Page 1

AdvancedPunch

Operation Instructions Manual

GB

F

Manuel d’utilisation

E

Manual de instrucciones

Page 2

AdvancedPunch

GB

English 3

Français 9

Español 15

GB

Please read these instructions carefully and keep them in a safe place for future reference.

F

Lisez attentivement le présent manuel et conservez-le en lieu sûr afin de pouvoir le consulter

en cas de besoin.

E

Lea detenidamente el manual de instrucciones y consérvelo para futuras consultas.

7712568

Page 3

Table of Contents

AdvancedPunch

GB

1. SAFETY INSTRUCTIONS 3

Important safeguards 3

Cleaning 3

Service 4

Safety messages 4

2. INTRODUCTION 4

3. OPERATION CONTROLS 5

4. PUNCHING PA TTERNS 6

1. SAFETY INSTRUCTIONS

THE SAFETY OF YOU AND OTHERS IS VERY IMPOR T ANT T O GBC.

IMPORTANT SAFETY MESSAGES AND INFORMATION ARE

CONTAINED IN THIS MANUAL AS WELL AS ON THE MACHINE

ITSELF. PLEASE MAKE SURE YOU CAREFULLY READ AND

UNDERSTAND ALL OF THESE BEFORE OPERATING THE

MACHINE.

THE SAFETY ALER T SYMBOL PRECEDES EACH SAFETY

MESSAGE IN THIS OPERATION INSTRUCTIONS

MANUAL. THIS SYMBOL INDICATES A POTENTIAL

PERSONAL SAFETY HAZARD THAT COULD HURT YOU

OR OTHERS.

THE FOLLOWING PICTORIAL IS FOUND ON THE

ADVANCEDPUNCH:

This safety message means you could get an

electrical shock because disconnecting power

from this section does not cut off power from

adjacent sections of the machine.

5. CHANGING THE INTERCHANGEABLE DIE SETS 7

6. PUNCHING OPERATIONS 7

Punching T abs 7

7. P APER JAMS 7

8. PUNCH CONTAINER 8

9. PROBLEM SOLVING 8

Fault Codes 8

10. SPECIFICATIONS 8

Important safeguards

Use the AdvancedPunch only for its intended purpose of punching

paper and covers according to the indicated specifications.

Retain this Operation Instructions manual for future use.

CAUTION: THE PRINTER ON/OFF SWITCH DOES NOT

CUT OFF POWER FROM THE PUNCH.

CAUTION: THE PUNCH ON/OFF SWITCH DOES NOT CUT

OFF POWER FROM THE PRINTER.

The AdvancedPunch must be connected to a supply voltage

corresponding to the electrical rating of the machine operation

instructions (also listed on the serial number label).

The grounding plug is a safety feature and will only fit into the

proper grounding-type power outlet. If you are unable to insert the

plug into an outlet, contact a qualified electrician to have a suitable

outlet installed.

Do not alter the plug on the end of the cordset (if provided) of the

AdvancedPunch. It is provided for your safety.

Unplug the AdvancedPunch before moving the machine or

whenever the machine is not in use for an extended period of time.

Do not operate the AdvancedPunch if the machine has a damaged

power supply cord or plug. Do not operate the machine after any

malfunction. Do not operate the machine in case of liquid spills, or

if the machine has been damaged in any other way.

Do not overload electrical outlets beyond their capacity. To do so

may result in fire or electrical shock.

This safety message means that you might get

seriously hurt or killed if you open the product

and expose yourself to hazardous voltage.

NEVER remove the screwed on covers.

ALW A YS refer service requirements to qualified

service personnel.

Cleaning

You may clean the exterior of the AdvancedPunch using a soft,

damp cloth.

Do not use detergent or solvents as damage to the machine may

occur.

3

Page 4

AdvancedPunch

GB

Safety messages

MAIN CORDSET SELECTION

(THE FOLLOWING NOTE ONLY APPLIES ONLY TO THE UNITS

RATED 230V 50HZ, AND LOCATED IN THE EUROPEAN UNION)

CAUTION: WHEN CHOOSING A DETACHABLE LINE

CORD FOR USE WITH YOUR ADVANCEDPUNCH,

ALWAYS FOLLOW THE FOLLOWING PRECAUTIONS

The cordset consists of three parts: the attachment plug, the cord and

the appliance inlet. Each of these components must have European

regulatory safety approvals.

The following minimum electrical ratings for the specific cordset are

published for safety purposes.

DO NOT USE CORDSETS THAT DO NOT MEET THE FOLLOWING

MINIMUM ELECTRICAL REQUIREMENTS.

PLUG: 3 amperes, 250 volts, 50/60 Hz, Class 1, 3 conductor, European

safety approved.

CORD: Type H05VV-F3G0.75, Harmonized (< HAR>). The “< >”

symbols indicate cord approved according to appropriate European

standard (NOTE: “HAR” may be substituted for approval mark of

European safety agency that approved the cord. An example would be

“< VDE >“).

APPLIANCE CONNECTOR: 3 amperes, 250 volts, 50/60 Hz, European

safety approved, Type IEC 320. The cordset shall not exceed 3 meters

in length. A cordset with component electrical ratings greater than the

minimum specified electrical ratings may be substituted.

Service, AdvancedPunch

Do not attempt to service your AdvancedPunch yourself. Contact an

authorized service representative for any required repairs or major

maintenance for your AdvancedPunch.

DO NOT REMOVE THE MACHINE’S COVER.

Safety messages

FCC NOTE

(THE FOLLOWING NOTE ONLY APPLIES TO THE UNITS RATED

115V 60HZ.)

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the Operation

Manual, may cause harmful interference with radio communications.

Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct

the interference at his/her own expense.

CAUTION: CHANGES OR MODIFICATIONS NOT

EXPRESSLY APPROVED BY GENERAL BINDING

CORPORATION COULD VOID YOUR AUTHORITY TO

OPERATE THE EQUIPMENT.

Canada Class A Notice - Avis Canada, Classe A

This Class A digital apparatus complies with Canadian ICES-3.

Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada.

2. INTRODUCTION

Thank you for purchasing the AdvancedPunch. It is a versatile

production system that will enable you to punch documents for a variety

of binding styles by means of a simple die change. It has also been

designed for easy operation.

The AdvancedPunch is an innovative solution for punching paper and

offers the following design features:

There are NO user-serviceable parts inside the machine in order to

avoid potential personal injury and/or damage to property or the machine

itself.

Service, Diesets

Every dieset is thoroughly oiled at the factory prior to shipping. During

normal use this oil will be exhausted and should be replaced. As part

of regular maintenance, each dieset should be oiled after approximately

50K punch cycles. GBC recommends use of brand 3-IN-ONE oil as it

is readily available. Other light machine oils can also be used.

To oil the dieset, simply apply a small bead of oil along the entire

length of the felt strip that is located on the dieset. After oil has been

applied, re-install the dieset into the AdvancedPunch and run a small

test print job. Please note that it is normal for oil to be present on the

first set of sheets punched after oiling the dieset. After approximately

25 to 50 sheets oil will no longer be found on the punched sheet. At

this time the AdvancedPunch can be utilized for punching of print jobs.

Quick-change die sets that are self-latching without tools or levers.

All AdvancedPunch die sets include an Identification Label providing

the user with the hole pattern and name.

Convenient storage area for three extra Die Sets located above the

sheet bypass.

4

Page 5

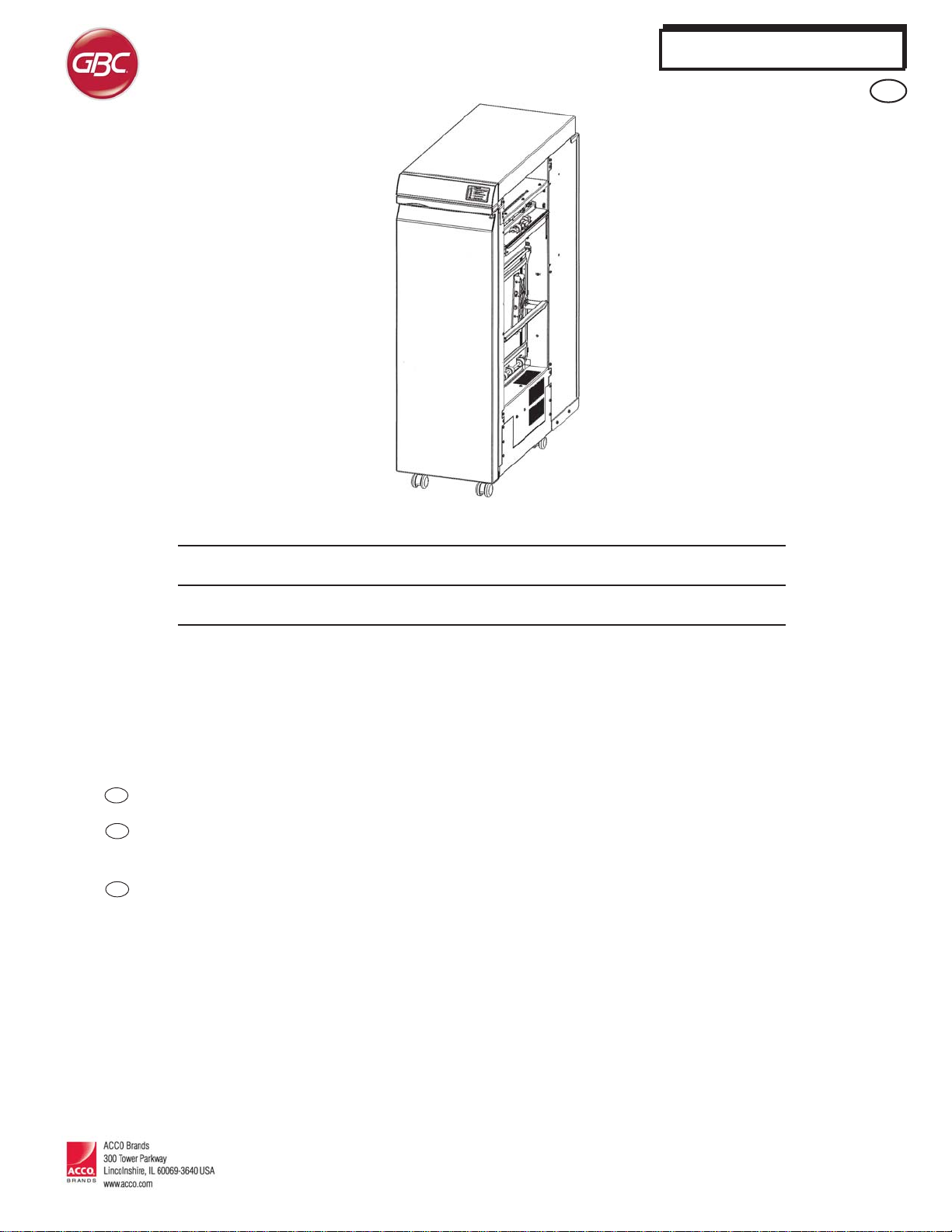

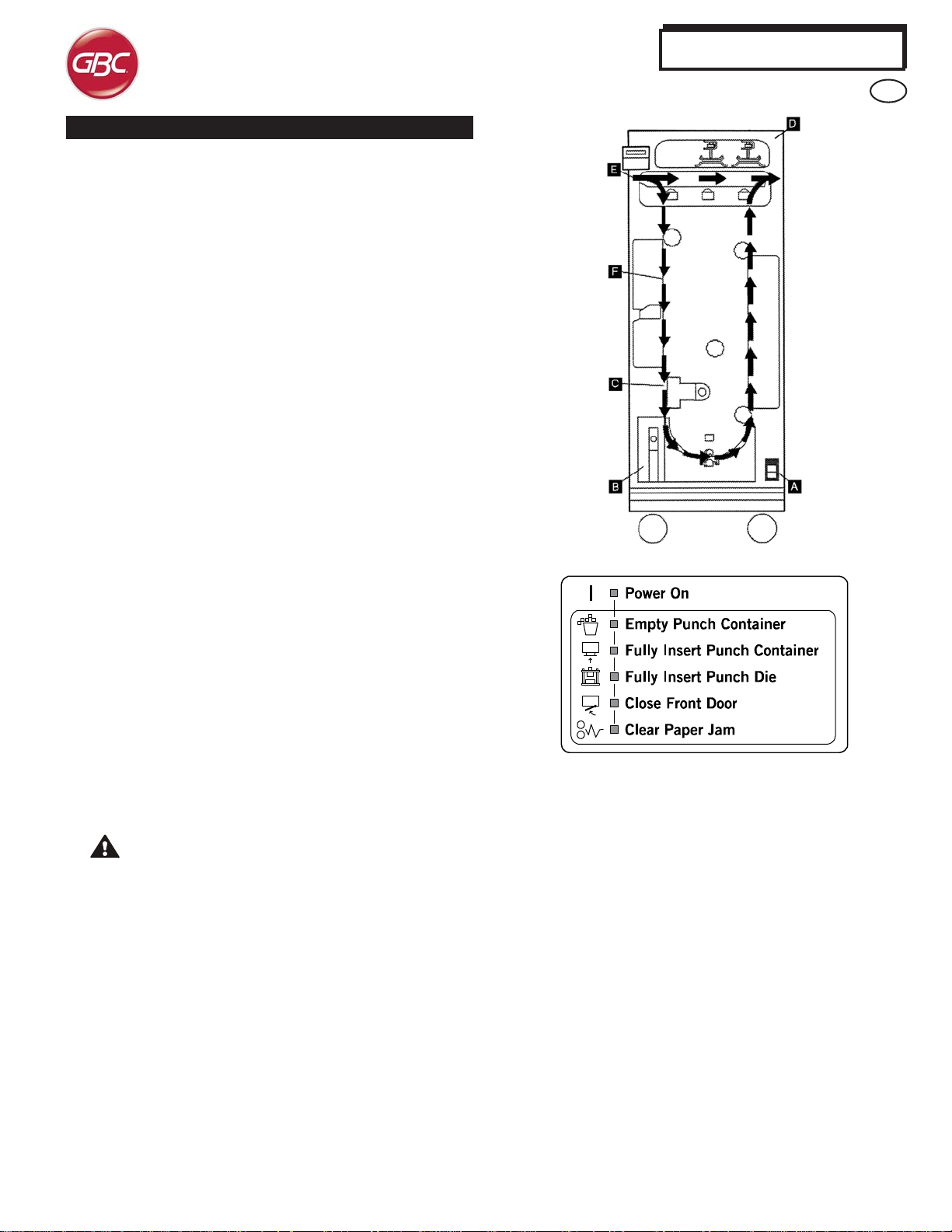

3. OPERA TION CONTROLS

A. On/Off Switch “I/O”

Must be in the “ON” position at all times

B. Punch Container:

Easy-to-access chip tray for quick chip disposal

C. Die Set Changes:

Are completed without tools and only take seconds to perform

D. Die Set Storage:

Holds up to 3 spare Die Sets

E. Punch Bypass:

Short straight-through paper path for unpunched documents

F. Punch Mode Path:

Wide radius turn can support stocks up to 216 g/m

Located on the front of the AdvancedPunch is a panel that provides

information relating to the operational state of the punch unit. LED

lights indicate when the AdvancedPunch requires attention from the

operator.

1. Power On:

The green LED will illuminate when the power switch on the

AdvancedPunch is set to the on position. NOTE: The power cord

for the AdvancedPunch must be plugged into the appropriate

power source prior to setting the power switch to the on position.

2. Empty Punch Container:

When the punch container becomes full of waste paper chips,

the yellow LED will illuminate.

3. Fully Insert Punch Container:

When the punch container is removed or not fully inserted into

the punch unit, the yellow LED will illuminate.

4. Close Front Door:

When the front door is open or not completely closed the yellow

LED will illuminate.

5. Clear Paper Jam:

When a sheet of paper becomes jammed within the punch unit,

the yellow LED will illuminate. See the section of this manual titled

PAPER JAMS for instructions on how to remove a sheet that has

become jammed within the AdvancedPunch.

2

cover

AdvancedPunch

GB

NOTE: The LED lights on the AdvancedPunch will glow dimly

if the printer is turned on while the AdvancedPunch power

switch is in the off position. Af ter setting the AdvancedPunch

power switch to the on position, the LED lights will illuminate

to their full intensity.

5

Page 6

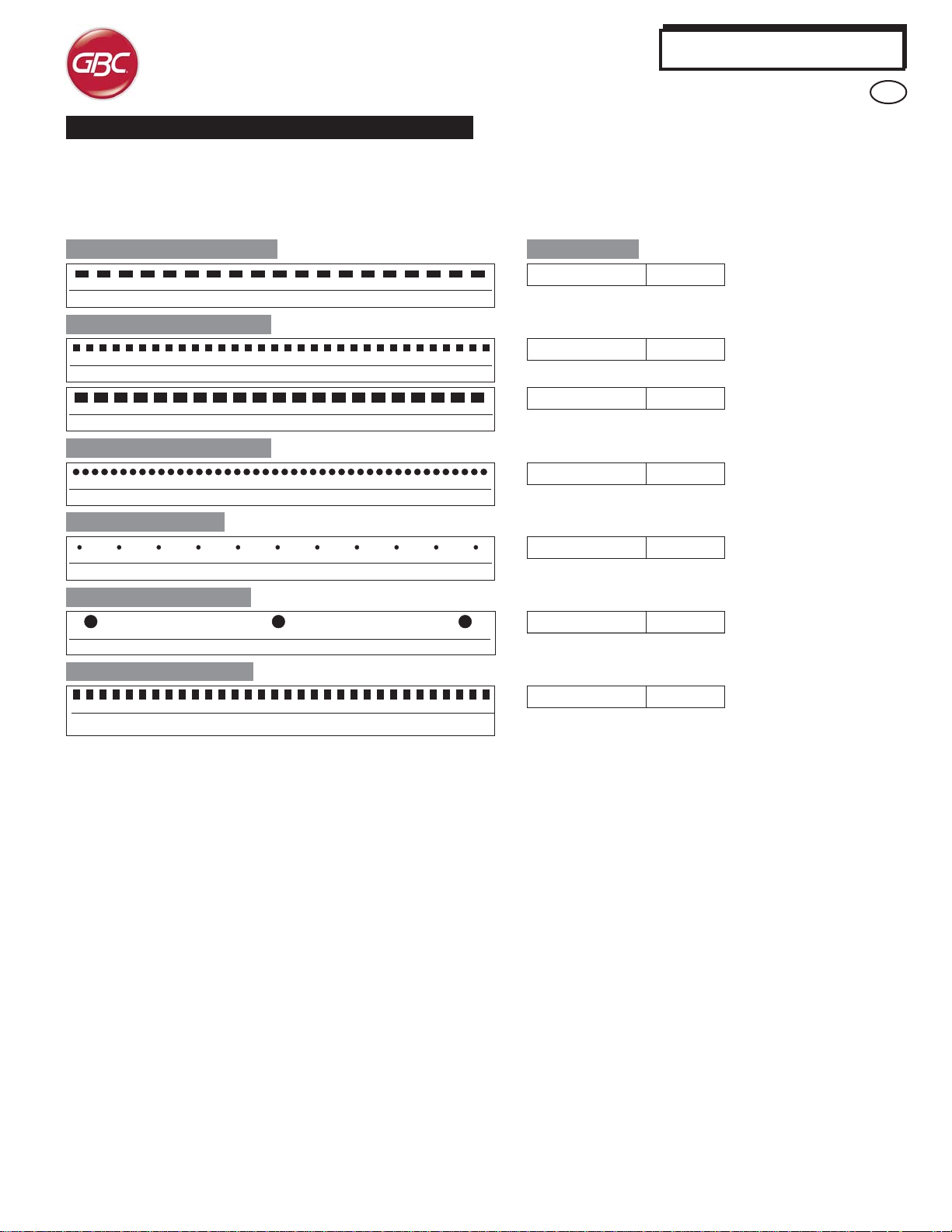

4. PUNCHING P ATTERNS

The AdvancedPunch uses a variety of easily interchangeable die

sets that allow you to punch documents in line for several different

binding styles. By selecting the appropriate die set, you can use your

AdvancedPunch to punch documents in any of the binding styles

indicated in Table 1.

AdvancedPunch

GB

For Plastic Comb Binding choose from:

1 19

PB Plastic Bind; Hole Size: 8mm x 2.9mm (0.313" x 0.116") (LxW); Center-to-Center Hole Spacing: 14.3 mm (0.563")

For Twin Loop™ Binding choose from:

1

W3 Wire; Square; 3 Holes per inch; Hole Size: 4mm x 4mm (0.156" x 0.156") ( L x W); Center-to-Center Hole Spacing: 8.5 mm (0.333")

1

W2 Wire; Rectangle; 2 Holes per inch; Hole Size: 6.4mm x 5.4mm (0.250" x 0.214")(L xW); Center-to-Center Hole Spacing: 12.7 mm (0.500")

21

For Color Coil™ Binding choose from:

C4 Coil; Round; 4 Holes per inch; Hole Size: 4.4mm ( 0.174") Diameter; Center-to-Center Hole Spacing: 6.3mm (0.2475")

For Velo® Bind choose from:

1

VB Velobind®; Round; 1 Hole per inch Hole Size: 3.2mm ( 0.125") Diameter; Center-to-Center Hole Spacing: 25.4mm (1")

For V elo® Bind choose fr om:

For Looseleaf Binding choose from:

1

3 Ring Binder; U.S. (Standard Looseleaf Patterns); Hole Size: 8mm (0.316") Diameter

11

3

For Proclick® Binding choose from:

1

W3 Proclick®; Rectangle; Hole Size: 4.9mm x 5.5mm; 0.196”x0.215”(LxW); Center-to-Center Hole

Spacing:8.5mm(0.333”)

©2003 GBC, Northbrook Illinois - All rights reserved. Rev 10/02 R2 3/03

Graphics do not represent actual punch pattern dimensions or spacing.

Xerox Part Number:

XEROX PB-19H 008R13066

32

XEROX W3-32H-SQ 008R13069

XEROX W2-21H-SQ 008R13068

441

XEROX C4-44H 008R13067

XEROX VB-11H 008R13070

XEROX 3H 008R13072

32

XEROX PC-32H 008R13071

6

Page 7

5. CHANGING THE INTERCHANGEABLE DIE SETS

Your AdvancedPunch offers the convenience of interchangeable die

sets, allowing you to economically punch documents for a wide variety

of binding styles. Changing the machine's die sets is both quick and

easy, as the following instructions illustrate:

Removing Die Sets from the Machine: The inter-changeable die

set slot of the AdvancedPunch is located on the left front side of the

machine. If a die set is already installed in your AdvancedPunch, you

can easily remove the die set by following these instructions:

Step 1: Stop the printer/copier.

Step 2: Open the AdvancedPunch access door panel.

Step 3: Securely grasp the handle and pull firmly. This firm pull

disengages the Automatic Latching Mechanism and allows the die set

to slide out.

Step 4: Continue to pull the handle until the Die Set is fully removed,

supporting it with both hands.

Step 5: Properly store the removed Die Set in the Die Set storage area

at the top of the AdvancedPunch (keep away from dust, dirt, accidental

falls from the edge of counters, etc.).

Step 6: Select the desired Die Set for your new job and slide it into the

Die Set slot. Push Die Set in firmly until it latches.

WARNING: POSSIBLE PINCH POINT HAZARD. WHEN

INSTALLING DIE SETS IN YOUR ADVANCEDPUNCH, AL WA YS

KEEP FINGERS AND OTHER BODY PARTS OUT OF THE

MACHINE’S DIE SET SLOT AND AWAY FROM ALL AREAS

OF THE DIE SET , EXCEPT FOR THE FINGER HOLE IN THE DIE

SET. FAILURE TO FOLLOW THESE PRECAUTIONS MAY

RESULT IN INJURY .

Step 7: Close the Access Door Panel.

Step 8: Proceed with your printing and punching job.

Please note that when using a new die some oil will be present

around the punched holes on the sheet. After punching 25 to 50

sheets the die will no longer leave oil on the sheets. It is recommended

that a short test print job be run after installing a new die or a die that

has recently been oiled.

6. PUNCHING OPERA TIONS

7. P APER JAMS

Area

AdvancedPunch

GB

This symbol indicates a paper jam. To assist in

clearing paper jams in any of the following areas,

turn one or more of the small knobs to advance

the paper.

Description

If paper is jammed in the Punch Bypass, lift the

paper guide plate located just inside, reach in

and remove the jammed paper.

If paper is jammed in the downward paper path

chute, move the door to the right, reach in and

remove the jammed paper.

Prior to beginning a print job in which the punching feature of the

AdvancedPunch will be used, make certain that no yellow LED lights

are illuminated on the front panel of the AdvancedPunch. If a yellow

LED light is illuminated, then correct the fault prior to starting the punch

job. See section (3. OPERATION CONTROLS) for information regarding

the LED lights. The AdvancedPunch will not operate in punch mode if

any yellow LED is illuminated.

Prior to starting the punch job, check to make certain that the punch

die installed in the AdvancedPunch is the correct die/hole pattern for

the job. If the die is not the correct die, then replace it at this time.

To enable the AdvancedPunch punching feature, use the printer user

interface screen. Follow the steps below to enable the punch feature.

Using the printer user interface screen, go to the Copy menu. Then

select Copy Output to enter the Hole Punch & More menu. Once in

this menu an option will appear in the hole punch column titled

AdvancedPunch. Select this option, then press Save to return to the

Copy menu. The AdvancedPunch will now operate in the punch mode.

Punching Tabs

The AdvancedPunch punches the leading edge of a sheet. Because

of this Tabs must be fed with the tab on the trailing edge. The manner

in which Tabs are loaded into the tray to cause the correct tab-trailing

feeding varies depending upon the tray that is utilized.

If paper is jammed or the Die Set is jammed, turn

Knob J3 to the HOME position, (arrows line up)

slide the Die Set out and remove paper.

If paper is jammed in the bottom chute of the

Punch Paper path, press the bottom chute latch,

reach in and remove any jammed paper.

If paper is jammed in the upward paper path

chute, move the door to the left, reach in and

remove the jammed paper.

7

Page 8

AdvancedPunch

GB

8. PUNCH CONT AINER

The Punch Container for your AdvancedPunch is located at the front

of the machine’s base. The drawer should periodically be pulled out

and emptied. The AdvancedPunch uses a sensor to determine when

the punch container is full. Once the punch container becomes full

the LED light on the front panel of the AdvancedPunch will illuminate

and a message will appear on the printers user interface screen.

9. PROBLEM SOL VING

Probable Cause

No power, won’t punch

Die Set will not come out using

a moderate pull

Fault Codes

Fault codes for the AdvancedPunch are displayed on the machine's UI

as an AdvancedPunch fault code. Listed below are fault codes that

apply specifically to the AdvancedPunch product.

Probable Cause

Power cord not attached to back of

machine or not properly plugged into

the wall Power On/Off Switch not

activated

The Die Set is in partial cycle. Turn

the Die Set knob (J3) to the HOME

position. Home position is when the

arrows line up. The Die Set should

now slide out easily.

Also see Paper Jams.

10. SPECIFICA TIONS

Speed

Punch Sheet Size

Punch Edge

Paper Stock

Paper Bypass Mode

Sheet size

Punch Capacity

Power Supply

Electrical

Safety

Dimensions

Weight

Shipping Weight

Manufactured

115V Machines

Up to 127 sheets per minute

Letter - 8.5" x 11"

11"

20# bond to 80# cover

Paper sizes and stocks same as

printer

Single Sheet

115V, 60 Hz,

Single Phase

BTUs/Hour 1057BTU/HR

Watts 310W

Amps 2.8A

TUV/GS, CE

12" (30.5cm) (W) x 38.5" (97.8cm)

(H) x 28.5" (72.3cm) (D)

154 lbs. (70 Kg)

254 lbs. (115.5 Kg)

Assembled in Taiwan

Fault

Code

040-100

040-101

040-900

040-901

040-300

040-940

040-941

040-942

140-700

Possible Cause Recommended Solution

Jam is detected in

AdvancedPunch.

Front door of

AdvancePunch is not

closed.

Dieset is missing or not

fully installed.

Punch container is

mising or not fully

installed

Punch container is full.

Punch container is

near full.

Open front door and

inspect for paper jam.

Remove papaerjam if found,

then close front door.

Close front door of

AdvancedPunch.

Install dieset or fully insert

dieset, then close front door.

Install and/or fully insert

punch container, then close

front door.

Empty punch container and

then re-install.

Empty punch container and

then re-install.

8

Page 9

Table des matières

AdvancedPunch

F

1. CONSIGNES DE SÉCURITÉ 9

Consignes importantes 9

Nettoyage 9

Entretien 10

Messages de sécurité 10

2. INTRODUCTION 10

3. COMMANDES 11

4. MODÈLES DE PERFORATION 12

1. CONSIGNES DE SÉCURITÉ

VOTRE SÉCURITÉ ET LA SÉCURITÉ DES PERSONNES QUI VOUS

ENTOURENT SONT TRÈS IMPOR TANTES POUR GBC. LES CONSIGNES

ET MESSAGES DE SÉCURITÉ ESSENTIELS DÉLIVRÉS DANS LE

PRÉSENT MANUEL APP ARAISSENT ÉGALEMENT SUR LA MACHINE.

VEUILLEZ LIRE A TTENTIVEMENT CE MANUEL A V ANT D’UTILISER LA

MACHINE.

DANS CE MANUEL D’UTILISA TION, VOUS TROUVEREZ UN

SYMBOLE D’AVER TISSEMENT EN REGARD DE CHAQUE

MESSAGE DE SÉCURITÉ. CE SYMBOLE SIGNALE UN RISQUE

POTENTIEL. VOUS POURRIEZ VOUS BLESSER, BLESSER

UN TIERS OU ENDOMMAGER LE PRODUIT .

VOUS TROUVEREZ LES ÉTIQUETTES SUIVANTES SUR

L‘ADVANCEDPUNCH:

Ce message de sécurité indique que vous

pouvez recevoir un choc électrique, car

débrancher le courant de cette section ne

coupe pas le courant des sections adjacentes

de la machine.

5. CHANGEMENT DE MATRICE 13

6. PERFORATION 13

Perforation d’intercalaires 13

7. INCIDENTS PAPIER 13

8. RÉSERVOIR À CONFETTIS 14

9. EN CAS DE PROBLÈME 14

Codes de panne 14

10. SPÉCIFICATIONS 14

Consignes importantes

Utilisez l’AdvancedPunch uniquement pour perforer le papier et

les couvertures conformément aux spécifications indiquées.

Gardez ce manuel d’utilisation à portée de main.

ATTENTION: L’INTERRUPTEUR MARCHE/ARRÊT DE

L’IMPRIMANTE NE MET PAS LA PERFORATRICE HORS

TENSION.

ATTENTION: L’INTERRUPTEUR MARCHE/ARRÊT DE LA

PERFORATRICE NE MET PAS L ’IMPRIMANTE HORS TENSION.

La tension d’alimentation de l’AdvancedPunch doit correspondre

aux caractéristiques électriques de la machine (elles sont

indiquées sur l’étiquette du numéro de série).

Une prise de terre est prévue par mesure de sécurité. Elle doit

être raccordée à une prise électrique prévue à cet effet. Si vous

ne parvenez pas à introduire la fiche dans la prise, faites appel à

un électricien qualifié pour qu’il installe une prise adéquate.

Ne modifiez pas la fiche située au bout du cordon d’alimentation

de l’AdvancedPunch (si elle est fournie). Elle a été conçue pour

votre sécurité.

Débranchez l’AdvancedPunch avant de déplacer la machine ou si

vous prévoyez de ne pas l’utiliser durant une longue période.

N’utilisez pas l‘AdvancedPunch si le cordon ou la fiche

d’alimentation de la machine est endommagé. N’utilisez pas la

machine après un quelconque dysfonctionnement. Ne mettez pas

la machine sous tension si vous avez renversé un liquide ou si

elle est endommagée de quelque façon que ce soit.

Ne surchargez pas les prises électriques. Cela pourrait provoquer

un incendie ou une décharge électrique.

Ce message signale qu'une décharge

électrique pourrait vous blesser gravement,

voire vous tuer si vous ouvrez la machine. Ne

retirez JAMAIS les plaques vissées sur les

couvercles de la machine. Faites TOUJOURS

confiance au personnel d’entretien qualifié.

Nettoyage

Vous pouvez nettoyer la surface externe de l’AdvancedPunch à

l’aide d’un chiffon doux et humide.

N’utilisez pas de détergent ou de solvants, car vous pourriez

endommager la machine.

9

Page 10

AdvancedPunch

F

Messages de sécurité

SÉLECTION DU CORDON D’ALIMENTA TION SECTEUR

(LE PARAGRAPHE SUIVANT NE S’APPLIQUE QU’AUX MODÈLES

ALIMENTÉS PAR UN COURANT DE 230V 50HZ UTILISÉS DANS L’UNION

EUROPÉENNE.)

ATTENTION: LORSQUE VOUS CHOISISSEZ UN CORDON

D’ALIMENTATION AMOVIBLE POUR VOTRE

ADVANCEDPUNCH, RESPECTEZ TOUJOURS LES

PRÉCAUTIONS SUIVANTES.

Le cordon est constitué de trois parties: la fiche, le cordon et la

connexion à la machine. Chacun de ces composants dispose de

l’homologation européenne requise en matière de sécurité.

Les caractéristiques électriques minimales applicables au cordon sont

publiées pour des raisons de sécurité.

N’UTILISEZ PAS DE CORDONS NE RESPECTANT PAS LES

EXIGENCES ÉLECTRIQUES MINIMALES SUIVANTES.

FICHE: 3 A, 250V, 50/60Hz, Classe 1, à 3 conducteurs, homologuée

par l'Union Européenne.

CORDON: Type H05VV -F3G0.75, harmonisé (< HAR>). Les symboles

«< >» indiquent que le cordon est homologué conformément à la norme

européenne appropriée (REMARQUE: «HAR» équivaut à la marque

d’homologation de l’agence de sécurité européenne qui a approuvé le

cordon. Exemple: «< VDE >»).

CONNECTEUR DE L’APPAREIL: 3 A, 250V, 50/60Hz, homologué par

l’Union Européenne, type IEC 320. Le cordon ne doit pas excéder 3 m

de long. Vous pouvez remplacer le cordon électrique par un câble

d'alimentation présentant des caractéristiques électriques supérieures

aux minima indiqués.

Entretien, AdvancedPunch

Ne tentez pas de réparer votre AdvancedPunch par vous-même.

Contactez un représentant agréé pour effectuer les réparations ou le

gros entretien de votre AdvancedPunch.

NE RETIREZ PAS LES COUVERCLES DE LA MACHINE.

AUCUNE pièce interne ne peut être remplacée par l’utilisateur. Les

risques de blessure et/ou d’endommagement de la machine sont ainsi

éliminés.

Entretien des matrices

Chaque matrice doit être soigneusement lubrifiée en usine avant d’être

livrée au client. Dans des conditions normales d’utilisation, ce lubrifiant

disparaît progressivement et doit être remplacé. Dans le cadre de

l’entretien de routine de l’appareil, chaque matrice doit être lubrifiée

après environ 50,000 cycles de perforation. GBC recommande d'utiliser

de l’huile 3-IN-ONE disponible chez tous les bons revendeurs. D’autres

huiles pour machine légère peuvent également être utilisées.

Pour lubrifier la matrice, il suffit d’appliquer une petite goutte d’huile

sur toute la longueur de la bande de feutrine située sur la matrice. Une

fois l’huile appliquée, réinstallez la matrice dans l’AdvancedPunch et

effectuez un petit test d’impression. À noter qu’il est tout à fait normal

que de l’huile soit présente sur le premier jeu de feuilles perforé après

avoir lubrifié la matrice. Au bout d’environ 25 à 50 feuilles, toute trace

d’huile sur les feuilles perforées aura disparu. L’AdvancedPunch peut

désormais être utilisé pour perforer des travaux d’impression.

Messages de sécurité

NOTE FCC

(LE PARAGRAPHE SUIVANT NE S’APPLIQUE QU’AUX MODÈLES

ALIMENTÉS PAR UN COURANT DE 115V 60HZ.)

Cet équipement a été testé et il satisfait aux normes relatives aux

appareils numériques de Classe A, conformément à la Partie 15 des

règles FCC. Ces limites ont été prévues pour garantir une protection

raisonnable contre les interférences nocives lors de l’utilisation de

l’équipement dans une zone de travail.

Cet équipement génère, utilise et irradie des ondes radio. Par

conséquent, si vous ne l’installez pas ou ne l’utilisez pas conformément

au manuel d’utilisation, vous risquez de provoquer des interférences

dans les communications par radio. L’utilisation de cet équipement

dans une zone habitée risque de provoquer des interférences. Dans

ce cas, vous devrez corriger ces interférences à vos frais.

ATTENTION: LE F AIT D'EFFECTUER UNE MODIFICA TION

OU UN CHANGEMENT SANS L'ACCORD EXPLICITE DE

GENERAL BINDING CORPORATION ANNULE VOTRE

DROIT D’UTILISER L’ÉQUIPEMENT .

Canada Class A Notice - Avis Canada, Classe A

Cet appareil numérique de Classe A est conforme à la norme

canadienne ICES-3.

Cet appareil numérique de la classe A est conforme à la norme

canadienne NMB-003.

2. INTRODUCTION

Nous tenons à vous remercier d’avoir acheté un AdvancedPunch. Ce

système de production polyvalent vous permettra de perforer des

documents de nombreuses manières en remplaçant tout simplement

le bloc à colonnes. Cet appareil a été conçu dans un souci de simplicité

d'utilisation.

L’AdvancedPunch est une solution innovante pour perforer le papier.

Il offre en outre les caractéristiques suivantes:

Les blocs à colonnes peuvent être remplacés rapidement sans outil

ni levier.

Tous les blocs à colonnes de l’AdvancedPunch disposent d’une

étiquette d'identification indiquant la configuration de perforation et

son nom.

Une zone de stockage des matrices de rechange a été aménagée

au-dessus du By-pass.

10

Page 11

3. COMMANDES

A. Interrupteur marche/arrêt: “I/O”

Il doit être en position “ON” à tout moment

B. Réservoir à confettis:

Plateau facile d’accès permettant une évacuation rapide des

confettis

C. Changement de blocs à colonnes:

Facile, sans outil et en quelques secondes

D. Stockage des matrices:

Prévu pour stocker jusqu’à trois matrices

E. By-pass perforatrice:

Chemin papier court et direct pour les documents non perforés

F. Chemin papier en mode perforation:

Le grand rayon de la courbe permet d’utiliser des supports d’un

grammage allant jusqu’à 216 g/m

L’avant de l’AdvancedPunch comporte un panneau qui fournit des

informations concernant l’état de fonctionnement de la perforatrice.

Un voyant s’allume lorsque l’AdvancedPunch requiert l’attention de

l’opérateur.

1. Marche:

Le voyant vert s’allume lorsque le bouton marche/arrêt de

l’AdvancedPunch est placé en position « on » (marche).

REMARQUE : le cordon d’alimentation de l’AdvancedPunch doit

être branché sur une prise murale adaptée avant de mettre le

bouton marche/arrêt en position « on » (marche).mpel.

2. Réservoir à confettis plein:

Lorsque le réservoir à confettis est plein, le voyant jaune s’allume.

3. Réservoir à confettis mal inséré:

Lorsque le réservoir à confetti a été retiré ou est mal inséré dans

le module de perforation, le voyant jaune s’allume.

4. Porte avant ouverte ou mal refermée:

Lorsque la porte avant est ouverte ou mal refermée, le voyant

jaune s’allume.

5. Incident papier:

Lorsqu’une feuille de papier se coince dans le module de

perforation, le voyant jaune s’allume. Consultez la section

INCIDENTS PAPIER du présent manuel pour plus d’instructions

concernant la manière de retirer une feuille coincée dans

l’AdvancedPunch.

REMARQUE: Les voyants de l’AdvancedPunch s’allument

avec une faible intensité si l’imprimante est mise sous tension

alors que l'interrupteur marche/arrêt de l’AdvancedPunch

est en position « off » (arrêt). Une fois l'interrupteur marche/

arrêt de l’AdvancedPunch en position « on » (marche), les

voyants s’allument avec une intensité lumineuse normale.

2

.

AdvancedPunch

F

Marche

Réservoirà confettis plein

Réservoirà confettis mal inséré

Matrice de perforation mal insérée

Porte avant ouverte ou mal refermée

Incident papier

11

Page 12

4. MODÈLES DE PERFORA TION

L’AdvancedPunch utilise une grande variété de matrices faciles à

remplacer afin de perforer les documents en fonction des différents

styles de reliure. En sélectionnant la matrice appropriée, vous pouvez

utiliser votre AdvancedPunch pour perforer les documents en fonction

des différents styles indiqués dans le tableau 1.

AdvancedPunch

F

Pour une reliure à anneaux plastiques, choisissez la matrice:

1 19

PB Plastic Bind; taille de l’orifice: 8 mm (0,313") (L) x 2,9 mm (0,116") (l); distance entre les orifices (de centre à

centre): 14,3 mm (0,563")

Pour une reliure Twin Loop™, choisissez la matrice:

1

W3 Wire; Carr; 3 orifices par pouce; taille de l’orifice: 4 mm (0,156") (L) x 4 mm (0,156") (l); distance entre les

orifices (de centre à centre): 8,5 mm (0,333")

1

W2 Wire; rectangle; 2 orifices par pouce; taille de l'orifice: 6,4 mm (0,250") (L) x 5,4 mm (0,214") (l); distance

entre les orifices (de centre à centre): 12,7 mm (0,500")

21

Pour une reliure Color Coil™, choisissez la matrice:

C4 Coil; rond; 4 orifices par pouce; taille de l’orifice: 4,4 mm (0,174") de diamètre; distance entre les orifices

(de centre à centre): 6,3 mm (0,2475")

Pour une reliure VeloBind®, choisissez la matrice:

1

VB VeloBind®; rond; 1 orifice par pouce; taille de l’orifice: 3,2 mm (0,125") de diamètre; distance entre les

orifices (de centre à centre): 25,4 mm (1")

11

Pour une reliure à feuillets mobiles, choisissez la matrice:

3 Ring Binder; U.S. (modèles standard de feuillets mobiles); taille de l’orifice: 8 mm (0,316") de diamètre

31

Réf. Xerox:

XEROX PB-19H 008R13066

32

XEROX W3-32H-SQ 008R13069

XEROX W2-21H-SQ 008R13068

441

XEROX C4-44H 008R13067

XEROX VB-11H 008R13070

XEROX 3H 008R13072

Pour une reliure Proclick® choisissez la matrice:

For Velo® Bind choose fr om:

1

W3 Proclick®; rectangle; taille de l'orifice: 4,9 x 5,5 mm; 0,196” x 0,215” (L x l); distance entre les orifices (de

centre à centre): 8,5 mm (0,333")

©2003 GBC, Northbrook Illinois – Tous droits réservés. Rév.10/02 R2 3/03

Les modèles de perforation représentés sur les illustrations ne sont pas à l’échelle

32

XEROX PC-32H 008R13071

12

Page 13

5. CHANGEMENT DE MA TRICE

Votre AdvancedPunch utilise des matrices interchangeables, ce qui vous

permet de perforer, à moindres frais, les documents en fonction de

différents styles de reliure. Le remplacement des matrices de la machine

est rapide et facile. Pour ce faire, suivez les instructions suivantes:

Retrait des matrices de la machine: La fente des matrices

interchangeables de l’AdvancedPunch est située sur la droite, à l’avant

de la machine. Si une matrice est déjà installée dans votre

AdvancedPunch, vous pouvez facilement la retirer en procédant

comme suit:

Étape 1: Arrêtez l’imprimante/copieur.

Étape 2: Ouvrez la porte d’accès à l’AdvancedPunch.

Étape 3: Tenez fermement la poignée et tirez. Ce faisant, vous

déclenchez le loquet automatique et vous pouvez retirer la matrice.

Étape 4: Continuez de tirer la poignée jusqu’à ce que le bloc à colonnes

soit complètement retiré, en le soutenant avec les deux poignées.

Étape 5: Rangez la matrice dans la zone de stockage située en haut

de l’AdvancedPunch (protégez-la de la poussière, des chutes

accidentelles, etc.).

Étape 6: Choisissez une matrice appropriée pour le travail que vous

souhaitez accomplir et placez-la dans la fente pour matrices. Poussez

la matrice jusqu’à ce qu’elle s’enclenche.

ATTENTION: F AITES ATTENTION DE NE P AS VOUS COINCER

LES DOIGTS. LORS DE LA MISE EN PLACE DE LA MA TRICE

DANS L’ADV ANCEDPUNCH, ÉLOIGNEZ VOS DOIGTS DE LA

FENTE POUR MA TRICE ET NE TENEZ LA MA TRICE QU’À L’AIDE

DE L’ORIFICE PRÉVU À CET EFFET. SOYEZ PRUDENT, CAR

VOUS POURRIEZ VOUS BLESSER.

Étape 7: Fermez la porte d’accès.

Étape 8: Poursuivez votre travail d’impression/perforation.

À noter que lorsque vous utilisez une matrice neuve, quelques traces

d’huile peuvent être présentes autour des trous de perforation de la

feuille. Après environ 25 à 50 feuilles, la matrice ne laissera plus

aucune trace d’huile sur les feuilles. Il est recommandé d’effectuer un

court test d’impression après avoir installé une matrice neuve ou

récemment lubrifiée.

7. INCIDENTS P APIER

Ce symbole indique un incident papier. Pour

éliminer un incident papier dans une des zones

suivantes, tournez la (ou les) manette(s)

nécessaires pour faire avancer le papier.

Zone

Si l'incident papier se produit au niveau du Bypass, relevez la plaque de guidage du papier

située à l’intérieur et retirez les restes de papier.

Si l'incident se produit au niveau de la descente

du chemin papier, poussez la porte vers la droite

et retirez les restes de papier.

AdvancedPunch

F

Description

6. PERFORA TION

Avant de commencer un travail d’impression impliquant l’utilisation de

la fonction de perforation de l’AdvancedPunch, assurez-vous

qu’aucun voyant jaune n’est allumé sur le panneau avant de

l’AdvancedPunch. Si un voyant jaune est allumé, résolvez la panne

avant de commencer le travail de perforation. Consultez la section (3.

COMMANDES) pour plus d’informations concernant les voyants.

L’AdvancedPunch ne fonctionnera pas en mode Perforation si un

voyant jaune est allumé.

Avant de commencer un travail d’impression impliquant l’utilisation de

la fonction de perforation de l’AdvancedPunch, assurez-vous

qu’aucun voyant jaune n’est allumé sur le panneau avant de

l’AdvancedPunch. Si un voyant jaune est allumé, résolvez la panne

avant de commencer le travail de perforation. Consultez la section (3.

COMMANDES) pour plus d’informations concernant les voyants.

L’AdvancedPunch ne fonctionnera pas en mode Perforation si un

voyant jaune est allumé.

Dans l’écran de l’interface utilisateur de l’imprimante, allez dans le

menu Copier. Puis, sélectionnez Sortie copie pour accéder au menu

Perforation et autres. Dans ce menu, l’option AdvancedPunch

apparaît dans la colonne perforation. Sélectionnez cette option, puis

appuyez sur Enregistrer pour revenir au menu Copier.

L’AdvancedPunch fonctionne maintenant en mode Perforation.

Perforation d’intercalaires

L’AdvancedPunch perfore le bord d’attaque des feuilles. De ce fait,

les intercalaires doivent être chargés en veillant à ce que les onglets

se trouvent sur le bord de queue. La manière dont les Intercalaires

sont chargés dans le plateau de manière à être perforés du bon côté

varie en fonction du plateau utilisé.

Si l'incident papier se produit au niveau de la

matrice, tournez la manette J3 en position initiale

(les flèches s’alignent), retirez la matrice et

éliminez les restes de papier.

Si l'incident papier se produit dans la partie

basse du chemin papier, appuyez sur le loquet

du canal et retirez les restes de papier.

Si l'incident papier se produit dans la montée du

chemin papier, poussez la porte vers la gauche

et retirez les restes de papier.

13

Page 14

AdvancedPunch

F

8. RÉSERVOIR À CONFETTIS

Le réservoir à confettis de votre AdvancedPunch est situé à l’avant

de la base de la machine. Le tiroir doit être périodiquement retiré et

vidé. Un capteur permet à l’AdvancedPunch de savoir lorsque le

réservoir à confettis est plein. Lorsque tel est le cas, le voyant

situé sur le panneau avant de l’AdvancedPunch s’allume et un

message apparaît sur l’écran de l'interface utilisateur.

9. EN CAS DE PROBLÈME

Problème

Hors tension, la perforatrice

ne fonctionne pas

La matrice ne peut pas être

extraite en tirant en douceur

Codes de panne

Les codes de panne de l’AdvancedPunch s’affichent sur l’interface

utilisateur de la machine. Voici les codes de panne spécifiques à

l’AdvancedPunch.

Code de

panne

040-100

040-101

040-900

Cause possible Solution préconisée

Un incident papier

s’est produit dans

l’AdvancedPunch.

040-901

040-300

La porte avant de

l’AdvancedPunch

n’est pas fermée.

040-940

La matrice de

perforation est

absente ou mal

insérée.

040-941

Le réservoir à

confettis est absent

ou mal inséré

040-942

140-700

Le réservoir à

confettis est plein.

Le réservoir à

confettis est

presque plein.

Cause possible

Le cordon d’alimentation n’est pas

correctement branché au secteur.

La touche marche/arrêt n’est pas

activée

La matrice est en cours d’utilisation.

T ournez le bouton de la matrice (J3)

en position initiale. Pour ce faire,

alignez les flèches. Retirez alors la

matrice.

Voir aussi les incidents papier.

Ouvrez la porte avant et

recherchez les feuilles de

papier coincées. Le cas

échéant, retirez le papier

coincé, puis refermez la porte

avant.

Refermez la porte avant de

l’AdvancedPunch.

Installez ou insérez

complètement une matrice, puis

refermez la porte avant.

Installez et/ou insérez

complètement un réservoir à

confettis, puis refermez la

porte avant.

Videz le réservoir à confettis,

puis remettez-le en place.

Videz le réservoir à confettis,

puis remettez-le en place.

10. SPÉCIFICA TIONS

Vitesse

Format de la feuille à

perforer

Marge de perforation

Types de papier

Format Feuille en

Mode Contournement

Papier

Capacité de la

perforatrice

Alimentation

Puissance

Certification de

sûreté

Dimensions

Poids

Poids à l’expédition

Fabriqué

Modèles 115V

Jusqu’à 127 feuilles par minute

Letter - 8.5" x 11"

11"

20# bond à 80# couverture

Mêmes formats et types que ceux

supportés par l'imprimante

Simple feuille

115V, 60Hz, monophasé

BTU/heure 1057BTU/h

Watts 310W

Ampères 2,8A

TUV/GS, CE

12" (30,5 cm) (L) x 38,5" (97,8 cm)

(H) x 28,5" (72,3 cm) (P)

154 lb. (70 kg)

254 lb. (115,5 kg)

Assemblé à Taiwan

14

Page 15

ÍNDICE

AdvancedPunch

E

1. INSTRUCCIONES DE SEGURIDAD 15

Instrucciones importantes 15

Limpieza 15

Reparación 16

Avisos de seguridad 16

2. INTRODUCCIÓN 16

3. MANDOS DE OPERACIÓN 17

4. PA TRONES DE PERFORACIÓN 18

1. INSTRUCCIONES DE SEGURIDAD

SU SEGURIDAD Y LA DE LAS PERSONAS QUE LE RODEAN SON MUY

IMPORT ANTES P ARA GBC. LOS MENSAJES E INTRUCCIONES DE

SEGURIDAD IMPORT ANTES AP ARECEN EN ESTE MANUAL Y EN LA

MÁQUINA. LEA A TENT AMENTE ESTE MANUAL ANTES DE USAR LA

MÁQUINA.

EN ESTE MANUAL DE USO ENCONTRARÁ UN SÍMBOLO DE

ADVERTENCIA EN CADA MENSAJE DE SEGURIDAD. ES TE

SÍM BOL O INDICA UN RIES GO PO TE NCIAL: PODRÍA

LESIONARSE, LESIONAR A TERCEROS O DAÑAR EL

PRODUCTO.

LAS SIGUIENTES ETIQUETAS AP ARECEN EN EL ADV ANCEDPUNCH:

Este mensaje de seguridad le alerta que puede

recibir una descarga eléctrica aunque haya

desconectado la corriente en esta sección,

ya que la corriente no está desconectada en

las secciones adyacentes.

5. SUSTITUCIÓN DE LOS JUEGOS DE TROQUELES 19

6. PERFORACIÓN 19

Perforación de pestañas 19

7. AT ASCOS DE P APEL 19

8. CONTENEDOR DEL PAPEL 20

9. SOLUCIÓN DE A VERÍAS 20

Códigos de fallas 20

10. ESPECIFICACIONES 20

Instrucciones importantes

Use el AdvancedPunch únicamente para perforar el papel y la

cubierta de acuerdo con las especificaciones indicadas.

Conserve este manual de instrucciones para usos en el futuro.

PRECAUCIÓN: EL INTERRUPTOR PARA ENCENDER O

APAGAR LA IMPRESORA NO DESCONECTA LA

PERFORADORA.

PRECAUCIÓN: EL INTERRUPTOR PARA ENCENDER O

APAGAR LA PERFORADORA NO DESCONECTA LA

IMPRESORA.

La tensión de alimentación del AdvancedPunch debe corresponder

a las características eléctricas de la máquina (están indicadas en

la etiqueta del número de serie).

La máquina dispone de una toma de tierra para garantizar su

seguridad. Debe conectarse a un enchufe adecuado para toma

de tierra. Si no consigue conectar el enchufe a la toma, contacte

a un electricista calificado para que instale una toma adecuada.

No modifique el conector del cable de alimentación del

AdvancedPunch (en caso de haberlo). Se ha diseñado para

garantizar su seguridad.

Desconecte el AdvancedPunch si desea desplazar la máquina o

si no la va a usar durante un largo periodo

No use el AdvancedPunch si el cable o la toma de alimentación de

la máquina están dañados. No use la máquina en caso de avería,

derrame de algún líquido o si está dañada.

No sobrecargue la toma de alimentación. Podría provocar un

incendio o una descarga eléctrica.

Este mensaje señala que una descarga

eléctrica podría lesionarle gravemente e

incluso provocarle la muerte si abre la

máquina. NUNCA retire las placas atornilladas

en las tapas de la máquina. Refiera SIEMPRE

los requisitos del servicio al servicio

cualificado personal.

Limpieza

Puede limpiar la superficie externa del AdvancedPunch con un

trapo suave y húmedo.

No use detergente ni disolventes, ya que podría dañar la máquina.

15

Page 16

AdvancedPunch

E

Avisos de seguridad

SELECCIÓN

(LA SECCIÓN SIGUIENTE SÓLO ES VÁLIDA PARA LAS UNIDADES

230V 50/60HZ UTILIZADAS EN LA UNIÓN EUROPEA)

PRECAUCIÓN: A LA HORA DE SELECCIONAR UN CABLE

DE ALIMENTACIÓN AMOVIBLE PARA SU

ADVANCEDPUNCH, RESPETE SIEMPRE LAS

PRECAUCIONES SIGUIENTES.

El cable está compuesto por tres partes: el enchufe, el cable y la

conexión a la máquina. Cada uno de esos componentes dispone de la

homologación europea para la seguridad.

A continuación le indicamos las características eléctricas

correspondientes al cable de alimentació..

NO USE CABLES QUE NO RESPETEN LAS EXIGENCIAS ELÉCTRICAS

MÍNIMAS AQUÍ MENCIONADAS.

ENCHUFE: 3 amperios, 250 voltios, 50/60 Hz, Clase 1,3 conductores,

homologado por la Unión Europea.

CABLE: Tipo H05VV-F3G0.75, armonizado (< HAR >). Los símbolos

“< >” indican que el cable ha sido homologado de acuerdo con la

norma europea correspondiente (NOTA: “HAR” equivale a la marca

de homologación de la agencia de seguridad europea que aprobó el

cable. Ejemplo: “< VDE >”).

CONEXIÓN A LA MÁQUINA: 3 amperios, 250 voltios, 50/60 Hz,

homologado por la Unión Europea, Tipo IEC 320. El cable no debe

sobrepasar 3 metros de largo. Puede sustituir el cable por uno que

tenga las características eléctricas superiores a las mínimas aquí

especificadas.

Reparación, AdvancedPunch

No trate de reparar su AdvancedPunch por su cuenta. Contacte a un

representante certificado para efectuar reparaciones o el

mantenimiento de su AdvancedPunch.

Avisos de seguridad

NOTA SOBRE LA FCC

(LA SECCIÓN SIGUIENTE SÓLO ES VÁLIDA PARA LAS UNIDADES

115V 60HZ.)

Este equipo ha sido probado y satisface las normas relativas a los

aparatos digitales de la Clase A (Parte 15 de las normas de la FCC). Se

han previsto esos límites para garantizar una protección razonable

contra las interferencias durante el uso del equipo en un entorno

comercial.

Este equipo genera, usa y emite ondas de radio. Por lo tanto, si no lo

instala o si no lo usa de acuerdo con el manual de instrucciones,

podría provocar interferencias en las comunicaciones por radio. El

uso de este equipo en una zona habitada podría provocar

interferencias. En este caso, los gastos de corrección de las

interferencias correrán a su cargo.

PRECAUCIÓN: SI CAMBIA O MODIFICA LA MÁQUINA

SIN LA APROBACIÓN EXPLÍCITA DE LA GENERAL

BINDING CORPORATION, PERDERÁ EL DERECHO A USAR

EL EQUIPO.

Canada Class A Notice – Advertencia de Canadá, Clase A

Este aparato digital de la clase A cumple la norma ICES-3 de Canadá.

Cet appareil numérique de la classe A est conforme à la norme NMB-

003 du Canada.

2. INTRODUCCIÓN

Ante todo, le damos las gracias por adquirir un AdvancedPunch. Este

sistema de producción versátil le permitirá perforar documentos de

numerosas maneras y sustituir simplemente el juego de troqueles.

Este aparato ha sido concebido para ser fácil de manejar.

El AdvancedPunch es una solución innovadora para perforar el p apel.

Ofrece las características siguientes.

NO RETIRE LAS TAPAS DE LA MÁQUINA.

NINGUNA pieza interna puede ser reemplazada por el usuario para

así evitar que se lesione que se lesione, que se produzcan daños en

la propiedad o en la máquina.

Servicio, juegos de troqueles

Cada juego de troqueles viene bien lubricado de la fábrica antes de

enviarse. Durante el uso regular, el lubricante se gastará y tendrá que

reemplazarse. Como parte del mantenimiento regular, cada juego de

troqueles debe lubricarse después de cada 50 mil ciclos de

performación. GBC recomienda utilizar el lubricante de la marca 3-INONE, que se encuentra disponible. También se pueden utilizar otros

lubricantes ligeros para máquinas.

Para lubrica el juego de troqueles, simplemente añada una gota de

lubricante a lo largo de la cinta de fieltro ubicado en el juego de

troqueles. Luego de aplicar el lubricante, reinstale el juego de troqueles

en el AdvancedPunch y haga una prueba pequeña de impresión.

Tenga en cuenta que es normal que el primer conjunto de hojas

perforadas contenga lubricante luego de aplicarlo al juego de troqueles.

El lubricante desaparecerá de las hojas perforadas luego de la

perforación de 25 a 50 hojas. A partir de ese momento, el

AdvancedPunch podrá ser utilizado para perforar trabajos impresos.

Se pueden sustituir los juegos de troqueles rápidamente sin

herramientas ni palancas.

Cada juego de troqueles del AdvancedPunch dispone de una etiqueta

de identificación con su nombre y su patrón de perforación.

Una zona de almacenamiento para tres juegos de troqueles

adicionales situada por encima del bypass.

16

Page 17

3. MANDOS DE OPERACIÓN

A. Interruptor de puesta en marcha

Siempre debe estar en posición de encendido (“ON”).

B. Recipiente de perforación:

Bandeja de residuos de fácil acceso para desechar los residuos.

C. Cambios de juegos de troqueles:

Fácil, sin herramienta y en unos segundos

D. Almacén para juegos de troqueles:

Almacena hasta tres juegos de troqueles de repuesto

E. Carril para los documentos sin perforar (bypass):

Carril para los documentos no perforados.

F. Carril para el modo perforación:

El ángulo radial permite soportar hasta 216 g/m

Hay un panel ubicado en la parte delantera del AdvancedPunch que

ofrece información acerca del estado operativo de la unidad de

perforación. Las luces LED indican cuando el AdvancedPunch necesite

la atención del operador.

1. Encendido (“On”):

El indicador LED verde se iluminará cuando el interruptor del

AdvancedPunch se coloque en la posición de encendido (“On”).

NOTA: El cable de toma de alimentación del AdvancedPunch debe

estar conectado a una toma de corriente adecuada antes de

colocar el interruptor en la posición de encendido.

2. Contenedor de perforación vacío:

El indicador LED amarillo se iluminará cuando el contenedor de

perforación se llene de desechos de papel.

3. Contenedor de perforación completamente insertado:

El indicador LED amarillo se iluminará cuando se remueva el

contenedor de perforación y no se inserte completamente.

4. Cerrar puerta delantera:

El indicador LED amarillo se iluminará cuando la puerta delantera

esté abierta o no esté cerrada por completo.

5. Despejar los atascos de papel:

El indicador LED amarillo se iluminará cuando una hoja de papel

se atasque en la unidad de perforación. Consulte la sección de

este manual titulada ATASCOS DE PAPEL para leer las

instrucciones sobre cómo remover una hoja que se haya

atascado en el AdvancedPunch.

NOTA: El indicador LED amarillo se iluminará de forma tenue

si la impresora está encendida, mientras que el interruptor

del AdvancedPunch está en la posición de apagado (“Off”).

Luego de cambiar el interruptor del AdvancedPunch a la

posición de encendido (“On”), el indicador LED amarillo se

iluminará con toda su intensidad.

2

AdvancedPunch

Encendido (“On”)

Contenedor de perforación vacío

Contenedor de perforación

completamente insertado

Juego de troqueles completamente

insertado

Cerrar puerta delantera

Despejar los atascos de papel

E

17

Page 18

4. P A TRONES DE PERFORACIÓN

El AdvancedPunch utiliza una variedad de juegos de troqueles

intercambiables que le permiten perforar documentos en serie para

utilizar con diversos estilos de encuadernación. Al seleccionar el

juego de troqueles adecuado, puede usar su AdvancedPunch para

perforar documentos en maneras que correspondan con cualquiera

de los estilos de encuadernación que aparecen en la Tabla 1.

AdvancedPunch

E

Para una encuadernación con anillas plásticas, seleccione:

1 19

PB Plastic Bind; tamaño de orificio: 8 mm (0,313") (L) x 2,9 mm (0,116") (l); distancia entre los orificios (de

centro a centro): 14,3 mm (0,563")

Para una encuadernación Twin Loop™, seleccione:

1

Alambre W3; cuadrado; 3 orificios por pulgada; tamaño del orificio: 4 mm (0,156") (L) x 4 mm (0,156") (l);

distancia entre los orificios (de centro a centro): 8,5 mm (0,333")

1

Alambre W2; rectángulo; 2 orificios por pulgada; tamaño del orificio: 6,4 mm (0,250") (L) x 5,4 mm (0,214") (l);

distancia entre los orificios (de centro a centro): 12,7 mm (0,500")

21

Para una encuadernación Color Coil™, seleccione:

C4 Coil; redondo; 4 orificios por pulgada; tamaño del orificio: 4,4 mm (0,174") de diámetro; distancia entre los

orificios (de centro a centro): 6,3 mm (0,2475")

Para una encuadernación Velo® Bind, seleccione:

1

VB VeloBind®; redondo; 1 orificio por pulgada; tamaño del orificio: 3,2 mm (0,125") de diámetro; distancia entre

los orificios (de centro a centro): 25,4 mm (1")

11

Para una encuadernación con hojas móviles, seleccione:

3 Ring Binder; U.S. (modelos estándar de hojas móviles); tamaño del orificio: 8 mm (0,316") de diámetro

31

Nº de pieza Xerox:

XEROX PB-19H 008R13066

32

XEROX W3-32H-SQ 008R13069

XEROX W2-21H-SQ 008R13068

441

XEROX C4-44H 008R13067

XEROX VB-11H 008R13070

XEROX 3H 008R13072

Para una encuadernación Proclick® seleccione:

1

W3 Proclick®; rectángulo; tamaño del orificio: 4.9mm x 5.5mm; 0.196”x0.215” (LxW); distancia entre los orificios

(de centro a centro): 8.5mm (0,333")

©2003 GBC, Todos los derechos reservados Rev 10/02 R2 3/03

Los gráficos no representan las dimensiones o el espacio actuales de las perforaciones

32

XEROX PC-32H 008R13071

18

Page 19

5. SUSTITUCIÓN DE LOS JUEGOS DE TROQUELES

Su AdvancedPunch usa juegos de troqueles intercambiables que le

permiten perforar de manera económica, los documentos en función

de los diferentes estilos de encuadernación. La sustitución de los

juegos de troqueles de la máquina es rápida y fácil. Para ello, siga las

instrucciones siguientes:

Para extraer los juegos de troqueles de la máquina: La ranura

de los juegos de troqueles intercambiables del AdvancedPunch está

situada a la derecha en la parte delantera de la máquina. Si el juego de

troqueles ya está instalado en su AdvancedPunch, puede extraerlo

fácilmente siguiendo las instrucciones siguientes:

Paso 1: Pare la impresora/copiadora.

Paso 2: Abra la puerta de acceso del AdvancedPunch.

Paso 3: Sujete firmemente el asa y tire de ella. Una vez suelto el

mecanismo de bloqueo automático, puede extraer el juego de

troqueles.

Paso 4: Continúe tirando el mango hasta quitar por completo el juego

de troqueles, apoyándolo con ambos mangos.

Paso 5: Coloque el juego de troqueles en la zona de almacenado

arriba del AdvancedPunch (protéjalo del polvo, de las caídas

accidentales, etc.).

Paso 6: Elija el juego de troqueles deseado para la operación siguiente

y colóquelo en su ranura. Empuje el juego de troqueles hasta que

encaje.

PRECAUCIÓN: TENGA CUIDADO DE NO PILLARSE LOS

DEDOS. AL COLOCAR EL JUEGO DE TROQUELES EN EL

ADVANCEDPUNCH, ALEJE LOS DEDOS DE LA RANURA

PARA LA ORIFICIO PREVISTO P ARA ELLO. SEA PRUDENTE

YA QUE PODRÍA LESIONARSE.

Paso 7: Cierre la puerta de acceso.

Paso 8: Proceda con su trabajo de perforación.

Tenga en cuenta que cuando utilice un nuevo juego de troqueles,

puede haber un poco de lubricante en los orificios de la perforación.

Luego de perforar de 25 a 50 hojas, el juego de troqueles dejará de

manchar las hojas con lubricante. Se recomienda hacer una prueba

pequeña de impresión después de instalar un nuevo juego de troqueles

o de lubricar un juego de troqueles recientemente.

6. PERFORACIÓN

Antes de comenzar un trabajo de impresión para el que se utilizará el

servicio de perforación del AdvancedPunch, asegúrese de que el

indicador LED amarillo no esté iluminado en el panel delantero del

AdvancedPunch. Si el indicador LED amarillo está iluminado, corrija la

falla antes de comenzar el trabajo de perforación. Consulte la sección

(3. MANDOS DE OPERACIÓN) para obtener más información acerca

de los indicadores LED. El AdvancedPunch no operará en modo de

perforación si hay un indicados LED amarillo encendido.

Antes de comenzar el trabajo de perforación, verifique y asegúrese

de que el juego de troqueles instalado en el AdvancedPunch contiene

el patrón correcto de perforación para este trabajo. Si el juego de

troqueles no es el correcto, debe reemplazarlo en esta etapa.

Para activar la característica de perforación del AdvanedPunch, utilice

la pantalla de la interfaz del usuario. Siga los pasos para poder activar

esta característica.

En la pantalla de la interfaz del usuario, vaya al menú Copia. Luego

seleccione Resultado de la copia para ingresar al menú Orificio

de perforación y más. Una vez entre a este menú, aparecerá una

opción en la columna de los orificios de perforación llamada

AdvancedPunch. Seleccione esta opción y luego oprima Guardar

para regresar al menú Copia. El AdvancedPunch operará ahora en el

modo de perforación.

7. A T ASCOS DE P APEL

Este símbolo indica un atasco del papel. Para

eliminar un atasco de papel en una de las zonas

siguientes, gire el/los botones necesarios para

empujar el papel.

Zona

Si el atasco del papel se produce en el Carril

para los documentos sin perforar (bypass),

levante la placa donde se coloca el papel

ubicada adentro y retire los restos de papel.

Si el atasco se produce del contenedor, empuje

la puerta hacia la derecha y retire los restos de

papel.

Si el atasco se produce a la altura del juego de

troqueles, gire el botón (J3) en posición inicial

(la flechas están alineadas) retire el juego de

troqueles y elimine los restos de papel.

Si el atasco del papel se produce al final del

carril de los documentos perforados, presione

el bloqueo del contenedor y retire los restos de

papel.

AdvancedPunch

E

Descripción

Perforación de pestañas

El AdvancedPunch perfora el borde inicial de una hoja. Debido a esto,

las hojas con pestañas deben ser introducidas con la pestaña en el

borde del carril. La manera en que las hojs con pestañas se colocan

en la bandeja para lograr la introducción encarrilada correcta depende

del tipo de bandeja que se utilice.

Si el atasco se produce sobre el contenedor,

empuje la puerta hacia la izquierda y retire los

restos de papel.

19

Page 20

AdvancedPunch

E

8. CONTENEDOR DE PERFORACIÓN

El contenedor de perforación de su AdvancedPunch está ubicado

en la parte delantera de la base de la máquina. Debe sacar y vaciar

la bandeja periódicamente. El AdvancedPunch utiliza un sensor

para determinar cuando el contenedor está lleno. Una vez el

contenedor de perforación se llena, el indicador LED del panel

delantero del AdvancedPunch se iluminará y aparecerá un mensaje

en la pantalla de la interfaz del usuario de la impresora.

9. SOLUCIÓN DE A VERÍAS

Problema Posible causa

No hay corriente; la perforadora

no funciona.

No consigue extraer el juego

de troqueles

El cable de toma de alimentación no

está conectado en la parte trasera

de la máquina, no se conectó

adecuadamente al enchufe de toma

de tierra o no se activó la puesta en

marcha mediante el botón para

encender o apagar el aparato (“On/

Off”).

El juego de troqueles se está

usando. Gire el botón del juego de

troqueles (J3) hasta la posición

inicial. Para ello, alinee las flechas.

Ahora debe poder retirar el juego

de troqueles.

Consulte la sección de Atascos de

papel.

10. ESPECIFICACIONES

115V Máquinas

Velocidad

Tamaño de la hoja

Borde del punzónó

Stock de papel

Modo de alimentación

Sheet size

Capacidad de la

perforadora

Alimentación

Eléctrico

Seguridad

Dimensiones

Peso

Shipping Weight

Fabricado

Hasta 127 hojas por minuto

8.5" x 11"

11"

Papel bond de 9 kg (20 libras) a papel

de cubierta de 36 kg (80 libras)

Tamaños de papel similares y mismo

almacén que para la impresora

Hoja simple

115V, 60Hz, Monofásico

BTU/Hora 1057BTU/HR

Vatios 310W

Amperios 2.8A

TUV/GS, CE

30,5 cm (12") (ancho) x 97,8 cm (38,5")

(alto) x 72,3 cm (28,5") (profundidad)

154 lbs. (70 Kg)

115,5 kg (254 libras)

Ensamblado en Taiwán

Códigos de fallas

Los códigos de fallas del AdvancedPunch aparecen en la interfaz del

usuario de la máquina como un código de falla del AdvancedPunch.

producto continuación se enumeran los códigos de fallas que

corresponden específicamente con el producto AdvancedPunch.

Código

de falla

040-100

040-101

040-900

040-901

040-300

040-940

040-941

040-942

140-700

Posible causa

Se detectó un atasco

de papel en el

AdvancedPunch.

La puerta delantera del

AdvancedPunch no

está cerrada.

El juego de troqueles

no se encuentra, o

está instalado

correctamente.

El contenedor de

perforación no se

encuentra, o no está

instalado

correctamente.

El contenedor de

perforación está lleno.

El contenedor de

perforación está casi

lleno.

Solución recomendada

Abra la puerta delantera

para inspeccionar el atasco

de papel. Remueva el papel

atascado y cierre la puerta

delantera.

Cierre la puerta delantera

del AdvancedPunch.

Instale el juego de

troqueles o insértelo

completamente y cierre la

puerta delantera.

Instale y/o inserte

completamente el

contenedor de perforación

y cierre la puerta

delantera.

Vacíe el contenedor de

perforación y reinstálelo.

Vacíe el contenedor de

perforación y reinstálelo.

20

Loading...

Loading...