Gaylord CG3-BDL-BB Specifications

MODEL “CG3-BDL-BB”

WATER-WASH VENTILATOR

ITEM NO. _______________

Furnish Gaylord Ventilator Model CG3-BDL-BB-___as shown on plans and in

GENERAL SPECIFICATIONS

accordance with the following specifications:

GENERAL: Ventilator shall incorporate two extraction chambers mounted backto-back each with an air inlet opening above and parallel to the cooking surface.

Each extraction chamber shall utilize three full-length horizontal self draining

baffles for centrifugal grease extraction providing a grease extraction rate of up

to 95% of the mechanically extractable particulate when operated at design

specifications. The use of filters, cartridges or constant running water to extract

grease is not acceptable. The baffle at the air inlet shall be a three position

damper controlled by an electrically driven actuator. In position number one, the

fan on mode, the damper shall be a grease extracting baffle, position two the

damper shall be in the wash mode and position number three in the fire mode.

The main grease gutter shall have a 1" slope to the drain opening and the drain

shall be equipped with a pre-flush line to purge the drain during a wash cycle.

Continuous brackets shall be provided to facilitate hanging from the overhead

structure. o (Optional)The ventilator shall include “Custom Air” baffles to reduce

the exhaust air volume over specific cooking equipment as indicated on the plans

(add suffix “CA” to model number). The ventilator shall operate at air quantities

as shown on plans.

AUTOMATIC WASHDOWN SYSTEM: The ventilator shall include a full length

wash manifold equipped with two rows of brass spray nozzles. When the wash

cycle is initiated the exhaust fan is shut off, the damper shall close forward to seal

off the air inlet slot exposing the entire grease gutter to the wash sprays. At the

conclusion of the wash cycle the damper shall remain closed, in the “System Off”

position, preventing conditioned air from escaping the occupied space via thermal

drafts, and then re-open when the exhaust fan is started. All controls and

components for operation of the wash system shall be housed in the Ventilator

Control Cabinet.

INTERNAL FIRE PROTECTION: The ventilator shall be equipped with an

internal fire protection system activated by thermostat(s) located at the duct

collar. When the temperature of the exhaust air reaches the set point, the fire

damper shall automatically close in the direction of the exhaust air flow, sealing

against the back wall of the ventilator , and act as a barrier to prevent flame from

entering the extraction chamber and duct system. The exhaust and make up

air fans shall shut off, and the internal wash system shall be initiated, acting as

a deterrent to fire in the plenum and exhaust ductwork. In addition, the internal

water sprays shall continuously bathe the fire damper to eliminate warping of the

damper during a severe fire condition. The water sprays shall remain on until

the thermostat temperature drops below it’s set point, then stay on for a two

minute cool down cycle. During the cool down cycle the damper shall open and

upon completion the water sprays shall shut off and the exhaust fan re-start.

o (Optional) A remote fire switch shall be provided and shall be located at an

exit. Pulling the fire switch shall turn on the water sprays, open the fire damper

to the fan on position and turn on the exhaust fan.

o (Optional Fuse Link Fire Dampers) Provide fuse link activated fire damper

located at the duct collar. Specifier note: This arrangement eliminates the three

position inlet damper and is replaced by a fixed baffle. This option is identified

by the model number prefix CG3-FDD.

o (Optional No Fire Damper) This option is identified by the model number prefix

CG3-ND.

ACCESSIBILITY AND INSPECTION: The ventilator shall be equipped with fulllength non-gasketed hinged inspection doors so that service can be performed

on fire suppression system nozzles, fusible links, wash system manifolds and

nozzles, drains and other interior components without removing any panels,

dampers or baffles. No tools shall be required to access the interior of the

extraction chamber or plenum.

CONSTRUCTION: The ventilator shall be of all stainless steel construction, not

less than 18 gauge, type 300 series. All exposed surfaces shall be a number

4 finish. The use of aluminized steel, galvanized steel, or 430 stainless steel

is not acceptable.

ELECTRICAL: The ventilator shall be factory pre-wired to a single connection

point. Ventilators built in multiple sections shall be furnished with coiled flex

conduit for interconnecting sections by applicable trades.

LIGHT FIXTURES: The ventilator shall be equipped with o 100 watt surface

mounted incandescent, o 150 watt recessed incandescent, o recessed

fluorescent, light fixtures. Light fixtures shall be factory interwired. Ventilators

built in multiple sections shall be furnished with coiled flex conduit for interconnecting sections.

ACCEPTANCE & APPROVALS: The ventilator shall be UL Listed under the

category “Exhaust Hood with Exhaust Damper” and listed by NSF. The ventilator

shall comply with all requirements of NFPA-96, IMC, UMC, BOCA and SBCCI

model codes. In Canada the ventilator shall be ULC Listed and CSA Certified.

Patent Pending

APPLICATION

Used for typical island style cooking arrangements where medium, heavy,

or extra heavy-duty equipment is used on both sides or when the distance

between the equipment exceeds 30" regardless of the type of equipment.

Refer to the Master Engineering Data Sheet in the Gaylord catalog for

determining medium, heavy, and extra heavy-duty equipment.

FEATURES

• Three Position, Inlet Slot, Damper

• 95% Grease Extraction Efficiency

• CUL and NSF Listed

• Complies With The IMC, UMC, BOCA and

SBCCI Mechanical Codes

• Complies with all Requirements of NFPA-96

• Fail Safe Damper Control Switch

DESCRIPTION

The Gaylord Model “CG3” Series Ventilator has been tested to UL

Standard 710 and is UL Listed under the category “Exhaust Hood with

Exhaust Damper”. The ventilator extracts up to 95% of the mechanically

extractable grease by centrifugal force when operated and maintained

in accordance with design specifications. The extracted grease

remains out of the airstream until washed away by the hot water,

detergent injected wash cycle, which is manually activated by pushing

the “Start Wash” button on the control cabinet or automatically activated

by the control cabinet if equipped with optional time clock. The 24 hour

fire protection is accomplished by the action of the thermostat(s) located

at the duct collar. Whenever temperatures reach the set point, the fire

cycle is activated which closes the damper at the air inlet of the ventilator,

releases fire extinguishing water spray into the interior of the ventilator,

and shuts off the exhaust and supply fan.

OPTIONAL EQUIPMENT

1. Decorative Facings and Trim

2. Exhaust Fans, Supply Fans, & Roof Top Units

3. Fire Extinguishing Systems

4. Custom Air (low air volume ventilators)

5. Continuous Cold Water Mist

6. Utility Distribution Systems

7. Pollution Control Systems

GAYLORD INDUSTRIES

10900 SW AVERY ST. • TUALATIN, OREGON 97062 U.S.A.

PHONE: 800-547-9696 • FAX: 503-692-6048 • email: info@gaylordusa.com

www.gaylordusa.com

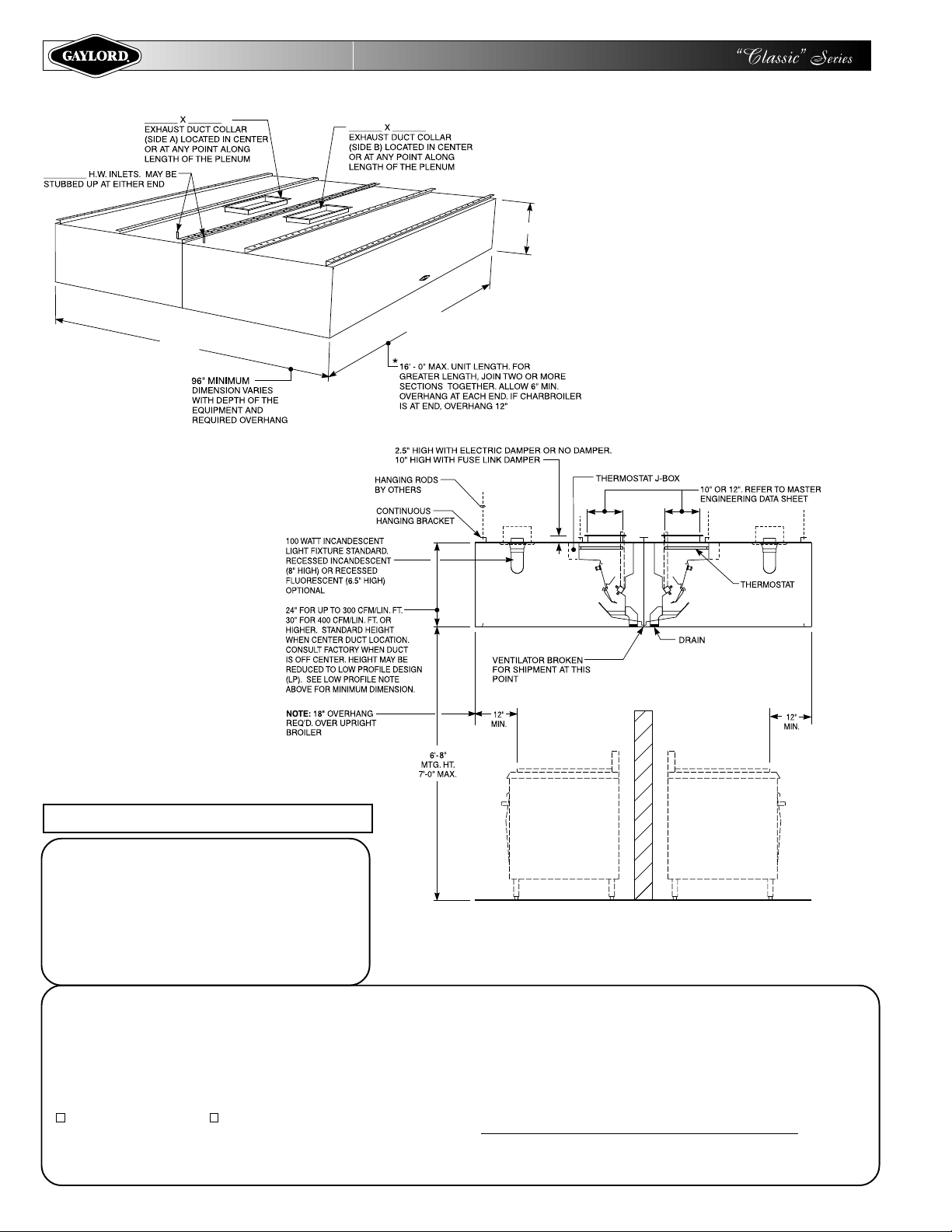

MODEL “CG3-____-BDL-____-BB-____”

**

DAMPER

**

Leave blank = Standard 3 position inlet damper

OPTION

LOW

PROFILE

(LP)

DEPTH

OF

VENTILATOR

FDD = Fuse link damper at the duct collar

ND = No damper

For exact model designation add depth following the

letters “CG3-BDL-BB-”.

Example: “CG3-BDL-BB-108”

LOW PROFILE (LP) MINIMUM HEIGHT AT FRONT:

Light & Medium Duty Equipment (400°F) 12" Min.

Heavy Duty Equipment (600°F) 18" Min.

Extra Heavy Duty Equipment (700°F) "LP" Not Available

The manufacturer reserves the right to modify the materials and specifications resulting

from a continuing program of product improvement or the availability of new materials.

ITEM NO. ______________________ EST. WT. _________________________

LENGTH ____________ WIDTH ______________ HEIGHT ______________

EXHAUST - CFM ________________ DUCT SIZE ____________ S.P. ______

(SIDE A)

EXHAUST - CFM ________________ DUCT SIZE ____________ S.P. ______

(SIDE B)

H.W. SIZE _____________________ DRAIN SIZE ______________________

___________ GPM @ 40 PSI WATER TEMP 140° F - 180° F

TYPICAL SECTION VIEW

Note:

All Gaylord Ventilators are provided with a Gaylord Ventilator

Control Cabinet. Refer to Control

Cabinet specification sheet.

ENGINEERING DATA

Mechanical Requirements

The amount of exhaust volume required is dependent upon the type of cooking

equipment and the type and volume of cooking. Refer to the Master Engineering Data Sheet in the Engineering Data section of the Gaylord catalog for the

charts on determining exhaust volume, duct sizes, static pressure, water

consumption, hot water requirements, and drain sizes.

Electrical

XXProvide 120 volt 20 amp, XX220/240 volt, 50-60 Hz., 24 hour service to

Gaylord Ventilator Control Cabinet (refer to Control Cabinet specification

sheet). To be fused separately. Lights to be on separate circuit, 120 volt

standard, 220/240 volt optional.

Form No. CG3-BDL-BB 806-30713 © Copyright 2006, Gaylord Industries Litho USA

Ventilator Lengths

Maximum unit length 16'-0" . For greater lengths, join two or more sections

together. Check to ensure that there is adequate access into building and kitchen

area.

Note: Ventilators manufactured outside North America; maximum unit length

*

10'-0".

Hanging Weight

Ventilator Width 8'-0" 9'-0" 10'-0" 11'-0"

Wt./ lineal ft. 180 190 200 210

Loading...

Loading...