Page 1

Commercial and Retail Series

Atlas

™

Start-up/Service Manual

MDE-4334D

Page 2

Computer Programs and Documentation

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

All dispensers and self-contained pumping

units

MH6418

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP , 72X, 73 and

1820

MH7404

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

95-136 Dispenser 9800 Series 91-057 Controller

1000 Series FMS,

2000S-CFN Series

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

9800A, 9840A, 9850A, 9852A,

9853A, 9140

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

9800Q, 9840Q, 9852Q, 9853Q

5087 8753K, 8853K, 9153K, 9853K

(restricted to diesel and non-

retail gasoline sales)

5091 8752K, 9152K

5129 9122K, 9123K, 9822K, 9823K

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Registered trademarks

ASTRA

®

Fuel Point

®

Gasboy

®

Keytrol

®

Slimline

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

Non-registered trademarks

Atlas™

Consola™

Infinity™

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Trademarks

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

2013 GASBOY · All Rights Reserved

Page 3

Table of Contents

Table of Contents

1 – Read This First 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Important Information About Releases. . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Topics in This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Who Must Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Service Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Common Terms Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

DEF Special Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting DEF Freeze. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

If DEF Freezes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Important Requirements for

Model Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E85 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Mechanical Retail Pump/Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Electronic Retail Pump/Dispenser . . . . . . . .

Serial Number Plate and Date Codes . . . . .

Atlas Model Number Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

. . . . . . . . . . . . . . . . . . . . 1-11

. . . . . . . . . . . . . . . . . . . . 1-12

. . . . . 1-6

. . . . . . . 1-10

2 – Important Safety Information 2-1

3 – Start-up Procedures 3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Important Information About Releases. . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Topics in This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

How to Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Certificate of Conformance (CoC) Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Start-up Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Checklists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Meter Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gasboy Atlas (Gallon Unit of Measure) . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

. . . . . . . . 3-2

. . . . . . . . 3-4

4 – Pump Programming 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Important Information About Releases. . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Programming Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9800 Series Electronic Commercial Units . . . . . . . . . . . . . . . . . . . . . . . 4-1

8800 Series Electronic Retail Units . . . . . .

Mechanical Commercial Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Configuring 9800 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Configuration Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Configuration Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

ATC Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

. . . . . . . . . . . . . . . . . . . . . . 4-2

. . . . . 4-1

. . . . . . 4-3

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page i

Page 4

Table of Contents

Programming 8800 Series Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

General Programming Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Display Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Programming Steps for 8800 Series Units . . . . . . . . . . . . . . . . . . . . . .4-15

Level 1 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Level 2 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Level 3 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Option and Miscellaneous Programming/Data Acquisition. . . . . . . . . .4-24

Displaying Pump Totals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Error Codes and Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Programming 8700 Series Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Programming Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Programming Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

. .4 -27

5 – Electronic and Electrical Components 5-1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Important Information About Releases . . . . .

Topics in This Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

How to Use This Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Electronics Highlights. . . . . . . . . . . . . . . . . . . . . . .

Retail Parts by Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Retail Parts by Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Commercial Parts by Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

8800 Series Electronic Retail Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

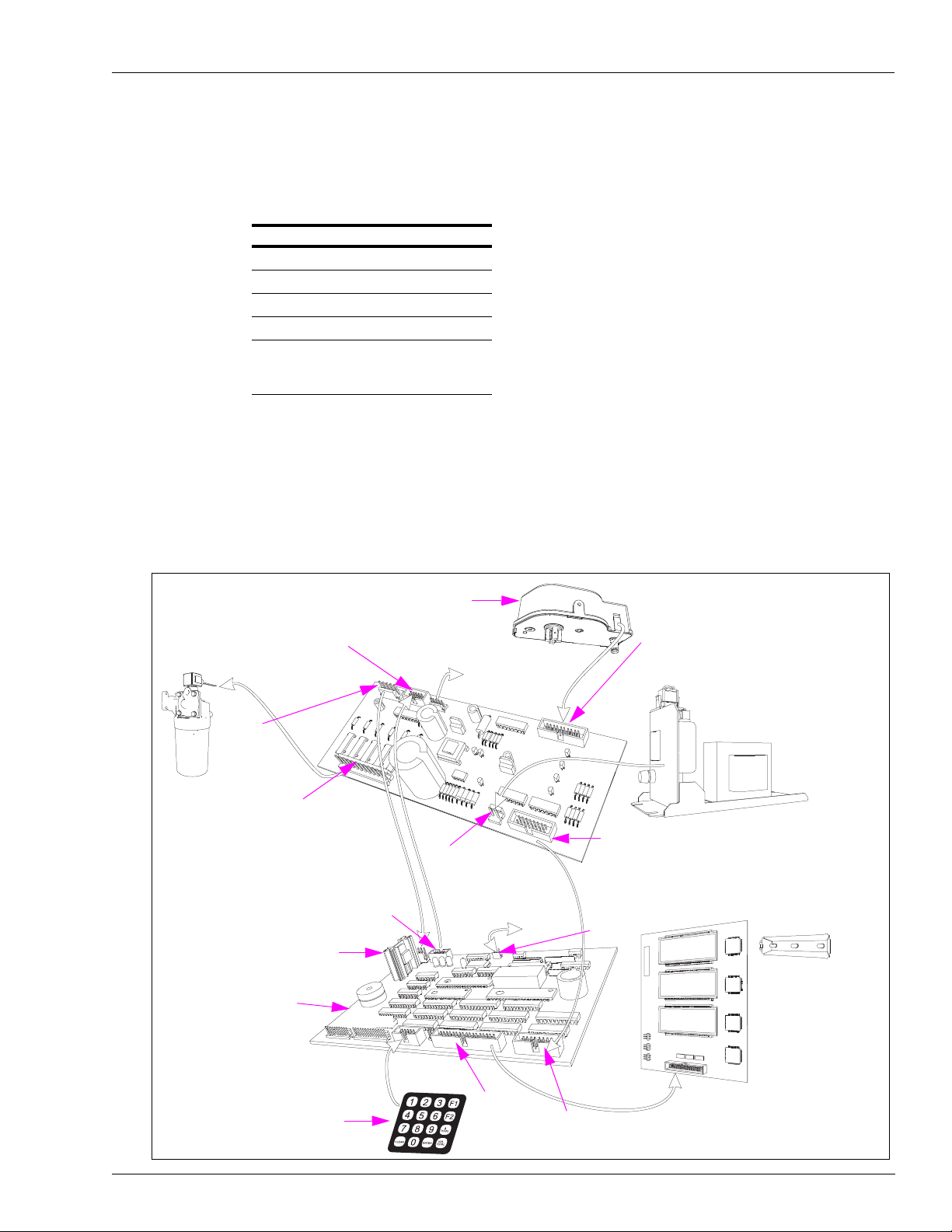

System and Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

About Service Procedures . . . .

Working on Electronic and Electrical Components. . . . . . . . .

Component Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCAs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Atlas 9800 Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Electronic Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Atlas 9800 Power Supply

Installing Atlas 9800 CPU Board (M06333KXXXX) . . . . . . . . . . .

Installing Atlas 9800 Pulse-out I/F with EM Totaliz

Atlas 8800 Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Preparing for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Preventing ESD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Hazardous Materials . . . .

Atlas 9800 PCAs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Atlas 9800 CPU Board (M06333KXXXX) . . . . . . . . . . . . . . . . . . . . . . .5-25

Atlas 9800 Power Supply (M07588A00X). . . . . . . . . . . . . . . . . . . . . . .5-28

Atlas 9800 Serial EEPROM Board (M06656K00X). . . . . . . . . . . . . . . .5-29

Atlas 9800 Pulse-out I/F Board with

EM Totalizer Drive (M06587A001) . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-30

K-pump RS-485 with Totalizer (M06725A001) . . . . . . . . . . . . . . . . . . .5-31

(M07588A00X). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-32

Jumpers JP1, JP2, and JP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

Jumpers JP4 and JP5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-35

Pump Interface PCA [T18994 (Atlas 8800 Only)] . . . . . . . . . . . . . . . . .5-37

Pump Controller PCA [T20092 (Atlas 8800 Only)] . . . . . . . . . . . . . . . .5-38

ATC Component Overview (Atlas 8800 Only). . . . . . . . . . . . . . . . . . . .5-40

Manager Keypad [T17549-G1 (Atlas 8800 Only)]

Display Backlight PCA (0.6-inch) [T17622-G9 (Atlas 8800 Only)] . . . .5-43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

. . . . . . . . . . . . . . . . . . . . . . . . . . .5-33

er Drive Board (M06587A001). . . . . . . . . . . . . . .5-34

. . . . . . . . . . . . . . . . . . . . .5-1

. . . . . .5-11

. . . . . . . . . . .5-12

. . . . . . .5-25

.5-31

. . . . . . .5-37

. . . . . . . . . . . . . . . . .5-42

Page ii MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 5

Table of Contents

LCD Display (0.6-inch) [T17701-G1 (Atlas 8800 Only)]. . . . . . . . . . . . 5-44

LCD Display (0.6-inch) [T18981-G1 (Atlas 8800 Only)]. . . . . . . . . . . . 5-45

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-46

Main Power Supply (T19868-G1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-48

I.S Barrier Assembly ATC (T19428-G1). . . . . .

Q10131-03 Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Electro-mechanical Registers and Totalizers . . . . . . . . . . .

About Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

Pulsers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Standard Pulsers . . . . . . . . . . . . . . .

Testing Pulsers and I.S Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

Pulser Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-54

About Ultra-Hi Pulsers . . . . . . . . . . . . . . . .

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEF Heating System (Commercial Cold W

Coriolis Meter Interface Board (M10030A001).

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-50

. . . . . . . . . . . . . . . . . . 5-50

. . . . . . . . . . . . . . . . . . . . . 5-53

. . . . . . . . . . . . . . . . . . . . . 5-55

eather DEF Units Only) . . 5-55

. . . . . . . . . . . . . . . . . . 5-57

. . . . . . . 5-46

. . . . . . . . . . 5-53

. . . . . . . . . . 5-55

6 – Hydraulic/Mechanical Components 6-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Important Information About Releases. . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Topics in This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

How to Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Hydraulic and Mechanical Highlights. . . . . . . . . . . . . . .

2-stage Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

General Service Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Working on Hydraulic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Servicing Hydraulic Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Servicing Seals, O-rings, and Gaskets . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Pipes and Hydraulic Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Purging Air from System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Purging System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Purging Product Lines (New Installations). . . .

Purging Pumps and Dispensers (with Fuel in Product Lines) . . . . . . . 6-11

Purging Air in DEF Systems. . . . . . . . . . . .

Measuring Flow Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measuring Pressure and Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Pressure Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Pressure Measuring Locations on Unit . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Measuring Pressure Drop for Pumps and Dispensers

Analyzing Pressure Drop for Pumps

Measuring Vacuum for Pump. . . . . . . . . . . .

About Vacuum Readings . . . . . . . . . . . . . .

Measuring Dry Vacuum for Pump . . . . . . . .

Measuring Wet Vacuum and Pressure for Pump

Meter Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Calibrating Meters . . . . . . . . . . . . . .

CFT Meter Calibration Adjustment for

Super-Hi™ Models (All Models Excluding 9850K and 9850KX) . . . . . 6-23

LC Meter Calibration Adjustment for Ultra-Hi

Models 9850K and 9850KX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Calibration Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

. . . . . 6-4

. . . . . . 6-9

. . . . . . . . . . . . . . . . . . 6-10

. . . . . . . . . . . . . . . . . . . . . 6-12

. . . . . 6-13

6-14

. . . . . . . . . . . . . 6-16

and Dispensers . . . . . . . . . . . . . 6-17

. . . . . . . . . . . . . . . . . . . . 6-19

. . . . . . . . . . . . . . . . . . . . . 6-19

. . . . . . . . . . . . . . . . . . . . 6-19

. . . . . . . . . . . . . . . . . 6-20

. . . . . . . 6-22

. . . . . . . . . . . . . . . . . . . . . 6-22

Standard, Hi-Flow, and

for E85/DEF Units

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page iii

Page 6

Table of Contents

[Electronic Calibration (ECAL)] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .6-26

About Meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

CFT/E85 Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-27

Repairing CFT/E85 Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Replacing Cylinder Cover and Gasket (Cy

Replacing O-rings (Body and Cover Leaks) . . . .

linder Cover Leaks) . . . . . .6-29

. . . . . . . . . . . . . . . . .6-30

Calibrating Wheel Parts Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-31

Replacing Piston Cups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-31

Removing/Replacing Shaft Seal and Gasket (Upper Seal Leaks) . . . .6-33

LC Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

Removing/Replacing LC Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

Coriolis Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-35

Filters and Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .6-37

About Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-37

Servicing Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

About Strainers . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-40

DEF Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-40

Servicing Strainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-40

Hanging Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Hanging Hardware . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

. . . . . . .6-41

Hoses and Flow Restrictors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

Breakaway Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-44

Testing Hose and Hanging Hardware Continuity . . . . . . . . . . . . . . . . .6-46

Internal Hose Retrievers

Pumping Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and Clamps. . . . . . . . . . . . . . . . . . . . . . . . . .6-48

. . . . . . . . .6-50

GPU Pumping Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-50

Servicing Strainer Check Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-52

Servicing Pressure Control Valve (PCV)

Servicing Bypass/Pressure Relief

Servicing Rotor and Shaft Assembly

. . . . . . . . . . . . . . . . . . . . . . . .6-54

Valve (PRV) . . . . . . . . . . . . . . . . . .6-55

. . . . . . . . . . . . . . . . . . . . . . . . . . .6-57

XU2A Pumping Unit for 9850K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-58

Sump for 9850K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-61

Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Electric Motor for Self-contained Pump Units

. . . . . . . . . . . . . . .6-62

. . . . . . . . .6-62

Belts and Pulleys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-63

Belt Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-64

Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .6-65

Solenoid Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-65

Solenoid Valve and Filter Manifold . . . . . . . .

. . . . . . . . . . . . . . . . . . . .6-67

Solenoid Valves for 9 X 40, 9850 and 9 X 53 with

Satellite Outlet Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-68

Meter Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-69

Shear Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-70

T-52A Pressure Regulator Valve Option. . . . . . . . . . . . . . . . . . . . . . . .6-72

Vapor Recovery Stage 2 Balance Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-73

Mechanical Computers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DEF Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .6-73

. . . . . . . . .6-74

Nozzle Door Mechanism (Cold Weather Units Only) . . . . . . . . . . . . . .6-74

-72

Page iv MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 7

Table of Contents

7 – Troubleshooting Tables 7-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Important Information About Releases. . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Topics in This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Troubleshooting Tables (Commercial Electronic and Retail Elec

Sample Troubleshooting Form. . . . . . . . . . .

Priority Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Table 1: Communications to Console . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Table 2: Fuel Delivery (All Units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Table 3: Electronic Displays, Electric Reset,

Table 4: Error Codes 10-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Table 5: Handle Responses, Leaks, Noise, and

Table 6: Repeated Problems and STPs. . . . . . . . . . . . . . . . . . . . . . . . 7-10

tronic Units) . . . . . . . . . . . . . . . . . . 7-2

. . . . . . . . . . . . . . . . . . . . . 7-3

and Calibration . . . . . . . . 7-6

Presets (All Units) . . . 7-9

8 – Wiring and Configuration 8-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Important Information About Releases. . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Topics in This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Cable Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram Atlas Commercial (Including DEF and

E85 Models) M05193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Atlas Hydraulics, Bezel, and Door Configurat

ions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

. . . . . . 8-1

9 – Preventive Maintenance and Inspection 9-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Important Information About Releases. . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Topics in This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

How to Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Procedures and Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Maintenance of Vendor Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Performing Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Replacements and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filter Strainer Replacement . . .

Adjusting Belts (Suction Pumps Only) . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Preserving Finish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preserving Finish of Fueling Equipment . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Preventive Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

. . . . . . 9-1

. . . . . . 9-2

. . . 9-4

. . . . . . . . 9-5

. . . 9-6

Index Index-1

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page v

Page 8

Table of Contents

This page is intentionally left blank.

Page vi MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 9

Introduction Read This First

1 – Read This First

Introduction

Purpose

This section contains a general introduction, service protocol, safety, and model number

information.

Sections of this manual provide start-up and service information for

dispensers. This manual is a general service guide and not a replacement for Gasboy

certified training. Certified training includes instructions on safety procedures, use of test

equipment and common tools, wiring requirements, and electrical service procedures. The

sections in this manual cover the following topics:

Topics Page

Read This F

Important Safety Information 2-1

Start-up Procedures 3-1

Pump Programming 4-1

Electronic and Electrical Components 5-1

Hydraulic/Mechanical Components 6-1

Troubleshooting Tables 7-1

Wiring and Configuration 8-1

Preventive Maintenance and Inspection 9-1

irst 1-1

Important Information About Releases

Sections of this manual may be released or updated independently to supply the most current

data. Information about release date and version for independently released sections will be

included in the section title and footer of the document. For the latest updates, refer to

Gilbarco Online Documentation (GOLD

Atlas™ pumps and

®

Atlas

®

).

This section was last updated

in July 2013.

Topics in This Section

Topic Page

DEF Special Considerations 1-6

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-1

Page 10

Read This First Introduction

Who Must Use This Manual

This manual is intended for Gasboy Atlas Authorized Service Contractors (ASCs) who have

been trained and certified by attending Gasboy certified training classes. These ASCs must be

aware of the safety requirements and basic troubleshooting techniques, such as reading a

volt/ohmmeter, reading pressure, and so on, and understanding the differences

between

various Gasboy Atlas products, options, and functionalities.

If you have not attended the Gasboy training, contact the Gasboy Training Department. For

contact information, refer to “

Gasboy Contact Information”.

Service Protocol

A Service Technician requesting technical assistance must do the following:

1 Be available at the site.

2 When placing the call, ensure that the following are available:

• Unit model and serial number

• Site name and telephone number

• Your technician number

• Problem description and history

• All required recommended spare parts

• Manuals available for reference

3 Call the Technical Support Department at 1-800-444-5529. Refer to the Customer Service

Report (CSR) number, if previously assigned.

Using Replacement Parts

Use only genuine Gasboy Atlas replacement parts. Use of other parts will void warranty and

could affect unit conformance to various national, local or state codes.

Gasboy

Information Required Contact Details

Schedule training Gasboy Training Department

Technical assistance, customer service, and

warr

Explanation of Gasboy’s warranty policy For assistance, contact your local Ga

T

echnical literature, parts manuals, and other

documents

Contact Information

anty service

TechnicalTraining@gilbarco.com

Gasboy Technical Support at 1-800-444-5529

Helpdesk@gasboy.com

sboy Distributor

y Literature Department at (336) 547-5661

Gasbo

Page 1-2 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 11

Introduction Read This First

Related Documents

Following documents may be helpful when servicing the Gasboy Atlas equipment:

For a complete list of documents available,

refer to P-7001 Gasboy GOLD and Literature

Guide. For information regarding Gasboy Atlas documentation, contact the Literature

Department at 336-547-5661.

Document

Number Description GOLD Library

®

C35963 CFN

FE-356 Atlas Pump and Dispenser Field Wiring Gasboy Parts List & Wiring Diagrams

FE-357 Atlas Pump Retail/Commercial Field Wiring Gasboy Parts List & Wiring Diagrams

FE-361 Atlas Master & Satellite Field Wiring Diagram Gasboy Parts List & Wiring Diagrams

MDE-2188 Kits K35222 & K35222-01 Meter Quad Ring Top Seal Kit Advantage

MDE-3892 C+ Meter Master Seal Service Kit Installation • Encore

MDE-4255 Gasboy Warranty Policy Statement for USA and Canada Gasboy Atlas Pumps/Dispensers

MDE-4298 CFN Series Site Controller III Installation Manual Gasboy CFN Series

MDE-4319 TopKAT

MDE-4320 Gasboy UHF Pump Blackmer

MDE-4331 Atlas Fuel Systems Installation Manual Gasboy Atlas Pumps/Dispensers

MDE-4333 Atlas Fuel Systems Site Prep Manual Gasboy Atlas Pumps/Dispensers

MDE-4363 Atlas Fuel Systems Owner’s Manual Gasboy Atlas Pumps/Dispensers

MDE-4404 Atlas Technician Programming Quick Ref Gasboy Atlas Pumps/Dispensers

MDE-4447 Gilbarco

MDE-4811 Islander PLUS and ICR PLUS Installation Manual Gasboy Fleet PLUS System

MDE-4813 Islander PLUS and ICR PLUS Installation Manual Gasboy Fleet PLUS System

MDE-5013 TopKAT PLUS Installation Manual Gasboy Series 1000/Fleetkey & T opkat

PT-1949 Atlas Pump and Dispenser Illustrated Parts Manual • Gasboy Atlas Pumps/Dispensers

PT-1950 Gasboy Atlas Recommended Spare Parts Gasboy Atlas Pumps/Dispensers

RP-100 PEI Recommended Practices for Underground Liquid

RP-400 PEI Recommended Procedures for Testing Electrical

RP-500 PEI Publication N/A

Note: In addition to these documents, Gasboy Atlas marketing and information sheets are sources of information.

Islander™ II Installation Manual Gasboy CFN Series

NIST Handbook 44 (National Institute of Standards and

Technology)

™

Fuel Management System Installation Manual • Gasboy Fleet PLUS System

®

Installation Manual

®

Global Pumping Unit Operation & Service

Manual

Storage Systems

Continuity of Petroleum Dispensing Systems

XU2A Rebuild Kit

N/A

• Encore and Eclipse Installers

• Gasboy Series 1000/Fleetkey &

TopKAT

Gasboy Q, A&E Series

Pumps/Dispensers

Advantage & Legacy Models

• Parts Manual

N/A

N/A

®

& Legacy® Models

®

and Eclipse

®

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-3

Page 12

Read This First Introduction

Abbreviations and Acronyms

Term Description

API Application Programming Interface

ASC Authorized Service Contractor

ATC Automatic Temperature Compensation

CFN Cash Flow Network

CFR Code of Federal Regulations

CFT Meter Center Flow Through Meter

CPU Central Processing Unit

DEF Diesel Exhaust Fluid

EC Error Code - a number that identifies an error condition reported by the software

ESD Electrostatic Discharge

FMS Fuel Management System

GOLD Gilbarco Online Documentation

GPM Gallons Per Minute

GPU Global Pumping Unit

I.S Intrinsic Safety

LAN Local Area Network

LC Liquid Control

LCD Liquid C rystal Display

LED Light Emitting Diode

MOC Major Oil Company

NEC National Electrical Code

NFPA National Fire Protection Association

OSHA Occupational Safety and Health Administration

PAM Pump Access Module

PCA Printed Circuit Assembly

PCB Printed Circuit Board (may be used interchangeably with PCA)

PCV Pressure Control Valve

PEI Petroleum Equipment Institute

PIN Personal Identification Number

POS Point of Sale

PPG Pulse Per Gallon, of the associated grade

PPL Pulse Per Liter, of the associated grade

PPP Programmable Pump Preset

PPU Price Per Unit (that is, price per gallon or liter)

PRV Pressure Relief (Bypass) Valve

PSI Pounds (of Pressure) per Square Inch

RAM Random Access Memory

SAE Society of Automotive Engineers

STP Submersible Turbine Pump

TCP Transmission Control Protocol

®

UL

UST Underground Storage Tank

W&M Weights and Measures

Underwriters’ Laboratories

Page 1-4 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 13

Introduction Read This First

Common Terms Used

Term Description

Allocation Maximum amount of fuel that can be dispensed from a nozzle for a g

Cold Start Clears pump and configuration data.

Command Code Listing under Command Level for setting software parameters.

Command Level A level of programming accessed by PIN(s).

Turbine Pump (STP) in the storage tank to

Dispenser A dispensing unit that relies on an Submer

Diesel Exhaust Fluid

(DEF)

Dual Hose Same as Twin Hose.

E85 Gasoline ethanol blend with 85% ethanol.

Five Button Preset This is a keypad that cont ains five buttons on which the customer

Function Code One or more procedures within a Command Code.

Grade Indicates the fuel grade available at the nozzle. In case of blen

Manager Keypad Device within the dispenser for setting programming parameters.

Money Display A display that shows the total value of the pro

Option Code A choice that is available on entering a Function Code.

Product Indicates the base fuel grade available in the stor

Prover Can A calibrated container used by W&M officials and calibrating technicians to accur

Pump Refers to a dispensing unit that has a self-con

Side 1 Indicates the electrical acce

Two-wire Proprietary communication system for Atlas 8800 series units

Variator The variator section of the computer register(s

Volume Display A six-digit display that shows the total volume of prod

send fuel to the dispenser.

clear, colorless, non-toxic, non-flammable, non-combustible liquid. It is made up of 32.5%

A

urea with the balance distilled or de-ionized water. Urea and water are completely miscible

and do not separate in storage. DEF is mildly corrosive.

value and/or increment or decrement in the selected sale or volume value, before fueling.

created by blending products.

however, in a non-blending environment, a grade is the same as a product.

or calibr

ate meters in a fuel dispenser.

Side 1 of the dispenser.

ss side of the dispenser. The Manager Keypad is accessed from

sible

duct d

ispensed during normal operation.

age t

ank. Not to be confused with “Grade”;

t

ained suction pump in the unit’s cabinet.

) is exposed to allow for price changes.

uct dispensed during normal operation.

iven transaction.

can enter a predetermined

der dispensers, a grade is

ately check

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-5

Page 14

Read This First DEF Special Considerations

DEF Special Considerations

Several important considerations exist for DEF. The service technician must be aware of the

following when servicing or supporting DEF units:

• DEF is non-flammable or explosive.

• The fluid is slightly corrosive and can damage tools or equipme

steel or plastic. It can also damage the electronic components.

• DEF spills can be cleaned with water and a damp rag.

may result in corrosive damage to components or metals.

• DEF can cause serious eye injury if sprayed in t

skin. Wear protective gloves and eye protection, as required. Flush eyes i mmed iately with

water, if sprayed.

• DEF freezes at approximately 11.3 °F (-11.5 °C). If it freezes

may permanently damage the meters, valves, breakaways, and possibly other devices. It is

extremely important that DEF fluid in the dispenser does not fall below that temperature.

• DEF must not be contaminated with dies

Such contamination can cause serious damage to vehicle’s catalytic converters.

• A dedicated stainless steel calibration prover (with SS

with DEF to avoid contamination of the product with diesel fuel or gasoline. No

exceptions are allowed.

• DEF can be returned to the storage tank only if it is not conta

must be disposed of in an environmentally safe manner. Do not dump DEF in storm

sewers or any location, where the fluid or its constituents may enter a waterway.

• DEF must never be introduced into diese

engine may occur. Only dispense DEF into vehicle tanks dedicated for DEF.

• DEF when stored at temperatures above 100 °F (37.7 °C) may break down into ammonia

ga

s over a time. Take care when opening the cabinets, tank vaults, or other areas, where

DEF may have leaked or been spilt to avoid inhaling any toxic ammonia vapors.

• When exposed to air, the water in DEF will evapora

crystals. Crystals may be fine and sharp. They will dissolve in water.

• DEF is much heavier than fuels such as gasoline. Be

heavier Prover Cans and so on, by following proper safe lifting techniques.

el fuel, contaminants or other fluids or materials.

l fuel tanks or serious damage to the vehicle’s

Failure to thoroughly clean spills

he eyes or may affect those with sensitive

valve, if equipped) must be used

te and result in development of urea

careful to avoid injury when lifting

nt that are not stainless

in hydraulic components, it

minated. Contaminated DEF

Page 1-6 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 15

DEF Special Considerations Read This First

CAUTION

WARNING

Applicable during Installation and Operation of the Dispenser: DEF freezes at approximately 11 °F

(-11.5 °C). Power to the dispenser and heater must always remain ON in cold weather. If power is

lost and the temperature drops below this point, the system must be inspected for freeze damage

before restart. For sites that experience occasional power losses or for sites that are located in very

cold climates, it is recommended that a back up power generator be used to maintain constant

power to the dispenser. Do not use any additives to lower the freezing point of DEF. Additives of

any type must not be used in DEF.

Prolonged storage at temperatures above 77 °F (25 °C) can impair the quality of DEF and reduce

its shelf life.

CAUTION

DEF is mildly corrosive. It can corrode components that are made from incompatible material(s)

and reduce their integrity. The use of incompatible material(s) may lead to leaks and spills, and can

contaminate and degrade the DEF. When dispensing DEF, verify with the manufacturer if the

material of all plumbing components are compatible with the DEF being dispensed.

CAUTION

Do not use Prover Cans meant for engine fuel with DEF or vice versa. Use stainless steel Prover

Cans for DEF. DEF and engine fuel must not be mixed with each other or be contaminated by each

other. Else, damage to a vehicle’s engine or pollution control devices could occur. DEF crystallizes

as its water base evaporates. Pouring out liquid will not guarantee that no corrosive DEF remains in

the Prover Can. DEF must not be contaminated with diesel fuel, contaminants, or other fluids or

materials. Such contamination can cause serious damage to vehicle catalytic converters.

Troubleshooting DEF Freeze

DEF freezes at approximately 11.3 °F (-1 1.5 °C). If it freezes in hydraulic components, it may

permanently damage the meters, valves, breakaways and possibly other devices. It is

extremely important that DEF fluid in the dispenser does not fall below that temperature.

If the unit experiences a freeze, it will be required to thaw all components and repair the

damage that may have occurred. Units can be thawed using directed exhaust from a vehicle (if

no electronic boards are in the area being thawed). Although DEF is non-flammable, diesel

fuel is flammable. Therefore, other close proximity heating devices that are non-explosion

proof cannot be used. However, before using electrical heating devices with heat extension

ducting, ensure that such devices or their power cords are not in hazardous vicinity near diesel,

gasoline, other fueling equipment, or hazardous vapors or liquids. To determine any hazard

zone involved, consult the installation or service manuals for other equipment. As other

damage either missed or not detected may exist, very closely monitor the equipment looking

for leaks when the lines are pressurized. Wear eye protection.

• Conventional fluid handling precautions are also applicable to DEF.

• Avoid contact with eyes, skin, and clothing. Ensure that

showers are close to the work location.

eyewash stations and safety

• DEF is mildly corrosive and non-flammable.

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-7

• Clean the DEF spill with water and dry the area wit

contain metallic parts. Spilt DEF can be slippery and will corrode certain types of metallic

parts. Wear eye protection and rubber gloves during any cleanup activity.

• DEF is heavier than gasoline. Be aware that Pr

so on will be considerably heavier than gasoline.

h clean rags, especially areas that

over Cans, containers filled with DEF, and

Page 16

Read This First DEF Special Considerations

CAUTION

Certain special alternative fuels such as E85 and additives can degrade pump/dispenser

performance or integrity, if the dispensers are not designed for use with such fuels. Additionally,

converting to certain standard fuels (gasoline, diesel, kerosene, and so on) from alternative fuels

such as those with ethanol (E85), methanol, or biodiesel or from alternative fuels to standard fuels

can degrade dispenser performance or integrity. Similar effects can also occur when converting

units to different standard fuel types. As per Underwriters’ Laboratories (UL) 87A requirements,

nozzles dispensing E85 fuel and DEF must not be used to dispense any other type of fuel

such as Gasoline.

Leaks and potential environmental hazards can result or components may fail prematurely.

To avoid these issues, follow the guidelines for dispensing E85 fuel and DEF in this manual.

If DEF Freezes

If DEF freezes, proceed as follows:

1 Remove power to the pump and dispenser.

2 Check for any damage to breakaways, nozzles, hoses/hanging hardware, and meter. Perform

required repairs. Valve damage can often be detected by looking for seals slightly protruding

from the valve body (compared to the new valve). Hose breakawa ys may only partially

separate.

3 Correct the issue that is causing the loss of heat.

4 Thaw components of the dispenser . Dispenser units can be thawed using directed exhaust from

a vehicle, as long as electronic boards or connections are not present in the area. They can also

be thawed using a non-flame heating device.

Notes: 1) Electronic bo ards or connections must not be present in the area wher e you thaw th e

componen

electronics.

2) Electrical cords or the heating device mu

hazardous area around any fueling pump or dispenser. To identify the designated

hazardous area, refer to MDE-4331 Atlas Fuel Systems Installation Manual.

ts of the dispenser, as any resulting condensation may damage the

st not be used within a designated

5 Check for leaks. Some leaks can be significant. You may be required to turn off the unit

immediately.

6 Check if there is any damage to the above ground tank system or heated above ground

plumbing. For assistance, consult the tank manufacturer.

7 For more details on the significance and impact of freezing in DEF, refer to “DEF Heating

System (Commercial Cold We

ather DEF Units Only)” on page 5-55.

Page 1-8 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 17

Important Requirements for E85 Units Read This First

CAUTION

Certain special alternative fuels such as E85 and additives can degrade pump/dispenser

performance or integrity, if the dispensers are not designed for use with such fuels. Additionally,

converting to certain standard fuels (gasoline, diesel, kerosene, and so on) from alternative fuels

such as those with ethanol (E85), methanol, or biodiesel or from alternative fuels to standard fuels

can degrade dispenser performance or integrity. Similar effects can also occur when converting units

to different standard fuel types. As per UL 87A requirements, units dispensing E85 fuel must not

be used to dispense any other type of fuel such as Gasoline.

Leaks and potential environmental hazards can result or components may fail prematurely.

To avoid these issues, follow the guidelines in this section.

Important Requirements for E85 Units

Following equipment and materials are required to properly install E85 units:

UL-listed E85 Hose (Q13486)

SM

• Veyance

• Veyance

Note: Extended reach hoses are not available for E85 applications.

UL-listed E85 Nozzle (M11298)

®

21GE

OPW

Note: Approved for use with E85 dispen

UL-listed E85 Swivel (N23748-04)

OPW 241 TPS-0492

Note: Approved for use with E85 dispen

UL-listed E85 Shear Valve (T19695-23)

OPW 10P-0152E85

Note: Approved for use with E85 dispens

Flexsteel™ Futura® Ethan-All for E85

Flexsteel Futura for E25

sers, as required under UL 87A.

sers, as required under UL 87A.

ers,

as required under UL 87A.

UL-listed E85 Breakaway (N23010-10)

OPW 66V-0492

Note: Approved for use with E85 dispensers,

as required under UL 87A.

Filter

Use only filters specifically marked for use with E85.

UL-listed Pipe Sealant

Use only UL-listed TPS PTFE Pipe Sealant manufactured by

UL-listed Teflon

®

Tape

SAF-T-LOC International Corp.

Use only UL-listed Taega Technologies Inc. Teflon tape.

Note: Teflon tape must be used only at the inlet pipe connection.

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-9

Page 18

Read This First Model Information

Boot Area

Total Monetary

Sale Display

Volume Dispensed

Display

Access Door

Door Lock

Nozzle and

Pump Handle

On/Off Lever

Control

Warning Labels

PPU Display

Monetary Totalizer

Volume Totalizer

Mechanical Retail Unit

Model Information

Mechanical Retail Pump/Dispenser

The external components of a Gasboy pump/dispenser (Mechanical Retail unit) are shown in

Figure 1-1. Mechanical units have mechanical type displays as opposed to electronic di

type displays. In units that

are Commercial instead of Retail, the external components are the

same, except that they do not have a Monetary Sale amount, a Price Per Unit (PPU) display, or

Monetary Totalizer display.

Figure 1-1: Atlas Mechanical Retail Unit

gital

Page 1-10 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 19

Model Information Read This First

Boot Area

Digital Main Display

PPU

Warning Label

Door Lock

Access Door

Nozzle and

Pump Handle

Electro-mechanical Totalizer

Electronic Retail Unit

Volume Dispensed Display

On/Off

Lever

Control

Electronic Retail Pump/Dispenser

The external components of a Gasboy pump/dispenser (Electronic Retail unit) are shown in

Figure 1-2. Electronic units have digital displays as opposed to mechanical dis

that are Electronic Commercial instead of Retail, the

external components are the same, except

that they do not have a Monetary Sale amount, a PPU display, or Monetary Totalizer display.

Figure 1-2: Atlas Electronic Retail Unit

plays. In units

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-11

Page 20

Read This First Model Information

Serial Number

Model Number

Serial Number Plate and Date Codes

A two-letter date code is stamped on the serial number plate before the serial number. This

code shows the month and year of manufacture. For warranty purposes, refer to the date code

to determine the age of the equipment. The serial number plate is locate d on the “A” side at the

bottom of the unit attached to the inside of the frame.

To determine the date code on a Gasboy pump or dispenser, refer to the following tables:

Month Codes

A = January E = May J = September

B = February F = June K = October

C = March G = July L = November

D = April H = August M = December

Year Codes

P = 2005 U = 2009

R = 2006 W = 2010

S = 2007 X = 2011

T = 2008 Y = 2012

Figure 1-3: Serial Number/Model Identification

For example, a serial number plate stamped “BP AT000199” contains the following

information:

• Date code [BP] - This unit was manufactured in B = February, P = 2005.

• Serial Number [AT000199]

Page 1-12 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 21

Model Information Read This First

Model Series

Series Description

9100K Mechanical Commercial Pumps and Dispensers

9800K Electronic Commercial Pumps and Dispensers

8700K Mechanical Retail Pumps and Dispensers

8800K Electronic Retail Pumps and Dispensers

9860KX Electronic DEF Dispensers Only

9870KX Electronic Commercial Dispensers for Alternative Fuels (E85)

Model Flow Rates

Series Designation (Digits 1 and 2) Flow Rate Designation (Digits 3, 4, and 5) Flow Rate Quantity

91/98/87/88 52K 15 GPM (57 LPM)

91/98/87/88 53K 22 GPM (83 LPM)

91/98/87/88 40K 40 GPM (151 LPM)

98 50K 50 GPM (190 LPM)

98 60K (DEF Only) 10 GPM (38 LPM)

98 72K 15 GPM (57 LPM)

Note: The flow rates shown are under ideal conditions a

involved, Submersible Turbine Pump (STP) sizing, number of units dispensing at the same time, and

inlet piping to the unit. These are not guaranteed flow rates.

nd will va

ry depending on the hanging hardware

Atlas Model Number Table

The Atlas model number uses a series of four numbers and five letters stamped into the serial

plate to denote the machine type and configuration. To determine the pump/dispenser type that

is denoted on the serial plate, refer to the following table:

Gasboy Atlas Model Code

Retail Model Code

Breakdown

8 X X X X X X X X 9 X X X X X X X X

Product Name

ATLAS 8 ATLAS 9

Product Series: Product Series:

- Retail,

Mechanical

- Retail, Electronic 8 - Satellite 2

Type: - Commercial

- Full Size Cabinet 5 Type:

Flow Rates: - Narrow 1

- Ultra-Hi

Gallonage (40 to

50 gpm)

- Not used 1 - Full Size Cabinet 4

- Std Gallonage

(10 to 15 gpm)

: Product Name:

7 - Commercial,

™

0 - Compact Cabinet 2

2 - Full Size Cabinet 5

Commercial Model

Code Breakdown

Mechanical

Non-computing

onic

r

Elect

1

8

6

7

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-13

Page 22

Read This First Model Information

Gasboy Atlas Model Code

- Hi Gallonage (18

to 22 gpm)

Hydraulic Series - Ultra-Hi Gallonage

- Murray A - Not used 1

- Gasboy

Hydraulics with

Gibar

co C meter

- Gilbarco

Hydraulics with

Center

Flow

Through (CFT)

Meter

®

- Tokheim

Hydraulics

Pump or

Dispenser

- Pump Blank Hydraulics Series:

- Dispenser X - Murray A

Hydraulic

Configurat

- 1 Grade, 1 Hose Blank Blank Blank - Improved Gasboy K

- 1 Grade, 2 Hose T W 1 - Tokheim

- 2 Grades, 2

Hoses

- Combo T W 3 - Pump 0

ion

3 Flow Rates:

(

40 to 50 gpm)

Q - Std Gallonage 10

K - Hi Gallonage 18 to

E 215 Standard or

T W 2 Pump or Dispenser

to 15 gpm)

pm)

22 g

High Speed

Satellite

- 216 Super or

Ultra

-Hi Speed

Satellite

- Gasboy Q

Hydr

aulics

- Dispenser X

Hydraulic

Co

nfiguration

- 1 Grade, 1 Hose Blank Blank Blank

- 1 Grade, 2 Hoses T W 1

- 2 Grades, 2 Hoses T W 2

- Combo T W 3

0

2

3

5

6

E

Listing of Atlas Model Suffixes

For information on options that are available for a particular unit, refer to “Atlas Model

Number Table” on page 1-13. Following is a list of some of the opt

some models:

• B - Display Battery Backup

• CX - 10:1 Pulser, Quantity

• CC - 100:1 Pulser, Quantity

• CM - 100:1 Pulser, Money

• D5 - TopKAT PLUS Mounting Kit

• D9 - TopKAT Mounting Kit

• EK - Electric Keytrol

• F - Internal Filter Adapter

• I - Internal Hose Retrievers

• J - Manual Reset (Export Only)

Page 1-14 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

ions that are available on

Page 23

Model Information Read This First

•K - Hand Crank

• L - Lighted Display Panel

• PP - Slowdown Valve

• PPS - Satellite Internal Piping - 9850K

• R - Liters Registration

• S - Internal Satellite Piping

• SS - Stainless Steel - All Panels

• SSA - Stainless Steel - Front and Back

• SSTS - Stainless Steel - Top and Sides

• TW1 - Dual Hose Single Product

• TW2 - Dual Hose Dual Product

• TW3 - Satellite Combo Unit

• V - Vapor Recovery Complete

• WW - Warm Weather (DEF Units Only)

• X - Remote Dispenser

• Y - Vapor Recovery Ready

• Z - Front Load Nozzle Boot

• 25 - 230 VAC, 50 Hz

• 35 - 380 VAC, 50 Hz

• 36 - 380 VAC, 60 Hz

Options Overview

This section provides an overview of the options available in Atlas dispensers.

TopKAT

The TopKAT Fuel Management System (FMS) can be ordered factory mounted on any 9800

unit except Atlas DEF dispenser. TopKAT PLUS FMS can be ordered factory mounted on any

9800 unit. This Plug and Play option increases the ease of installation and provides customers

with a user-friendly fuel reporting system. The TopKAT system is also available as a pedestal

mounted unit and for use with Mechanical pumps.

Electric Keytrol (EK)

The Electric Keytrol can be ordered factory mounted on the 9100 series. The EK provides

each customer with a personal key slot and totalizer to record their fueling amounts.

Configurations are available for both single and twin units.

Vapor Recovery

Balanced Vapor Recovery kits are available for all the K pump units except Atlas DEF and

E85 dispensers. Following two kits are available:

• Vapor Recovery Complete

•Vapor Recovery

The Vapor Recovery Complete k

the high hose retriever to the splitter, all the way to the nozzle.

it provides everything required for a balanced system from

The Vapor Recovery kit i s a retrofit kit used when p roviding your own vapor recovery system.

This kit will provide a new nozzle boot and hook to allow a stage two nozzle to be mounted on

the dispenser.

High Hose Retriever

High Hose Retrievers are also available for standard hoses. Hose clamps are available for a

variety of hose sizes, up to lengths of 15 inches.

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 1-15

Page 24

Read This First Model Information

Internal Hose Retriever

Internal Hose Retrievers are also available for all Atlas pump models. The Atlas DEF cold

weather unit has a built-in hose reel.

Satellite Piping

Satellite Piping is available on the 9850 pump and all remote dispensers except Atlas DEF and

E85 dispensers. This option will provide the internal piping required to connect to a 9215 or

9216 satellite dispenser.

Hand Crank

Hand Cranks are available for installations in locations, where power availability is a concern.

This option is only available for suction pumps.

Solenoid Valve

A two-stage slow down valve is available for units in retail applications. This option is

standard on all remote dispensers.

Pulse Output

Pulse output is available for all the 9800 pump models and some 8800 models. The pulse

®

output board for the 8800 model will be different from the 9800 model. Veeder-Root

will be provided for mechanical units, when specified. An additional pulse output board must

be ordered when connecting an Electronic unit to an FMS requiring mechanical type pulses.

Factory installation as well as field retrofit kits will be available for all pulse output options.

pulsers

RS-485 Interface

When connecting a 9800 model to a Gasboy Cash Flow Network (CFN), TopKAT PLUS or

T opKAT system, an RS-485 Interface Board must be installed in the unit. The interface can be

ordered and installed at the factory. Field installation kits are also available.

Note: The RS-485 Interface Board is not

available for the 8800 model.

Local Area Network (LAN) Interface

When a T op KAT PLUS is mounted on the 9800 model, a LAN cable is factory installed with a

LAN jack at the end in the Junction Box (J-box) for Transmission Control Protocol/Internet

Protocol (TCP/IP) communications.

Battery-backed Power Supply

Until summer of 2012, a battery-backed power supply was an option for all the 9800 models.

This option was required for units used in a Retail application. If power was lost to the unit,

the battery allowed the last transaction amount to remain on the display to meet Weights and

Measures (W&M) requirements. The 8800 series and current 9800 series displays are backed

up by a super cap that performs this function at the display.

Manual Reset

Manual resets are available for mechanical units and export orders only.

Page 1-16 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

Page 25

2 – Important Safety Information

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier ’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in th e cas e of an emerge nc y a nd not

the console’s ALL STOP and PUMP STOP or

similar keys.

!

WARNING

!

Important Safety Information

Notes: 1) Save this Important Safety Information section

in a readily accessible location.

2) Although DEF is non-flammable, diesel is

flammable. Therefore, for DEF cabine ts that are

attached to diesel dispensers, follow all the

notes in this section that pertain to flammable

fuels.

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death o r serious injury,

if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate

the switch or circuit breakers that shut off all power to all fueling

equipment, dispensing devices, and Submerged Turbine

Pumps (STPs).

Read the Manual

Read, understand and follow this manua l and any other labels

or related materials supplied with this equipment. If you do not

understand a procedure, call a Gasboy Authorized Serv ice

Contractor or call the Gasboy Support Center at

1-800-444-5529. It is imperative to your safety and the safe ty of

othe

rs to understand the procedures before beginning wo rk.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupatio nal Safety and Health Administration

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement p art s and re trofit kits on

your pump/dispenser. Using parts other than genuine Gasboy

replacement parts could create a safe ty hazard and violate

local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical component s or

the electronics of the dispenser requires total electrical shut off

of that unit. Understand the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles from

the work area

• Use of safety tape, cones or barricades at the affected unit(s)

• A total electrical shut-off of the affected unit(s)

MDE-4334D Atlas™ Start-up and Service Manual · July 2013 Page 2-1

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prev

safety directives that follow this symbol to avoid possib le inj ury

or death.

ent potential personal safety hazards. Obey

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions below must be followed to prevent death, injury or

damage to the equipment:

DANGER: Alerts y

!

which will result in death or serious injury.

WARNING: Alert

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

un

safe practice which may result in minor injury.

CAUTION wi

unsafe practice which may result in property or

equipment damage.

ou to a hazard or unsafe practice

s

you to a hazard or unsafe practice

thout Alert symbol: Designates a ha zard or

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

DEF is non-flammable. Therefore, explos

warnings do not apply to DEF fluid lines.

ion and fire safety

Page 26

Important Safety Information

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the

State of California to ca use birth defects or other

reproductive harm.

WARNING

!

Gasoline/DEF ingested may cause

unconsciousness and burns to internal organs.

Do not induce vomiting. Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

DEF generates ammonia gas at high er temperatures.

When opening enclosed panels, allow the unit to air out to

avoid breathing vapors.

If respiratory difficulties develop, move victim away from

source of exposure and into fresh air. If symptoms persist,

seek medical attention.

WARNING

!

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to

eye tissue.

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

!

DEF is mildly corrosive. Avoid cont act with eyes , skin, and

clothing. Ensure that eyewash stations and safety

showers are close to the work location. Seek medical

advice/recommended treatment if DEF spills into eyes.

WARNING

!

No Open Fire

Open flames from matches, lighters, welding torches or

other sources can ignite fuels an

d their vapors.

No Sparks - No Smoking

Sparks from st arting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and their

vapors. Static electricity, including an electrostatic charge on

your body, can cause a spark sufficient to ignite fuel vapors.

Every time you get out of a vehicle, touch the metal of your

vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods, if

you work with or around high voltages. This information is

available from the American Red Cross . Alw ay s advise the

station personnel about where you will be working, and caution

them not to activate power while you are working on the

equipment. Use the OSHA Lockout/Tagout procedures. If you

are not familiar with this requirement, refer to this information in

the service manual and OSHA documentation.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

ple,

• Location of accident (for exam

building, and so on)

• Nature of accident (for example

over by car, burn s, and so on)

• Age of victim (for example, baby, teenager, middle-age,

derly)

el

• Whether or not victim has received first aid (for example,

opped bleeding by pressure, and so on)

st

• Whether or not a victim has vomited (for example, if

al

lowed or inhaled something, and so on)

sw

address, front/back of

,

possible heart attack, run

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing devices

and compounds are in place. Ensure that you do not pinch wires

when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service contractors need

to understand and comply with this program completely to

ensure safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly . Ensure that you

clean hands after handling equipment. Do not place any

equipment in the mouth.

Page 2-2 MDE-4334D Atlas™ Start-up and Service Manual · July 2013

IMPORTANT: Oxygen may be needed at scene if gasoline has

been ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of machines

and equipment in which the unexpected energization or st art-up

of the machine(s) or equipment or release of stored energy

could cause injury to employees or personnel. Lockout/Tagout

applies to all mechanical, hydraulic, chemical, or other energy,

but does not cover electrical hazards. Subpart S of 29 CFR Part

1910 - Electrical Hazards, 29 CFR Part 1910.333 contains

specific Lockout/Tagout provision for electrical hazards.

Page 27

Hazards and Actions

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

DEF is non-flammable. However it can create a slip hazard. Clean up spills promptly.

!

Collision of a Vehicle with Unit Fire at Island Fuel Spill

The following actions are recommended regarding these hazards:

Important Safety Information

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system

• Do not use console E-STOP, ALL STOP, and PUMP STOP to shut off power. These keys do not

remove

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

AC power and do not always stop product flow.

circuit breakers to the island(s).