Page 1

Series 9800Q Pumps and Dispensers

Installation/Operation Manual

MDE-4340A

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key control unit, Model GKE-B Series

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP, 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100K, 9140K, 9152K, 9153K,

4997 9822K, 9823K, 9822A, 9823A

5046 9100K, 9140K, 9152K, 9153K,

9800K, 9840K, 9850K, 9852K,

9853K, 9140, 9100A, 9140A, 9152A,

9153A, 9800A, 9840A, 9850A,

9852A, 9853A, 9100

9800K, 9840K, 9852K, 9853K,

9100Q, 9140Q, 9152Q, 9153Q,

9800Q, 9840Q, 9852Q, 9853Q, 9850Q

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2006 GASBOY · All Rights Reserved

Page 3

Table of Contents

Table of Contents

1 – Introduction 1-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2 – Important Safety Information 2-1

In an Emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

3 – Installation 3-1

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Suction Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Remote Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Supply Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Nozzle, Hose, and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

4 – Control Lines 4-1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Micro Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Micro Neutral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Control/Pump Motor Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

External Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Neutral Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Control/Submersible Feed (Control/SubM Feed) . . . . . . . . . . . . . . . . . . . . .4-2

Submersible Starter Drive (SubM Starter Drive) . . . . . . . . . . . . . . . . . . . . .4-3

Submersible Pump Drive (SubM Pump Drive). . . . . . . . . . . . . . . . . . . . . . .4-4

Reset Complete (Switch Detect)/Slow Flow. . . . . . . . . . . . . . . . . . . . . . . . .4-4

Fast Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Phase 2 Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Slow/Fast Satellite Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Light Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Light Neutral. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Pulser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

RS-232 and RS-422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

5 – Wiring 5-1

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

The Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Motor Amp Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Conduit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Pulse Output or RS-485 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page i

Page 4

Table of Contents

6 – Pump/Remote Dispenser Operation 6-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Electronic Component Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

CPU Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

SW1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

SW2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Pulser Output Rate Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Timeout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

ATC Information Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Battery Back-Up Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

View/Reset Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Operating Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Standalone Mode Error Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

7 – Start-Up and Test 7-1

Installation Completion Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Post Start-Up Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8 – Preventive Maintenance 8-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Hints for Better Pump Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Preventive Maintenance Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Page ii MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 5

1 – Introduction

Purpose

The Gasboy Series 9800Q Pumps and Dispensers Installation/Operation Manual is provided to

assist the installer in installing and operating the unit. This manual should be supplied to the

electrician prior to the installation of conduit and wiring to ensure that the Series 9800Q

dispensing unit is installed properly. Faulty installations are the major cause of unit

malfunctions. The unit must be installed and operated as described in this manual to ensure the

reliability and proper operation of the Series 9800Q dispensing unit. In addition to installation

information, this manual contains warnings, safeguards and procedures on the use and care of

the Series 9800Q pumps and remote dispensers. Ensure that you leave this manual with the

pump/remote dispenser owner after the installation is complete.

Note: Customers and installers having any questions pertaining to the installation should

contact their Gasboy distributor.

This manual provides instructions for safely operating, programming, and maintaining the

Atlas™ Fuel Systems pumps/dispensers.

Introduction

General Description

The Gasboy Series 9800Q dispensing units are UL®-listed and are available in a self-contained

(suction pump) package or in a remote-controlled (remote dispenser) package. Both packages

offer a variety of models which are available as single hose outlets or dual hose outlets (with

single or dual product capability). The self-contained models are available in standard speed

(up to 15 GPM/56 LPM) or in high speed (up to 22 GPM/83 LPM). The self-contained

package also boasts a single hose model with high capacity speed (up to 26 GPM/98 LPM), a

dual flow unit (up to 40 GPM/151 LPM) and a high flow unit (up to 50 GPM/189LPM). The

rate of delivery for the remote-controlled packages will vary according to the size of the

submersible pump. The delivery rate of both packages will also vary depending upon

installation conditions and added accessories.

The Series 9800Q offers the following features:

Standard

Speed

Models

High Speed

Models

Super

Speed

Model (up to

40 GPM)

Suction Pumps Remote Dispensers Features

9852Q

9852QTW1

9852QTW2

9853Q

9853QTW2

9853QTW1M

9840Q 9840QX Inlet: 2" NPT

9852QX

9852QXTW1

9852QXTW2

9853QX

9853QXTW1

9853QXTW2

Inlet: 1-1/2" NPT

Discharge: 3/4" NPT (female threads)

Motor: 3/4 HP continuous duty

Valves (when used): 3/4"

Inlet: 1-1/2" NPT

Discharge: 1" NPT (female threads)

Motor: 3/4 HP continuous duty

Valves (when used): 1"

Discharge: 1-1/4" NPT (female threads)

with 1-1/4"x1" reducer bushing

Motor: two 3/4 HP continuous duty

Valves (when used): 1-1/2"

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 1-1

Page 6

Introduction

All models of the Series 9800Q offer electronic registration of the quantity dispensed. The

following lists detail the standard features and the available options found in the 9800Q:

Standard Features

• Cabinet: Painted black top and sides, white front and rear doors and white dial enclosures.

Dimensions are 29-1/16"W, 18-3/8"D, 52-5/8"H.

• Meter: Four piston, positive displacement.

• Pump: Belt-driven, positive-displacement rotary vane with an 80 mesh (300 micron)

strainer and integral air separation.

• Motor: (See chart earlier in this section).

• Reset Complete (switch detect) output which allows monitoring of the unit's operation

when it is connected to an automated Fuel Management System.

• Dual stage solenoid valves (standard only on remote dispensers).

• Island-oriented nozzle boots.

• UL-listed hose assembly, 3/4"x 12' for standard speed; 1" x 12' for high and super speed.

• Designed to support UL-listed Interchangeable service station nozzles (not included).

• Hose hangers.

• Dual phase, error-checking pulsers.

• Non-computing register (volume only) displays, 1" backlighted LCD displays. Records up

to 999.000 gallons.

• Electronic totalizers, viewed from the back side of the unit, records, up to 999,999 liters or

gallons. Battery-backed, resettable.

• Fluids: Gasoline, diesel, kerosene. Not suitable for methanol/ethanol blends.

• Agencies: UL, CUL, W&M.

Optional accessories

• Pulser output drive lines (open collector) capable of driving 1, 10, 100, 250, or 500 pulses

per unit (gallons) or 1, 10, or 100 pulses per unit (liters)

• Inlet check valve

• Internal hose retractor

• Internal fuel filter adapter

• Solenoid valve

• Satellite piping

• Stainless steel exterior or special painting

• 230 or 380 VAC operation

• Liter registration

• Listed automatic nozzles

• Special lengths of hose

• Listed swivels and breakaways

• Spin-on filter elements

• Listed emergency shutoff valves

• Listed pressure regulating valve for aboveground tank applications used with suction

pumps

•Front load nozzle arrangement

• TopKAT mounting

• Battery-backup for electronic display

• Export packaging

• Automatic Temperature Compensation (ATC)

• RS-485 communication for direct connect to Gasboy CFN or TopKAT equipment

Page 1 -2 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 7

Introduction

• Submersible drive relays capable of handling 3/4 HP at 115 VAC or 1-1/2 HP at 230 VAC

• Fluorescent lighting for the faceplate and brand panel

Related Documentation

Document

Number

035286 215A/216A Installation /Operation Manual Gasboy Commercial & Retail Pumps

C01918 CFN Site Controller II Installation Manual. Gasboy Fuel Management Products

C35628 Fuel Point Reader Installation and Retrofit Manual Gasboy Fuel Management Products

C35963 CFN Series Islander II Installation Manual Gasboy Fuel Management Products

MDE-4298 CFN Site Controller I Installation Manual Gasboy Fuel Management Products

MDE-4344 Series 1000 Installation Manual Gasboy Fuel Management Products

Document Title GOLD Library

Acronym Table

The following table contains a list of acronyms used in this manual.

Note: Refer the glossary section for more detailed definitions.

Acronym Definition

AC or ac Alternating Current

ASC Authorized Service Contractor

AWG American Wire Gauge

CFR Code of Federal Regulations

CPR Cardiopulmonary Resuscitation

CPU Central Processing Unit

CSA Canadian Standards Association (Canadian equivalent of UL)

DC (or dc) Direct Current

DIP Dual In-line Package

DLT Displaying Last Transaction

FMS Fuel Management System

FPR Fuel Point Reader

GPM (or gpm) Gallons Per Minute

HP Horse Power

IFSF International Forecourt Standards Forum

LPM Liters Per Minute

MOC Major Oil Company

NEC National Electrical Code

NFPA National Fire Protection Association

OSHA Occupational Safety and Health Association

PCB Printed Circuit Boards (preferred term: board)

POS Point Of Sale

PPG Pulses Per Gallon

PPL Pulses Per Liter

PPP Programmable Pump Preset

RS Request-to-Send (modem application)

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 1-3

Page 8

Introduction

Acronym Definition

RS-485 Recommended Standard number 485 [from Electronic

Industry Association (EIA)]

STP Submerged Turbine Pump

UL Underwriters Laboratory

VAC ( o r vac) Volts Alternating Current

Page 1 -4 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 9

2 – Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump and island. Locate the

switch or circuit breakers that shut-off all power to all fueling

equipment, dispensing devices, and submerged turbine

pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser.

Total Electrical Shut-Off Before Access

Any procedure requiring access to electrical components or

the electronics of the dispenser requires total electrical shutoff of that unit. Know the function and location of this switch

or circuit breaker before inspecting, installing, maintaining, or

servicing Gasboy equipment.

Evacuation, Barricading and Shut-Off

Any procedures requiring accessing the pump/dispenser or

STPs requires the following three actions:

This means that even if you activate these

stops, fuel may continue to flow uncontrolled.

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not only

these cashier station “stops.”

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call the Gasboy Customer

Service at 1-800-444-5579, Tech Support 1-800-444-5529. It

is imperative to your safety and the safety of others to

understand the procedures before beginning work.

Follow the Regulations

There is applicable information in NFPA 30A; Automotive and

Marine Service Code, NFPA 70; National Electrical Code (NEC),

OSHA regulations and federal, state, and local codes which

must be followed. Failure to install, inspect, maintain or

service this equipment in accordance with these codes,

regulations and standards may lead to legal citations with

penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions that follow must be followed to prevent

death, injury or damage to the equipment

DANGER - This signal word is used to alert you to a

hazard to unsafe practice which will result in death or

serious injury

!

WARNING - This alerts you to a hazard or unsafe

practice that could result in death or serious injury.

!

CAUTION with Alert symbol - This signal word

designates a hazard or unsafe practice which may

!

result in minor injury.

CAUTION without Alert symbol - When used by itself,

CAUTION designates a hazard or unsafe practice

which may result in property or equipment damage.

- An evacuation of all unauthorized persons and vehicles

using safety tape, cones or barricades to the effected units

- A total electrical shut-off of that unit

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 2-1

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will become explosive if ignited.

Spilled or leaking fuels cause vapors. Even filling customer

tanks will cause explosive vapors in the vicinity of dispenser

or island.

Page 10

No Open Flames

Emergency First Aid

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuels and their vapors. After getting out of a vehicle, touch the

metal of your vehicle to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Be familiar

with Cardiopulmonary Resuscitation (CPR) methods if you

are working with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA tag out and lock out

procedures. If you are not familiar with this requirement, refer

to information in the service manual and OSHA

documentation.

Working With Electricity Safely

Be sure to use safe and established practices in working with

electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Be sure grounding connections

are properly made. Make sure that sealing devices and

compounds are in place. Be sure not to pinch wires when

replacing covers Follow OSHA Lock-Out and Tag-Out

requirements. Station employees and service contractors

need to understand and comply with this program completely

to ensure safety while the equipment is down.

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Be sure to

clean hands after handling equipment. Do not place any

equipment in mouth.

!

WARNING

This area contains a chemical known to the State of

California to cause cancer.

WARNING

!

This area contains a chemical known to the State of

California to cause birth defects or other reproductive

harm.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Informing Emergency Personnel

• Compile the following information for emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on.)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on.)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on.)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on.)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear/water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of

Machines and equipment in which the unexpected

energization or start up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Reference Subpart S of 29 CFR Part 1910

- Electrical Hazards, 29 CFR Part 1910.333 contains specific

Lockout/Tagout provision for electrical hazards.

Page 2-2 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 11

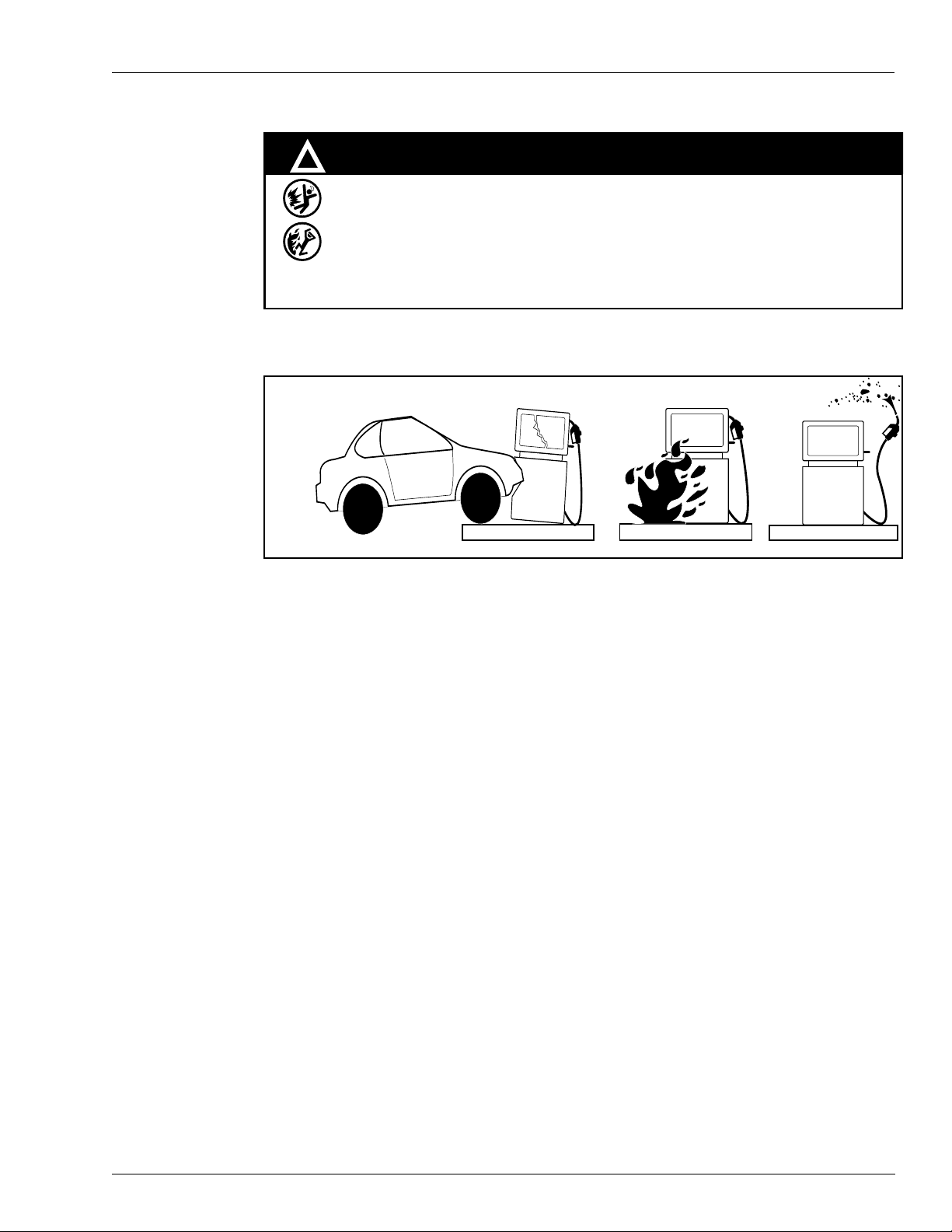

In an Emergency

The following actions are recommended regarding these hazards:

WARNING

!

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow creates

a serious hazard.

Fire or explosion may result causing serious injury or death.

Follow established emergency procedures.

Collision of Vehicle with Unit Fire at Island Fuel Spill

• Do not go near fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system circuit breakers to

the island(s).

• Do not use console E-STOP, ALL STOP keys to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. No

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed

wiring.

• Call emergency numbers.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 2-3

Page 12

This page is intentionally left blank.

Page 2-4 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 13

3 – Installation

Installation Precautions

All installations must conform with all building/fire codes, all Federal, State, and Local codes,

National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine Service Station

Code (NFPA 30A) codes and regulations. Canadian users must also comply with the Canadian

Electrical Code.

Plan your installation carefully. A pump/remote dispenser cannot be expected to work

satisfactorily unless the underground installation is correct. Dispensing troubles, which seem

to be pump-related, are frequently traced to faulty installation. Review the following list of

installation DOs and DON’Ts to avoid potential problems:

1 DO read the Important Safety Information pages at the front of this manual. It contains

important information regarding the safe use of your dispensing equipment.

2 DO install an emergency power cutoff. In addition to circuit breaker requirements of NFPA 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all local codes.

Installation

3 In a Fuel Management System application, the EMERGENCY STOP and STOP keys on the

console and/or the optional EMERGENCY STOP button on the Island Card Reader do not

remove AC power from equipment and under certain conditions, will not stop product flow.

4 In order to provide the highest level of safety to you, your employees, and customers, we

recommend that all employees be trained as to the location and procedure for turning off

power to the entire system.

5 DO have the pump/remote dispenser installed by a competent installer/electrician.

6 DO install breakaway coupling on discharge hose. If using a high hose retriever, install

breakaway approximately 12" downstream of hose clamp on nozzle side of clamp.

7 DO NOT attempt to wire a pump/remote dispenser without first reviewing the appropriate

wiring diagram and notes. Wiring diagrams contain important restrictions regarding the

connection of additional equipment. Failure to follow the correct wiring diagram may result in

damage to the CPU PCB.

8 DO NOT experiment with a pump if you are not sure the installation is correct.

9 DO NOT overload sub- or main-breaker panels.

10 DO NOT install any underground piping without proper swing joints (Always use shoulder

nipples, never close nipples).

11 DO NOT cover any lines until they have been both air- and liquid-tested.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-1

Page 14

Installation

12 DO NOT back-fill the tank or supply line with cinders or ashes. (Back-fill with clean sand,

crushed rock, or pea gravel).

13 DO NOT use black iron pipe or fittings for underground installations. (Use only new

galvanized or fiberglass* pipe and fittings). *Install all fiberglass pipe and fittings according to

manufacturer's specifications and requirements.

14 DO NOT use power line wiring of inadequate capacity. (Use gauge specified by the wiring

diagram or wire chart provided in

15 DO NOT use a circuit breaker of improper size (See “Wiring” on page 5-1).

16 DO NOT install fill pipe to tank where it can be submerged with standing water.

17 DO NOT use the Gasboy fuel dispensing equipment to remove water ballast from the storage

“Wiring” on page 5-1).

tank.

18 DO NOT use gaskets on covers of explosion-proof type boxes. The sealing compound found

around wires at all junction box entrances is a requirement of the National Electrical Code and

should not be disturbed. Ensure that the mating surfaces between the junction box and cover

are free of dirt, debris, nicks, and scratches. Tighten junction box covers before replacing

panels.

Foundation

19 DO NOT use knock-out boxes or flexible conduit for installing this unit. All power and

lighting wires should be run in threaded, rigid, metal conduit. All threaded connections must

be drawn up tight with five (5) threads minimum engagement. Only one opening in the AC

junction box is provided with a plug at the factory. On completion of the installation, it is the

installer's responsibility to ensure that any unused openings are plugged.

When constructing the pump island for the dispensing equipment, be sure to extend the island

excavation beyond the depth of the frost line. Leave open an area from the inside edge of the

unit's base as shown on the specific base layout. Unless required by local regulations, do not

cement the pipes and conduits into the island. The open area within the base will provide

access for future servicing of the fittings, check valve and conduit assemblies. Fill in the

boxed-in section with dry sand to keep condensation in the pump housing to a minimum and to

help prevent fogging of the totalizer window.

Secure the pump/remote dispenser to the island using anchor bolts through the two mounting

holes, which are 13 inches (330mm) apart and are indicated on each base layout by an X. If the

dispensing unit is not securely fastened to the island, supply line leaks at unions and pipe joints

may occur. Use one of two types of bolts to anchor the pump to the island. Use two (2) 1/2" x

5" (13mm x 125mm) machine bolts imbedded in the concrete, or, to meet minimum UL and

API requirements for universal interchangeability of pumps, use two 1/2" x 3 1/2" (13mm x

90mm) lag screws with 2" (51mm) expansion shields.

Page 3-2 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 15

Suction Pump

Installation

The pump and the tank should be located close to each other with as few changes in direction

of the supply line, as possible. This reduces the possibility of vaporization (gasoline only),

attains the highest possible flow rate, and results in a lower installation cost. Avoid long

supply lines and excessive vertical lifts. The dynamic lift for this unit is rated at 12 feet (4m)

for gasoline and 13 feet (4m) for diesel and can vary according to conditions of the installation

and fuel temperature.

If a pump is to be used with an above-ground tank, a pressure regulator valve is required on the

suction side of the pump; consult your Gasboy representative for details. The tank should be

free of water and dirt. It is recommended that the tank be pressure tested to verify it is tight.

This type of installation is not recommended for Models 9840Q and 9853QTW1M; consult

your Gasboy representative for details.

Note: The outlet fitting at the top of the float chamber should be connected to drain back to

the storage tank. The pipe size for the return line to the storage tank should be at least

3/8" (10mm).

Remote Dispenser

Locate the remote dispenser and tank with submersible pump as close to each other as possible

to attain minimum possible pressure drop and the highest possible flow rate, consistent with

the pump capacity. Consult the submersible pump manufacturer's recommendations for pipe

sizing and installation instructions pertaining to the model of submersible pump being

installed.

A Listed emergency shut-off valve (OPW 10RUS or equal) must be installed under each

remote dispenser with the shear groove at the same level as the top of the concrete island +

(plus) 1/2" (13mm). The shear valve should be rigidly supported to ensure proper shearing and

closure of the valve in the event that the remote dispenser is dislodged. According to the type

of shear valve, a different supply nipple may be required.

After a shear valve has operated on an emergency basis from fire or mechanical shock, or if it

does not operate correctly when inspected, repairs must be made before putting the remote

dispenser into service.

It is required by the Flammable and Combustible Liquids Code that a leak detector be installed

in the system to prevent underground leaks from going unnoticed.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-3

Page 16

Installation

Supply Line

IMPORTANT INFORMATION

Use a Model 52 pressure regulator valve with all self-contained models

except 9840Q and 9853QTW1M. These models are not recommended for

aboveground tanks. A zero differential of pressure, electric solenoid valve is

required in the line at the top of the tank. Do not use an anti-siphon valve.

Use new galvanized or fiberglass (see note) pipe, 1 1/2" (38mm) minimum diameter. When

installing a 9840Q or 9840QX, 9850Q or 9850QX model, use a minimum of 2" (51mm)

diameter supply pipe to obtain the highest possible flow rate and to reduce the possibility of

vaporization (gasoline only).

Note: Fiberglass pipe is to be installed according to manufacturer's specifications and

requirements.

Ensure that both the pipe and the tank are clean. Foreign matter entering the pump can cause

extensive damage. Obstructions in the supply line can create pump problems and reduced flow

rate.

Ensure that all pipe threads are properly cut and the inside reamed to remove burrs. Use Listed

gasoline-resistant compound on all joints of gasoline handling piping. Sealing compound must

also be resistant to Gasohol (Ethanol and Methanol). Do not use Teflon

®

Pipe Sealing Tape.

Use gasoline-resistant pipe compound on male threads only; pipe compound used on female

threads can be squeezed into the supply line where it can enter the product stream and become

lodged in the pump or meter. Install swing joints under the pump and at the tank to avoid

breaks in the supply line from settling or frost heave.

To avoid product delivery problems on suction pumps, ensure that there are no traps in the

supply line. Supply lines, for both suction pumps and submersible pumps, should go straight

down beneath the pump to a point 18 inches (46cm) below the ground level and pitch at a rate

of 1/8 inch (3mm) per foot (.305m) from there down to the storage tank. The supply line

should be as short and direct as possible with swing joints at all turns. Support the horizontal

run of pipe at 10-foot (3.05m) intervals to maintain pitch and prevent traps. Do not use wood

as pipe supports.

New EPA regulations require that only one check valve be used per supply line and located

directly below, and as close as practical to the suction pump. Do not use spring-loaded or

union check valves since these will unnecessarily reduce the flow rate and contribute to the

reduction of atmospheric pressure necessary to keep gasoline in a liquid state. Upon

completion of installation, all liquid-carrying lines must be checked for leaks.

Page 3-4 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 17

Nozzle, Hose, and Accessories

This unit is normally equipped for use with a UL-listed interchangeable service station type

nozzle. Only UL-listed hose assemblies and accessories are to be used with this device. A

Listed breakaway connector must be installed on all hose assemblies.

Single/Twin Pump/Remote Dispenser Dimensions

Note: Unit shown is a twin unit.

Installation

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-5

Page 18

Installation

Single/Twin Pump/Remote Dispenser Front Load Nozzle Dimensions

Note: Unit shown is a front load twin unit.

Page 3-6 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 19

012011 Base Layout, Model 9852QTW1

Installation

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-7

Page 20

Installation

012012 Base Layout, Models 9852QTW2, 9853QTW2

Page 3-8 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 21

012013 Base Layout, Model 9853QTW1M

Installation

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-9

Page 22

Installation

012014 Base Layout, Models 9852Q, 9853Q

Page 3-10 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 23

012015 Base Layout, Models 9852QXTW2, 9853QXTW2

Installation

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-11

Page 24

Installation

012016 Base Layout, Model 9840QX

Page 3-12 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 25

012017 Base Layout, Models 9852QX, 9853QX

Installation

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-13

Page 26

Installation

012018 Base Layout, Models 9852QXTW1, 9853QXTW1

Page 3-14 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 27

012019 Base Layout, Model 9840Q

Installation

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 3-15

Page 28

Installation

This page is intentionally left blank.

Page 3-16 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 29

4 – Control Lines

Purpose

This section is provided to familiarize the installer with the control inputs and outputs that are

available for the Series 9800Q dispensing unit. It is recommended that the installer read these

descriptions to obtain a better working knowledge of the unit in order to guide him in planning

the site wiring. Refer to

notes.

The Series 9800Q may be provided for use with 230 VAC power for international

applications. The operating voltage for control lines to these units is shown in parentheses as

(230 VAC Int'l).

If connecting the 9800Q to a Gasboy Fuel Management System, refer to:

• C01918 CFN Site Controller II Installation Manual

• C35963 CFN Series Islander II Installation Manual

• MDE-4298 CFN Series SC III Install Manual

• MDE-4319 TopKAT FMS Installation Manual

• MDE-4344 Series 1000 Fuel Management System

Control Lines

“Wiring” on page 5-1 for specific wiring diagrams and installation

Ground

Micro Feed

To ensure proper operation of the equipment and provide the necessary safety factors, a good

ground line must be provided. A ground wire (preferably green) must be connected between

the ground wire of the system and the main electrical service panel. One (1) earth ground

connection is required per unit. The ground rod is to be a solid, corrosion-resistant conductor

and must be installed at the main electrical panel in accordance with the National Electrical

Code. It should be properly tied into the ground bus strip of the panel. We recommend that the

neutral and ground bus strips be bonded together (unless prohibited by Local Codes).

The Micro Feed is a 115 VAC (230 VAC Int'l) input required to power the microprocessor of

the register's electronics. This power must always remain on and must be on a separate breaker

from the control lines (Control/Pump Motor Feed or Control/SubM Feed - Side 1, Side 2).

This must also be on a separate breaker from the fluorescent lights to reduce electrical noise

and allow for separate control of the lights. In a site configuration using multiple dispensing

units, the power for the microprocessors of up to eight units can be supplied by one breaker.

This line also supplies power to the optional TopKAT. If this unit is equipped with a TopKAT

option, see the TopKAT Installation Manual for wiring requirements and information.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 4-1

Page 30

Control Lines

Micro Neutral

The Micro Neutral is a return line for AC current from the microprocessor of the dispensing

unit to the breaker panel. This line also serves as the return for the optional TopKAT.

Control/Pump Motor Feed

The Control/Pump Motor Feed is a 115 VAC (230 VAC Int'l) input which is required to power

and authorize the control line. This line is used to provide authorization for the dispensing unit

(when enabled through the DIP switches). If this line is controlled by a Fuel Management

System using solid state relays, a resistor assembly must be installed between the Control Feed

line and Feed Neutral to prevent false triggering of the authorization input. The resistor

assembly is 8.2K OHM, 10 Watt (P/N C05818) for 115/230 VAC domestic and 30K OHM, 10

Watt (P/N C06683) for 230 VAC international wiring. Two Control/Pump Motor Feed lines

are provided for twins.

The Control/Pump Motor Feed line is used to power the slow flow and fast flow valves (when

installed). The power used to control the pump is also provided by this line. It is possible to

combine the control lines for twins and supply them from one breaker; however, the gauge of

the wire needs to be adjusted to handle the load of two motors. The Reset Complete signal

used for external monitoring of the pump also originates from the Control/Pump Motor Feed

line.

External Valve

The External Valve line is used to directly power an anti-siphon valve mounted on top of an

above-ground tank. The valve must operate at the same voltage as the pump motor and the

current draw must not exceed 1 Amp, or the valve must be switched through an external relay

controlled by the External Valve line. Do not connect two or more External Valve lines

together. If more than one pump is drawing from the tank, separate anti-siphon valves must be

installed, or each External Valve line must operate an external relay which then operates the

valve.

Neutral Feed

The Neutral Feed is the AC current return line back to the breaker panel for all attached

devices (pump motor, solenoid valves).

Control/Submersible Feed (Control/SubM Feed)

The Control/SubM Feed is a 115 VAC (230 VAC Int'l) input which is required to power and

authorize the control line. This line is used to provide authorization for the dispensing unit

(when enabled through the DIP switches). If this line is controlled by a Fuel Management

System using solid state relays, a resistor assembly must be installed between the Control Feed

line and Feed Neutral to prevent false triggering of the authorization input.

Page 4-2 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 31

Control Lines

The resistor assembly is 8.2K OHM, 10 Watt (P/N C05818) for 115/230 VAC domestic and

30K OHM, 10 Watt (P/N C06683) for 230 VAC international wiring. The TopKAT and CFN

systems require the resistor assembly only when they are used with the 9800 pump/dispenser

operating in standalone mode. Operating the 9800 in standalone mode with a TopKAT

requires the TopKAT mechanical interface option; with a CFN system, requires an optional

mechanical pump control unit. This line also supplies the power which is switched to the slow

flow and fast flow valves along with the switch detect signal. Two lines are provided for twins.

If the 9800 is to be controlled through authorization of this line, special care must be taken in

the wiring of the submersible control lines when a common submersible is used for more than

one hose outlet. See “Submersible Starter Drive” & “Submersible Pump Drive” for more

information.

Units with Standard Submersible Drive (SubM Drive)

Power for the SubM Drive line originates from this input. The submersible starter relay line, in

standard remote dispensers, is not capable of directly powering a submersible pump. A starter

relay must be used. The control lines for twin remote dispensers can be combined together and

powered by one breaker if individual control of each side is not desired. In a site configuration

using multiple remote dispensers, the power for the control lines of up to eight hose outlets (8

singles or 4 twins) can be supplied from one breaker.

Units with Submersible Drive Relay Option

Power for the SubM Drive line originates from this input. Units equipped with the optional

relays for direct submersible pump drive can be connected directly to submersible pumps up to

3/4 HP at 115 VAC or 1-1/2 HP at 230 VAC. The gauge of this wire should be determined

according to the size of the motor, the voltage at which the motor will be powered, and the

distance from the breaker panel to the pump.

Submersible Starter Drive (SubM Starter Drive)

The SubM Starter Drive is a 115 VAC (230 VAC Int'l) output used to control a submersible

starter relay. Two lines are provided for twins. This line is capable of supplying 300mA of AC

current to control the coil of the submersible motor contactor (starter relay). This is sufficient

for directly connecting to the popular models, but if in doubt, check the contactor (relay)

manufacturer's data sheet for the sealed VA rating. Divide the sealed VA rating by the coil

voltage to determine the current.

CAUTION

CAUTION

This line must not be connected directly to the submersible pump, shorted to any

conduit or chassis metal, or mis-wired, or the CPU PC board will be instantly

damaged.

This line must be left capped when not in use. Follow the checks in Section 6 prior to applying

power, to avoid accidental damage.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 4-3

Page 32

Control Lines

Note: When multiple dispensers are used to control a common submersible starter-relay or

pump, and the 9800 is controlled (authorized) through the Control/Pump MotorFeed

line (as in the case of some Fuel Management Systems), it is important that the lines

from the 9800 to the submersible equipment be isolated from each other. This can be

accomplished by running the submersible control lines through a secondary set of relay

contacts in the Fuel Management System. If a secondary set of contacts is not available,

external control relays must be used between the 9800 and the submersible starter relay

or pump. Another option is to provide a separate submersible starter relay for each

hose outlet. In no case can the submersible drive lines from the 9800 be tied together.

Submersible Pump Drive (SubM Pump Drive)

This line is always present for remote dispensers, but is active only when SubM drive relays

are supplied. The SubM drive is a 115/230 VAC (230 VAC Int'l) output used to control the

submersible starter relay or submersible pump. When connected directly to the submersible

pump, the motor size cannot exceed 3/4 HP at 115 VAC or 1-1/2 HP at 230 VAC. Two lines

are provided for twins. In cases where both lines will be controlling the same starter relay or

pump, they can be combined. This line is also used to control an external valve used on

aboveground tank installations.

Note: See Special Note in Submersible Starter Drive for situation where more than one hose

outlet will be using the same submersible pump.

Reset Complete (Switch Detect)/Slow Flow

The Reset Complete/Slow Flow is a 115 VAC (230 VAC Int'l) output which is used to indicate

that the reset process is complete and the unit is ready to dispense product, such as may be

required when used with a Fuel Management System (FMS). It may also be used to control a

remote (satellite) slow flow valve. Two lines are provided for twins.

In addition to the internal load of the slow flow valve, this line is capable of supplying 170 mA

AC maximum to the satellite valve and FMS. When connecting to a non-Gasboy satellite or

FMS, ensure that this limit is not exceeded. This line must not be shorted to any conduit or

chassis metal, mis-wired, used to control both stages of a satellite valve, or be connected to

equipment requiring more than 170 mA AC from this line to operate, or the CPU PC board

will be instantly damaged! This line must be left capped when not in use.

Follow the checks in “Pump/Remote Dispenser Operation” on page 6-1 before applying power

to avoid accidental damage.

Fast Flow

This is a 115 VAC (230 VAC Int'l) line that can be used to control a remote (satellite) fast

flow valve. Two lines are provided for twins. In addition to the internal load of the fast flow

valve, this line is capable of supplying 170 mA AC to the satellite valve. When connected to

a non-Gasboy satellite, ensure that this limit is not exceeded.

Page 4-4 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 33

CAUTION

CAUTION

This line must not be shorted to any conduit or chassis metal, mis-wired, used to

control both stages of a satellite valve, or be connected to equipment requiring

more than 170mA from this line to operate, or the CPU PC board will be

instantly damaged.

This line must be left capped when not in use. Follow the checks in “Pump/Remote Dispenser

Operation” on page 6-1 before applying power to avoid accidental damage.

Phase 2 Feed

The Phase 2 feed is a hot feed that is the opposite phase of the pump motor feed. This line

and the pump motor feed are used for 230 VAC domestic motor applications. If connected to

equipment requiring control of the authorization input, the Phase 2 Feed should be switched

through a separate relay to prevent false triggering of the authorization signal.

Slow/Fast Satellite Returns

These lines are used only in units that come equipped with satellite piping. They are used in

applications where the remote dispenser and satellite may not dispense product at the same

time. These lines are not connected internally as they leave the factory. Four lines are provided

for twins.

Control Lines

Light Feed

Light Neutral

CAUTION

CAUTION

These lines must not be shorted to any conduit or chassis metal, or be connected to

equipment requiring more than 170mA from each line to operate, or the CPU PC

board will be instantly damaged.

These lines must be left capped when not in use. Follow the checks in “Pump/Remote

Dispenser Operation” on page 6-1 before applying power to avoid accidental damage.

The Light Feed is a 115 VAC input required to power the fluorescent lights. In a site

configuration that use multiple remote dispensers (or pumps), the power for the lights of up to

eight units can be supplied by one breaker. It is recommended that this be on a separate

breaker from the Micro/Heater Feed to reduce electrical noise and allow for separate control of

the lights.

The Light Neutral is a return line for AC current from the lights to the breaker panel. When

a separate breaker is not used to control the lights, the light neutral is attached to the Micro

Neutral.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 4-5

Page 34

Control Lines

Pulser

When the dispensing unit includes the optional pulser interface, a pulser output is provided.

This pulser output provides a DC output to indicate the quantity dispensed. The pulse rate can

be configured by a sealable DIP switch for rates of 1, 10, 100, 500 pulses per gallon or 1, 10,

or 100 pulses per liter. For the 9840Q pump, the pulse rates are 1, 10, 100, or 500 pulses per

gallon or 1, 10, or 100 pulses per liter. For the 9850Q pump, the pulse rates are 1, 10, and 100

per US Gallon, or 1 or 10 pulses per liter.

The output is an open collector transistor output capable of sinking up to 100 milliamps DC at

voltages up to 24 VDC. The DC ground for the circuit comes from the Fuel Management

System (FMS). Since the transistor switches between ground and high-impedence, the

installer must provide a voltage reference when the transistor is in the high-impedence state.

This reference voltage is provided by a pull-up resistor installed at the FMS between the pulser

input and the reference voltage. The value of this resistor is calculated based on the voltage

and current requirements of the FMS pulser circuit.

The J-Box used in the optional pulser interface contains four wires. Any unused wires in the

J-Box must be individually capped.

RS-485

When the dispensing unit includes the optional RS-485 interface, RS-485 lines are provided.

This interface allows the user to connect a Gasboy CFN Series System directly to the Series

9800Q dispensing unit. These lines must be individually capped when not in use. The RS-485

interface is included with the TopKAT option.

RS-232 and RS-422

When the dispensing unit includes the optional TopKAT, lines for communication to the

TopKAT are provided. These lines allow the user to communicate directly to the TopKAT via

RS-232 or RS-422. These lines must be capped when not in use.

Page 4-6 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 35

Wiring

5 – Wiring

Note: Customers and installers having any questions pertaining to the installation should

contact their Gasboy distributor.

Wiring Precautions

The quality of the electrical installation is a major factor in maintaining proper safety levels

and providing trouble-free operation of your Gasboy pump/remote dispenser. To assure a

quality installation, follow these rules:

1 All wiring must be installed to conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2 Use only threaded, rigid, metal conduit.

3 Use only UL-labeled insulated gasoline- and oil-resistant stranded copper wiring of the proper

size.

4 Wire connections should be tightly spliced and secured with a wire nut; close off the open end

of the wire nut with electrical tape.

5 The line to the motor should be on a separate circuit and installed on a 20 to 30 AMP breaker

depending on the motor size and/or the voltage setting.

6 Install an emergency power cutoff. In addition to circuit breaker requirements of NFPA 70 and

NFPA 30A, a single control which simultaneously removes AC power from all site dispensing

equipment is recommended. This control must be readily accessible, clearly labeled, and in

accordance with all local codes.

In a Fuel Management System application, the EMERGENCY STOP and STOP keys on the

console and/or the optional EMERGENCY STOP button on the Island Card Reader do not

remove AC power from equipment and under certain conditions will not stop product flow.

In order to provide the highest level of safety to you, your employees, and customers, we

recommend that all employees be trained as to the location and procedure for turning off

power to the entire system.

WARNING

!

To reduce the risk of electrical shock when servicing, turn off and lock out all power to the pump/

remote dispenser. In submersible pump applications, turn off and lock out power to the submersible

pump and any other remote dispensers that use that submersible pump. AC power can feed back

into a shut-off dispenser when remote dispensers share a common submersible pump or starter

relay.

7 Have the pump/remote dispenser installed by a competent installer/electrician.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 5-1

Page 36

Wiring

Ground

To ensure proper operation of the equipment and provide the necessary safety factors, this unit

must be grounded. A ground wire (preferably green) must be connected between the ground

wire of the pump/remote dispenser and the main electrical service panel. One (1) earth ground

connection is required per unit. The ground rod is to be a solid, corrosion resistant conductor

and must be installed at the main electrical panel in accordance with the National Electrical

Code. It should be properly tied into the ground bus strip of the panel. We recommend that the

neutral and ground bus strips be bonded together (unless prohibited by local codes).

Circuit Breakers

Power to the unit must be supplied from dedicated breakers. No other equipment should be

powered from these breakers. AC power for the micro feed must come from a different

breaker than that of the pump or remote dispenser control. This not only provides electrical

isolation for the micro feed, but allows the unit to be disabled without shutting off power to the

microprocessor PCB. The AC power for the micro feed may be grouped together for multiple

units. It is recommended that no more than eight units be supplied from one breaker. Remote

dispensers may be grouped together on a single breaker when the submersible pump has its

own breaker. It is recommended that no more than two remote dispensers be powered from

one breaker to maintain isolated control with the circuit breaker panel in case of problems.

Units directly driving pumps (suction or submersible) should be supplied power from a

separate breaker. A tag on the motor identifies the maximum current drawn by the motor. If

two (2) pumps are supplied from one breaker, that breaker must be capable of handling the

load of both motors. In cases where multiple remote dispensers supply power to a single

submersible pump, all breakers controlling the remote dispenser must be on the same phase of

power. Failure to do this will damage the equipment. Provisions must be made to break both

legs of any AC circuit.

The Pump Motor

Pumps are shipped from the factory with motors wired according to the specifications given

on the order as to kind of current, frequency and voltage.

Very often, on installation, it becomes necessary to change the original setting to suit the AC

power source. To do this, locate the motor change-over plate; typically located on the shaft

end of the motor, and remove the screw which secures it in place. Slide the plate so that the

desired voltage, as marked on the plate, lines up with the screw hole. Re-insert the screw and

secure the plate in place.

CAUTION

CAUTION

Many motor failures result from improper setting of the motor change-over plate. If set

for 115 VAC and a 230 VAC feed is used, the motor will burn out after running only a

short time. If set for 230 VAC and a 115 VAC feed is used, the motor will run very

slowly and the starting field will soon burn out.

Page 5-2 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 37

Wiring

Motor Amp Ratings

The following chart shows the maximum running amperage that can be expected for each

pump motor, unless noted otherwise:

Models 115V/60Hz units 230V/60Hz units 230V/50Hz units

9852Q, 9852QTW2,9852QTW1, 9853Q,

9853QTW2, 9853QTW1M

9840Q (2 motors combined) Not available 10 (See NOTES) 12.0 (See NOTES)

10.0 5.0 6.0

Note: These numbers do not account for the higher load upon startup, nor up to one

additional amp associated with other electrical components (lights, solenoid

valves, etc.).

Note: The 9852QTW2, 9853QTW2, and 9853QTW1M have one pump motor per side.

Note: The 9840Q model should use no less than a 20-Amp breaker to account for the

high current upon startup.

Wire Size

The table below shows the required AC wire size for suction and submersible pumps based on

the HP rating of the pump motor and the distance from the circuit breaker to the pump/remote

dispenser for both 115 and 230 volt units. Use this table as a guide for selecting the proper size

wire for the Control/Pump Motor Feed, Control/SubM Feed (Optional Drive), SubM Drive,

Neutral Feed, and Phase 2 Feed.

The AC wire size for the Micro Feed, Micro Neutral, Light Feed and Light Neutral should be

14 American Wire Gauge (AWG) for runs up to 300 feet (98m) from the breaker panel or 12

AWG for distances over 300 feet (98m).

The AC wire size for the Control/SubM Feed (Standard Drive), SubM Starter Drive, and

Neutral Feed of a remote dispenser should be 12 AWG. These control lines are used to power

the solenoid valves and the submersible starter relay (the submersible pump cannot be directly

powered from the Standard SubM Drive line).

If multiple units are powered from the same breaker through the same wires, you must

increase the gauge of the wires to handle the added load according to the distance from the

breaker panel and the HP rating (if applicable).

The AC wire size for the Reset Complete (Switch Detect)/Slow Flow, Fast Flow, and Slow/

Fast Satellite Return lines should be 14 AWG (when they are used).

The DC wire size for the Pulse Output lines must be 18 AWG (when they are used). Shielded

cable, as described in the Pulse Output or RS-485 Wiring section, allows pulser lines to run

with the AC wires.

The DC wire size for the RS-485 lines for connection to a Gasboy Fuel Management System

should be two twisted pair cables (when they are used). Refer to

“Pulse Output or RS-485

Wiring” on page 5-5 and the Installation Manual for the Gasboy Fuel Management System for

specific requirements.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 5-3

Page 38

Wiring

Conduit

The DC wire for RS-232 and RS-422 lines for connection to a TopKAT are described in The

TopKAT Installation Manual.

115 VOLT WIRE GUAGE SIZES PER FEET/METERS OF RUN

FEET

METERS

MOTOR HP

1/2 14 12 10 8 8 8 8

3/4 14 12 10 8 6 6 4

230VOLT

1/2 14 12 12 12 10 10 10

3/4 14 12 12 10 10 10 8

1/1/2 12 12 10 10 8 8 6

25’8m50’

15m

100’

31m

150’

46m

200’

61m

250’

76m

300’

91m

OVER 300’ (91cm) USE RELAY

AT MOTOR LOCATION

All wiring to the Gasboy Series 9800Q dispensing unit must be installed in threaded, rigid,

metal conduit. PVC is not acceptable. When the Series 9800Q dispensing unit is used with a

Gasboy Fuel Management System, it is recommended that AC power wires be installed in a

separate conduit from the DC wires; they should not run in any sort of common conduit or

trough. However, if AC and DC power wires share conduit, DC wiring must use the cable as

specified in

“Pulse Output or RS-485 Wiring” on page 5-5. Wiring between a Fuel Point

Reader (FPR) and its pre-amp junction box is intrinsically safe and must be run in a conduit

with only other intrinsically safe wiring. It cannot be run in conduit with AC, DC, RS-485, or

pulser wiring, regardless of the cable type used. See the Fuel Point Reader Installation and

Retrofit Instructions Manual, C35628 for details.

When using a Fuel Management System other than a Gasboy system, see the manufacturer's

installation manual for specific conduit requirements. All wiring and conduit runs must also

conform with the National Electrical Code (NFPA 70) and the Automotive and Marine

Service Station Code (NFPA 30A). All wiring and conduit runs must conform to local codes.

Canadian users must also comply with the Canadian Electrical Code.

Use the charts below as a guideline to determine the proper conduit sizes for the Gasboy Series

9800Q dispensing unit. When planning the orientation of the wiring runs, follow the

applicable Gasboy wiring diagram and consider the layout of the components at the site. Long

runs or a large number of bends may require you to increase conduit size over what is listed.

THHN/THWN Wire Areas

Gauge

Diameter

in mm

18 .090 2.29 .007 4.1

16 .104 2.64 .009 5.5

14 .118 2.95 .011 6.8

12 .135 3.43 .014 9.2

10 .169 4.29 .022 14.5

8 .216 5.49 0.37 23.7

.259 6.60 0.53 34.2

A r e a ( S q U n i t s )

in mm

Page 5-4 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 39

Wiring

THHN/THWN Wire Areas

4 .331 8.41 .086 55.5

3 .359 9.14 .102 65.6

2 .394 10.01 .122 78.7

1063A .417 10.59 .137 88.4

Areas of Trade Size Conduit

Trade Size

Int Diameter

in mm

1/2 .629 16 .303 196 .076 49

3/4 .826 21 .532 343 .133 86

1 1.063 27 .862 556 .215 139

1-1/4 1.378 35 1.50 968 .375 242

1-1/2 1.614 41 2.04 1314 .509 329

2 2.087 53 3.36 2165 .839 541

A r e a ( S q U n i t s )

in mm

Fill Area (Sq

U n i t s ) 2 5 % F i l l

in mm

To determine conduit size needed, use the THHN/THWN Wire Areas table (above) to find the

area for each wire gauge. Add up all wire areas. Use the Areas of Trade Size Conduit Table

(above) to select the smallest number in the 25% fill area (based on NEC 501-1) that comes

closest without exceeding the total wire area.

Pulse Output or RS-485 Wiring

Pulse Output

When installed in a separate DC conduit, 18 AWG wires are required for installation.

Although it is recommended that DC pulser wires be run in a conduit separate from AC wires,

they can be combined in the same conduit with AC wires providing UL-listed cable with the

following specifications is used:

Conductor 18 AWG stranded wire. Number of conductors to

Shield Foil-wrapped 100% coverage and/or tinned copper

Drain Wire Stranded, tinned copper, 20 AWG or larger/or

Voltage Rating Maximum operating voltage of 600V

Environmental Gas- and oil-resistant; suitable for wet or dry

RS-485 Wiring

Twisted pair shielded cable is highly recommended for RS-485 wiring. Although it is

recommended that wires be run in a conduit separate from AC wires, they can be combined in

the same conduit with AC wires providing UL-listed cable with the following specifications is

used:

be determined by number of hoses (2 conductors for

1 hose; 3 conductors for 2 hose)

braid 90% coverage

braided shield

locations

Conductor 18 AWG stranded wire. 2 twisted-pairs

Shield Foil-wrapped 100% coverage and/or tinned copper

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 5-5

braid 90% coverage

Page 40

Wiring

Conductor 18 AWG stranded wire. 2 twisted-pairs

Drain Wire Stranded, tinned copper, 20 AWG or larger/or

braided shield

Voltage Rating Maximum operating voltage of 600V

Environmental Gas- and oil-resistant; suitable for wet or dry

locations

Gasboy can supply Belden® 1063A (P/N C09655) which is a UL-listed, 4-conductor cable that

meets the requirements listed above.

Note: Belden 1063A is UL-listed but not CSA listed. Cable with a voltage rating of less than

600V must be installed in a conduit separate from all AC wires.

Dual Pulse Output Wiring

The wiring diagram shown at right shows the changes in wiring when using a pump equipped

with the dual pulse output option. The dual pulse output option provides two isolated pulse

outputs from a single pulser. It is available only on 9800Q single dispensers.

Page 5-6 MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006

Page 41

Wiring

Wiring Diagrams

While wiring pumps/dispensers, ensure to consult the appropriate wiring diagram and follow

all notes.

CAUTION

Failure to follow the correct wiring diagram and all the listed notes and precautions

may result in damage to the CPU PCB.

Wiring diagrams are presented in numerical order. Wiring diagram 024257 has two diagrams:

one for simultaneous operation of master and satellite and one for non simultaneous operation.

Ensure to use the correct one for your application.

All diagrams in this section show domestic wiring (US and Canada). Breakaway drawings are

shown for international applications where wiring is different.

MDE-4340A Series 9800Q Pumps and Dispensers Installation/Operation Manual · January 2006 Page 5-7

Page 42

Wiring

024251 Wiring Diagram Models 9852QTW1

Notes:

1 All wiring and conduit runs must conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2 Pump motor can be wired as 230 VAC to reduce current draw. See breakaway view of 230

VAC WIRING. All other wiring should remain the same except for the addition of the L2

(requires 230 VAC breaker for control). If connected to equipment requiring control of the

authorization input, the Phase 2 Feed should be switched through a separate relay to prevent

false triggering of the authorization signal.

3 To avoid damage to the CPU PC board, all unused wires must be individually capped, and

before applying power, you must verify that the RESET COMPLETE and FAST FLOW wires

are not shorted to conduit or chassis.

4 COMPLETE (switch detect) line can supply 170 mA AC maximum for connecting to fuel

management system circuitry.

5 FAST FLOW line can supply 170 mA AC maximum for remote control or monitoring of the

fast flow valve found in the pump.

6 If the CONTROL/PUMP MOTOR FEED line is controlled by a fuel management system

using solid state relays, a resistor assembly must be installed between the Control Feed line

and Feed Neutral to prevent false triggering of the authorization input. The resistor assembly is

8.2K OHM, 10 Watt (P/N C05818) for 115/230 VAC domestic and 30K OHM, 10 Watt (P/N

C06683) for 230 VAC international wiring.

7 When used with an aboveground tank, the anti-siphon valve mounted on the tank must be

driven from the EXTERNAL VALVE line, have the same operating voltage as the pump

motor, and the current draw must not exceed 1 Amp. If these conditions are not met, it must be

controlled by an external relay driven from the EXTERNAL VALVE line. DO NOT connect

the anti-siphon valve or external relay to the RESET COMPLETE line. DO NOT connect two

or more EXTERNAL VALVE lines together. If more than one pump is drawing from the tank,

separate anti-siphon valves must be installed, or each EXTERNAL VALVE line must operate

an external relay which then operates the valve.

8 Use the wire size chart listed on page 5-4 when determining the wire size for the control

wiring.

9 If this unit is equipped for 230 VAC operation (international), wire as shown in the standard

115 VAC wiring layout diagram.

10 If this unit is equipped with a TopKAT option, there will be 10 wires in the junction box. See