Page 1

EBA 721-05 LT GB Operating Instructions

- 1 -

Page 2

EBA 721-05

Children must not operate the machine!

Never leave the blade unattended. Do not extract or

transport the blade without protection!

Danger! Risk of injury!

Do not reach beneath the blade!

Paper clips or hard material will damage the cutting blade!

Do not cut hard materials or materials which may splinter!

- 2 -

Page 3

Table of contents

1. General .......................................................... 4

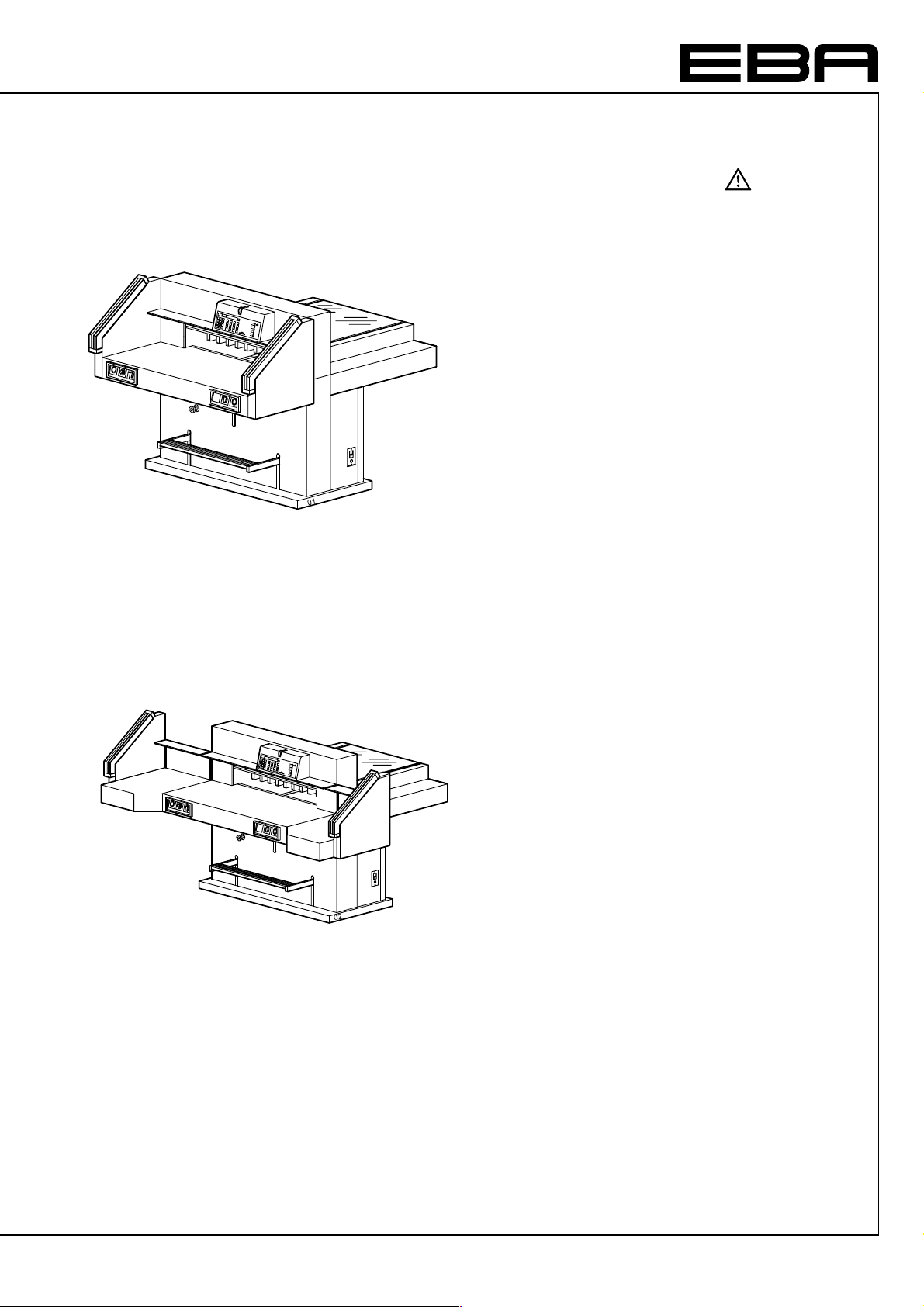

without side tables

1.1 Safety Precautions

1.2 Application ................................................... 4

2. Installation ................................................... 5

2.1 Preparing for installation ............................. 5

2.2 Power supply ............................................... 6

3. Operation .................................................... 7

Checklist...................................................... 7

3.1 Operating elements ..................................... 8

3.2 Start-up........................................................ 8

Manual foot pedal ........................................ 8

Cutting to a specified dimension ................. 8

Calculating: ................................................. 9

Cut according to markings .......................... 9

Optical cutting line indicator ........................ 9

Mechanical cutting line indicator ................. 9

Eject function ............................................. 9

Multiple cuts function start ......................... 10

Exiting program-mode ............................... 10

3.3 Cutting activation ....................................... 10

Cutting stop or interruption: ....................... 10

3.4 False clamp plate ...................................... 11

3.5 Programming ............................................ 12

Entering a program ................................... 12

Eject function program .............................. 12

Changing select program .......................... 13

Insert a step .............................................. 13

Delete a step ............................................. 13

Delete a program ...................................... 13

Example of a program ............................... 13

How the example works ............................ 13

Changing the basic settings ...................... 13

Working with programs ............................. 14

Exiting program-mode. .............................. 14

3.6 Basic Settings ........................................... 14

.................. 4

with side tables

4. Maintenance .............................................. 15

Safety check ............................................. 15

4.1 Setting the cutting depth ........................... 15

4.2 Turning or replacing the cutting stick ........ 16

Cutting test ................................................ 16

4.3 Blade replacement .................................... 17

Removing the blade .................................. 17

Mounting the blade .................................... 18

4.4 Maintenance every 7 days ........................ 19

4.5 Maintenance every 6 months .................... 19

Type of grease .......................................... 19

5. Malfunctions .............................................. 20

6. Technical data ........................................... 22

7. Accessories ............................................... 22

EC-declaration of conformity..................... 23

- 3 -

Page 4

EBA 721-05

1. General

This instruction manual will help you to learn the

safe and comfortable operation of this machine.

Please read these operating instructions before

putting the machine into operation and observe the

safety regulations.

1.1 Safety Precautions

Danger!

Non-compliance with the instructions may

endanger persons.

Warning!

Non-compliance with the instructions may

cause damage to the machine.

The operating instructions must always be

available for the operator.

All components which could endanger the operator

are covered by a guard. The side panels are

screwed to the machine.

This machine is constructed for "one-man

operation" only!

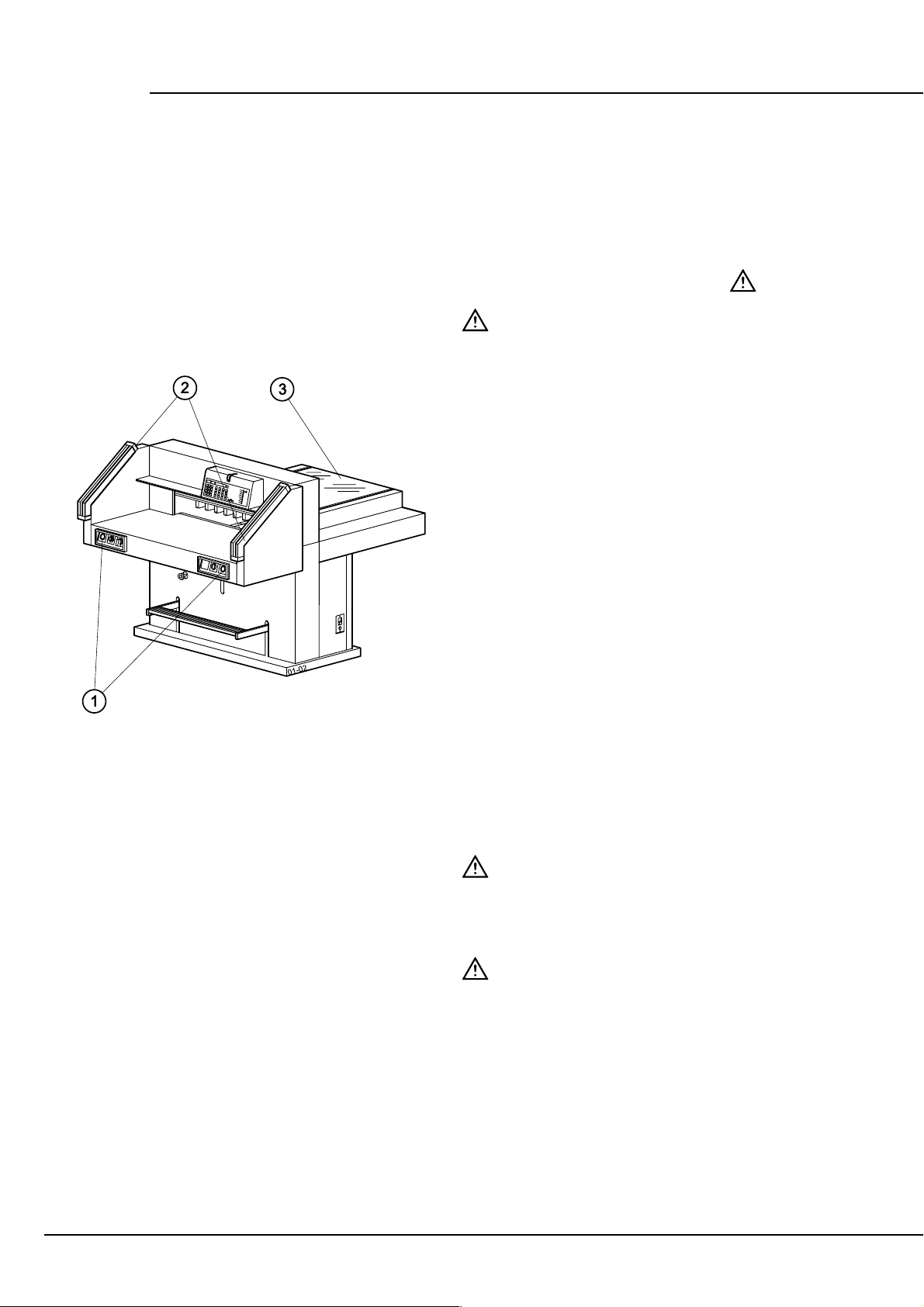

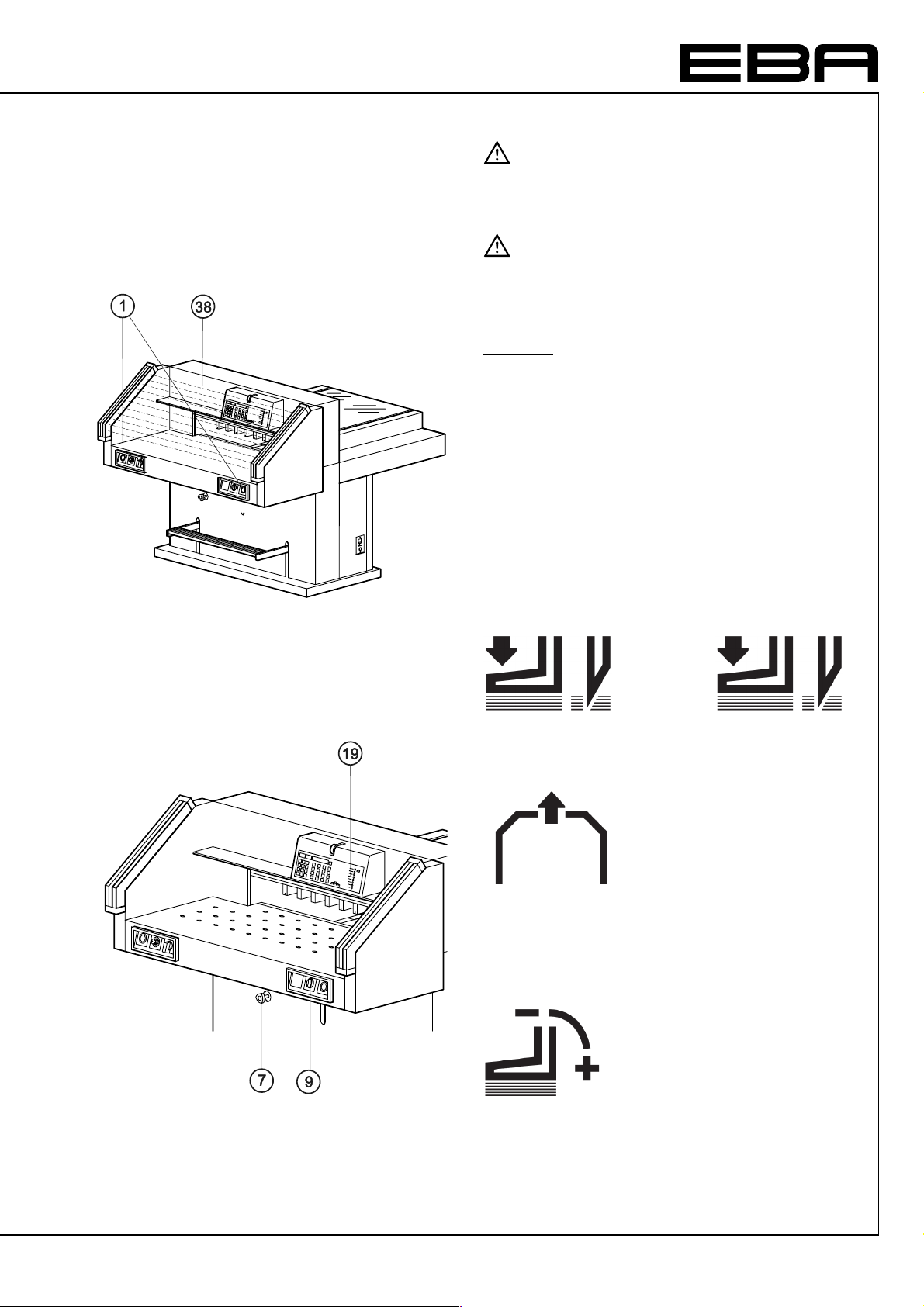

The dangerous cutting movement is safeguarded by

a cover (3), a two-handed control system (2) and a

safety beam guard (1).

1.2 Application

The machine is designed for cutting stacks of paper

to a specified size. Setting the measurement is

done via buttons or hand wheel. Cutting is released

by a "two-handed control system".

Danger!

Only instructed persons are allowed to operate

the machine.

Children must not operate the machine!

Danger!

Do not cut hard materials or materials which

may splinter.

Warning!

The machine may only be used for cutting

paper or similar materials. Paper clips or hard

material will damage the cutting blade.

- 4 -

Page 5

2. Installation

- Transport the machine on the pallet to its

destination using a pallet truck.

- 6 strong people are required to lift the machine

from the pallet.

- The machine must be installed on a sturdy, dry

and level floor.

Danger!

- The machine must not be located outside.

- Do not use in the vicinity of inflammable

liquids or gases.

- Do not use in humid environments.

- Protect mains cable against heat, oil and

sharp edges.

2.1 Preparing for installation

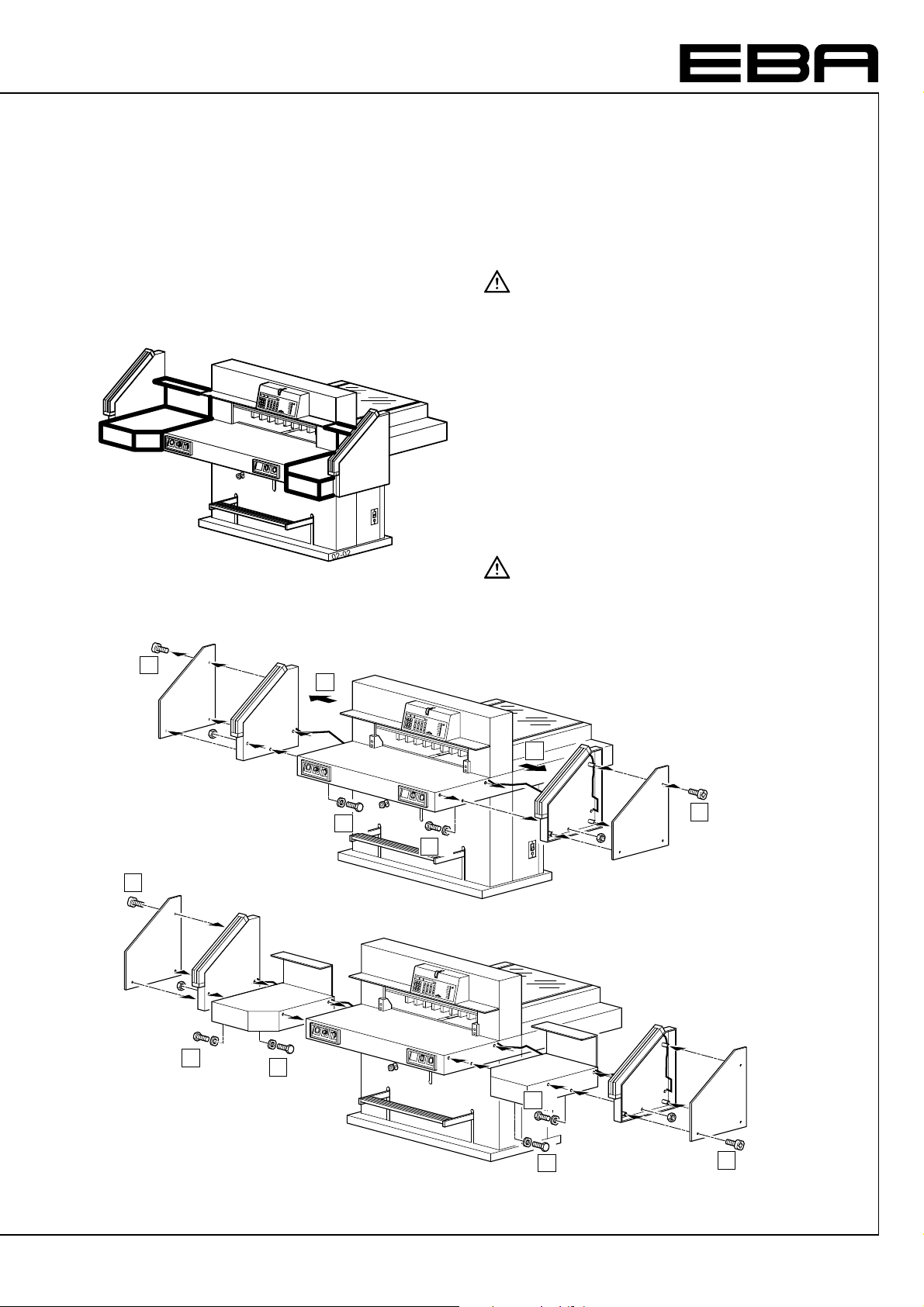

The machine is delivered ready for operation. As

an option, side tables, left and right, are available.

These should be mounted so that the surfaces are

level with the main table.

Danger!

The machine must not be put into operation

without the safety light beam.

1.

3x

6.

3x

3.

3.

1.

2.

3x

2.

3x

3x

4.

3x

5.

3x

5.

3x

68

4.

3x

6.

3x

- 5 -

Page 6

EBA 721-05

01-03

2.2 Power supply

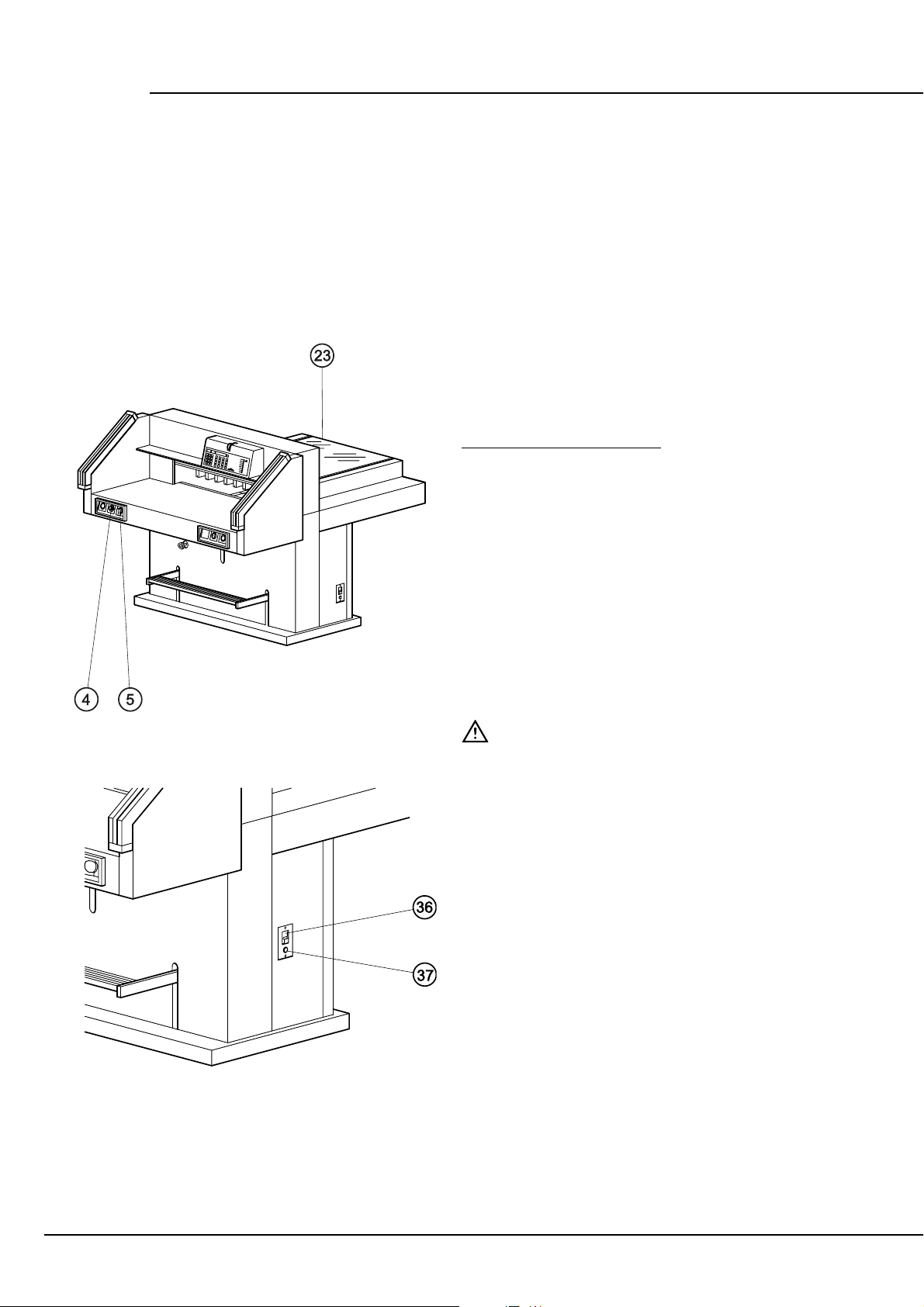

The name plate (23) is located at the rear of the

machine.

- Data stated on the name plate

- Voltage "V",

- Frequency "Hz",

- Power consumption "A"

must correspond to the values of the power supply

unit.

- Connect the machine to the mains.

- Earth wire must be available.

Standard machines are factory-set as follows:

- Voltage 400V (220V) 3 phase

- Frequency 50Hz (60Hz).

Machine does not function

- Machine (5) is switched on?

- Key-switch (4) on?

- Green overload switch (36) is pressed?

- Black overload switch (37) is pressed?

- Check on-site fuse.

If the machine still does not function then the

rotation must be reversed.

The machine is wired according to the IEC

standards. We recommend that alterations to the

rotary direction be made in the socket. It is also

possible to make alterations in the plug by

exchanging "L1" and "L2".

01-04

Danger!

Incorrect exchanging of the connections will

endanger the operator. This work must be

carried out by an electrician.

- 6 -

Page 7

04-01

3. Operation

Danger!

It is forbidden to operate the machine if the

operating and safety instructions have not

been understood.

Danger!

Please check the safety devices are

functioning and complete before use and after

replacing the blade.

Checklist

- Machine panels:

All panels have to be mounted

- Cutting activation:

The release for cutting is allowed only if the

"two-hand safety device" (1) is operated at the

same time.

- Safety light beam

Do not reach into the cutting area (38) when in

motion.

We recommend you keep a record of your test

results.

Cutting sequence (1) with automatic clamping:

03-01

+

Airtable (9) optional

The airtable allows paper to be easily positioned.

Setting clamping pressure (7)

The clamp pressure can be adjusted using the

adjustment knob (7).

© The clamping pressure can be read on the light

panel (19).

- 7 -

Page 8

EBA 721-05

01-01

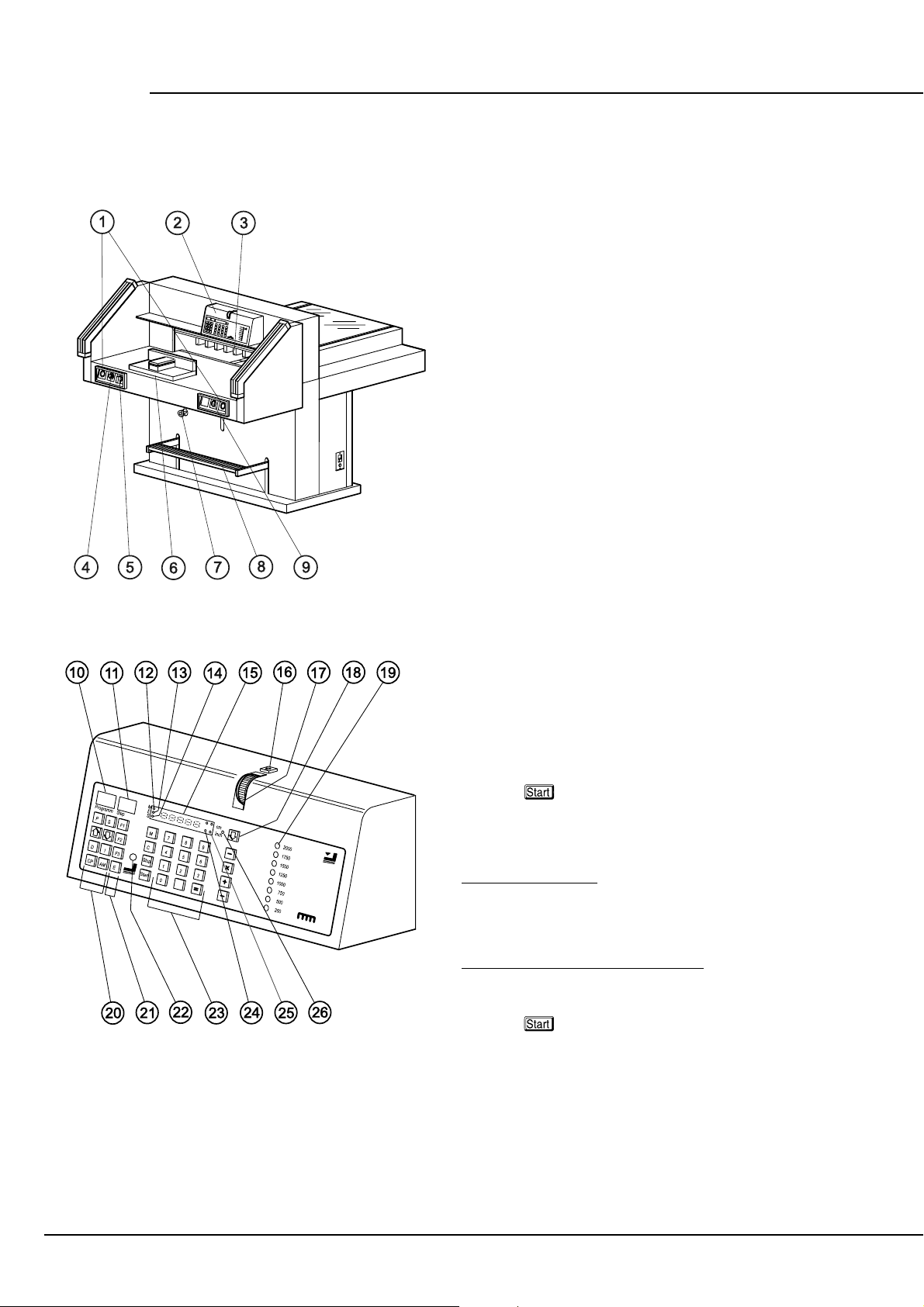

3.1 Operating elements

(1) Safety two-handed control system

(2) Backgauge control

(3) Backgauge

(4) Key switch

(5) Main switch

(6) Paper knock-up block

(7) Clamp pressure adjustment

(8) Foot pedal

(9) Airtable switch

(10) Program number

(11) Program step

(12) LED "M" display memory

(13) LED "E" display eject

(14) LED "S" dsplay error indication

(15) Display cutting size

(16) Backgauge, backwards fast

(17) Electronical hand-wheel for fine adjustment

(18) Backgauge, forwards fast

(19) Clamp pressure

(20) Program keys

(21) Basic setting F1, F2, F3, eject

(22) Display false clamp plate

(23) Keypad with calculator

(24) Display impuls of backgauge movement

(25) Display in cm or inch

(26) Changeover cm-inch.

3.2 Start-up

- Position the main switch (5) to "I".

- Insert the key (4) for the control panel and turn to

the right.

88

88

- Press

rear and searches for the reference position, wait

until a measurement is shown on the display.

Manual foot pedal

Pre-clamping can be performed using the foot pedal

(8) (e.g. folded stacks).

67-01

Cutting to a specified dimension

- Enter dimension on the numerical key © LED "S"

(14) appears.

- Press

LED "S" disappears.

- Insert paper and move by means of the paper

knock-up block to the backgauge (6).

- Release the cut (see 3.3 "Cutting activation").

button © backgauge (3) moves to the

button © dimension is approached,

- 8 -

Page 9

Calculating:

e.g.

2 0 - 2 © Backgauge advances to

the calculated measurement of 18.

Cut according to markings

- Adjust the backgauge (16) to the back.

- Insert paper and move by means of the paper

knock-up block to the backgauge.

88

88

- Turn the hand-wheel (17) to the front until the

marking on the paper to be cut is below the

cutting line indicator. The more the hand-wheel is

turned the faster the backgauge will move. For

quick motion use key (18).

- Release the cut.

67-02

Optical cutting line indicator

An optical cutting line (45) indicates the exact

position of the cut. The light beam indicates where

the cut will be made.

Mechanical cutting line indicator

The clamp (24) can be used as cutting line

indicator for exact cutting. Pre-clamping can be

performed using the foot pedal (8).

Eject function

If button

E is pressed, the backgauge will advance

to the preset measurement, ejecting the material to

be cut, then automatically return to the position

shown on the display.

- 9 -

Page 10

EBA 721-05

88

88

67-03

Multiple cuts function start

- Enter the cut size on the display.

- Press button © advances to the

measurement.

- Push the paper to the backgauge.

- Release the cut.

- Press

button © "A" appears on the middle

display.

- Enter the multiple cut size.

- Press

button © backgauge will advance by

the multiple cut size.

- After the cut the backgauge advances to the next

multiple cut size.

If, when inserting the multiple cut size, the

is pressed instead of the

button the LED "M"

(12) will light and after every cut the

M button

button

must be pressed.

Exiting program-mode

- Press

M button © LED "M" (12) is cleared on the

display. The actual size is shown.

04-01

3.3 Cutting activation

Danger!

Do not reach into the cutting area when the

blade is in motion.

A cut can only be activated when the specified size

is approached. The LED "S" on the display must be

deleted and the safety area (38) free.

- Press both buttons of the safety two-handed

control system (1) simultaneously and keep them

pressed until the paper is completely cut.

Cutting stop or interruption:

- Release both buttons of the two-hand control (1).

- 10 -

Page 11

45

3.4 False clamp plate

A cover plate (39) can be fitted to prevent pressure

marks on sensitive material. The LED (22) light is

on when the cover plate is fitted.

To dismount:

- Remove the clamp plate (39) by pulling it down

- Store the clamp plate in the provided holder (45)

© The remaining cut is 2 cm.

14-02

To mount:

- The clamp plate (39) is inserted to the top into

the clamp (24) © The remaining cut is 9 cm

- 11 -

Page 12

EBA 721-05

3.5 Programming

This control system enables you to store 40

programs with 36 programmable steps. One step

represents one measurement or max. 9 multiple

cuts.

P Program

S Step

M Memory (multiple cut)

Memory (multiple cut with automatic control

after the cut)

Program up

Program down

C Clear

D Delete

I Insert

E Eject

Clear Program

The indicated program step can be overwritten at

any time. These programs remain stored when the

machine is off. Should you change to another

dimension unit all programmed measures are

converted into the new unit (cm and inch).

Entering a program

- Press

- Enter program number

number will be shown on the display (10). If

measurement is shown on the display (15) the

program is reserved.

- Enter a measurement or advance with the hand-

88

88

67-04

wheel.

= Store the measurement.

-

- Enter the next measurement.

= Store the measurement.

-

P Escape the program mode.

-

Eject function program

This eject function can be added each time a

measurement is entered and ejects before

advancing to the next measurement.

- Enter the measurement.

- Press

- Press

Multiple cut program

- Press

Maximum 9 multiple cuts can be entered.

- Enter multiple cut size.

= Store the dimension.

-

P © "PR" appears on the display.

0 1...4 0. © The

E © LED "E" appears.

=

until the multiple cut size is reached.

- 12 -

Page 13

Changing select program

- Press

- Enter desired program number

- Press

- Enter step number 0 1...3 6.

- Or enter the next program step with

button

Insert a step

The program step is entered first.

- Choose a step number with button or

- Press button I.

- Enter measurement.

- Press button

Delete a step

- Choose a step number with button

- Press button D twice

Delete a program

- Enter program number

- Press button

P © “PR“ appears on the display.

0 1...4 0.

S

or .

=.

or

0 1...4 0.

twice

Example of a program

-

P 0 8 program 08

delete previous program

88

88

67-01

-

1 9 = step 1 on 19,0cm

-

2 7 step 2 on 27,0cm

-

E = eject

-

P escape the program mode

-

How the example works

-

P 0 8 start program 08

-

- Insert paper

- Release cut 1

- Paper is ejected

- Release cut 2

P escape the program mode.

-

Changing the basic settings

Frequently used measurements are stored in the

control system.

Basic setting 21 cm (8,267").

-

Basic setting 14,85 cm (5,846").

-

Basic setting 10,5 cm (4,133").

-

E (Eject) Basic setting 20 cm (7,87")

-

Changing a basic setting:

- Press

- Enter new setting.

- Press

P + © setting blinks.

= © setting is stored.

proceed to position

- 13 -

Page 14

EBA 721-05

cm

inch

Working with programs

- Press P.

- Enter program number

- Press

© proceeds to position.

0 1...4 0.

- Insert the paper and push it with the paper knockup block (6) to the backgauge.

- Release the cut © after every cut the backgauge

advances to the next position.

The cutting activation is described under

No. "3.3 Cutting activation".

With buttons

and you are able to change

between several program steps.

With

the backgauge moves to the indcated

dimension.

With

the backgauge stops.

LED "S" is on © specified dimension not achieved.

LED "S" is off © specified dimension achieved.

button is pressed - backgauge stops and the

actual dimension is shown.

Exiting program-mode.

Press

P

3.6 Basic Settings

Display in cm or inch

Press

© display changes between cm and

inch. The corresponding LED light will be on.

Display brightness

Press

+ D display changes between light

and dark.

Cutting counter

Press

88

88

67-06

Press

Press

D twice to delete the counter.

+ S number of cuts are shown.

to escape the program mode

- 14 -

Page 15

4. Maintenance

Danger!

- Maintenance work may only be performed

by trained staff.

- Before replacing the blade or cutting stick

switch off the main switch.

- Disconnect from the mains before

starting any service work or before

removing the cover.

Safety check

The safety regulations are according to the

regulations of the country where the cutting

machine is operated. The manufacturer

recommends a safety check is made every

5 years by an authorised service team.

4.1 Setting the cutting depth

If the last sheet of paper is not completely cut, the

cutting depth must be adjusted.

- Lower the blade depth adjustment (27) 1/12

using a spanner.

- Remove spanner.

- Perform cutting test as described.

05-01

If the cutting stick (26) is very worn it must be

turned.

Warning!

Do not cut into the cutting stick too deep as

this shortens the life time of the blade.

24

DIN

894

07

- 15 -

Page 16

EBA 721-05

05-02

4.2 Turning or replacing the cutting stick

- Turn the blade depth adjustment (27) to the top

until it stops (spanner in tool set).

- Remove spanner.

Danger! Risk of injury!

- Take out the cutting stick (26) with a small

screwdriver.

- Turn the cutting stick (the non-used side must be

near to the blade) and plug it into the holding bolt.

The cutting stick can be used eight times.

- Put a sheet of paper onto the whole width of the

cutting area.

- Lower the blade by pressing both cut buttons.

Keep one button pressed and turn main switch to

position "0".

- Lower the blade depth adjustment (27) until the

paper is cut along the entire length.

- Remove spanner.

- Turn main switch to position "I".

Cutting test

- Put a sheet of paper onto the whole width of the

cutting area.

- If the sheet of paper is not completey cut, lower

the blade adjustment (27) 1/12 using the spanner.

- Remove spanner.

- Repeat this procedure until the paper is cut along

the entire length.

- 16 -

Page 17

05-02

4.3 Blade replacement

A reduction in the cutting quality indicates that the

blade must be sharpened or a blade change is

necessary.

Danger! Risk of injury!

- The blade is extremely sharp. Do not

remove or transport the blade without

protection.

- Changing the blade may only be

performed by trained staff.

.

Removing the blade

- Turn the blade depth adjustment (27) to the top

until it stops (spanner in tool set).

- Remove spanner.

- Lower the blade by pressing both cut buttons.

Keep one button pressed and turn the main

switch to position "0".

21-02

- The eccentrics (28) are now exposed and should

be turned to position "0". The special wrench (40)

is in the tool set.

- Remove the special wrench.

- Turn main switch to position "I".

- Wait until the blade is at the top.

- Turn main switch to position "0".

- Remove the 2 blade screws (29).

- Put the blade changing tool (31) into place and

fasten it to the blade.

- Remove remaining screws.

- Loosen the grips of the blade changing tool (31)

lightly.

- Allow the blade to be taken downwards out of the

machine.

- Place the blade into the blade carrier and screw it

into place.

23-01

- 17 -

Page 18

EBA 721-05

Mounting the blade

- Turn or replace the cutting stick © see „Turning or

replacing the cutting stick“.

- Push the replacement blade with the blade changing tool (31) mounted into the blade carrier (30)

to the top and screw into place with the grips.

- Lightly tighten 4 of the 6 blade screws (29) (with

washers).

- Remove the blade changing tool.

- Lightly tighten the remaining blade screws (with

washers) (2).

- Remove all tools.

- Position a sheet of paper along the entire cutting

length.

- Lower the blade by pressing both cut buttons.

Keep one button pressed and turn off the main

switch.

- Lower the blade depth adjustment (27) until the

blade touches the paper.

05-02

- The 3 eccentrics (28) should then be used to

lower the blade until the paper is cut along the

entire length of the blade © (The blade must

remain parallel to the cutting stick).

- Turn main switch to position "I".

- When the blade is in the upper position tighten the

6 blade screws firmly.

- Cut a stack of paper to test.

The blade cannot be ground if the blade height is

82 mm/ 3,23 inches a new blade must be used.

Warning!

Blades may only be sharpened by a specialist.

21-02

- 18 -

Page 19

4.4 Maintenance every 7 days

- Advance the backgauge as far as possible to the

front.

- Lubricate the grease nipple (32).

Type of grease

- Non-resinous oil or grease.

max

min

4.5 Maintenance every 6 months

- Turn main switch off.

- Disconnect from the mains.

- Remove the front upper housing (43) © taking

il

O

Oil

24-02

care of the cable.

- Check oil (34). If oil is below minimum contact

your dealer.

- Remove paper debris.

- Lubricate all grease nipples.

- Check the 4 joining bolts and 2 pushing bars (33)

for wear.

- If necessary inform your service personnel.

- Reassemble the machine.

If the machine is used more than 10 hours per day

maintenance work must be more frequent.

Type of grease

- Non-resinous oil or grease.

- 19 -

Page 20

EBA 721-05

5. Malfunctions

Danger!

Disconnect from the mains before starting

any service work or before removing the

cover. Afterwards attach the covers.

Malfunction:

Display illumination off.

Cause:

Power supply.

Remedy:

- Machine is plugged in?

- Main switch is on?

- Green overload switch (36) is pressed?

- Key switch on?

- Check the units fuse and the on-site circuit

breaker!

01-04

Malfunction:

Optical cutting line indicator does not function

after the machine has been moved to another

position.

Cause:

Phase direction wrong.

Remedy:

See "Installation and Power supply".

Malfunction:

Backgauge blocked.

Cause:

Motor is overloaded.

Remedy:

Press safety switch (37).

Malfunction:

Cut cannot be activated.

a) Cause:

Safety light beam is interrupted / dirty?

Remedy:

Remove any items and clean the sender.

b) Cause:

Measurement has not been reached correctly.

© LED "S" does not turn off.

Remedy:

Press

c) Cause:

Size under 9 cm.

Remedy:

Put the false clamp in the provided holder.

again.

- 20 -

Page 21

Malfunction:

Machine is switched on but cut cannot be made.

Cause:

Safety clutch is activated.

Remedy:

Contact your dealer.

Malfunction:

Does not cut through the last sheet.

Remedy:

Adjust replace or turn the cutting stick (see

Cutting stick).

Malfunction:

Poor cutting quality or blade stays in the paper

stack.

Remedy:

Change the blade or adjust as necessary.

EBA

"Service"

Malfunction:

No clamp pressure

Cause:

Hydraulic oil needs refilling

Remedy:

Contact your dealer.

If you have further questions please contact your

dealer or directly on the internet www.eba.de

© "service" service@krug-priester.com

Subject to alteration wihout notice

- 21 -

Page 22

EBA 721-05

6. Technical data

Height of blade > 82 mm.

Sound level DIN 45635-27: max. 70 dB(A)

Minimum space requirement w x d:

without side tables 130 cm x 151 cm

with side tables 210 cm x 160 cm

Clamping pressure 250 dN bis 2000 dN

Weight without side tables: 613 kg

Weight with side tables: 620 kg

Capacity of hydraulic oil

Shell Tellus C32 or similar 1,5 l

Used oil must be disposed of at the

authorised place.

The exact technical specifications can be found on

the technical specifications sticker on the machine.

Safety light beam

Total reaction time of safety device: 95 ms

Resolution top 20 mm; 30 mm

Resolution front 40 mm

Minimum distance: 238 mm; 20 mm

Minimum distance: 318 mm; 30 mm

Minimum distance: 460 mm; 40 mm

7. Accessories

Attention!

16

27

Only use accessories recommended by the

manufacturer.

Paper knock-up block (6) 9000 521

Blade changing tool (31) 9000 514

Grease gun (44) 9004 683

* HSS - Blade (42) 9000 141

* 6 Cutting sticks (26) 9000 039

* Side tables left and right 9000 550

Accessories marked * must be ordered separately.

- 22 -

Page 23

EG-KONFORMITÄTSERKLÄRUNG

EC-declaration of conformity

Déclaration de conformité CE

Declaración CE de conformidad

Dichiarazione CE di conformità

EG-verklaring van overeenstemming

Declaraçao CE de conformidade

EF-overensstemmelseserklæring

- Hiermit erklären wir, daß die Bauart von

- Herewith we declare that

- Par la présente, nous déclarons que

- Por la presente, declaramos que la

- Si dichiara che il modello della

- Hiermede verklaren wij, dat de in de handel gebrachte machine

- Com a presente, declaramos que o modelo da

- Hermed erklæres, at produkttypen

721-05 LT

- folgenden einschlägigen Bestimmungen entspricht:

- complies with the following provisons applying to it:

- est conforme aux dispositions pertinentes suivantes:

- satisface las disposiciones pertinentes siguientes:

- è conforme alle seguenti disposizioni pertinenti:

- voldoet aan de eisen van de in het vervolg genoemde bepalingen:

- está em conformidade com as disposições pertinentes, a saber:

- er i overensstemmelse med følgende bestemmelser:

EG 98-37; EG 73/23; EG 89/336

- Angewendete harmonisierte Normen insbesondere

- Applied harmonized standards in particular

- Normes harmonisées utilisées, notamment

- Normas armonizadas utilizadas particularmente

- Norme armonizzate applicate in particolare

- Gebruikte geharmoniseerde normen, in het bijzondere

- Normas harmonizadas utilizadas, em particular

- Harmoniserede standarder, der blev anvendt, i særdaleshed

EN 60204-1; prEN 1010-1; EN 1010-3;

EN 55014-1; EN 55014-2; EN 50100-1; EN 50100-2;

EN ISO 12100-1; EN ISO 12100-2; EN 294; ISO 7779

Krug & Priester GmbH u. Co KG 26. 10. 2004

72336 Balingen, Germany Datum Wolfgang Priester

- General Manager -

- 23 -

Page 24

EBA 721-05

EBA Krug & Priester 72336 Balingen Germany www.eba.de

- 24 -

Printed in Germany B_721_ 10/2004

Loading...

Loading...