Page 1

Atlas™ 9216K/9216KTW Satellite Dispensers

Installation/Operation Manual

MDE-4906

Page 2

Computer Programs and Documentation

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

Federal Communications Commission (FCC) Warning

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314 All dis p e n s e r s a n d s e l f - c o n t a i n e d p u m p i n g u n i t s

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

95-136 Dispenser 9800 Series 91-057 Controller

9100 Retail Series, 8700

Series, 9700 Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

91-019 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2010 GASBOY. All Rights Reserved.

Page 3

Table of Contents

Table of Contents

1 – Introduction 1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Intended Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2 – Important Safety Information 3

3 – Installation 7

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Foundation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Nozzle, Hose, and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Supply Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

9216K Front Load Satellite Dispensing Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

9216KTW Twin Satellite Dispensing Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Base Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Model 9216K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Model 9216KTW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4 – Wiring 15

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Wire Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Wire Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

9100K/8700K Series Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .18

9800K Series Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

9850K Series Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5 – Start-up 25

Completion Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6 – Operating the Satellite Dispenser 27

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page i

Page 4

Table of Contents

7 – Preventive Maintenance 29

General Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tips for Better Pump Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Demand Competent Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Use Authorized Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operate with Reasonable Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Preventive Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Keep Water Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Preserve the Finish of Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page ii MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 5

Purpose Introduction

1 – Introduction

Purpose

This manual provides instructions for the installation and operation of Gasboy® Atlas™

9216K/9216KTW satellite dispensers. This manual must be supplied to the electrician prior to

the installation of conduit and wiring to ensure the satellite dispensing unit is installed

properly. Faulty installations are the major cause of unit malfunctions.

The unit must be installed and operated as described in this manual to ensure the reliability and

proper operation of the satellite dispensing unit. Ensure that this manual is left with the owner

after the installation is complete.

Note: For any assistance pertaining to the installation, contact the Gasboy distributor.

Intended Users

This manual is intended for Authorized Service Contractors (ASCs) who will be involved in

the installation of Atlas satellite dispensers.

General Description

Gasboy Atlas satellite dispensing units are used in conjunction with Gasboy-listed Atlas

dispensers. This unit provides additional control of a remote dispensing line.

The features and specifications of the 9216K/9216KTW satellite dispenser are as follows:

• Hose hangers

• Discharge elbows

• A 12 feet gasoline hose assembly

• A working voltage of 115 VAC, 60 Hz for domestic units or 230 VAC, 50 Hz or 60 Hz for

international use

• Unions are provided at the inlet of all suction pumps and dispensers.

• The top and side panels are painted black and the front and rear panels are painted white

for the standard cabinet.

• The height of the cabinets is 39.92” (1013.90 mm). For other dimensions of the base

layout for each model, refer to

• Available options and accessories for the satellite dispensing units include automatic

nozzles, high or low slowdown valves, special lengths of hose, dual swivels, front and

back panels painted to the color specified by the customer, stainless steel panels, and

emergency shutoff valves.

“Installation” on page 7.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispenser Installation/Operation Manual · June 2010 Page 1

Page 6

Introduction Related Documents

Related Documents

Document Number Title GOLD Library

FE-361 Atlas Master and Satellite Field Wiring Diagram Gasboy Parts List and Wiring Diagrams

MDE-4331 Atlas Fuel Systems Installation Manual Gasboy Atlas Pumps/Dispensers

MDE-4333 Atlas Fuel Systems Site Preparation Manual Gasboy Atlas Pumps/Dispensers

Abbreviations and Acronyms

Term Description

AC Alternate Current

ASC Authorized Service Contractor

DC Direct Current

NEC National Electric Code

NFPA National Fire Protection Association

STP Submerged Turbine Pump

®

UL

Underwriters’ Laboratories

Warranty

For information on warranty, refer to MDE-4255 Gasboy’s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its Greensboro

location.

Page 2 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispenser Installation/Operation Manua l · June 2010

Page 7

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Tot al Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and islan d.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser. This means that even if you

activate these stops, fuel may continue to flow

uncontrolled.

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at

1-800-444-5529. It is imperative to your safety and the safety

of others to understand the procedures before beginning

work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL

SHUT-OFF in the case of an emergency and

not the console’s ALL STOP and PUMP STOP

or similar keys.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit(s)

• A total electrical shut-off of the affected unit(s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 3

Page 8

Important Safety Information

No Open Fire

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic charge

on your body, can cause a spark sufficient to ignite fuel

vapors. Every time you get out of a vehicle, touch the metal of

your vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power when you are working on

the equipment. Use the OSHA Lockout/Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing

devices and compounds are in place. Ensure that you do not

pinch wires when replacing covers. Follow OSHA

Lockout/Tagout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safety when the equipment is down.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately

15 minutes.

Seek medical advice immediately.

WARNING

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

Lockout/Tagout covers servicing and maintenance of

WARNING

!

machines and equipment in which the unexpected

energization or start-up of the machine(s) or equipment or

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific

Lockout/Tagout provision for electrical hazards.

Page 4 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 9

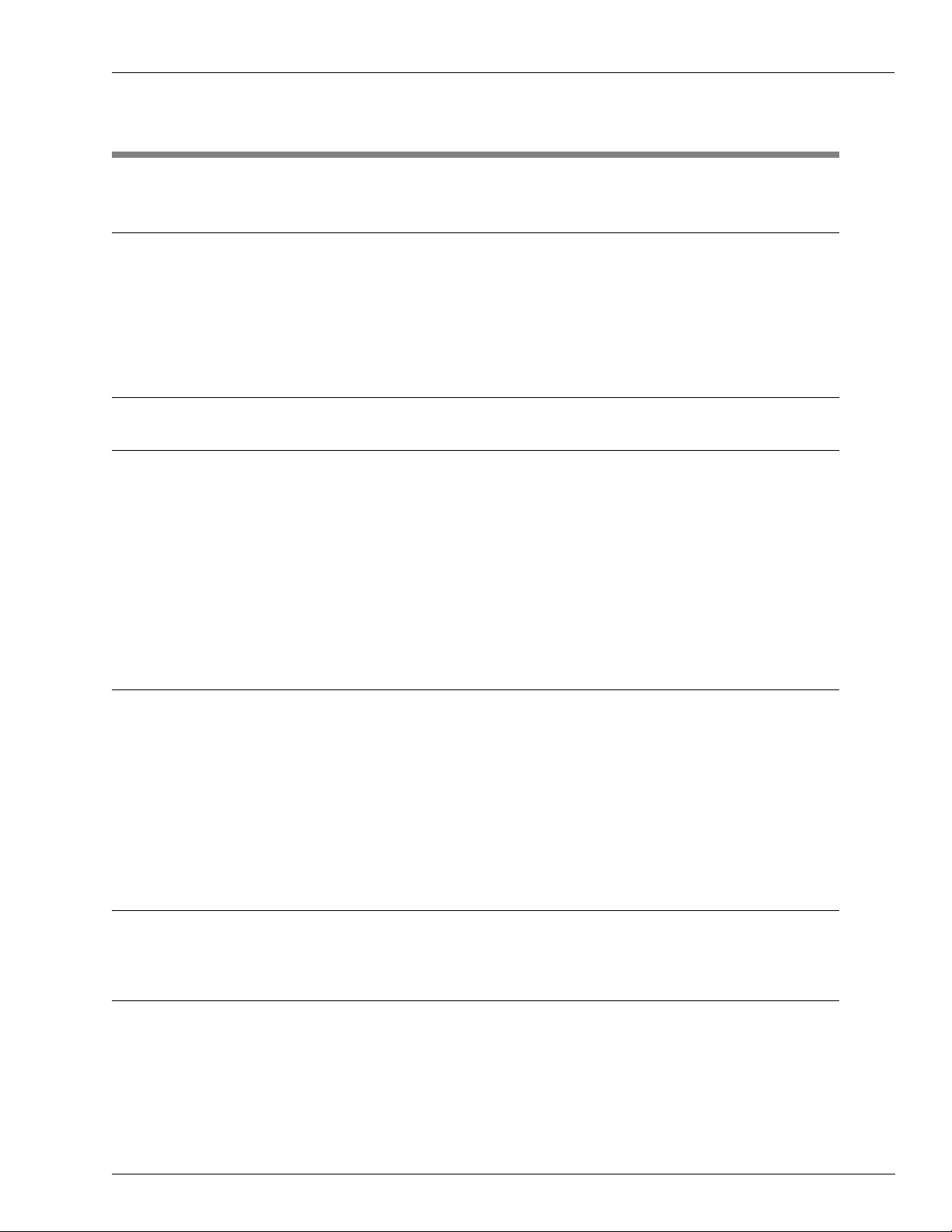

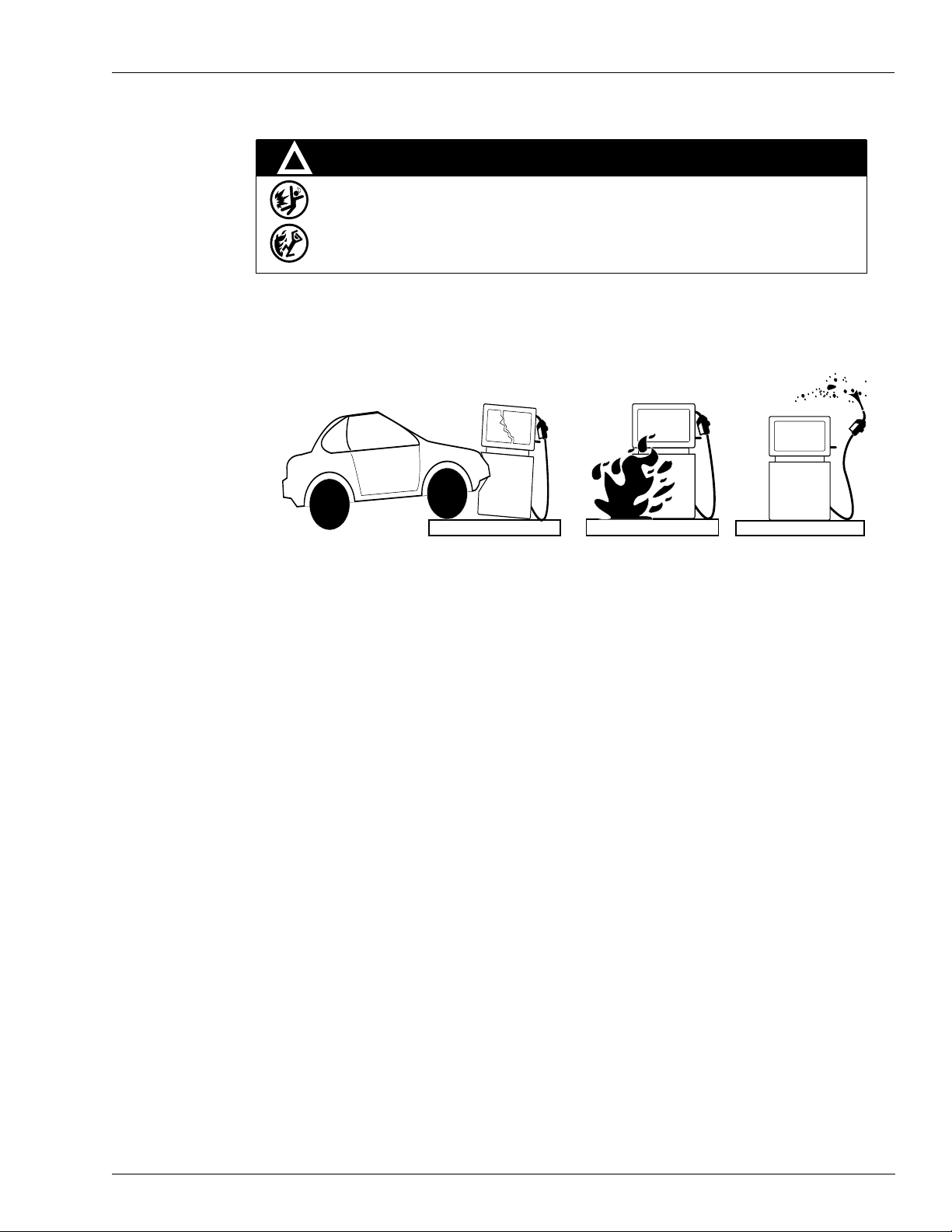

Hazards and Actions

Important Safety Information

!

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

The following actions are recommended regarding these hazards:

Collision of a Vehicle with Unit Fire at Island Fuel Spill

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately . Turn off all system circuit breakers to the island(s).

• Do not use console E-STOP, ALL STOP and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 5

Page 10

Important Safety Information

This page is intentionally left blank.

Page 6 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 11

Installation Precautions Installation

3 – Installation

Installation Precautions

All installations must confirm with all building or fire codes, all Federal, State, and Local

codes, NEC, NFPA 70, NFPA 30, and Automotive and Marine Service Station Code

(NFPA 30A) codes and regulations. Canadian users must also comply with the Canadian

Electrical Code.

Plan the installation carefully. A dispensing unit cannot be expected to work satisfactorily

unless the underground installation is correct. Dispensing troubles are frequently traced to

faulty installation. Review the following list of installation DO’s and DO NOT’s to avoid

potential problems:

•Read the “Important Safety Information” on page 3. It contains important information

regarding the safe use of dispensing equipment.

• Install an emergency power cutoff. In addition to circuit breaker requirements of NFP A 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all Local codes. In a fuel management system application,

the EMERGENCY STOP and STOP keys on the console and/or the optional

EMERGENCY STOP button on the Island Card Reader do not remove AC power from

equipment and under certain conditions, will not stop product flow. To provide the highest

level of safety to individual, staff, and customers, we recommend that all personnel be

trained as to the location and procedure for turning off power to the entire system.

• A competent installer/electrician must install the satellite dispensing unit.

• Install breakaway coupling on discharge hose. If using a high hose retriever, install

breakaway approximately 12” downstream of hose clamp on nozzle side of the clamp.

• DO NOT attempt to wire a pump or remote dispenser without first reviewing the

appropriate wiring diagram and notes. This manual contains instructions for wiring

mechanical and electronics units. If the mechanical wiring diagram is used for an

electronic pump, then it will cause CPU PCB damage to the electronic pump.

• DO NOT experiment with a pump if you are not sure the installation is correct.

• DO NOT overload sub or main breaker panels.

• DO NOT install any underground piping without proper swing joints (always use shoulder

nipples, never close nipples).

• DO NOT cover any lines until they are both air-tested and liquid-tested.

• DO NOT back-fill the tank or supply line with cinders or ashes (back-fill with clean sand,

crushed rock, or pea gravel).

• DO NOT use black iron pipe or fittings for underground installations (use only new

galvanized or fiberglass pipe and fittings).

Note: Install all fiberglass pipe and fittings according to manufacturer’s specifications

and requirements.

• DO NOT use power line wiring of inadequate capacity.

Note: Use gauge specified by the wiring diagram or wire chart provided in “Wiring

Diagrams” on page 18.

• DO NOT use a circuit breaker of improper size (refer to “Wiring” on page 15).

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 7

Page 12

Installation Foundation

• DO NOT install fill pipe to tank where it can be submerged with standing water.

• DO NOT use the Gasboy fuel dispensing equipment to remove water ballast from the

storage tank.

• DO NOT use gaskets on covers of explosion-proof type boxes. The sealing compound

found around wires at various locations within conduit is a requirement of the NEC and

must not be disturbed. Ensure that the mating surfaces between the junction box and cover

are free of dirt, debris, nicks and scratches. Tighten the junction box covers before

replacing panels.

• DO NOT use knock-out boxes or flexible conduit for installing this unit. All power and

lighting wires must be run in a threaded, rigid, metal conduit. All threaded connections

must be drawn up tight with five (5) threads minimum engagement. Only one opening in

the AC junction box is provided with a plug at the factory. At completion of the

installation, ensure that any unused openings are plugged.

Foundation

When constructing the island for the dispensing equipment, ensure to extend the island

excavation beyond the depth of the frost line. Leave open an area from the inside edge of the

unit’s base as shown on the specific base layout. If required by local regulations, do not

cement the pipes and conduits into the island. The open area within the base provides access

for future servicing of the fittings and conduit assemblies. Fill in the boxed-in section with dry

sand to keep condensation in the satellite housing to a minimum.

Dispenser

Secure the dispensing unit to the island using anchor bolts through the mounting holes (see

Figure 3-3 on page 12). If the dispensing unit is not securely fastened to the island, supply line

leaks at unions and pipe joints may occur. Use one of two types of bolts to anchor the satellite

to the island. Use two 1/2 x 5” (13 x 125 mm) machine bolts embedded in the concrete, or to

meet minimum UL and API requirements for universal interchangeability of pumps, use two

1/2 x 3-1/2” (13 x 90 mm) lag screws with 2” (51 mm) expansion shields.

For proper installation and operation of this unit, refer to the following installation/operation

manuals supplied with the dispenser.

• M DE-4333 Atlas Fuel Systems Site Preparation Manual

• MDE-4331 Atlas Fuel Systems Installation Manual

• FE-361 Atlas Master and Satellite Field Wiring Diagram

Page 8 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 13

Nozzle, Hose, and Accessories Installation

Nozzle, Hose, and Accessories

This unit is equipped for use with a UL-listed interchangeable service station type nozzle.

Units equipped with suffix N are equipped for use with a UL-listed Richards Mark XIIL

nozzle. Use only UL-listed hose assemblies and accessories with this device. A listed

breakaway connector must be installed on all hose assemblies. On twin satellites, each start

lever corresponds with the hose outlet to its right.

Supply Line

The supply line for satellite dispensing units is connected to the satellite outlet of the

dispenser. Use new galvanized or fiberglass pipe, 1.91” (48.51 mm) minimum diameter

(1-1/2” Standard Pipe Nipple).

Note: Fiberglass pipe must be installed according to manufacturer’s specifications and

requirements.

Ensure that both the pipe and tank are clean. Foreign matter entering the satellite can cause

extensive damage. Obstructions in the supply line can create pump problems and reduce the

flow rate.

Ensure that all pipe threads are properly cut and the inside reamed to remove burrs. Use listed

gasoline-resistant compound on all joints of gasoline handling piping. Sealing compound mu st

also be resistant to Gasohol (Ethanol and Methanol). Do not use Teflon Pipe Sealing T ape. Use

gasoline-resistant pipe compound on male threads only. Pipe compound used on female

threads can be squeezed into the supply line where it can enter the product stream and become

lodged in the pump or meter. Install swing joints under the pump and at the satellite to avoid

breaks in the supply line from settling or frost heave.

Note: After completion of installation, all liquid-carrying lines must be checked for leaks.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 9

Page 14

Installation 9216K Front Load Satellite Dispensing Unit Dimensions

9216K Front Load Satellite Dispensing Unit Dimensions

Figure 3-1: 9216K Front Load Satellite Dispensing Unit

28.82

[732.01]

20.61

(i)

[523.42]

19.56

[496.82]

39.92

[1013.97]

(ii)

Note: All dimensions are in inches. Dimensions in parentheses are in millimeters.

18.43

[468.1]

(iii)

Page 10 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 15

9216KTW Twin Satellite Dispensing Unit Dimensions Installation

9216KTW Twin Satellite Dispensing Unit Dimensions

Figure 3-2: 9216KTW Twin Satellite Dispensing Unit

28.82

[732.01]

20.61

(i)

[523.42]

19.56

[496.82]

39.92

[1013.97]

(ii)

Note: All dimensions are in inches. Dimensions in parentheses are in millimeters.

18.43

[468.1]

(iii)

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 11

Page 16

Installation Base Layout

Base Layout

Model 9216K

Figure 3-3: Base Layout - Model 9216K

Conduit Inlet for Electrical Fittings (3/4” NPT)

Slots (3/4” x 1-1/2”)

[314.71]

12.39

7.9

[200.7]

[616.97]

6.3

[160.1]

24.29

28.41

[721.61]

(i)

8.03

[203.96]

9.94

[252.48]

Product Inlet (1 1/2” NPT)

3.9

[99.1]

4.75

[120.65]

[155.45]

5.34

[135.64]

14.04

[356.62]

6.12

Conduit Inlet for Electrical

Fittings (1” NPT)

15.7

[398.78]

AC Junction Box

12.5

[317.5]

(ii)

2

[50.8]

Conduit (Electrical Fittings)

9.58

[243.33]

Top of Island

Note: All dimensions are in inches. Dimensions in parentheses are in millimeters.

Product Inlet

Top of Conduit for

Seal Fittings

Page 12 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 17

Base Layout Installation

Model 9216KTW

Figure 3-4: Base Layout - Model 9216KTW

Slots (3/4” x 1-1/2”)

6.12

[155.5]

5.18

[131.57]

4.8

[121.9]

Conduit Inlet for Electrical Fittings (3/4” NPT)

9.94

[252.48]

12.39

[314.71]

4.02

[102.1]

8.04

[204.23]

6.3

[160.1]

28.41

[721.61]

(i)

24.29

[616.97]

8.03

[203.96]

9.94

[252.48]

Product Inlet (1 1/2” NPT)

3.9

[99.1]

4.75

[120.65]

5.34

[135.64]

14.04

[356.62]

6.12

[155.45]

Conduit Inlet for Electrical

Fittings (1” NPT)

15.7

[398.78]

Top of Conduit

for Seal Fittings

12.5

[317.5]

9.58

[243.3]

Top of Island

Note: All dimensions are in inches. Dimensions in parentheses are in millimeters.

2

[50.8]

Conduit (Electrical Fittings)

(ii)

Product Inlet

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 13

Page 18

Installation Base Layout

This page is intentionally left blank.

Page 14 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 19

Wiring Precautions Wiring

4 – Wiring

Wiring Precautions

Note: For any questions pertaining to the installation, contact Gasboy distributor.

The quality of the electrical installation is a major factor in maintaining proper safety levels

and provides trouble-free operation of Gasboy pump/dispenser. To assure a quality

installation, follow these rules:

• All wiring must be installed to conform with all building/fire codes, all Federal, State, and

Local codes, NEC, (NFPA 70), NFPA 30, and Automotive and Marine Service Station

Code (NFPA 30A) codes and regulations. Canadian users must also comply with the

Canadian Electrical Code.

• Use the proper wiring diagram. This manual contains instructions for wiring mechanical

and electronic units. Using the mechanical wiring diagram for an electronic pump will

cause CPU PCB damage to the electronic pump.

• Use only threaded, rigid, metal conduit.

• Use only UL-labeled insulated gasoline- and oil-resistant stranded copper wiring of the

proper size.

• Wire connections must be tightly spliced and secured with a wire nut. Close the open ends

of the wire nut with an electrical tape.

• The line to the motor must be on a separate circuit and installed on a 20 to 30 Amp breaker

depending on the motor size and/or the voltage setting.

• Have the pump/dispenser installed by a competent installer/electrician.

• Install an emergency power cutoff. In addition to circuit breaker requirements of NFP A 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all Local codes.

In a fuel management system application, the EMERGENCY STOP and STOP keys on the

console and/or the optional EMERGENCY STOP button on the Island Card Reader do not

remove AC power from equipment and under certain conditions, will not stop product flow.

In order to provide the highest level of safety to you, your employees, and customers, we

recommend that all employees be trained as to the location and procedure for turning off

power to the entire system.

WARNING

To reduce the risk of electrical shock when servicing, turn off all power to the

pump/dispenser. In submersible pump applications, turn off power to the submersible

pump and any other dispensers which use that submersible pump. AC power can be fed

back into a shut-off dispenser when dispensers share a common submersible pump or

starter relay.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 15

Page 20

Wiring Grounding

Grounding

To ensure proper operation of the equipment and provide the necessary safety factors, a good

ground line must be provided. A ground wire (preferably green) must be connected between

the unit’s AC junction box ground lug and main electrical service panel. One earth ground

connection is required per unit. The ground rod must be a solid corrosion-resistant conductor

that must be installed at the main electrical panel as per the NEC. It must be properly tied into

the ground bus strip of the panel. It is recommended that the neutral and ground bus strips be

bonded together (unless prohibited by Local codes).

Wire Size

The AC wire size of the satellite, can be a maximum of 10 AWG and a minimum of 14 AWG.

Page 16 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 21

Wire Connections Wiring

Wire Connections

Wires to the satellite unit must be connected to the board-mounted green terminal blocks on

the Front Load Satellite Relay board inside the junction box. 9216KTW models will have two

junction boxes and two boards.

Figure 4-1: Wire Connections

A001 115 VAC

A002 230 VAC

Terminal Blocks for Pump Wire Connections

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 17

Page 22

Wiring Conduit

Conduit

All wiring to the satellite dispensing unit must be installed in threaded, rigid, metal conduit.

PVC is not acceptable.

All wiring and conduit runs must also conform with the NEC (NFPA 70) and the Automotive

and Marine Service Station Code (NFPA 30A). All wiring and conduit runs must conform to

Local codes. Canadian users must also comply with the Canadian Electrical Code.

Wiring Diagrams

The following section contains wiring notes and wiring diagrams for both Atlas mechanical

and electronic pumps. For pump/dispenser model and follow all notes, refer to the appropriate

wiring diagram. For more information, refer to FE-361 Atlas Master and Satellite Field Wiring

Diagram.

Note: Ensure that the correct wiring diagram is used. Incorrect wiring of a 9800K Series unit

will cause damage to the CPU PCB.

Wiring diagrams show simultaneous and non-simultaneous operation of master and satellite

dispensers. Ensure that the correct wiring diagram is used for the suitable application.

9100K/8700K Series Wiring Diagram

Models - Satellite 9216K/9153K, 9153KX, 9152KTW, 9153KTW, 9153KXTW, 9140K,

9140KX, 9216K/8753K, 8753KX, 8752KTW, 875 3KTW, 8753KXTW

Notes: 1) All wiring and conduit runs must conform with all building/fire codes, all Federal,

State, and Local codes, NEC, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations.

2) T o determine which mode of satellite operation is r elevant for your applicat ion, r efer

to Weights and Measur es Handbook 44. In many cases, the satellite must be wired so

that, it cannot dispense the product when the master dispenser is dispensing and vice

versa. Use the correct wiring diagram according to your application.

3) This wiring diagram is intended only to show the connections between the satellite

and the dispenser. For app licab le warnin gs and proper connection of all wires, see

wiring diagram for the master dispenser (according to model number). For the

complete wiring information for the dispenser, refer to MDE-4331 Atlas Fuel

Systems Installation Manual.

4) When a submersible pump is used, submersible starter relays are always

recommended for wiring the dispensers. However, the control circuit is capable of

directly driving a submersible pump up to 1 HP at 115/230 VAC. Any pump over

these ratings will require a submersible starter relay.

Page 18 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 23

Wiring Diagrams Wiring

Figure 4-2: 9100K/8700K Series Wiring Diagram

Satellite Dispenser

Simultaneous Wiring

Master Dispenser

Satellite Dispenser

Non-simultaneous Wiring

Master Dispenser

Note: For some models of the dispenser the brown wire was previously gray.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 19

Page 24

Wiring Wiring Diagrams

9800K Series Wiring Diagram

Models - Satellite 9216K/9853K, 9853KTW, 9853KX, 9852KXTW1, 9853KXTW, 9840KX,

9216K/8853K, 8853KTW, 8853KX, 8852KXTW1, 8853KXTW

Notes: 1) All wiring and conduit runs must conform with all building/fire codes, all Federal,

State, and Local codes, NEC, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also

comply with the Canadian Electrical Code.

2) To determine which mode of satellite operation is r elevant for your application, refer

to Weights and Measur es Handbook 44. In many cases, the satellite must be wired so

that, it cannot dispense product when the master dispenser is dispensing and vice

versa. Use the correct wiring diagram according to your application.

3) If using a Gasboy 9800K and satellite in an application where both master and

satellite cannot dispense the product at the same time, a minor change to the factory

wiring in the 9800K must be made. Wire the dispenser to the satellite as shown in the

wiring diagram labeled “Non-Simultaneous”.

4) If this unit is equipped for 230 VAC operation (international), connect the wires as

shown in the standard 115 VAC wiring layout diagram.

5) This wiring diagram is intended only to show the connections between the satellite

and the dispenser. For app licab le warnin gs and proper connection of all wires, see

wiring diagram for master dispenser (according to model number). For the complete

wiring information for the dispenser, refer to MDE-4331 Atlas Fuel Systems

Installation Manual.

Page 20 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 25

Wiring Diagrams Wiring

Figure 4-3: 9800K Series Wiring Diagram

Non-simultaneous Wiring

Master Dispenser

Satellite Dispenser

Master Dispenser

Satellite Dispenser

Simultaneous Wiring

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 21

Page 26

Wiring Wiring Diagrams

9850K Series Wiring Diagram

Models - Satellite 9216K/9850K, 9850KX, 9850KTW3, 9850KXTW

Notes: 1) All wiring and conduit runs must conform with all building/fire codes, all Federal,

State, and Local codes, NEC, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also

comply with the Canadian Electrical Code.

2) To determine which mode of satellite operation is r elevant for your application, r efer

to Weights and Measur es Handbook 44. In many cases, the satellite must be wired so

that, it cannot dispense product when the master dispenser is dispensing and vice

versa. Use the correct wiring diagram according to your application.

3) If using a Gasboy 9850K and satellite in an application where both master and

satellite cannot dispense the product at the same time, a minor change in the 9850K

wiring must be made at the terminal block. Wire the dispenser to the satellite as

shown in the wiring diagram labeled “Non-Simultaneous”.

4) If this unit is equipped for 230 VAC operation (international), connect the wires as

shown in the standard 115 VAC wiring layout diagram.

5) This wiring diagram is intended only to show the connections between the satellite

and the dispenser. For app licab le warnin gs and proper connection of all wires, see

wiring diagram for master dispenser (according to model number). For the complete

wiring information for the dispenser, refer to MDE-4331 Atlas Fuel Systems

Installation Manual.

Page 22 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 27

Wiring Diagrams Wiring

Figure 4-4: 9850K Series Wiring Diagram

Non-simultaneous Wiring

Master Dispenser

Satellite Dispenser

Master Dispenser

Satellite Dispenser

Simultaneous Wiring

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 23

Page 28

Wiring Wiring Diagrams

This page is intentionally left blank.

Page 24 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 29

Completion Checklist Start-up

5 – Start-up

Completion Checklist

The following information must be reviewed to verify the proper installation of the satellite

dispensing unit. If the installation does not meet the following criteria, correct the problem

before the start-up is performed.

1 If connected to an Atlas Series 9800K dispenser, to avoid damage to the CPU PCB board,

verify if the RESET COMPLETE, FAST FLOW, SUBM. STARTER DRIVE, and SLOW and

FAST SATELLITE RETURN wires are not shorted to conduit or chassis.

2 The unit must be properly secured to the island.

3 All plumbing must be complete and tight. All liquid-carrying lines must be checked for leaks.

Start-up

4 All conduit work must be complete. All junction box covers must be secured. Conduits must

not be sealed until the wiring is verified through proper operation.

5 The unit must be properly grounded.

6 Before any testing begins, remove any water in the tank through a fill opening, using a suitable

pump. Do not use the Gasboy pump or dispenser and submersible pump to remove water.

Serious damage may occur.

7 A sufficient volume of fuel must be put in the tank to ensure that the liquid level is high

enough to allow the submersible pump to operate efficiently (dispensers). This section

provides information specific to the installation of Atlas pumps/dispensers.

After successfully verifying the installation against the completion checklist, the unit is ready

for start-up. To perform start-up of the satellite dispensing unit, proceed as follows:

1 Turn on the circuit breaker(s) for the various control lines to the dispenser to be tested.

2 Remove the nozzle for Side 1 from its holder and turn on the pump handle.

3 Dispense fuel. If the unit contains a slow/fast flow valve, verify if it opens. Check all plumbing

for leaks at this time.

4 Turn the pump handle off. Open the nozzle. No fuel must be dispensed.

5 For twin models, repeat steps 1 to 4 for the other untested dispenser.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 25

Page 30

Start-up Start-up

This page is intentionally left blank.

Page 26 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 31

6 – Operating the Satellite Dispenser

To operate the satellite dispenser, proceed as follows:

1 Provide AC power (115 or 230 VAC) to the submersible feed and slow flow/reset motor feed.

If a submersible starter relay is used, AC power (115 or 230 VAC) must be supplied to the

input contacts of the submersible starter relay.

2 Dispense the product.

3 At the master dispenser, the register displays the total volume. If an optional pulser kit is

attached, it supplies pulses which may be recorded by an external monitoring system.

4 The fueling transaction continues to run until the user turns off the dispenser handle.

Operating the Satellite Dispenser

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 27

Page 32

Operating the Satellite Dispenser

This page is intentionally left blank.

Page 28 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 33

General Maintenance Preventive Maintenance

7 – Preventive Maintenance

General Maintenance

Gasboy recommends a periodic inspection, at least twice a year. If such a procedure is

followed, any small adjustments that are necessary can be made before expensive, annoying

breakdowns occur. The result of this sound approach is continuous, pr ofitable service from all

of your Gasboy equipment.

Note: Only a qualified service personnel must disassemble parts of the dispenser.

WARNING

To reduce the risk of electrical shock when servicing, turn off all power to the dispenser. In

submersible pump applications turn off power to the submersible pump and any other

dispensers which use that submersible pump. AC power can feed back into a shut-off

dispenser when dispensers share a common submersible pump or starter relay. Always

turn off all power to the dispenser and submerged pumps at the master panel and close

any impact valve before performing any maintenance or service to the dispenser, including

the changing of any fuel filters or strainers. Also block islands such that no vehicles can pull

up to the dispenser when the dispenser is being worked on.

Tips for Better Pump Performance

Demand Competent Service

If the pump stops or fails to operate properly, do not depend upon the repair service of a

general mechanic unless the mechanic is thoroughly familiar with the mechanism. Experience

shows that the repair results are more satisfactory if you demand the service of a competent

representative of the pump manufacturer. Gasboy has a distributor network which services fuel

dispensing and management systems in every section of the country.

Use Authorized Parts

If excessive wear, rust, or corrosion of parts cause inefficient operation, it is always best to

replace them immediately . However , if you wan t the best results and continuity of the UL label

on your pump, ensure that they are new and authorized service parts supplied by Gasboy.

Every part of a pump or dispenser is carefully designed for a particular purpose. If it is

replaced by an incorrect or substandard substitute, pump operation will be unsatisfactory.

Always use new gaskets or seals when servicing or rebuilding Gasboy equipment. Do not

reuse old ones.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 29

Page 34

Preventive Maintenance Preventive Maintenance Checklist

Operate with Reasonable Care

The pump or dispenser that is operated with reasonable care will last longer and give better

service. Abuse must be avoided such as dropping the nozzle on the ground, operating the unit

with a dirty strainer, dragging the hose across the concrete island or driveway, running the

pump with the nozzle closed for more than two minutes, and so on. The time and care given to

your pumps will be returned to you in the form of dependable service.

Preventive Maintenance Checklist

Keep Water Out

Water tends to collect in underground and aboveground storage tanks. This is due to

condensation of the moisture laden air drawn into the storage tank, or defective fill openings

that are not properly protected with watertight covers. Storage tanks must be checked after

every fill-up for water and removed with a sump pump, to forestall serious damage to

equipment. Water , sedi ment, and other foreign matter that accumulates in the tank can be

drawn up into the pump or dispenser and cause failures.

Preserve the Finish of Pumps

Nearly all gasoline pumps are installed outdoors where their surfaces are subjected to the

action of the weather. As a result, it is necessary to give the finish a reasonable amount of care

if an attractive appearance is to be maintained.

The finish on Gasboy pump housings is a high-heat baked synthetic enamel, similar to that

used on automobiles. The life of this finish can be lengthened several years, if at regular

intervals the painted surfaces are thoroughly cleaned with a high-grade automobile polish and

then protected with a coat of paste wax. Do not use abrasive cleaners or polish. Do not use

high pressure spraying equipment.

In order to retain the unmarked finish on stainless steel, occasional cleaning is required. In

corrosive atmospheres, such as coastal areas, a more frequent cleaning schedule is required.

Under ordinary conditions, washing with detergent or soap and water, followed by a clean

water rinse, is sufficient. If hard water is used, the surface must be wiped dry with a soft clean

cloth to prevent the formation of water spots. Marks or spots, such as grease, oily finger prints

and smudges which resist soap and detergents, will have to be removed with a stronger

cleaner.

Note: DO NOT use ordinary steel wool as iron particles may adher e to the surface and cause

corrosion.

Exercise care in choosing a cleaner because any cleaning compounds or powders that contain

abrasives can scratch a mill-rolled finish. Care must be exercised in their use to run in the

direction of the polishing lines in the steel, never across them. After cleaning, an application of

paste wax is recommended to protect the surface and prolong the interval between cleaning.

Page 30 MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Page 35

Preventive Maintenance Checklist Preventive Maintenance

This page is intentionally left blank.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010 Page 31

Page 36

UL® is a registered trademark of Underwriters’ Laboratories Inc.

© 2010 GASBOY

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone 1-800-444-5529 · http://www.gasboy.com · Printed in the U.S.A.

MDE-4906 Atlas™ 9216K/9216KTW Satellite Dispensers Installation/Operation Manual · June 2010

Loading...

Loading...