Group April 2000

Turn counter

clockwise

▲▲

▲ to 1 in. setting.

▲▲

PRESSURE

Page 42

InstallationF - 160 CE Operation and Maintenance Manual

m) T urn the pull roller lift handle towards the rear

of the machine to lower the upper pull roller .

Stop after initial contact with the lower pull

roller plus 1/2 turn.

n) Raise the rear safety shield

o) Place the level across the top of the upper pull

roller in the center. Refer to Figur e 4.8.4

Drive to control side rear

Figure 4.8.4 Drive to control side rear

4.9 Connecting power

ELECTRICAL

SHOCK

Only a qualified electrician should connect

power to the laminator. You can be severely

shocked, electrocuted or cause a fire if

power is improperly applied.

a) Ensure the power at the junction box is in the

OFF position.

Level

p) Verify all four leveling points. Make any

adjustments neccessary . If all four points are

leveled, secure all nuts in place.

b) Remove the drive side leg cover with a #2

phillips screw driver.

q) Lower the front and rear safety shields.

r) Turn MAIN POWER to “OFF “.

© GBC Films Group April 2000

Page 4 - 15

Page 43

Installation F - 160 CE Operation and Maintenance Manual

c) Feed the power cable through the power cable

strain relief located at the bottom of the drive

side leg.

Strain relief

WARNING

e) Turn the junction box power to the ON

position.

f) Verify line voltage with regards to the type of

power being supplied to the laminator at the line

terminal block.

Line

terminal

block

Follow the correct wiring diagram when

supplying power to the laminator. If

improperly connected, you can be seriously

injured or cause damage to the laminator.

d) Connect the power cord to the line terminal

block. Refer to Figure 4.9.1 Single phase or

Figure 4.9.2 Wye thr ee phase.

Figure 4.9.1 Single phase illustrates proper

single phase wiring for the U.S. and Canada.

g) Once the power cord has been properly

connected, replace the drive side leg cover .

h) Proceed with 4.10 Safety check.

Figure 4.9.2 Wye thr ee phaseillustrates proper

Wye 3 phase wiring for Europe.

Page 4 - 16

© GBC Films Group April 2000

Page 44

Figure 4.9.1 Single phase, U.S. and Canada

InstallationF - 160 CE Operation and Maintenance Manual

Figure 4.9.2 Wye 3 phase, Europe only

Ground wire

Line 1

Line 2

N

L1 L2 L3 N N N PE

© GBC Films Group April 2000

Ground wire

Line 1

Line 2

Line 3

Neutral

N

L1 L2 L3 N N N PE

Remove

Jumper

bars

Page 4 - 17

Page 45

Installation F - 160 CE Operation and Maintenance Manual

4.10 Safety check

The safety check will ensure that all safety devices

and interlocks are functioning properly .

This procedure describes how to check one

E-STOP, the front E-CABLE, the front safety shield

and the front feed table. Repeat the steps for the remaining

three E-STOPS, the rear E-CABLE and the rear safety

shield. The rear feed table is not removable. ALL

SAFETY FEA TURES MUST BE CHECKED!

WARNING

4.10.1 Front feed table

a) Turn MAIN POWER to “ON” .

Power

ON/OFF

b) Press RESET. The front control panel will be

illuminated.

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

WARNING

If a safety feature is not working

properly, contact your local service

representative immediately.

Contacts:

Machine reset

c) Press SEL. SEL stops flashing.

GBC National Service: ( 800 ) 790 - 7787

GBC Europe Service: 33 - 45 - 535 - 7676

Page 4 - 18

SAV

JOB

0

SE L

STANDBY

= Flashing

© GBC Films Group April 2000

Page 46

InstallationF - 160 CE Operation and Maintenance Manual

d) Press FWD ▲ to set a forward motor

direction.

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

e) Press SPEED ▲ to set a speed of 6 ft/min.

g) Slightly lift the front feed table. SAFETY

indicator and GO begin flashing and the

bottom rollers stop.

G

O

6.0

SPEED

SAFETY

STOP

= Flashing

FWD

REV

h) Lower the front feed table.SAFETY

indicator reverts to white and GO remains

flashing.

6.0

SPEED

SAFETY

GO

STOP

FWD

REV

f) Press GO. The bottom rollers begin turning.

6.0

SPEED

SAFETY

GO

STOP

FWD

REV

G

O

6.0

SPEED

SAFETY

i) Press STOP. GO stops flashing.

STOP

= Flashing

GO

6.0

SPEED

SAFETY

STOP

FWD

REV

FWD

REV

© GBC Films Group April 2000

Page 4 - 19

Page 47

Installation F - 160 CE Operation and Maintenance Manual

4.10.2 Safety shield

a) Press GO. The bottom rollers begin turning.

6.0

SPEED

SAFETY

GO

STOP

FWD

REV

c) Lower the front safety shield. SAFETY

indicator reverts to white and GO remains

flashing.

G

O

6.0

SPEED

SAFETY

STOP

= Flashing

FWD

REV

WARNING

Caution should always be exercised

when using the laminator with

the safety shields raised.

You can be seriously HURT or INJURED!

b) Raise the front safety shield. SAFETY indicator

and GO begin flashing and the bottom rollers

stop.

d) Press STOP .GO stops flashing.

6.0

SPEED

SAFETY

GO

STOP

FWD

REV

e) Repeat steps “ a ” through “ d ” for the rear

safety shield.

Page 4 - 20

6.0

SPEED

SAFETY

G

O

STOP

= Flashing

FWD

REV

© GBC Films Group April 2000

Page 48

InstallationF - 160 CE Operation and Maintenance Manual

4.10.3 E-STOP

a) Press GO. The bottom rollers begin turning.

GO

6.0

SPEED

SAFETY

b) Press PRESSURE ▼ to illuminate 3 bars in

the pressure dsiplay .

STOP

FWD

REV

d) Unlatch the E-STOP.

Unlatch

e) Press machine RESET. The front control panel

is illuminated.

GAP

PRESSURE

0

c) Press down on the front control side E-ST OP.

The E-STOP latches in the down position,

bottom rollers stop, the upper main roller

raises and the control panel is blank.

Push

Machine reset

f) Repeat steps “ a ” through “ e ” for the

remaining three E-STOPs.

Front

E-STOP

Rear

© GBC Films Group April 2000

E-STOPs

Page 4 - 21

Page 49

Installation F - 160 CE Operation and Maintenance Manual

4.10.4 E-CABLE

a) Press GO. The bottom rollers begin turning.

GO

6.0

SPEED

SAFETY

b) Press PRESSURE ▼ to illuminate 3 bars in

the pressure dsiplay .

STOP

FWD

REV

d) Latch the E-CABLE by pushing in on the E-

CABLE reset located in the front at the bottom

of the control side leg.

Push in

e) Press machine RESET. The front control panel

is illuminated.

GAP

PRESSURE

0

c) Press on the front E-CABLE with your foot.

The bottom rollers stop, the upper main roller

raises and the control panel is blank.

Machine reset

f) Repeat steps “ a ” through “ e ” for the

rear E-CABLE.

Page 4 - 22

© GBC Films Group April 2000

Page 50

InstallationF - 160 CE Operation and Maintenance Manual

4.11 Function check

The function check ensures that the laminator

functions properly when operating. This check is

recommended before performing any applications.

If a step that does not react according to the

description, call your local area service representative

immediately .

WARNING

b) Press BOT TEMP ▲ to a value of 120

o

F

( 48 oC ). BOT TEMP DISPLAY begins

flashing.

TOP TEMP BOT TEMP

120 120

--

c) SEL can not be tested until you have saved

parameters within a JOB location. Refer to

Section 5.4 Job programming for SEL and

SAV.

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

4.11.1 Control panel

a) Press TOP TEMP. ▲ to a value of 120

( 48 oC ). TOP TEMP DISPLAY begins

flashing.

o

F

SAV

JOB

0

SE L

STANDBY

= Flashing

d) Press GAP ▼ once. GAP DISPLAY

decreases 1/16th of an inch per press. The

upper main roller moves accordingly . Once to

“0”, the upper main roller is contacting the

lower main roller.

TOP TEMP BOT TEMP

120 68

-

© GBC Films Group April 2000

GAP

1-0

PRESSURE

Page 4 - 23

Page 51

Installation F - 160 CE Operation and Maintenance Manual

e) Press GAP ▲. GAP DISPLAY increases

1/16th of an inch per press. The upper main roll

moves accordingly . Once to “1”, the upper

main roller stops.

GAP

PRESSURE

0-1

f) Press and hold PRESSURE ▼. The upper

main roller travels in a constant downward

motion. Once making contact with the lower

main roller, the bars turn solid one at a time until

all 10 bars are solid.

h) Press JOB ▲. The JOB DISPLAY increases

in increments of 1 to 9.

SEL SAV

JOB

9

STANDBY

i) Press JOB ▼ . The JOB DISPLAY should

decreases in increments of 1 from 9 to 0.

GAP

PRESSURE

0

g) Press and hold PRESSURE ▲. The upper

main roller travels in a constant upward motion.

The pressure bars turn hollow one at a time until

no bars are solid and GAP DISPLAY changes

to “ 1 ” then stops.

GAP

PRESSURE

SEL SAV

JOB

0

STANDBY

INFORMATION

To continue with the function checks, you

must press SEL so that it discontinues

flashing.

Page 4 - 24

1

© GBC Films Group April 2000

Page 52

InstallationF - 160 CE Operation and Maintenance Manual

j) Press SPEED ▲ once. SPEED DISPLAY

increases in increments of .5 per press up to 15.

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

k) Press FWD ▲. FWD is solid.

m) Press STOP. The bottom rollers stop turning.

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

n) Press REV ▼ . REV is solid and FWD

reverts to hollow .

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

l) Press GO. The bottom rollers turn in a forward

motion at a speed of 15 ft./min.

( 4.57 m / min. ).

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

o) Press GO. The bottom rollers turn in a reverse

motion at a speed of 15 ft./min.

( 4.57 m / min. ).

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

© GBC Films Group April 2000

Page 4 - 25

Page 53

Installation F - 160 CE Operation and Maintenance Manual

p) Press STOP. The bottom rollers stop turning.

WARNING

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

q) Press SPEED ▼ once. SPEED DISPLAY

decreases in increments of .5 per press down to

00.0.

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

Caution should always be exercised

when using the laminator with

the safety shields raised.

You can be seriously HURT or INJURED!

s) Raise the front safety shield, remove the front

feed table.

t) T ouch the upper and lower main rollers. They

should feel warm to the touch.

r) The T OP TEMP DISPLA Y and BOT TEMP

DISPLAY are solid indicating the actual

temperature is within a +/- 6 oF of the set point

temperature.

TOP TEMP BOT TEMP

120 120

Page 4 - 26

u) Replace the front feed table and lower the

front safety shield.

INFORMATION

The SAFETY indicator should not be

flashing when the tables are properly

seated and the safety shields are in

the closed position..

© GBC Films Group April 2000

Page 54

InstallationF - 160 CE Operation and Maintenance Manual

u) Press STANDBY. The laminator reverts to

the default settings and ST ANDBY is solid.

Refer to Figure 4.1 1.1 Default settings

SEL SAV

JOB

0

STANDBY

Figure 4.11.1 Default settings

4.11.2 Variable speed

footswitch

This check is to ensure that the footswitch works.

For complete instructions on the footswitch and its relation

to “Footswitch” mode to “ Panel” mode, refer to Section

5.1 Controls / ( 28 ) Footswitch.

a) Press SEL on the front control panel to “wake”

the laminator from SLEEP mode. SLEEP

indicator reverts to hollow .

TOP TEMP BOT TEMP

68 68

PRESSURE

IIIIIII

SE L

STANDBY

GO

1/16

JOB

GAP

0

00.0

SPEED

SAFETY

= Flashing

STOP

FWD

REV

SAV

SAV

JOB

0

SE L

STANDBY

= Flashing

b) Press FWD ▲ for a forward motor direction.

FWD is solid.

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

© GBC Films Group April 2000

Page 4 - 27

Page 55

Installation F - 160 CE Operation and Maintenance Manual

c) Press down on the variable speed footswitch.

GO begins flashing and the bottom rollers are

turning.

ATTUNG

WARNING

ADVERTENCIA

INFORMATION

Caution should always be exercised

when using the laminator with

the safety shields raised.

You can be seriously HURT or INJURED!

a) Raise the rear safety shield.

WARNING

Footswitch speed is not indicated in the

SPEED DISPLAY on the control panel.

4.11.3 Unwind shafts and

unwind brakes

The unwind shafts swing out and the unwind

brakes tension the turning of the shaft from no tension to

complete stop tension.

b) Lift the clevis pin up from the saddle of the

upper unwind shaft.

Saddle

Clevis pin

c) Swing the upper unwind shaft to its fully

extended position. Swing back and reseat the

shaft in the saddle. The swing movement should

be smooth and easy .

Should you detect or experience complications

with the unwind shaft movement or the unwind brake

tension, call you local area service representative.

Page 4 - 28

d) Ensure that the upper unwind brake adjustment

knob is backed off completly . The counter

clockwise turn should be easy .

© GBC Films Group April 2000

Page 56

INFORMATION

j

Steps " e" and " f" will be performed

simultaneously.

e) W ith one hand, slowly turn the upper unwind

shaft in either direction.

f) W ith the other hand, slowly turn the upper

unwind brake adjustment knob clockwise.

InstallationF - 160 CE Operation and Maintenance Manual

h) Slowly turn the upper unwind brake adjustment

knob counter clockwise.

i) Y ou should feel a decrease in resistance on the

turning of the upper unwind shaft as you turn the

upper unwind brake adjustment knob counter

clockwise.

j) Lower the rear safety shield.

Upper unwind brake

adjustment dial

k) Repeat steps “ b ” through “ h ” again for

the lower unwind shaft.

Lower unwind brake

ad

ustment dial

g) You should feel an increase in resistance on the

turning of the upper unwind shaft as you turn the

upper unwind brake adjustment knob

clockwise.

© GBC Films Group April 2000

Page 4 - 29

Page 57

Installation F - 160 CE Operation and Maintenance Manual

This page intentionally left blank.

Page 4 - 30

© GBC Films Group April 2000

Page 58

F - 160 CE Operation and Maintenance Manual

Operations

Section 5 Operations

The operator control panel for the Falcon 160

CE Laminator is located on the front of the machine, to

the right of the front operating position.

For an illustration of the complete front control

panel, please refer to Figure 5.1.1. The names and

functions of these controls are as follows:

INFORMATION

When any command is pressed on the

control panel, a "beep" will sound. If the

command is held down, the panel will

"beep" only once.

( 2 ) TOP TEMP DISPLA Y : The display will show the

set point temperature of the top main roller as the default

display . When the top roller temperature has reached in

the +/- 6 oF range of the set point, the display will be

solid. When outside of this range, the display will flash.

TOP TEMP BOT TEMP

68 68

2

( 3 ) TOP TEMP ▲ : When pressed, will increase the

set point value of the top main roller in increments of 2

degrees. If held down, it will only increase to the maximum

temperature setting of 290oF ( 143oC ).

3

5.1 Control Panel

( 1 ) ST ANDBY : If flashing, the machine is in standby

mode. This will occur after 3 hours of no activity . To wake

the laminator from standby mode or manual engage standby

mode, press STANDBY.

SEL SAV

JOB

0

STANDBY

1

TOP TEMP BOT TEMP

68 68

( 4 ) TOP TEMP ▼ : When pressed, will decrease the

set point value of the top main roller in increments of 2

degrees. If held down, it will only decrease to the minimum

temperature setting of 68oF ( 20oC ).

TOP TEMP BOT TEMP

68 68

4

© GBC Films Group April 2000

Page 5 - 1

Page 59

Operations F - 160 CE Operation and Maintenance Manual

( 5 ) BOT . TEMP . DISPLAY : The display will show

the set point temperature of the bottom main roller as the

default display . When the bottom roller temperature has

reached in the +/- 10oF range of the set point, the display

will be solid. When outside of this range, the display will

flash.

TOP TEMP BOT TEMP

68 68

5

( 6 ) BOT . TEMP . ▲ : When pressed, will increase the

set point value of the bottom main roller in increments of

2 degrees. If this key is held down, it will only increase to

the maximum temperature setting of 290oF ( 143oC ).

( 8 ) OVER/ UNDER INDICA TORS : Dislays a “+”

if the temperature is above the set point. Display a “–” if

the temperature is below the set point. If neither (+/ -) is

displayed, the temperaure is within the +/- 6 oF range.

TOP TEMP BOT TEMP

68 68

+

8

-

( 9 ) GAP DISPLA Y : Displays the current main roller

nip opening. The nip has a range of 0 to 1” gap.

6

TOP TEMP BOT TEMP

68 68

( 7 ) BOT . TEMP . ▼ : When pressed, will decrease the

set point value of the bottom main roller in increments of

2 degrees. If held down, it will decrease to the minimum

temperature setting of 68oF ( 20oC ).

TOP TEMP BOT TEMP

68 68

GAP

PRESSURE

1/16

9

( 10 ) GAP ▲ : When pressed, will increase the gap by

1/16 in. increments. If held down, it will automatically

increase the gap by 1/16 in. increments until it has reached

a maximum opening of 1 in. on the GAP DISPLA Y.

10

GAP

PRESSURE

1/16

Page 5 - 2

7

© GBC Films Group April 2000

Page 60

F - 160 CE Operation and Maintenance Manual

Operations

( 11 ) GAP ▼ : When pressed, will decrease the gap by

1/16 in. increments. If held down, it will automatically

decrease the gap by 1/16 in. increments until it has reached

a minimum opening of 0 in. on the GAP DISPLA Y.

GAP

PRESSURE

1/16

11

( 12 ) PRESSURE DISPLA Y : Displays the amount of

pressure being used. Each bar represents 10% of the

maximum allowable pressure. All ten bars illuminated

equals 100% of the maximum allowable pressure.

( 13 ) PRESSURE ▲ : When pressed once, will

decrease the pressure by 5%. If held down, it will decrease

from 100% of the maximum allowed pressure to 0% at

which point no bars will be illuminated.

13

GAP

PRESSURE

1

WARNING

Keep hands and fingers clear of

the laminator roller nip when

adjusting PRESSURE.

You can be CRUSHED or BURNED!

GAP

PRESSURE

1/16

12

INFORMATION

When adjusting the pressure, the gap

will be affected as well.

( 14 ) PRESSURE ▼ : When pressed once, will increase

the pressure by 5%. If held down, it will increase from

0% of the minimum allowed pressure to 100% at which

point all bars will be illuminated.

GAP

PRESSURE

0

14

© GBC Films Group April 2000

Page 5 - 3

Page 61

Operations F - 160 CE Operation and Maintenance Manual

( 15 ) JOB DISPLA Y : Displays the job number selected

and will set the operating parameters saved for that number

once SEL has been pressed.

SEL SAV

JOB

0

STANDBY

15

INFORMATION

Job programming is explained in

Section 5.4

( 17 ) JOB ▼ : When pressed once will decrease the job

number in JOB DISPLA Y by increments of 1. If pressed

and held, the JOB DISPLA Y will decrease to 0 at which

point it will stop.

SEL SAV

JOB

0

STANDBY

17

( 18 )SEL : When pressed will send the operating

parameters for the stored job number selected to the

correct devices. Any time JOB ▲ or JOB ▼ is pressed,

SEL will flash indicating a change in job number.

( 16 ) JOB ▲ : When pressed once will increase the job

number in JOB DISPLA Y by increments of 1. If pressed

and held, the JOB DISPLA Y will increase to 9 at which

point it will stop.

16

SEL SAV

JOB

9

STANDBY

18

SAV

JOB

0

SE

L

STANDBY

= Flashing

INFORMATION

If not using a JOB number, Press

SEL before changing parameters on

the control panel.

Page 5 - 4

© GBC Films Group April 2000

Page 62

F - 160 CE Operation and Maintenance Manual

Operations

( 19 ) SAVE : When pressed and held ( approximately 4

seconds ), will beep and save the current settings for the

number showing in the JOB DISPLAY. For more

information, refer to Section 5.4 Job Programming on

how to save parameters.

19

SEL SAV

JOB

9

STANDBY

( 20 ) SPEED DISPLA Y : Displays the current speed

setting of the laminator.

20

( 22 ) SPEED ▼: When pressed, decreases the speed

of the laminator in increments of 0.5 ft/min. When pressed

and held, speed will automatically decrease by 0.5 ft/min

increments until it has reached 0 ft/min.

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

22

( 23 ) GO: When pressed, starts the rollers in motion.

GO is solid. This solid indication is referred to as the “panel

mode”. If a safety shield is raised during “panel mode”,

GO and SAFETY ( refer to ( 27 ) SAFETY for

explanation ) begin flashing enabling “footswitch” mode.

( refer to ( 28 ) FOOTSWITCH for explanation )

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

( 21 ) SPEED ▲: When pressed, increases the speed of

the laminator in increments of 0.5 ft/min. When pressed

and held, speed will automatically increase by 0.5 ft/min

increments until it has reached the maximum allowed speed

of 15 ft/min.

21

15.0

SPEED

SAFETY

GO

STOP

FWD

REV

23

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

( 24 ) STOP : When pressed, stops the rollers and GO

becomes white.

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

24

© GBC Films Group April 2000

Page 5 - 5

Page 63

Operations F - 160 CE Operation and Maintenance Manual

( 25 ) FORWARD ▲ : When pressed, signals the

laminator to run in a forward motion and FORWARD ▲

becomes solid.

25

00.0

SPEED

SAFETY

GO

STOP

FWD

REV

( 26 ) REVERSE ▼ : When pressed, signals the

laminator to run in a reverse motion and REVERSE ▼

becomes solid.

( 28 ) V ariable Speed Footswitch : The variable speed

footswitch, operates the laminator in “Footswitch” mode.