Page 1

Series 580

Installation/Operation/Parts

Manual

MDE-4766

(formerly C35393)

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Changes or modifications not expressly

approved by the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP , 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

5087 8753K, 8853K, 9153K, 9853K

5091 8752K, 9152K

5129 9122K, 9123K, 9822K, 9823K

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

(restricted to diesel and nonretail gasoline sales)

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179 Dispenser

95-136 Dispenser 9800 Series 91-057 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

05-002 Atlas

8700K, 8800K,

9100K, 9200K, 9800K

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2009 GASBOY. All Rights Reserved.

Page 3

Table of Contents

1 – Introduction 1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Intended Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2 – Important Safety Information 3

3 – Installation 7

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Foundation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Suction Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Typical Installation Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Supply Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Base Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 – Wiring 13

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Circuit Breakers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pump Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pulsers and Pulser Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5 – Startup and Operation 19

Pre-startup Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Startup and Pump Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Post Startup Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Meter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Strainer Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Reconfiguration of Pump Pulley for Hand Crank Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6 – Maintenance and Troubleshooting 23

When Your Pump Needs Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Maintaining Trouble-free Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Pump Does Not Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Pump Hums but Does Not Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page i

Page 4

Pump Runs but Does Not Prime or Deliver Product . . . . . . . . . . . . . . . . 26

Pump Delivers Product but Does Not Register. . . . . . . . . . . . . . . . . . . . 26

Pump Delivery is Slow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pump Loses Prime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Inaccurate Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pump Delivers Product When not Turned On. . . . . . . . . . . . . . . . . . . . . 27

Meter Register Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4860 4 - Wheel Register Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 – Parts List 29

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

582/583 Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

582/583 Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

582/583 Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

582/583 Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

582/583 Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pumping Unit Breakdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Model M04920B003 - Pumping Unit Parts List . . . . . . . . . . . . . . . . . . . . 38

582/583 Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

023070 Pipe Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

023079 Pipe W/Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

582/583 Pulser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Hand Crank Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Accessories and Field Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

External Low Flow Filter Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

External High Flow Filter Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Replacement Elements (For both 582 and 583 Models). . . . . . . . . . . . . 43

Pulser Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pumping Unit Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Index Index-1

Page ii MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 5

Purpose Introduction

1 – Introduction

Purpose

The Gasboy® Series 580 Installation/Operation/Parts Manual is provided to assist the installer

in installing and operating the unit. This manual should be supplied to the electrician prior to

the installation of conduit and wiring to ensure that the unit is installed properly. Faulty

installations are the major cause of unit malfunctions. This unit must be installed and operated

as described in the manual to ensure reliable operation. Ensure that you leave this manual with

the pump owner when the installation is complete, as the manual contains unit operating

instructions.

Note: Customers and installers who have questions pertaining to installation should contact

their Gasboy distributor.

Intended Users

This manual in intended for those responsible for the installation of the 580 unit, such as

installers and electricians.

Overview

The Gasboy 580 Series dispensers are heavy-duty suction pumps designed for the needs of

local and state governments, industrial, commercial, and private fleet operations. Important

information regarding 580 Series dispenser is provided below:

• Dimensions: Base 13-31/32-inch (35 cm) x 18-1/16-inch (46 cm), Height 40-1/8-inch

(102 cm).

• Construction: All panels are galvanized steel and painted with a two-part urethane paint

for rust resistance.

• Cabinet Colors: Painted black with red front door.

• Motor: Model 582 - 1/2 HP continuous duty, dual voltage/dual frequency, 115/230 VAC,

• Pump: A durable rotary vane pump with carbon blades is utilized to produce suction

power. Air elimination achieved through a patented static device using a vortex effect.

• Inlet Control Valve: The valve i s provided with the pump and is installed in the upstream

of the pump strainer.

• Register: 4-wheel push-button reset, 7-digit master totalizer, in US gallons or liters.

50/60 Hz

Model 583 - 3/4 HP continuous duty, dual voltage/dual frequency, 115/230 VAC,

50/60 Hz

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 1

Page 6

Introduction Abbreviations and Acronyms

• Meter: Nutating disk phenolic measuring chamber in aluminum die-cast housing,

adjustable calibration

±.5% at full flow.

• Display: Single-sided

• Dial Face: Black with silver stripes highlighting register readings.

• Hose: 582 - 3/4-inch (2 cm) x 12 feet (3.6 m); 583 - 1-inch (2.5 cm) x 12 feet (3.6 m)

• Suction Connection: 1-1/2-inch NPT union provided.

• Delivery Rate: Model 582 up to 15 GPM/57 LPM. Model 583 up to 22 GPM/83 LPM.

Delivery rates are maximum test rates. Actual rates will vary depending upon installation

conditions, product dispensed, and added accessories.

• Nozzle: Must be purchased separately. Automatic nozzles available. Nozzle boot and

®

hook are designed for use with a UL

-listed interchangeable automatic service-station-

type nozzle.

Optional accessories include internal filter adapter, external filter kits, stainless steel cabinet,

manual hand crank, 50 Hz version, 380 V/50 Hz motor, 1:1 or 10:1 pulser, and liter

registration.

Abbreviations and Acronyms

Term Description

CARB California Air Resources Board

CoC Certificate of Compliance

FCC Federal Communications Commission

NCWM National Conference of Weights and Measures

NYFD New York City Fire Department

PC Personal Computer

Warranty

For information on warranty, refer to MDE-4255 Gasboy’s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its

Greensboro location.

Page 2 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 7

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and island.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical po wer to the p ump/

dispenser. This means that even if you activate

these stops, fuel may continue to flow

uncontrolled.

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at 1800-444-5529. It is imperative to your safety and the safety of

others to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or

similar keys.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit (s)

• A total electrical shut-off of the affected unit (s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor injury.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 3

Page 8

Important Safety Information

No Open Fire

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuel vapors. Every time you get out of a vehicle, touch the

metal of your vehicle, to discharge any ele c tro static charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA Lockout/ Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing

devices and compounds are in place. Ensure that you do not

pinch wires when replacing covers. Follow OSHA Lockout/

Tagout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safety while the equipment is down.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

Hazardous Materials

WARNING

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

Lockout/Tagout covers servicing and maintenance of

machines and equipment in which the unexpected

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or other

reproductive harm.

energization or start-up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical hazards.

Page 4 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 9

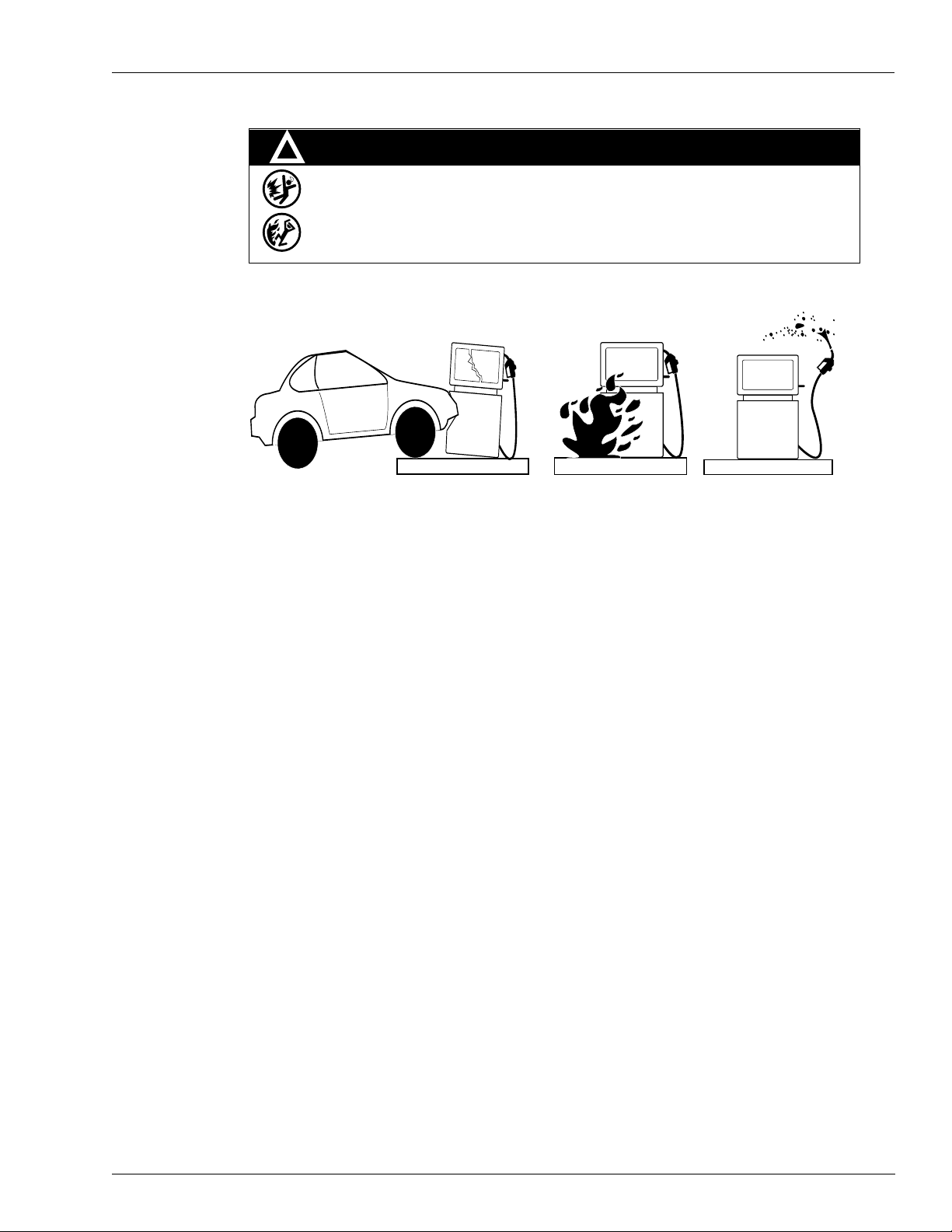

Hazards and Actions

Important Safety Information

!

WARNING

Spilled fuels, accidents involving pump s/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

The following actions are recommended regarding these hazards:

Collision of a Vehicle with Unit Fire at Island Fuel Spill

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. Turn off all system circuit breakers to the

island(s).

• Do not use console E-STOP, ALL STOP and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 5

Page 10

Important Safety Information

This page is intentionally left blank.

Page 6 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 11

Before You Begin Installation

3 – Installation

Before You Begin

Before uncrating the pump, inspect the crate for damage. A damaged crate indicates possible

internal damage to the dispenser, and the delivering carrier should be notified of possible

concealed damage. It is recommended that the original shipping crate be used for any pump

returns.

Installation Precautions

All installations must conform with all building/fire codes, all Federal, State, and Local codes,

National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine Service Station

Code (NFPA 30A) codes and regulations.

Plan your installation carefully. A pump cannot be expected to work satisfactorily unless the

underground installation is correct. Dispensing troubles, which seem to be pump-related, are

frequently traced to faulty installation. Review the following list of installation DOs and

DON’Ts to avoid potential problems:

1 DO read the “Important Safety Information” on page 3. It contains important information

regarding the safe use of your dispensing equipment.

2 DO install an emergency power cutoff. In additio n to circuit breaker requirements of NFPA 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all local codes.

3 DO have the pump installed by a competent installer/electrician familiar with all applicable

local, state and national codes that may apply.

4 DO install breakaway coupling on discharge hose. If using a high hose retriever, install

breakaway approximately 12-inches downstream of hose clamp on nozzle side of clamp.

5 DO NOT experiment with a pump if you are not sure that the installation is correct.

6 DO NOT overload sub or main breaker panels.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 7

Page 12

Installation Foundation

7 DO NOT install any underground piping without proper swing joints (always use shoulder

nipples, never close nipples).

8 DO NOT cover any lines, or UL and code approved flexible pipes approved for the fuels and

application, until they have been both air and liquid tested.

9 DO NOT back-fill the tank or supply line with cinders or ashes (back-fill with clean sand,

crushed rock, or pea gravel).

10 DO NOT use black iron pipe or fittings for underground installations (use only new

galvanized or fiberglass pipe and fittings).

Note: Install all fiberglass pipe and fittings according to manufacturer’s specifications and

requirements.

Foundation

When constructing the pump island for the dispensing equipment, ensure that you extend the

island excavation beyond the depth of the frost line. Leave open an area from the inside edge

of the unit’s base as shown on the specific base layout. Unless required by local regulations,

do not cement the pipes and conduits into the island. The open area within the base will

provide access for future servicing of the fittings and conduit assemblies. Fill in the boxed-in

section with dry sand to keep condensation in the pump housing to a minimum and to help

prevent fogging of the totalizer window.

Secure the pump to the island using anchor bolts through the two mounting holes, which are

indicated on each base layout. If the dispensing unit is not securely fastened to the island,

supply line leaks at unions and pipe joints may occur. Use one of two types of bolts to anchor

the pump to the island. Use two (2) 1/2-inch x 5-inch (13 mm x 125 mm) long machine bolts

embedded in the concrete or to meet minimum UL and API requirements for universal

interchangeability of pumps, use two 1/2-inch x 3-1/2-inch (13 mm x 90 mm) long lag screws

with 2-inch (51 mm) long expansion shields.

Suction Pump

If a pump is to be used with an above-ground tank, a pressure regulator valve (model 52) is

required on the suction side of the pump; consult your Gasboy representative for details. The

tank should be free of water and dirt. It is recommended that the tank be pressure-tested to

verify it is tight.

Note: The outlet fitting at the top of the float chamber should be connected to drain back to

the storage tank. The pipe size for the return line to the storage tank should be at least

3/8-inch (9.525 mm). Ensure that this line is not kinked or reduced in diameter.

Page 8 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 13

Typical Installation Layout Installation

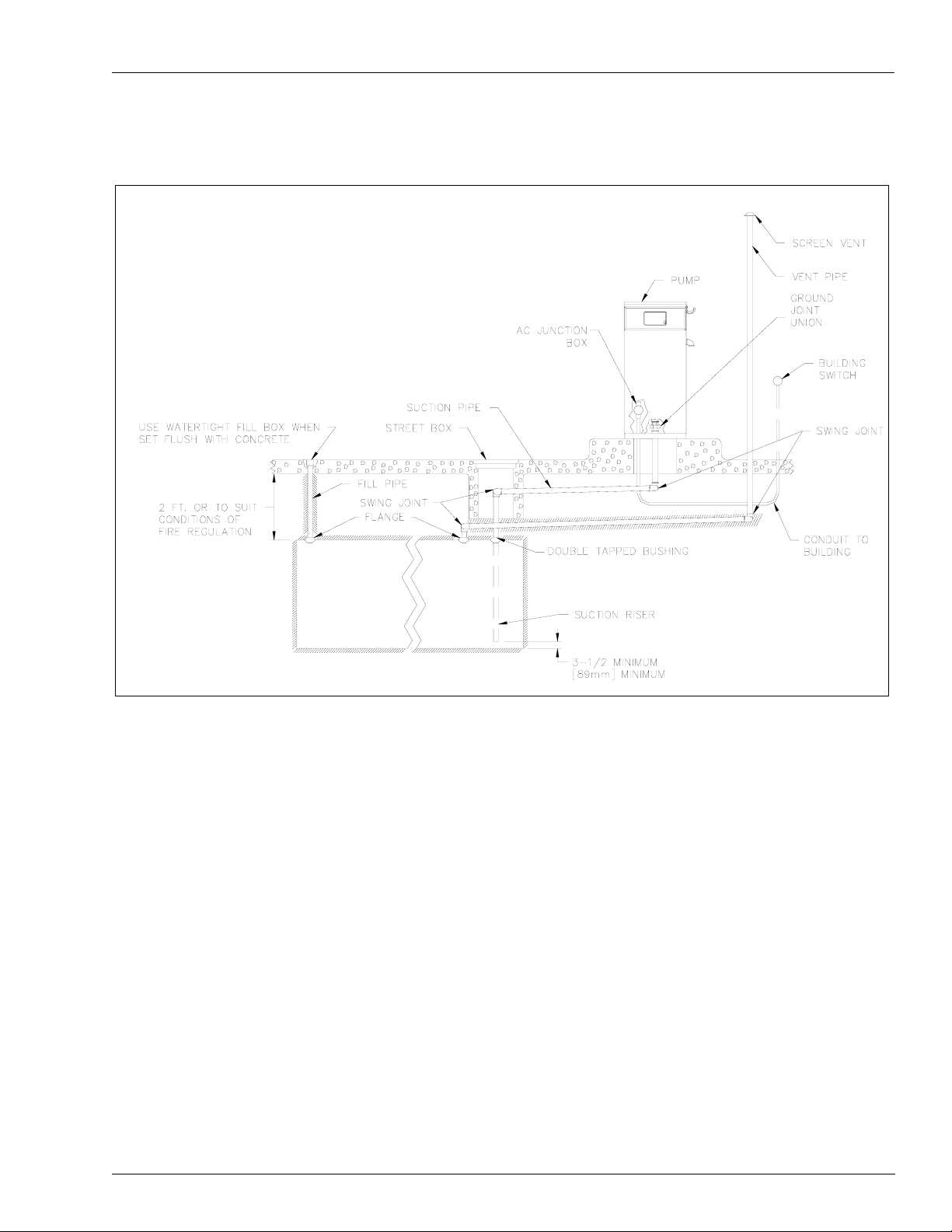

Typical Installation Layout

Supply Line

The pump and the tank should be located close to each other (preferably within 50 feet) with

as few changes in direction of the supply line, as possible. This reduces the possibility of unit

vapor lock (gasoline only), attains the highest possible flow rate, and results in a lower

installation cost. Avoid long supply lines and excessive vertical lifts. The dynamic lift for this

unit is rated at 12 feet (3.66 m) for gasoline and 13 feet (3.96 m) for diesel and can vary

according to conditions of the installation and fuel temperature. To increase maximum flow

rate, attempt to keep the lift as small as possible.

Use new galvanized or fiberglass pipe. The riser should be 1-1/2-inches (38.1 mm) diameter.

Note: Fiberglass pipe is to be installed according to manufacturer’s specifications and

Note: Do not install an in-line

check valve, as the unit

already has an internal

valve.

requirements.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 9

Page 14

Installation Supply Line

Use a 2-inches pipe for standard flow units (excluding the riser) for runs up to 50 feet from the

tank. Use 2-1/2-inches to 3-inches for longer (excluding the riser) runs up to 75 feet. High

gallonage units should use larger pipes such as 3-inches (excluding the riser) for runs up to

50 feet. Use 3-1/2-inches to 4-inches (excluding the riser) for runs up to 75 feet.

Ensure that both the pipe and the tank are clean. Foreign matter entering the pump can cause

extensive damage. Obstructions in the supply line can create pump problems and reduced flow

rate.

Ensure that all pipe threads are properly cut and the inside reamed to remove burrs. Use

UL-listed, non hardening sealing compound suitable for the fluid being dispensed, on all joints

of the fuel handling plumbing. The sealing compound must also be resistant to Gasohol

(Ethanol and Methanol) when used with those fuels. Do not use Teflon Pipe Sealing Tape. Use

the sealing compound on male threads only; pipe compound used on female threads can be

squeezed into the supply line where it can enter the product stream and become lodged in the

pump or meter. Install swing joints or approved flexible pipes under the pump and at the tank

to avoid breaks in the supply line from settling or frost heave.

To avoid product delivery problems on suction pumps, ensure that there are no traps in the

supply line. Supply lines should go straight down beneath the pump to a point 18-inches

(45.7 cm) below the ground level and pitch at a rate of 1/8-inch (3.18 mm) per fo ot (.305 m)

from there down to the storage tank. The supply line should be as short and direct as possible

with swing joints at all turns. Support the horizontal run of pipe at 10 foot int ervals to maintain

pitch and prevent traps. Do not use wood as pipe supports. No additional check valves are

required as the suction pump contains an inlet check valve.

Note: After completion of installation, all liquid-carrying lines must be checked for leaks.

Page 10 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 15

Dimensions Installation

Dimensions

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 11

Page 16

Installation Base Layout

Base Layout

Page 12 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 17

Wiring Precautions Wiring

4 – Wiring

Wiring Precautions

Note: Customers and installers having any questions pertaining to the installation should

contact their Gasboy distributor.

The quality of the electrical installation is a major factor in maintaining proper safety levels

and providing trouble-free operation of your pump. To assure a quality installation, follow

these rules:

1 All wiring must be installed to conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2 Use only threaded, rigid, metal conduit.

3 Use only UL-approved insulated gasoline and oil-resistant stranded copper wiring of the

proper size.

4 W ire connections should be tightly spliced and secured with a wire nut; close off the open end

of the wire nut with electrical tape.

5 The line to the motor should be on a separate circuit and installed on a 20 to 30 AMP breaker

depending on the motor size and/or the voltage setting.

6 Install an emergency power cutoff . In addition to circuit breaker requirements of NFPA 70 and

NFPA 30A, a single control which simultaneously removes AC power from all site dispensing

equipment is recommended. This control must be readily accessible, clearly labeled, and in

accordance with all local codes.

WARNING

To reduce the risk of electrical shock when servicing, turn off and lock out all power to the

pump, including the motor.

7 Qualified electricians who are familiar with installation of this type of equipment must

perform the installation of the pump.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 13

Page 18

Wiring Grounding

Grounding

T o ensure proper operation of the equipment and provide the necessary safety factors, this unit

must be grounded. A ground wire (green or green with yellow stripe) must be connected

between the unit’s AC junction box ground lug and the main electrical service panel. One (1)

earth ground connection is required per unit. The ground rod is to be a solid, corrosionresistant conductor and must be installed on the main electrical panel in accordance with the

National Electrical Code. It should be properly tied into the ground bus strip of the panel. We

recommend the neutral and ground bus strips be bonded together (unless prohibited by local

codes).

Circuit Breakers

Power to the unit must be supplied from a dedicated breaker. No other equipment should be

powered from this breaker. A tag on the motor identifies the maximum current draw of the

motor. If t wo units are supplied from one b reaker , that breaker must be capable of handling the

load of both motors.

Pump Motor

Pumps are shipped from the factory with motors wired according to the specifications given

on the order regarding kind of current, frequency and voltage.

Very often on installation, it becomes necessary to change the original setting to suit the AC

power source. To do this, locate the motor change-over plate (typically located on the shaft

end of the motor) and remove the screw which secures it in place. Slide the plate so that the

desired voltage, as marked on the plate, lines up with the screw hole. Reinsert the screw and

secure the plate in place. 380 VAC pumps are permanently set and cannot be changed.

Many motor failures result from improper setting of the motor change-over plate. If set for

120 VAC and a 240 VAC feed is used, the motor will burn out after running only for a short

time. If set for 240 VAC and a 120 VAC feed is used, the motor will run very slowly and the

starting field will soon burn out.

Models 115 V/60 Hz Units 230 V/60 Hz Units 230 V/50 Hz Units 380 V/50 Hz Units

582 6.8 3.4 4.0 N/A

583 10.6 5.3 6.3 1.5

Note: These numbers do not account for the higher level upon startup.

Motor Amp Ratings

Page 14 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 19

Pulsers and Pulser Wiring Wiring

Pulsers and Pulser Wiring

A pulser is an optional device which is used when external monitoring of the dispensing unit

operation is desired. The pulser transmits one electrical signal (pulse) for each predetermined

amount of fuel dispensed. The signal is received by the external monitor (fuel management

system) which keeps a running total of the quantity of fuel being dispensed during each

transaction.

All Series 580 pulsers are operated with DC voltages. These are reed pulsers which are

available as either 1:1 or 10:1 pulses per unit of measure. The pulser type should be selected

according to the monitoring equipment, the application, and the regulations that must be met.

All Series 580 pulsers are mechanically driven by the register. The shaft which drives the

pulser does not turn during reset.

Conduit

Use threaded, rigid metal conduit or a rigid non-metallic conduit for applications below the

Gasboy Series 580 dispensing unit, to carry electrical wires. If you use non-metallic conduit, it

must be at least 2 feet underground. The last 2 feet of the underground run to the ground

interface must be a rigid metal conduit or threaded steel intermediate metal conduit. Tighten

all threaded conduits. When the Series 580 dispensing unit is used with a Gasboy Fuel

Management System, it is recommended that AC power wires be installed in a separate

conduit from the DC pulser; they should not run in any sort of common conduit or trough.

However, if AC and DC power wires share conduit, pulser wiring must use the cable as

specified in the Pulsers section.

When using a fuel management system other than a Gasboy system, see the manufacturer’s

installation manual for specific conduit requirements.

All wiring and conduit runs must also conform with the National Electrical Code (NFPA 70)

and the Automotive and Marine Service Station Code (NFPA 30A). All wiring and conduit

runs must conform to local codes. Canadian users must also comply with the Canadian

Electrical Code.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 15

Page 20

Wiring Conduit

Use the charts below as a guideline to determine the proper conduit sizes. When planning the

orientation of the wiring runs, follow the applicable Gasboy wiring diagram and consider the

layout of the components at the site. Long runs or a large number of bends may require you to

increase conduit size over what is listed, to aid in pulling wires through the conduit.

To determine conduit size needed, use the THHN/THWN Wire Areas table (left) to find the

area for each wire gauge. Add up all wire areas. Use the Areas of Trade Size Conduit Table

(right) to select the smallest number in the 25% fill area (based on NEC 501-1) that comes

closest without exceeding the total wire area.

Notes:1) Pulling of spare wires is highly recommended should wire damage occur at a later

date.

2) All wiring and conduit runs must conform with all building/fire codes, all Federal,

State, and Local codes, National Electrical Code, (NFPA 70), NFPA 30, and

Automotive and Marine Service Station Code (NFPA 30A) codes and regulations.

3) Some motors contain a brown wire (Switch Detect) which is capped at the factory.

When used, it connects to a solenoid valve or fuel management system. Do not connect

this wire without first checking the ON voltage of this line to ascertain compatibility

with the equipment being connected.

4) All wiring must be installed according to the requirements outlined in this section.

Page 16 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 21

Wiring Diagram Wiring

C

e

otor

230

Sing

oto

380

C

T

ase

otor

Wiring Diagram

115 VAC Wiring

115 VA

Single Phas

M

230 VAC Wiring

M

VAC

le Phase

r

380 VAC Wiring

VA

hree Ph

M

Pulser Wiring

Note: This diagram is for domestic (U.S.) installations. For Canada

and other locations refer to local requirements for circuit

breaker wiring.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 17

Page 22

Wiring Wiring Diagram

This page is intentionally left blank.

Page 18 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 23

Pre-startup Checklist Startup and Operation

5 – Startup and Operation

Pre-startup Checklist

The information below should be reviewed to help verify the proper installation of your

Gasboy pump. If the installation does not meet criteria listed, as well as any Federal, State, and

Local codes and requirements, correct the problem before powering on the unit.

1 The unit must be properly secured.

2 All plumbing must be complete and tight. All below ground piping must be checked for leaks.

All liquid carrying lines must be checked for leaks.

3 When DC pulsers are used in the pump, the AC and DC wires must not share any conduits,

junction boxes, or troughs.

4 All conduit work must be complete. All junction box covers must be secured with all

fasteners. Conduit seals should not be sealed until the wiring is verified through proper

operation.

5 The unit must be properly grounded.

6 Before any testing begins, remove any water in the tank through a fill opening, using a suitable

pump. Do not use the Gasboy pump to remove water. Serious damage may occur.

7 A sufficient volume of fuel must be present in the tank to ensure that the liquid level is above

the bottom of the suction pipe.

Startup and Pump Operation

Note: In order to provide the highest level of safety to you, your employees, and customers, it

is recommended that all employees be trained r ega rding the location and procedure for

turning off power to the entire system.

After successfully verifying the installation against the pre-startup checklist, the unit is ready

for startup. Follow the procedure listed below to perform an orderly start-up.

1 Turn on the circuit breaker for the pump.

2 Remove the nozzle from the boot.

3 On the right side panel, pull out the switch rod and knob assembly. This will turn on the motor

and activate the pump.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 19

Page 24

Startup and Operation Post Startup Tests

4 Push the reset button to zero the register.

5 Dispense fuel. Check all plumbing for leaks at this time.

6 Push the switch rod and knob assembly in to shut off the pump motor. Open the nozzle. No

fuel should be dispensed. The amount delivered should be displayed on the register. If an

optional pulser kit is attached, it will be supplying pulses which may be recorded by an

external monitoring system. Verify if the external monitoring system is reading properly.

7 Repeat steps 3 through 6 several times to ensure that the pump is operating satisfactorily.

Post Startup Tests

Voltage

The incoming voltage to the pump should be checked and any reading not within 10% of rated

voltage should be corrected before testing is continued. When dealing with suction pumps, it is

a good practice to note down voltage readings while the suction pump is operating on bypass

(turned on but not dispensing product) and also while making a delivery. Any voltage drop in

excess of 10% during either of these operating states should be considered a low voltage

condition. Corrective action should be taken to ensure adequate power supply to the pump.

Tightness

After determining that the pump is operating satisfactorily and the system is fully primed,

check the pump and piping to make sure that all connections are tight.

Meter Calibration

The 580 Series Pump is adjusted for accurate measure of the specified fuel (gasoline or diesel)

within +.05 gallons at the factory. However, since the conditions of the installation can affect

pump accuracy, it is the responsibility of the installer to check the pump for accuracy and

make any needed adjustments.

Choose the flow rate at which the meter will be used most often for the zero calibration point.

For example, if the pump is being used with an automatic nozzle, calibrate with the nozzle set

on the middle or top notch position, whichever is used most frequently.

Use a certified seraphin can to conduct the test. Fill and drain the test measure to completely

wet the interior surfaces. Reset the register to zero and deliver an exact amount into the test

can at the selected flow. Read the level of the liquid in the sight glass on the scale in + cubic

inches.

The calibration adjustment screw is located on the underside of the meter just behind and to

the left of the meter inlet. Using a flat-blade screwdriver , turn the adjusting screw clockwise to

correct for plus cubic inches or counterclockwise for minus cubic inches in the test measure.

Count the number of full turns and fractional turns each time for reference in judging the

number and direction of any additional turns required to calibrate the meter to exact zero.

Page 20 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 25

Reconfiguration of Pump Pulley for Hand Crank Operation Startup and Operation

Strainer Cleaning

Clean the strainer immediately after the pump has been installed and tested, and again after a

few hundred gallons have been delivered. Thereafter, once every six months, or as required.

The procedure for cleaning the strainer can be found in the Maintenance and Troubleshooting

section.

Belt

Since belts do stretch slightly during the first few minutes of operation, check the belt tension

after completing the operational test. See the Maintenance and Troubl esho oti ng section for

details.

Reconfiguration of Pump Pulley for Hand Crank Operation

1

2

3

4

Before a hand crank can be used to pump fuel, you must reconfigure the pump pulley as

follows:

1 Unscrew and remove the screw (4), lock washer (3), washer (2), and pump pulley (1).

2 Flip the pump pulley (1) around so the shorter groove at the back is exposed at the front end.

3 Replace the pump pulley (1), washer (2), lock washer (3), and screw (4) and tighten the screw.

4 Engage the hand crank belt to the shorter groove.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 21

Page 26

Startup and Operation Reconfig ur ation of Pump Pulley for Hand Crank Operation

This page is intentionally left blank.

Page 22 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 27

When Your Pump Needs Service Maintenance and Troubleshooting

6 – Maintenance and Troubleshooting

When Your Pump Needs Service

When your pump needs service, follow these guidelines:

• Procedures requiring disassembly of portions of the pump should be performed by

competent service personnel. Gasboy has a distributor network which services fuel

dispensing equipment in every part of the country.

• Turn off all power to the pump to reduce the risk of electrical shock when servicing

(including changing of fuel filters or strainers). Also block islands so that no vehicles can

pull up to the pump when it is being worked on.

• Replace worn, rusted, or corroded parts immediately with new authorized service parts

supplied by Gasboy. Replacing parts with incorrect or substandard substitutes will result

in unsatisfactory pump operation. Always use new gaskets or seals when servicing or

rebuilding Gasboy equipment; do not re-use old ones. Using authorized parts will ensure

the continuity of the Underwriters’ Label on your pump.

“Parts List” on page 29 lists parts and service procedures for the 580 Series. Using part

numbers when ordering will expedite your order and reduce the possibility of the wrong

parts being shipped.

The remainder of this section contains troubleshooting information and assembly/disassembly

procedures for various components that may need service.

Maintaining Trouble-free Operation

• Operate with Reasonable Care: Like any machine, the pump or remote dispenser that is

operated with reasonable care will last longer and give better service. Abuse should be

avoided (such as dropping the nozzle on the ground, operating the unit with a dirty

strainer, dragging the hose across the concrete island or driveway, running the pump with

the nozzle closed for more than two minutes and so on). The time and care given to your

pumps will be returned to you in the form of dependable service.

• Remove Water from Tank: After every fill-up, check your tanks for water. Water can

accumulate in both underground and above ground storage tanks due to condensation or

defective fill openings that are not properly protected with watertight covers. Remove any

water with a sump pump to forestall serious damage to equipment. Water, sediment, and

other foreign matter that accumulates in the tank can be drawn up into the pump and cause

failures.

• Clean the Dial Face: Use a soft, clean, damp cloth as needed.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 23

Page 28

Maintenance and Troubleshooting Maintaining Trouble-free Operation

• Filter: If the unit is equipped with a filter, check and change it at regular intervals. A dirty

filter in a pump or remote dispenser will cause a slower delivery rate. Refer to the

accessories section of your parts manual to ensure that you replace the filter with one

designed for your model. Always use a drip pan directly below the filter when removing

the cartridge to prevent contamination of both the soil and the electrical components

within the cabinet.

• Clean the Strainer: Clean the strainer immediately after the pump has been installed and

tested, and again after a few hundred gallons have been delivered. Thereafter, once every

six months, or as required. The symptoms of a dirty or clogged strainer in a pump are slow

delivery, noisy operation, and pulsation.

Note: This procedure should be performed only by an authorized Gasboy distributor or

installer.

To clean the strainer, proceed as follows:

1 Turn off and lock out AC power to the pump.

2 Unthread the drain plug located near the bottom of the strainer (marked “Filter”) cap. Ensure

that you use a container of sufficient capacity to catch the fuel as it drains from the pump.

3 Loosen the four bolts that hold the cap in place.

4 Carefully remove this cap which holds the spring, strainer, and inlet check valve assembly in

place.

5 Use compressed air to blow the dirt from the strainer. Always wear protective safety goggles

or glasses when using compressed air.

6 Replace the inlet check valve, strainer , and spring and reinstall the strainer cap. Ensure that the

O-Ring that seals the cap is installed properly before tightening the bolts.

7 Reinstall the drain plug using sealing compound approved for this application.

• Lubrication: Lubricate the start/stop linkage. Apply one drop of oil (SAE10) at each

pivot point of the start/stop linkage every six months.

• Adjusting the Belts (Suction Pumps Only): With proper care, belts will give

exceptionally good service. A loose belt not only cuts down dispensing speed due to

slipping, but also results in excessive wear. A properly tightened belt will allow twisting

the belt 180 degrees midway between the motor and the pump pulleys. Before adjusting

any belt, turn off AC power to the pump/remote dispenser.

The belt can be tightened by loosening the hex nut which holds the idler pulley and sliding

the pulley to the side to obtain the correct belt tension of 6-3/4 lbs. + 3/4 (30N, +3.3N).

When the adjustment is complete, remember to retighten the hex nut.

• Preserve the Finish of Your Pumps: Nearly all gasoline pumps are installed outdoors

where their surfaces are subjected to the action of the weather. As a result, it is necessary

to give the finish a reasonable amount of care if an attractive appearance is to be

maintained.

Page 24 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 29

Troubleshooting Maintenance and Troubleshooting

The finish on Gasboy pump housings is a high-heat baked synthetic enamel, similar to that

used on automobiles. The life of this finish can be lengthened several years if, at regular

intervals, the painted surfaces are thoroughly cleaned with a high grade automobile polish

and then protected with a coat of paste wax. Do not use abrasive cleaners or polish. Do not

use high pressure spraying equipment.

In order to retain the unmarked finish on stainless steel, occasional cleaning is required. In

corrosive atmospheres, such as coastal areas, a more frequent cleaning schedule is

necessary. Under ordinary conditions, washing with deter gent or soap and water, followed

by a clean water rinse, is sufficient. If hard water is used, the surface should be wiped dry

with a soft clean cloth to prevent the formation of water spots. Marks or spots, such as

grease, oily fingerprints and smudges which resist soap and detergents, will have to be

removed with a stronger cleaner. (DO NOT use ordinary steel wool as iron particles may

adhere to the surface and cause corrosion). Care should be taken in choosing a cleaner

because any cleaning compounds or powders which contain abrasives can scratch a millrolled finish. Care must be exercised in their use to run in the direction of the polishing

lines in the steel, never across them. After cleaning, an application of paste wax is

recommended to protect the surface and prolong the interval between cleaning.

Troubleshooting

If problems are encountered in operation of the pump, follow the procedures below in an

attempt to isolate the problem.

Pump Does Not Start

Is the breaker at the panel turned on?

Is there power at pump? Check at junction box. Voltage cannot be below 104 V on a

115 V pump; 204 V on a 230 V pump.

Is motor overheated (thermal switch cutoff)? Be careful, the external motor surface could

be hot enough to cause injury. Let cool and re-try.

Replace motor if above checks do not solve the problem.

!

Pump Hums but Does Not Start

Is voltage adequate? Check voltage with pump on bypass with nozzle closed. Voltage

cannot be below 104 V on a 115 V pump; 204 V on a 230 V pump.

Check pump drive shaft for free operation.

Replace motor if above checks do not solve the problem.

!

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 25

Page 30

Maintenance and Troubleshooting Troubleshooting

Pump Runs but Does Not Prime or Deliver Product

Is there fuel in the tank?

If register is recording but no product is being dispensed, you may have a supply line air

leak.

Check for an air leak on suction side of pump. Is check valve seated properly?

Reassemble and prime pump using liberal quantity of motor oil in pump cavity; if it

primes, run pump full flow and snap nozzle closed; shut off motor and check for leak on

suction side of pump above check valve. Any observed liquid leakage would indicate an

air leak when pump is running with nozzle open and would prevent priming when pump

was empty.

Is there an air leak in the suction line below check valve. Make accuracy check using 5

gal Seraphin test can. Any clock fast error (refer to “Inaccurate Delivery” on page 27) in

excess of 2-1/2% indicates an air leak in the suction line. The most common source of an

air leak in the suction line is the union - check union for alignment and tightness before

checking balance of suction line. If pump does not prime using oil, suction line is

blocked or has a severe air leak.

Pump Delivers Product but Does Not Register

Is main totalizer recording? If yes, problem is in the register assembly. Check to ensure

that the reset mechanism is working properly. Reset button should return fully to its

original position after being pressed. The reset lever (that is activated by the reset button)

should also return to its original position.

If the main totalizer is not working, the problem could be a broken/jammed measuring

chamber or a jammed pulser drive. If the unit has a pulser, check to ensure that the pulser

drive operates freely. Excessive drag exerted by this assembly will lock up the register

and totalizer.

Pump Delivery is Slow

Check for dirty strainer.

If pump has a filter, change filter.

Check for supply line restriction by testing the pump with a vacuum gauge. If vacuum is

abnormally high, there is a restriction.

Pump Loses Prime

Inspect check valve poppet and seat for clean mating surfaces.

If, after a period of non-use, a pump delivers product initially, followed by air and then

full flow, there is an air leak in the suction line.

Install pressure gauge between hose and nozzle. Operate pump at full flow. Snap nozzle

closed and turn off pump. If pressure falls to zero rapidly, replace check valve and clean

and inspect valve seat.

Page 26 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 31

Meter Register Disassembly Maintenance and Troubleshooting

Inaccurate Delivery

Calibrate the meter (refer to “Wiring” on page 13).

A clock-fast error (more on the register than is delivered) in excess of 2.5% is due to air in the

suction line or vaporization of gasoline in the pump. Check pump for loss of prime and suction

line for air leak.

A clock-slow condition may result from: any slowing of the register or measuring chamber

due to excessive friction resistance or mechanical failure; inadvertent bypassing of the

measuring chamber. Check register for zero setback; check reset lever return to top of slot in

meter cover after setback; check for “hang-up” of number wheels in register or gears not

meshing.

Pump Delivers Product When not Turned On

In above ground storage tank, if fluid level is higher than pump, positive head pressure

may force product through pump. Install a pressure regulating valve or a solenoid valve

in the supply line to the pump.

Meter Register Disassembly

The B size measuring chamber can be removed for cleaning by taking out four meter body

screws, lifting off register assembly and removing three measuring chamber screws. After

separating and cleaning top and bottom half, reassemble, making sure baffle is seated in

grooves in top and bottom halves and through slot in measuring disc. Do not drop or sharply

strike chamber parts while handling. Rotate disc to make sure it turns freely and replace in

meter body. Do not overtighten screws. A torque of 20-25 ft-lbs is sufficient. When

reassembling register to meter body, use a new O-Ring.

4860 4 - Wheel Register Service

Note: Numbers in parentheses correspond to the numbers shown on the parts illustration and

parts list in

Replacing the Bearing and Seal Assembly

To replace the bearing and shaft seal assembly, or service the gear train on back of register

housing, remove housing from meter by taking out four screws.

Note: The meter housing will be full of liquid so some means should be available to catch

what drains from the case and lines.

“Parts List” on page 29 labeled 4860 4 - Wheel Register.

To remove gears, remove three retaining rings and drive key. Withdraw the drive shaft and

gear, spacer, and all parts of bearing and seal assembly. Remove the nylon washer from item

26 and note its location. Remove both oilite bearings and both

O-Rings from bore in register housing. Using new parts, which consist of a new nylon washer,

two oilite bearings, and two O-Rings, reassembly parts in reverse order. Ensure that you

lubricate both O-Rings with an O-Ring lubricant before assembling.

Reassemble gear train in following sequence: gear, key, cluster gear, retaining ring, control

block, and retaining ring.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 27

Page 32

Maintenance and Troubleshooting Meter Register Disassembly

This page is intentionally left blank.

Page 28 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 33

General Parts List

7 – Parts List

General

This section lists parts information for the Gasboy 580 Series pumps. Using part numbers

when ordering will expedite your order and reduce the possibility of the wrong parts being

shipped.

Procedures requiring disassembly of portions of the pump should be performed by competent

service personnel. Do not depend upon the repair service of a general mechanic unless he is

thoroughly familiar with the mechanism. Gasboy has a distributor network which services fuel

dispensing and management systems in every part of the country.

WARNING

To reduce the risk of electrical shock when servicing, turn off and lock out all power to the

pump. Always turn off and lock out all power to the pumps at the master panel before

performing maintenance or service, including the changing of any fuel filters or strainers.

Also block islands so that no vehicles can pull up to the pump while it is being worked on.

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 29

Page 34

Parts List 582/583 Front View

582/583 Front View

See Detail “A”

9

1

2

3

4, 5

6

7

10

118

Detail “A”

Item Description Part Number

1 Cover-Top Painted (See Note) 042206

Cover-Top SS 042207

2 Bezel-580 (also specify standard Gasboy silk-screen, below) 012328

Silk-screen, Standard *029703

3 Dial Glass-580 028650

4 Grommet, 1-inch 028960

5 Discharge Elbow, 1-inch 024895

6 Reducer Bushing, 1 x ¾, 582 Only 017278

7 Door-Front-Painted, 580 (See Note) 024581

Door-Front-SS, 580 024852

8 Panel-Side Right Painted (See Note) 041386

Panel-Side Right SS 041393

9 Panel-Side Left Painted, 580 (See Note) 041385

Panel-Side Left SS, 580 041391

Page 30 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 35

582/583 Side View Parts List

Item Description Part Number

10 Plate 045804

11 Grommet 058021

Note: Painted standard Gasboy colors unless otherwise specified. Refer to

“Introduction” on page 1 for details on standard colors.

582/583 Side View

1

2, 7

3

4, 5

6

Item Description Part Number

1 Hook Hose 003740

2 Boot Nozzle 003338

3 Panel Rear Painted, 580 (See Note) 030847

Panel Rear SS, 580 041394

4 Switch Rod and Knob Assembly 033007

5 Bushing, Switch Rod 017123

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 31

Page 36

Parts List 582/583 Chassis

Item Description Part Number

6 Hook-Nozzle Mach. 003700

7 Gasket-Nozzle Boot 026850

Note: Painted standard Gasboy colors unless otherwise specified. Refer to

“Introduction” on page 1 for details on standard colors.

582/583 Chassis

1

10

8

2, 3

4

5 See Detail “A”

6

7

8

13

12

Detail “A”

11

11

9

14

Page 32 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 37

582/583 Chassis Parts List

Part

Item Description

1 Pulser Assembly, CX (See Breakdown for parts) 023062

2 Meter Register, Gallon with Pulser 036326

Meter Register, Liter with Pulser 036327

Meter Register, Gallons 036328

Meter Register, Liters 036329

Meter Register, Liters 029706

3 Dial Mask (Must specify liters {029702}, Liters

{029704}, Liters {029706}, Gallons {029705}, or

Gallons {029708})

4 Plate 023869

5 Discharge Assembly 023088

6 Motor Assembly (See breakdown for your model) 7 Pump Assembly (See breakdown for your model) 023083

8 Column Brace 015797

9 Base 011902

10 Pipe Assembly (See breakdown for your model) 11 Gasket 027055

12 Spacer Plate, Meter Register 023077

13 Elbow Flange 003560

14 Discharge Pipe 044016

Number

035217

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 33

Page 38

Parts List 582/583 Motor

582/583 Motor

See Detail “A”

1

15

18

16, 3

3

17

4, 532

6

7, 8

10

11

10

12

13, 14

Detail “A”

22

21

Item Description Part Number

1 Bracket-Motor Support 023072

2 Motor, Franklin, 3/4HP, DF, CW, 61FR, Model 583 only F37609

Motor, Franklin, 3/4HP, 61FR, Model 583, 380 V option only F37320

Motor, Franklin, 1/2HP, DVDF, CW, 61FR, Model 582 only F37630

3 Cotter Pin, 1/16 x 1/2 042430

4 Pulley, 5/8 Bore, 2-3/4, 583 50 Hz 047006

Pulley, 5/8 Bore, 2.4, 583 60 Hz 047005

Pulley, 5/8 Bore, 1-3/4, 582 60 Hz 047203

Pulley, 5/8 Bore, 2.0, 582 50 Hz 047204

5 Key 031315

19

Page 34 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 39

582/583 Motor Parts List

Item Description Part Number

6 Conduit, Motor to J-Box 023075

7 Rod-Motor Bracket 023093

8 Cotter Pin, 3/32 x 3/4 042355

9 Pulley-Idler 047009

10 Belt, 4L400-A38, 583 012121

Belt, Tri-Power, V-AX37, 582 012133

11 1/2-inch UNY Explosion Proof Conduit Union 066400

12 Bracket, Junction Box 023074

13 Junction Box Machining 003337

14 Junction Box Cover, Machining 003461

15 Bracket-Motor Support 015458

16 Pin-Rod End 042145

17 Rod End 050250

18 Rod-Switch Handle 051209

19 Bracket, Support 017001

20 Switch Arm 017002

21 Rod Switch 023096

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 35

Page 40

Parts List 582/583 Pump

582/583 Pump

7

3

12, 13

9

1

6

8

14

5

10 15

Item Description Part Number

1 Pumping Unit M04920B003

2 Union, 1-1/2-inches K12179

3 Fitting, E1, 3/8 Flare X 1/4 NPTM 026038

4 Pump Support Plate 023071

5 Inlet Adapter 023146

6 O-Ring, 2.237 X 0.103 Q10067-31

7 Tube Air Vent M08687B001

8 Screw, Tap 1/4-20 X 5/8 Long K85736-39

9 Screw, M6 X 20 M04973B001

10 Bolt, M8 X 1-25 X 20 mm Q11106-06

11 Nipple, 1 1/2 X 1-3/4 Long R11493-77

12 Outlet Flange 023092

13 O-Ring 1-1/8 X 1-3/8 X 1/8 Q10068-07

14 Motor Support Bracket 014565

15 Screw, M10 X 20 Long M04973B004

16 Gasket, Seal Suction 054190

11

4

2, 16

View A - A

Page 36 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 41

Pumping Unit Breakdown Parts List

Pumping Unit Breakdown

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 37

Page 42

Parts List Pumping Unit Breakdown

Model M04920B003 - Pumping Unit Parts List

Notes:1) Parts listed in the following table are not available for individual purchase. Repair

kits may be purchased. Refer to “Accessories and Field Kits” on page 43.

2) Refer to “Adjustable Bypass Parts Breakdown” on page 39 for additional parts and

graphics.

Item Part Description Quantity Item Part Description Quantity

1 Body (non-reverse float) 1 31 Seal, Lip (with plug) 1

Body (reverse float) 1 32 Seal, Retainer 1

2 Blade, Rotor 6 33 Seal, Square 1

3 Clamp (refer to note 1) 1 34 Rotor and Shaft Assembly 1

4 Connector, Male 1 19 Key 1

5 Cover, Atmos. Chamber 1 35 Ring, Retaining 1

6 Cover, Bypass Valve 1 36 Screw (refer to no te 1) 1

7 Cover, Control Valve 1 37 Screw, M8 1.25x15 mm 1

8 Cover, Filter 1 38 Screw, M8 1.25x20 mm (refer to note 1) 9 Float, Non-Reversing 1 39 Screw, M8 1.25x25 mm 24

11 Gasket, Atmos. Cham. Cover 1 40 Screw, M6 1x20 mm 6

12 Gasket, Bypass Valve 1 41 Separator & Air Eliminator 1

13 Gasket, Clamping Ring 1 42 Sleeve, Tube (refer to note 1) 1

14 Gasket, Control Valve Cover 1 43 Spring, Control Valve (H.D.) 1

15 Gasket, Filter Cover 1 44 Spring, Filter 1

16 Gasket, Inlet (Separator) 1 45 Stator, H.D. 1

17 Gasket, Outlet (Separator) 1 46 Stop, Filter Insert 1

18 Insert 1 47 Strainer Assembly-149 micron 1

19 Key 1 Strainer, 70 Micron 1

20 Nut, Tube (refer to note 1) 1 Paper Filter (not shown) 1

21 Nut 1 48 Tube, Vent Assy- 9024 (refer to note 1) 2

22 O-ring 1 Tube, Vent Assy- 9033 & 9036 3

23 Plug, Pipe 1/4-inch 2 Tube, Vent Assy- 9044 & 9048 4

24 Pulley 1 49 Valve Assembly, Bypass 1

25 Ring, Throw Out (H.D.) 2 50 Valve Assembly, Control 1

26 Ring, Clamping 1 51 Valve, Relief 30-50 psi 1

27 Ring, Retaining 1 52 Valve Assembly, Float 1

28 Rotor Support Assembly 1 53 Washer 1

29 Cover, Rotor 1 54 Washer (refer to note 1) 2

30 Screw, M3.5 Flat Hd 3 55 Washer, Lock 1

Notes:

1. Not part of the pumping unit.

2. Current pumping unit use a 10-blade assembly. If you have a 6-blade rotor assembly, you can replace blades, but the

replacement rotor assembly uses a 10-blade design. When you need to replace the blades, it ia also recommended that you

replace 6-blade rotor assemblies with a 10-blade rotor assembly for quieter operation and better performance.

Page 38 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 43

582/583 Piping Parts List

Adjustable Bypass Parts Breakdown

60

61

Item Part Description

58 Nut

59 Screw - Adjustable

60 Cover

61 Gasket - screw

582/583 Piping

58

2

5

59

1

3

8, 10

5

1

2

3

4

4

9

023070 Pipe 023079 Pipe W/Filter Assembly

6

7

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 39

Page 44

Parts List 582/583 Piping

023070 Pipe Assembly

Item Description Part Number

1 Gasket-Inlet/Outlet 027055

2 Flange-Meter Inlet 015496

3 Flange Plate-Meter Inlet 015495

4 Piping-Pump Outlet 015497

5 O-Ring 023091

023079 Pipe W/Filter Assembly

Item Description Part Number

1 Gasket-Inlet/Outlet 027055

2 Flange, 1-inch 003650

3 Pipe TBE, 1 x 3 044525

4 Elbow, 1-inch x 90 024895

5 Pipe TOE, 1 x 4 045235

6 Adapter, 1-inch Cimtek 400

Filter

7 Coupling Nipple, 4-3/4 015498

8 Elbow, Dresser 1 x 90 024910

9 Pipe TOE, 1 x 2-1/2 045218

10 Dresser Elbow Seal, 1-inch 054207

003087

Page 40 MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009

Page 45

582/583 Pulser Parts List

582/583 Pulser

2

3

4

5

1

6

1

10, 9

7

8

Item Description Part Number

1 Cotter Pin, 3/64 x 1/2 042290

2 Elbow-Conduit, ½ x 90 M/F 025045

3 Cable Assembly, Pulser Drive 023089

4 Pulser, 10:1, VR 021788

5 Bracket-Pulser 015919

6 Conduit, J-Box Pulser 014031

7 1/2-inch UNY Explosion Proof Conduit Union 066400

8 Bracket, Junction Box 023074

9 J-Box Machining 003340

10 J-Box Cover Machining 003515

MDE-4766 Series 580 Installation/Operation/Parts Manual · April 2009 Page 41

Page 46

Parts List Hand Crank Assembly

Hand Crank Assembly

17

2

1

9

21

13

This view shown

without pulley

bracket

To Pumping Unit

Item Description Part Number

1 Screw, 5/16-18 x 1/2 Hex Washer 053910

2 Bearing-Pltd Assembly 030803

3 Housing/Bearing Assembly 030024

4 Shaft, Drive 055007

5 Pulley, 5-1/4 x 3/4-inch bore 047015

6 Screw, 1/4-20 x 5/8 Sq. Head Set

Cad Case Hardened

7 Bushing, Hand Crank 017130

8 Bracket, Pulley 014864

9 Belt, 4L230, A21 012166

10 Screw, 5/16-18-3/4 HHC Pl 051895

11 Washer, Std. Spring Lock, 5/16 068875

12 Washer, 5/16-18 x 1/2 068080

13 Belt, 4L460-A44 012177

14 Pulley, 2-inch x 5-inch Bore 048709

15 Screw, Set 5/16-18 x 1/2 052010

16 Shaft, Drive 055005

17 Hand Crank Assembly 023139

Front

1

1

Rear

8

053731

5

1

5

2

Detail “B”

3

5

4

7

16

5

5

See Detail “B”

15

3

14