Page 1

62FM Laminator

INSTALLATION &

OPERATION MANUAL

Document Number: 930-124 REV: - REV DATE: 11-24-04

Do not duplicate without written permission.

Page 2

62FM LAMINATOR

Operating Instructions

2

Page 3

Operating Instructions

TABLE OF CONTENTS

62FM LAMINATOR

1. Safety

Important Safety Instructions .................................1-1

Important Safeguards .............................................1-1

General ............................................................... 1-1

Electrical ............................................................1-2

Service ....................................................................1-2

2. Warranty

Limited 90-Day Warranty ........................................2-1

3. Specifications

Laminator Specifications ........................................3-1

FCC Note ................................................................ 3-2

Intended Films and Applications ........................... 3-2

Thermal and PSA Films ..................................... 3-2

Applications ....................................................... 3-2

4. Installation

Pre-Installation ........................................................4-1

Installation ...............................................................4-1

5. Control Guide

Control Panel ..........................................................5-1

Control Panel Display .........................................5-1

Roller Position Indicator ......................................5-1

Ready/Wait Indicator ..........................................5-1

Positioning Indicator ...........................................5-1

Master Dial ..........................................................5-1

Top Temp. ...........................................................5-1

Bottom Temp. .....................................................5-1

Press/Release .....................................................5-1

Cooling ................................................................5-1

Job ......................................................................5-1

Speed ................................................................. 5-2

Rev ..................................................................... 5-2

Stop .................................................................... 5-2

Run ..................................................................... 5-2

Rewinder Selection Switch ................................ 5-2

Upper Rewinder Direction Switch ..................... 5-2

Lower Rewinder Direction Switch ..................... 5-2

Rear Control Switch ........................................... 5-3

Enable Rear Control Switch ............................... 5-3

Disable Rear Control Switch .............................. 5-3

Foot SW Enable ................................................. 5-3

Features ................................................................ 5-4

Power I/O (On/Off) ............................................ 5-4

Emergency Stop ................................................ 5-4

Safety Shield ...................................................... 5-4

Safety Shield Interlock Latch ........................ 5-5

Feed Table ......................................................... 5-5

Heat Rollers ....................................................... 5-5

Film Shaft ........................................................... 5-5

Lower Shaft Cradle ............................................ 5-5

Tension Adjustment Knobs ................................ 5-5

Rewind Shaft ..................................................... 5-5

Rewind Tube ...................................................... 5-5

Rewind Adaptors ............................................... 5-5

Idler Bar ............................................................. 5-6

Chill Idler ............................................................ 5-6

Cooling Fan ........................................................ 5-6

Pull Rollers ......................................................... 5-6

Rear Table .......................................................... 5-6

Core Chucks ...................................................... 5-6

Separator Bar ..................................................... 5-6

Roller Handle ..................................................... 5-6

Film Web ............................................................ 5-

Nip Point ............................................................ 5-6

Foot switch .........................................................5-7

6. Operating Instructions

General Operation ......................................................1

Standby Mode .......................................................2

Setting Jobs Into Memory .....................................2

Film Loading & Threading ..........................................2

Loading Film ...............................................................3

Loading Thermal Film ................................................3

Top Thermal Film ..................................................3

Bottom Thermal Film .............................................4

Loading AccuShield Film ...........................................4

Loading PSA Film .......................................................5

Top PSA Film .........................................................5

Bottom PSA Mount Film ........................................6

Loading Mount Adhesive ...........................................6

Top Mount Adhesive ............................................. 6

Bottom Mount Adhesive ........................................ 7

Threading Card Procedure ........................................7

Tacking New Film to Existing Film .............................8

To Unweb the Laminator ............................................9

Clearing a Film Jam (Wrap-up) ..................................9

Applications .............................................................10

Tips for Pre-coating Boards ................................10

Tips for Using the Rear Rollers ............................ 10

Tips for Mounting on Pre-coated Boards ............ 11

Tips for PSA Encapsulation ................................. 11

Tips for Thermal Encapsulation ........................... 11

Tips for AccuShield ..............................................12

Lamination Guide ..................................................... 12

Basic Rules ..........................................................12

Film Tension .........................................................13

Heat ......................................................................13

Output ..................................................................13

6

i

Page 4

62FM LAMINATOR

7. Operator Maintenance

Maintaining the 62FM Laminator ............................ 7-1

Cleaning the Rollers ............................................7-1

Troubleshooting ......................................................7-2

Operating Instructions

ii

Page 5

Operating Instructions

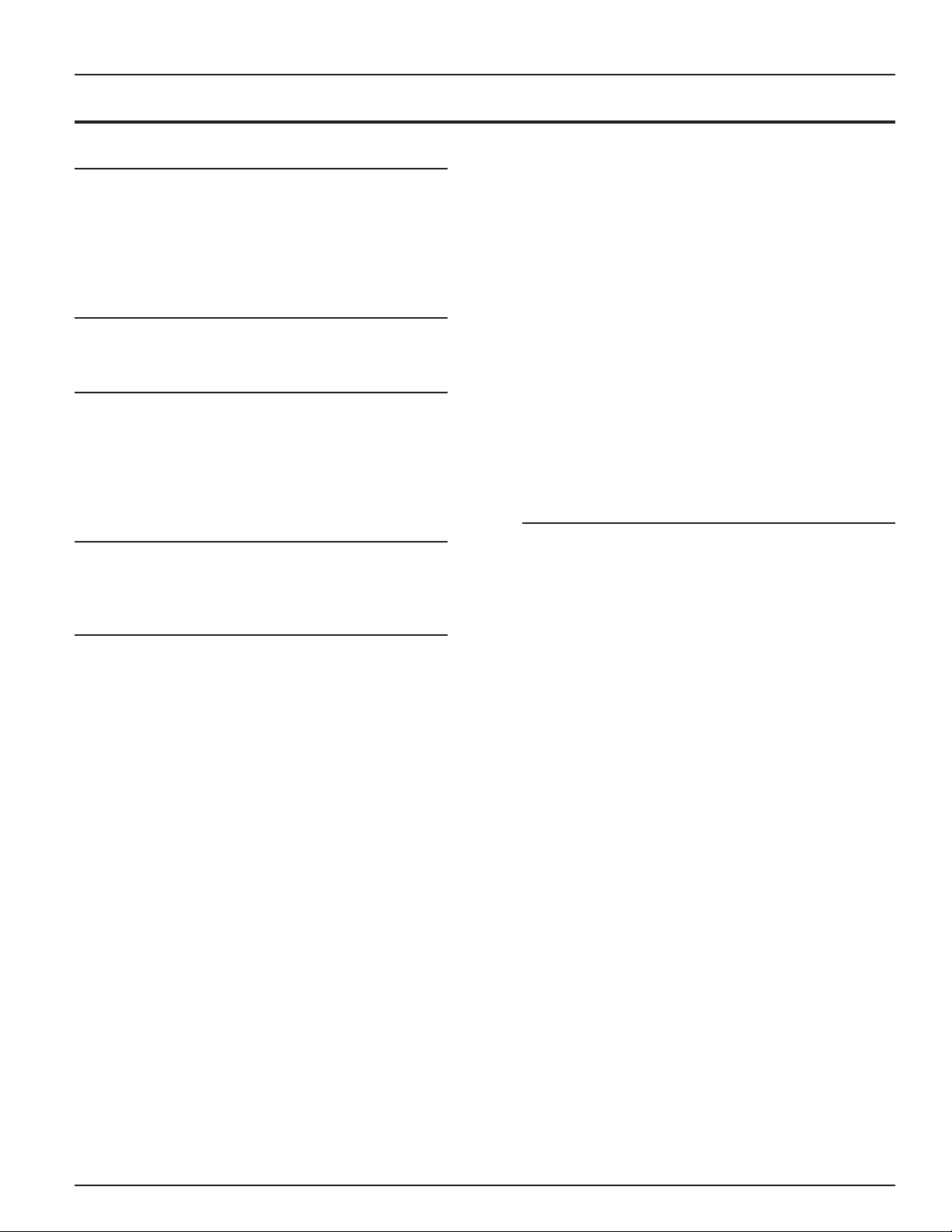

ADVERTENCIA

!

Riesgo de choque

eléctrico

No abra:

Adentro no hay

piezas reparables

por el usuario.

Mantenimiento

solamente por

personal

calificado

ATTENTION

!

Risque de

secousse

électrique.

Ne pas ouvrir.

Pas de pièces

réparables par

l'utilisateur.

Entretien

seulement par

personnel qualifié.

WARNING

!

Electrical shock

hazard.

Do not open.

No user

serviceable

parts inside.

Refer servicing to

qualified service

personnel.

ADVERTENCIA

ATTENTION

!

CAUTION

!

RODILLOS

CALIENTES.

PUNTO DE

PINCHAMIENTO.

Mantener manos y

ropa a distancia.

ROULEAUX

CHAUDS.

POINT DE

PINCEMENT.

Tenir mains et

vêtements à l'écart.

HOT ROLLS.

PINCH POINT.

Keep hands and

clothing away.

!

1. SAFETY

IMPORTANT SAFETY INSTRUCTIONS

Your safety as well as the safety of others is

important. In this instruction manual and on the

product, you will find important safety messages

regarding the product. Read these messages

carefully. Read all of the instructions and save these

instructions for later use.

WARNING: The safety alert symbol precedes

each safety message in this instruction manual. The

symbol indicates a potential personal safety hazard

to you or others.

This safety alert symbol indicates a potential

electrical shock. It warns you to not open the

laminator and expose yourself to hazardous voltage.

62FM LAMINATOR

Hot surface. Use caution as hot surface could cause

burns.

The following warnings are found upon this product.

This safety message means that you could be

seriously hurt or killed if you open the product and

expose yourself to hazardous voltage.

This safety message means that you could be

burned and your fingers and hands could be trapped

and crushed in the hot rollers. Clothing, jewelry and

long hair could be caught in the rollers and pull you

into them.

IMPORTANT SAFEGUARDS

WARNINGS:

Do not attempt to service or repair the laminator.

•

Do not connect the laminator to an electrical

•

supply or attempt to operate the laminator until

you have completely read these instructions.

Maintain these instructions in a convenient

location for future reference.

To guard against injury, the following safety

•

precautions must be observed when installing and

using the laminator.

Failure to observe these warnings could result in

severe bodily damage or death.

GENERAL

Keep hands, long hair, loose clothing, and articles

•

such as necklaces or ties away from the front of

the heat and pull rollers to avoid entanglement and

entrapment.

The heat rollers can reach temperatures over

•

300 ˚F (150 °C). Avoid contact with the heat rollers

during operation or shortly after power has been

removed from the laminator.

Do not use the laminator for other than its

•

intended purpose.

Avoid moving the laminator on uneven floor

•

surfaces. Never tilt the laminator.

Do not defeat or remove electrical and mechanical

•

safety equipment such as interlocks, shields and

guards.

Do not insert objects unsuitable for lamination or

•

expose the equipment to liquids.

1-1

Page 6

62FM LAMINATOR

ELECTRICAL

The laminator should be connected only to a source

of power as indicated in these instructions and on

the serial plate located on the rear of the laminator.

Contact an electrician should the attachment

plug provided with the laminator not match the

receptacles at your location.

CAUTION: The receptacle must be located

near the equipment and easily accessible.

Disconnect the plug from the receptacle and contact

your dealer/distributor when one or more of the

following has occurred.

The power supply cord or attachment plug is

•

damaged.

Liquid has been spilled into the laminator.

•

The laminator is malfunctioning after being

•

mishandled.

The laminator does not operate as described in

•

these instructions.

Operating Instructions

SERVICE

Perform only the routine maintenance procedures

referred to in these instructions.

Warning : Do not attempt to service or repair

the laminator. Failure to observe this warning could

result in severe bodily damage or death.

1-2

Page 7

Operating Instructions

2. WARRANTY

LIMITED 90-DAY WARRANTY

The Manufacturer warrants to the original purchaser

for a period of ninety days on labor and one year on

parts after installation that this laminator is free from

defects in workmanship and material under normal

use and service. The Manufacturer’s obligation

under this limited warranty is limited to replacement

or repair, at The Manufacturer’s option, of any part

found defective by the Manufacturer without charge

for material or labor.

THIS LIMITED WARRANTY IS IN LIEU OF ALL

OTHER WARRANTIES EXPRESSED OR IMPLIED.

WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE ARE

EXPRESSLY EXCLUDED. ANY REPRESENTATIONS

OR PROMISES INCONSISTENT WITH, OR IN

ADDITION TO, THIS LIMITED WARRANTY ARE

UNAUTHORIZED AND SHALL NOT BE BINDING

UPON THE MANUFACTURER. IN NO EVENT

SHALL THE MANUFACTURER BE LIABLE FOR

ANY SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER OR NOT FORESEEABLE.

62FM LAMINATOR

This limited warranty shall be void if the laminator

has been misused; mishandled; damaged by

negligence, by accident, during shipment, or

due to exposure to extreme conditions; repaired,

altered, moved, or installed by anyone other than

the Manufacturer or its authorized agents; or if

incompatible film was used. The Manufacturer’s

obligation under this limited warranty does not

include routine maintenance, cleaning, adjustment,

normal cosmetic or mechanical wear, or freight

charges.

Without limiting the generality of the previous

paragraph, the Manufacturer’s obligation under this

limited warranty does not include:

Damage to the rollers caused by knives, razors,

1.

or other sharp tools; by any foreign objects

falling into the working area of the laminator;

or by cleaning the laminator with solutions or

materials that harm its surfaces;

Damage caused by adhesives; nor

2.

Damage caused by lifting, tilting or attempting to

3.

position the laminator other than rolling it on its

casters across even surfaces.

2-1

Page 8

62FM LAMINATOR

Operating Instructions

2-2

Page 9

Operating Instructions

3. SPECIFICATIONS

62FM LAMINATOR

LAMINATOR SPECIFICATIONS

Operating Speed:

Up to 10 fpm (3 mpm)

Max Temperature:

300 °F (150 °C)

Max. Mounting Thickness:

1/2 in. (1.3 cm)

Max. Film Width:

61 in. (155 cm)

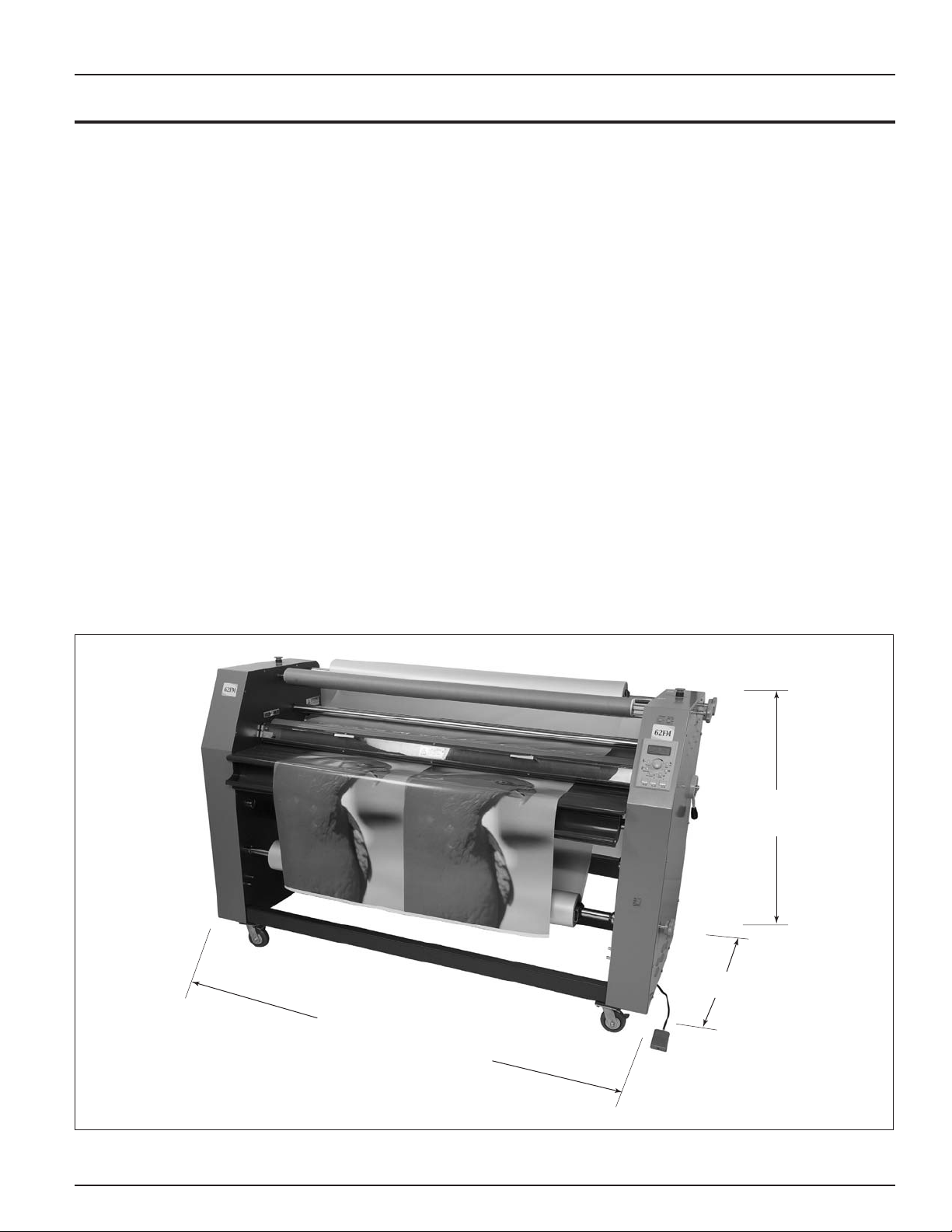

Dimensions (W X D X H)

Unit alone:

83 in. × 40.25 in. × 51.5 in.

(211 cm × 102 cm × 131 cm)

Shipping: 85 in. × 43 in. × 62.5 in.

(216 cm × 109 cm × 159 cm)

Weight:

Unit alone: 1030 lb. (467 kg.)

Shipping: 1250 lb. (567 kg.)

Electrical Requirements:

Refer to the serial plate located on the rear of the

laminator for the specific electrical rating applicable

to the unit.

U.S. Receptacle: NEMA 6-50R

Voltage: 220 V, 60 Hz

Current: 20.5 A

Power: 4500 W

Phase:

Interrupting Capacity: 1500 A

Ambient Air Temperature: 41 to 104 °F (5 to 40 °C)

Humidity Rating: 30 to 95% non-condensing

Altitude Rating: Up to 2540 Feet (1000 Meters Min..)

1

83 (211 cm)

Fig. 3-1. 62FM Dimensions. (Shown in inches (cm).)

51.5 (131 cm)

40.25 (102 cm)

3-1

Page 10

62FM LAMINATOR

Operating Instructions

FCC NOTE

This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment. This

equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference in which case the

user will be required to correct the interference at

his/her own expense.

Changes or modifications not expressly approved by

the manufacturer could void the user’s authority to

operate the equipment.

This Class A digital apparatus complies with

Canadian ICES-003.

(Cet appareil numérique de las Classe A est

conforme a la norme NMB-003 du Canada.

INTENDED FILMS AND APPLICATIONS

THERMAL AND PSA FILMS

Octiva™ Thermal

•

Octiva™ Lo-Melt

•

Artic™ Pressure Sensitive

•

Artic™ Mounting Films

•

AccuShield™

•

APPLICATIONS

Signs

•

Posters

•

Event Graphics

•

Trade Show Graphics

•

Presentations

•

Banners

•

Store Signage

•

Floor Graphics

•

Backlit Displays

•

Vehicle Graphics

•

3-2

Page 11

Operating Instructions

4. INSTALLATION

PRE-INSTALLATION

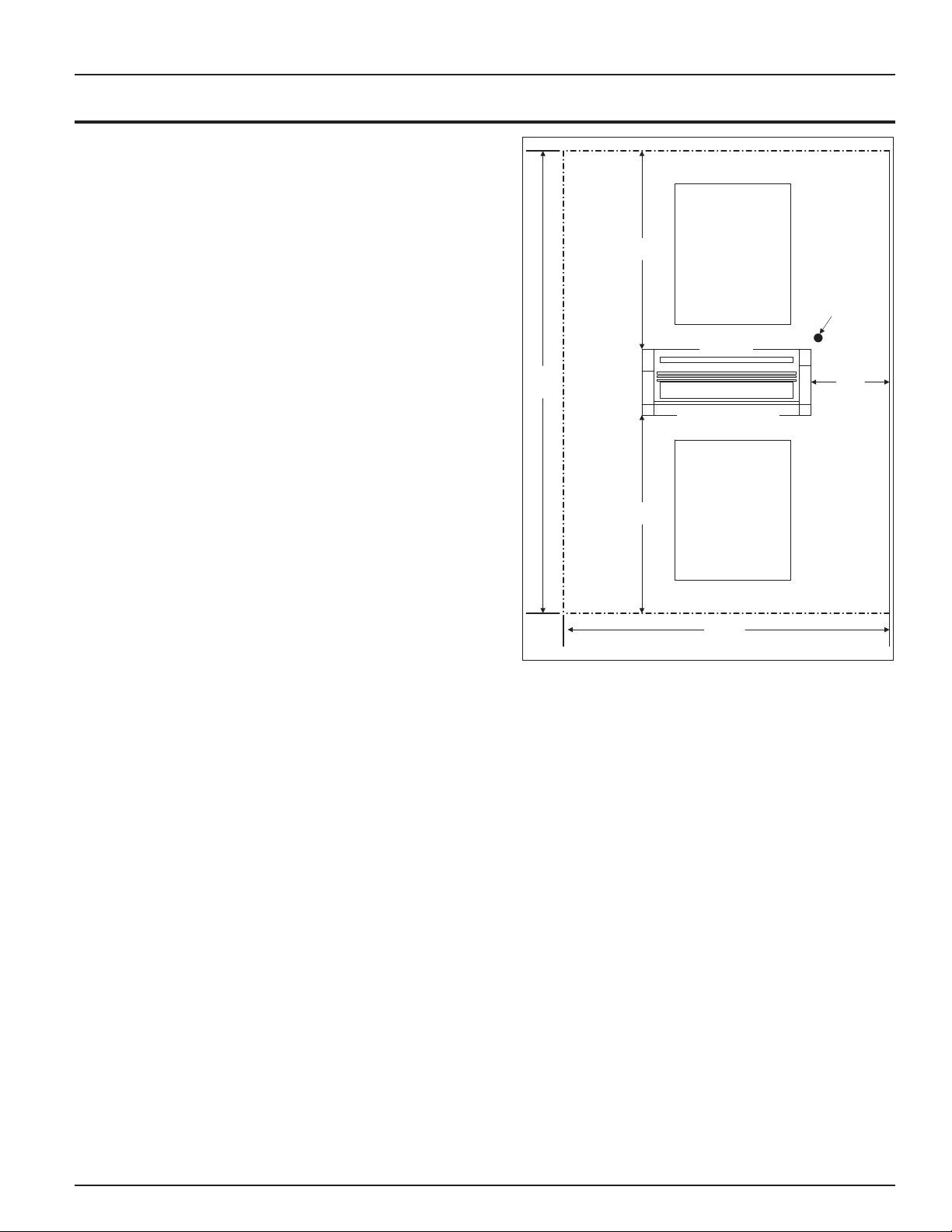

Before 62FM laminator can be installed, ensure the

following requirements are met;

Are doorways and hallways wide enough for the

1.

laminator to be moved to the installation site?

Is there ample room for the laminator?

2.

A work area must be established that

a.

allows for operation in both the front and

rear of the laminator and provides space

for efficient material flow. (Fig. 4-1)

Is the environment appropriate for the laminator?

3.

The laminator requires a clean, dust

a.

and vapor free environment to operate

properly.

Avoid locating the laminator near sources

b.

of heat or cold. Avoid locating the

laminator in the direct path of forced,

heated or cooled air.

CAUTION: Air flow can cause uneven heating/ cooling

of the rollers and result in poor output quality.

20 ft

(508 cm)

8 ft 8 in

(220 cm)

8 ft 8 in

(220 cm)

62FM LAMINATOR

4 ft. × 6 ft.

(101.6 × 152 cm)

Work table on

wheels

Back

Front

4 ft. × 6 ft.

(101.6 × 152 cm)

Work table on

wheels

13 ft

(330 cm)

Electrical

cord

drop

3 ft

(91 cm)

Have you contacted a certified electrician to

4.

wire the receptacle and ensure that adequate

power is being supplied, having the appropriate

capacity, over current protection and safety

lockouts available?

INSTALLATION

Shipping damage should be brought to the

1.

immediate attention of the delivering carrier.

With assistance, carefully roll the laminator into

2.

position over flat and even surfaces.

The laminator should be positioned to allow

3.

exiting film to flow freely to the floor or a work

table. Accumulation of laminate immediately

behind the laminator as it exits the equipment

may cause the film to wrap around the pull

rollers, resulting in a jammed condition.

Once the laminator has been properly positioned,

4.

lock the casters in place. Locking the casters

prevents the machine from rolling during set up,

operation, and servicing.

Fig. 4-1. Space Requirements.

The heaters must be installed by a qualified

5.

service technician.

Connect the attachment plug provided with the

6.

laminator to a suitably grounded outlet. Avoid

connecting other equipment to the same branch

circuit to which the laminator is connected, as

this may result in nuisance tripping of circuit

breakers or blowing fuses.

4-1

Page 12

62FM LAMINATOR

Operating Instructions

4-2

Page 13

Operating Instructions

Top Temp.

Bottom Temp.

Rev. Stop Run

Cooling

Press/Release

Job

Speed

TOP>032˚F

BOT>032˚F

RELEASE

WAIT

SPEED>03

JOB>01

5. CONTROL GUIDE

62FM LAMINATOR

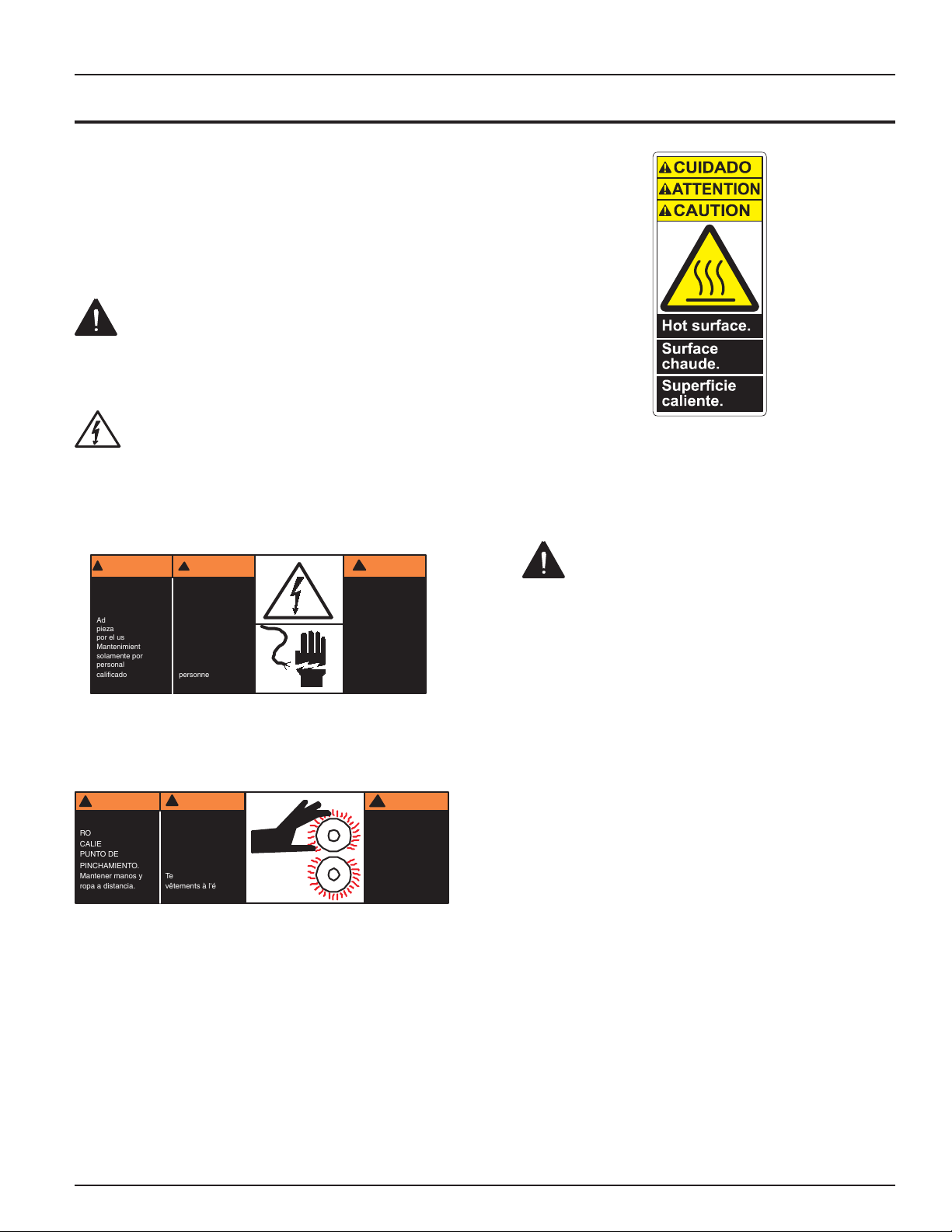

CONTROL PANEL

POSITIONING INDICATOR

Positioning... appears in place of the ready/wait

indicator any time the main rollers are traveling in an

upward or downward motion.

MASTER DIAL

Increases (+) or decreases (-) the numeric value for

the selected setting when turned. Press and hold the

dial to display actual temperature of top and bottom

main rollers.

TOP TEMP.

When pressed, permits increasing or decreasing of

the top temperature by turning the Master Dial

and is indicated on the control panel display. Range

is room temperature up to 300 °F (150 °C).

BOTTOM TEMP.

When pressed, permits increasing or decreasing

of the bottom temperature by turning the MASTER

DIAL and is indicated on the control panel

display. Range is room temperature up to 300 °F

(150 °C).

CONTROL PANEL DISPLAY

Illuminates when the laminator is plugged in and

POWER I/O is in the on, (I), position. Displays

settings for top heater, bottom heater, speed, job,

mode, and ready/wait status and roller position

indicator.

ROLLER POSITION INDICATOR

Displays the current main roller position. In Fig. 5-1,

the roller is shown in the Release position. Refer to

Roller Handle for more information.

READY/WAIT INDICATOR

READY appears when actual temperature is equal

to (+/- 5) set temperature. WAIT appears when

actual temperature is lower or higher than the set

temperature.

Fig. 5-1. Control Panel.

PRESS/RELEASE

When pressed, raises the upper main roller

overriding the pull roller handle setting. When

pressed again, reverts to current pull roller handle

setting.

COOLING

When pressed, turns on the cooling fans. When

pressed again, turns off the cooling fans.

JOB

When pressed, permits scrolling of job numbers by

turning the MASTER DIAL and is indicated on the

control panel display. Range is 1 to 10. Job 10 is

reserved for running AccuShield material.

To store parameters for a particular job number,

select the desired job number location, enter the

upper and lower temperatures and speed, then press

Job.

5-1

Page 14

62FM LAMINATOR

SPEED

When pressed, permits increasing or decreasing of

speed by turning the MASTER DIAL and is indicated

on the control panel display. Range is 1 to 10.

Operating Instructions

UPPER REWINDER DIRECTION SWITCH

This switch enables the operator to control the

direction of the upper rewind/unwind shafts.

FWD: In this position, the motor runs in a forward

direction.

REV

When pressed and held, reverses roller movement to

clear film jams and wrap-ups.

STOP

Stops the movement of the rollers.

RUN

When pressed, activates rollers for normal operation.

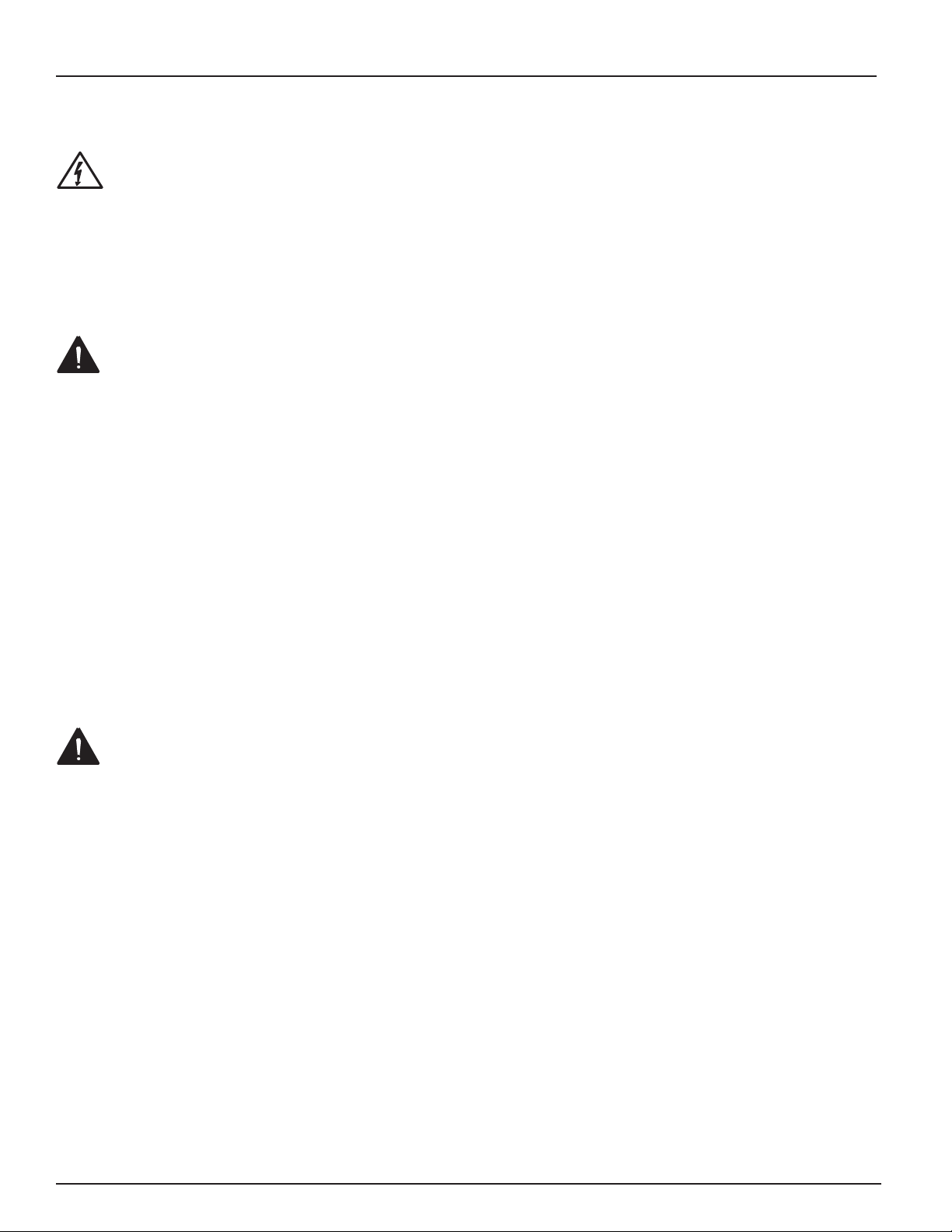

REWINDER SELECTION SWITCH

These switches enable the operator to control the

function of the upper rewind/unwind shafts.

Rewinder

switch

Upper rewinder direction switch

STOP: Stops the rewinder motor for the

rewind/unwind shaft selected.

REV.: In this position, the motor runs in a reverse

direction.

LOWER REWINDER DIRECTION SWITCH

(Not shown.) This switch enables the operator to

control the direction of the lower rewind/unwind

shaft.

FWD.: In this position, the motor runs in a forward

direction.

STOP: Stops the rewinder motor for the

rewind/unwind shaft selected.

REV. In this position, the motor runs in a reverse

direction.

Fig. 5-2. Rewinder Selection Switches.

I In this position, turns the power on to the upper

front rewind/unwind shaft.

In this position, neither the upper front or upper

rear rewind/unwind shaft is selected for motor power.

II In this position, turns the power on to the upper

rear rewind/ unwind shaft.

5-2

Page 15

Operating Instructions

REAR CONTROL SWITCH

This switch enables the operator to run jobs from the

rear operating position of the laminator when rear

controls are enabled.

Rear control switch

Fig. 5-3. Rear Control Switch.

62FM LAMINATOR

REVERSE: In this position, the rollers turn from the

front operating position towards the rear operating

position.

STOP: Stops the movement of the rollers.

RUN: In this position, the rollers turn from the rear

operating position towards the front operating

position.

ENABLE REAR CONTROL SWITCH

To enable the rear control switch, press and hold

Job until you hear a beep, approximately 3 seconds.

REAR CONTROL replaces READY/WAIT on the

control panel display.

DISABLE REAR CONTROL SWITCH

Press and hold Job again to disable the rear control

switch.

FOOT SW ENABLE

In this mode permits operation using the foot switch.

To enable the foot switch, press and hold the STOP

button for three seconds. Repeat this process to

disable it. Refer to Foot switch for operation.

5-3

Page 16

62FM LAMINATOR

Operating Instructions

Idler bar

Heat rollers

Safety shield

Safety

shield

interlock

latch

Feed table

Rewind

Emergency stop

button

Tension knobs

Control panel

Roller handle

Tension knob

Fig. 5-4. 62FM Laminator Identification.

FEATURES

POWER I/O (ON/OFF)

Located at the back left of the machine applies

power to the laminator. The control panel display will

illuminate when switch is rotated to the “l” position.

The off position, marked “O”, removes power from

the laminator.

EMERGENCY STOP

Two emergency stop buttons exist on the laminator.

One on each side of the upper cabinet. To engage,

press either push button, roller movement is

stopped. To disengage, turn the push button

clockwise once the emergency condition has been

resolved.

Film shaft

Foot switch

SAFETY SHIELD

Prevents entanglement, entrapment and inadvertent

contact with the heat rollers. The laminator will

operate in the continuous mode only when

the safety shield is located in the fully locked

position. The foot switch operates the rollers at 3

fpm (0.9 mpm). The safety shield is removed only

when you load films or clear jams.

To remove the safety shield, unlock the safety shield

interlock latch and lift the safety shield up and away

from the safety shield mounting pins.

This shield must also be used on the rear of the

laminator when the laminator is operated from the

rear.

5-4

Page 17

Operating Instructions

62FM LAMINATOR

Safety Shield Interlock Latch

Used to lock the safety shield into position and

activate an interlock switch. The interlock latch is

located on the left side of the safety shield. When

pushed to the full left, the safety shield is locked.

When pushed to the full right, the safety shield is

unlocked.

FEED TABLE

The feed table is used to position items for

lamination. The laminator will operate only when the

feed table and feed table latch are properly installed.

The laminator will operate in the continuous

mode only when the feed table is located in the

fully locked position. The foot switch operates the

rollers at 3 fpm (0.9 mpm). The table is removed only

when you load films or clear jams.

HEAT ROLLERS

Silicone rubber coated steel tubes heat the

laminating film and press the heated film to the items

being laminated. Heat is provided by an internal

heating element. The heat rollers are motor driven for

ease of loading new film.

FILM SHAFT

The film shaft holds the film supply on the machine.

TENSION ADJUSTMENT KNOBS

(Three): Used to apply resistance to the film shaft.

To increase film shaft tension, turn the film shaft

tension knob clockwise. Counter clockwise will

decrease film shaft tension.

Tension adjustment knobs

Fig. 5-5. Two of the Tension Adjustment Knobs.

REWIND SHAFT

The rewind shaft holds the rewind tube on the

machine.

REWIND TUBE

The two rewind tubes located at the front of the

machine are used to rewind release liners. The one

located at the rear of the machine is used to rewind

the finished product.

To remove the film shaft, lift up on the round end of

the unwind/ rewind shaft then pull the hex end of the

shaft out and away from the laminator.

LOWER SHAFT CRADLE

(Not shown.) Supports the left side of the lower

shafts. To remove a shaft, lift the bearing end up and

out of the cradle and then pull the other end of the

shaft out.

REWIND ADAPTORS

(Not shown.) Hold and lock the rewind tube on the

rewind shafts to prevent side to side shifting.

Idler bar

Cooling fan

Chill idler

Heat roller

Pull roller

Fig. 5-6. Inside the 62FM, Viewed From the Front.

5-5

Page 18

62FM LAMINATOR

Operating Instructions

IDLER BAR

The idler bars, located near each heat roller, are used

to direct the film to the heat roller nip.

CHILL IDLER

Assist in the cooling process of the web material as it

exits the heat rollers.

To remove the chill idler, lift it out of its cradle and set

aside, taking care to not damage the bearings.

COOLING FAN

Assist in the cooling process by pushing unheated

air onto the web

PULL ROLLERS

The pull rollers, located at the back of the laminator,

are motor driven. They simultaneously pull the film

and improve the quality of the laminated item.

Rewind tube

ROLLER HANDLE

The roller handle manually sets the position of the

pull rollers while simultaneously electronically setting

the main rollers.

Fig 5-8. Roller Handle.

Available settings are;

Release

•

1/2 in. Mounting

•

Core Chuck

Idler bar

Chill idler

Pull roller

Rear table

Fig. 5-7. Rear View of 62FM.

REAR TABLE

Provides a working surface when operating the

machine from the rear. This table may also be

lowered when webbing for roll to roll applications.

To lower, slide the left and right side rear table

latches to the unlatched position and lower the rear

table.

CORE CHUCKS

Hold and lock the rolls of film on the shafts to

prevent side to side shifting.

3/8 in. Mounting

•

3/16 in. Mounting

•

1/8 in. Mounting

•

Low Laminating

•

Mid Laminating

•

High Laminating

•

FILM WEB

(Not shown.) The path the laminating film and/or

mounting film mounted on the machine takes

through the machine.

NIP POINT

The point at which the top and bottom rollers come

into contact. The Nip Point of the heat rollers is

the place at which the items for lamination are

introduced into the laminator.

SEPARATOR BAR

(Optional) Required if running AccuShield material.

5-6

Page 19

Operating Instructions

FOOT SWITCH

Operates the laminator when pressed and released

by the operator’s foot. Pressing it again stops the

laminator. When the feed table is lowered or the

safety shield is not latched, the foot switch must be

pressed and held to move the rollers at 3 fpm (0.9

mpm).

62FM LAMINATOR

5-7

Page 20

62FM LAMINATOR

Operating Instructions

5-8

Page 21

Operating Instructions

6. OPERATING INSTRUCTIONS

GENERAL OPERATION

For thermal processes, the heat rollers need to be

brought up to the proper temperature before you

load films or run items through the laminator. If the

laminator will be idle for more than four hours, lower

the temperature of both rollers to 180 °F (80 °C).

For PSA films and mounting processes, remove the

chill idler.

The safety shield and feed table must be in the

1.

normal operating position.

Select a job mode and ensure the proper speed

2.

and temperatures are set.

Set the roller handle to one of the laminating

3.

positions.

Press the Press/Release button.

4.

The main rollers gap.

62FM LAMINATOR

Fig 6-1. Aligning the Item With The Rollers.

With both hands, and an outward force, push the

9.

image slower than the speed of the rollers into

the nip of the heat rollers.

WARNING: Hot surfaces and pinch points.

Keep fingers and hands away from the heat pressure

and pull rollers. Clothing, jewelry and long hair could

be caught in the rollers and pull you into them.

Failure to adhere to this warning could result in

serious personal injury.

Press the Run button.

5.

Press the Press/Release button.

6.

The main rollers close.

Adjust unwind and rewind tensions as necessary.

7.

Align the leading edge of the item square to the

8.

heat roller nip.

Fig. 6-2. Feeding Items Into the Laminator.

CAUTION: Avoid forcing the image into the main

roller nip as this action will cause the corners of the

leading edge to buckle and create a wave.

1

Page 22

62FM LAMINATOR

Operating Instructions

STANDBY MODE

The 62FM automatically goes to standby mode

after 3 hours of inactivity. At this time, the laminator

beeps and the heat roller temperature is lowered to

180 °F (80 °C), if they were on. STAND BY blinks on

the LCD. After another hour of inactivity, the heat is

turned off. POWER-OFF blinks on the LCD.

To take the laminator out of standby mode, press the

Run button. If the heat was lowered or turned off,

you will have to wait until READY is displayed on the

control panel.

IMPORTANT: Whenever the laminator will be idle for

an hour or more, press the Press/Release button .

SETTING JOBS INTO MEMORY

Job settings can be saved into memory for easy

retrieval later.

To save a job into memory:

Press the Job button and select a job number

1.

with the MASTER DIAL

Set the temperature and speed for the job

2.

application.

Press the Job button again.

3.

.

FILM LOADING & THREADING

The top and bottom rolls of laminating film must be

of the same width and be present simultaneously. A

small amount of adhesive will “squeeze out” during

lamination. Hardened adhesive deposits can damage

the heat rollers. To avoid any damage, select

Low – Laminating on the roller handle, rotate

the rollers at slowest speed with heat on. Refer

to the chapter entitled Operator Maintenance for

instructions regarding removal of the accumulated

adhesive.

Adhesive will deposit on the rollers if:

Only one roll is used.

•

Different widths of rolls are loaded together.

•

Either roll is loaded adhesive side against a

•

heat roller.

One or both rolls of film are allowed to run

•

completely off its core.

The adhesive side of the film is on the inner side of

the web. The shiny side of clear film must contact

the heat rollers. The dull side of the film contains

the adhesive. Use extreme caution when loading

delustered (matte) film as both sides appear dull.

Always change the top and bottom supply rolls at the

same time. Near the end of each roll of laminating

film is a label stating Warning-End of Roll. The

appearance of this label on either the top or bottom

roll requires that new rolls of film be installed as soon

as the item presently being laminated completely

exits the rear of the laminator. Do not introduce any

additional items into the laminator when the warning

label is visible.

2

Page 23

Operating Instructions

Poly-in

62FM LAMINATOR

LOADING FILM

Lift up on the round end, left side, of the

1.

unwind/rewind shaft.

Pull the hex end, right side, of the shaft out and

2.

away from the laminator.

Slide the roll of film onto the film shaft ensuring

3.

adhesive side is out.

Adhesive surface

Polyester surface

Poly-out

Adhesive surface

Polyester surface

Fig. 6-3. Poly-in and Poly-out Configurations.

Replace the shaft with the hex end in first then

4.

the round end.

Center the roll of film.

5.

LOADING THERMAL FILM

TOP THERMAL FILM

This procedure describes how to load the upper roll

of film onto the laminator. Fig. 6-4 shows poly-in

film and the upper rear unwind/rewind position for

illustration purpose.

Fig. 6-4. Loading Top Thermal Film.

Turn the Power I/O (On/Off) to ON (I).

1.

Set top heat temperature for the film type you

2.

are using.

Ensure no brake tension is applied to the film

3.

shaft.

Remove the safety shield and pivot the feed

4.

table down.

3

Page 24

62FM LAMINATOR

Pull the top roll of film down under the idler bar

5.

and allow to drape over the top heat roller.

Reference one of the loading bottom material

6.

procedures.

BOTTOM THERMAL FILM

This procedure describes how to load a roll of

thermal film using the lower unwind position for

encapsulation. At this point you should have an

upper roll of thermal film loaded onto the laminator.

Operating Instructions

LOADING ACCUSHIELD FILM

This procedure describes how to load a roll of

AccuShield film and attach the liner to the take-up.

IMPORTANT: When starting to laminate, always

start the rollers BEFORE applying pressure to the

rollers to prevent AccuShield build up on the roller.

When stopping, release the pressure on the rollers

BEFORE stopping the motor.

Fig. 6-5. Loading Bottom Thermal Film.

Ensure no brake tension is applied to the film

1.

shaft.

Guide the bottom film around the lower idler.

2.

Adhere the film to the loaded upper roll of

3.

thermal film by pulling the film up towards the

existing draped thermal film over the main

rollers.

NOTE: You may follow this procedure to load a roll of

kraft paper for single side lamination.

Reference Threading Card Procedure

5.

.

Fig. 6-6. Configuration for AccuShield Film.

Pull the film down, thread it under the idler bar

1.

and drape it over the top heat roller.

Fig. 6-7. AccuShield Draped Over the Top Heat Roller.

Press the straight edge of the threading card

2.

into the film at the nip until the card and film is

slightly past the nip.

The threading card for webbing AccuShield

film can be any stiff print. The film should be

wrapped around the leading edge of the card.

4

Page 25

Operating Instructions

Fig. 6-8. Threading Card Inserted Into the Film.

Press the RUN button on the control panel.

3.

Press the Press/Release button to apply

4.

pressure to the threading card and guide the

card into the machine until the rollers pull it on its

own.

62FM LAMINATOR

LOADING PSA FILM

TOP PSA FILM

This procedure describes how to load the upper

roll of film onto the laminator. Fig. 6-9 shows PSA

film and the upper rear unwind/rewind position for

illustration purpose.

WARNING: Keep your fingers and hands away

from the nip point while the machine is running.

They could be trapped and crushed in the rollers.

Clothing, jewelry, and long hair could be caught in

the rollers and pull you into them.

Release the card and ensure that the film and

5.

card are being pulled into the laminator.

The card will guide the film into the rollers.

After the threading card exits the laminator, set

6.

the roller pressure handle to Release.

Press the STOP button.

7.

Separate the release liner from the card.

8.

Pull the film up to the take-up core and tape it to

9.

the core.

Replace the safety shield.

10.

Fig. 6-9. Loading Top PSA Film.

Turn the Power I/O (On/Off) to ON (I).

1.

If the laminator is already hot, turn it to the OFF

(O) position and allow the unit to cool. Once

cool, turn the laminator back on.

Ensure no brake tension is applied to the film

2.

shaft.

Remove the safety shield and pivot the feed

3.

table down.

Set the roll of film in the rear unwind/rewind

4.

position and the rewind tube in the front

unwind/rewind position.

Pull the top roll of film down under the idler bar

5.

and up to the upper front rewind tube.

Place one piece of masking tape in the center of

6.

the film and secure to the rewind tube.

Make two full wraps around the rewind tube,

7.

then carefully score the laminate without cutting

the release liner.

Pull the laminate down, allowing it to drape over

8.

the upper main roller.

5

Page 26

62FM LAMINATOR

Reference one of the loading bottom material

9.

procedures.

BOTTOM PSA MOUNT FILM

This procedure describes how to load a roll of

mount adhesive using the lower unwind position for

decaling. At this point you should have an upper roll

of PSA film loaded onto the laminator.

Operating Instructions

Make two full wraps around the rewind tube,

4.

then carefully score the laminate without cutting

the release liner.

Adhere the lower PSA film to the loaded upper

5.

roll of film by pulling the film straight up towards

the main rollers.

Reference Threading Card Procedure next.

5.

LOADING MOUNT ADHESIVE

TOP MOUNT ADHESIVE

This procedure describes how to load a roll of mount

adhesive using the upper position for pre-coating.

Fig. 6-10. Loading Bottom PSA Film Without Liner.

Fig. 6-11. Loading Bottom PSA Film With Liner.

Ensure no brake tension is applied to the film

1.

shaft.

Pull the lower roll of film around the lower idler

2.

bar and towards the lower rewind.

Place one piece of masking tape in the center of

3.

the film and secure to the rewind tube.

Fig. 6-12. Loading Mount Adhesive for Pre-Coating a

Board.

Turn the Power I/O to ON (I).

1.

If the laminator is already hot, turn it to the OFF

(O) position and allow the unit to cool. Once

cool, turn the laminator back on.

Ensure no brake tension is applied to the film

2.

shaft.

Remove the safety shield.

3.

Set the roll of mount adhesive in the upper rear

4.

unwind/rewind position.

Pull the mount adhesive over the upper idler and

5.

upper main roller allowing the material to rest on

the top of the feed table.

Reference Threading Card Procedure next.

5.

6

Page 27

Operating Instructions

62FM LAMINATOR

BOTTOM MOUNT ADHESIVE

This procedure describes how to load a roll of

mount adhesive using the lower unwind position for

decaling. At this point you should have an upper roll

of film loaded onto the laminator.

Fig. 6-13. Loading Bottom Mount Adhesive for Decalling.

THREADING CARD PROCEDURE

This procedure describes how to feed two loaded

films through the main rollers. At this point you

should have the upper lower rolls of film loaded onto

the laminator with the appropriate material for your

application. The figure shows threading for thermal

(solid lines) and PSA (dashed lines) films.

NOTE: When loading PSA films, the chill idler must

be removed.

PSA film

PSA film

Thermal film

Thermal film

Ensure no brake tension is applied to the film

1.

shaft.

Adhere the mount adhesive to the loaded upper

2.

roll of film by pulling the mount adhesive straight

up towards the main rollers. Do not web around

the lower idler.

Reference Threading Card Procedure next.

3.

Fig. 6-14. Threading With a Threading Card.

Install the table and safety shield.

1.

Push the threading card into the main roller nip.

2.

The threading card becomes sandwiched

between the upper and lower loaded films.

Set the roller handle to a laminating position.

3.

Press the Run button.

4.

Once the threading card has exited the laminator,

5.

press the STOP button.

If you are not running the laminator, set the roller

6.

handle to the RELEASE position.

Now refer to the section entitled Start

7.

Laminating

.

7

Page 28

62FM LAMINATOR

TACKING NEW FILM TO EXISTING FILM

The following describes a method for loading film

whereby the existing film present on the heat rollers

may be used in place of the threading card to draw

the new film through the laminator. The adhesive of

the existing film must be tacky or liquefied. Leading

edges of the new film will be overlapped onto the

tacky adhesive of the old film. The existing film and

the new film will be pulled through the laminator

together. In Fig. 6-15, solid lines represent thermal

films and dashed lines represent PSA films.

Cut remaining top and bottom film webs

1.

between the idler bar and heat rollers.

Operating Instructions

Tack the new film to the existing film on the heat

6.

rollers.

For PSA film, attach the release liner to the

rewind tube.

New film

New film

Cut here

Cut here

Cut here

Fig. 6-15. Cutting Existing Films Prior to Re-loading.

CAUTION: Do not cut the heat rollers when cutting

the film web

Remove the safety shield and tilt the feed table

2.

down.

Do not allow the adhesive side of the film to

3.

contact the heat or pull rollers.

Liquefied or tacky adhesive deposited on heat

rollers will require the rollers to be cleaned per

the chapter entitled Operator Maintenance.

Fig. 6-16. Tacking New Film to Existing Film.

Replace the safety shield and feed table.

7.

Use the foot switch to advance the film into the

8.

heat roller nip.

Observe the film being pulled through the

9.

laminator to assure that the remaining existing

film and the new film are advancing concurrently.

Any separation between the films will require

stopping the motor immediately and the situation

corrected.

Press Stop once the newly threaded film has

10.

completely exited the pull rollers.

Replace both the top and bottom rolls of film

4.

with new rolls.

Ensure the adhesive side is facing out.

Pull the film around the idler bars, with the

5.

exception of PSA mounting adhesives without a

release liner.

8

Page 29

Operating Instructions

62FM LAMINATOR

TO UNWEB THE LAMINATOR

Unweb the laminator if you are changing film widths,

cleaning the rollers, or have finished using the

machine for the day.

Set the roller handle to the Release position.

1.

Remove the safety shield and tilt the feed table

2.

down.

Cut remaining top and bottom film webs

3.

between supply rolls and heat rollers. Be careful

not to cut any of the rollers!

Cut web

Cut web

CLEARING A FILM JAM (WRAP-UP)

Film jams (wrap-ups) may occur if the film is loaded

backwards or if the area at which film exits the

equipment is blocked. The film, when jammed, wraps

around the rollers. Jams also occur if something is

too large to pass through the rollers.

Determine the best course of action to clear the

jam. It may be necessary to rotate the rollers in the

reverse direction. Set the speed to 1. Press and hold

the Reverse button on the control panel.

CAUTION: Be careful to not cut the pressure rollers

when cutting the film. Failure to observe this notice

can result in damage to the rollers.

Immediately press the STOP button to stop the

1.

machine.

Remove the safety shield and feed tray.

2.

Do one of the following.

3.

Pull one of the webs while running the

a.

laminator in reverse.

Fig. 6-17. Unwebing the Laminator.

Carefully grab hold of the web (top and bottom

4.

film), from the back operating position and pull

towards you.

Do not allow the adhesive side of the film to

contact the heat or pull rollers.

Pull web

Cut the film near the rollers, set the

b.

pressure adjustment to Release, and pull

the film out the back of the machine.

Cut the film near the rollers, set the

c.

pressure adjustment to Release, grasp

the loose ends of the web, and pull

straight out the front of the machine.

Replace the safety shield and feed tray.

4.

Re-load the film if necessary. See the

5.

Film

section in this chapter.

Loading

Fig. 6-18. Pulling Film Out of the Laminator.

9

Page 30

62FM LAMINATOR

Operating Instructions

APPLICATIONS

TIPS FOR PRE-COATING BOARDS

Load the laminator as shown.

•

Mount adhesive

Trailer board

Board

Fig. 6-19. Pre-coating Boards With Mount Adhesive.

Leader board

TIPS FOR USING THE REAR ROLLERS

If the front rollers are heated, you may perform

certain applications from the rear operating position

of the laminator. You may perform mounting

applications, pre-coating applications, and single

side applications from the rear of the machine.

Release liner

PSA film

Fig. 6-20. Running From the Rear.

Mounting film

Remove the chill idler.

•

Set the roller pressure handle to the correct

•

thickness.

The width of the roll should not exceed the

•

width of the board by more than ½ in. (1.3

cm).

Use a leader board to start the run and a

•

trailer board to finish the run.

Using the pull rollers will allow you to leave

•

gaps between boards.

If not using the pull rollers, have the boards

•

nearby to butt end to end during feeding.

Remove the chill idler if using boards.

•

Ensure the safety shield is located in the

•

rear position and latched or use the foot

switch for slow speed operation.

Ensure the REAR CONTROLS have been

•

enabled.

Use the foot switch to run the laminator.

•

10

Page 31

Operating Instructions

TIPS FOR MOUNTING ON PRE-COATED

B

OARDS

Liner

Print

62FM LAMINATOR

The separation of the laminate and the release

•

liner should be maintained close to the heat

rollers.

A little heat, 125 °F (52 °C), may help eliminate

•

silvering effects associated with PSA films.

Board

Fig. 6-21. Mounting a Print on a Board.

Load the laminator as illustrated as shown.

•

Heat at 125 °F (52 °C), may assist the process

•

and increase output quality.

Do not stop once you have started the

•

mounting process through the machine.

TIPS FOR PSA ENCAPSULATION

Use of the chill idler may or may not help in

•

the output quality. Try both methods.

TIPS FOR THERMAL ENCAPSULATION

Print

Fig. 6-23. Thermal Encapsulation With Poly-in Film.

Load the laminator as shown for poly-in film.

•

Print

Fig. 6-22. PSA Encapsulation With Poly-in Film.

Load the laminator as shown.

•

Always use two rolls of the same width.

•

Use minimal brake tension to achieve flat

•

output.

Always use two rolls of film the same width.

•

Use minimal brake tension to achieve flat

•

output.

Increase speed gradually to maintain the

•

activating temperature required for the

laminate you are using.

Length and width of image, ink coverage and

•

paper type may effect the temperature and

speed required.

11

Page 32

62FM LAMINATOR

Operating Instructions

TIPS FOR ACCUSHIELD

Print

Fig. 6-24. Applying AccuShield.

Load the laminator as shown.

•

You must have the separator bar option to

•

accurately run this material.

Liner rewind tension will be greater than

•

normal operating standards.

Do not attempt to run this material greater

•

than a speed setting of 4.

LAMINATION GUIDE

BASIC RULES

Do not attempt to laminate abrasive or metal objects

such as staples, paper clips and glitter, as they may

damage the rollers.

Do not force items into the nip area of the rollers. An

item that is not easily drawn into the laminator by the

rollers is probably too thick to laminate.

Wrinkles may result if an attempt is made to

reposition an item once it has been grasped by the

rollers.

Do not stop the laminator before an item has

completely exited the pull rollers. Even a momentary

stop may cause a mark on the laminated item.

Good, consistent lamination is a result of combining

proper tension, heat, and dwell time. Dwell time is

controlled by the speed of the motor and is defined

as the amount of time the material to be laminated is

compressed between the rollers.

As a general rule, thicker items and film need to run

at slower speeds. Setting the speed control at slower

settings gives the laminator longer dwell time thus

allowing proper lamination of thick items. Thinner

items, such as standard copier paper (20 lb. bond)

and tissue paper can be run at faster speeds.

12

Do not combine thick and thin items at the same

time, as this will result in a poor edge seal around

the thinner material. If you are unsure that the

laminator is set at the proper speed for the item to

be laminated, run a test piece (scrap) of the same or

similar material through the laminator. Make speed

adjustments if necessary.

This manual provides general guidelines and is only

a general reference guide. Different settings may be

suitable as the lamination time and materials change.

Important: Test materials before running good

materials through the laminator.

Page 33

Operating Instructions

62FM LAMINATOR

FILM TENSION

Proper film tension, known as brake tension, is the

minimum amount required to eliminate wrinkles in

the finished item. The film should be taut. A properly

adjusted roll of film should not require excessive

force to turn by hand.

Film tension should be enough to introduce a minor

amount of drag as the film unrolls. Insufficient

tension causes wrinkles, while too much tension

causes stretching (necking). Uneven tension

between the top and bottom rolls creates curl. Too

much upper tension creates upward curl while too

much bottom tension causes downward curl.

The heat roller clutch is set at the factory. Periodic

adjustments may be necessary if after adjusting

unwind and rewind brake tensions do not improve

your output quality.

HEAT

The WAIT (Too COLD) indicator may appear if the

speed is set too fast for the material being laminated.

Either lower the speed setting or press Stop and

wait until the READY indicator appears.

OUTPUT

“D” waves in the image ( Fig. 6-25 A).

1.

Fig. 6-25. “D” Waves In Image.

Check paper tension.

•

Paper may be damp or not dry.

•

“D” waves in the laminate (Fig. 6-25 B).

2.

Operation of the laminator for more than thirty

minutes at a time may necessitate a lower speed

setting. It is recommended that, during periods of

long runs, the items being laminated are alternated

between thick and thin. Do not combine thick and

thin items at the same time, as this will result in a

poor edge seal around the thinner material. If you

are unsure that the laminator is set at the proper

speed for the item to be laminated, run a test piece

(scrap) of the same or similar material through the

laminator. This procedure is recommended because

rotating the heat roller prior to lamination will more

evenly distribute the heat. Make speed adjustments

if necessary.

Change roller handle pressure.

•

13

Page 34

62FM LAMINATOR

Operating Instructions

Straight waves in output ( Fig. 6-26 A).

3.

Fig. 6-26. Straight Waves in Output.

Check operational settings for materials being

•

used.

Insufficient cooling time.

•

Angled waves in the output ( Fig. 6-27 A & B).

5.

Fig. 6-27. Angled Waves in Output.

Change roller handle pressure.

•

Check for even paper tension

•

(Fig. 6-27 A only).

Output was handled prior to cooling.

•

Use cooling feature if not on.

•

Indent waves in output after pull rollers

4.

(Fig. 6-26 B).

Machine was stopped on print.

•

14

Page 35

Operating Instructions

7. OPERATOR MAINTENANCE

MAINTAINING THE 62FM LAMINATOR

The only maintenance required by the operator

is to periodically clean the rollers. The following

procedure will help keep them free of dirt and

adhesive, which has been deposited along the edge

of the laminating film. Proper alignment of the rolls of

film reduces the amount of adhesive on the rollers.

Perform only the routine maintenance procedures

referred to in these instructions.

WARNING: Do not attempt to service or

repair the laminator. Failure to observe this warning

could result severe personal injury or death or

damage the machine.

CLEANING THE ROLLERS

62FM LAMINATOR

Use the dampened rag to remove any dust, dirt,

5.

and other foreign materials from the rollers.

Use the foot switch to rotate the rollers to an

6.

unclean portion.

Keep your hands, fingers, and the rag away while

running the machine. Be sure to remove any

dust, dirt, and other foreign materials from the

rollers.

Install the feed table and safety shield.

7.

Keeping the rollers clean ensures that your finished

items will not be damaged by dirt and adhesives.

You will need a 3M™ Scotch-Brite™ pad and a clean

rag moistened with water and dish soap.

Never clean rollers with abrasive, sharp, or

•

pointed objects.

Do not use any other cleaning agents other

•

than those listed above.

Accumulated adhesive deposits on the rollers

•

can cause damage to the rollers. Rotate the

rollers at the lowest speed setting on the

control panel.

WARNING: Hot surfaces and pinch points.

Keep fingers and hands away from the heat pressure

and pull rollers when the laminator is running. Failure

to adhere to this warning could result in serious

personal injury.

Remove the safety shield and feed table.

1.

Remove the film from the laminator.

2.

Refer to Loading Film in the Operation chapter.

Preheat the laminator until the READY indicator

3.

appears

Gently rub the heat and pull rollers, and idlers

4.

with a 3M Scotch-Brite pad.

DO NOT USE METAL SCOURING PADS! Do

not use any abrasives to clean the rollers.

7-1

Page 36

62FM LAMINATOR

Operating Instructions

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

The control panel display

does not illuminate when

POWER I/O is in the ON

marked “I”, position.

Heat rollers do not turn when

I press the Run button.

Heat rollers only turn if I use

the foot switch.

Rear controls do not

operate.

Laminated items exhibit

curling.

,

Laminator not connected to electrical

supply.

Safety shield is not properly installed. Remove safety shield and properly

Feed table not properly installed Tilt feed table and properly replace it.

Emergency Stop is engaged Pull out on the emergency stop push

Laminator is in foot switch mode. Disengage the foot switch mode.

Rear controls are not enabled. Enable rear controls.

Safety shield is not installed in rear

position.

Tension between the top and bottom film

roll is unequal.

Insert attachment plug into receptacle.

replace it.

button.

Install the safety shield.

Adjust film tension.

Adhesive deposited on heat

rollers.

Tension on top or bottom roll of film is

too film loose.

Bottom film roll may be improperly

loaded.

Top and bottom film webs not aligned. Release heat and pull roller pressure,

Laminate improperly loaded. Adhesive (matte) side of laminate film

Adjust film tension.

Make sure bottom roll of film is around

idler bar and the it is in the normal

operating position.

align the rolls of film.

may be against the heat rollers. Unweb

and reload the film properly.

7-2

Page 37

Operating Instructions

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

62FM LAMINATOR

Unsatisfactory adhesion of

laminate.

Waves in my output

Speed setting too fast for type of

material being laminated.

Insufficient heat. Wait for READY indicator to appear in

Laminate improperly loaded. Adhesive side of film must be facing

Heat rollers require cleaning. Clean heat rollers per procedure in

Laminated item unsuitable for adhesion. Item may be dirty or may have

See sub section Output

Nips may be out of calibration. Place a service call for calibration check.

. Under section titled Lamination Guide.

Lower speed setting by pressing Slow

button to slower speed

the control panel display.

away from the heat rollers.

Bottom roll of film not threaded behind

the idle bar.

section Maintaining the 62FM Laminator.

nonporous surface that is extremely

difficult to laminate.

7-3

Page 38

62FM LAMINATOR

Operating Instructions

7-4

Page 39

Page 40

Loading...

Loading...