Page 1

SERIES 9820A

ELECTRONIC

COMMERCIAL PUMPS

INSTALLATION/OPERATION

MANUAL

035391

Rev. 03/07/03

INSTALLERS - IMPORTANT

In addition to installation information, this manual contains warnings,

safeguards and procedures on the use and care of the Series 9820A pumps.

Please leave this manual with the pump owner after the installation is

complete.

The information in this document is confidential and proprietary. No further disclosure shall be made

without permission from Gasboy International LLC. Gasboy International believes that the information in

this document is accurate and reliable. However, we assume no responsibility for its use, nor for any

infringements of patents or other rights of third parties resulting from its use. We reserve the right to make

changes at any time without notice.

Copyright 2003 by Gasboy International LLC All rights reserved.

GASBOY INTERNATIONAL LLC

Page 2

IMPORTANT WARNINGS AND SAFEGUARDS

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to th e en ti re syste m. Inst ruct ion s

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

DO NOT use Teflon tape for any pipe

threads in the product.

DO NOT use consumer pumps for

pumping fuel or additives into aircraft.

DO NOT use commercial pumps for

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT use where sanitary design is

required (for food products for human

consumption) or with water-based

liquids.

DO NOT smoke near the pump or when

using the pump.

DO NOT use near open flame or

electrical equipment which may ignite

fumes.

DO NOT permit the dispensing of

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT permit the dispensing of

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

includin g tru cks. All conta iners mu st be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT block open the nozzle in any

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO ensure that the pump is equipped

with proper filters based on the product

being dispensed and its intended use.

DO wear safety goggles and protective

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO keep all parts of body and loose

clothing clear of belts, pulleys, and

other exposed moving parts at all times.

OF A FUEL SPILL.

DO require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO provide a receptacle for catching

product from pump/meter when

servicing.

DO clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO insure pump is properly grounded.

DO insure hose is compatible with fluid

being dispensed.

DO inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

035282 Rev. 1267

GASBOY INTERNATIONAL LLC.

707 North Valley Forge Rd. Lansdale, PA, 19446 ● (215) 855-4631 ● FAX: (215) 855-0341

Page 3

FCC INFORMATION

The US Federal Communications Commission (FCC) requires specific information be supplied to

the users of any equipment which may emit radio frequency energy. Please read the following

information.

FCC PART 15

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the device is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful inter ference, in which

case, the user will be required to correct the interference at his own expense.

Page 4

Page 5

CONTENTS

IMPORTANT WARNINGS AND SAFEGUARDS

FCC Information

Section 1: INTRODUCTION

Purpose .................................................................................................... 1-1

General Description .................................................................................. 1-1

Standard Features............................................................................... 1-1

Optional Features ................................................................................ 1-2

Section 2: INSTALLATION

Installation Precautions ............................................................................ 2-1

Vapor Recovery Option ............................................................................ 2-2

Hose Length Estimator ............................................................................. 2-2

Typical Installation .................................................................................... 2-4

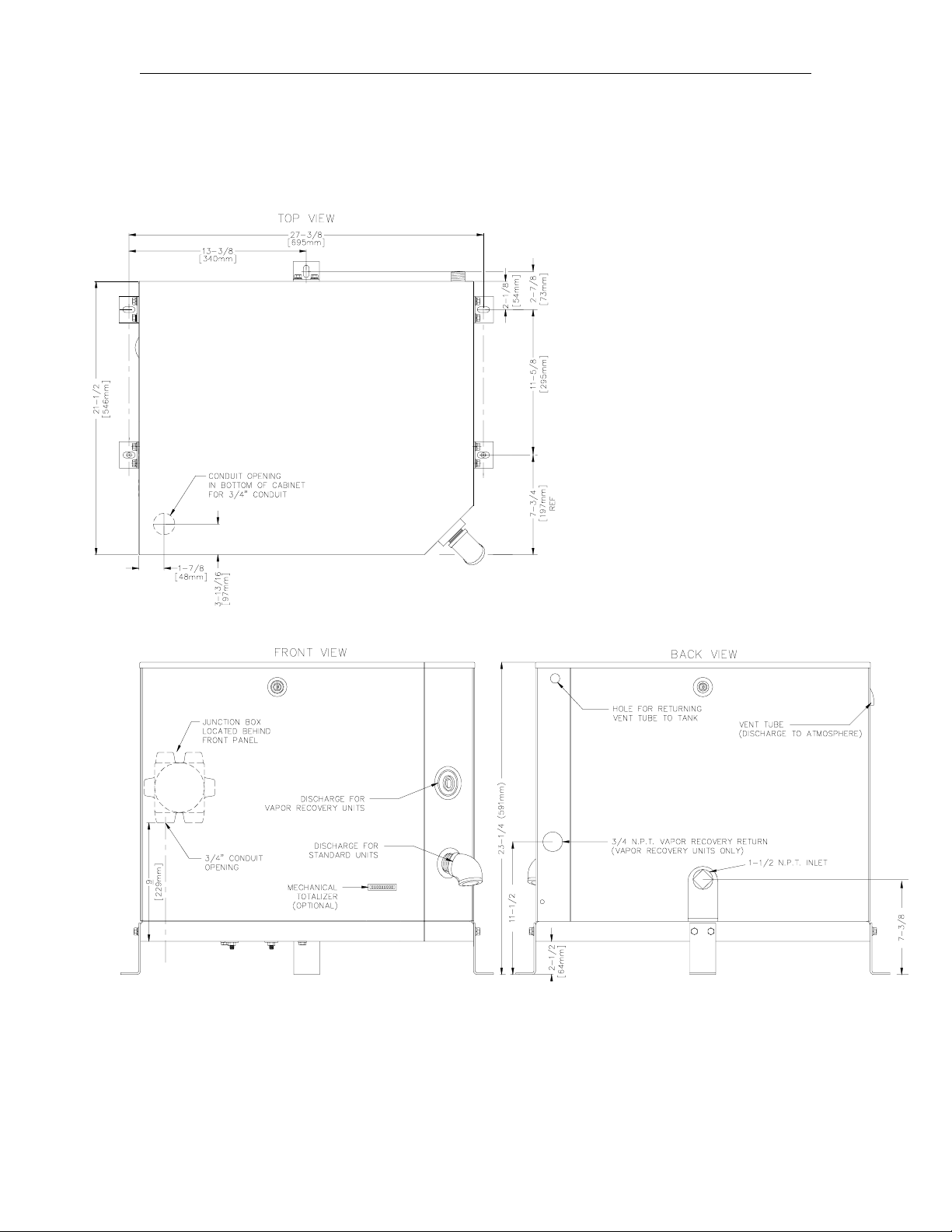

011930 Base Layout (View 1 - Pumping Unit Assembly).......................... 2-5

011930 Base Layout (View 2 - Register Assembly).................................. 2-6

011884 Base Layout (Optional Post) ........................................................ 2-7

011885 Base Layout (Side and Rear Brackets - View 1).......................... 2-8

011885 Base Layout (Side and Rear Brackets - View 2).......................... 2-9

Section 3: CONTROL LINES

Purpose .................................................................................................... 3-1

Ground ..................................................................................................... 3-1

Micro Feed ................................................................................................ 3-1

Micro Neutral............................................................................................. 3-1

Pump Motor Feed .................................................................................... 3-1

Neutral Feed ............................................................................................ 3-2

Slow Flow (Reset Complete/Switch Detect).............................................. 3-2

Fast Flow................................................................................................... 3-2

Phase 2 Feed ........................................................................................... 3-2

Pulser ....................................................................................................... 3-2

Pulse Output.............................................................................................. 3-3

RS-485...................................................................................................... 3-3

Section 4: WIRING

Wiring Precautions ................................................................................... 4-1

Ground ..................................................................................................... 4-2

Circuit Breakers ........................................................................................ 4-2

Pump Motor .............................................................................................. 4-2

Pulse Output ............................................................................................. 4-2

RS-485 ..................................................................................................... 4-2

Wire Size .................................................................................................. 4-3

Conduit ..................................................................................................... 4-4

Terminal Block ID...................................................................................... 4-5

023866 Wiring Diagram (9822A, 9823A) .................................................. 4-6

023867 Wiring Diagram (9822A-25, 9823A-25)........................................ 4-8

03/07/03 Contents-1

Page 6

GASBOY Series 9820A

Section 5: PUMP OPERATION

Overview ................................................................................................... 5-1

Electronic Component Access .................................................................. 5-2

CPU Switch Settings................................................................................. 5-3

Battery Back-up Power Supply.................................................................. 5-6

View/Reset Totalizers................................................................................ 5-6

Electronic Totalizer............................................................................... 5-6

Mechanical Totalizer............................................................................ 5-7

Operating Sequence ................................................................................. 5-8

Nozzle Locking ......................................................................................... 5-9

Section 6: START-UP AND TEST

Installation Completion Checklist ............................................................. 6-1

Start-Up .................................................................................................... 6-1

Post Start-Up Tests .................................................................................. 6-2

Voltage ................................................................................................ 6-2

Tightness ............................................................................................. 6-2

Belts .................................................................................................... 6-2

Calibration ........................................................................................... 6-2

Section 7: PREVENTIVE MAINTENANCE

General .................................................................................................... 7-1

Hints for Better Pump Performance ......................................................... 7-1

Demand Competent Service................................................................ 7-1

Use Authorized Parts........................................................................... 7-1

Operate With Reasonable Care........................................................... 7-1

Preventive Maintenance Checklist ........................................................... 7-2

Keep Water Out .................................................................................. 7-2

Lubricate the Pumping Unit ................................................................. 7-2

Clean the Dial Face ............................................................................. 7-2

Clean the Strainer ............................................................................... 7-2

Change the Filter ................................................................................ 7-2

Adjust the Belts ................................................................................... 7-2

Preserve the Finish of Your Pumps .................................................... 7-3

Warranty

Contents-2 03/07/03

Page 7

Section 1

INTRODUCTION

PURPOSE

The GASBOY ASTRA Series 9820A Electronic Commercial Pumps Installation/Oper ation Manual

is provided to assist the installer in installing and operating the unit. This manual should be

supplied to the electrician prior to the installation of conduit and wiring to ensure the unit is

installed properly. Faulty installations are the major cause of unit malfunctions. The unit must be

installed and operated as described in this manual to ensure the reliability and proper operation of

the Series 9820A unit. In addition to installation information, this manual contains warnings,

safeguards and procedures on the use and care of the Series 9820A pumps. Be sure to leave this

manual with the pump owner after the installation is complete.

GENERAL DESCRIPTION

The GASBOY Series 9820A ASTRA (aboveground storage tank remote access) pump units are

UL-listed and are available in two models. Model 9822A is available in standard speed (up to 15

GPM/56 LPM) with an intermittent-duty motor. Model 9823A is available in high speed (up to 22

GPM/83LPM) with a continuous-duty motor. The deliver y rate varies depending upon installation

conditions and added accessories. Both models of the 9820A offer electronic registration of the

quantity dispensed.

NOTE: NFPA regulations do not allow tank-mounted pumps to be used for the resale of fuel.

The Series 9820A consists of two metal cabinet assemblies. One assembly is mounted on top of

the tank and contains the pumping unit, meter, electronic pulser, and all hydraulics. The hose and

nozzle are connected to this assembly. The second assembly is mounted at a height to permit

easy access by a user. It contains the electronic register, controls, display and nozzle boot.

The following lists detail the standard and optional features for the Series 9820A.

Standard Features

• One-inch high, 6-digit, backlighted LCD display

• 1000:1 dual-phase, error-checking pulser (gallons); 250:1 dual-phase, er ror-checking pulser

(liters)

• AC authorization line for control of the unit

• Reset complete (switch detect) output which allows monitoring of the unit's operation when it

is connected to an automated fueling system

• Resettable electronic totalizer

• Discharge elbow

• Both models use a quiet and efficient gear pump which features an air eliminator, built into

the pump casting. The pump meter is a three piston, positive displacement meter which is

tested and calibrated for accuracy at any speed or pressure up to the maximum working

pressure of 50 psi.

• The standard pumping cabinet finish is white. The electronic r egister cabinet is black with a

blue graphics panel.

03/07/03 1-1

Page 8

GASBOY Series 9820A

Optional Features

• Pulser output drive line (open collector), capable of driving 1, 10, 100, 250, 500, or 1000

pulses per unit (gallons) or 1, 10, 100, or 250 pulses per unit (liters)

• RS-485 communication for direct connect to Gasboy CFN equipment

• Battery backup for display of last transaction and capture of remnant pulse count in the event

of a power failure

• Mechanical totalizer

• Dual stage solenoid valve

• A working voltage of 115 VAC (115/230 for motor) 60 HZ for domestic use, 230 VAC 50

HZ/60 HZ for international use

• Other options include Listed automatic nozzles, special lengths of Listed hose assembly,

Listed dual swivels, UL-recognized filters, vapor recovery, and vapor recovery ready.

1-2 03/07/03

Page 9

Section 2

INSTALLATION

INSTALLATION PRECAUTIONS

All installations must conform with all building/fire codes, all Federal, State, and Local codes,

National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine Service Station Code

(NFPA 30A) codes and regulations. Canadian users must also comply with the Canadian

Electrical Code.

Plan your installation carefully. A pump cannot be expected to work satisfactorily unless the

installation is correct. Dispensing troubles, which seem to be pump-related, are frequently traced

to faulty installation. Review the following list of installation DO's and DON'T's to avoid potential

problems:

1. DO read the WARNINGS page at the fr ont of this manual, preceding the Table of Contents.

It contains important information regarding the safe use of your dispensing equipment.

2. DO install an emergency power cutoff. In addition to circuit breaker requirements of NFPA 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all local codes.

In a fuel management system application, the EMERGENCY STOP and STOP keys on the

console and/or the optional EMERGENCY STOP button on the Island Card Reader do not

remove AC power from equipment and under certain conditions, will not stop product flow.

In order to provide the highest level of safety to you, your employees, and customers, we

recommend that all employees be trained as to the location and procedure for turning off

power to the entire system.

3. DO have the pump installed by a competent installer/electrician.

4. DO install breakaway coupling on discharge hose. If using a high hose retriver, install

breakaway approximately 12" downstream of hose clamp on nozzle side of clamp.

5. DO NOT experiment with a pump if you are not sure the installation is correct.

6. DO NOT overload sub- or main breaker panels.

7. DO NOT use power line wir ing of inadequate capacity. (Use gauge specified by the wiring

diagram or wire chart provided in Section 4).

8. DO NOT use a circuit breaker of improper size. (See Section 4).

9. DO NOT use the GASBOY fuel dispensing equipment to remove water ballast from the

storage tank.

10. DO NOT use gaskets on covers of explosion-proof type boxes. The sealing compound found

around wires at various locations within conduit is a requirement of the National Electrical

Code and should not be disturbed. Ensure that the mating surfaces between the junction box

and cover are free of dirt, debris, nicks and scratches. Tighten junction box covers before

replacing panels.

11. DO NOT use knock-out boxes or flexible conduit for installing this unit. All power wires

should be run in threaded, rigid, metal conduit. All threaded connections must be drawn up

tight. All but one opening in the power junction box are provided with plugs at the factory. At

completion of the installation, it is the installer's responsibility to ensure that any unused

openings are plugged.

03/07/03 2-1

Page 10

GASBOY Series 9820A

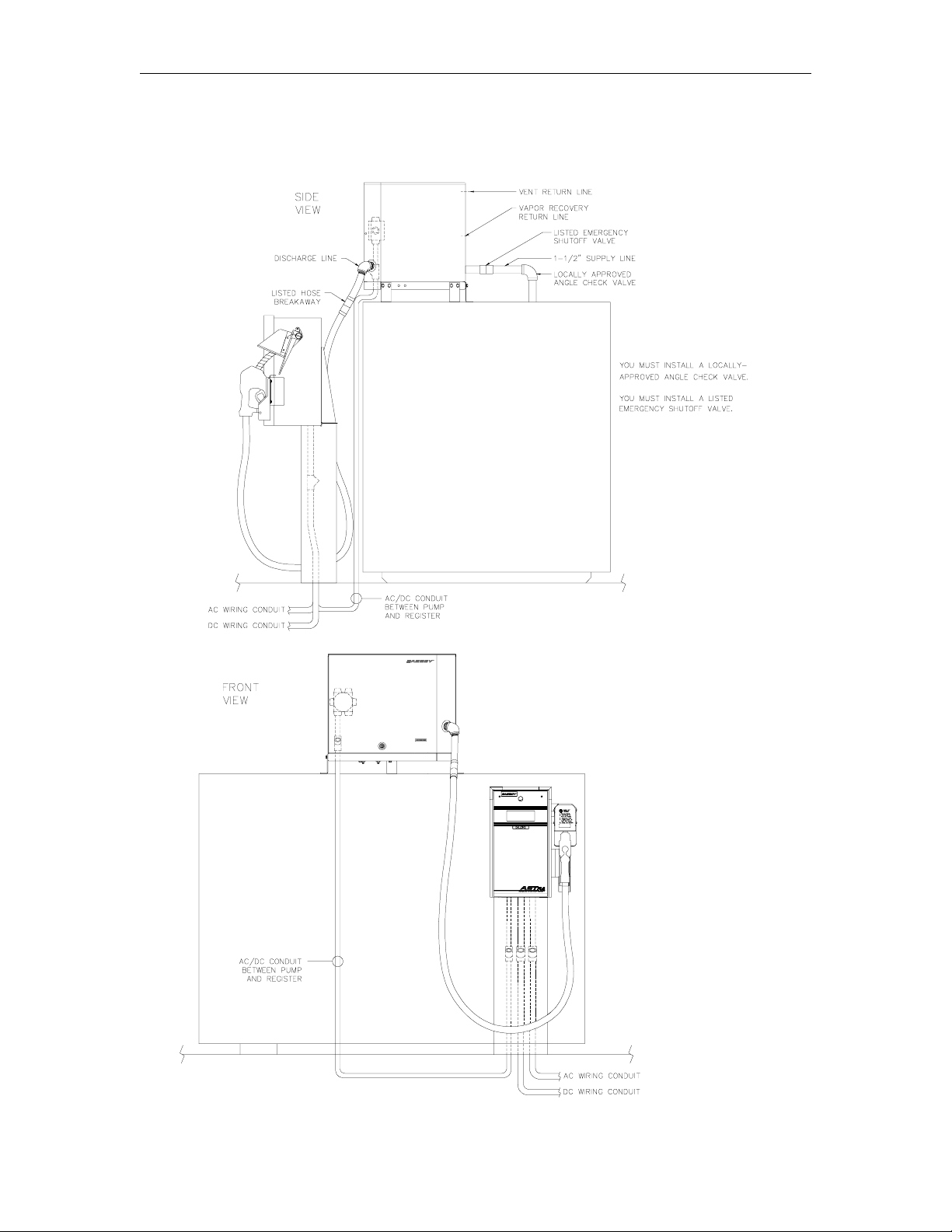

VENT LINE

The vent line for standard units is vented to the atmosphere. Whenever possible, it is

recommended that the line be returned to the tank. A hole is pr ovided above the normal vent

opening to allow this line to exit the pumping unit and return to the tank.

VAPOR RECOVERY OPTION

This dispenser can be supplied with components necessary to provide vapor recovery. If the

dispenser is equipped for vapor recovery, a splitter is located in the pump housing. A 3/4"

discharge line will exit from the rear of the pump housing to return vapor/fluid to the tank. No

changes are required to the nozzle hook or boot assembly when using vapor re covery nozzles.

Please note that the vapor recovery nozzles approved for use ar e the "short spout" type. The

following nozzles and hose are approved for use with vapor recovery systems:

Nozzles: Emco Wheaton Model A4015

Husky Corp. Model 5010

OPW Model 211V

Hose: UL-Listed Hose Assembly

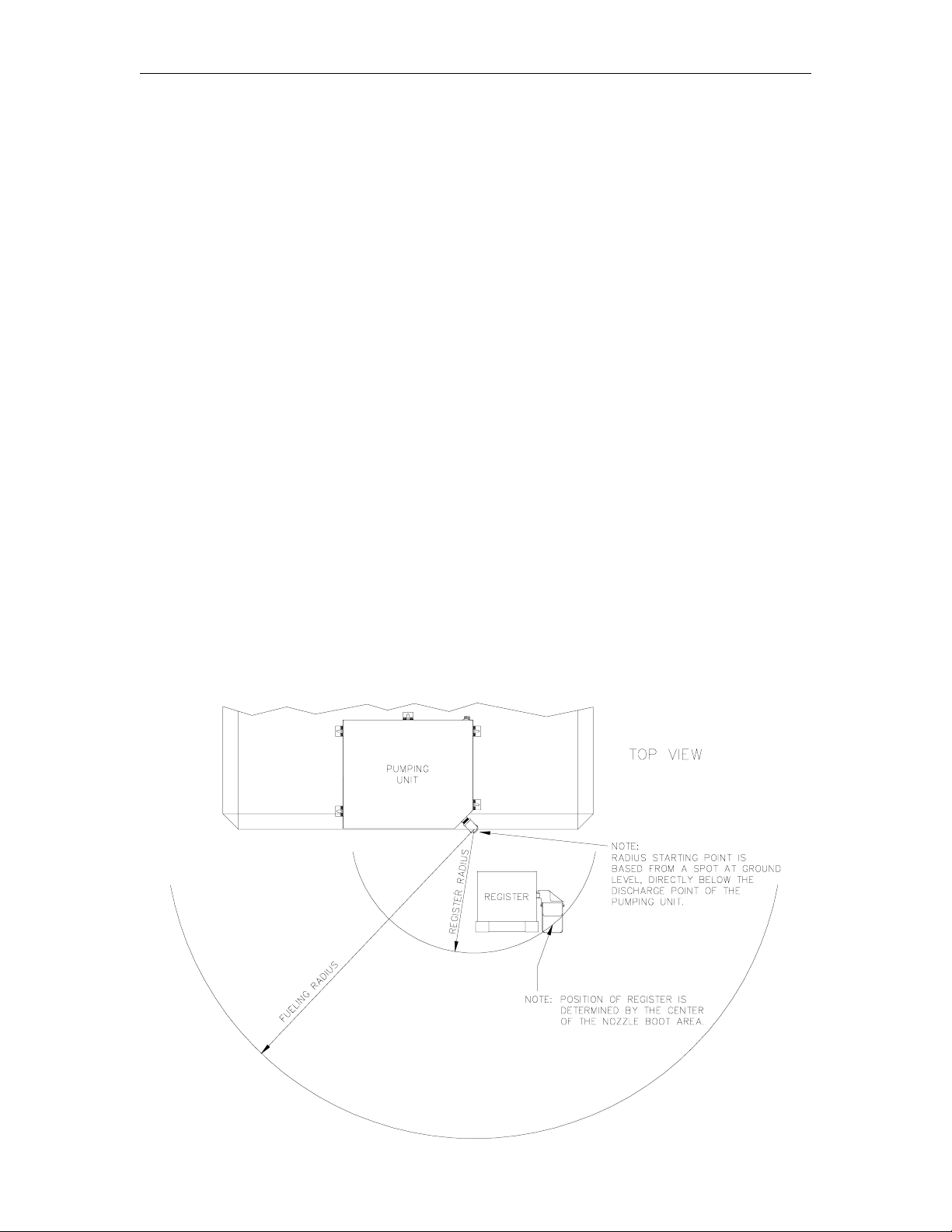

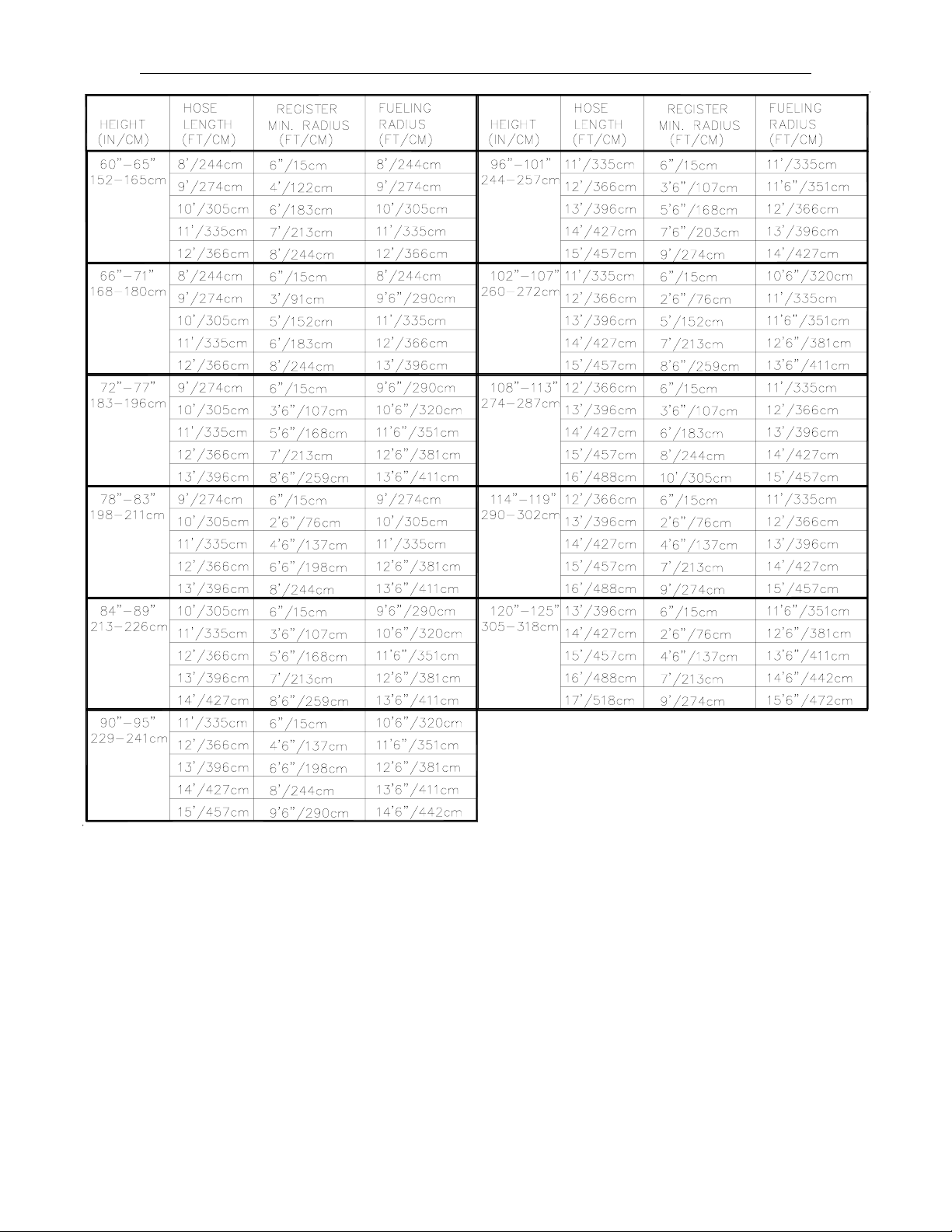

HOSE LENGTH ESTIMATOR

Use the chart on the next page to estimate the length of hose needed for your 9820A application.

The correct length will prevent the hose from touching the ground when the nozzle is placed into

the nozzle boot/hook arrangement of the register. This chart assumes that the 9820A register is

mounted on the standard pedestal and that the bottom of the pedestal is mounted flush with the

bottom of the tank. The illustration below provides a visual reference for the chart.

2-2 03/07/03

Page 11

Installation

Key for Chart Headings

Height Measurement from the ground to the hose connection assuming the

Tank height + 6" , standard units; tank height + 12" for vapor recovery units.

Hose Length Length of hose less nozzles and fittings.

Register Minimum Radius Indicates the closest the register assembly can be to the specified starting

Fueling Radius Indicates the approximate fueling radius. Measured from a point directly

pumping unit is mounted on top of the tank with the feet provided.

point; any closer than this distance may allow hose to touch the ground

when unit is not in use. This radius is measured starting from a point

directly below pumping unit discharge to the center of the nozzle boot/hook

of the register assembly.

below pumping unit discharge to the nozzle.

03/07/03 2-3

Page 12

GASBOY Series 9820A

TYPICAL INSTALLATION

2-4 03/07/03

Page 13

Installation

011930 BASE LAYOUT Models 9822A

(View 1 - Pumping Unit Assembly) 9823A

03/07/03 2-5

Page 14

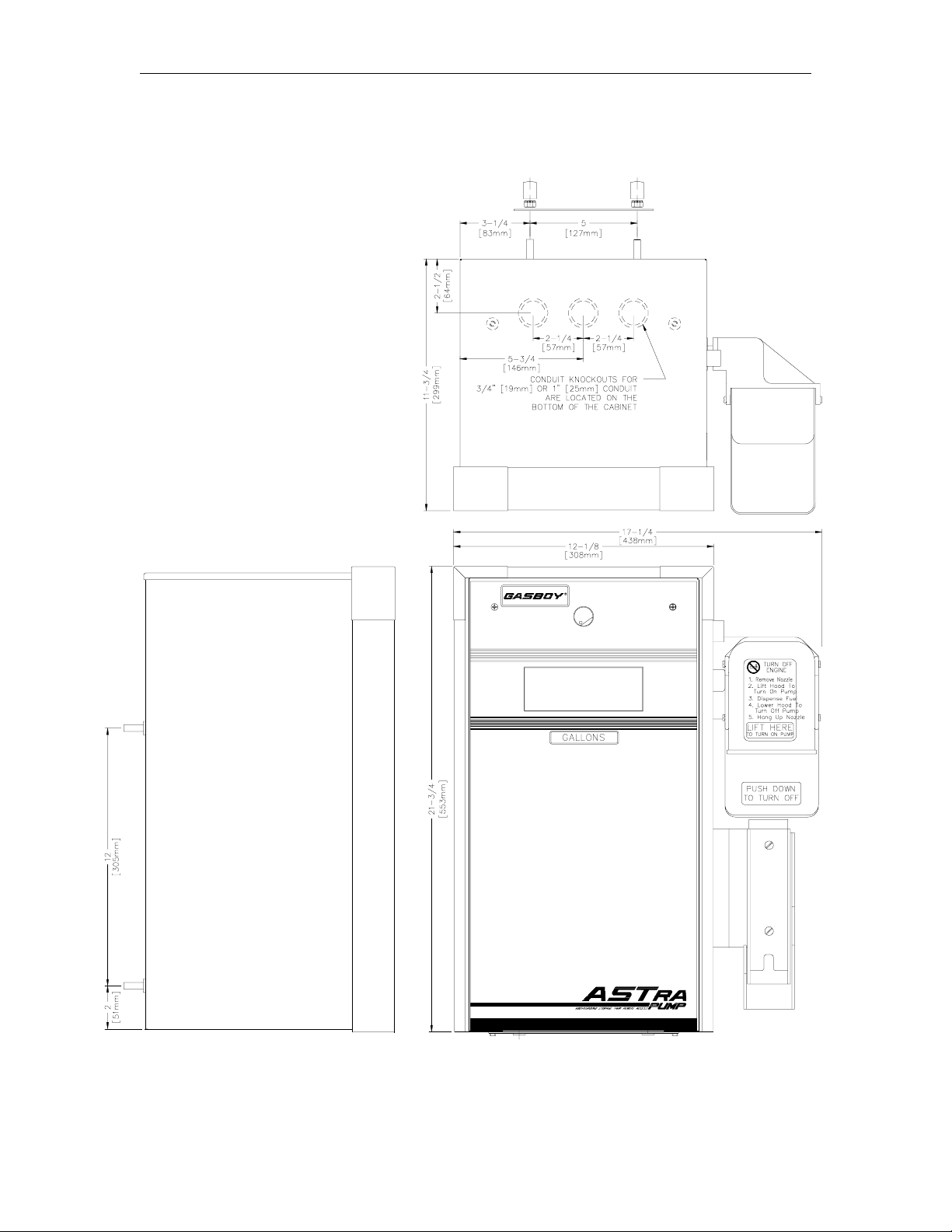

GASBOY Series 9820A

011930 BASE LAYOUT Models 9822A

(View 2 - Register Assembly) 9823A

2-6 03/07/03

Page 15

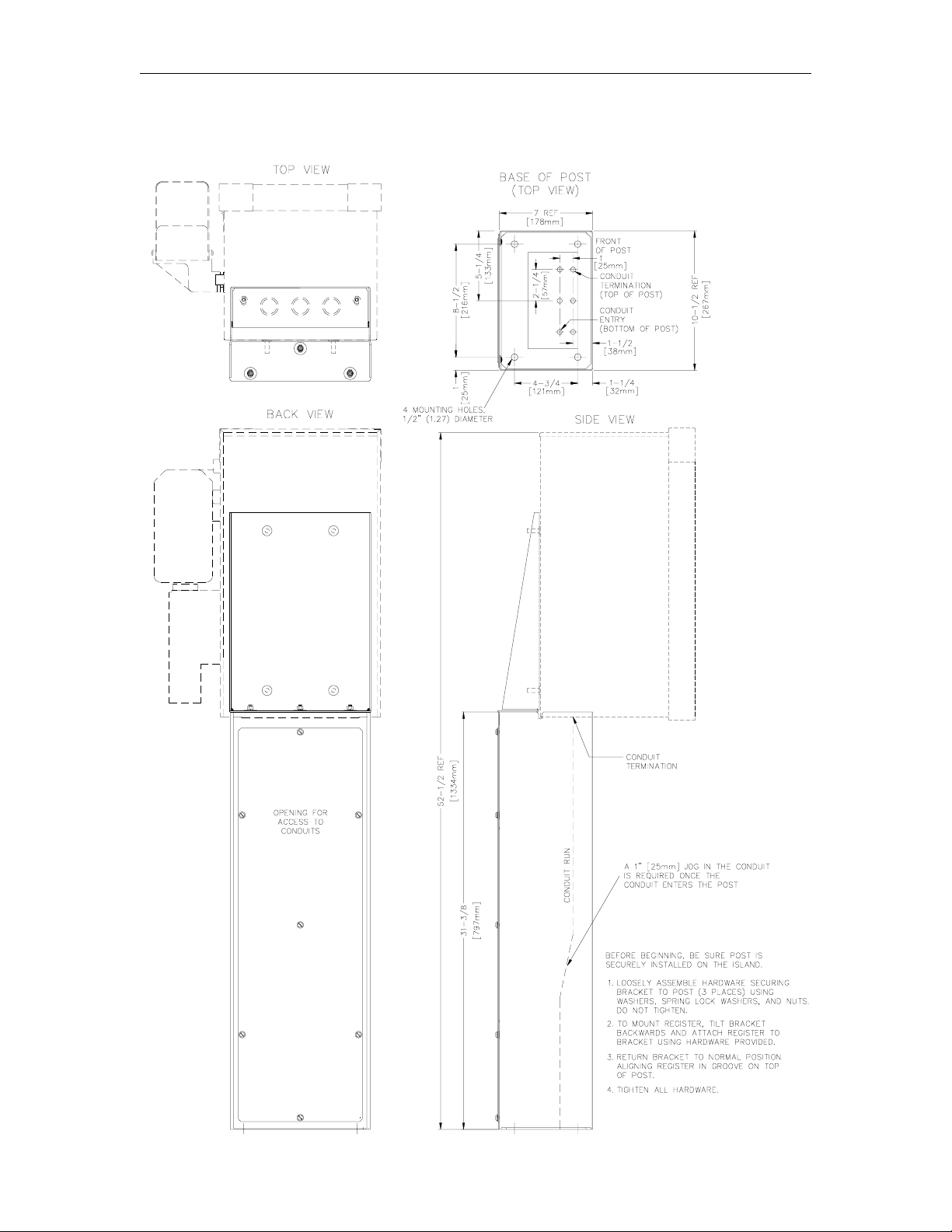

Installation

011884 BASE LAYOUT Models 9822A

(Optional Post) 9823A

03/07/03 2-7

Page 16

GASBOY Series 9820A

011885 BASE LAYOUT Models 9822A

(Side and Rear Brackets - View 1) 9823A

2-8 03/07/03

Page 17

Installation

011885 BASE LAYOUT Models 9822A

(Side and Rear Brackets - View 2) 9823A

03/07/03 2-9

Page 18

Page 19

Section 3

CONTROL LINES

PURPOSE

This section is provided to familiarize the installer with the control inputs and outputs that are

available for the Series 9820A. It is recommended the installer read these descriptions to obtain a

better working knowledge of the unit in order to guide him in planning the site wiring. Reference

Section 4 for a specific wiring diagram and installation notes.

The Series 9820A may be provided for use with 230 VAC power for international applications.

The operating voltage for control lines to these units is shown in parentheses as (230 VAC Int'l).

If connecting the 9820A to a GASBOY fuel management system, refer to the appropriate fuel

management system Installation Manual for detailed installation information.

GROUND

To ensure proper operation of the equipment and provide the necessary safety factors, a good

ground line must be provided. A ground wire (prefer ably green) must be connected between the

ground screw of the register and the main electrical service panel. One (1) earth ground

connection is required per unit. The ground rod is to be a solid, corr osion-resistant conductor and

must be installed at the main electrical panel in accordance with the National Electrical Code. It

should be properly tied into the ground bus strip of the panel. We recommend the neutral and

ground bus strips be bonded together (unless prohibited by local codes).

MICRO FEED

The Micro Feed is a 115 VAC (230 VAC Int'l) input required to power the microprocessor of the

register's electronics. This power must always remain on and must be on a separate breaker from

the control lines (Pump Motor Feed). In a site configuration using multiple units, the power for the

microprocessors of up to 8 units can be supplied by one breaker.

MICRO NEUTRAL

The Micro Neutral is a return line for AC current fr om the microprocessor of the dispensing unit to

the breaker panel.

PUMP MOTOR FEED

The Pump Motor Feed is a 115VAC (230 VAC Int'l) input which is required to power the pump and

authorize the control line. This line is used to provide authorization for the unit ( when enabled

through the DIP switches). If this line is controlled by a fuel management system using solid state

relays, a resistor assembly must be installed between the Pump Motor Feed line and Feed Neutral

to prevent false triggering of the authorization input. The resistor assembly is 8.2K OHM, 10 Watt

(P/N C05818) for 115/230 VAC domestic and 30K OHM, 10 Watt (P/N C06683) for 230 VAC

international wiring.

03/07/03 3-1

Page 20

GASBOY Series 9820A

The Pump Motor Feed line is used to power the slow flow and fast flow valves (when installed) .

The power used to control the pump is also provided by this line. The Reset Complete signal

used for external monitoring of the pump originates from the Pump Motor Feed line.

NEUTRAL FEED

The Neutral Feed is the AC current return line back to the breaker panel for all attached devices

(pump motor, solenoid valves).

SLOW FLOW (RESET COMPLETE/SWITCH DETECT)

The Slow Flow line is a 115VAC (230VAC Int'l) output which is used to control the slow flow valve

of the optional solenoid valve. This line also indicates when the reset pr ocess is complete and the

unit is ready to dispense product. This line can be used in conjunction with a fuel management

system (for systems other than the Gasboy CFN Series systems).

This line is capable of supplying 300 mA AC maximum (170 mA maximum if already connected to

the optional valve). This line must not be shorted to any conduit or chassis metal, mis-

wired, or be conn ected to any equipment requiring more than stated maximum allowable

current. If these restrictions are not followed, damage to the CPU PCB will occur.

FAST FLOW

The Fast Flow line is a 115VAC (230VAC Int'l) output which is used to control the fast flow valve of

the optional solenoid valve.

This line is capable of supplying 300 mA AC maximum (170 mA maximum if already connected to

the optional valve). This line must not be shorted to any conduit or chassis metal, mis-

wired, or be conn ected to any equipment requiring more than stated maximum allowable

current. If these restrictions are not followed, damage to the CPU PCB will occur.

PHASE 2 FEED

The Phase 2 Feed is a hot feed which is the opposite phase of the pump motor feed. This line

and the pump motor feed are used for 230VAC motor applications. If connected to equipment

requiring control of the authorization input, the Phase 2 Feed should be switched through a

separate relay to prevent false triggering of the authorization signal.

PULSER

These lines are used to connect the pulser, mounted in the pumping unit, to the electronics in the

register assembly. These are DC voltage lines and provide the information necessary for the

register assembly to monitor the quantity of product dispensed. These lines are for internal use

only and must not be used for the pulse output (for external monitoring of the unit). Use the

optional Pulse Output interface if external pulses are required.

3-2 03/07/03

Page 21

Control Lines

PULSE OUTPUT

This option provides a DC pulser output to indicate the quantity dispensed. This is an open

collector output. This output can sink up to 150 milliamps DC at voltages up to 24 VDC. The

pulse rate can be configured by a sealable DIP switch for rates of 1, 10, 100, 250, 500, or 1000

pulses per gallon or 1, 10, 100 or 250 pulses per liter. This output should only be used when

monitoring of the unit's operation is desired.

RS-485

When the dispensing unit includes the optional RS-485 interface, RS-485 lines are provided. This

interface allows the user to connect a GASBOY CFN Series System directly to the Series 9820A

dispensing unit.

03/07/03 3-3

Page 22

Page 23

Section 4

WIRING

☎ Customers and installers having any questions pertaining to the installation should

contact their GASBOY distributor.

WIRING PRECAUTIONS

The quality of the electrical installation is a major factor in maintaining proper safety levels and

providing trouble-free operation of your GASBOY pump. To assure a quality installation, follow

these rules:

1. All wiring must be installed to conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2. Use only threaded, rigid, metal conduit.

3. Use only UL-Labeled insulated gasoline- and oil-resistant stranded copper wiring of the

proper size.

4. Wire connections should be tightly spliced and secured with a wire nut; close off the open end

of the wire nut with electrical tape.

5. The line to the motor should be on a separate cir cuit and installed on a 20 to 30 AMP breaker

depending on the motor size and/or the voltage setting.

6. Install an emergency power cutoff. In addition to circuit breaker requirements of NFPA 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all local codes.

In a fuel management system application, the EMERGENCY STOP and STOP keys on the

console and/or the optional EMERGENCY STOP button on the Island Card Reader do not

remove AC power from equipment and under certain conditions, will not stop product flow.

In order to provide the highest level of safety to you, your employees, and customers, we

recommend that all employees be trained as to the location and procedure for turning off

power to the entire system.

WARNING:

To reduce the risk of electrical shock when servicing, turn off and lock out all power to

the pump.

AVERTISSEMENT

Pour réduire le risque de choc électrique lors de l'entretien/révision, coupez totalement

le courant à la pompe/distributeur.

7. Have the pump installed by a competent installer/electrician.

03/07/03 4-1

Page 24

GASBOY Series 9820A

GROUND

To ensure proper operation of the equipment and provide the necessary safety factors, this unit

must be grounded. A ground wire (preferably green) must be connected between the ground

screw of the register and the main electrical service panel. One (1) earth ground connection is

required per unit. The ground rod is to be a solid, corrosion-resistant conductor and must be

installed at the main electrical panel in accordance with the National Electrical Code. It should be

properly tied into the ground bus strip of the panel. We recommend the neutral and ground bus

strips be bonded together (unless prohibited by local codes).

CIRCUIT BREAKERS

Power to the unit must be supplied from dedicated breakers. No other equipment should be

powered from these breakers. AC power for the micro power must come from a different breaker

than that of the pump. This not only provides electrical isolation for the micro power, but allows

the unit to be disabled without shutting off power to the microprocessor PCB. The AC power for

the micro power may be grouped together for multiple units. It is recommended that no more than

8 units be supplied from one breaker.

PUMP MOTOR

Pumps are shipped from the factory with motors wired according to the specifications given on the

order as to kind of current, frequency and voltage.

Very often on installation, it becomes necessary to change the original setting to suit the AC power

source. To do this, locate the motor change-over plate and remove the scr ew which secures it in

place. Slide the plate so that the desired voltage, as marked on the plate, lines up with the screw

hole. Reinsert the screw and secure the plate in place.

Many motor failures result from improper setting of the motor change-over plate. If set for 115

VAC and a 230 VAC feed is used, the motor will burn out after running only a short time. If set for

230 VAC and a 115 VAC feed is used, the motor will run very slowly and the starting field will soon

burn out.

PULSE OUTPUT

The Pulse Output option provides the means for an external system to monitor the quantity that is

dispensed by the 9820A dispensing unit. A description of the interface is provided in Control

Lines, Pulse Output, in Section 3. Consult the wiring diagrams provided in Wiring in Section 4,

along with the installation manual of the system that will be connected to the 9820A dispensing

unit.

RS-485

The RS-485 option provides the means for direct connection to a GASBOY CFN Series System.

Consult the wiring diagrams provided in Wiring in Section 4, along with the installation manual of

the CFN Series System for proper wiring.

4-2 03/07/03

Page 25

Wiring

WIRE SIZE

The AC wire size for the Micro Feed and Neutral should be 14 AWG. This gauge of wire will be

sufficient for runs up to 300 feet from the breaker panel to the dispensing unit. Sites with

distances over 300 feet should use 12 AWG wire. In cases where multiple units are powered from

the same breaker through the same wires, the gauge of the wires should be increased to handle

the added load according to the distance from the breaker panel.

The AC wire size of the Pump Motor Feed, Pump Motor, Feed Neutral, and Neutral is

dependent upon the HP rating of the pump motor, the voltage at which the pump will be oper ated

(115/230 VAC), and the distance from the circuit breaker panel to the pump. The chart below

should be used as a guide in selecting the proper wire size according to the specific installation

requirements.

The AC wire size for the Slow Flow, Fast Flow lines should be 14 AWG (when they are used).

The DC wire size for the Pulser lines connecting the pumping unit to the register assembly must

use four conductor, 18 AWG shielded cable (Belden 89418, Gasboy P/N C08864). This cable

allows the pulser wires to run in the same conduit as the AC wiring for the short distance between

the pumping unit and the register assembly. Belden 89418 is rated as follows:

Gas and Oil resistant insulation & jacket

18 AWG tinned, stranded, copper

Four conductors

300 volt maximum operating voltage

Aluminum/Mylar shielded with drain wire

Twisted-pair shielded cable is highly recommended for the Pulse Out put or RS-485 field wiring

(when they are used). This type of cable provides superior noise immunity and must be used for

distances over 100 feet or any time pulse output or RS-485 wiring is included in the same conduit

as the AC wires. This cable must meet the following specifications:

Conductor: 18 AWG stranded wire. 2 twisted-pairs.

Shield: Foil-wrapped 100% coverage and/or tinned copper braid 90% coverage

Drain Wire: Stranded, tinned copper, 20 AWG or larger/or braided shield

Voltage Rating: Maximum operating voltage of 600V

Environmental: Gas- and oil-resistant; suitable for wet or dry locations.

GASBOY can supply Belden 1063A (P/N C09655) which is a UL-Listed, 4-conductor cable that

meets the requirements listed above. NOTE: Belden 1063A is UL-Listed but not CSA listed.

Cable with a voltage rating of less than 600V must be installed in a conduit separate from all AC

wires.

See the GASBOY Fuel Management System Installation Manual for specific requirements.

03/07/03 4-3

Page 26

GASBOY Series 9820A

CONDUIT

All wiring to the GASBOY Series 9820A dispensing unit must be installed in threaded,

rigid, metal conduit. PVC IS NOT ACCEPTABLE. Wiring between the 9820A register and

pumping unit is installed in a single conduit. This includes the wiring for the AC control of the

pumping unit and the internal pulser. A special cable, as described in Section 4, Wire Size, must

be used for the connection between the pulser inside the pumping unit to the register assembly.

It is recommended that high voltage AC power wires to the register assembly (not between the

register and pumping unit), be installed in separate conduit from the low voltage pulser output

wires (when used). However, if AC and DC power wires share conduit, DC wiring must consist of

UL-Listed cable with the specifications described in Section 4, Wire Size. Only AC wires for the

system and dispensers can be installed in this conduit for this application. Wiring between a Fuel

Point Reader (FPR) and its pre-amp junction box is intrinsically safe and must be run in a conduit

with only other intrinsically safe wiring. It cannot be run in conduit with AC, DC, RS-485, or pulser

wiring, regardless of the cable type used. See the Fuel Point Reader Installation and Retrofit

Manual, C35628 for details.

The GASBOY Warranty will not apply to any dispenser in which the AC and DC wires are run in

the same conduit, J-Box or wireway except as noted. The GASBOY Warranty will not apply to any

dispenser using PVC as conduit.

When the GASBOY Series 9820A dispensing unit is being installed with a fuel management

system other than a GASBOY system, see the manufacturer's installation manual for their specific

conduit requirements.

All wiring and conduit runs must conform with all building/fire codes, all Federal, State, and Local

codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine Service

Station Code (NFPA 30A) codes and regulations. Canadian users must also comply with the

Canadian Electrical Code.

Use the following charts as a guideline for determining the necessary conduit sizes for wiring of

the GASBOY Series 9820A dispensing unit. When actually determining the size of conduit, it may

be necessary to increase the size of conduit because of a long run or large amount of bends. The

installer should determine the orientation of the wire runs according to the layout of the

components at the site and the applicable GASBOY wiring diagrams.

To determine conduit size needed, use the THHN/THWN Wire Areas table (left) to find the area

for each wire gauge. Add up all wire areas. Use the Areas of Tr ade Size Conduit Table (r ight) to

select the smallest number in the 25% fill area (based on NEC 501-1) that comes closest without

exceeding the total wire area.

4-4 03/07/03

Page 27

Wiring

TERMINAL BLOCK ID

The terminal blocks shown below are located in the register assembly.

03/07/03 4-5

Page 28

GASBOY Series 9820A

023866 WIRING DIAGRAM Models 9822A

Domestic 115/230 VAC 9823A

NOTES:

1. All wiring and conduit runs must conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2. Pump motor can be wired as 230 VAC to reduce current draw. See breakaway view of 230

VAC PUMP MOTOR. All other wiring should remain the same except for the addition of the

L2 (requires 230 VAC breaker for control). If connected to equipment requiring control of the

authorization input, the Phase 2 Feed should be switched through a separate relay to prevent

false triggering of the authorization signal.

3. If the PUMP MOTOR line is contr olled by a fuel management system using solid state relays,

a resistor assembly must be installed between the Pump Motor Feed line and Neutral to

prevent false triggering of the authorization input. The resistor assembly is 8.2K OHM, 10

Watt (P/N C05818) for 115/230 VAC domestic and 30K OHM, 10 Watt (P/N C06683) for 230

VAC international wiring.

4. SLOW FLOW and FAST FLOW lines are typically used when connecting to an optional

valve. Each of these lines is capable of supplying 300 mA AC maximum (170 mA AC

maximum if already connected to the optional valve). These lines must not be short ed to

any conduit or chassis metal, mis-wired, or connected to any equipment requiring

more than stated maximum allowable current . If these restrictions are not followed,

damage to the CPU PCB will occur.

5. Use the wire size chart listed when determining the wire size for the control wiring.

4-6 03/07/03

Page 29

Wiring

023866 WIRING DIAGRAM Models 9822A

Domestic 115/230 VAC 9823A

WARNING:

Failure to follow the correct wiring diagram and all the listed notes and

precautions may result in damage to the CPU PCB.

03/07/03 4-7

Page 30

GASBOY Series 9820A

023867 WIRING DIAGRAM Models 9822A-2

International 230VAC 9823A-2

NOTES:

1. All wiring and conduit runs must conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2. If the PUMP MOTOR line is contr olled by a fuel management system using solid state relays,

a resistor assembly must be installed between the Pump Motor Feed line and Neutral to

prevent false triggering of the authorization input. The resistor assembly is 30K OHM, 10

Watt (P/N C06683) for 230 VAC international wiring.

3. SLOW FLOW and FAST FLOW lines are typically used when connecting to an optional

valve. Each of these lines is capable of supplying 300 mA AC maximum (170 mA AC

maximum if already connected to the optional valve). These lines must not be short ed to

any conduit or chassis metal, mis-wired, or connected to any equipment requiring

more than stated maximum allowable current . If these restrictions are not followed,

damage to the CPU PCB will occur.

4. Use the wire size chart listed when determining the wire size for the control wiring.

4-8 03/07/03

Page 31

Wiring

023867 WIRING DIAGRAM Models 9822A-2

International 230VAC 9823A-2

WARNING:

Failure to follow the correct wiring diagram and all the listed notes and

precautions may result in damage to the CPU PCB.

03/07/03 4-9

Page 32

Page 33

Section 5

PUMP OPERATION

OVERVIEW

This section describes the operation of the pump. It shows how to access the electronic

components, how to set the internal switches, the optional battery back-up power supply, how to

view and reset the electronic totalizers using the actuator, how to operate the pump, and how to

lock the nozzle.

03/07/03 5-1

Page 34

GASBOY Series 9820A

ELECTRONIC COMPONENT ACCESS

Before attempting to start-up the 9820A, it is important to become familiar with the location of

some key components as well as the various switch-selectable operating modes.

1. Unlock and remove the front panel.

Remove the two screws located at the

top of the door assembly. Pull out on

the top of the door and lift the door

assembly to remove it.

2. Loosen the two screws located on the left

and right door support brackets and pivot

display panel down.

5-2 03/07/03

Page 35

Pump Operation

CPU SWITCH SETTINGS

The 9820A can be configured for

various operating conditions using the

switches located on the CPU PCB.

Check these switches and change

their settings if necessary. Switch

settings should be changed with the

power switch OFF. The new settings

are read by the CPU PCB when the

power is turned ON again.

SW1

SW1-1 Baud Rate

This switch is set to reflect the communication rate

of the GASBOY RS-485 pump loop; open for 9600

baud or closed for 1200 baud. The GASBOY CFN

system and TopKAT communicate at 9600 baud.

SW1-2 Mode

If the 9820 is controlled by a GASBOY

CFN or TopKAT electronic fuel

management system, the switch should

Mode

On-line

be open (on-line mode). If the 9820 is

controlled by a GASBOY Series 1000 or

TopKAT mechanical system, or

controlled by any non-GASBOY system,

or not controlled by any fuel

management system at all, the switch

should be closed (standalone mode).

NOTE: The 9820 is shipped in standalone mode.

SW1-3, SW1-4 Delay Time

These two switches set the delay time used by leak detectors in

submersible pump applications. The delay time is the period

between activation of the submersible pump and activation of the

slow flow valve. This time should be set according to the type of

leak detector installed on the submersible pump to allow a normal

leak test for each transaction. The delay time should be set to

zero seconds for suction pumps.

SW1-5

Not used.

Baud Rate

9600

SW1-2

Open

Closed Series 1000Standalone

SW1-1

Open

Fuel System

CFN

TopKAT top-mount

TopKAT electronic

None currentlyClosed1200

supported

Fuel System

CFN

TopKAT top-mount

TopKAT electronic

TopKAT Mechanical

All non-GASBOY systems

No fuel system

Delay Time

0 seconds

4 seconds

5 seconds

6 seconds

SW1-3

Closed

Closed

Open

Open Open

SW1-4

Closed

Open

Closed

03/07/03 5-3

Page 36

GASBOY Series 9820A

SW1-6 Authorization

This switch allows activation of the 9820A from

some types of fuel management systems. When

the switch is closed, a 115 VAC (230 VAC Int’l)

signal must be present on the Control Feed line

for pump activation to occur (required setting for

Series 1000, TopKAT mechanical, and all nonGASBOY systems ). When open, the 9800

Authorization

Yes

SW1-6

Closed

OpenNo CFN

Fuel System

Series 1000

TopKAT mechanical

All Non-GASBOY systems

TopKAT top-mount

TopKAT electronic

No fuel system

ignores the Control Feed line (required setting for

CFN, TopKAT electronic, or no fuel system).

SW1-7 Totalizers

This switch should be set to open for normal operation. When closed,

this switch enables the reset of the electronic totalizers. See

View/Reset Totalizers later in this section for details.

Reset

Normal

SW1-7Totalizers

Closed

Open

SW1-8

Not used.

SW2

This four-position switch pack serves a dual purpose: as an address setting when communicating

on the GASBOY RS-485 loop or TopKAT, or as a pulser output rate selector when pulser data is

sent to a fuel management system other than a GASBOY CFN or TopKAT.

Address Switches

A unique address identifier must be set when the

9820A is connected to the GASBOY RS-485 pump

loop via the 9820A RS-485 I/F PCB. Because there

are 16 possible address combinations, up to 16 units

(single or twin) may be connected to the pump loop.

Addressing should start at 1 and continue

sequentially through 16. The physical wiring order

does not have to correspond with the address order;

that is the first unit on the RS-485 loop doesn't have

to be address 1. The char t at right gives the switch

settings and address selections.

Address

SW2-1

1Closed

2

Open Closed

3Closed

4

Open

5Closed

6

Open

7Closed

8

Open

9

Closed ClosedClosed Open

10

Open ClosedClosed Open

11

Closed ClosedOpen Open

12

Open ClosedOpen Open

13

Closed

14

Open

15

Closed

Open

SW2-2

Closed

Open

Open

Closed

Closed

Open

Open

Closed

Closed Open Open

Open

Open Open Open16

SW2-3

ClosedClosed

Closed

Closed

Open

Open

Open

Open

Open

Open

SW2-4

Closed

Closed

Closed

Closed

Closed

Closed

Closed

Closed

Open

Open

5-4 03/07/03

Page 37

Pump Operation

Pulser Output Rate Switches

When the 9820A is connected to external control

equipment other than a GASBOY CFN system

(standalone), the pulser signals are sent out via the 9820A

Pump I/F PCB. The pulse rate required by the monitoring

equipment can be configured by setting the switches as

shown in the chart at right. The pulse rate represents

pulses per gallon (PPG, domestic) or pulses per liter ( PPL,

international). For domestic units, the pulse rate can be up

to 1000 PPG. For international units, the pulse rate can be

up to 250 PPL for all other models. This switch may need

Pulse Rate SW2-1 SW2-2 SW2-3

1Closed

10

100

250

500

1000

None

None

Open Closed

Closed

Open

Closed

Open

Closed

Open

Closed

Open

Open

Closed

Closed

Open

Open

ClosedClosed

Closed

Closed

Open

Open

Open

Open

to be sealed by a Weights and Measures paper seal if the

9820A is used for the resale of product.

Leading zeros are always suppressed in the hundreds and

tens positions to the left of the decimal point. When in

standalone mode, positions to the right of the decimal point

are displayed based on the pulse rate selected as shown in

the table at right.

Pulse Rate Display

1:1 XXX.

10:1

100:1

250:1

500:1

1000:1

XXX.X

XXX.XX

XXX.XXX

XXX.XXX

XXX.XXX

Timeout Switch

When the 9820A is in standalone mode, it will turn off an

active hose if it doesn't detect pulses for 4 minutes, 15

seconds. This timeout feature can be disabled by setting

Timeout

Enabled

Disabled

SW2-4

Closed

Open

switch SW2-4 to OPEN.

03/07/03 5-5

Page 38

GASBOY Series 9820A

BATTERY BACK-UP POWER SUPPLY

9820A models can be equipped with an optional battery back-up power supply. This allows the

last transaction data to be displayed for a minimum of 15 minutes. After the batteries reach a

certain low-voltage point, the power will automatically shut off. If you need to shut off the battery

power before the low-voltage point is reached, momentarily disconnect, then re-connect, the cable

that plugs into P1 on the power supply.

VIEW/RESET TOTALIZER

Electronic Totalizer

The 9820A stores a running quantity total. This electronic totalizer works independent of the

optional mechanical totalizer that may be installed, and is shown as whole gallons (liters) on the

displays (decimal point is shown, although it is disregarded). The totalizer data is stored in

battery-backed memory. The 9820A is supplied with an actuator (shown in the above illustration)

which allows you to view and reset the electronic totalizer. When the 9820A is shipped, the

actuator is attached with a tie wrap to the electronic chassis behind the register door. At

installation or startup, cut the tie wrap and remove actuator. Retain for future use.

5-6 03/07/03

Page 39

Pump Operation

To view the pump totalizer, make sure the pump handle is off and no transaction is in progress.

Locate the unit of measure indication (i.e., GALLONS) below the display window. Touch this area

with the actuator as shown. The totalizer data will be displayed for 10 seconds. If more time is

needed, touch the actuator to the same area for an additional 10 second period.

To reset the electronic totalizer, follow the disassembly procedure outlined under Electronic

Component Access earlier in this section. Turn off the breaker supplying the 9820A AC power .

Close SW1-7 on the CPU PCB. Hold the actuator against the totalizer bracket and have someone

turn the breaker on. The display should change to all zeroes. Remove the actuator and open

SW1-7.

NOTE: Returning switch 1-7 to the open position prevents the totalizer from being reset the next

Mechanical Totalizer

time the actuator is used to read it.

Some 9820A models contain an optional mechanical totalizer. The totalizer has 8 digits; 7 whole

gallons and 1 tenth-gallon column, 8 whole digits for liters. The mechanical totalizer is located on

the front right side of the pumping unit.

03/07/03 5-7

Page 40

GASBOY Series 9820A

OPERATING SEQUENCE

The exact sequence of events that occurs during the operation of the pump is determined by

various switch settings, inputs, and the user. A typical transaction is explained below.

1. Turn on the pump handle. If AC is present on the Pump Motor Feed line, the reset cycle

begins. The display:

• goes blank for one second

• shows all 8's for one second

• goes to 0.000 (gallons) or 0.00 (liters) and remains for one second.

The pump motor turns on. If equipped, the slow flow valve turns on.

2. The user begins to dispense fuel. Quantity will not be recorded on the display until 0.010

gallons (0.04 liters) are reached, however, all pulses will be sent out on the Pulse Output line,

if equipped. At 0.010 gallons (0.04 liters), the fast flow valve turns on, if equipped.

3. The pump continues to run until one of the following conditions occurs. These conditions turn

off all relays.

• The handle is turned off.

• The Pump Motor Feed line is turned off.

• A pulser error is detected.

• A timeout of 255 seconds is reached. If connected to a fuel management system, the

4. The 9820A continues to monitor for pulses until a 2 second period with no pulses occurs. At

timeout loaded into the system will be used.

• A quantity of 990.000 gallons (9900.00 liters) is reached. If connected to a fuel

management system, the limit set in the system will be used.

• The pump is halted by an operator of a fuel management system.

• An AC power failure occurs.

this time the transaction is considered completed.

5-8 03/07/03

Page 41

Pump Operation

NOZZLE LOCKING

A locking mechanism is supplied as part of the hook arrangement on each 9820A. This will allow

the unit to be locked thus preventing use of the dispenser. A lock with a shackle clearance of at

least 2-1/2" is required to lock the pump (i.e., Master No. 1LJ-D). T o lock the nozzle in place,

follow the instructions below:

1. Insert the nozzle onto the hook assembly with the nozzle tip inside of the boot.

2. Slide the rear bracket of the nozzle hook assembly upward until the holes near the bottom of

the nozzle are aligned.

3. Slide the open padlock through holes in the moveable and stationary portions of the hook

arrangement, thus capturing the nozzle in place. (Note that the four holes will not align until

the moveable bracket has been slid upward.)

4. Close the lock.

While the nozzle is locked in place, the nozzle cannot be removed from the nozzle hook and the

dispenser cannot be turned on.

03/07/03 5-9

Page 42

Page 43

Section 6

START-UP AND TEST

INSTALLATION COMPLETION CHECKLIST

Review the information below to verify the proper installation of the Series 9820A dispensing unit.

If the installation does not meet criteria listed, correct the problem before the start-up is

performed.

1. To avo id damage to the CPU PC board, verify that t he SLOW FLOW and FAST FLOW

wires are not shorted to any conduit or chassis metal, mis-wired, or connected to any

equipment requiring more than stated maximum allowable current.

2. The register and pumping unit must be properly secured.

3. All plumbing must be complete and tight. All liquid-carrying lines mu st be checked for

leaks.

4. When DC pulse output lines are used in the pump for connecting to GASBOY fuel

management systems, the AC and DC wires must not share any conduits, junction boxes, or

troughs except as noted in Section 4, Wire Size.

5. All conduit work must be complete. All junction box covers must be secured. Conduits

should not be sealed until the wiring is verified through proper operation.

6. The unit must be properly grounded.

7. Before any testing begins, remove any water in the tank through a fill opening, using a

suitable pump. Do not use the GASBOY pump to remove water. Serious damage may

occur.

8. A sufficient volume of fuel must be put in the tank to insure that the liquid level is above the

bottom of the suction pipe.

03/07/03 6-1

Page 44

GASBOY Series 9820A

START-UP

After successfully verifying the installation against the completion checklist, the unit is ready for

start-up. Follow the procedure below to perform an orderly start-up of the Series 9820A.

1. Verify that all switches on the CPU PCB are set properly for the various operating conditions

as explained in Section 5.

2. Turn on the circuit breakers for the microprocessor.

3. Authorize the unit through the fuel management system, if available.

4. Remove the nozzle from its holder and turn on the pump handle. Verify that the display goes

through the proper reset sequence as explained in Section 5, Operating Sequence.

5. Dispense fuel. Verify that the high flow valve opens, if equipped. Check all plumbing for

leaks at this time.

6. Turn the pump handle off. Open the nozzle. No fuel should be dispensed at this time.

7. Verify that the correct quantity was recorded by the fuel management system, if available.

8. Run the unit through all standard calibration procedures.

9. Reset the electronic totalizer as described in View/Reset Totalizer in Section 5.

6-2 03/07/03

Page 45

Start-Up and Test

POST START-UP TESTS

Voltage

The incoming voltage to the pump should be checked and any reading not within 10% of rated

voltage should be corrected before testing is continued. It is good practice to take voltage

readings while the pump is operating on bypass and also while making a delivery. Any voltage

drop in excess of 10% during either of these operating states should be considered a low voltage

condition. Corrective action should be taken to insure an adequate power supply to the pump.

Tightness

After determining that the pump is operating satisfactorily and the system is fully primed, check the

pump and piping to make sure that all connections are tight.

Belts

Since belts do stretch slightly during the first few minutes of operation, check the belt tension after

completing the operational test; a properly tightened belt will permit twisting the belt 180 degrees

midway between the motor and pump pulleys.

On the 9822A and 9823A, the belt can be tightened by loosening the cap screw which holds the

idler arm and sliding the arm to obtain the correct belt tension of 6-3/4 lbs. (+

adjustment is complete, remember to retighten the cap screw.

Calibration

All GASBOY pumps are adjusted for accurate measure at the factory. However, since the

conditions of the installation can affect pump accuracy, it is the responsibility of the installer to

check the pump for accuracy and make any needed adjustments. Where required, it is the

owner's responsibility to report this device to the local Weights and Measures officials for their

inspection before the unit is put into service.

The adjustment of measurement is accomplished

by breaking the seal wire and removing the Seal

Pin. This will permit the Index Disc, to be turned

either counterclockwise (-), decreasing the

measurement, or clockwise (+), increasing the

measurement. A variation of approximately one

cubic inch in measurement is obtained by turning

the Index Disc five holes. After measurement

has been properly adjusted, the Seal Pin and

seal wire should be replaced.

3/4). When the

03/07/03 6-3

Page 46

Page 47

Section 7

PREVENTIVE MAINTENANCE

GENERAL

GASBOY pumps are designed and constructed to give many years of uninterrupted service. In

fact, operators report years of trouble-free operation with absolutely no service expense. Yet,

certain parts of a pump are bound to wear, and GASBOY therefore recommends a periodic

inspection, at least twice a year, for such things as fuel leaks, belt tension and condition,

lubrication and strainer cleanliness. If such a procedure is followed, any small adjustments that

are necessary can be made before expensive, annoying breakdowns occur. The result of this

sound approach is continuous, profitable service from all of your GASBOY equipment.

To reduce the risk of electrical shock when servicing, turn off all power to the

pump.

HINTS FOR BETTER PUMP PERFORMANCE

Demand Competent Service

If your pump should stop or fail to operate properly, don't depend upon the repair service of a

general mechanic unless he is thoroughly familiar with the mechanism. Experience shows that the

repair results will be much more satisfactory if you demand the service of a competent

representative of the pump manufacturer. GASBOY has a Distributor Network which services fuel

dispensing and management systems in every section of the country.

Use Authorized Parts

Should excessive wear, rust, or corr osion of parts cause inefficient operation, it is always best to

replace them immediately; but if you want the best results and continuity of the Underwriters' Label

on your pump, be sure they are new authorized service parts supplied by GASBOY. Every part of

a pump is carefully designed for a particular purpose. If it is replaced by an incorrect or

substandard substitute, pump operation will be unsatisfactory. Always use new gaskets or seals

when servicing or rebuilding GASBOY equipment; do not re-use the old ones.

Operate With Reasonable Care

Like any machine, the pump that is operated with reasonable care will last longer and give better

service. Abuse should be avoided (such as dropping the nozzle on the ground, operating the unit

with a dirty strainer, dragging the hose across the concrete island or driveway, running the pump

with the nozzle closed for more than two minutes, etc.). The time and care given to your pumps

will be returned to you in the form of dependable service.

WARNING:

03/07/03 7-1

Page 48

GASBOY Series 9820A

PREVENTIVE MAINTENANCE CHECKLIST

Keep Water Out

Water tends to collect in storage tanks. This is due to moisture-laden air being drawn into the

storage tank and condensing, or to defective fill openings that are not properly protected with

watertight covers. Storage tanks should be checked after every fill-up for water and removed with

a sump pump, to forestall serious damage to equipment. Water, sediment, and other foreign

matter that accumulates in the tank can be drawn up into the pump and cause failures.

Lubricate the Pumping Unit

The pumping unit should be lubricated every six months or every 100,000 gallons. Do this by

applying a few drops of a light grade oil (SAE 10) to the felt pad located on the pump body slightly

above the shaft which connects to the pump pulley. Oil used should be suitable for temperatures

ranging from -40 F to 180 F.

Clean the Dial Face

Clean the dial face with a soft, clean, damp cloth as often as necessary.

Clean the Strainer

Clean the strainer immediately after the pump has been installed and tested, and again after a few

hundred gallons have been delivered. Thereafter, once every six months, or as required.

The symptoms of a dirty or clogged strainer in a pump are slow delivery, noisy operation, and

pulsation. To clean the strainer, turn off AC power to the pump. Locate the Suction Strainer Cap

on the plumbing unit and unscrew it to access and remove the strainer. Use compressed air

blow the dirt out of the strainer.

*Wear protective safety goggles or glasses when using compressed air.

Change the Filter

If the unit is equipped with a filter, check and change it at regular inter vals. A dirty filter in a pump

will cause a slower delivery rate. Refer to the accessories section of your parts manual to ensure

that you replace the filter with one designed for your model. Always use a drip pan directly below

the filter when removing the cartridges to pr event contamination of both the soil and the electrical

components within the cabinet.

Adjust the Belts

With the proper care, belts will give exceptionally good ser vice. A loose belt not only cuts down

dispensing speed, due to slipping, but also results in excessive wear. A properly tightened belt will

allow twisting the belt 180 degrees midway between the motor and the pump pulleys.

On the 9822A and 9823A models, the belt can be tightened by loosening the cap screw which

holds the idler arm and sliding the arm to obtain the correct belt tension of 6 3/4 lbs (+

the adjustment is complete, remember to retighten the cap screw.

3/4). When

* to

7-2 03/07/03

Page 49

Preventive Maintenance

Preserve the Finish of Your Pumps

Nearly all gasoline pumps are installed outdoors where their surfaces are subjected to the action

of the weather. As a result, it is necessary to give the finish a r easonable amount of care if an

attractive appearance is to be maintained.

The finish on GASBOY pump housings is a heat baked urethane paint. The life of this finish can

be lengthened several years if, at regular intervals, the painted surfaces are thor oughly cleaned

with a high grade automobile polish and then protected with a coat of paste wax. Do not use

abrasive cleaners or polish. Do not use high-pressure spraying equipment.

03/07/03 7-3

Page 50

GW01 - 6/04/02 Rev. 1

WARRANTY

General Statements:

Gasboy International LLC. warrants all new equipment manufactured by Gasboy agai nst defective material and/or workmanship, for t he warranty

period specified below, when the equipment i s installed in accordanc e with specifications prepared by Gasboy.

This warranty does not cover damage caused by acci dent, abuse, Acts of God, lack of surveillance of autom atic recording systems, negligence,

mis-application, faulty installation, i mproper or unauthorized maintenance, installation or use in vi ol ation of product manuals, instructions , or warnings.

Under no circumstanc e shall Gasboy be liable for any indirect, special, or cons equential damages, losses, or expenses to include, but not limited

to, loss of product, los s of profits, litigation fees, or the use, or inability to use, our produc t for any for any purpose whatsoever.

Parts Only - During the warranty period, Gasboy will, at its option, repair or replace def ective parts returned transportat i on prepai d to its factory.

On-Site Labor Included - Gasboy will also provide, within the Continental United St ates and during the warranty period, the services of an

Authorized Service Representati ve (A SR) for on-site repair or replacem ent of defective parts.

Replacement Parts - Any system components that are not part of the original system order, i ncluding Island Card Readers, Pump Control Units, et c.,

are considered replacement part s.

Equipment Term Coverage

Commercial Pumps and Dispensers

Full-Cabinet Consumer Pumps

Small Transfer Pumps, Meters,

Pressure Regulators

Keytrol One year from date of instal l ation or 18 mos. from date of

Fuel Management Systems :

- CFN/ Profit Point

- Series 1000/Fleetkey

- TopKAT

- Fuel Point Readers

(sold with new systems)

Additional Fuel Point Items:

- Fuel Point Readers sold for

retrofitting existing sys t ems.

- Fuel Point vehicle and dispenser

components.

Encoders, Embos sers, Modems,

CRTs, and Logger Printers

Air Diaphragm Pumps Three years from date of purchas e (for full warranty

Items not m anufactured by Gasboy

(ex. automatic nozzles, hoses, swivels,

etc.)

Replacement Parts One year from date of Gasboy International's invoice to the

To the extent permitted by law, this warranty is made in lieu of all other warranties, expressed or implied, inc l udi ng warranti es of freedom from patent

infringement, or merchant ability, or fitness for a particular purpose, or arising from a cours e of dealing or usage of trade. No one is authori zed t o

vary the terms of the warranty nor may anyone make any warranty of representation, or assume any liability other than that herein stat ed, in

connection with the sale described herein. The acceptance of any order by Gasboy International is expressly made subject to the purchaser's

agreement to these condit i ons.

One year from date of instal l at i on or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of instal l at i on or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.- Excepting the Model 2020 Hand Pump, which

has a 90-day warranty from date of GASBOY International’s

invoice.

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first .- The basic warranty only applies to s ys tems

which have been started up by a Gasboy Authorized Servi ce

Representative (ASR).

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser,

whichever comes first.

Purchased with Fuel Management Syst em (Encoders,

Embossers only):

90 days from the date of s tart-up by a Gasboy ASR, or 180

days from date of Gasboy I nternational's invoice, whichever

occurs first.

Purchased with Fuel Management System

(Modems, CRTs, and Logger Printers only):

Matches system warranty.

Purchased Separately:

90 days from date of Gasboy I nt ernational's

invoice to the purchaser.

description, see Price List).

Not warranted by Gasboy International (consul t original

manufacturer’s warranty).

purchaser.

Parts and Labor.

Parts Only.

Parts and Labor.

Parts and Labor.

Parts Only.

Purchased with System

(Encoders, Embos sers only):

Parts only.

Purchased with System (Modems,

CRTs, Logger Printers only):

Matches system warranty.

Purchased Separately:

Parts Only.

Parts Only.

Not Applicable.

Parts Only.

GASBOY INTERNATIONAL LLC

P.O. Box 309, Lansdale, PA 19446 ● (800) 444-5579 ● FAX: (800) 444-5569 ● www.gasboy.com

Loading...

Loading...