Page 1

Atlas

®

DEF Operation, Diagnostics, and

Recommended Spare Parts

Manual

MDE-5044A

Page 2

Computer Programs and Documentation

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

All dispensers and self-contained pumping

units

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

Card reader terminals, Models 1000, 1000P

Site Controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

95-136 Dispenser 9800 Series 91-057 Controller

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Registered trademarks

ASTRA

®

Atlas

®

Fuel Point

®

Gasboy

®

Keytrol

®

Slimline

®

Non-registered trademarks

Consola

™

Infinity

™

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

Federal Communications Commission (FCC) Warning

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be re quired to correct the inte rference at his own exp ense. Changes or modifications not expressly approved by

the manufacturer could void the user’s authority to operate this equipment.

Approvals

Trademarks

Additional US and foreign trademarks pending.

Other brand or product names shown may be trademarks or registered trademarks of their respective holders.

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

2014 GASBOY. All Rights Reserved.

Page 3

Table of Contents

Table of Contents

1 – Introduction 1-1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Intended Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 – Important Safety Information 2-1

3 – Operation Modes 3-1

Fueling Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Fueling at Idle State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cold Weather DEF Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

DEF LED Functions - Cold Weather Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

9800 CPU Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Coriolis Meter Interface Board . . . . . . . . . .

Temperature Control Board . . . . .

DEF Warm Weather Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . 1-1

. . . . . . . . 1-1

. . . . . . 1-1

. . . . . 1-1

. . . . . 3-2

4 – Diagnostics, Calibration, and Troubleshooting 4-1

DEF Dispenser Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Diagnostics Procedure for Cold Weather Problems

Atlas 9862 DEF Dispenser Status/Error Codes.

Electronic Calibration (E-CAL) Adjust

Calibration and Accuracy Checks - DEF Dispensers. . . . . . . . . . . . . . . 4-9

ment for E-85/DEF Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

. . . . . . . . . . . . . . . . . . 4-5

5 – Recommended Spare Parts 5-1

Electronic Head Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Lower Hydraulic Section . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Index Index-1

MDE-5044A Atlas® DEF Operation, Diagnostic, and Recommended Spare Parts Manual · April 2014 Page i

Page 4

Table of Contents

This page is intentionally left blank.

Page ii MDE-5044A Atlas® DEF Operation, Diagnostic, and Recommended Spare Parts Manual · April 2014

Page 5

Purpose Introduction

1 – Introduction

Purpose

This manual provides information on the operations, diagnostics, and recommended spare

parts for the Atlas

Intended Users

This manual is intended to assist the Authorized Service Representative (ASR) or technician

in troubleshooting, operating, and identifying the parts for the Atlas DEF dispenser.

Required Tools

®

Diesel Exhaust Fluid (DEF) dispensers.

Following tools are required for diagnosing and repairing the Atlas DEF dispenser:

• Digital Voltmeter

®

• Flat-blade and Phillips

Screwdrivers

• Set of Hydraulic Wrenches

• Rubber Mallet

• Magnetic Ring Tool (M10656B001) for units without M10257B002 Nozzle

Related Documents

Document

Number Title GOLD

FE-356 Field Wiring Diagram Atlas Retail, Commercial, E-85, and

DEF Dispenser

MDE-4331 Atlas

MDE-4334 Commercial and Retail Series Atlas St

Fuel Systems Installation Manual Gasboy Atlas Pumps/Dispensers

s with Electronic and Mechanical Displays

Abbreviations and Acronyms

Term Description

ASR Authorized Service Representative

CPU Central Processing Unit

DEF Diesel Exhaust Fluid

E-CAL Electronic Calibration

®

GOLD Gilbarco

I/O Input/Output

J-box Junction Box

LED Light Emitting Diode

Online Documentation

SM

Library

Gasboy® Parts List & Wiring Diagrams

art-up/Service Manual Gasboy Atlas Pumps/Dispensers

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 1-1

Page 6

Introduction Abbreviations and Acronyms

Term Description

LSD Least Significant Digit

MSD Most Significant Digit

PCA Printed Circuit Assembly

PCB Printed Circuit Board

RAM Random Access Memory

ROM Read Only Memory

W&M Weights and Measures

Page 1-2 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 7

2 – Important Safety Information

Notes: 1) Save this Important Safety Information section

in a readily accessible location.

2) Although DEF is non-flammable, diesel is

flammable. Therefore, for DEF cabine ts that are

attached to diesel dispensers, follow all the

notes in this section that pertain to flammable

fuels.

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death o r serious injury,

if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important in formation you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate

the switch or circuit breakers that shut off all power to all fueling

equipment, dispensing devices, and Submerged Turbine

Pumps (STPs).

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier ’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in th e cas e of an emerge nc y a nd not

the console’s ALL STOP and PUMP STOP or

similar keys.

!

WARNING

!

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical component s or

the electronics of the dispenser requires total elect rical shut off

of that unit. Understand the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles from

the work area

• Use of safety tape, cones or barricades at the affected unit(s)

• A total electrical shut-off of the affected unit(s)

Read the Manual

Read, understand and follow this manual and any other labels

or related materials supplied with this equipment. If you do not

understand a procedure, call a Gasboy Authorized Serv ice

Contractor or call the Gasboy Support Center at

1-800-444-5529. It is imperative to your safety and the safe ty of

oth

e

rs to understand the procedures before beginning work .

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupatio nal Safety and Health Administration

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lea d to leg al citation s

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement p art s and re trofit kits on

your pump/dispenser. Using parts other than genuine Gasboy

replacement parts could create a safety hazard and violate

local regulations.

Safety Symbols and Warning Words

This section provides important information about wa rn ing

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prev

ent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible injury

or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions below must be followe d to prevent death, injury or

damage to the equipment:

DANGER: Al

erts yo

u to a hazard or unsafe practice

which will result in death or serious injury.

WARNING: Alerts

you to a hazard or unsafe practice

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

un

safe practice which may result in minor injury.

CAUTION w

i

thout Alert symbol: Designates a hazard or

unsafe practice which may result in property or

equipment damage.

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

DEF is non-flammable. Therefore, expl

osion and fire safety

warnings do not apply to DEF fluid lines.

!

!

!

Important Safety Information

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 2-1

Page 8

Important Safety Information

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the

State of California to ca use birth defects or other

reproductive harm.

WARNING

!

Gasoline/DEF ingested may cause

unconsciousness and burns to internal organs.

Do not induce vomiting. Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

DEF generates ammonia gas at high er temperatures.

When opening enclosed panels, allow the unit to air out to

avoid breathing vapors.

If respiratory difficulties develop, move victim away from

source of exposure and into fresh air. If symptoms persist,

seek medical attention.

WARNING

!

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to

eye tissue.

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled on skin may cause burn s.

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

!

DEF is mildly corrosive. Avoid cont act with eyes , skin, and

clothing. Ensure that eyewash stations and safety

showers are close to the work location. Seek medical

advice/recommended treatment if DEF spills into eyes.

WARNING

!

No Open Fire

Open flames from matches, lighters, welding torches or

other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ig nite fuels and their

vapors. Static electricity, including an electrostatic charge on

your body, can cause a spark sufficient to ignite fuel vapors.

Every time you get out of a vehicle, touch the metal of your

vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capab l e of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods, if

you work with or around high voltages. This informa tion is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and caution

them not to activate power while you are working on the

equipment. Use the OSHA Lockout/Tagout procedures . If you

are not familiar with this requirement, refer to this information in

the service manual and OSHA documentation.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made . Take care that sealing devices

and compounds are in place. Ensure that you do not pinch wires

when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service contractors need

to understand and comply with this program complete ly to

ensure safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly . Ensure that you

clean hands after handling equipment. Do not place any

equipment in the mouth.

Page 2-2 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

IMPORTANT: Oxyg en may be needed at scene if gasoline has

been ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Lockout/Tagout covers servicin g and maintenance of machines

and equipment in which the unexpecte d energization or sta rt-up

of the machine(s) or equipment or release of stored energy

could cause injury to employees or personnel. Lockout/Tagout

applies to all mechanical, hydraulic, chemical, or other energy,

but does not cover electrical hazards. Subpart S of 29 CFR Part

1910 - Electrical Hazards, 29 CFR Part 1910.333 contains

specific Lockout/Tagout provision for electric al haz ards.

Page 9

Hazards and Actions

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

DEF is non-flammable. However it can create a slip hazard. Clean up spills promptly.

!

Collision of a Vehicle with Unit Fire at Island Fuel Spill

The following actions are recommended regarding these hazards:

Important Safety Information

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately . Turn off all system circuit breakers to the island(s).

• Do not use console E-STOP, ALL STOP, and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 2-3

Page 10

Important Safety Information

This page is intentionally left blank.

Page 2-4 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 11

Fueling Process Operation Modes

The DEF nozzle with the blue cover requires a magnetic actuator to dispense the

product. The DEF nozzle with the black cover does not require a magnetic actuator.

IMPORTANT INFORMATION

3 – Operation Modes

Fueling Process

Fueling at Idle State

When the dispenser is at idle state, the following will occur while fueling:

• Electronic head-assembly displa

• Dispenser is in the prime state and urea is at the i

(M02321A005).

• The nozzle is removed from a cold weather dispenser or

weather dispenser.

• Display resets and shows all 8s, then 0s with decimal point.

• Solenoid valve opens (with an audible click).

• Nozzle is inserted into the tank labeled for urea.

• Nozzle is squeezed and product is dispensed.

• Display shows the amount of product being dispensed.

• Nozzle is turned off and product stops

• Nozzle is returned to the cradle or

• Solenoid valve closes and the fueling transaction is terminated.

• Display shows the total amount of product dispensed.

y shows the last sale or a decimal point.

ntake of the Solenoid Valve

handle is turned on a warm

dispensing.

the handle is turned off.

Cold Weather DEF Dispenser

Following will occur in cold weather DEF unit while fueling:

• The dispenser is primed and the product is at the intake of the sol

• When the nozzle is removed, sensor switch sends signal to 9800 Central Proc

(CPU) Board (M06333KECAL):

- Side 1 “Handle” Light Emitting Diode (LED) lights.

- Customer display shows all 8s, then 0s with decimal point.

- Side 1 “Fast”, “Slow”,

- Submersible motor activates in the tank.

- 9800 CPU board sends the AC hot signal to the solenoid valve.

- Solenoid valve opens.

• The product flows and enters into the Coriolis

then to the nozzle (hose jumps).

• When the nozzle is opened, product starts to flow.

• The coriolis meter senses and monitors the product flow and

Coriolis Meter Interface Board (M10030A001) and then to the 9800 CPU board.

• The pulse A LED flashes for pump #1 on the 9800 CPU board.

• If the optional Dual Pulse Input/Outp

9800 CPU board, the two pulsar LEDs will flash when product flow is detected.

• When fueling stops, pulsar LEDs on the 9800 CPU board and optional dual pulse I/O

board stop flashing.

• Customer display shows the total amoun

• Nozzle is placed back into the cradle, dispense

• The fast, slow, and sub LEDs on the 9800 CPU board

TRANSACTION.

enoid valve.

essing Unit

“Sub” LEDs light.

Meter/Pulsar Assembly (M10006B501) and

sends the pulse signal to the

ut (I/O) Board (M06587A001) is attached to the

t of product dispensed in gallons.

r motor stops, and the solenoid valve closes.

are now OFF. END OF

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 3-1

Page 12

Operation Modes DEF LED Functions - Cold Weather Units

DEF LED Functions - Cold Weather Units

9800 CPU Board

Following table shows the LEDs on the 9800 CPU board:

LED LED Status Condition

Pump Handle On Nozzle out

Pulsar On (Flashing) Product flowing

+5 VDC On Always

Slow LED

On Nozzle out and authorizedFast LED

Sub LED

Coriolis Meter Interface Board

Following table shows the LEDs on the coriolis meter interface board:

LED LED Status Condition

CR 1 On +24 VDC power supply enabled

CR 2 - CR 3 On Meter side ‘A’ enabled with the pump handle

CR 4 On +5 VDC power supply enabled

CR 5 Off Pump not in frozen state

Temperature Control Board

Following table shows the LEDs on the temperature control board:

LED LED Status Condition

CR 1 On Power supplied to the fan

CR 2 On Power supplied to the heater

Note: Both CR 1 and CR 2 will activate together when the thermostats

ature o

detect a temper

f 43 °F (6.1 °C) in the cabinet.

DEF Warm Weather Units

DEF warm weather units operate and function the same as the DEF cold weather units without

the functions of the heater/fan assembly, thermostats, and temperature control board, as these

items are not included in the DEF warm weather unit.

Page 3-2 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 13

Diagnostics, Calibration, and Tr oubleshooting DEF Dispenser Problems

An intermitting or bad 9800 power supply can cause the symptoms mentioned in

“Problem 1: Entire unit is down/dead.”, always with the exception of AC power (+5 VDC)

present in the unit.

IMPORTANT INFORMATION

4 – Diagnostics, Calibration, and Troubleshooting

DEF Dispenser Problems

Following section is provided to guide you through possible DEF dispenser problems. For

more information, refer to MDE-4331 Atlas Fuel Systems Installation Manual, MDE-4334

Commercial and Retail Series Atlas Start-up/Service Manual, and FE-356 Field Wiring

Diagram Atlas Retail, Commercial, E-85, and DEF Dispensers with Electronic and

Mechanical Displays.

Before beginning any troubleshooting session, it is advisa

• Perform a visual inspection of the dispenser to ensure that

ble to follow these steps:

it is installed according to

MDE-4331 Atlas Fuel Systems Installation Manual.

• Ensure that all cables and switch settings are connected and set

properly according to

MDE-4331 Atlas Fuel Systems Installation Manual and MDE-4334 Commercial and

Retail Series Atlas Start-up/Service Manual.

• Measure the DC power supply output voltages to

ensure that they are proper operating

tolerances.

• Observe all the LEDs on all the Printed Circuit Boards (PCBs) to ensure that proper s

is present.

• Observe the customer display and verify if any error messages are present.

• Verify if this is a new start-up or an existing unit,

and for how long has it been in

operation.

Note: Before beginning any troubleshooting

session, it is helpful to use the “Flow Chart” on

page 4-3 and the “Atlas DEF Block Diagram” on page 4-4.

Following table shows possible symptoms,

Problem 1: Entire unit is down/dead.

Symptoms • No customer display.

• Display is blank.

• Unable to reset unit.

• Unable to dispense product.

• No LEDs light on any PCBs.

Possible Causes • No 115 VAC feed to dispenser.

• Dispenser’s circuit breaker is off.

• Blown system fuse.

• Loose or disconnected AC wiring in Junction Box (J-box).

Corrective Action • Turn on AC breaker for the dispenser, if off.

• Ensure 115 VAC at all power supplies input.

• Check system fuse if AC is not present in the power supply.

• Check and measure the AC voltage in the J-box, if all of the above fails.

causes, and corrective actions:

ignal

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 4-1

Page 14

DEF Dispenser Problems Diagnostics, Calibration, and Troubleshooting

Problem 2: No product dispenses/flows.

Symptoms • Dispenser electronically resets.

Possible Causes • Solenoid valve does not activate.

Corrective Action • Ensure to hear the solenoid valve opening.

• Display shows all 0s.

• No error messages.

• No product dispenses.

• 9800 CPU board does not send the AC signal to the solenoid valve or submersible motor in the tank.

• Bad submersible motor in the product’s tank.

• Bad coriolis meter interface board (possibly due to the coriolis meter).

• Bad nozzle.

• Check valve is stuck at the closed position.

• Feel the hose jump.

• Observe fast, slow, and sub LEDs on the 9800 CPU board.

• Check fast and slow fuses on the 9800 CPU board, replace if open.

• If the solenoid valve activates, check for proper AC signal at the sub fuse on the 9800 CPU board.

• Replace the fuse, if open. If the fuse is OK but there is no sub LED, replace the 9800 CPU board.

• If the 9800 CPU board displays a proper AC signal, open the inlet line to verify if the product flows when the

unit is on.

• Replace the submersible motor, if there is no product flow at the inlet.

• Verify if the check valve is not stuck at the closed position by loosening the inlet cap. Also, verify if the

product is present.

Problem 3: Dispenser does not calibrate.

Symptoms • Display shows error code 993 on DEF unit.

Possible Causes • Air in product line needs to be purged.

Corrective Action • Verify that the tank is not low in product, request a delivery if the product level is low.

Problem 4: DEF unit dispenses product very slowly, slow flow.

Symptoms • No error messages appear, but the product dispenses very slowly as in slow flow mode.

Possible Causes • Dirty filter, product contamination.

Corrective Action • Remove inlet filter and replace, if dirty.

• No product can be dispensed.

• Product leak in the plumbing.

• Bad 9800 CPU board or program.

• Very low product level in the tank.

• Product contamination.

• Recalibrate the DEF unit by performing the calibration procedure described in MDE-4331 Atlas Fuel

Systems Installation Manual and MDE-4334 Commercial and Retail Series Atlas Start-up/Service Manual.

• Dispense product until there is no visual evidence of air in the product (may take two to three prover cans).

• Check for any product leaks in all the product lines and the internal plumbing. Correct the leaks, if visible.

• Verify that the filter is clean and free of debris.

• Change the 9800 CPU board, if all of the above fails.

• Check valve not opening completely.

• Defective solenoid valve.

• Defective 9800 CPU board.

• Defective submersible motor in tank.

• Defective nozzle filter or the nozzle.

• On the 9800 CPU board, measure for 115 VAC on both sides of the fast flow fuse (F2).

• If AC is not present, perform a continuity test across the F2 fuse. Replace the fuse, if open.

• If the F2 fuse is not open, replace the 9800 CPU board.

• If 115 VAC is present on the blue and black wire on the two stage solenoid valve, replace the solenoid

valve.

• Check the submersible motor to see if the running is at full speed due to low voltage or defective motor.

• DEF nozzle could restrict the flow (remote possibility), replace the nozzle and retry dispensing the product.

Page 4-2 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 15

STOP

Below

Operating

Temperature

Specs.

YES

NO

Wait Until Local

Temperature

Increases

and Warms

Test 9800

CPU

Board

PROBLEM 1

Hear Fan ON

Feel Heat in Lower Cabinet

Feel Heaters

YES

Verify

Solenoid

Valve is

Open

NO

NO

Coriolis

Interface

CR1 and

CR2 ON

YES

NO

Replace

Coriolis

Meter

M10006A003

Temperature Control Board

CR1 and CR2 is ON

Replace

Power

Supply

M04151B005

YES

Test Fuse on

Heater/Fan

Assembly

Replace

Heater and

Fan

Assembly if

Fuse is good

NO

YES

NO

YES YES

YES

YES

NO

NO

NO

NO

NO

Verify

110 VAC

is on P3 AC

Input

Connector

Temperature

Control Board

Mearure for

+5 VDC

at TP1 and TP2

Temperature

Control Board

Mearure

+5 VDC

on P130 Pin 1

Measure

110 VAC

at P1301A at Pins

1 and 4

Replace

Temperature

Control

Board

Replace

Bottom

Temperature

Sensor

Verify

110 VAC

is Measured

at J-box

Check Power

Cable

Connection to

Temperature

Control

Board

Coriolis

Interface

Board

Measure

+5 VDC at

J1401 Pins

1 and 3

Check Circuit

Breaker is ON

9800 CPU Board

Measure +5 VDC at

P9 Pins 1 and 6

No or Low

Voltage

Measured

YES

Is

Outside

Temperature

Below - 30

DISPLAY

999

No Product

Frozen Condition: The coriolis interface board monitors the temperature at the

solenoid valve using the temperature sensor known as the frozen thermostat. The

purpose is to remove power to signal the 9800 CPU board not to active the solenoid

valve on the coriolis meter. This prevents the solenoid valve to potentially leak and

also prevent damage to the coriolis meter.

The CR5 LED on the coriolis interface board will light when a freeze condition

exists, which is normally caused by other component failure, causing the heaters

not to turn on as shown Figure 4-1.

Calibration Test: When the freeze problem has been

corrected and the heater/fans are working, to keep the inside

cabinet temperature in 30° F (-1.1° C) range or higher, you

need to recalibrate the unit to remove the error message 999

displayed.

Symptoms: In very cold weather conditions, the display shows 999 and is unable to dispense product.

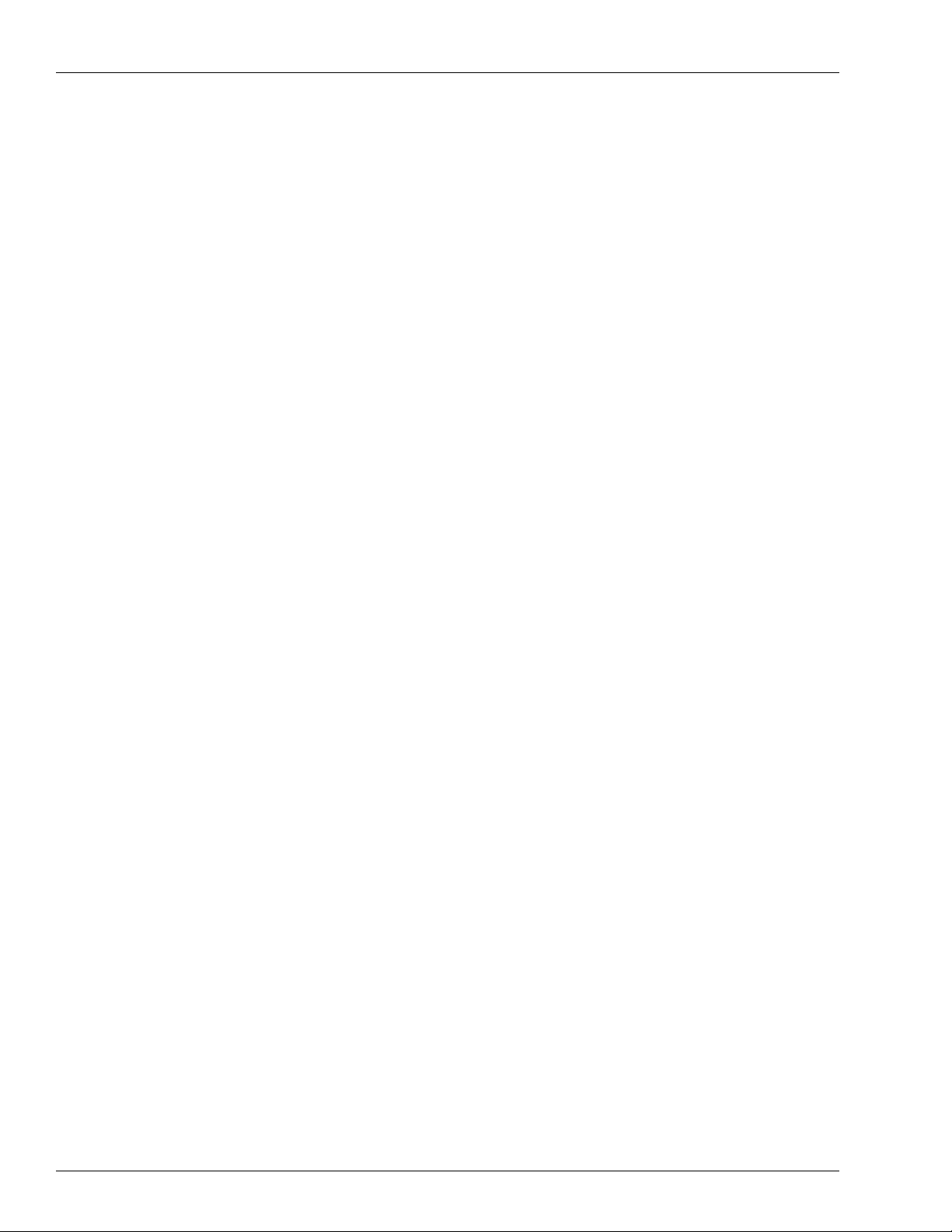

Diagnostics, Calibration, and Tr oubleshooting Diagnostics Procedure for Cold Weather Problems

Diagnostics Procedure for Cold Weather Problems

Figure 4-1 shows the flow chart of diagnostics procedure for cold weather problems for Atlas

9862 DEF units.

Figure 4-1: Flow Chart

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 4-3

Page 16

Diagnostics Procedure for Cold Weather Pro bl ems Diagnostics, Calibration, and Troubles hooting

P2112

P2110

P1401

P1405A

P2402

P1400

J-3 AC IN

CR2

Heater ON

CR1

Fan ON

P-2

P-3

P1301A

P1

P2

P3

P4

P5

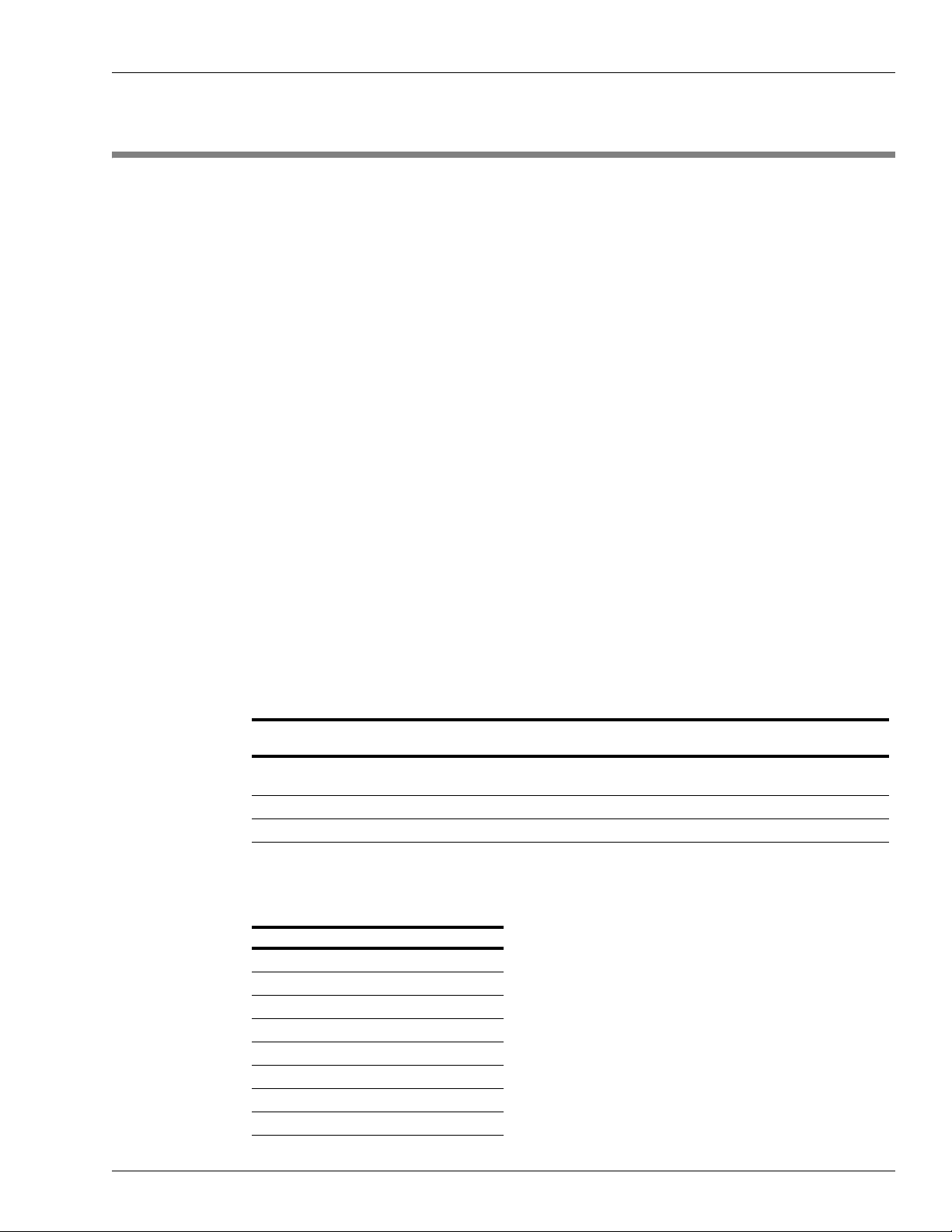

Atlas®9862 DEF Block Diagram

+5 VDC

+5 VDC

110 VA C

+5 VDC

P9

Nozzle Boot

Switch

(M06600K001)

Frozen

Thermostat

(M10131A008)

Two Stage

Valve

(M02321A005)

Heater

Thermostat

(M10131A006)

Coriolis Meter [M10006A001

(Complete Assembly)]

[M10006B501 (Electronics)]

Fan/Heater Assembly

(M12260A001) for Nozzle

Fan and Heater Assembly

(Q13254-03)

Motor

Relay

40 Amp

(Q11008-02)

Switching Power Supply

(M04161B005)

24 VDC

IN

Atlas 9862

CPU

M06783A001

Temperature Control Board

M10030

Coriolis Interface

Figure 4-2: Atlas DEF Block Diagram

Page 4-4 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 17

Diagnostics, Calibration, and Tr oubleshooting Diagnostics Procedure for Cold Weather Problems

The DEF nozzle with the blue cover requires a magnetic actuator to dispense the

product. The DEF nozzle with the black cover does not require a magnetic actuator.

IMPORTANT INFORMATION

Atlas 9862 DEF Dispenser Status/Error Codes

Code Status

01 Random Access Memory (RAM) failure

02 Read Only Memory (ROM) failure

55 Power failure

56 Pulsar error

57 Timed out

58 Limit cutoff

59 Flow error meter 1

60 Flow error meter 2

99 Product unavailable

554 Power failure (calibration mode)*

564 Pulsar failure (calibration mode)*

574 Timed out (calibration mode)*

584 Limit cutoff (calibration mode)*

993 Invalid calibration factor*

994 Invalid calibration transaction

*During calibration testing.

Customer Display

Code Definition

7 Calibration switch on

5, 10, 15, 20, 50 Prover can sizes

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 4-5

Page 18

Electronic Calibration (E-CAL) Adjustment for E-85/DEF Unit Diagnostics, Calibration, and Troubleshooting

Calibration Switch

(i)

(ii)

Electronic Calibration (E-CAL) Adjustment for E-85/DEF Unit

The E-85/DEF unit must be calibrated electronically. To calibrate the unit, proceed as follows:

Notes: 1) If the unit is two-sided, then the calibra

individually on each side.

2) The calibration switch is located on the J-box side of all thr

(see Figure 4-3).

Figure 4-3: Calibration Switch and J-box

tion procedure must be performed

ee E-85 unit types

1 Slide the back cover and turn the calibration switch to “Calibrate” position (up).

a Locate the calibration assembly, slide the Weights and Measures (W&M) seal metal cover

toward the exterior of the unit.

b Locate the inside switch for side B or the outside switch for side A. Place the switch in the

up position to activate the calibration procedure.

Number “7” appears in the Most Significant Digit (MSD), left-most digit of the pump display

and will remain throughout the procedure (see Figure 4-4).

Figure 4-4: Turning on Calibration Switch

Page 4-6 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 19

Diagnostics, Calibration, and Troubl eshooting Electronic Calibration (E-CAL) Adjustment for E-85/DEF Unit

After five seconds, the prover can size appears in the two Least Significant Digits (LSD),

right-most digit of the pump display (see Figure 4-5). The can size will appear for five seconds

before advancing to the next can size. The display will continue to scroll through can sizes

until the nozzle is removed and pump handle is switched on.

Note: If the nozzle is not removed within 10 minutes of turning the switch to calibrate position,

error code 574 appears (57 indicates time out and 4 indicates calibration mode error).

Turn the calibration switch to off position (down) to clear the error.

Figure 4-5: Displaying Can Size

2 After the required can size appears on the display, remove the nozzle and switch on the pump

handle. This selects the can size for calibration.

Note: If the pump handle is switched on for an inap

propriate can size and if the dispensing

has not started, switch off the pump handle. Scrolling will resume. If dispensing has

begun, switch off the pump handle, turn the calibration switch to off position, and

restart calibration from step 1 on page 4-6.

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 4-7

Page 20

Electronic Calibration (E-CAL) Adjustment for E-85/DEF Unit Diagnostics, Calibration, and Troubleshooting

DEF fluid tends to dissipate air much slower than for gasoline or diesel fuel. Wait for

three minutes and gently tap the prover can with a rubber mallet to ensure entrapped air

is dissipated and an accurate reading can be taken.

IMPORTANT INFORMATION

3

Dispense fuel into the prover can exactly to the zero mark. The uncalibrated volume appears.

Notes: 1) If the fuel/DEF is not dispensed within four minutes (about) of switching on the

pump handl

e (or within the time period set by the contr oller for pulsar time out), the

error code 574 appears indicating that the pump handle must be switched off to

clear the error. Scrolling will resume after you replace the nozzle.

2) If the fuel/DEF dispensing has started but stopped and the pump times out, the

calibra

as shown in Figure 4-6 (99 indicates that the pr oduct is

the product is not calibrated). The procedure must then be restarted from step 1

tion switch must be turned to off position. Otherwise, error code 993 appears

not available and 3 indicates

on page 4-6.

Figure 4-6: Displaying Error Code

4 Switch off the pump handle and return nozzle to boot. After three seconds, the calibration

factor appears on the display for three seconds and then zeros are displayed indicating that the

meter is now calibrated. No further transactions will be allowed until the calibration switch is

turned to off position.

Note: If an additional transaction is attempted, err

or code 994 appears (99 indicates product

not available and 4 indicates calibration mode err or). Turn the calibration switch to off

position and switch off the pump handle to clear the error. The error code 993 appears

indicating that the calibration procedure must be restarted from step 1 on page 4-6.

5 Turn the calibration switch to off position and slide the switch cover back over the switch.

Page 4-8 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 21

Diagnostics, Calibration, and Troubl eshooting Electronic Calibration (E-CAL) Adjustment for E-85/DEF Unit

The settling time for freshly dispensed DEF is longer than for gasoline or diesel.

Therefore, a three-minute wait time between dispensing the DEF into the prover can

and taking the reading from the sight glass is recommended.

IMPORTANT INFORMATION

Units must be properly purged before calibration or calibration verification. Incomplete

purging of air can result in inaccurate calibration or errors in calibration verification

testing.

IMPORTANT INFORMATION

A stainless steel prover can must be used to calibrate DEF. Do not use a can that has

been used for other fluids. Contaminated DEF can cause damage to vehicle engines,

contaminated fuel can corrode dispenser material(s), vehicle catalytic converter(s), or

damage vehicle engines.

CAUTION

Calibration and Accuracy Checks - DEF Dispensers

An ELAFIX 40 Magnetic Adapter (M10656B001) must be pushed over the spout when you

dispense DEF into the prover can during calibration or service.

Each time a meter is calibrated, a volume of DEF is generated. This DEF must be properly

managed and cannot be discarded into the storm drain or where it can possibly reach surface

water or groundwater. If the DEF is to be returned to the supplier, store it in a closed

leak-proof container.

Avoid dispersal of spilled material and runoff. Ensure that DEF does not come in contact wi th

soil, waterways, drains, and sewers. Inform the relevant authorities if the product has caused

environmental pollution (sewers, waterways, soil, or air).

DEF poured back into the tank must be kept clean. Do not allow DEF to become contaminated

during handling.

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 4-9

Page 22

Electronic Calibration (E-CAL) Adjustment for E-85/DEF Unit Diagnostics, Calibration, and Troubleshooting

This page is intentionally left blank.

Page 4-10 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 23

Electronic Head Assembly Recommended Spare Parts

5 – Recommended Spare Parts

Electronic Head Assembly

Following table lists the recommended spare parts for the electronic head assembly of the

Atlas DEF dispenser:

Part Number Part Description

M10030A001 Coriolis Interface Printed Circuit

M06783A001* E2 Temperature Control PCA

M06333A002 Atlas 9800 CPU PCA

M05110A001 AC Bracket Cable

M10203A001* Temperature Sensor PCA

M12260A001* Fan/Heater Assembly for Nozzle

M10131A008 Frozen Thermostat

M04161B005 Switching Power Supply

M07588A002 9800 Power Supply PCA

Q11008-02* Solid State Relay

M12158A003 Main Display and Backligh

*Parts not used in warm weather units.

Assembly (PCA)

s Atlas Assembly

t

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 5-1

Page 24

Recommended Spare Parts Electronic Head Assembly

Coriolis Interface PCA

(M10030A001)

Main Display and Backlights Atlas Assembly

(M12158A003)

9800 Power Supply PCA

(M07588A002)

Switching Power Supply

(M04161B005)

Line Filter (Q10362-02)

Atlas 9800 CPU PCA

(M06333A002)

E2 Temperature Control PCA

(M06783A001)

Solid State Relay

(Q11008-02)

J1400

Figure 5-1: Electronic Head Assembly

Page 5-2 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 25

Lower Hydraulic Section Recommended Spare Parts

Lower Hydraulic Section

Following table lists the recommended spare parts for the lower hydraulic section of the Atlas

DEF dispenser:

Part Number Part Description

M10006A003 Coriolis Meter

M10006B501 Meter, Electronics Module

M10164B001 Flange Seal

M10258B001 Swivel SST DEF Breakaway

M10257B001 DEF Nozzle with Misfiling Option

M10257B002 DEF Nozzle Without Misfiling Option

M10170B002 Check Valve, 3/4” - 14 NPT

M10131A006* Heater Thermostat

M10226B101 DEF Outlet Hose

M10820A001 Y-Strainer (Thread End)

M10820B002 Replacement Strainer

M02321B005 Valve/Coil

M06600K001 Nozzle Boot Switch

*Parts not used in warm weather units.

Note: Magnetic Ring T ool (M10656B001) is requir ed for each technician servicing DEF units

except when a M10257B002 Nozzle is used.

MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014 Page 5-3

Page 26

Recommended Spare Parts Lower Hydraulic Section

Fan/Heater Assembly

(M12260A001) for Nozzle

Heater Fan Assembly

(Q13254-03)

Check Valve, 3/4” - 14 NPT

(M10170B002)

Freezing Sensor

(M10131A008)

M02321B005 Valve

M010820A001

Strainer

M11270B002 Swivel

Hose Reel Assembly

Figure 5-2: Atlas DEF Dispenser Hydraulics

Page 5-4 MDE-5044A Atlas® DEF Operation, Diagnostics, and Recommended Spare Parts Manual · April 2014

Page 27

Index

Index

Numerics

9800 CPU Board 3-2

9800 CPU board 4-3

A

Atlas 9862 DEF Dispenser Status/Error

Codes 4-5

C

Calibration and Accuracy Checks 4-9

Cold Weather DEF Dispenser 3-1

Coriolis Meter Interface Board 3-2

CR5 LED 4-3

D

DEF Dispenser Problems 4-1

DEF LED Functions - Cold Weather

Units 3-2

DEF Warm Weather Units 3-2

Diagnostics Procedure for Cold Weather

Problems 4-3

Diagnostics, Calibration and

Troubleshooting 4-1

E

E-85 4-6

Electronic Calibration (E-CAL)

Adjustment 4-6

Electronic Head Assembly 5-1

F

F2 4-2

Fueling at Idle State 3-1

I

Important Safety Information 2-1

Intended Users 1-1

Introduction 1-1

L

Lower Hydraulic Section 5-3

M

M04161B005 5-1

M05110A001 5-1

M06333A002 5-1

M06600K001 5-3

M06783A001 5-1

M07588A002 5-1

M10006A003 5-3

M10006B501 5-3

M10030A001 5-1

M10131A006 5-3

M10131A008 5-1

M10164B001 5-3

M10170B002 5-3

M10203A001 5-1

M10226B101 5-3

M10257B001 5-3

M10257B002 5-3

M10258B001 5-3

M10656B001 4-9

M10820A001 5-3

M10820B002 5-3

M12158A001 5-1

Mode 3-1

P

Possible symptoms, causes, and

corrective actions 4-1

Problem 1

Entire unit is down/dead 4-1

Problem 2

No product dispenses/flows. 4-2

Problem 3

Dispenser does not Calibrate. 4-2

Problem 4

DEF unit dispenses product very

slowly, slow flow 4-2

Prover can 4-5, 4-2, 4-7, 4-8, 4-9

Purpose 1-1

Q

Q11008 5-1

Q13254-03 5-1

R

Recommended Spare Parts 5-1

Related Documents 1-1

Required Tools 1-1

S

sewers 4-9

soil 4-9

storm drain 4-9

T

Temperature Control Board 3-2

V

vehicle catalytic converter 4-9

W

W&M 4-6

waterways 4-9

Z

zero mark 4-8

MDE-5044A Atlas® DEF Operation, Diagnostic, and Illustrated Parts Manual · April 2014 Index-1

Page 28

Gilbarco® is a registered trademark of Gilbarco Inc. GOLDSM is a service mark of Gilbarco Inc. Phillips® is a registered trademark of Phillips

Screw Company. UL

®

is a registered trademark of Underwriters’ Laboratories Inc.

© 2014 GASBOY

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone 1-800-444-5529 · http://www.gasboy.com · Printed in the U.S.A.

MDE-5044A Atlas® DEF Operation, Diagnostic, and Illustrated Parts Manual · April 2014

Loading...

Loading...