Page 1

ORCA 80-99 OPERATION

& MAINTENANCE MANUAL

© June 2000 GBC Pro-Tech

Do not duplicate without written permission.

GBC Pro - Tech

4151 Anderson Road

DeForest, WI 53532

Revision : Ph: ( 608 ) 246 - 8844

Part number : 930 - 055

Fx: ( 608 ) 246 - 8645

Page 2

Section 1: Safety

Safety features .............................................................................. 1 - 1

Section 2: Warranty

Limited warranty information ..................................................... 2 - 1

Exclusions to the warranty .......................................................... 2 - 1

Table of ContentsOrca 80-99 Operation and Maintenance Manual

Table of Contents

Section 3: Specifications

Section 4: Installation

Uncrating ........................................................................................ 4 - 1

Uncrating Diagram........................................................................4 - 2

Electrical Requirements ................................................................4 - 3

Suggested Layout ...........................................................................4 - 4

Air Requirements...........................................................................4 - 5

© GBC Pro - Tech June 2000

Page I

Page 3

Table of Contents Orca 80-99 Operation and Maintenance Manual

Section 5: Operations

Operation....................................................................................... 5 - 1

Front control panel diagram ........................................................ 5 - 2

Rear control panel diagram ......................................................... 5 - 3

Front control panel....................................................................... 5 - 4

Rear control panel........................................................................ 5 - 4

Setup .............................................................................................. 5 - 5

Processes....................................................................................... 5 - 7

Process control chart (blank) ...................................................... 5 - 10

Process control diagram (blank)................................................. 5 - 11

Hot mount (Chart 2.2) .................................................................. 5 - 12

Hot mount (Diagram 2.2) ............................................................. 5 - 13

Hot mount/Laminate (Chart 2.3)................................................. 5 - 14

Page II

Hot mount/Laminate (Diagram 2.3)............................................ 5 - 15

© GBC Pro - Tech June 2000

Page 4

Table of ContentsOrca 80-99 Operation and Maintenance Manual

Encapsulation (Chart 2.4)............................................................ 5 - 16

Encapsulation (Diagram 2.4) ........................................................5 - 17

Hot laminate/PSA mount (Chart 2.5)...........................................5 - 18

Hot laminate/PSA mount (Diagram 2.5)......................................5 - 19

Hot laminate/PSA mount (Second pass - Chart 2.6) ..................5 - 20

Hot laminate/PSA mount (Second pass - Diagram 2.6) ............5 - 21

Cold overlaminate/ PSA mount (Chart 2.7) ................................5 - 22

Cold overlaminate/PSA mount (Diagram 2.7) ............................5 - 23

Cold overlaminate/PSA mount (Second pass - Chart 2.8).........5 - 24

Cold overlaminate/PSA mount (Second pass - Diagram 2.8)....5 - 25

Cold laminate only using a sled (Chart 2.9) ................................5 - 26

Cold laminate only using a sled (Diagram 2.9)...........................5 - 27

© GBC Pro - Tech June 2000

Page III

Page 5

Table of Contents Orca 80-99 Operation and Maintenance Manual

Section 6: Maintenence

Daily ................................................................................................ 6 - 1

Monthly...........................................................................................6 - 1

Six Month .......................................................................................6 - 2

Chain Diagram ...............................................................................6 - 3

Page IV

© GBC Pro - Tech June 2000

Page 6

SAFETY

SafetyOrca 80-99 Operation and Maintenance Manual

READ THIS SECTION BEFORE

OPERATING THE ORCA 80-99 LAMINATOR!

FOR YOUR SAFETY:

Your safety as well as the safety of others is important to

GBC Pro-Tech. In this instruction and on the product

are important safety messages. Read these messages

carefully.

1. Read all these instructions.

2. Save these instructions for later use.

3. Follow all warning and instructions marked on the

product.

4. Unplug this product from the wall outlet before cleaning.

Do not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

5. Do not use this product near water.

6. This product should be operated from the type of

power source indicated on the marking label. If you are

not sure of the type of power available, consult your dealer

or a qualified and certified electrician.

10. Unplug this product from the wall outlet and refer

servicing to qualified service personnel under the following

conditions:

A. When the power cord is damaged or frayed.

B. If liquid has spilled into the product.

C. If the product has been exposed to rain or water.

WARNING:

Never place fingers or arms between the rollers

when they are turning or when the rollers are in

the closed position.

D. If the product does not operate normally when the

operating instructions are followed. Adjust only those

controls that are covered by the operating instructions

since improper adjustment of other controls may result in

damage and will often require extensive work by a qualified

technician to restore the product to normal operation.

E. If the product exhibits a distinct change in performance,

indicating a need for service.

Safety Information

7. Do not allow anything to rest on the power cord. Do

not locate this product where persons will walk on the

cord.

8. Never push objects of any kind into this

product through any slots as they may touch dangerous

voltage points or short out parts that could result in a risk

of fire or electric shock. Never spill liquid of any kind on

the product.

9. Do not attempt to service this product yourself, as

opening or removing covers may expose you to dangerous

voltage points or other risks. Refer all servicing to service

personnel.

© GBC Films Group June 2000

WARNING:

It is vital that everyone working around the

laminator rolls avoid wearing loose-fitting clothing,

ties or dangling jewelry which could be caught in

the nip.

The GBC Pro-Tech laminator has been designed with

operator safety as a primary consideration. However,

operators must become thoroughly familiar with the

controls, and proper operation and safety features of the

machine before starting to use the unit.

Page 1 - 1

Page 7

Safety Orca 80-99 Operation and Maintenance Manual

GBC Pro-Tech laminators are powerful machines which

are designed to accomplish specific tasks such as

mounting, laminating and encapsulating. The forces

required to accomplish laminating can vary from negligible

to very large. The air-cylinder system used to provide

downward pressure on the top roll is capable of producing

forces greater than 1000 pounds (454 kg). This force

can be applied to any object that may be present in the

opening (called the nip) between the two rollers.

As a safety measure, the laminator is equipped with a

photoelectric eye system which stops the machine when

objects or hands are located in the nip area. Once the

blocking object is removed and the light beam is

reestablished, the laminator rolls resume turning.

Operators should use care in lowering the top laminating

roll and know how to react quickly in an emergency. The

laminator roll UP-DOWN switch is located on the front

instrument panel labeled “Laminator Roll Controls” on

the left-hand side of the machine. As the name implies,

this switch controls the up and down motion of the top

laminator roll. Before turning this switch to the DOWN

position, assure that nothing is in the nip area.

machine, or by stepping on or kicking the E-Stop

cable located at the bottom of the machine.

Quick action in this regard can aid in preventing or

minimizing injury or machine damage.

Because of the electrical shock hazard and the

chance that a person might get either fingers or

clothing into the drive mechanism, the cabinets

should only be opened by a qualified service person,

after the machine is shut off and the power

disconnected.

Most GBC Pro-Tech machines are designed to heat the

lamination rollers. Temperatures can be set to over 200

degrees F (100 degrees C). Thus there is a danger of a

severe burn if the

rollers are touched during set-up or operation.

The machines have steel end cabinets that are bolted

closed. They serve to isolate the electrical- and drivesystem components.

WARNING:

Please note: All persons working on or near the

Orca 80-99 Laminator must be advised of the

following:

If any clothing, tools, or anything other than film

or paper is inadvertently drawn into the nip, the

action of the rolls may be halted immediately (and

the top roll lifted) by pushing or striking any of the

red E-Stop switches located at the top of the

Page 1 - 2

© GBC Films Group June 2000

Page 8

Orca 80-99 Operation and Maintenance Manual

WARRANTY

Limited Warranty

Warranty

CAUTION:

Unauthorized customer alterations will void this

warranty.

GBC Pro-Tech warrants the equipment sold is free from

defects in material and workmanship for a period of one

(1) year from the date of delivery to the customer.

This warranty is the only warranty made by Pro-Tech

and can not be modified or amended.

GBC Pro-Tech’s sole and exclusive liability and the

customer’s sole and exclusive remedy under this

warranty shall be, at GBC Pro-Tech’s option, to

repair or replace any such defective part or product.

These remedies are only available if GBC Pro-Tech’s

examination of the product discloses to GBC ProTech’s satisfaction that such defects actually exist

and were not caused by misuse, neglect, attempt to

repair, unauthorized alteration or modification,

incorrect line voltage, contaminated air supply, or

by fire, accident or flood or other hazard.

Exclusions to the Warranty

This warranty specifically does not cover:

1. Damage to the laminating rollers caused by knives, razor

blades, other sharp objects, or

failure caused by adhesives.

2. Damage to the machine caused by lifting, tilting, and/or

any attempt to position the machine other than rolling on

the installed casters.

3. Improper use of the machine.

This warranty specifically does not cover damage to the

laminating rollers caused by knives, razor blades, other

sharp objects, failure caused by adhesives or improper

use of the machine. Warranty repair or replacement does

not extend the warranty beyond the initial one year period

from the date of delivery.

THE WARRANTY MADE HEREIN IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING ANY WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. GBC PRO-TECH

WILL NOT BE LIABLE FOR PROPERTY

DAMAGE OR PERSONAL INJURY (UNLESS

PRIMARILY CAUSED BY ITS NEGLIGENCE),

LOSS OF PROFIT OR OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT

OF THE USE OR INABILITY TO USE THE

EQUIPMENT.

© GBC Films Group June 2000

Page 2 - 1

Page 9

ORCA 80-99

SPECIFICATIONS

SpecificationsOrca 80-99 Operation and Maintenance Manual

Description:

Floor-standing laminator with multiple unwind

positions for high productivity heat-activated laminating,

encapsulating, heat transfer and mounting. The

laminator can also be used with pressure-sensitive films

for cold mounting and laminating applications.

Includes:

Outfeed edge slitters for in line trimming of finished

product.

Dimensions:

L - 120", D - 50", H - 66" (L- 3M, D- 1.27M, H-

1.68M)

Weight (uncrated):

Laminating Material:

Uses heat-activated 0-74” and pressure-sensitive

materials 0 - 80" (0- cm) wide with films on 3" (7.6

cm.) ID core.

Laminating Speeds:

0 to 30 fpm ( 0 to 9 Mpm) with variable speed,

reversible action, START and STOP controlled via the

front instrument-panel switch or with a foot switch.

Unwind - Rewind:

Three unwind positions; three rewind positions

Safety Features:

(1) Photo-eye motor stop, 4 emergency stop buttons

and two kick cables to stop the machine and raise rolls.

2800 pounds (1270 kg)

Laminating Rolls:

86.5" length (220 cm) roll face with thermally

conductive silicone covered with high release silicone

surface, upper and lower rolls internally heated.

Temperature controlled by state of the art infrared

sensors with closed loop digital control systems,

independently adjustable for both top and bottom rolls.

Laminating Opening:

1_” (4.75 cm) maximum opening controlled with dual

air cylinders.

© GBC Films Group June 2000

Warranty:

One year parts warranty (except silicone roll coverings

and table tops).

Electric:

220 VAC, 50 or 60 Hz, single phase, 60-65 Amps.

Three phase 32 Amps (Europe only).

Compressed Air:

2 CFM @ 100 PSI.

Page 3 - 1

Page 10

INSTALLATION

Uncrating the Machine

InstallationOrca 80-99 Operation and Maintenance Manual

CAUTION:

When taking the top off, care should be taken so

that the top does not fall into the crate, possibly

damaging the laminator. It might be necessary to

use two or three people for this task.

During the uncrating process make sure that the

screws do not end up on the floor. They can cause

problems later when trying to roll the machine into

position.

To uncrate the Orca 80-99 Laminator you will need a

phillips head screwdriver. It helps to have a cordless drill

with the screwdriver bit, because there are quite a few

screws to remove throughout this procedure. In order to

minimize the possibility of damage to your new Orca 8099 Laminator, please follow this procedure exactly.

1. The top of the crate is the first piece to be removed

(see diagram on page 4-3).

2. Next, remove one side of the crate (see diagram). At

this point it is necessary to have someone support the

remaining side of the crate while the remaining end is being

removed. Maintain support of the side until all mounting

screws are removed and the side is off the crate.

6. When all the accessories have been removed from the

crate you will notice that there are two ramps that are

bolted down to the crate bottom: these will need to be

removed, using the phillips head screwdriver.

The ramps must then be secured to the edge of the crate

bottom using the screws left over from crate disassembly

(see diagram).

PLEASE NOTE: The Orca 80-99 Laminator is a

large and heavy piece of mechanical equipment.

Casual movement of equipment of this type can be

hazardous to the average person; and poses the

potential of serious damage to the machine.

It will be necessary to employ qualified and

trained personnel (licensed, certified RIGGERS)

if any movement of the machine other than rolling

on a flat, level surface is contemplated.

The Orca 80-99 Laminator is not designed to be

tipped up or sideways in anyway. Such action may

disturb the exact alignment of the rolling parts of

the machine and require extensive re-alignment.

GBC Pro-Tech’s warranty does not cover

malfunction of the equipment due to mis-handling

and/or tipping.

3. Remove the end of the crate (see diagram).

CAUTION:

Do not use a knife or other sharp instrument to

remove any protective covering. This could cause

irreparable damage to the machine.

4. Remove the shrink wrap from the machine and its

contents.

5. Once the shrink wrap is off, remove any accessories

from the crate. While doing this, take care not to scuff

the machine.

© GBC Films Group June 2000

GBC Pro-Tech bears no responsibility for parties

who fail to follow these directions. Any injury or

damage to the machine due to improper moving is

the sole responsibility of the mover.

Before the machine can be rolled off the crate, the foot

bolts must be freed from the four shipping hold-down

plates. Loosen the lock-nut on each of the foot bolts.

Unscrew the foot bolts from the hold-down plates. Raise

but do not remove the bolts and lock nuts from the foot

bracket. (At this time, you may wish to remove the holddown plates from the crate to provide unrestricted removal

of the machine from the crate).

Page 4 - 1

Page 11

Page 4 - 2

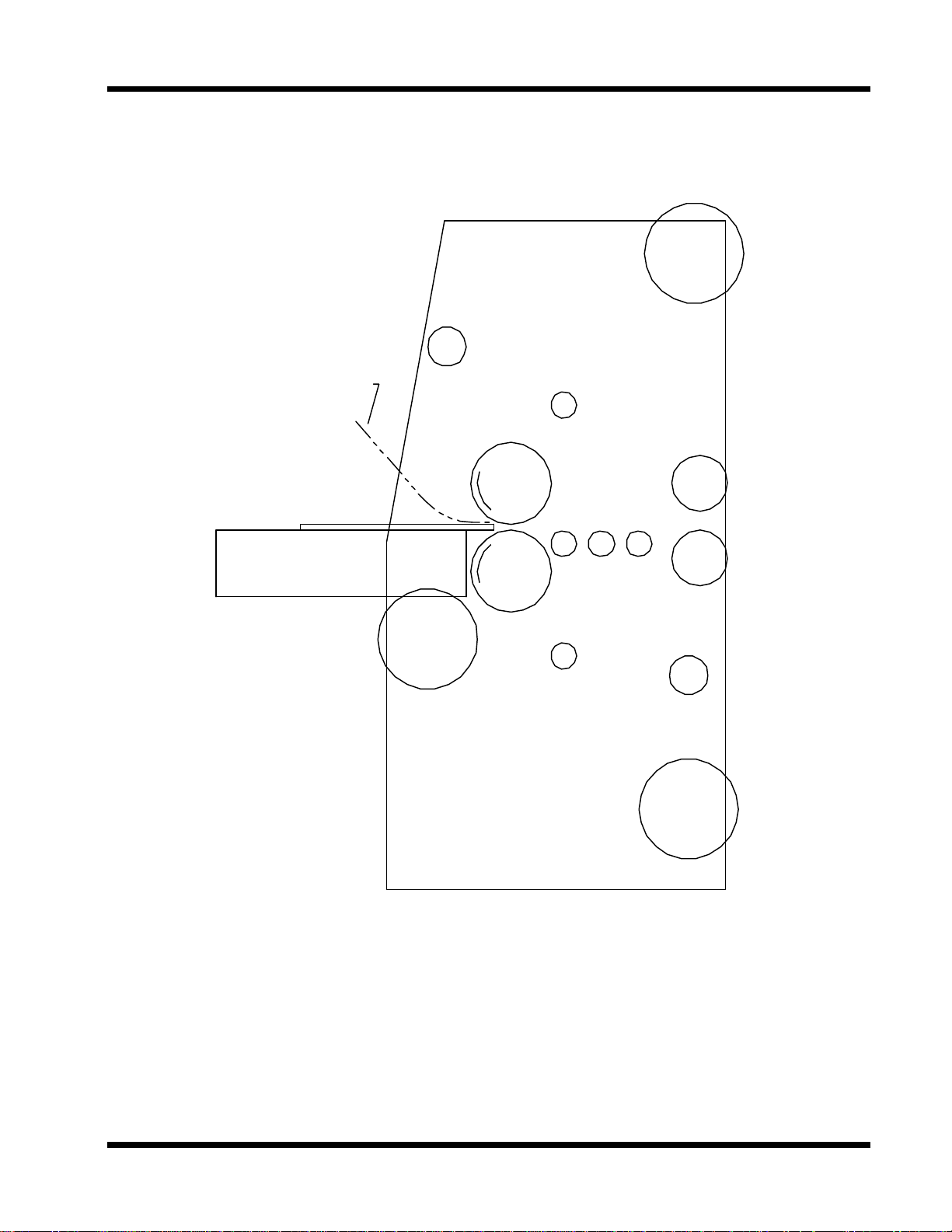

Installation

UNCRATING DIAGRAM

ORCA-80-99

1

5

© GBC Films Group June 2000

4

INSTALL SCREWS

Orca 80-99 Operation and Maintenance Manual

2

23 in.

[59 cm]

3

Page 12

InstallationOrca 80-99 Operation and Maintenance Manual

7. Once the ramps are secured and the hold down plates

are removed, the machine can be rolled off the crate

bottom. This will require four people handling the machine

on its four corners and carefully rolling the machine off the

crate bottom (see diagram). The machine can now be

rolled into its final operating position.

Choose a spot with sufficient space around the unit so

that there can be front and back work tables and adequate

space for efficient material flow. Thus, a typical room area

requirement for the ORCA 80-99 is 20 X 24 feet (6.0 x

7.3 Meters) to allow use of work tables in front and to

the rear of the machine. See the suggested layout in Fig.

1-1 (page 4-4).

Once the Orca 80-99 Laminator has been placed in its

final position, optimum performance is obtained by

installing the supplied leveling pads and leveling the

machine. Install one leveling pad on each foot-bolt,

tightening securely.

Lower the leveling pad to the floor by turning down the

foot bolts. Turn all the bolts sufficiently to lift all four of

the casters off the floor.

CAUTION:

Some generation of static electricity is

unavoidable during the laminating process due to

the nature of the materials used. In order to avoid

any hazard of ignition, fire or explosion due to

static spark, it is imperative that the operating

environment is free of dust, flammable liquids, and

vapors.

Then, face the machine and place a carpenter’s level leftto-right on one of the idlers. Adjust the bolts on the front

two foot brackets so that the machine is level left-to-right.

Then, move the level to the rear of the machine and adjust

the rear two leveling pads.

Next, place the level front-to-rear on one of the air cylinder

brackets and adjust the bolts equally on the two foot

brackets on that side. Move the level to the other air

cylinder bracket and repeat the procedure for the other

side.

After both sides have been leveled front-to-back, go back

and check the side-to-side level condition of the front

and rear of the machine to insure that it has not changed.

If it has, repeat the procedure until the machine’s front,

rear, and both sides are all level. Tighten the lock nuts

securely to the foot brackets.

8. At this point a qualified electrician connects power to

the machine. Make sure before supply power is provided

that the machine circuit breaker is in the off position. This

is also the point where the appropriate supply of clean,

dry compressed air is connected to the machine (see power

and air requirements).

Electrical Requirements

The ORCA 80-99 is designed to accept 220 to 240-volt

AC, 50/60-Hz, 60 Amps, single phase 3 wire (USA).

The peak power required by the unit is 55 Amperes. Or,

in Europe only 3-N phase 230/400 VAC, 50 Hz, 25

Amps per phase.

Before attempting to electrically connect or operate your

new Orca 80-99 Laminator, a qualified, licensed electrician

should be consulted to ensure that an adequate power

supply, having the appropriate capacity, overcurrent

protection, safety lockouts, etc., is available; and to ensure

that the power supply of the Orca 80-99 is in accordance

with all established national and regional electrical codes

and standards.

CAUTION:

The air supply to the Orca must be clean and dry

or the machine will be damaged.

GBC Pro-Tech, will not be responsible for damage

to the equipment caused by improper connection,

incorrect power supply or other incorrect electrical

installation.

Before initial power is applied to the machine assure that

all toggle switches on the front and rear control panels

and the main power circuit breaker (inside/bottom of the

left-side cabinet) are set to OFF. The AC connection is

located on the bottom/front of the left-side cabinet.

© GBC Films Group June 2000

Page 4 - 3

Page 13

Installation

AIR SUPPLY

Orca 80-99 Operation and Maintenance Manual

Work Table

6' X 6'

[2m x 2m]

(on wheels)

REAR

10' [3m]

ELECTRICAL

SUPPLY

20' [6m]

FRONT

10' [3m]

Work Table

6' X 6'

[2m x 2m]

(on wheels)

4' [1.2m]

3'

[1m

]

24' [7.3m]

Page 4 - 4

Fig. 1-1

SUGGESTED WORKSPACE

LAYOUT

ORCA 80-99

© GBC Films Group June 2000

Page 14

Air Requirements

CAUTION:

Do not use a knife or other sharp object to remove

the paper coverings. This would cause irreparable

damage to the rolls and necessitate their

replacement.

The Orca 80-99 laminator requires filtered air at 2 cubic

feet per minute (CFM), (50 liters/minute) at a pressure of

at least 100 pounds (700 kPa) per square inch (PSI).

The air supply must be clean (free of dirt) and dry.

Moisture will cause corrosion and particles can block

pneumatic controls. Either can cause the laminator to

malfunction.

InstallationOrca 80-99 Operation and Maintenance Manual

2 Additional slitter knives

1 T-handle wrench, 5/16"

1 T-handle wrench, 1/4"

1 Masking Tape

1 Tape Measure

1 Rubber Cement Pick-Up

1 Shim Set

4 Leveling Pads

2 Outfeed Slitters

2 O-Rings, Brake

1 Oil, Air Tool

These items are needed to put the machine into operation.

RECYCLING INSTRUCTIONS:

It is the customer’s responsibility to provide appropriate

filters and water traps for the air line before the air is routed

to the laminator.

GBC Pro-Tech suggests that the best approach to the air

requirement is to provide a dedicated small compressor

for the laminator. A standard light-duty 1/2 to 3/4

horsepower (1 kW) electric air compressor with 1.5 to

2.5 CFM output with a 2.5 - gallon (20 Liter) storage

tank is appropriate.

Air is fed to the machine via a 1/4-inch quick-disconnect

male connector. This connector is located below the

cabinet on the left side of the machine. (Once the air

supply and electrical power are connected to the machine,

proceed to the section on Operation in this manual).

9. Next, remove the paper coverings from the roll. After

the roll coverings have been removed, you will need to

open the accessory pack. The accessory pack contains:

The crate components can be reused for shipping

the machine again, or may be disassembled and

the wood and screws recycled. The shrink wrap

however, is not recyclable so therefore must be

discarded.

In order to begin operation of the machine, the Up/Down

rates for the main and pull rolls and the nips must be set

(see the Operation section of this manual). Once set, the

machine is ready for operation.

Qty Description

1 Set, Allen wrenches

1 Slitting knife

1 Manual

1 Bottle of Isopropyl Alcohol

1 100 % white cotton terry rags

1 Set, spare fuses

© GBC Films Group June 2000

Page 4 - 5

Page 15

OPERATION

OperationsOrca 80-99 Operation and Maintenance Manual

Safety

Safety is always the primary concern. If you have not

read the safety information at the front of this manual,

do so now. Do not attempt operation of the machine

until you fully understand this safety information.

General Precautions

1. Keep razor blades, knives, and all other sharp

objects away from the chrome and silicone rollers. They

are easily damaged and very expensive to replace.

CAUTION:

Insert shims to keep the laminating and pull rolls

apart when the machine is not in use. Do not rely

on the air supply. Prolonged contact can damage

the rolls.

2. Harsh chemicals such as Toluene or MEK will

destroy the silicone covering on the laminating rolls. The

rolls should be cleaned daily following the procedure

outlined in the Maintenance section of this manual.

CAUTION:

If silicone adhesives contact the top or bottom roll,

remove it IMMEDIATELY using isopropyl

alcohol. It will harden within an hour.

3. Do not allow liquid silicone adhesives to contact the

top or bottom silicone roll. These materials will bond to

the roll in much less than one hour. If some adhesive

does get on the roll, wipe it off IMMEDIATELY using

isopropyl alcohol.

5. Use a 100-percent cotton terry cloth to remove

heat-activated laminating residue, while the rolls are hot.

Follow this procedure every time heat-activated

laminates are used.

WARNING:

1. Never place fingers or arms between the

rollers, both main and pull, or in roller slots no

matter what the operational status the machine is

in.

2. It is vital that everyone working around the

laminator rolls avoid wearing loose-fitting clothing,

ties or dangling jewelry, which could be caught in

the nip.

WARNING:

Extra caution must be used when operating the

laminator with the provided foot switch. The foot

switch acts as an “over-ride” to the photoelectric

eye; i.e., it allows the rolls to continue operation

even if the photoelectric eye detects an

obstruction near the nip.

This function is necessary a) to allow initial handfeeding of process materials to the rolls and b) to

prevent damage to the process at the end of a

sheet due to “curl-up” of the sheet end.

Operators are cautioned to use the foot switch for

as short a time as practicable, and to exercise

caution when doing so.

4. The laminating rolls will develop flat spots if left in

contact with each other when not in use. Always insert

the shims when shutting off the laminator. Do not rely on

the air supply to keep the top roller in the raised

position, as the air supply can fail at any time.

© GBC Films Group June 2000

Page 5 - 1

Page 16

Operations

AIR PRESSURE

GAUGE

PRESSURE

PRESSURE

TOP CLUTCH CONTROLS

PRESSURE

LAMINATOR ROLL CONTROLS

PRESSURE

Orca 80-99 Operation and Maintenance Manual

A

TOP UNWINDS (3)

ON/OFF

AIR PRESSURE

OFF

ON

TOP BRAKE CONTROLS

OFF

ON

ON

OFF

OFF

ON

ADJUST

ADJUST

ADJUST

ADJUST

ADJUSTMENT

(TOP BRAKE)

B

TOP REWIND

ON/OFF

C

LAMINATOR ROLL

UP/DOWN

D

BOTTOM UNWIND

ON/OFF

TOP HEATER SWITCH

ON/OFF LAMP

BOTTOM HEATER SWITCH

ON/OFF LAMP

PHOTOEYE

LAMP

MAIN POWER

ON/OFF

LAMP

MAIN POWER

SWITCH

M

E

J

PRESSURE

BOTTOM BRAKE CONTROLS

OFF

ON

ADJUST

K

BOTTOM CLUTCH CONTROLS

Photoeye

Blocked

L

OFF ON

LIGHTS

OFF ON

POWER

SEL

RST

PRO-TECH ENGINEERING, MADISON, WISCONSIN380-3440

N

JOG RUN

STOP

REV

FWD

R

E

W

0

L

S

MOTOR CONTROLS

F

A

S

T

E

R

I

SPEED READOUT

BOTTOM REWIND

ON/OFF

F

RUN/JOG

SWITCH

G

FORWARD/REVERSE

SWITCH

H

SPEED CONTROL

Fig. 2-1

FRONT CONTROL PANEL

Page 5 - 2

© GBC Films Group June 2000

Page 17

OperationsOrca 80-99 Operation and Maintenance Manual

TOP HEATER

A

ON/OFF

TOP HEATER

B

CONTROL

TOP FAN BANK

C

ON/OFF

PULL ROLL CLUTCH

PRESSURE GAUGE

PULL ROLL

PRESSURE GAUGE

BOTTOM UNWIND

TENSION PRESSURE

GAUGE

TOP HEAT

OFF

ON

ONOFF ONOFF

PULL ROLLER CLUTCH

PULL ROLLER PRESSURE

BOTTOM HEAT

BOTTOM COOLING FANSTOP COOLING FANS

ONOFF

ONOFF

ONOFF

OFF ON

D

BOTTOM HEATER

ON/OFF

E

BOTTOM HEATER

CONTROL

F

BOTTOM FAN BANK

ON/OFF

ADJUSTPRESSURE

AIR PRESSURE

ADJUSTMENT

G

PULL ROLL CLUTCH

ON/OFF

ADJUSTPRESSURE

AIR PRESSURE

AIR PRESSURE

ADJUSTMENT

ADJUSTMENT

H

PULL ROLL

UP/DOWN

ADJUSTPRESSURE

AIR PRESSURE

ADJUSTMENT

BOTTOM REWIND

TENSION PRESSURE

GAUGE

BOTTOM BRAKE

ADJUSTPRESSURE

OFF ON

BOTTOM CLUTCH

Fig. 2-2

REAR CONTROL PANEL

I

BOTTOM BRAKE

ON/OFF

AIR PRESSURE

ADJUSTMENT

J

BOTTOM CLUTCH

ON/OFF

© GBC Films Group June 2000

Page 5 - 3

Page 18

Operations

Orca 80-99 Operation and Maintenance Manual

Operator Controls

The operator controls for the Orca laminator are

operator position. See Figures 2-1 and 2-2. The names

and functions of these controls are as follows:

FRONT CONTROL PANEL

Please note that in each of the control sections there is a

Pressure Gauge, an On/Off switch and an Air Pressure

Regulator. The Pressure Gauge shows the operational

pressure. The On/Off switch turns the control function

on or off. The Air Pressure Regulator adjusts the air

pressure for the control function.

A. TOP BRAKE CONTROLS - Regulation of the

upper unwind shaft brakes.

B. TOP CLUTCH CONTROLS - Front upper rewind

shaft clutch regulation.

C. LAMINATOR ROLL CONTROLS - Regulation of

the main laminating rolls.

J. ON/OFF LAMP (Top Heater) - Denotes whether

the top heater controller is on or off.

K. ON/OFF LAMP (Bottom Heater) - Denotes

whether the bottom heater controller is on or off.

L. PHOTO EYE LAMP - Denotes whether or not the

PHOTO EYE is blocked.

M. MAIN POWER LAMP - Denotes whether or not

the main power is on the machine.

N. MAIN POWER SWITCH - Turns the

main power on and off.

REAR CONTROL PANEL

A. ON/OFF (Top Heater Controller) - Controls

whether or not the top heater controller is on or off.

B. TOP HEATER CONTROLLER - Controls the

upper main roll’s operational temperature and provides

a readout of the actual temperature.

D. BOTTOM BRAKE CONTROLS - Regulation of

the front lower unwind brake.

E. BOTTOM CLUTCH CONTROLS - Regulation of

the shaft’s lower front rewind clutch.

F. RUN/JOG SWITCH - Changes control of the

machine drive from a foot switch operation to

continuous run. It also allows the operator to “Jog” the

rolls for a short period of time.

G. REV-FWD - This switch controls the direction of

the drive system, forward or reverse.

H. SPEED CONTROL - Adjusts the speed of the

machine from zero to maximum as the control is turned

clockwise.

I. SPEED READOUT - Digital readout of the machine

speed and total throughput in either metric or standard

units.

C. ON/OFF (Top Fan Bank) - Controls whether or

not the top fan bank is on or off.

D. ON/OFF (Bottom Heater Controller) - Controls

whether or not the bottom heater controller is on or off.

E. BOTTOM HEATER CONTROLLER - Controls

the lower main roll’s operational temperature and

provides a readout of the actual temperature.

F. ON/OFF (Bottom Fan Bank) - Controls whether or

not the bottom fan bank is on or off.

G. PULL ROLLER CLUTCH CONTROLSRegulation for the bottom pull roller clutch.

CAUTION:

Use the minimum laminator roll pressure

consistent with good results. Excess pressure can

damage the laminating rollers.

Page 5 - 4

© GBC Films Group June 2000

Page 19

OperationsOrca 80-99 Operation and Maintenance Manual

H. PULL ROLLER PRESSURE CONTROLS -

Regulation for the upper pull roll pressure and up/down.

I. BOTTOM BRAKE CONTROL - Regulation for

the bottom rear unwind brake.

J. BOTTOM CLUTCH CONTROL - Regulation for

the bottom rear rewind shaft’s clutch.

Setup

Set up of the Orca laminator is quick and

straightforward when instructions are followed directly.

When you first receive the Orca Laminator the nips

must be set before operation. The procedures for

setting the main and pull roll nips are on pages 8-1 and

8-2.

Laminator Roll Pressure:

points to remember when loadingfilm:

CAUTION:

Assure that film is always mounted so that the

adhesive side will face outward from the

laminating roller.

1. The adhesive side of the film must be oriented away

(on the outside) of the laminating roller. Otherwise it will

immediately bond to the roller, creating a major cleanup project. Films have a shiny side and a dull side. The

dull side is the one with the adhesive. Thus, the dull side

should ALWAYS face outward from the laminating roll.

2. The film must be centered on the unwind for best

performance. This is vital when two films are fed

together. If the two films are not aligned, feed problems,

wrinkles, excess glue on rolls and other assorted

troubles will result.

1. You should use only the minimum amount of roll

pressure needed to accomplish the task. While higher

nip pressure can make the adhesive bond faster, excess

pressure can damage the rollers. Wrinkles, bubbles and

such have causes that generally cannot be cured with

more pressure.

2. A typical roll pressure for soft substrates such as

Foamcore or Orca-Board is between 20 to 30 pounds

per square inch (PSI) or 32 to 205 kPa.

3. The range of typical values for hard substrates is 25

to 50 PSI, 170 to 345 kPa.

Loading the Film

Film is loaded on the appropriate unwinds. Instructions

later in this section will cover loading and aligning film.

For applications such as encapsulation, film will be fed

from both top and bottom unwinds.

The process of loading and aligning film is the same for

both the top and the bottom. There are two important

CAUTION:

Unless the two films fed to the nip are carefully

aligned, poor results will be seen.

Positioning Film

The following procedure is applicable to both the top

and the bottom feed unwinds:

1. Remove the ball detent retaining pins and carefully

remove the unwind/rewind shaft from its saddles. Pay

particular attention to the drive side saddles. The drive

side of the shafts must be oriented so as to not pry on

the brake or clutch protrusion. To do so would

irreparably damage both brakes and clutches.

2. Slide the film onto the unwind shaft.

3. Install the shaft back into its saddles again paying

careful attention to the drive side end of the shaft.

Return ball detent pins to secure the shaft in its saddles.

© GBC Films Group June 2000

Page 5 - 5

Page 20

Operations

Orca 80-99 Operation and Maintenance Manual

4. Center the film by sliding it back and forth on the

shaft until centered. As soon as the film is unwound

from the shaft, the core support will lock the roll into

position.

5. Recheck the centering of the film roll with a tape

measure.

WARNING:

Normal operation of the Orca 80 laminator

involves the application of large amounts of heat

to the process materials. The surfaces of the rolls

are at a high enough temperature to cause burns if

they are touched.

Operators are cautioned not to touch, lean or fall

against the rolls of an operating laminator. Do not

become unbalanced when working near an

operating laminator.

laminating roller(s) to reach operating temperature.

When the pre-set operating temperature has been

reached, the machine is ready to use.

Cooling

(with optional cooling fans)

The following procedure is the fastest way to cool

down the machine. Natural cooling can also be

employed:

1. Set the heater switches to OFF.

2. Position the two rear fan banks so that they are tilted

to direct air flow at the rolls.

3. Set the Laminator Roll Control to the DOWN

position.

4. Set the Forward/Reverse switch to the FORWARD

position.

Heating

The following instructions should be employed when

heating one or both of the laminating rolls. The

procedure is the same for top and bottom:

1. Set the heater switch to ON.

2. Adjust the temperature controller for the desired

operating temperature using the controller push

bottoms.

For the Syrlec type controller use the up and down

arrows to adjust the set point. Hold down the desired

arrow until the correct set point is achieved.

For the CAL3200 it is necessary to press the * button

at the same time as the up or down arrow to adjust the

set point temperature.

3. When heating the rolls, keep the top roll down and

turning at a moderate speed to prevent uneven heating.

4. It will take approximately 25 minutes for the

5. Set the speed control to 5 fpm (150 cpm).

6. Let the machine run until the laminating rolls return to

room temperature.

Paper Tips

1. Always cut the leading edge of a print straight so they

can be fed perpendicular to the laminating rolls.

Process Control Charts

Chart 2-1 and 2-1B show a blank set of process

control charts for the ORCA 80. These charts are

where you record the way you thread film through the

machine’s rolls and idlers (called webbing) and the

setting of controls and switches for each product and

process.

GBC Pro-Tech laminators respond in a very accurate

and repeatable manner. The charts provide a way to set

up each time, every time, for repeatable performance

by assuring all controls are set to optimum.

Page 5 - 6

© GBC Films Group June 2000

Page 21

The process charts are also an excellent tool for training

new operators. They provide a “road map” for correct

machine setup and operation.

OperationsOrca 80-99 Operation and Maintenance Manual

B. Put a piece of contact/release paper over the print.

Otherwise, adhesive will be applied to the laminating

roller which can cause damage and the ink from

electrostatic prints will be deposited on the roll.

The process control charts should be kept in this

manual or in a book close to the Orca. Use the machine

to encapsulate the popular charts so they can withstand

coffee spills and will be available for ready reference.

In the rest of this section you will find completed

process control charts for the basic operations of the

machine. These are based on Orca-Film and OrcaBoard and typical prints. If you have a special

application use the blank charts to make your own

records.

Information:

When trying new products and processes,

remember that GBC Pro-Tech’s customer service

technicians are only a phone call away.

Mounting Only

1. Setup:

C. Feed the print/Orca board package though the nip.

Mounting/Laminating

The following procedure is for one-step mounting and

heat-activated laminating using mounting board with one

adhesive side such as Orca-Board.

1. Setup:

A. The setup is shown in process chart 2-3 and 2-3B.

B. Mount the film and web as shown in chart 2-3B.

C. Shims: Set the two front shim dials to 1/32 less than

board height.

D. Laminator Roll Pressure: 40 PSI, 275 kPa.

E. Speed: 3 fpm (90 cpm).

A. See process chart 2-2 and 2-2B.

B. Set Shims:

C. Upper Laminator Roll Pressure: 40 to 80 PSI, 275 -

550 kPa.

D. Speed: 3.

E. Upper Laminator Roll Heat: 245 degrees F, 118

degrees C.

Mounting Only (continued)

2. Procedure:

A. Lay the print on the board. Using a tack iron, tack

the leading edge of the print down onto the board so it

is held in place.

F. Upper Laminator Roll Heat: 245 degrees F, 118

degrees C.

G. Cooling: Off.

H. Film Roll Brake Pressure 20 PSI, 135 kPa.

2. Procedure:

A. Feed the Orca board dull (adhesive) side up with

the print positioned as desired. A tack iron may be used

to hold the leading edge of the print in place.

Encapsulation

1. Setup:

A. Refer to process chart 2-4 and 2-4B for webbing

instructions.

© GBC Films Group June 2000

Page 5 - 7

Page 22

Operations

Orca 80-99 Operation and Maintenance Manual

B. Shims: none.

C. Laminating Roller Pressure: 60 PSI, 410 kPa.

D. Pull Roller Clutch Pressure: On, 80 PSI, 550 kPa.

E. Pull Roller: Down, 60 PSI, 410 kPa.

F. Speed: 4 to 6 fpm

G. Top Roll Temperature: 220-230 degrees F (90 -

110 degrees C).

H. Bottom Roll Temperature: 220-230 degrees F (90 110 degrees C).

I. Cooling: Optional.

J. Use of the rear rewind for the finished material is

optional. It is a good procedure for long runs. If a

rewind is used in this application the clutch pressure

should be 15 PSI.

2. Procedure:

A. Feed the work into the nip with the leading edge

tight and entering the nip evenly from side to side. For

thin paper from electrostatic printers in roll form, it is

best to fold over the leading edge approximately 6

inches to create a square leading edge.

B. Trim to slightly larger than the desired finished size.

WARNING:

Take care when repositioning rewind/unwind

shafts or other heavy parts or materials, used in

the various web-up patterns. They are heavy and

can cause injury to fingers and/or toes if not

handled properly.

Procedure, Pass 2:

A. Prepare to put the print through a second time to

mount the print to the substrate. — anything from

wood, to Masonite, to Gator foam. Start by setting the

shims to the appropriate spacing for the material used.

B. Trim the board to the size of the print.

C. Align the work to the board and assure an exact fit.

Place weights on the center of the print to assure that it

does not move relative to the board during the next

steps.

D. Raise one end of the print and peel back

approximately two inches of the liner to expose the

adhesive that was applied to the print in pass 1. Fold it

under. Lay the print back down evenly and extremely

flat. From the center outward, tack the exposed

adhesive to the substrate.

Two-Pass Mount and

Laminate (Hot and Cold)

Cold/Mount Laminate

A. See charts 2-5, 2-5B, 2-6 and 2-6B for settings.

B. Assure that the mounting film from the bottom side

has the sticky adhesive side riding up around the outside

of the bottom laminating roller.

Procedure, Pass 1:

A. Run the print through to apply adhesive and

laminate.

Page 5 - 8

E. Position the piece so that the end with the liner

peeled back is facing the nip. Insert the first one inch of

the board into the nip.

F. Very carefully wrap the print back and over the top

laminating roll. Be sure there are no wrinkles in the nip

area. Carefully peel off the liner as the board progresses

through the laminator.

G. Trim the piece to the finished size.

Hot/Mount Laminate

A. Refer to charts 2-7, 2-7B, 2-8 and 2-8B.

B. Encapsulate image. (see chart 2-7)

© GBC Films Group June 2000

Page 23

C. Raise Main Roll (Hot).

D. Reverse Motor.

E. 2nd Pass: Set Nip Height and tack leading edge.

Run through as liner is being pulled off.

Cold Overlamination (Using a Sled)

1. Setup:

A. Refer to charts 2-9 and 2-9B

B. Set main roll shims to 3/16"

2. Procedure:

OperationsOrca 80-99 Operation and Maintenance Manual

A. Use a starter board to get the film started and

feeding without wrinkles.

B. Lay image on the sled and place it up against the

leader board.

C. Feed image through the nip following the leader

board into the nip. Maintain paper tension on the image

until it is through the nip.

D. Cut around the image with a sharp knife to remove

it from the leader board.

© GBC Films Group June 2000

Page 5 - 9

Page 24

Operations

Process:

Materials (top/bottom):

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-1

Front Control Panel

Adjustments

Top Brake Top Heat

Top Clutch Bottom Heat

Laminator Roller Top Cooling Fans

Bottom Brake (front) Bottom Cooling Fans

Bottom Clutch (front) Pull Roller Clutch

Forward/Reverse Pull Roller Pressure

Speed Bottom Brake (rear)

Laminator Roller Shims Bottom Clutch (rear)

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims

Page 5 - 10

© GBC Films Group June 2000

Page 25

OperationsOrca 80-99 Operation and Maintenance Manual

(I) REMOVABLE IDLER

(F) FIXED IDLER

(U) UNWIND SHAFT

(R) REWIND

(M) MAIN ROLL

(P) PULL ROLL

U

R

F

M

P

OUTFEED

SLITTER

I

F F F

M

U

F

P

R

IDENTIFICATION DIAGRAM

© GBC Films Group June 2000

R

U

Chart 2-1B

Page 5 - 11

Page 26

Operations

Process: Hot Mount, One Pass

Materials (top/bottom): /3/16" thick Hot tissue coated board

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-2

Front Control Panel

Adjustments

Top Brake OFF / NA Top Heat ON / 245o F (118o C)

Top Clutch OFF / NA Bottom Heat OFF / NA

Laminator Roller ON / 40 p.s.i. Top Cooling Fans OFF

Bottom Brake (front) OFF / NA Bottom Cooling Fans OFF

Bottom Clutch (front) OFF / NA Pull Roller Clutch OFF / NA

Forward/Reverse FORWARD Pull Roller Pressure OFF / NA

Speed 2 - 3 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims 3/16" Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims NA

Lay the image to be mounted on the board and push the board into the nip while the rolls are not

turning. Then, quickly, depress the foot switch to turn the rolls. Make sure to maintain good

paper tension while mounting the image.

Page 5 - 12

© GBC Films Group June 2000

Page 27

IMAGE

OperationsOrca 80-99 Operation and Maintenance Manual

245 °F

118 °C

COLD

CHART 2-2B

ONE PASS HOT MOUNT

© GBC Films Group June 2000

Page 5 - 13

Page 28

Operations

Process: Hot Mount and Laminate, One Pass

Materials (top/bottom): / 3/16" thick Hot tissue board

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-3

Front Control Panel

Adjustments

Top Brake ON / 20 p.s.i. Top Heat ON / 245o F (118o C)

Top Clutch OFF / NA Bottom Heat OFF / NA

Laminator Roller ON / 40 p.s.i. Top Cooling Fans OFF

Bottom Brake (front) OFF / NA Bottom Cooling Fans OFF

Bottom Clutch (front) OFF / NA Pull Roller Clutch OFF / NA

Forward/Reverse FORWARD Pull Roller Pressure OFF / NA

Speed 2 - 3 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims 3/16" Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims NA

Start the overlaminate with a leader board the same thickness as the board being mounted to.

While maintaining paper tension, lay the image to be mounted on the board and follow the leader

board into the nip.

Page 5 - 14

© GBC Films Group June 2000

Page 29

IMAGE

245

°F

118

°C

OperationsOrca 80-99 Operation and Maintenance Manual

COLD

CHART 2-3B

ONE PASS HOT MOUNT AND LAMINATE

© GBC Films Group June 2000

Page 5 - 15

Page 30

Operations

Process: Encapsulation

Materials (top/bottom): 3 mil Gloss / 3mil Gloss

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-4

Front Control Panel

Adjustments

Top Brake ON / 20 p.s.i. Top Heat ON / 230o F (110oC)

Top Clutch ON / 20 p.s.i. Bottom Heat ON / 230o F (110oC)

Laminator Roller ON / 60 p.s.i. Top Cooling Fans ON

Bottom Brake (front) ON / 20 p.s.i. Bottom Cooling Fans ON

Bottom Clutch (front) OFF / NA Pull Roller Clutch ON / 80 p.s.i.

Forward/Reverse FORWARD Pull Roller Pressure ON / 60 p.s.i.

Speed 4 - 6 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims 0 Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims 0

Page 5 - 16

© GBC Films Group June 2000

Page 31

230

°F

110

°C

OperationsOrca 80-99 Operation and Maintenance Manual

UNWIND

230

°F

110

°C

Chart 2-4B

© GBC Films Group June 2000

ENCAPSULATION

Page 5 - 17

Page 32

Operations

Process: Hot Overlaminate with Pressure Sensitive Mount Adhesive

Materials (top/bottom): 3 mil Gloss / Mount Adhesive

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-5

Front Control Panel

Adjustments

Top Brake ON / 20 p.s.i. Top Heat ON / 230o F (110oC)

Top Clutch OFF / NA Bottom Heat OFF / NA

Laminator Roller ON / 60 p.s.i. Top Cooling Fans OFF

Bottom Brake (front) ON / 20 p.s.i. Bottom Cooling Fans OFF

Bottom Clutch (front) OFF / NA Pull Roller Clutch ON / 80 p.s.i.

Forward/Reverse FORWARD Pull Roller Pressure ON / 60 p.s.i.

Speed 4 - 6 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims 0 Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims 0

The encapsulated image will have waves running 90 degrees to the feed of the film. This is due

to the moisture in the mount adhesive’s release liner. Once mounted the waves disappear.

Page 5 - 18

© GBC Films Group June 2000

Page 33

230 °F

110 °C

OperationsOrca 80-99 Operation and Maintenance Manual

UNWIND

COLD

UNWIND

Chart 2-

5B

TWO PASS HOT OVERLAMINATE

WITH PRESSURE SENSITIVE MOUNT ADHESIVE

FIRST PASS

© GBC Films Group June 2000

Page 5 - 19

Page 34

Operations

Process: Hot overlaminate with Pressure Sensitive Mount Adhesive (Second Pass)

Materials (top/bottom): / 3/16" Foamcore

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-6

Front Control Panel

Adjustments

Top Brake OFF / NA Top Heat OFF / NA

Top Clutch OFF / NA Bottom Heat OFF / NA

Laminator Roller OFF / NA Top Cooling Fans OFF

Bottom Brake (front) OFF / NA Bottom Cooling Fans OFF

Bottom Clutch (front) OFF / NA Pull Roller Clutch ON / 40 p.s.i.

Forward/Reverse REVERSE Pull Roller Pressure ON / 30 p.s.i.

Speed 2 - 3 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims N/A Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims 3/16"

When mounting keep an even wrap around the upper pull roll to eliminate any wrinkles due to

uneven feed of the image. During the mounting process, it is also helpful to have a table the

same height as the pull roller nip to help feed the board and image into the pull rollers.

Page 5 - 20

© GBC Films Group June 2000

Page 35

COLD

OperationsOrca 80-99 Operation and Maintenance Manual

RELEASE

LINER

COLD

Chart 2-6B

TWO PASS HOT OVERLAMINATE

WITH PRESSURE SENSITIVE MOUNT ADHESIVE

SECOND PASS

© GBC Films Group June 2000

Page 5 - 21

Page 36

Operations

Process: Cold overlaminate with pressure sensitive mount adhesive

Materials (top/bottom): PSA Laminate/ PSA Mount Adhesive

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-7

Front Control Panel

Adjustments

Top Brake ON / 40 p.s.i. Top Heat ON / 115° F (46oC)

Top Clutch ON / 20 p.s.i. Bottom Heat OFF / NA

Laminator Roller ON / 40 p.s.i. Top Cooling Fans OFF

Bottom Brake (front) ON / 20 p.s.i. Bottom Cooling Fans OFF

Bottom Clutch (front) OFF / NA Pull Roller Clutch ON / 60 p.s.i.

Forward/Reverse FORWARD Pull Roller Pressure ON / 60 p.s.i.

Speed 4 - 6 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims 0 Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims 0

Page 5 - 22

© GBC Films Group June 2000

Page 37

RELEASE

PAPER

REWIND

OperationsOrca 80-99 Operation and Maintenance Manual

UNWIND

115 °F

46 °C

COLD

MOUNT

ADHESIVE

UNWIND

Chart 2-7B

TWO PASS COLD OVERLAMINATE

WITH PRESSURE SENSITIVE MOUNT ADHESIVE

FIRST PASS

© GBC Films Group June 2000

Page 5 - 23

Page 38

Operations

Process: Cold overlaminate with pressure sensitive mount adhesive (second pass)

Materials (top/bottom): / 3/16" Foamcore

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-8

Front Control Panel

Adjustments

Top Brake OFF / NA Top Heat OFF / NA

Top Clutch OFF / NA Bottom Heat OFF / NA

Laminator Roller ON / 30 p.s.i. Top Cooling Fans OFF

Bottom Brake (front) OFF / NA Bottom Cooling Fans OFF

Bottom Clutch (front) OFF / NA Pull Roller Clutch OFF / NA

Forward/Reverse FORWARD Pull Roller Pressure OFF / NA

Speed 2 - 3 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims 3/16" Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims N/A

When mounting keep an even wrap around the upper main roll to eliminate any wrinkles due to

uneven image feed.

Page 5 - 24

© GBC Films Group June 2000

Page 39

RELEASE

LINER

115

46

°F

°C

OperationsOrca 80-99 Operation and Maintenance Manual

COLD

Chart 2-8B

TWO PASS COLD OVERLAMINATE

WITH PRESSURE SENSITIVE MOUNT ADHESIVE

SECOND PASS

© GBC Films Group June 2000

Page 5 - 25

Page 40

Operations

Process: Cold Overlam only (using a sled)

Materials (top/bottom): Pro-Gloss / 3/16" board (to be used for the sled)

Orca 80-99 Operation and Maintenance Manual

PROCESS CONTROL CHART 2-9

Front Control Panel

Adjustments

Top Brake ON / 40 p.s.i. Top Heat ON / 115o F (46oC)

Top Clutch ON / 20 p.s.i. Bottom Heat OFF / NA

Laminator Roller ON / 40 p.s.i. Top Cooling Fans OFF

Bottom Brake (front) OFF / NA Bottom Cooling Fans OFF

Bottom Clutch (front) OFF / NA Pull Roller Clutch OFF / NA

Forward/Reverse FORWARD Pull Roller Pressure OFF / NA

Speed 4 - 6 f.p.m. Bottom Brake (rear) OFF / NA

Laminator Roller Shims 3/16" Bottom Clutch (rear) OFF / NA

Helpful Hints/Notes:

Rear Control Panel

Adjustments

Pull Roller Shims NA

Use a starter board of the same thickness as the sled being used to start the laminate into the nip.

Lay the image on the sled and follow the leader board into the nip while maintaining paper

tension on the image being overlaminated.

Page 5 - 26

© GBC Films Group June 2000

Page 41

3/16"STARTER

BOARD

3/16" FOAMBOARD

OperationsOrca 80-99 Operation and Maintenance Manual

UNWIND

RELEASE

PAPER

REWIND

IMAGE

115 °F

46 °C

COLD

© GBC Films Group June 2000

Chart 2-9B

COLD OVERLAMINATE

Page 5 - 27

Page 42

MAINTENANCE

MaintenanceOrca 80-99 Operation and Maintenance Manual

Introduction

WARNING:

Some maintenance procedures require opening the

cabinets while the power and air are still

connected to the machine.

Because of the potential for electrical shock from

wiring and crushing of fingers or arms in rotating

apparatus, only properly trained personnel should

perform these tasks.

CAUTION:

Never attempt maintenance on an operating

machine unless the instructions specifically call for

it.

GBC Pro-Tech laminators require minimal

maintenance. However, regular maintenance is

essential to keep any piece of precision machinery

at peak performance. The following procedures

are segmented into daily, monthly, biannual, and

as-required procedures.

Monthly

Setting the Nip:

The gap between the two laminator rolls and the

secondary drive rollers is called the nip or roll nip. It

should be checked once a month. They should be

adjusted according to the following procedures.

Main Roll Nip Setting Procedure:

1. Make sure that the machine has both power and air.

It is also necessary to make sure that the up/down rates

of the upper main roll are even prior to setting the nip; if

not follow the rate adjusting procedure on page 4-2.

Please note that the main rolls have to be cold (room

temperature) when performing this procedure.

2. Remove the shims and set the main roll pressure to

40 psi. Note that this must be done with the upper

main roll in its fully up position.

3. Loosen main roll air cylinder caps and spin them to

their fully up position.

Daily

1. Clean the Laminating Rolls:

The silicone laminating rolls can be cleaned of dust and

dirt by passing an adhesive-coated board through the

nip. (Of course, the nip should be set for the thickness

of the board used). A mild dishwashing detergent can

also be used to clean the rolls. However a better

procedure is to use isopropyl alcohol and a 100percent cotton terry rag.

Samples of these two items were supplied in the

accessory kit shipped with the machine.

© GBC Films Group June 2000

4. Lower the upper main roll and spin down the main

roll air cylinder caps until they are finger tight and

secure.

5. Raise the upper main roll. The main roll nip is now

set.

Pull Roll Nip Setting Procedure:

1. Make sure that the machine has both power and air

and that both cabinets are open. It is also necessary to

make sure that the up/down rates of the upper pull roll

are even prior to setting the nip; if not follow the rate

adjusting procedure on the adjacent column.

2. Remove the shims and set the pull roll pressure to

40 psi. The upper pull roll should be in the fully up

position when making these adjustments.

Page 6 - 1

Page 43

Maintenance

Orca 80-99 Operation and Maintenance Manual

3. Loosen both pull roll air cylinder caps and spin them

to their fully up position.

4. Lower the upper pull roll and spin down the pull roll

air cylinder caps until they are finger tight and secure

them. The pull roll nip is now set.

Cylinder Up/Down Rate Adjustment:

If the upper laminating roll or upper pull roll moves up

or down unevenly, the cylinder flow controls need to be

adjusted.

Turn them clockwise to slow the up/down rate and

counter-clockwise to increase the up/down rate. To

correct for uneven motion, when the roll is going up,

adjust the flow controls at the top of the air cylinders.

To adjust for uneven lowering, set the air pressure on

the laminating roll regulator at 100 pounds per square

inch (PSI), 690 kPa, and make the necessary

adjustments to the flow controls on the bottom of the air

cylinders.

As Needed

Chain Tensioning:

1. Make sure that the machine has air only, no power,

and that the right (drive side) cabinet is open (see the

diagram on page 8-3).

2. Using a large adjustable wrench turn the appropriate

chain tensioner until the desired chain tension is

achieved. Make sure that the chain tension of each of

the three chains is fairly close. If not it might cause

stuttering in the feed of the laminator.

Six Months

1. Lubrication:

Disconnect the power and air supply to the machine.

Then, remove the end panels.

Lubricate the bearings on the ends of each laminating

roll (two per roll) with a high temperature grade of

bearing grease, such as Lubriplate 930-2 or equivalent

from a standard grease gun. Also lubricate the flange

bearing on the bottom secondary drive roll (pull roller).

Lubricate by hand the slots that both the upper main

and pull rolls slide up and down in.

Complete the lubrication by wiping the entire length of

the chain with an oily rag. It is also important to note

that over-lubrication of bearings is a leading cause of

bearing failure. Close the side panels, and reconnect the

electrical power and air supply.

Page 6 - 2

© GBC Films Group June 2000

Page 44

PRIMARY

MaintenanceOrca 80-99 Operation and Maintenance Manual

SECONDARY

CHAIN

TENSIONERS

CHAIN 3

CHAIN 4

CHAIN TENSION

© GBC Films Group June 2000

DIAGRAM

Page 6 - 3

Loading...

Loading...