Page 1

Atlas™ Fuel Systems

Site Preparation Manual

MDE-4333E

Page 2

Computer Programs and Documentation

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

Federal Communications Commission (FCC) Warning

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

All dispensers and self-contained pumping

units

Card reader terminals, Models 1000, 1000P

Site Controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

95-136 Dispenser 9800 Series 91-057 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

Trademarks

Non-registered trademarks

™

Atlas

™

Consola

™

Infinity

Registered trademarks

®

ASTRA

®

Fuel Point

®

Gasboy

®

Keytrol

®

Slimline

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2011 GASBOY. All Rights Reserved.

Page 3

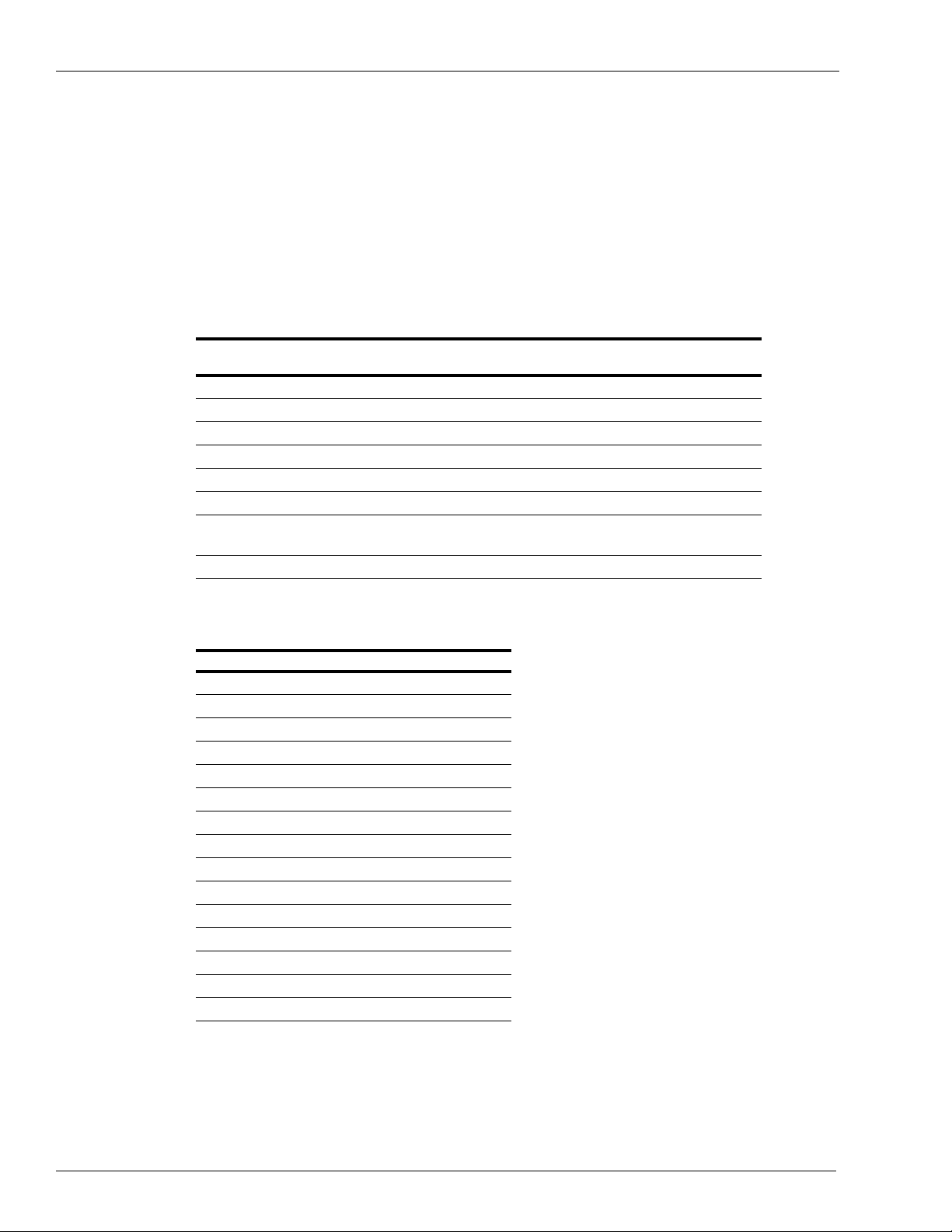

Table of Contents

Table of Contents

1 – Introduction 1

Read this First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Who Must Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Whom to Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Reference Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Read Manufacturer’s Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Read Gasboy Technical Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Common Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

English-to-Metric Conversion Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 – Important Safety Information 5

3 – Site Preparation 9

Station Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Product System Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Station Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Steps to Enhance Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Equipment and Materials Required at Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Electrical Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Emergency Power Cutoff Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Units with Ground Fault Interrupt (GFI) . . . . . . . . . . . . . . . . . . . . . . . . . .13

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

STP Control Relay Boxes for Dispensers . . . . . . . . . . . . . . . . . . . . . . . .14

STP Isolation Relays for Electronic Dispensers. . . . . . . . . . . . . . . . . . . .15

Conduit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Retail Data Wire Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Commercial Data Wire Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Electrical Control Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Wiring Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Pump Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Heater Load Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Sealing ‘Y’ Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Plumbing Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Connecting the Pump/Dispenser Inlet Pipes . . . . . . . . . . . . . . . . . . . . . .25

Important Considerations for DEF Dispensers. . . . . . . . . . . . . . . . . . . . .26

Important Considerations when Changing Fuel Types . . . . . . . . . . . . . .27

DEF Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Fuel Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Leak Detectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

STPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Pipe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page i

Page 4

Table of Contents

Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Shear Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Model 9850KXTW1 Shear Value Configuration . . . . . . . . . . . . . . . . . . . 33

OPW Shear Valve for 9862KXTW1 DEF Unit. . . . . . . . . . . . . . . . . . . . . 34

Pit Box Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Safety Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connecting the Vapor Return Line to the Vapor Shear Valve. . . . . . . . . 35

Index Index-1

Page ii MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 5

Read this First Introduction

1 – Introduction

Read this First

Purpose

This manual gives you information to prepare a site for Gasboy® Atlas™ Series pumps or

dispensers. It provides the following:

• Safety information

• Equipment required for installation

• Station layout information

• Electrical requirements

• Plumbing requirements

Perform all site preparation in accordance with NFPA 30A, NFPA 70, and applicable national,

state, and local codes/regulations. For non-US installation, other codes may apply. Plan your

site ahead of time. Use experienced, licensed personnel that practice accurate, safe

construction techniques. Time, expense, and extra effort in the early stages of preparing a site

can eliminate problems in later stages. Careful site preparation provides a sound

troubleshooting framework for field repairs. For additional information, consult manufacturer

installation instructions. This manual does not list all requirements for installation of outside

vender components.

Who Must Use this Manual

This manual is intended for individuals who are trained in the construction of gasoline

stations. If you do not have experience with this type of construction (gasoline stations),

contact a licensed, trained engineer or contractor, or Gasboy Authorized Service Contractor

(ASC).

Whom to Contact

For this Type of Information

To schedule training on Gasboy products Your local Gasboy distributor

For technical assistance Gasboy Technical Support at 1-800-444-5529

For warranty service and information Gasboy Call Center at 1-888-800-7498

For explanation of Gasboy’s warranty policy Contact your local Gasboy distributor

For additional technical literature, for example, installation,

parts manuals, and other documents

Solutions, Products, Services, and Support http://www.gasboy.com

Call the Following Phone Numbers

Gasboy Literature Department at 1-336-547-5661

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 1

Page 6

Introduction Reference Documents

Reference Documents

Read Manufacturer’s Instructions

Equipment manufacturers must provide instructions for other equipment, such as Submersible

Turbine Pumps (STPs), leak detectors, underground tanks, product lines, and shear valves.

Gasboy does not provide complete installation instructions for other manufacturer’s

equipment.

Read Gasboy Technical Manuals

Document

Number

FE-356 Atlas Retail/Commercial Dispenser Field Wiring Field Wiring Diagrams

FE-357 Atlas Pump Retail/Commercial Field Wiring Field Wiring Diagrams

FE-361 Atlas Master & Satellite Field Wiring Diagram Field Wiring Diagrams

MDE-4331 Atlas Fuel Systems Installation Manual Gasboy Atlas Pumps/Dispensers

MDE-4334 Atlas Start-up/Service Manual Gasboy Atlas Pumps/Dispensers

MDE-4363 Atlas Fuel Systems Owner’s Manual Gasboy Atlas Pumps/Dispensers

PT-1949 Atlas Pump and Dispenser Illustrated Parts Manual • Gasboy Atlas Pumps/Dispensers

PT-1950 Gasboy Atlas Recommended Spare Parts Gasboy Atlas Pumps/Dispensers

Title GOLD Library

• Parts Manual

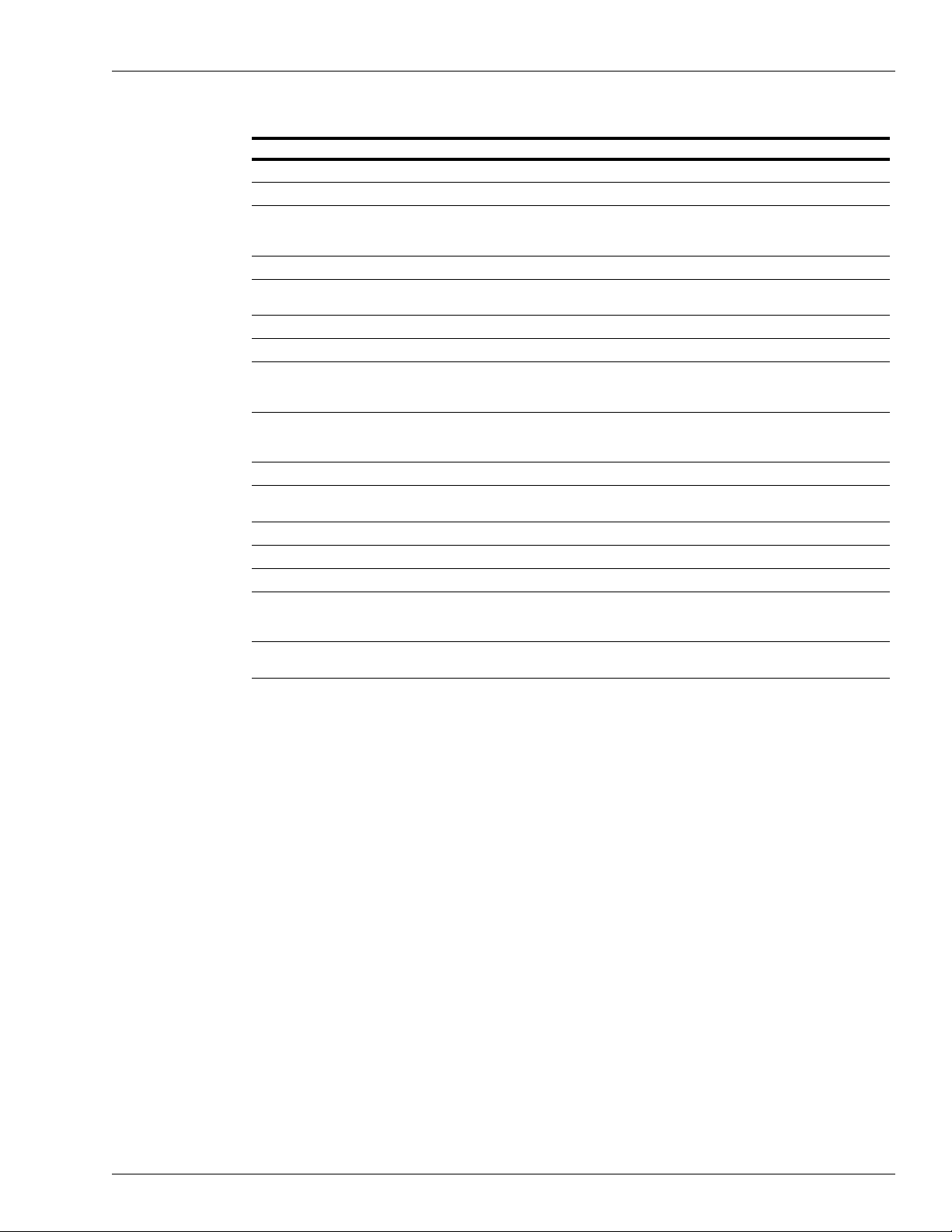

Abbreviations and Acronyms

Term Description

AC Alternate Current

ASC Authorized Service Contractor

CFN Cash Flow Network

DC Direct Current

DEF Diesel Exhaust Fluid

FMS Fuel Management System

GFI Ground Fault Interrupter

HDPE High Density Polyethylene

NCWM National Conference of Weights and Measures

NEC National Electrical Code

NFPA National Fire Protection Association

NPT National Pipe Taper

NTEP National Type Evaluation Program

STP Submer sible Turbine Pump

®

UL

Underwriters Laboratories (http://www.ul.com)

Page 2 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 7

Reference Documents Introduction

Common Terms

Term Definition

CoC Certificate of Compliance [see CoC#s on the back of the front cover for listing of numbers].

CSA Canadian Standards Association (http://www.csa.ca/).

DEF A clear, colorless, non-toxic, non-flammable, non-combustible liquid. It is made up of 32.5% Urea

Dispenser Dispensing device that uses STP in storage tank to move fuel from storage tank to dispenser.

Double-poppet

Shear Valve

High Hose Pumps/dispensers with hoses that connect overhead.

Low Hose Pumps/dispensers with hoses that connect at hydraulics level.

Master/Satellite Master dispensers are teamed with satellites for rapid fueling of trucks with saddle tanks. The

Pit Box If used, a rigid, anchored enclosure to be installed in the ground onto which the pump/dispenser

Pump Uses self-contained pumping unit and motor to move fuel from storage tank.

Single-poppet

Shear Valve

STP Submersible Turbine Pump.

UL

ULC Underwriters Laboratories of Canada (http://www.ulc.ca/).

UL-listed Products that bear the authorized Listing Mark of Underwriters Laboratories (UL). This is the

Valves Mechanical device by which the flow of fuel in bulk may be started, stopped, or regulated by a

with the balance distilled or de-ionized water. Urea and water are completely miscible and do not

separate in storage. DEF is mildly corrosive.

A double-poppet shear valve shuts off the flow of fuel, from the underground tank and from the

dispenser, at the dispenser base (hydraulics area) during vehicle impact or fires.

master unit meters and computes product flow for both units. The satellite is a dispenser without

the electronics module.

is mounted. The pit box is also the point to which plumbing and conduit are routed, and to which

the lower portion of the shear valve(s) is connected. “Pit box” is also known as “dispenser sump”.

A single-poppet shear valve shuts off the flow of fuel, from the underground tank, at the dispenser

base (hydraulics area) during vehicle impact or fires.

Underwriters Laboratories (http://www.ul.com).

manufacturer’s declaration that the product complies with UL’s requirements in accordance with

the terms of UL’s Listing and Follow-Up Service agreement.

movable part that opens, shuts, or partially obstructs one or more ports or passageways.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 3

Page 8

Introduction Reference Documents

English-to-Metric Conversion Chart

The following table lists English units used in this document and their metric equivalents.

Note: In some cases, a temperature is given in degree Celsius (°C). If the temperature in

degree Fahr enheit (°F) is r equir ed, sear ch down the Metric Equivalent column to locate

the required degree Celsius and then read the degree Fahrenheit from the left column.

English Unit

0.75 inches 1.905 centimeters

1 inch 2.54 centimeters

1-1/2 inches 3.81 centimeters

2 feet 60.96 centimeters

2 inches 5.08 centimeters

2-1/2 inches 6.35 centimeters

3 inches 7.62 centimeters

3-1/2 inches 8.89 centimeters

4 inches 10.16 centimeters

8 feet 2.4384 meters

10 feet 3.048 meters

18 inches 45.72 centimeters

32 °F 0 °C

50 feet 15.24 meters

60 inches 1.524 meters

75 feet 22.86 meters

100 feet 30.48 meters

176 °F 80 °C

200 feet 60.96 meters

1000 feet 304.8 meters

1500 feet 457.2 meters

2600 feet 792.48 meters

Metric Equivalent

Page 4 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 9

2 – Important Safety Information

Important Safety Information

Note: Although DEF is non-flammable, Diesel is

flammable. Therefore, for DEF cabinets that are

attached to Diesel dispensers, follow all the notes

in this section that pertain to flammable fuels.

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death o r serious injury,

if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environm ent of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is how

to stop all fuel flow to the pump/dispenser and island. Locate

the switch or circuit breakers that shut off all power to all fueling

equipment, dispensing devices, and Submerged Turbine

Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier ’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical component s or

the electronics of the dispenser requires total electrical shut off

of that unit. Understand the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gilbarco equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

uncontrolled.

You must use the TOTAL ELECTRICAL

SHUT-OFF in th e cas e of an emerge nc y a nd not

the console’s ALL STOP and PUMP STOP or

similar keys.

Read the Manual

Read, understand and follow this manua l and any other labels

or related materials supplied with this equipment. If you do not

understand a procedure, call a Gilbarco Authorized Service

Contractor or call the Gilbarco Support Center at

1-800-800-7498. It is imperative to your safety and the safe ty of

others to understand the procedures before beginnin g work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupatio nal Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gilbarco replacement pa rts and retrofit kit s on

your pump/dispenser. Using parts other than genuine Gilbarco

replacement parts could create a safe ty hazard and violate

local regulations.

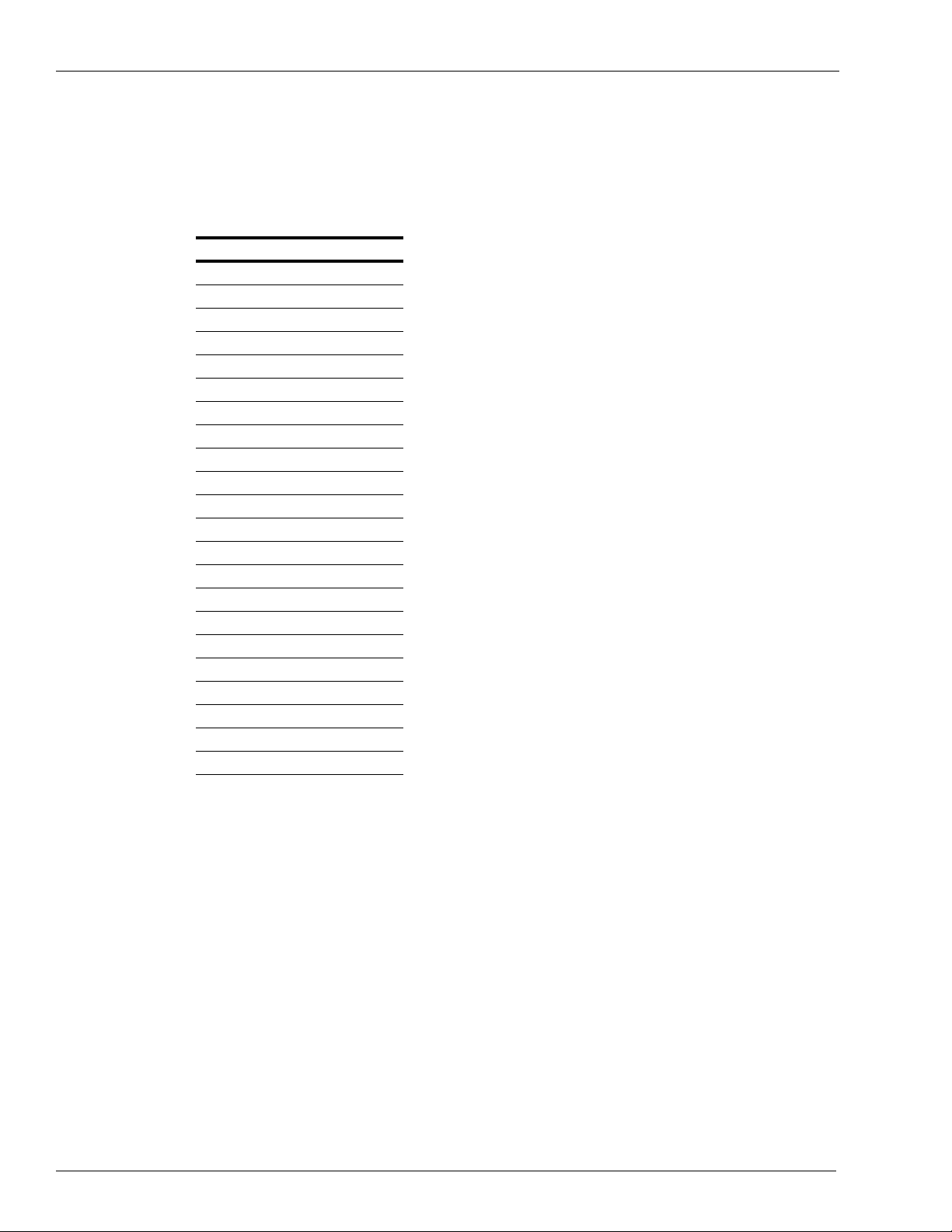

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possib le inj ury

or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions below must be followed to prevent death, injury or

damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Design ates a hazard or

unsafe practice which may result in property or

equipment damage.

Working With Fuels and Electrical Energy

• An evacuation of all unauthorized persons and vehicles from

the work area

• Use of safety tape, cones or barric ades at the affected unit(s)

• A total electrical shut-off of the affected unit(s)

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 5

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled or

leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

DEF is non-flammable. Therefore, explosion and fire safety

warnings do not apply to DEF fluid lines.

Page 10

Important Safety Information

No Open Fire

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

Open flames from matches, lighters, welding torches or

other sources can ignite fuels and their vapors.

No Sparks - No Smoking

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burn s, and so on)

Sparks from st arting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and their

vapors. Static electricity, including an electrostatic charge on

your body, can cause a spark sufficient to ignite fuel vapors.

Every time you get out of a vehicle, touch the metal of your

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

vehicle, to discharge any electrostatic charge before you

WARNING

approach the dispenser island.

!

Gasoline/DEF ingested may cause

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods, if

unconsciousness and burns to internal organs.

Do not induce vomiting. Keep airway open.

Oxygen may be needed at scene. Seek medical

advice immediately.

you work with or around high voltages. This information is

available from the American Red Cross . Alw ay s advise the

station personnel about where you will be working, and caution

them not to activate power while you are working on the

equipment. Use the OSHA Lockout/Tagout procedures. If you

are not familiar with this requirement, refer to this information in

the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing devices

and compounds are in place. Ensure that you do not pinch wires

when replacing covers. Follow OSHA Lockout/Tagout

requirements. Station employees and service contractors need

to understand and comply with this program completely to

ensure safety while the equipment is down.

WARNING

!

DEF generates ammonia gas at higher temperatures.

When opening enclosed panels, allow the unit to air out to

avoid breathing vapors.

If respiratory difficulties develop, move victim a way from

source of exposure and into fresh air. If symptoms persist,

seek medical attention.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline/DEF spilled in eyes may cause burns to

eye tissue.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly . Ensure that you

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

clean hands after handling equipment. Do not place any

WARNING

equipment in the mouth.

!

Gasoline/DEF spilled on skin may cause burns.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

WARNING

!

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

!

DEF is mildly corrosive. Avoid cont act with eyes , skin, and

clothing. Ensure that eyewash stations and safety

showers are close to the work location. Seek medical

advice/recommended treatment if DEF spills into eyes.

IMPORTANT: Oxygen may be needed at scene if gasoline has

been ingested or inhaled. Seek medical advice immediately.

Lockout/Tagout

Wash area thoroughly with clear water.

Seek medical advice immediately.

WARNING

Lockout/Tagout covers servicing and maintenance of machines

and equipment in which the unexpected energization or st art-up

of the machine(s) or equipment or release of stored energy

could cause injury to employees or personnel. Lockout/Tagout

applies to all mechanical, hydraulic, chemical, or other energy,

but does not cover electrical hazards. Subpart S of 29 CFR Part

1910 - Electrical Hazards, 29 CFR Part 1910.333 contains

specific Lockout/Tagout provision for electrical hazards.

Page 6 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 11

Hazards and Actions

!

The following actions are recommended regarding these hazards:

Important Safety Information

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

DEF is non-flammable. However it can create a slip hazard. Clean up spills promptly.

Collision of a Vehicle with Unit Fire at Island Fuel Spill

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. T urn of f all system circuit brea kers to the island(s).

• Do not use console E-STOP, ALL STOP, and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 7

Page 12

Important Safety Information

This page is intentionally left blank.

Page 8 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 13

Station Layout Site Preparation

3 – Site Preparation

IMPORTANT INFORMATION

When preparing the site, use safety tape, cones, or barricades to block the work area.

Station Layout

Recommended guidelines for the Station Layout are as follows:

• Consider traffic flow, kiosk, and store location when planning location of pumps/dispensers.

• Plan islands for efficient routing of plumbing and wiring. Arrange product lines by hose

and foundation layouts (refer to MDE-4331 Atlas Fuel Systems Installation Manual).

Follow local codes.

Note: Actual flow rates will depend on your specific installation and accessories used.

Remember pipe size and number of fittings can affect flow rate. Refer to

Considerations for DEF Dispensers” on page 26.

• Place pumps/dispensers such that the customers can dispense fuel safely and conveniently.

• Install pumps/dispensers at least 8-feet apart on island.

• Consider the service person who must have easy access to the entire pump/dispenser (top,

rear, front, and sides). Gasboy recommends at least 60 inches of clearance from any

structure (for example, wall, fence).

• Install protective posts at ends of island to protect pumps/dispensers against collision.

Posts must not interfere with customer fueling.

“Important

Product System Layout

• Distance from tank to pump must not be more than 50-feet.

• Fuel line dimensions, refer to “Pipe Size” on page 30.

• Fuel line minimum burial depth starting at inlet riser to the pumping unit is 18 inches.

• Fuel line piping sloping rate of 1-1/2 to 2 inches per 10-feet of piping run.

Note: Traps and sags are not acceptable.

• Avoid unnecessary elbows and/or turns in piping. Each elbow and turn decreases product

flow and if used in excess may cause issues with fuel delivery.

• Maximum lift is 10-feet (refer to “Fuel Tanks” on page 29).

• Pumps (self contained units) must have a vacuum actuated pressure regulating valve to

prevent positive pressure at the pump base when used with aboveground tanks.

• For aboveground tank installations, refer to “Shear Valves” on page 31 and

“Pipe Installation” on page 29.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 9

Page 14

Site Preparation Station Security

Station Security

This section includes information that is primarily applicable to Commercial sites and some

Retail sites. It may be impossible with any manufacturer’s unit even if it is designed for

security, to stop a knowledgeable, unobserved experienced thief. It is possible to greatly

reduce the probability that a theft will be successfully attempted, if security measures are

designed into the station layout and security minded actions are planned into site operation.

Steps to Enhance Security

The following recommendations are intended to decrease the probability of theft by

observance and/or incorporating obstacles that deter criminal activity:

• Design stations where employees have full unobstructed view of all fueling locations. Do

not block employee views with merchandise displays or other obstructions. If full view is

not possible, utilize video surveillance equipment. Monitoring of equipment must be made

obvious and signs stating its use must be posted.

• Use pump/dispenser security kits, when available.

• For Fuel management or console models with “time out” programming capabilities, plan

to use modular programming “time out” functions that shut down the unit if no pulser

activity occurs for a preselected time.

• Plan to provide periodic/frequent inspection of equipment security provision s to verify

their integrity.

• For electronic retail units, enter a new programming access code, as default codes are

commonly known. These codes must only be known by trusted station employees and the

involved ASCs.

• At installation and all times thereafter, ensure that lower door locks are adjusted correctly

and will not allow the panels to be removed easily without a key or tool. If you suspect

that keys are available to thieves in your area, consider using special locks or keys

available from locksmiths.

• Use surveillance cameras especially for high risk locations and locations potentially

blocked from view .

• Observe POS warnings or messages for units offline, when available.

Page 10 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 15

Equipment and Materials Required at Site Site Preparation

Equipment and Materials Required at Site

WARNING

Use of incompatible materials or components with alternative fuels such as E85 can result

in leaks or unexpected failures of components resulting in fire, explosion, or environmental

damage.

When dispensing alternative fuels such as E85, verify with the manufacturer if the material

of all plumping components are compatible with fuels such as E85 being dispensed.

• Fuel storage tanks

• STPs and leak detectors for dispensers

• Piping and fittings

• Pit boxes (also known as dispenser sumps)

• Shear valves for dispensers

• Check valves for pumps

• Conduit and gas/oil resistant wiring

• STP control relay boxes for dispensers

• Circuit breakers

• Isolation relays for electronic dispensers

• Emergency power cutoff switch

• Safety warning signs

Place warning signs (for example, No Smoking, Turn Off Engine) where fuel customers

will notice and read them. For warning signs, contact your local distributor.

• Conduit Seal (Potting) Compound (as required by seal manufacturer)

• For aboveground tanks with self-contained pumps, use vacuum-actuated

pressure-regulating valve with a shear section at the pump (Gasboy 52 valve)

• Distribution box(es) or service module(s) is required per unit type

• UL-approved sealant suitable for the application involved

• Wiring and conduit materials as outlined in the wiring diagram suitable for the fluid and

application involved

CAUTION

Applicable to Dispensers Rated for E85 Use:

Do not use tape at the very end of the pipe nipple to avoid tape entering the

dispenser hydraulics. Tape in the hydraulics can cause failures of valves, nozzles,

or other significant problems.

Use only UL-listed TPS PTFE Pipe Sealant manufactured by SAF-T-LOC

International Corp.

CAUTION

®

Use only UL-listed Taega Technologies Inc. Teflon

Note: Teflon tape must be used only at the inlet pipe connection.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 11

tape.

Page 16

Site Preparation Electrical Requirements

Electrical Requirements

• DEF is non-flammable and creates no explosive vapors. Therefore, installation

requirements for DEF units differ from units that handle hazardous fuels. However,

electrical safety requirements are applicable. If a DEF unit is installed in the Class 1

Division 2 hazard zone of a pump/dispenser delivering flammable fluids, consult Gasboy

Technical Support to determine requirements for installing DEF units in that area.

Generally, the unit must be installed to comply with requirements for units handling

flammable fluids for the area within the hazard zone.

• Prepare sites according to NFPA 30A, NFPA 70, and applicable national, state, and local

codes/regulations.

• Use licensed electricians to make all electrical connections.

• Use a dedicated circuit/phase system. Wire all electronic units to the same power leg.

• Use an earth ground for circuits.

• Mount all circuit breaker panels and relay boxes securely to the wall.

• Use UL recognized/approved components and/or systems.

• Recommended voltages for pumping unit motors are 220VAC- single phase or

380VAC-3 phase.

• Route product wiring to protect from damage using conduit, as required.

Notes: 1) Pumping units require higher load levels than dispensers. For details, refer to

FE-356 Atlas Retail/Commercial Dispenser Field Wiring, FE-357 Atlas Pump

Retail/Commercial Field Wiring, and FE-361 Atlas Master & Satellite Field Wiring

Diagram.

2) Switched Neutral is not allowed in Canada.

Emergency Power Cutoff Switch

WARNING

Spills and collisions expose highly flammable and explosive fuels. Failure to install and use

an Emergency Power Cutoff could result in severe injury or death. Observe all safety

precautions in this and other manuals.

IMPORTANT INFORMATION

Devices such as D-Boxes, Two-wire, and so on must be de-energized or have wiring

disconnected from the dispenser by the Emergency Stop or equivalent mechanism.

Third-party devices such as those supplying power to any form of communication to a

dispenser (intercoms, RS-485 communications, third-party controllers and such) must

also be de-energized or the wiring supplying that power be disconnected. Provisio n to

accommodate this must not introduce noise (RFI or electrical) into sensitive pump

dispenser electronic field wiring circuits during normal pump/dispenser operation.

De-energizing of the external equipment through the Emergency Stop or equivalent

device is recommended.

• NFPA 30A and Gasboy require that you install one or more emergency power

cutoff switches.

• An emergency power cutoff switch is a sing le control that removes AC power to all island

equipment (pumps/dispensers, STPs, canopies, lights, and so on).

Page 12 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 17

Electrical Requirements Site Preparation

• Make the emergency power cutoff switch accessible, label it clearly, and install it away

from any hazard that may occur at the pumps/dispensers. Do not install cutoff switches

more than 100-feet away from the pumps/dispensers.

• Show all employees where the emergency power cutoff switch is located and how to use

it. Remind them often.

Notes: 1) Do not use E-STOP, ALL-STOP, or PUMP STOP keys on Gasboy console/cash

registers to shut-off pump/dispenser power. These keys do not remove AC power and

do not always stop product flow.

2) Daisy Chain Wiring is used to reduce wiring cost. However, it is not recommended

as it results in loss of power to all pumps in the event of one bad wire or bad

connection. Wiring shown in this manual is for non-daisy chain applications.

Units with Ground Fault Interrupt (GFI)

GFI Breakers are required for DEF dispensers mounted on Skid Tanks because of no

underground piping, AC power in potentially wet area, and a potential for earth ground to

break if Skid Tank moves.

A GFI consists of a sensor that detects changes in the current to the load, by comparing the

current flowing to the load and the current flowing from the load. A drop-off in the current

equivalent to about 5 milliamperes, turns off all power by tripping a relay within the GFI

within a few hundredths of a second.

When powering a dispenser with a GFI, the return neutral of any device to which the dispenser

supplies power must be the same neutral as that of the dispenser. For example, the STP control

relay.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 13

Page 18

Site Preparation Electrical Requirements

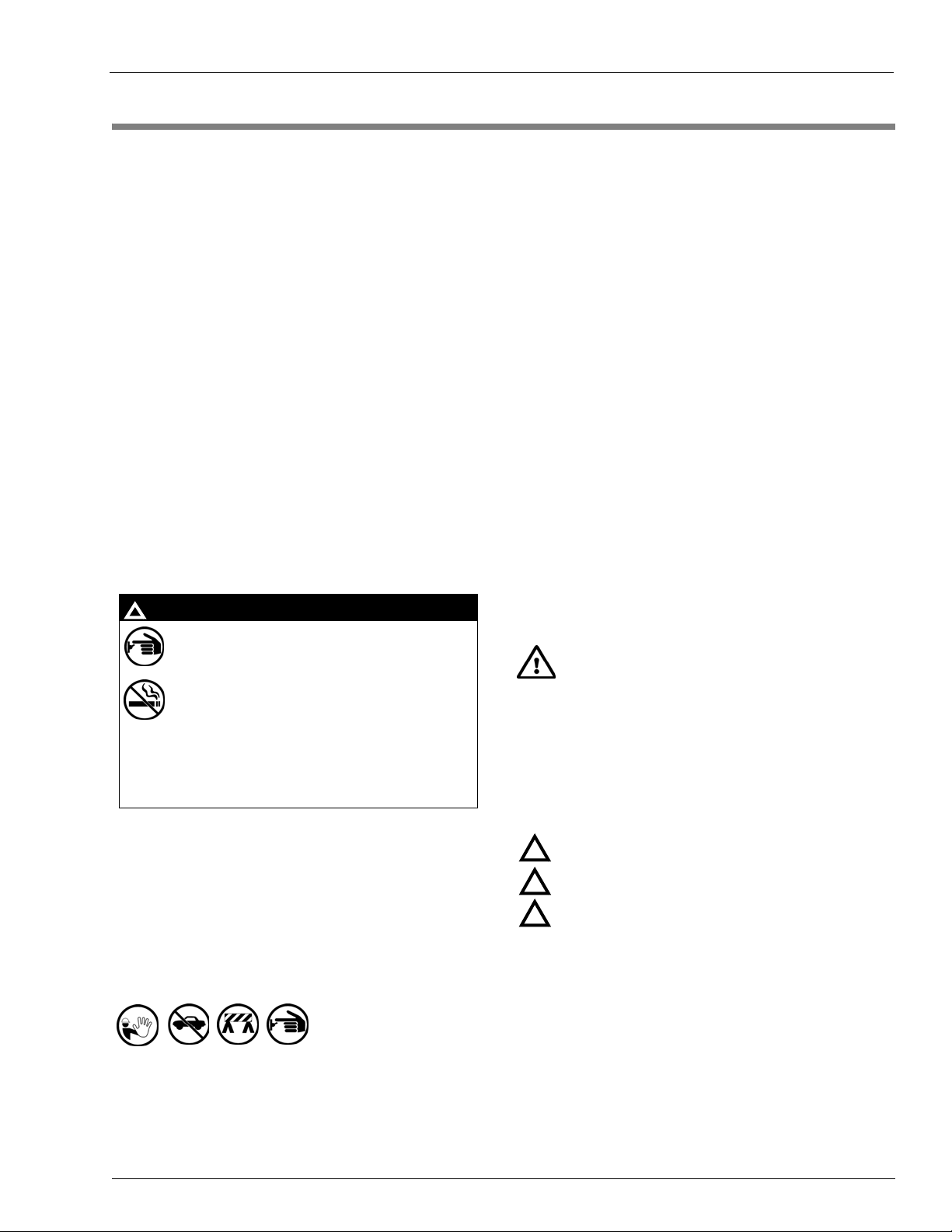

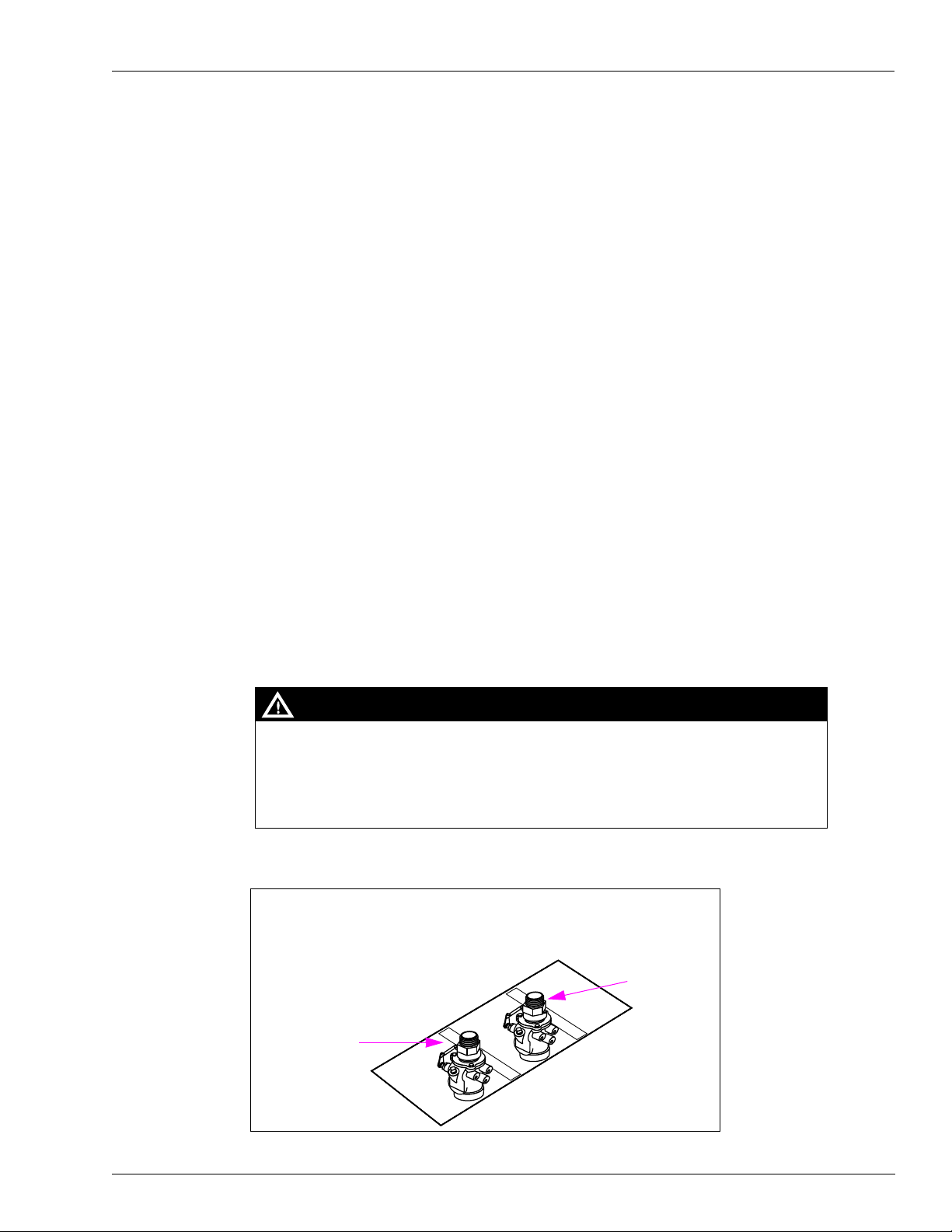

Circuit Breakers

Figure 3-1: Circuit Breakers

Do not Use Use

• Install a dedicated UL/ULC/CSA-listed switched-neutral breaker to each circuit leading to

a pump/dispenser or dispenser and STPs. It must be able to disconnect hot and neutral

conductors simultaneously. Single-pole breakers with handle ties must not be permitted.

Ref. NEC 514.11 (Switched Neutral is not allowed in Canada).

• Use only UL/ULC/CSA-listed circuit breaker panel as appropriate for that area.

• Install circuit breakers away from the pumps/dispensers. They must be readily accessible

and clearly marked.

• Install a separate circuit breaker for each STP (dispenser models) or each pump motor

(self-contained models).

• Install one circuit breaker for each pump/dispenser or small island group to allow

powering down of pump/dispenser for service.

Power to the unit must be supplied from a dedicated breaker.

• No other equipment must be powered from this breaker.

• Remote dispensers may be grouped together on a single breaker when the submersible

pump has its own breaker.

• It is recommended that no more than two remote dispensers be powered from one breaker

to maintain isolated control with the circuit breaker panel in case of problems.

• Units directly driving pumps (suction or submersible) must be supplied power from a

separate breaker. A tag on the motor identifies the maximum current draw of the motor. If

two pumps are supplied from one breaker, that breaker must be capable of handling the

load of both motors.

• DEF units contain a special heater to prevent the DEF fluid from freezing during very cold

weather. Properly size circuit breakers to handle normal pump/dispenser power

requirement plus that for the heater.

CAUTION

In cases where multiple remote dispensers supply power to a single submersible

pump, all breakers controlling the remote dispenser must be on the same phase of

power. Failure to do this will damage the equipment. Provisions must be made to

break both legs of any AC circuit.

STP Control Relay Boxes for Dispensers

• Install a separate control relay for each STP.

• Do not use the dispenser relay to power the STP.

• Combined STP Control Relay/Isolation Relay boxes are recommended.

Page 14 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 19

Electrical Requirements Site Preparation

STP Isolation Relays for Electronic Dispensers

STP isolation relays provide electrical isolation between dispensers and prevent damage from

Conduit

cross phasing. Refer to MDE-4334 Atlas Start-up/Service Manual and FE-356 Atlas

Retail/Commercial Dispenser Field Wiring.

Note: For 3-phase STP, use isolation relay at the input of the 3-phase STP control box.

• Gasboy requires installation of STP isolation relays in addition to STP control relays.

• Use isolation relays for each STP control line at each dispenser or dispenser grouping on a

single circuit breaker.

• Route neutral wire to the control relays from the dispenser circuit breaker (refer to FE-356

Atlas Retail/Commercial Dispenser Field Wiring, FE-357 Atlas Pump Retail/Commercial

Field Wiring, and FE-361 Atlas Master & Satellite Field Wiring Diagram).

• Combined STP Control Relay/Isolation Relay boxes are recommended.

• DEF is non-flammable and creates no explosive vapors. Therefore, installation

requirements for DEF units differ from units that handle hazardous fuels. However,

electrical safety requirements are applicable. If a DEF unit is installed in the Class 1

Division 2 hazard zone of a pump/dispenser delivering flammable fluids, consult Gasboy

Technical Support to determine requirements for installing DEF units in that area.

Generally the unit must be installed to comply with requirements for units handling

flammable fluids for the area within the hazard zone.

• Use 1-inch trade size rigid aluminum conduit with Gasboy pumps/dispensers to connect

wires to the pump/dispenser (Retail).

Two-wire data wires for retail electronics can share power wiring conduit (refer to

model-specific wiring diagrams).

Four-wire data wires for RS-485 communications can share power wiring conduit (refer to

model-specific wiring diagrams).

• Use a threaded, rigid metal conduit or a rigid non-metallic conduit for applications below

the pump/dispenser to carry electrical wires. Conduit must conform to national and local

electrical codes. If you use a nonmetallic conduit, it must be at least 2-feet underground.

The last 2-feet of the underground run to the junction box must be rigid metal conduit or

threaded steel intermediate metal conduit. Tighten all threaded conduits.

• Never share conduit or wire troughs with other manufacturers’ equipment (for example,

speaker wires, canopy lights, and so on). When using RS-485 communications with Atlas

Commercial units communicating with TopKAT

be in separate conduit. For more details, refer to

Note: You can use the same conduit for routing power to the pump/dispenser and the

Two-wire (Retail) data loop (Class 1 circuit). The Two-wire data loop is a Class 1

circuit.

• Never rely on metal conduit to provide an equipment ground. Run a separate ground wire.

• Never use knock-out boxes or flexible conduit for installation.

Note: Extra junction boxes added to the pump/dispenser must be listed Class 1, Div. 1,

Group C and D explosion-proof.

• Use electrical fittings that are listed for Class 1, Group C and D hazardous locations, as

required by NFPA 30A and NFPA 70.

™

or CFN®, all AC and DC wiring must

“Atlas - Commercial” on page 16.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 15

Page 20

Site Preparation Electrical Requirements

• A seal-off ‘Y’ fitting (for example, Killark® Type EY) must be installed on all units as a

first connection where conduit leaves the ground.

• If TopKAT is factory mounted, a separate conduit must be installed. Refer to the TopKAT

documentation for field wiring.

— MDE-4319 TopKAT Fuel Management System Installation Manual

— MDE-4331 Atlas Fuel Systems Installation Manual

Wiring

The distinction between the Commercial and Retail pump/dispenser units is that the

Commercial unit must use the separate conduit arrangement to keep the signals from

interfering with one another or other noise generating devices, whereas with the Retail unit

this is not required.

Atlas - Commercial

The Atlas Commercial pump/dispenser utilizes two conduits, one for AC power and second

for the DC signals (the two conduits must be kept separate to reduce signal interference). The

AC conduit carries AC power line and supplies power to the valves and motors, whereas the

DC conduit delivers the RS-485 signal when used with a CFN and TopKAT, or Pulse Output

when used with a series 1000 or other manufacturer’s control system.

When installed in a separate DC conduit, 18 American Wire Gauge (AWG) wires are required

for installation. Although it is recommended that DC Commercial pump interface wires

(RS-485 or Pulse Output) be run in a conduit separate from AC wires, they can be combined in

the same conduit with AC wires provided UL-listed cable with the following specifications are

used.

Components/Parameters Specification

Conductor 18 AWG stranded wire. Number of conductors to be determined by pulser

requirements (to determine number of wires used, refer to wiring diagram ).

Shield Foil-wrapped 100% coverage and/or tinned copper braid 90% coverage.

Drain Wire Stranded, tinned copper, 20 AWG, or larger/or braided shield.

Voltage Rating Maximum operating voltage of 600 V.

Environmental Gas and oil-resistant, suitable for wet or dry locations.

Gasboy can supply Belden

that meets the requirements listed above.

Note: Belden 1063A is UL-listed but not CSA-listed.

Atlas - Retail

The Atlas Retail pump/dispenser utilizes only one main conduit as it does not require a DC

conduit. The AC conduit is used to carry AC wire and Two-wire, twisted-pair wiring.

®

1063A (P/N C09655) which is a UL-listed, four-conductor cable

Page 16 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 21

Electrical Requirements Site Preparation

Wiring Requirements

• Wire all pumps/dispensers according to NFPA 30A, NFPA 70, and applicable national,

state, and local codes/regulations.

• Wire all circuits N.E.C Class 1.

• Use stranded gas and oil resistant copper wire rated for 300 V (up to 240VAC source) and

80 °C.

• In the main conduit of Retail units, for communications, use only twisted-pair, Two-wire

data pairs. Do not use shielded twisted-pair wiring.

• Unshielded twisted-pair wire is required per the following:

— Retail Two-wire communication wiring for new installations.

— Replacement units, depending on location of the wiring conduit and previous unit st yle,

may require new wiring or adaptive conduit, explosion proof junction box, and jumper

wiring to mate with the old wiring.

— Previously wired stations may continue to use tested existing non-twisted-pair wiring

that has been short and continuity tested and passed, where communication problems

between the older units and console have not been a problem. Twisted-pair wiring is

highly recommended for existing stations experiencing higher than national average

lightning strikes or for stations previously experiencing console to dispenser

communication problems.

• Leave 3-feet of wire out of conduit for connection to dispenser.

• Place dispensers on the same phase.

Note: If Gasboy isolation relay box is installed, dispensers are not required to be on the

same phase.

• Use listed wire nuts for all connections. Do not use tape.

• Pull spare wires for future use.

• Protect conduit ends and wire from water or damage prior to installation of the

pumps/dispensers.

• Seal-off ‘Y’ fitting(s) must be potted after all wires are run to termination points.

For additional wiring notes and requirements, refer to the following documents:

• FE-356 Atlas Retail/Commercial Dispenser Field Wiring

• FE-357 Atlas Pump Retail/Commercial Field Wiring

• FE-361 Atlas Master & Satellite Field Wiring Diagram

Retail Data Wire Lengths

Use the following table to determine maximum Retail data wire lengths.

For This Distribution Box

PA0133, PA0187 G-SITE

PA0242 Transac® System 1000™

PA0261 Universal D-Box

PA0306 Distribution Box

Distance Between the Distribution

Distance Between the Distribution

Box and Dispenser

®

“Total” data wire system run no more than 2600-feet with 14 AWG

No more than 2600-feet with 14AWG No more than 2600-feet with 14AWG

Box and

Console/Controller

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 17

Page 22

Site Preparation Electrical Requirements

Commercial Data Wire Lengths

Use the following table to determine maximum Commercial data wire lengths.

Distance Between the Distribution

Distance Between the Distribution

For this Distribution Box

RS-485 Cable No more than 1000-feet from junction

Box and Dispenser

box to farthest CFN or TopKAT

component

Box and

Console/Controller

No more than 1500-feet between all

CFN or TopKAT components

Grounding

GFI Breakers are required for DEF dispensers mounted on Skid Tanks because of no

underground piping, AC power in potentially wet area, and a potential for earth ground to

become broken if Skid Tank moves.

A GFI consists of a sensor that detects changes in the current to the load, by comparing the

current flowing to the load and the current flowing from the load. A drop-off in the current

equivalent to about 5 milliamperes, turns off all power by tripping a relay within the GFI

within a few hundredths of a second.

When powering a dispenser with a GFI, the return neutral of any device to which the dispenser

supplies power must be the same neutral as that of the dispenser. For example, the STP control

relay.

• NFPA 70 requires that you connect the following to system ground:

— Consoles

— Pumps and dispensers

— Submerged turbine pumps

— Relay control boxes

— Circuit breaker panel

— Electronic leak detectors

— Service module

— Distribution box

• Gasboy requires that you connect each pump/dispense r to an equipment grounding

conductor located in the conduit per NFPA 70, Article 250. The fol lowing is applicable to

ground conductor:

— Gasboy recommends using wire no smaller than 12 AWG. A larger wire may be

required per NFPA 70, Article 250.

— Use wire with green, or green and yellow striped insulation.

— Connect to grounding screw in junction box.

— Ground the providing power under NFPA 70, Article 250.

— Bond the neutral bus to an approved grounding electrode.

To ensure proper operation of the equipment and provide the required safety factors, this unit

must be grounded per the following:

• A ground wire (preferably green) must be connected between the unit’s AC junction box

ground lug and the main electrical service panel.

• One earth ground connection is required per unit.

• The ground rod must be a solid, corrosion-resistant conductor, and must be installed at the

main electrical panel in accordance with the National Electrical Code. It must be properly

tied into the ground bus strip of the panel.

• W e recommend the neutral and ground bus strips be bonded together (unless prohibited b y

local codes).

Page 18 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 23

Electrical Requirements Site Preparation

Figure 3-2: Grounding Plan

Refer to “Conduit”

on page 15 .

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 19

Page 24

Site Preparation Electrical Requirements

Electrical Control Lines

This section provides control input and output information for the Atlas pump/dispensing unit.

For electrical wiring information, refer to the following:

• FE-356 Atlas Retail/Commercial Dispenser Field Wiring

• FE-357 Atlas Pump Retail/Commercial Field Wiring

• FE-361 Atlas Master & Satellite Field Wiring Diagram

Light Feed

The light feed is a 115 VAC (230 VAC International) input required to power the fluorescent

lights. In a site configuration using multiple remote dispensers (or pumps), the power for the

lights of upto eight units can be supplied by one breaker . If separ ate control of the lights is not

required, the light feed for each dispensing unit may be taken from its Reset Motor Feed.

Light Neutral

The light neutral is a return line for AC from the lights to the breaker panel. When a separate

breaker is not used to control the lights, the light neutral is attached to the neutral which is

connected to the reset motor.

Phase 2 Feed

The phase 2 feed is a hot feed which is the opposite phase of the pump motor feed. This line

and pump motor feed are used for domestic 230 VAC motor applications.

Pulse Out (Commercial Only)

The Pump Interface Boards (Pulse Out and RS-485) supplies a DC output which is provided to

indicate the quantity dispensed. Pump Interface Boards are optional and are only used when

monitoring of the dispensing unit operation is required as when used with a fuel management

system.

Note: Customers and installers having any questions pertaining to the installation must

contact their Gasboy distributor.

Page 20 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 25

Electrical Requirements Site Preparation

Wiring Overview

The quality of the electrical installation is a major factor in maintaining proper safety levels

and providing trouble-free operation of your Gasboy pump/remote dispenser (refer to

“Electrical Requirements” on page 12). To assure a quality installation, follow these rules:

1 All wiring must be installed to conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, NFPA 70, NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2 Use only threaded, rigid, metal conduit. For more details, refer to “Conduit” on page 15.

3 Use only UL-labeled, insulated, gasoline and oil-resistant stranded copper wiring of the proper

size (refer to

4 Wire connections must be tightly spliced and secured with a wire-nut. Close off the open end

of the wire nut with electrical tape.

“Atlas - Commercial” on page 16).

5 The line to the motor must be on a separate circuit and installed on a 20 to 30 A breaker

depending on the motor size and/or the voltage setting (refer to

page 14).

“Circuit Breakers” on

6 Install an emergency power cutoff (refer to “Emergency Power Cutof f Switch” on page 12). In

addition to circuit breaker requirements of NFPA 70 and NFPA 30A, a single control which

simultaneously removes AC power from all site dispensing equipment is recommended. This

control must be readily accessible from all fueling positions, clearly labeled, and in

accordance with all local codes.

In a fuel management system application, the EMERGENCY STOP and STOP keys on the

console and/or the optional EMERGENCY STOP button on the Island Card Reader do not

remove AC power from equipment, and under certain conditions, will not stop product flow.

7 To provide the highest level of safety to you, your employees, and customers, all employees

must be trained as per the location and procedure for turning off power to the entire system.

WARNING

To reduce the risk of electrical shock when servicing, turn off all power to the pump/remote

dispenser. In submersible pump applications, turn off power to the submersible pump and

any other remote dispensers which use that submersible pump. AC power can feed back

into a shut-off dispenser when dispensers share a common submersible pump or starter

relay.

8 The distinction between the Commercial and Retail pump/dispenser units is that the

Commercial unit must use the separate conduit arrangement to keep the signals from

interfering with one another or other noise generating devices whereas with the Retail unit this

is not required.

9 Ensure that the pump/remote dispenser is installed by a competent installer/electrician.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 21

Page 26

Site Preparation Electrical Requirements

Pump Motors

Pumps are shipped from the factory with motors wired according to the specifications given

on the order as to kind of current, frequency, and voltage.

Very often on installation, it becomes necessary to change the original setting to suit the AC

power source. T o do this, locate the motor change-over plate, typically located on the shaft end

of the motor and remove the screw which secures it in place. Slide the plate so that the

required voltage as marked on the plate, lines up with the screw hole. Reinsert the screw and

secure the plate in place.

Many motor failures result from improper setting of the motor change-over plate. If set for

115 VAC and 230 VAC feed is used, the motor will burn out after running only a short ti me. If

set for 230 VAC and 115 VAC feed is used, the motor will run very slowly and the starting

field will soon burn out.

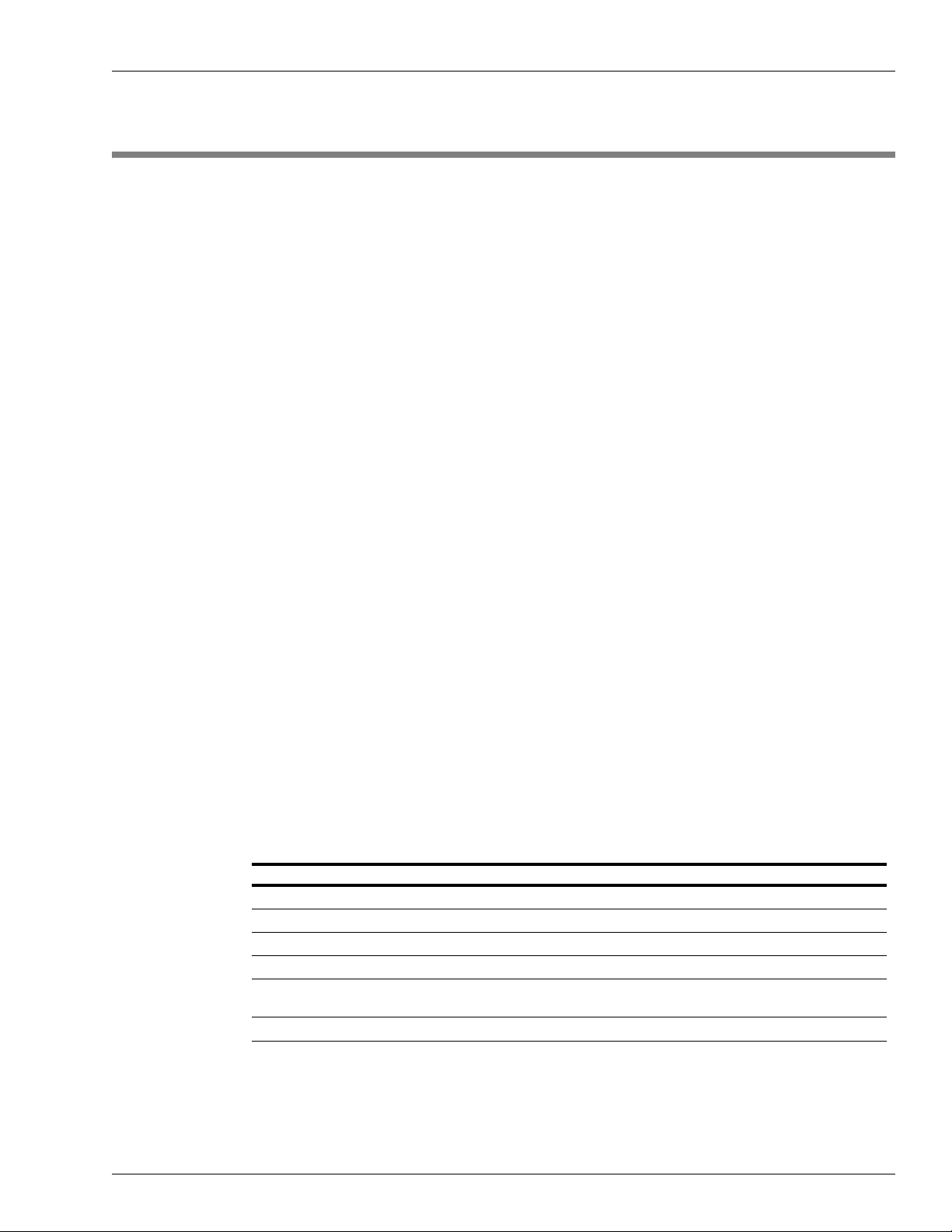

Motor Loads

The following table shows the maximum running amperage that can be expected for the pump

motor, unless noted otherwise.

Model

9152K, 9152KTW1, 9152KTW2

9852K, 9852KTW1, 9852KTW2

8152K, 8152KTW1, 8152KTW2

8852K, 8852KTW1, 8852KTW2

9153K, 9153KTW2

9853K, 9853KTW2

8153K, 8153KTW2

8853K, 8853KTW2

9140K

9840K

9850K N/A 10.0 A N/A N/A

9872KX, 9872KXTW1 N/A N/A N/A N/A

Notes: 1) Inadequate feed wiring (too long or too small a diameter wire) will incr ease current

draws on the motor and/or reduce voltage at the motor. This may also reduce motor

life.

2) These numbers do not account for the higher load upon start-up, nor up to one

additional Amp associated with other electrical components (lights, solenoid valves,

and so on).

3) All model numbers ending in TWIM or TW2 have one pump motor per side. 9140K

and 9840K also have one pump motor per side.

4) The 9140K and 9840K models must use no less than a 20 A breaker to account for

the high current upon start-up.

115 V 50/60 HZ

1 PH

13 A 6.5 A 3.4 A 2.3 A

13.0 A per motor 6.5 A per motor 3.4 A per motor 2.3 A per motor

Motor Rating

230 V 50/60 HZ

1 PH

230 V 50/60 HZ

3 PH

380 V 50/60 HZ

3 PH

Page 22 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 27

Electrical Requirements Site Preparation

Heater Load Table

Load Table Reference Locations - DEF Dispensers (Cold Weather Units Only)

A separate breaker is required for the heater (8.5 A @ 120 VAC 60 Hz). For more information,

refer to FE-356 Atlas Retail/Commercial Dispenser Field Wiring.

Note: Heaters are thermostatically controlled and will cycle between on and off during cold

weather to maintain a minimum cabinet temperatur e.

Sealing ‘Y’ Fittings

‘Y’ seals are installed in conduit runs to minimize passage of vapors, gases, or flames from

one portion of the electrical installation to another through the conduit. Fittings must be

installed in accordance with Articles 501-5 and 502-5 of the National Electric Code and fitting

manufacturers’ instructions.

DEF is non-flammable and creates no explosive vapors. Therefore, installation requirements

for DEF units differ from units that handle hazardous fuels. However, electrical safety

requirements are applicable. If a DEF unit is installed in the Class 1 Division 2 hazard zone of

a pump/dispenser delivering flammable fluids, consult Gasboy Technical Support to determine

requirements for installing DEF units in that area. Generally the unit must be installed to

comply with requirements for units handling flammable fluids for the area within the hazard

zone.

Gasboy uses Killark

conduit runs. The following sealing directions are for Killark fittings only and instructions

may vary for other manufacturer’s fittings. Read through all instructions completely before

beginning.

Figure 3-3: Sealing ‘Y’ Fittings

Conduit

Type EY fittings and recommends them or their equivalent for vertical

Wires

Close-up plug

Fill to bottom of

threads

Floor dam

Conduit

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 23

Sealing compound

Page 28

Site Preparation Electrical Requirements

1 Remove the close-up plug.

2 Separate conductors and fill conduit in and around conductors using Killark type “PF” packing

fiber to make a floor dam to hold fluid sealing compound.

Note: Floor dam must be even with the conduit stop in the lower hub of fitting. Exercise care

so as not to damage conductor insulation. Force packing between conductors and hubs,

pushing any shreds of packing fiber away from conductors to prevent leakage path.

3 Use only Killark Type “SC” sealing compound with Killark fittings and do the following:

• Use a clean mixing vessel for every batch of sealant.

• Mix compound at the rate of 3 parts compound to 1 part water by volume.

• Sprinkle compound in water while stirring until thick paste is formed.

Note:Do not mix more compound than can be used in 15 minutes.

• Continue mixing for at least 3 minutes, until consistency is just fluid enough to pour

slowly, like thick gravy (not watery).

4 Slowly pour approved fluid compound into sealing fitting to level of bottom of threads for

close-up plug.

Note: Pour slowly to avoid trapping air bubbles in s eal.

5 Immediately wipe off any spilled compound and close seal with the close-up plug.

Note: Initial setting of sealing compound will occur within 30 minutes. Compound requires a

minimum of eight hours above 32 °F to develop sufficient strength to withstand

explosion pressures.

Page 24 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 29

Plumbing Requirements Site Preparation

Plumbing Requirements

WARNING

Highly flammable and explosive fuels are present. Failure to observe all safety precautions

could result in severe injury or death. Observe all safety precautions in this and other

manuals.

Connecting the Pump/Dispenser Inlet Pipes

WARNING

DEF, flexible fuels such as Biodiesel, high alcohol percentage fuels, and so on, may be

incompatible with certain plumbing materials and hydraulic components.

®

Use recommended sealant, Loctite

(Part Number 21347) for DEF pipe threads. Do not use thread tape.

#567 (Part Number 56747) and Loctite Primer-N 7649

Use only UL-listed TPS PTFE Pipe Sealant manufactured by SAF-T_LOC International Corp.

for E85 pipe connections.

Use of incompatible materials or components with alternative fuels such as E85 or DEF can

result in leaks or unexpected failures of components resulting in fire or explosion or

environmental damage.

When dispensing alternative fuels such as E85 or DEF, verify with the manufacturer of the

material or component that all plumbing components are compatible with the fuels or DEF

being dispensed. Do not replace the dispenser or pump parts with those incompatible with the

fuel or DEF involved.

WARNING

The Shear Valves must be installed correctly.

Improperly or insufficiently anchored Shear Valves can lead to fire or explosion that could

result in severe injury or death.

Anchor all the Shear Valves as per the manufacturer’s instructions.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 25

Page 30

Site Preparation Plumbing Requirements

Important Considerations for DEF Dispensers

CAUTION

Applicable during Installation and Operation of the Dispenser: DEF freezes at approximate ly

11 °F (-11.5 °C). Power to the dispenser and heater must always remain ON in cold weather. If

power is lost and the temperature drops below this point, the system must be inspected for freeze

damage before restart. For sites that experience occasional power losses or for sites that are

located in very cold climates, it is recommended that a back up power generator be used to

maintain constant power to the dispenser. Do not use any additives to lower the freezing point of

DEF. Additives of any type must not be used in DEF.

Prolonged storage at temperatures above 77 °F (25 °C) can impair the quality of DEF and reduce

its shelf life.

CAUTION

DEF is mildly corrosive. It can corrode components that are made from incompatible material(s)

and reduce their integrity. The use of incompatible material(s) may lead to leaks and spills, and can

contaminate and degrade the DEF. When dispensing DEF, verify with the manufacturer if the

material of all plumbing components are compatible with the DEF being dispensed.

CAUTION

Do not use Prover Cans meant for engine fuel with DEF or vice versa. Use stainless steel Prover

Cans for DEF. DEF and engine fuel must not be mixed with each other or be contaminated by each

other. Else, damage to a vehicle’s engine or pollution control devices could occur. DEF crystallizes

as its water base evaporates. Pouring out liquid will not guarantee that no corrosive DEF remains in

the Prover Can. DEF must not be contaminated with Diesel fuel, contaminants, or other fluids or

materials. Such contamination can cause serious damage to vehicle catalytic converters.

• Conventional fluid handling precautions are also applicable to DEF.

• Avoid contact with eyes, skin, and clothing. Ensure that eyewash stations and safety

showers are close to the work location.

• DEF is mildly corrosive and non-flammable.

• Clean the DEF spill with water and dry the area with clean rags, especially areas that

contain metallic parts. Spilt DEF can be slippery and will corrode certain types of metallic

parts. Wear eye protection and rubber gloves during any cleanup activity.

Page 26 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 31

Plumbing Requirements Site Preparation

Important Considerations when Changing Fuel Types

WARNING

Certain special alternative fuels such as E85 and additives can degrade pump/dispenser

performance or integrity if the dispensers are not designed for use with such fu els.

Additionally, converting to certain standard fuels (gasoline, diesel, kerosene, and so on)

from alternative fuels such as those with ethanol (E85), methanol, or Biodiesel or from

alternative fuels to standard fuels can degrade dispenser performance or integrity. Similar

effects can also occur when converting units to different standard fuel types. As per UL

87A requirements, nozzles dispensing E85 fuel must not be used to dispense any

other type of fuel such as Gasoline.

Leaks and potential environmental hazards can result or components may fail prematurely.

To avoid these issues, follow the guidelines in this section.

Follow the guidelines given below when changing fuel types for a pump/dispenser or using

alternative fuels or fluids.

• Verify with your Gilbarco ASC or Distributor if the fuel which you will be using is

compatible with the pumps/dispensers to be dispensing the fuel.

• For flexible fuel dispensers, do not use standard hydraulic parts used in other Gilbarco

pumps/dispensers for service parts in these units. Standard dispenser parts may not be

compatible with fluids.

• Biodiesel fuels must be of ASTM standards for Biodiesel fuels. Mixes of diesel with

cooking oils, other plant or animal derived oils, and so on are not considered Biodiesel.

Use of such mixes may void warranty on the hydraulic components of the unit.

• Review the latest copy of the unit’s warranty statement regarding the use of fuel.

• Certain fuels (especially fuels enhanced with alcohol) when first used in tanks previously

containing a different fuel may clean out the tanks and force a large amount of

contaminant into the dispenser. Other than abnormally clogging filters, this large quantity

of contaminant may damage certain dispenser components. Do not run units without

filters at such times. It is normally required that tanks and lines be cleaned of all water,

sediment, and contaminant prior to such conversions to minimize potential

pump/dispenser downtime or damage. Damage to hydraulic components from

contamination when not using filters is not covered by Warranty. Consult your ASC or

Gilbarco Distributor for recommendations.

• Do not use any equipment that was formerly used to store or dispense any other fuel or

liquid with DEF. Dispensers designed for use with DEF must only be used with DEF.

• Do not use Prover Cans meant for engine fuel with DEF or vice versa.

• Although conversions from one fuel to an equivalent fuel (for example, from another

supplier) generally do not create issues, it is recommended that after making any fuel type

conversions (refer to the above warning), all units be visually inspected for leaks two days,

one week, and one month after fuel conversion. Have your ASC repair any leaks found.

This must also be performed for standard fuels when significant new additives are

incorporated.

IMPORTANT INFORMATION

The above guideline does not apply to Flexible fuel model dispensers.

MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011 Page 27

Page 32

Site Preparation Plumbing Requirements

• Whenever non-equivalent fuel conversions are performed, it is recommended that all units

be checked for calibration within one month of fuel conversion.

• Some non-equivalent fuel conversions will necessitate the requirement to change the

pump/dispenser filter type previously used. Consult your ASC or Gilbarco Distributor for

any changes required.

• In Flexible fuel dispensers, Gilbarco recommends the use of 10 micron filters for

gasoline-based flexible fuels. Although the use of finer filtration is allowable, filters will

tend to clog prematurely, causing excessive filter maintenance cost.

• Use only meters and registration devices for DEF that have a National Type Evaluation

Program (NTEP) Certificate of Compliance issued by the National Conference on W eight s

and Measures (NCWM).

• Non-metallic piping and components used in aboveground DEF service must have high

melting points and adequate strength and durability. Some plastic compounds that are

suitable for DEF may not be compatible with petroleum products. They must be avoided

at locations where they could come in contact with petroleum from a routine operation or

a spill.

• An anti-siphon valve must be installed on Aboveground Storage Tanks where the DEF

level can be at a higher elevation than the supply piping or the dispenser. The valve will

prevent a potential leak in the piping from creating a siphon that could cause a product

release.

DEF Plumbing

CAUTION

DEF freezes at approximately 11.3 °F. Model variations of DEF units exist with and without internal

heaters. Ensure you do not use a unit without a heater if the site may experience temperatures

12 °F or lower. If the unit freezes severe damage may occur to hydraulic components. Such

damage is not covered by warranty.

External exposed plumbing must be heated and insulated for sites that may experience

temperatures of 12

on at a higher temperature than 12

temperature lower than 12

weather.

Insulation used on piping for areas that may experience hot as well as very cold temperatures

must be shielded from direct sunlight or coated/painted with reflective or white color. DEF can

become very hot if dark or black insulation is heated by sunlight during hot weather.

Overhead plumbing sometimes used with DEF installations, presents special difficulties

(inability to purge air out of the lines, calibration issues, and so on) if not installed properly.

An automatic or manual bleed system must be installed at the high point of the plumbing to

facilitate air removal during installation or operation. For recommendations, consult Gasboy

Technical Support.

°F or lower. Thermostatic control is recommended. Heating mu st be turned

°F to ensure no localized section of the pipe experiences a

°F. Power to the heaters must never be disabled during very cold

Page 28 MDE-4333E Atlas Fuel Systems Site Preparation Manual · November 2011

Page 33

Plumbing Requirements Site Preparation

Fuel Tanks

Follow tank manufacturer instructions, national, state, and local regulations for storage tank

installation.

On pumps (self-contained units), it is recommended that a vertical lift of 10-feet must not be

exceeded. The EPA and API regulates the vapor pressure of gasoline. A lift greater than

10-feet may result in vapor suction rather than gasoline suction.

Notes: 1) The maximum lift is defined as the vertical distance from the bottom of the suction

pipe in the storage tank to the pump shaft centerline of the pumping device.

2) Install vacuum actuated valve with shear section (per NFPA 30A) directly beneath a

self-contained pump when aboveground storage tanks are used. Without vacuum

actuated valve, sump may overflow. For more information, refer to manufacturer’s

installation instructions, Gasboy Product Service Bulletin 26-91, and “Check

Valves” on page 31.

Tanks that contain DEF can be aboveground or underground depending on the ambient

temperature of the geographical area in which the tanks are located. It is not recommended to

use aboveground tanks that contain DEF where temperatures may reach lows of 10

°F.

Leak Detectors

Use only listed leak detectors. Follow manufacturer instructions for leak detector installation.

STPs

Use only listed STPs. Follow manufacturer instructions for installation of STPs.

Pipe Installation

Use of incompatible materials or components with alternative fuels such as E85 can result