Page 1

9120K and 9820K Series AST Pumps

Service and Parts Manual

MDE-4616B

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP , 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

5087 8753K, 8853K, 9153K, 9853K

5091 8752K, 9152K

5129 9122K, 9123K, 9822K, 9823K

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

(restricted to diesel and nonretail gasoline sales)

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

95-136 Dispenser 9800 Series 91-057 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice. · For information regarding Gasboy Literature, call (336) 547-5661

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2008 GASBOY · All Rights Reserved

Page 3

Table of Contents

1 – Introduction 1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Model 9120K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Model 9820K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2 – Important Safety Information 5

3 – Preventive Maintenance 9

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Hints for Better Pump Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Demand Competent Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Use Gasboy Authorized Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Operate with Reasonable Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Keep Water Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Clean the Dial Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Clean the Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Change the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power Reset External Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Adjust the Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Preserve the Finish of Your Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 – Parts 13

Base and Motor Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Pump Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Meter Shelf, J-Box, and 9123 Register, Reset and Pulser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Reset/Register Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Pulser Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Junction Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Meter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

9823 Pulser, Totalizer and Gear Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Panels, Remote Register, Mounting Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

9123K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

9823K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Remote Register - Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Remote Register - Side View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Remote Register Chassis Assembly - Top View . . . . . . . . . . . . . . . . . . .32

Remote Register Chassis Assembly - Front View . . . . . . . . . . . . . . . . . .33

Remote Register Mounting Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Series Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page i

Page 4

This page is intentionally left blank.

Page ii MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008

Page 5

Purpose Introduction

1 – Introduction

Purpose

This manual is provided to assist the Gasboy Authorized Service Contractor (ASC) in

servicing the following units used with Aboveground Storage Tanks (ASTs):

• 9120K compact mechanical commercial pump

• 9820K electronic commercial pump

This manual also provides the parts list for the 9X20K units.

Note: Whenever information in this document applies to all the units listed above, the 9X20K

model reference is used.

General Description

Model 9120K

The Gasboy Series 9120K pump units are UL®-listed.

Note: NFPA regulations do not allow tank-mounted pumps to be used for the resale of fuel.

Model 9120K offers four-wheel mechanical-interlock registers. Mechanical pump registers

show the total volume for a delivery up to 999.9 gallons.

Standard features and specifications of the 9120K Series pumps are as follows:

• Discharge elbows

• A 12-foot length of hose

• A working voltage of 115/230VAC, 50/60 Hz

• Mechanical Volume Totalizer

• A switch detect and optional pulser outputs which allow monitoring of the register's

operation when it is connected to an automated fuel management system.

• Four-piston, positive-displacement meter

• Belt-driven, positive-displacement rotary-vane pump with an 80 mesh (300 micron)

strainer and integral air-separation

• Cabinet height of 25.4 inches. The other dimensions may be found on the bas e layout.

• The standard cabinet finish has the top, sides, and back painted black while the front panel

is painted white.

• Filters

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 1

Page 6

Introduction General Description

The available options and accessories for the Gasboy Series 9120K pumps are as follows:

• Interchangeable Automatic Nozzles

•Pulsers

• Special Lengths of Hose

• Vapor Recovery System

• 380 VAC 3-Phase Motor

Model 9820K

The Gasboy Series 9820K Aboveground Storage Tank Remote Access (ASTRA) pump units

are UL-listed.

Note: NFPA regulations do not allow tank-mounted pumps to be used for the resale of fuel.

The 9820K Series consists of two metal cabinet assemblies.

• One assembly is mounted on top of the tank and contains the pumping unit, meter,

electronic pulser, and all hydraulics. The hose and nozzle are connected to this assembly.

• The second assembly is mounted at a height to permit easy access by a user. It contains the

electronic register, controls, display and nozzle boot.

The Standard features and specifications of the 9820K Series pumps are as follows:

• One-inch high, 6-digit, backlighted Liquid Crystal Display (LCD)

• 1000:1 dual-phase, error-checking pulser (gallons); 250:1 dual-phase, error-checking

pulser (liters)

• AC authorization line for control of the unit

• Reset complete (Switch Detect) output that allows monitoring of the unit's operation when

it is connected to an automated fueling system

• Resettable electronic totalizer

• Discharge elbow

• Both models use a quiet and efficient pump which features an air eliminator, built into the

pump casting. The pump meter is a three piston, positive displacement meter which is

tested and calibrated for accuracy at any speed or pressure up to the maximum working

pressure of 50 psi.

• The standard pumping cabinet finish is white. The electronic register cabinet is black with

a blue graphics panel.

• Dual Stage Solenoid Valve

• Filter

Available options and accessories for the Gasboy 9820K Series pumps are as follows:

• Pulser output drive line (open collector), capable of driving 1, 10, 100, 250 and 500 pulses

per unit (gallons) or 1, 10, & 100 pulses per unit (liters)

• RS-485 communication for direct connect to Gasboy CFN or TopKATΤΜ equipment

• Battery backup for display of last transaction and capture of stored pulse count in the event

of a power failure.

• Mechanical totalizer

• A working voltage of 115 VAC (115/230 for motor) 60 Hz for domestic use, 230 VAC 50

Hz/60 Hz for international use.

• Other options include listed automatic nozzles, special lengths of listed hose assembly,

listed dual swivels, UL-recognized filters, Vapor Recovery, and Vapor Recovery Ready.

Page 2 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008

Page 7

Abbreviations and Acronym s Introduction

Abbreviations and Acronyms

Term Description

AC (or ac) Alternating Current

ASC Authorized Service Contractor

AST Aboveground Storage Tank

ASTRA Aboveground Storage Tank Random Access

CFR Code of Federal Regulations

CPR Cardiopulmonary Resuscitation

CPU Central Processing Unit

DC (or dc) Direct Current

LCD Liquid Crystal Display

NEC National Electrical Code

NFPA National Fire Protection Association

OSHA Occupational Safety and Health Association

PCB Printed Circuit Boards (preferred term: board)

STP Submerged Turbine Pump

UL Underwriters Laboratory

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 3

Page 8

Introduction Abbreviations and Acronyms

This page is intentionally left blank.

Page 4 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008

Page 9

2 – Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and island.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical po wer to the p ump/

dispenser. This means that even if you activate

these stops, fuel may continue to flow

uncontrolled.

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at 1800-444-5529. It is imperative to your safety and the safety of

others to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or

similar keys.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit (s)

• A total electrical shut-off of the affected unit (s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage

Working With Fuels and Electrical Energy

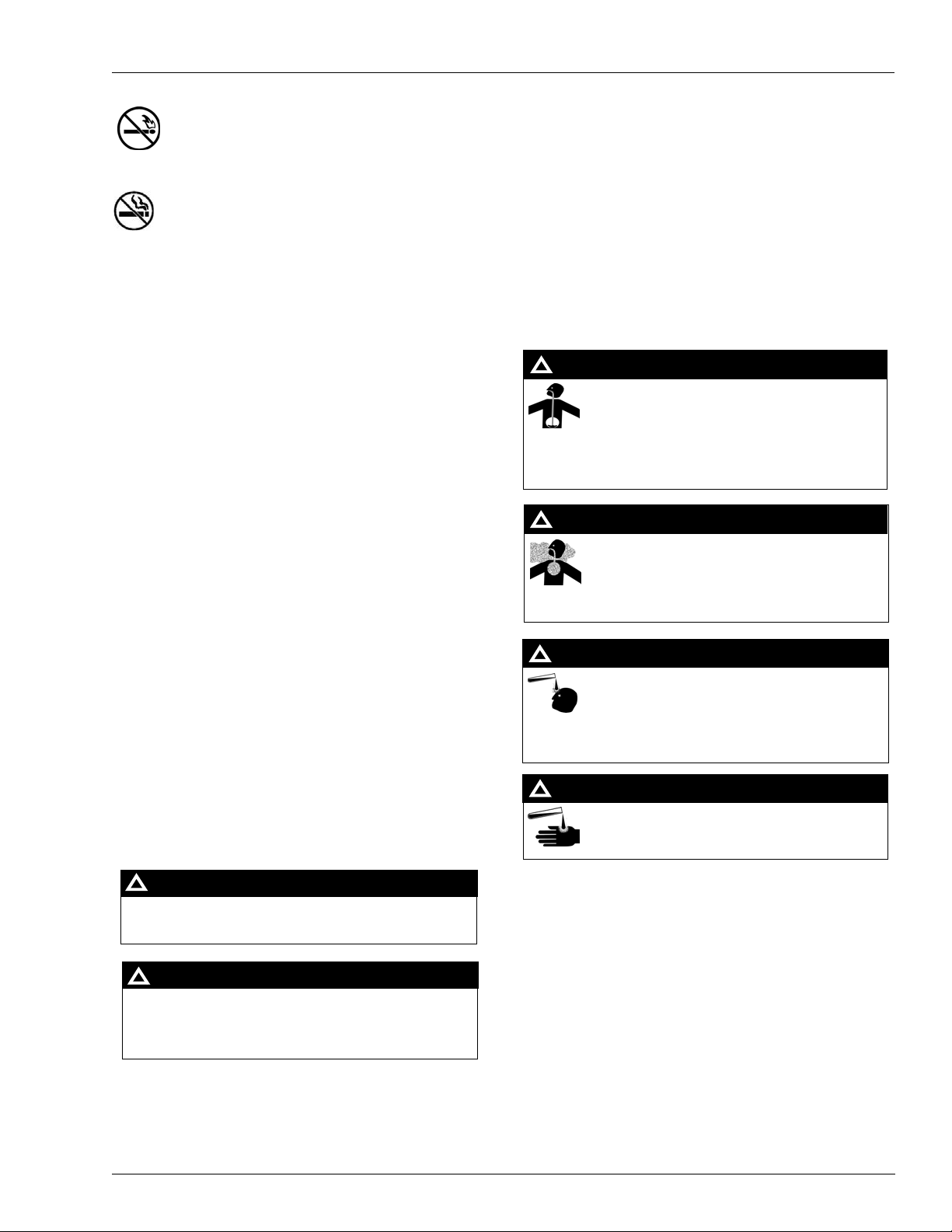

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 5

Page 10

No Open Fire

In an Emergency

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuel vapors. Every time you get out of a vehicle, touch the

metal of your vehicle, to discharge any ele c tro static charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA Lockout/ Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing

devices and compounds are in place. Ensure that you do not

pinch wires when replacing covers. Follow OSHA Lockout/

Tagout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safety while the equipment is down.

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

Hazardous Materials

WARNING

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

Lockout/Tagout covers servicing and maintenance of

machines and equipment in which the unexpected

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

energization or start-up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical hazards.

Page 6 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008

Page 11

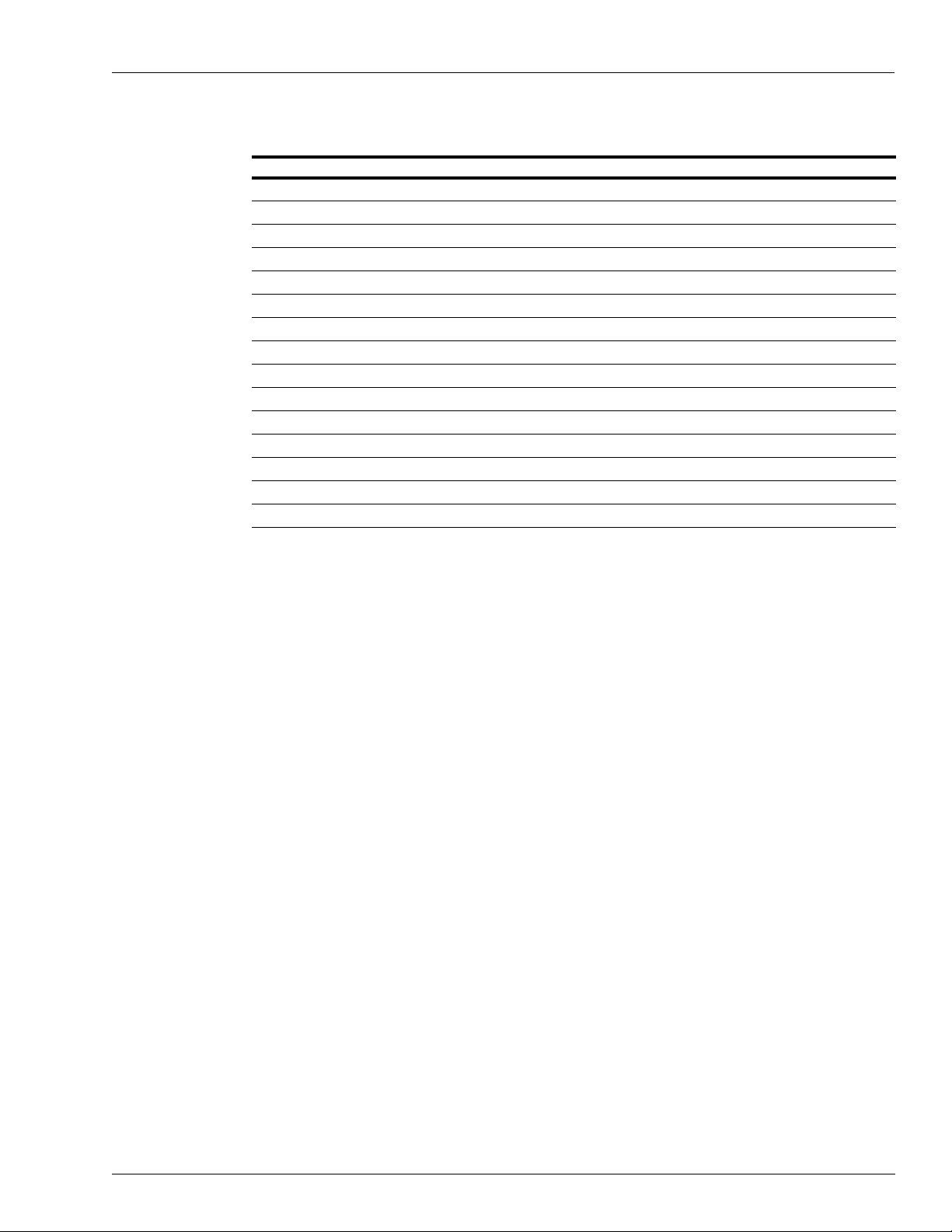

Hazards and Actions

!

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

The following actions are recommended regarding these hazards:

Collision of a Vehicle with Unit Fire at Island Fuel Spill

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system circuit breakers to the

island(s).

• Do not use console E-STOP, ALL STOP and PUMP STOP to shut off power. These keys do no t

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 7

Page 12

This page is intentionally left blank.

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 8

Page 13

General Preventive Maintenance

3 – Preventive Maintenance

General

Gasboy pumps are designed and constructed to give many years of uninterrupted service. In

fact, operators report years of trouble-free operation with absolutely no service expense. Yet,

certain parts of a pump are bound to wear, and Gasboy therefore recommends a periodic

inspection, at least twice a year, for such things as fuel leaks, belt tension and condition,

lubrication and strainer cleanliness. If such a procedure is followed, any small adjustments that

are necessary can be made before expensive, annoying breakdowns occur. The result of this

sound approach is continuous, profitable service from all of your Gasboy equipment.

!

!

WARNING

To reduce the risk of electrical shock when servicing a pump, turn off all power to the

pump.

Hints for Better Pump Performance

Demand Competent Service

Gasboy suggests all service be done by certified Gasboy Authorized Service Contractors

(ASCs) trained and familiar with the service of Gasboy products. Warranty service must be

done by Gasboy ASC. Gasboy has a Distributor Network which services fuel dispensing and

management systems in every section of the country.

Use Gasboy Authorized Parts

Should excessive wear, rust, or corrosion of parts cause inefficient operation, it is always best

to replace them immediately; but if you want the best results and continuity of the

Underwriters’ Label on your pump, ensure that new authorized service parts supplied by

Gasboy are used. Every part of a pump is carefully designed for a particular purpose. If it is

replaced by an incorrect or substandard substitute, pump operation can be unsatisfactory and

warranty will be voided. Always use new gaskets or seals when se rvicing or rebuilding

Gasboy equipment; do not re-use the old ones.

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 9

Page 14

Preventive Maintenance Preventive Maintenance

Operate with Reasonable Care

Like any machine, the pump that is operated with reasonable care will last longer and give

better service. Abuse should be avoided (such as dropping the nozzle on the ground, operating

the unit with a dirty strainer, dragging the hose across the concrete island or driv eway, running

the pump with the nozzle closed for more than two minutes and so on). Parts that fail from

abuse will not be covered by warranty . The time and care given to your pumps will be returned

to you in the form of dependable service.

Preventive Maintenance

Refer to the “Important Safety Information” on page 5 and read and understand all the

information contained there. It is recommended that all service to this unit be done by

Certified Gasboy ASCs familiar with the operation of this equipment and safety requirements

for servicing equipment in potentially hazardous condition or location.

Keep Water Out

Water tends to collect in storage tanks. This is due to moisture-laden air being drawn into the

storage tank and condensing, or to defective fill openings that are not properly protected with

watertight covers. Storage tanks should be checked after every fill-up for water and removed

with a sump pump, to forestall serious damage to equipment. Water, sediment, and other

foreign matter that accumulates in the tank can be drawn up into the pump and cause failures.

Clean the Dial Face

Clean the dial face with a soft, clean, damp cloth as often as necessary. Do not use abrasive

cleaners or those containing ammonia.

Clean the Strainer

Clean the strainer immediately after the pump has been installed and tested, and again after a

few hundred gallons have been delivered. Thereafter, once every six months, or whenever a

filter is changed. The symptoms of a dirty or clogged strainer in a pump are slow delivery,

noisy operation, and pulsation. To clean the strainer, turn off AC power to the pump. Locate

the Suction Strainer Cap on the plumbing unit and unscrew it to access and remove the

strainer. Use compressed air to blow the dirt out of the strainer. Clogged strainers can

commonly be cleaned using alcohol. Refer to item 3 in the parts list under

on page 24.

!

!

“Meter Assembly”

CAUTION

Always wear protective safety goggles or glasses when using compressed air.

Page 10 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008

Page 15

Preventive Maintenance Preventive Maintenance

Change the Filter

If the unit is equipped with a filter, check and change it at regular intervals. A dirty filter in a

pump will cause a slower delivery rate. Refer to the accessories section of your parts manual to

ensure that you replace the filter with one designed for your model. Always use a drip pan

directly below the filter when removing the cartridge to prevent contamination of the soil and

to aid in fluid recovery. Refer to item 2 in the parts list under

“Meter Assembly” on page 24.

Power Reset External Adjustment

If the pump or remote dispenser fails to reset or shut off properly, the reset motor may need to

be adjusted. To adjust, proceed as follows:

1 Loosen the lock nut on the adjusting screw and back screw out until it stops.

2 Move the reset lever to the ON position.

3 Turn adjustment screw in until reset motor starts.

4 Advance adjustment screw an additional 1/2 to 3/4 turn. Hold screw in this position and

tighten the lock nut.

5 Move the reset lever to the OFF position, and then back to the ON position to verify if the reset

motor operates properly. The reset coupling should make one revolution and stop.

Adjustment Screw

Lock Nut

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 11

Page 16

Preventive Maintenance Preventive Maintenance

Adjust the Belts

With proper care, belts will give exceptionally good service. A loose belt not only cuts down

pumping speed, due to slipping, but also results in excessive wear.

On the 9X20K units, the belt can be tightened by removing a link from the belt.

Preserve the Finish of Your Pumps

Nearly all gasoline pumps are installed outdoors where their surfaces are subjected to the

action of the weather. As a result, it is necessary to give the finish a reasonable amount of care

if an attractive appearance is to be maintained.

The finish on Gasboy pump housings is a high-heat baked synthetic enamel, similar to that

used on automobiles. The life of this finish can be lengthened several years if, at regular

intervals, the painted surfaces are thoroughly cleaned with a non abrasive detergent and then

protected with a coat of paste wax.

• Do not use abrasive cleaners.

• Do not use high pressure spraying equipment.

• Fuel stains can be removed using “Greased Lightening”.

In order to retain the unmarked finish on stainless steel, occasional cleaning is required. In

corrosive atmospheres, such as coastal areas, a more frequent cleaning schedule is necessary.

• Under ordinary conditions, washing with deter gent or soap and water, followed by a clean

water rinse, is sufficient.

Note: If hard water is used, the surface should be wiped dry with a soft clean cloth to

prevent the formation of water spots.

• Marks or spots, such as grease, oily fingerprints and smudges which resist soap and

detergents, will have to be removed with a stronger cleaner capable of removing all oil/

grease completely (DO NOT use ordinary steel wool as iron particles may adhere to the

surface and cause corrosion.)

Note: Care should be taken in choosing a cleaner because any cleaning compounds or

powders which contain abrasives can scratch a mill-rolled finish. Care must be

exercised in their use to run in the direction of the polishing lines in the steel,

never across them.

After cleaning, an application of paste wax is recommended t o protect the surface and prolong

the interval between cleaning.

Page 12 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008

Page 17

Base and Motor Shaft Parts

4 – Parts

Base and Motor Shaft

16

1, 3

5

17, 18

7

15

6

Item # Part Description Current Part Previous Part Quantity

1 Conduit, Motor to J-Box M06978B001 - 1

2 Motors, Cont. Duty 61 Frame R14213-32 - 1

3 Assembly Conduit Motor to J-Box M07039B001 - 1

4 Electric Motor Frank In M01068B302 - 1

5 Assembly, Bottom Panel 9x20k M06582A001 - 1

6 Mounting Foot,9820 SS Tum 026401 - 4

7 Screw, Metric M8 X 18 M00417B009 - 8

8 Mount, Universal M04871B001 - 4

9 Washer, Flat M20 Stl Znpl M00959B019 - 4

10 Screw Metric M8 X 40 M00415B017 - 4

11 Belt Adjustable M07022B002 - 0.0255

12 Flat Washer M00959B008 - 4

13 Bracket, Reinforced Corner Gussett (Not Shown) M06757B002 - 2

8, 9, 10, 11, 12

2, 4

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 13

Page 18

Parts Base and Motor Shaft

Item # Part Description Current Part Previous Part Quantity

14 Nut, Metric, Hex Serrd Flg (M8) (Not Shown) M00414B003 - 4

15 Shelf, Motor Support M06566A001 - 1

16 Union, Conduit 1/2 Inch Q10016-04 - 1

17 Pulley A Belt 2.50 Pd R18900-27 - 1

18 Pulley A Belt 3.00 Pd R18900-32 - 1

Page 14 MDE-461 6B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 19

Pump Assembly Parts

Pump Assembly

3

1

9

2

7

10

5

11

6

4

6

8

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 15

Page 20

Parts Pump Assembly

Item # Part Description Current Part Previous Part Quantity

1 Global Pumping Unit M04920B003 - 1

2 Adaptor - EPZ Inlet 023146 - 1

3 Connection 90 Elbow Compression (Male) Q12503-02 - 1

4 Elbow 1-1 1/2 90 deg 150 PSI MI K46046 - 1

5 Lockwasher Metric M10 Zinc Plate M01071B001 - 3

6 Nipple FEe Pipe 1 1/2 x 6.00 R11493-28 - 2

7 O-Ring 2.237 x 0.103 Q10067-31 - 1

8 Pipe Union, Female K12179 - 1

9 Plate, Pump Mounting M06738B001 - 1

10 Screw Metric M8 X 16 M00415B009 - 4

11 Socket Head Cap Screw, M10 X 25 M04973B005 - 3

12 Tube, Vent 9x20K (Not Shown) M06650B003 - 1

GPU Repair Kits

13 Bypass Valve M04920K100 - 1

14 Strainer M04920K101 - 1

15 Master Seal M04920K102 - 1

16 Blades M04920K103 - 1

17 Control Valves M04920K104 - 1

18 Lip Seal M04920K105 - 1

19 Pumping Element Field Rebuild M04920K106 - 1

20 Sump Float - OIML (B005) M04920K107 - 1

21 Pumping Element Shop Rebuild M04920K108 - 1

22 Inlet Check Valve M04920K109 - 1

23 Overflow Check Valve M04920K110 - 1

24 Sump Float - Non OIML (B001) M04920K111 - 1

Page 16 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 21

Meter Shelf, J-Box, and 9123 Register, Reset and Pulser Parts

Meter Shelf, J-Box, and 9123 Register, Reset and Pulser

Register

Junction Box

Pulser

Meter Shelf

CFT Meter

Assembled View

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 17

Page 22

Parts Meter Shelf, J-Box, and 9123 Register, Reset and Pulser

17

16

18

12

10 (Rear corners only)

1

7

2, 3, 4, 5, 8, 9, 13, 15 6

Exploded View

Item # Part Description Current Part Previous Part Quantity

1 Screw Hex Serr Flng Hd Q10253-02 - 3

2 Washr Lk Ext Th 1/4x.025 K50411-31 - 1

3 Stud Drive Gear N23567 - 1

4 Ball Swivel K93546-01 - 1

5 Pin Cotter 1/16x1/2 K02124 - 1

6 Mounting Bracket, Meter Shelf M06564A001 - 1

7 Screw, Metric M8 X 16 M00415B009 - 4

8 Gear Pinion 20 Th K55151-21 - 1

9 Assy Drv Gear & Bush 21 K55152 - 1

10 Bracket, Reinforced Corner M06757B002 - 2

11 Bracket Assy, Retriever (Not shown) M06768A002 - 1

12 Screw, Metric M8 X 18 M00417B009 - 13

Page 18 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 23

Meter Shelf, J-Box, and 9123 Register, Reset and Pulser Parts

Item # Part Description Current Part Previous Part Quantity

13 Screw Skt Hd Cap 5/16-18 Q12081-02 - 1

14 Assy Drive Gear + Bushi K53743 - 1

15 Gear Pinion 12 Th K51008-24 - 1

16 Elbow Conduit 1/2 X 90 Male & Female K42448 - 1

17 Bushing, Reducing K49827-22 - 1

18 Union Conduit Male & Female 1/2 Q10016-04 - 1

Reset/Register Module

6, 23, 24

1, 5

8

Item # Part Description Current Part Previous Part Quantity

1 Drive Register Assembly 9120K, Gallons 022834 - 1

2 Nut Hex Keps W/ext Lkwshr Q12068-06 - 1

3 Screw Hex Hd Cap Finished K03782 - 1

4 Washer 5/16in Sae-n (.38 X K65235-33 - 1

5 Drive Register Assembly 9120K, Liters 022835 - 1

6 Reset Assy Elec Unli 115/ 048568 - 1

7 Dial-mask GB91501G001 - 1

8 Bracket-gear & Shaft- 912 014040 - 1

9 Sleeve S/b As 1463-3 056710 - 1

10 Nut Hex 5/16-18 Chk K01933 - 1

11 Shaft-reset Interlock-912 054510 - 1

12 Gear-60t(9120K Reset) 028235 - 1

7

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 19

Page 24

Parts Meter Shelf, J-Box, and 9123 Register, Reset and Pulser

Item # Part Description Current Part Previous Part Quantity

13 Washer, SS .260 X .500 068037 - 2

14 Brng Oilt Flng N17706-43 - 1

15 Groovpin 1/8x7/8 Ils#2zn2 013128 - 1

16 Washer, lock Ext 1/4 1114 068891 - 3

17 Screw Hex Hd Cap Finished K05287 - 3

18 Screw Tf Pnh Phl 4-40x Q11769-02 - 2

19 Ring Ret 1/4 K76238-41 - 1

20 Bracket Assy, Side Frame 9120K (Not Shown) M04295A001 - 1

21 Screw, Metric M8 X 18 M00417B009 - 2

22 Elbow Cndt 1/2x90 M & F K42448 - 1

23 Reset/reg Mod 9120K Gal 1 042724 - 1

24 Reset Assy Elec Unli 230/ 048677 - 1

Pulser Module

15

1, 17, 18

2

Item # Part Description Current Part Previous Part Quantity

1 Plsr 10:1 Vr 769780-010 021788 - 1

2 Bracket, Pulser Shaft M06740B001 - 1

3 Bearing Nyliner#4l2ff 011954 - 2

4 Gear Miter-24 T Mach Tank 028422 - 1

5 Pin Grv Type 1 3/32x5/8 K48724 - 1

6 Spirol Pin .062 X .750 Q10038-30 - 1

7 Screw Hex Hd Cap Finished K05287 - 2

8 Washer, lock Ext 1/4 1114 068891 - 2

9 Shaft-totalizer-9120K 054526 - 1

10 Spirol Pin .052 X .375 Q10038-26 - 1

6

9

Page 20 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 25

Meter Shelf, J-Box, and 9123 Register, Reset and Pulser Parts

Item # Part Description Current Part Previous Part Quantity

11 Washer, SS .260 X .500 068037 - 1

12 Screw, Metric M8 X 18 M00417B009 - 2

13 Coupling-totalizer 9120K 054527 - 1

14 Spirol Pin .078 X .437 Q10038-35 - 1

15 Elbow Cndt 1/2x90 M & F K42448 - 1

16 Nipple Cndt 1/2 X 10-1/2 (Not Shown) R11976-80 - 1

17 Pulser Mod 9120K C+10:1 042737 - 0

18 Plsr 100:1 Vr 767181-332 047648 - 1

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 21

Page 26

Parts Meter Shelf, J-Box, and 9123 Register, Reset and Pulser

Junction Box Assembly

4

M07040A001

M07040A002

12

5

3

1

11

2

M07040A003

Page 22 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 27

Meter Shelf, J-Box, and 9123 Register, Reset and Pulser Parts

Item # Part Description Current Part Previous Part Quantity

1 Junction Box M04480B010 - 1

2 Bracket, J-Box Mounting M06649B001 - 1

3 Bushing, Reducing 3/4 - 1/2 K49827-22 - 2

4 Conduit, J-Box to Reset M07002A001 - 1

5 Elbow, 1/2 X 90 M X F K42448 - 4

6 Pipe Plug C-Sunk 1 K51440 - 1

7 Pipe Plug C-Sunk 1/2 K43850 - 1

8 Pipe Plug C-Sunk 3/4 K57624 - 4

9 Screw, Hex, Sltd, Thd Frng, Wshr Hd (10-32 X 1/2) K85736-05 - 1

10 Screw TF, Hex Whsr Hd M X 18 M00417B009 - 2

11 Union Conduit 1/2 Inch Q10016-04 - 3

12 Expansion Union (conduit) N16289-20 - 1

13 Cover Junction Box M04536B010 - 1

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 23

Page 28

Parts Meter Shelf, J-Box, and 9123 Register, Reset and Pulser

Meter Assembly

1

2

7

Assembled View

Item # Part Description Current Part Previous Part Quantity

1 CFT Meter Assembly T20150-G9

2 2- Stage Sol Valve and Filter Manifold M04607B002

3 Strainer Insert High Capacity R19457 - 1

4 Assy Meter Check Valve N23619-G2 - 1

5 O-Ring 1.234 X 0.139 Q10068-09 - 1

6 O-Ring 1.609X 0.139 Q10068-14 - 1

7 Fitting, Discharge M04624B040 - 1

8 O-Ring 0.862 X 0.103 N16891-32 - 1

9 Screw Metric M8 X 25 M00415B011 - 2

10 Bolt, Hx Hd Sems, 5/16-18x1” Lg Q10865-36 - 4

Exploded View

- 1

T20150-G10

- 1

M04607B001

Page 24 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 29

9823 Pulser, Totalizer and Gear Train Parts

9823 Pulser, Totalizer and Gear Train

Assembled View

Exploded View

28

33

25

26

Item # Part Description Current Part Previous Part Quantity

1 Assy, Pulser Mtg Bracket M07175A001 - 1

2 Nut, Metric Serrated M00414B002 - 4

3 Kit-Totalizer, 9820 Gal Factory 025934 - 1

4 Assy, Bracket Ast Totlzr M06737A001 - 1

5 Screw, Metric M8 X 18 M00417B009 - 2

24

31

11

34 35

Shelf Cutaway

1

4

8, 10

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 25

Page 30

Parts 9823 Pulser, Totalizer and Gear Train

Item # Part Description Current Part Previous Part Quantity

6 Tie Cable Q10178-02 - 2

7 Kit-Totalizer 9820 Ltr Factory 025936 - 1

8 Assy, Brkt Gear Train M07102A001 - 1

9 Nut, Metric Serrated M00414B002 - 4

10 Assy, Brkt Gear Train M07102A002 - 1

Vapor (Shown)

11 Nippl 3/4 X 6-1/2 Lg R11496 70 - 1

12 Assy, Feedline Tube M06810A001 - 1

13 Flange Pump Discharge M04686B001 - 1

14 Ring 0 1-1/8x1-3/8x1/8 Q10068-07 - 1

15 Screw Skt Hd Cap Metric M04973B001 - 2

16 Screw Hex Serr Flng Hd Q10253-02 - 4

17 Ring O 1-1/4x1-1/2x1/8 Q10068-09 - 2

18 Assy, Discharge Tube M06809A001 - 1

19 Assy, Bracket U-bolt Mtg M06767A001 - 1

20 Brakt U-bolt Mounting M06767B002 - 1

21 U-bolt, Metric, M8 M00703B001 - 2

22 Nut, Metric M8 Serrated M00414B003 - 6

23 Screw, Metric M8 X 18 M00417B009 - 6

24 Nipple 3/4 X 3-1/2 R11496-75 - 1

25 Nipple 3/4 X 4-3/8 Lg R11496-84 - 1

26 Elbow-3/4 X 90 (Paint) 024955 - 1

27 Label Gasboy V/r Hose M04039B003 - 1

28 Casting Splitter Vp Emco# 049980 - 1

29 Elbow Cndt 1/2x90 M & F K42448 - 1

30 Condt, J-box To Valve M07001B001 - 1

31 Screw Hex Hd Wshr Hd T-t K85736-51 - 4

32 Screw, Metric M8 X 16 M00415B009 - 2

33 Elbow St 3/4 X 90 Mi K21703 - 1

34 Bushg Red Hex Hd K02297 - 1

35 Bracket, Vapor Casting M06741B001 - 1

Non Vapor

36 Nippl 1x10-3/4 R11495-24 - 1

37 Condt, J-box To Valve M07001B001 - 1

38 Screw, Metric M8 X 16 M00415B009 - 2

Page 26 MDE-461 6B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 31

Panels, Remote Register, Mounting Kits Parts

Panels, Remote Register, Mounting Kits

9123K

7

24

5

17

15

16

3

2

4

8

10

11

9

19

12

26

18

14

13

1

6

25

Item # Part Description Current Part Previous Part Quantity

1 Assy, Front Panel 9120K M06583A002 - 1

2 Glass Window 9120K 028811 - 1

3 Brakt 9120K Totalizer Face M06739B001 - 1

4 Panel Lh Side 9120K M06584B002 - 1

5 Panel Back 9x20K M06578B0 03 - 1

6 Panel Rh Side 9X20K M06579B002 - 1

7 Assy, Top Panel 9X20K M06758A001 - 1

8 Cover Nozzle Boot 9120K 026420 - 1

9 Screw Tc Pnh Phl 10-32 X Q11769-76 - 6

10 Brkt Nozzle Boot Mtg 026403 - 1

11 Boot-noz;98a,88b/d (Mach) 003338 - 1

12 Screw Tpt Phil Fl Hd 8-32 Q13399-03 - 4

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 27

Page 32

Parts Panels , Remote Register, Mounting Kits

Item # Part Description Current Part Previous Part Quantity

13 Bracket Nozzle Boot 026421 - 1

14 Guide-nozzle 9120 029027 - 1

15 Bracket Lever Reset 9120K 033992 - 1

16 Bushing Lever Reset 9120K 017234 - 1

17 Stop-eccentric Plastic 063204 - 1

18 Washer,.264 X .500 X .030 N16599-123 - 1

19 Screw Rd Hd Phil 8-32x1/2 Q11560-53 - 1

20 Nut Hex Slf Lock 5/16-18 Q10218 10 - 2

21 Nut, Metric, Flange M00414B005 - 4

22 Nut, Metric Serrated M00414B002 - 8

23 Rivet 047211 - 2

24 Cap Plug 2" Blk Plastic Q10554-16 - 1

25 Plug Cap Plastic Q10554-06 - 1

26 Screw Hex Serr Flng Hd Q10253-02 - 4

27 Nut 1/2 Conduit Seal K89681 - 1

28 Hook-Noz; 87, 88B/D, 91 (Mach) 003732 - 1

29 Grommet, .875 OD X .375 N15941-42 - 1

30 Pin GRV Type 5 1/8X1 K63742 - 1

31 Cover Nozzle Boot BTM 026419 - 1

32 Grommet DSCH-3/4” 028930 - 1

Page 28 MDE-461 6B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 33

Panels, Remote Register, Mounting Kits Parts

9823K

5

1

3

8

Item # Part Description Current Part Previous Part Quantity

1 Panel RH Side 9X20K M06579B002 - 1

2 Panel LH Side 9820K M06581B002 - 1

3 Panel Back 9X20K M06578B003 - 1

4 Assembly, Front Panel 9820K M06580A002 - 1

5 Assembly, Top Panel 9X20K M06758A001 - 1

6 Window, Totalizer 9 Digit 069076 - 1

7 Nut, Metric, Flange M00414B005 - 2

8 Lock-Door w/Clip (2” CAM) 035017 - 2

9 Plug Cap Plastic Q10554-06 - 1

10 Grommet, .875 OD X .375 N15941-42 - 1

11 Nut, Metric Serrated M00414B002 - 8

12 Cap Plug 2” Blk Plastic Q10554-16 - 1

13 Grommet Dsch -3/4” 028930 - 1

4

6

7

2

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 29

Page 34

Parts Panels , Remote Register, Mounting Kits

Remote Register - Front View

Item # Part Description Current Part Previous Part

1 115 V Register (9823K) C06676 2 230 V Register (9823K) C06715 -

Page 30 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 35

Panels, Remote Register, Mounting Kits Parts

Remote Register - Side View

1

8

2, 3

6, 7

11

4

5

9

10

Item # Part Description Current Part Previous Part

1 Panel, Top Cover, 9820 Register 040996 2 Stop C09585 3 Cushion Sleeve C09584 4 Lever, Control, 9820 Mach 003771 5 Housing Weld Assy. 040999 6 Hood 029416 7 Hood, Support Assembly 063507 8 Bearing Plate Assembly 045988 9 Cover 015760 10 Bracket, Tamper Proof 015694 11 Roll Pin, 1/8 X 1-3/8 (Not Shown) 042657 -

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 31

Page 36

Parts Panels , Remote Register, Mounting Kits

Remote Register Chassis Assembly - Top View

1

12

2

11

3

4

5

6, 7

Item # Part Description Current Part Previous Part

1 Weld Assy., Chassis C35584 2 PCB Assy., CPU 120 VAC C06394 3 Reflector, LCD Backlight C35399 4 PCB Assy., LCD Display C06387 5 Bracket Assy., Display Door C35543 6 Cable Assy., Totalizer w/ Bracket C06673 7 Actuator, Totalizer (Not Shown) C01342 8 IC RAM 2K X 8 C01383 9 PCB Assy., LED Backlight C06372 10 Cable Assy., Display/Power Supply C06668 11 Cable Assy., Ground Strap C06454 12 Cable Assy., DC Power C06679 -

8

10

9

Page 32 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 37

Panels, Remote Register, Mounting Kits Parts

Remote Register Chassis Assembly - Front View

1

2

3

9

5

8

7

4

6

Item # Part Description Current Part Previous Part

1 Weld Assy, Chassis C35584 2 Cable Assy., DC Power C06679 3 PCB Assy., PS w/o Battery, 115V C06396 4 Bracket Assy., RH Hinge C35538 5 Relay Assy. C06681 6 Cable Assy., 5-pos. TB C06674 7 Cable Assy., 10-pos. TB C06675 8 Fuse Holder, Quick Conn. C09546 9 Bracket Assy., LH Hinge C35539 -

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 33

Page 38

Parts Panels , Remote Register, Mounting Kits

Remote Register Mounting Option

1

2

3

Item # Part Description Current Part Previous Part

1 Bracket Housing Mounting 042073 2 Weld Assembly, Pedestal Body 042080 3 Cover 042081 4 Side Mounting Bracket (not shown) 015128 5 Rear Mounting Bracket (not shown) 015127 -

Page 34 MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2 008

Page 39

Series Kits and Accessories Parts

Series Kits and Accessories

Part No Description

003043 Adapter, 9122, 3/4” NPT inlet and outlet

003044 Adapter, 9123, 1” NPT inlet and outlet

MDE-4617 Ast Totalizer Kit, Installation Instructions

MDE-4618 Ast Pulser Kit, Installation Instructions

MDE-4619 Ast Vapor Recovery Kit, Installation Instructions

M07087K001 Ast Pulser Kit; 10:1 Ratio

M07087K002 Ast Pulser Kit; 100:1 Ratio

M07087K003 Ast Pulser Kit; 1:1 Ratio

M07091K001 Ast Totalizer Kit; Gallons

M07091K002 Ast Totalizer Kit; Liters

M07425K001 Ast Adapter Kit; K-version

M07494K001 Ast Vapor Recovery Kit; 9820; K-version

M07494K002 Ast Vapor Recovery Kit; 9820 Vapor Complete

M07494K003 Ast Vapor Recovery Kit; 9120 Vapor Complete

M07494K004 Ast Vapor Recovery Kit; 9120; K-version

Other Options

R18189-10

R18189-30

R18896-G1

026019

030456

030457

C06718 CFN/TOPKT RS-485

C06717 Single Pulse Output

C06722 Dual Pulse Output

C05818 Resistor Assembly

C06683 Resistor Assembly

049043 Vapor Recovery Kit

032600 High Hose Retriever

Filter Type

Extra Length Hoses

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008 Page 35

Page 40

Spirol® is a registered tradema rk of Spirol International Holding Corporation. TopKAT TM is a trademark of Gasboy International. UL® is a registered

trademark of Underwriters Laboratories Inc.

© 2008 GASBOY

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone 1-800-444-5529 · http://www.gasboy.com · Printed in the U.S.A.

MDE-4616B 9120K and 9820K Series AST Pumps Service and Parts Manual · September 2008

Loading...

Loading...