Page 1

SERIES 552A/553A

COMMERCIAL PUMPS

INSTALLATION/OPERATION/PARTS

MANUAL

035299

REV. 03/07/03

INSTALLERS - IMPORTANT

In addition to installation information, this manual contains warnings, safeguards

and procedures on the use and care o f the Series 550A pumps. Please leave this

manual with the pump owner after the installation is complete.

The information in this document is confidential and proprietary. No further disclosure shall be made without

permission from Gasboy International LLC. Gasboy International LLC believes that the information in this document

is accurate and reliable. However, we assume no responsibility for its use, nor for any infringements of patents or

other rights of third parties resulting from its use. We reserve the right to make changes at any time without notice.

Copyright 2003 by Gasboy International LLC All rights reserved.

GASBOY INTERNATIONAL LLC LANSDALE, PA

Page 2

IMPORTANT WARNINGS AND SAFEGUARDS

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to th e enti re system. Instru ctions

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

DO NOT use Teflon tape for any pipe

threads in the product.

DO NOT use consumer pumps for

pumping fuel or additives into aircraft.

DO NOT use commercial pumps for

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT use where sanitary design is

required (for food products for human

consumption) or with water-based

liquids.

DO NOT smoke near the pump or when

using the pump.

DO NOT use near open flame or

electrical equipment which may ignite

fumes.

DO NOT permit the dispensing of

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT permit the dispensing of

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

includin g trucks. All contain ers must be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT block open the nozzle in any

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO ensure that the pump is equipped

with proper filters based on the product

being dispensed and its intended use.

DO wear safety goggles and protective

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO keep all parts of body and loose

clothing clear of belts, pulleys, and other

exposed moving parts at all times.

OF A FUEL SPILL.

DO require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO provide a receptacle for catching

product from pump/meter when

servicing.

DO clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO insure pump is properly grounded.

DO insure hose is compatible with fluid

being dispensed.

DO inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

035282 Rev. 1267

GASBOY INTERNATIONAL LLC.

707 North Valley Forge Rd. Lansdale, PA, 19446 ● (215) 855-4631 ● FAX: (215) 855-0341

Page 3

CONTENTS

IMPORTANT WARNINGS AND SAFEGUARDS

Section 1: INTRODUCTION

Purpose..................................................................................................... 1-1

Overview ................................................................................................... 1-1

Section 2: INSTALLATION

Before You Begin...................................................................................... 2-1

Installation Precautions............................................................................. 2-1

Foundation ................................................................................................ 2-2

Suction Pump............................................................................................ 2-2

Installation Layout ..................................................................................... 2-3

Supply Line................................................................................................ 2-4

Connecting the Suction Pipe................................................................ 2-4

Base Layout - 011982............................................................................... 2-5

Section 3: WIRING

Wiring Precautions.................................................................................... 3-1

Grounding ................................................................................................. 3-1

Circuit Breakers......................................................................................... 3-2

Pump Motor............................................................................................... 3-2

Wiring and Conduit.................................................................................... 3-2

Pump Wiring......................................................................................... 3-2

Pulser Wiring........................................................................................ 3-3

Conduit................................................................................................. 3-3

Wiring Notes.............................................................................................. 3-4

Wiring Diagram - 024206 .......................................................................... 3-5

Section 4: TESTING AND OPERATION

Testing the Installation .............................................................................. 4-1

Operating Instructions............................................................................... 4-1

Section 5: MAINTENANCE AND TROUBLESHOOTING

General ..................................................................................................... 5-1

Exterior Maintenance ................................................................................ 5-1

Lubricating the Pump’s Components ........................................................ 5-2

Cleaning the Strainer................................................................................. 5-3

Calibrating the Meter................................................................................. 5-3

Correcting Meter Drive Shaft Leak............................................................ 5-3

Adjusting the Belts..................................................................................... 5-4

Troubleshooting......................................................................................... 5-5

Preparing Used Pumps for Storage .......................................................... 5-6

03/07/03 Contents-1

Page 4

GASBOY 552A/553A Commercial Pumps

Section 6: PARTS LIST

General ..................................................................................................... 6-1

Panels and Trim Diagram.......................................................................... 6-2

Panels and Trim Parts............................................................................... 6-3

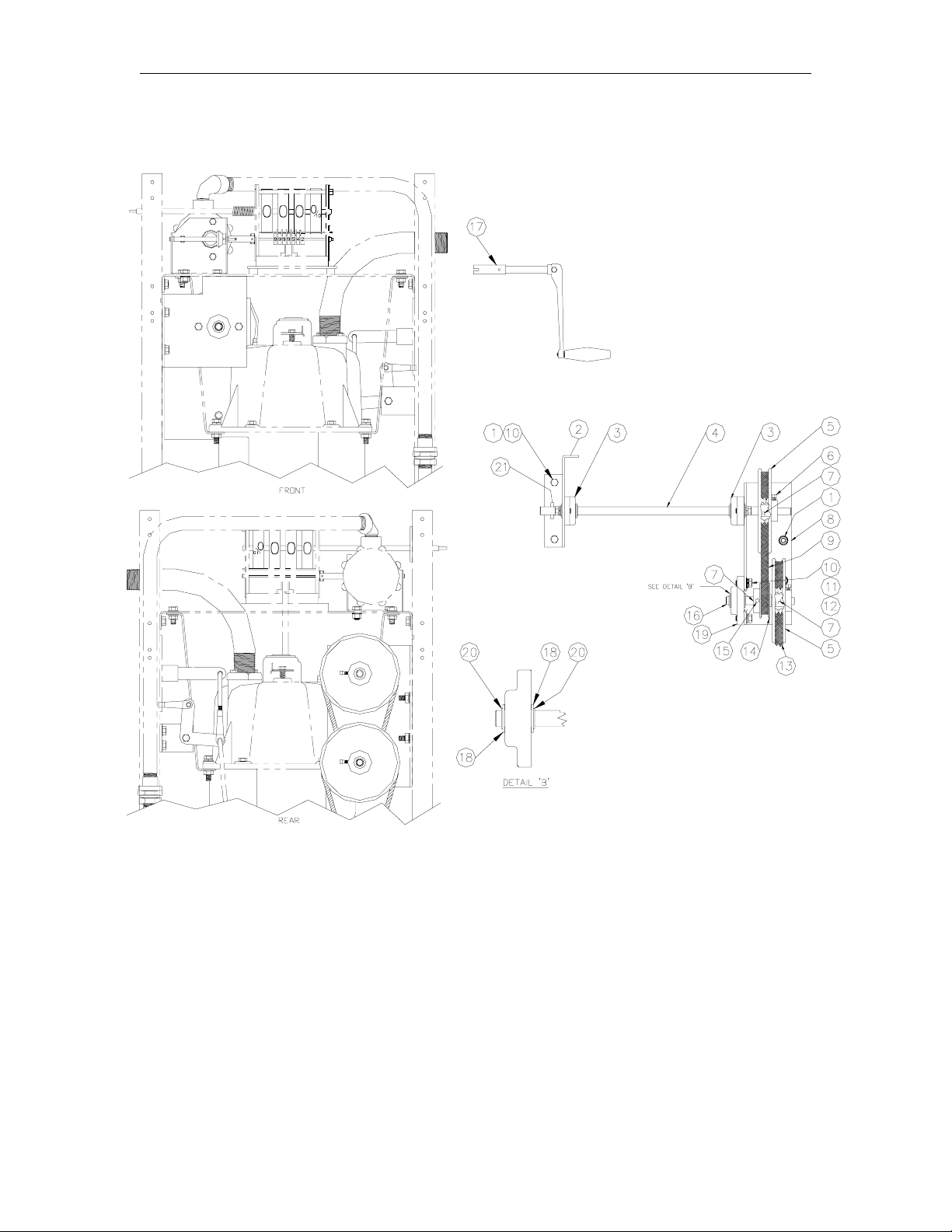

Chassis Assembly – Front and Rear View Diagram ................................. 6-4

Chassis Assembly – Front and Rear View Parts....................................... 6-5

Adapter Assembly..................................................................................... 6-6

Dial Enclosure Assembly........................................................................... 6-7

Meter Assembly Diagram.......................................................................... 6-8

Meter Assembly Parts............................................................................... 6-9

Meter Assembly Breakdown Diagram....................................................... 6-10

Meter Assembly Breakdown Parts............................................................ 6-11

Motor Assembly Diagram.......................................................................... 6-12

Motor Assembly Parts............................................................................... 6-13

Pumping Unit Assembly Diagram.............................................................. 6-14

Pumping Unit Assembly Parts................................................................... 6-15

Pumping Unit Assembly Breakdown Diagram........................................... 6-16

Pumping Unit Assembly Breakdown Parts................................................ 6-17

Register Assembly With Start-Stop Linkage Diagram............................... 6-18

Register Assembly With Start-Stop Linkage Parts.................................... 6-19

Register Assembly with Interlock Diagram................................................ 6-20

Register Assembly with Interlock Parts..................................................... 6-21

Hand Crank Assembly Diagram................................................................ 6-22

Hand Crank Assembly Parts..................................................................... 6-23

Pulser Assembly Diagram......................................................................... 6-24

Pulser Assembly Parts.............................................................................. 6-25

Accessories and Field Kits........................................................................ 6-26

Contents-2 03/07/03

Page 5

Section 1

INTRODUCTION

PURPOSE

The GASBOY 552A/553A Commer cial Pumps Installation/Operation/Parts Manual is provided to

assist the installer in installing and operating the unit. This manual should be supplied to the

electrician prior to the installation of conduit and wiring to ensure the unit is installed properly.

Faulty installations are the major cause of unit malfunctions. This unit must be installed and

operated as described in the manual to ensure the reliability and proper operation of the 550A

Series pumps. Be sure to leave this manual with the pump owner when the installation is

complete. Customers and installers having any questions pertaining to this installation should

contact their GASBOY distributor.

OVERVIEW

The GASBOY 552A/553A pumps are UL-listed, heavy-duty, suction pumps designed for the

needs of local and state governments, industrial, commercial, and private fleet operations. 550A

Series pumps have the following features:

• Dimensions: Base 13-31/32" (35cm) x 18-1/16" (46cm), height 40-1/8" (102cm)

• Construction: Top and side carbon steel panels; front and back hot-dipped galvanized steel,

for rust resistance.

• Cabinet: painted black with white door or color of your choice

• Motor:

1/2 HP intermittent duty, dual voltage/dual frequency, 115/230VAC, 50/60 Hz (552A);

3/4 HP continuous duty, dual voltage/dual frequency, 115/230 VAC, 50/60 Hz (553AMC);

3/4 HP continuous duty, 380 VAC, 50 Hz (553AMC)

• Pump: Rotary gear pump with air eliminator built into pump casting, positive displacement, no

priming necessary.

• Register: 4-wheel volume only, indicating up to 999.9 gallons/liters

• Totalizer: 999,999.9 gallons/liters

• Reset: manual or manual with interlock for use in retail sales

• Meter: positive displacement, Model 898-K

• Display: single-sided

• Dial Face: white with black text

• Hose: 552A - 3/4" (2cm) x 12 feet (3.6m); 553A - 1" (2.5cm) x 12 feet (3.6m)

• Suction connection: 1-1/2" NPT, unions provided

• Delivery Rate: up to 15 GPM/57 LPM (552A); up to 22 GPM/83 LPM (553A). Delivery rates

are maximum test rates. Actual rates will vary depending upon installation conditions,

product dispensed, and added accessories.

• Nozzle: Must be purchased separately. Automatic nozzles available.

03/07/03 1-1

Page 6

GASBOY 552A/553A Commercial Pumps

Optional accessories include: additional hose lengths, external filter kits, vertical check valve, high

speed hand attachment, Model 52 pressure regulating valve, pulsers, reset interlock, 380VAC/50

Hz. operation, imperial gallon or liter registration.

1-2 03/07/03

Page 7

Section 2

INSTALLATION

BEFORE YOU BEGIN

Before uncrating the pump, inspect the crate for damage. A damaged crate indicates possible

internal damage to the dispenser, and the delivering carrier should be notified of possible

concealed damage. It is recommended the original shipping crate be retained for pump reshipment at some later date.

INSTALLATION PRECAUTIONS

All installations must conform with all building/fire codes, all Federal, State, and Local codes,

National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine Service Station Code

(NFPA 30A) codes and regulations.

Plan your installation carefully. A pump cannot be expected to work satisfactorily unless the

underground installation is correct. Dispensing troubles, which seem to be pump-related, are

frequently traced to faulty installation. Review the following list of installation DO’s and DON’T’s

to avoid potential problems:

1. DO read the WARNINGS page at the front of this manual, preceding the Table of Contents.

It contains important information regarding the safe use of your dispensing equipment.

2. DO install an emergency power cutoff. In addition to circuit breaker requirements of NFPA 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all local codes.

In order to provide the highest level of safety to you, your employees, and customers, we

recommend that all employees be trained as to the location and procedure for turning off

power to the entire system.

3. DO have the pump/dispenser installed by a competent installer/electrician.

4. DO install breakaway coupling on discharge hose. If using a high hose retriever, install

breakaway approximately 12" downstream of hose clamp on nozzle side of clamp.

5. DO NOT experiment with a pump if you are not sure the installation is correct.

6. DO NOT overload sub- or main breaker panels.

7. DO NOT install any underground piping without proper swing joints. (Always use shoulder

nipples, never close nipples).

8. DO NOT cover any lines until they have been both air- and liquid-tested.

9. DO NOT back-fill the tank or supply line with cinders or ashes. (Back-fill with clean sand,

crushed rock, or pea gravel).

10. DO NOT use black iron pipe or fittings for underground installations. (Use only new

galvanized or fiberglass* pipe and fittings). *Install all fiberglass pipe and fittings according to

manufacturer’s specifications and requirements.

03/07/03 2-1

Page 8

GASBOY 552A/553A Commercial Pumps

11. DO NOT use power line wiring of inadequate capacity. (Use gauge specified by the wiring

diagram or wire chart provided in Section 3).

12. DO NOT use a circuit breaker of improper size. (See Section 3).

13. DO NOT install fill pipe to tank where it can be submerged with standing water.

14. DO NOT use the GASBOY fuel dispensing equipment to remove water ballast from the

storage tank.

15. DO NOT use gaskets on covers of explosion-proof type boxes. The sealing compound found

around wires at various locations within conduit is a requirement of the National Electrical

Code and should not be disturbed. Ensure that

free of dirt, nicks, and scratches.

16. DO NOT use knock-out boxes or flexible conduit for installing this unit. All wires should be

run in threaded, rigid, metal conduit. All threaded connections must be drawn up tight with

five (5) threads minimum engagement. Only one opening in the AC junction box is provided

with a plug at the factory. At completion of the installation, it is the installer’s responsibility to

ensure that any unused openings are plugged.

Tighten junction box covers before replacing panels.

mating surfaces between the box and cover are

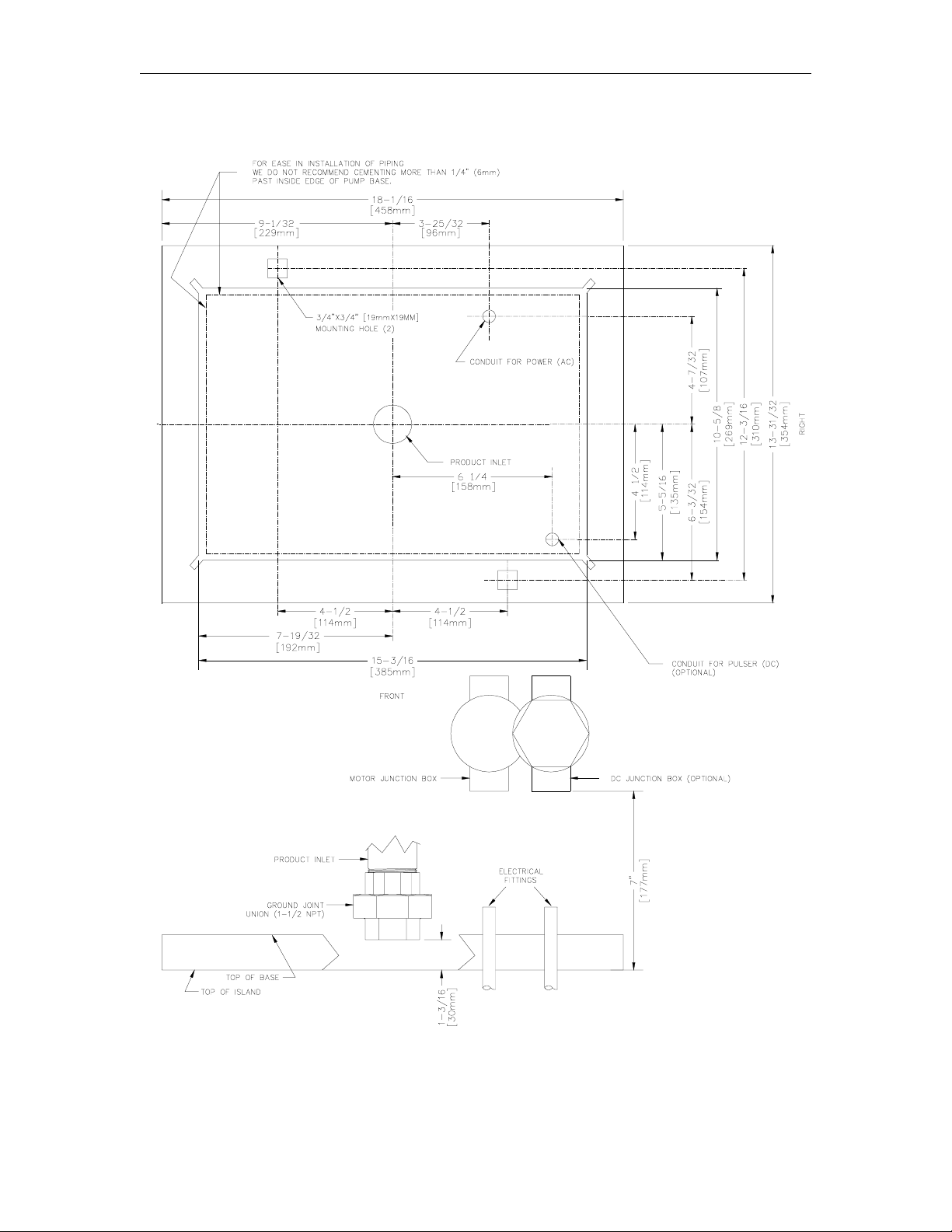

FOUNDATION

When constructing the pump island for the dispensing equipment, be sure to extend the island

excavation beyond the depth of the frost line. Leave open an area from the inside edge of the

unit’s base as shown on the specific base layout. Unless required by local regulations, do not

cement the pipes and conduits into the island. The open area within the base will provide access

for future servicing of the fittings and conduit assemblies. Fill in the boxed-in section with dry sand

to keep condensation in the pump housing to a minimum and to help prevent fogging of the

totalizer window.

Secure the pump/dispenser to the island using anchor bolts through the two mounting holes,

which are indicated on each base layout by an X. If the dispensing unit is not securely fastened to

the island, supply line leaks at unions and pipe joints may occur. Use one of two types of bolts to

anchor the pump to the island. Use two (2) 1/2" x 5" (13mm x 125mm) long machine bolts

imbedded in the concrete, or, to meet minimum UL and API requirements for universal

interchangeability of pumps, use two 1/2" x 3 1/2" (13mm x 90mm) long lag screws with 2" (51mm)

long expansion shields.

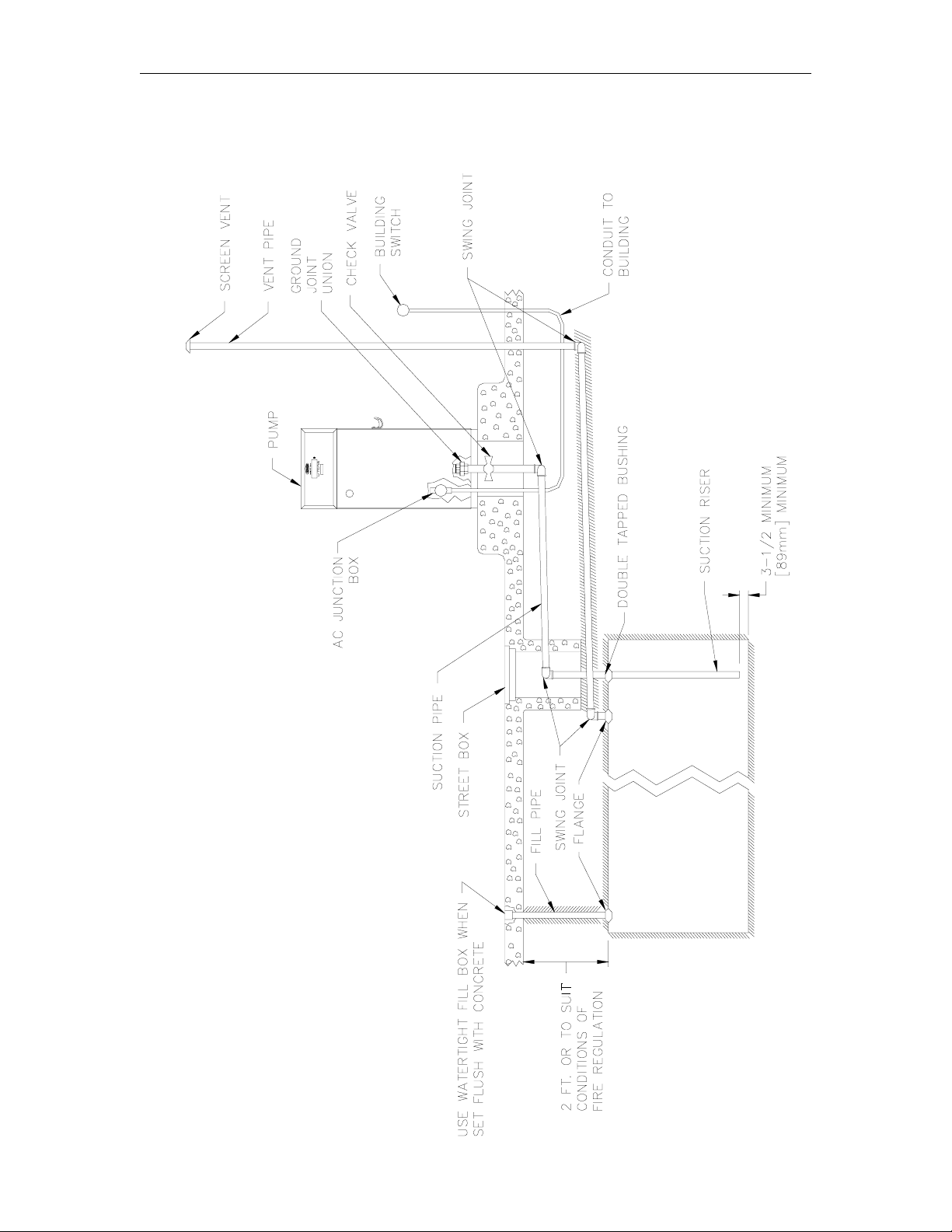

The drawing on the following page, Installation Layout, illustrates a recommended installation of

the Model 552A & 553A power pump. In selecting a location for the pump and tank, bear in mind

that a suction pump will draw liquid horizontally up to 100 feet, but on a vertical lift it is not

advisable to exceed 12 feet (3.6m) for gasoline, or 13 feet (4m) for diesel.

SUCTION PUMP

The pump and the tank should be located close to each other with as few changes in direction of

the supply line, as possible. This reduces the possibility of vaporization (gasoline only), attains the

highest possible flow rate, and results in a lower installation cost. Avoid long supply lines and

excessive vertical lifts. The dynamic lift for this unit is rated at 12 feet (3.6m) for gasoline and 13

feet (4m) for diesel and can vary according to conditions of the installation and fuel temperature.

2-2 03/07/03

Page 9

Installation

INSTALLATION LAYOUT

03/07/03 2-3

Page 10

GASBOY 552A/553A Commercial Pumps

SUPPLY LINE

Always start at the pump and work toward the tank. Use new galvanized or fiberglass (see note)

pipe, 1-1/2" minimum diameter. (NOTE: Fiberglass pipe is to be installed according to

manufacturer’s specifications and requirements.)

Be sure both the pipe and the tank are clean. Foreign matter entering the pump can cause

extensive damage. Obstructions in the supply line can create pump problems and reduced flow

rate.

Make sure all pipe threads ar e proper ly cut and the inside r eamed to remove bur r s. Use UL-listed

gasoline-resistant compound on all joints of gasoline handling piping. Sealing compound must

also be resistant to Gasohol (Ethanol and Methanol). Do not use Teflon Pipe Sealing Tape. Use

gasoline-resistant pipe compound on male threads only; pipe compound used on female threads

can be squeezed into the supply line where it can enter the product stream and become lodged in

the pump or meter. Install swing joints under the pump and at the tank to avoid breaks in the

supply line from settling or frost heave.

To avoid product delivery problems on suction pumps, be sure there are no traps in the supply

line. Supply lines, for both suction pumps and submersible pumps, should go straight down

beneath the pump to a point 18 inches (46cm) below the ground level and pitch at a rate of 1/8

inch per foot (1cm/m) from there down to the storage tank. The supply line should be as short and

direct as possible with swing joints (two 90

the horizontal run of pipe at 10-foot (305cm) intervals to maintain pitch and prevent traps. Do not

use wood as pipe supports.

New EPA regulations require that only one check valve be used per supply line and located

directly below, and as close as practical to the suction pump. Do not use spring-loaded or union

check valves since these will unnecessarily reduce the flow rate and contribute to the reduction of

atmospheric pressure necessary to keep gasoline in a liquid state.

Upon completion of installation, all liquid-carrying lines must be checked for leaks.

Connecting the Suction Pipe

To connect the suction pipe, remove the tin protector from the flange opening in storage tank.

Assemble suction pipe, double tapped bushing and foot valve with suction screen. Insert into

tank, and tighten in position. Starting at suction nipple at base of pump, take pipe measurements

to union elbow on suction pipe riser at top of tank. Cut pipe, assembly together loosely. If

measurements are correct, uncouple all pipe joints and coat them up with a good grade of

gasoline-resistant sealing compound. If pipe measurements are incorrect, a new pipe must be

cut.

NOTE: Underneath pump, a high grade valve with pressure relief must be used in suction

line.

o

elbows and one shoulder nipple) at all turns. Support

2-4 03/07/03

Page 11

Installation

BASE LAYOUT - 011982

03/07/03 2-5

Page 12

Page 13

Section 3

WIRING

Customers & installers having any questions pertaining to the installation should contact

their GASBOY distributor.

WIRING PRECAUTIONS

The quality of the electrical installation is a major factor in maintaining proper safety levels and

providing trouble-free operation of your pump. To assure a quality installation, follow these rules:

1. All wiring must be installed to conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations. Canadian users must also comply

with the Canadian Electrical Code.

2. Use only threaded, rigid, metal conduit.

3. Use only UL-approved insulated gasoline- and oil-resistant stranded copper wiring of the

proper size.

4. Wire connections should be tightly spliced and secured with a wire nut; close off the open end

of the wire nut with electrical tape.

5. The line to the motor should be on a separate circuit and installed on a 20 to 30 AMP breaker

depending on the motor size and/or the voltage setting.

6. Install an emergency power cutoff. In addition to circuit breaker requirements of NFPA 70

and NFPA 30A, a single control which simultaneously removes AC power from all site

dispensing equipment is recommended. This control must be readily accessible, clearly

labeled, and in accordance with all local codes.

In order to provide the highest level of safety to you, your employees, and customers, we

recommend that all employees be trained as to the location and procedure for turning off

power to the entire system.

WARNING:

To reduce the risk of electrical shock when servicing, turn off and lock out

all power to the pump.

7. Have the pump installed by a competent installer/electrician.

GROUNDING

To ensure proper operation of the equipment and provide the necessary safety factors, this unit

must be grounded. A ground wire (preferably green) must be connected between the unit’s AC

junction box ground lug and the main electrical service panel. One (1) ear th ground connection is

required per unit. The ground rod is to be a solid, corrosion-resistant conductor and must be

installed at the main electrical panel in accordance with the National Electrical Code. It should be

properly tied into the ground bus strip of the panel. We recommend the neutral and ground bus

strips be bonded together (unless prohibited by local codes).

03/07/03 3-1

Page 14

GASBOY 552A/553A Commercial Pumps

CIRCUIT BREAKERS

Power to the unit must be supplied from a dedicated 20 to 30 amp breaker. No other equipment

should be powered from this breaker. A tag on the motor identifies the maximum curr ent draw of

the motor. If two units are supplied from one breaker, that breaker must be capable of handling

the load of both motors.

PUMP MOTOR

Pumps are shipped from the factory with motors wired according to the specifications given on the

order as to kind of current, frequency and voltage.

Very often on installation, it becomes necessary to change the original setting to suit the AC power

source. To do this, locate the motor change-over plate (typically located on the shaft end of the

motor) and remove the screw which secures it in place. Slide the plate so that the desired

voltage, as marked on the plate, lines up with the screw hole. Reinsert the screw and secur e the

plate in place. 380 VAC pumps are permanently set and cannot be changed.

Many motor failures result from improper setting of the motor change-over plate. If set for 120

VAC and a 240 VAC feed is used, the motor will burn out after running only a short time. If set for

240 VAC and a 120 VAC feed is used, the motor will run very slowly and the starting field will soon

burn out.

WIRING AND CONDUIT

Pump Wiring

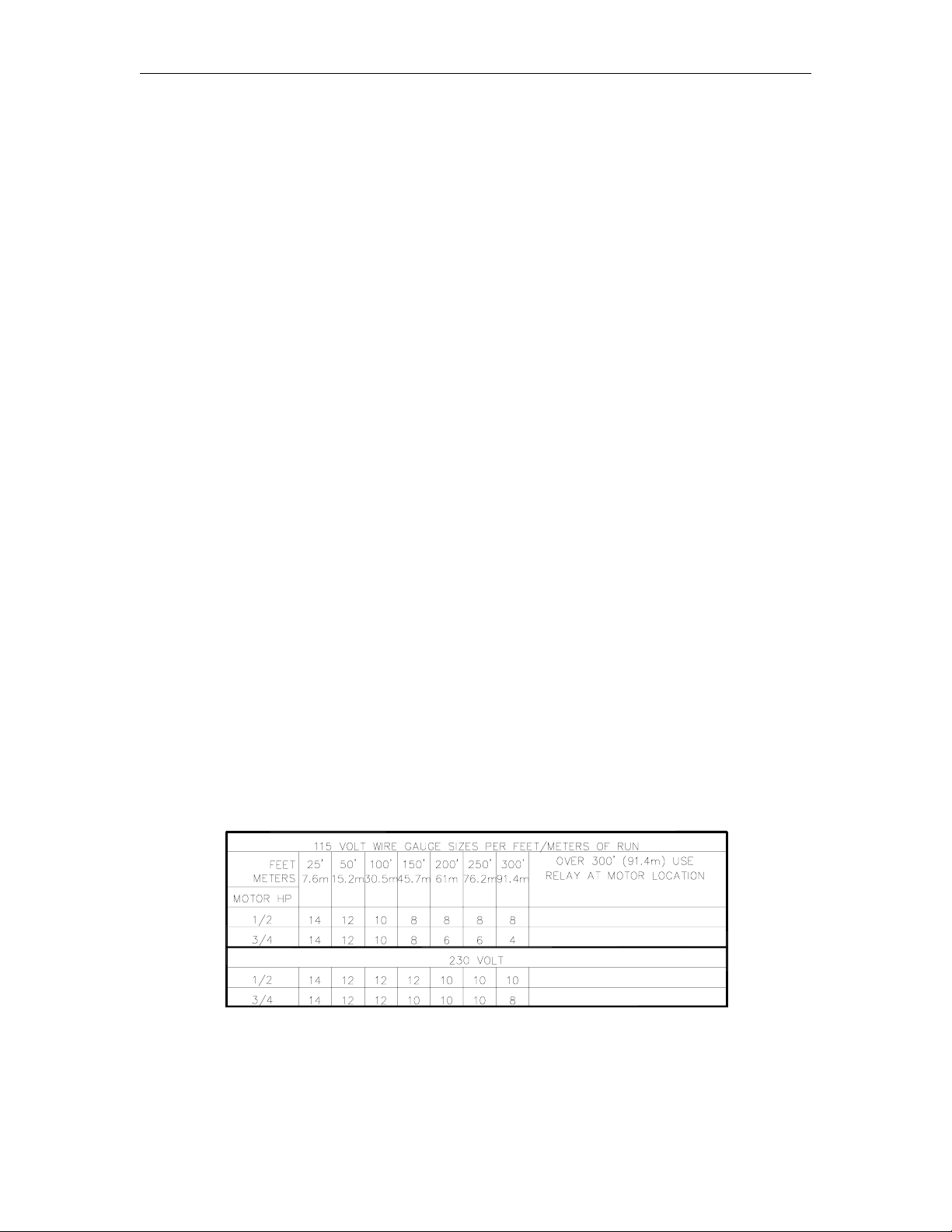

The table below shows the required AC wire size based on the HP rating of the pump motor and

the distance from the circuit breaker to the pump for both 115 and 230 volt units. Use this table as

a guide for selecting the proper size wire for your installation. Consult local wiring requirements

for wiring of 380 VAC motors.

If multiple units are powered from the same breaker through the same wires, you must increase

the gauge of the wires to handle the added load according to the distance from the breaker panel

and the HP rating (if applicable).

Wire Size

3-2 03/07/03

Page 15

Wiring

Pulser Wiring

Pulser wiring must be 18AWG. If it is run in the same conduit as the AC wiring, it must also

conform to the following wiring requirements:

• Wire must be 2-wire twisted-pair Belden 88760 (C08850) or 4-wire Belden 89418 or

equivalent (C08864).

Both types of cable provide superior noise immunity and are rated as follows:

Belden 88760

Gas and oil resistant insulation & jacket

18 AWG tinned, stranded, copper

One twisted pair (two conductors)

300 volt maximum operating voltage

Aluminum/Mylar shielded w/drain wire

NOTE: If using 88760 cable with a 3-wire pulser, you must run two lengths of cable to

attain two twisted pairs (four conductors). Cap off the unused wire.

Belden 89418:

Gas and oil resistant insulation & jacket

18 AWG tinned, stranded, copper

Stranded, four conductors

300 volt maximum operating voltage

Aluminum/Mylar shielded w/drain wire

• Cable connections to pulser must be made in DC junction box. Pulser cables will pass

through AC junction box.

• Cable drain wire must be connected to the grounding screw in the DC junction box in the

pump/dispenser. The drain wire is not connected at the fuel management system end.

• Rigid metal conduit must be used to connect the AC and DC junction boxes.

Conduit

All wiring to the Gasboy 550A Series dispensing unit must be installed in threaded, rigid, metal

conduit. PVC is not acceptable. It is recommended that DC pulser wiring be run in separate

conduit from any AC wiring; however, it is acceptable to run DC pulser wiring in the same conduit

as AC wiring as long as the requirements outlined in Pulser Wiring are met.

All wiring and conduit runs must also conform with the National Electrical Code (NFPA 70) and the

Automotive and Marine Service Station Code (NFPA 30A). All wiring and conduit runs must

conform to local codes. Canadian users must also comply with the Canadian Electrical Code.

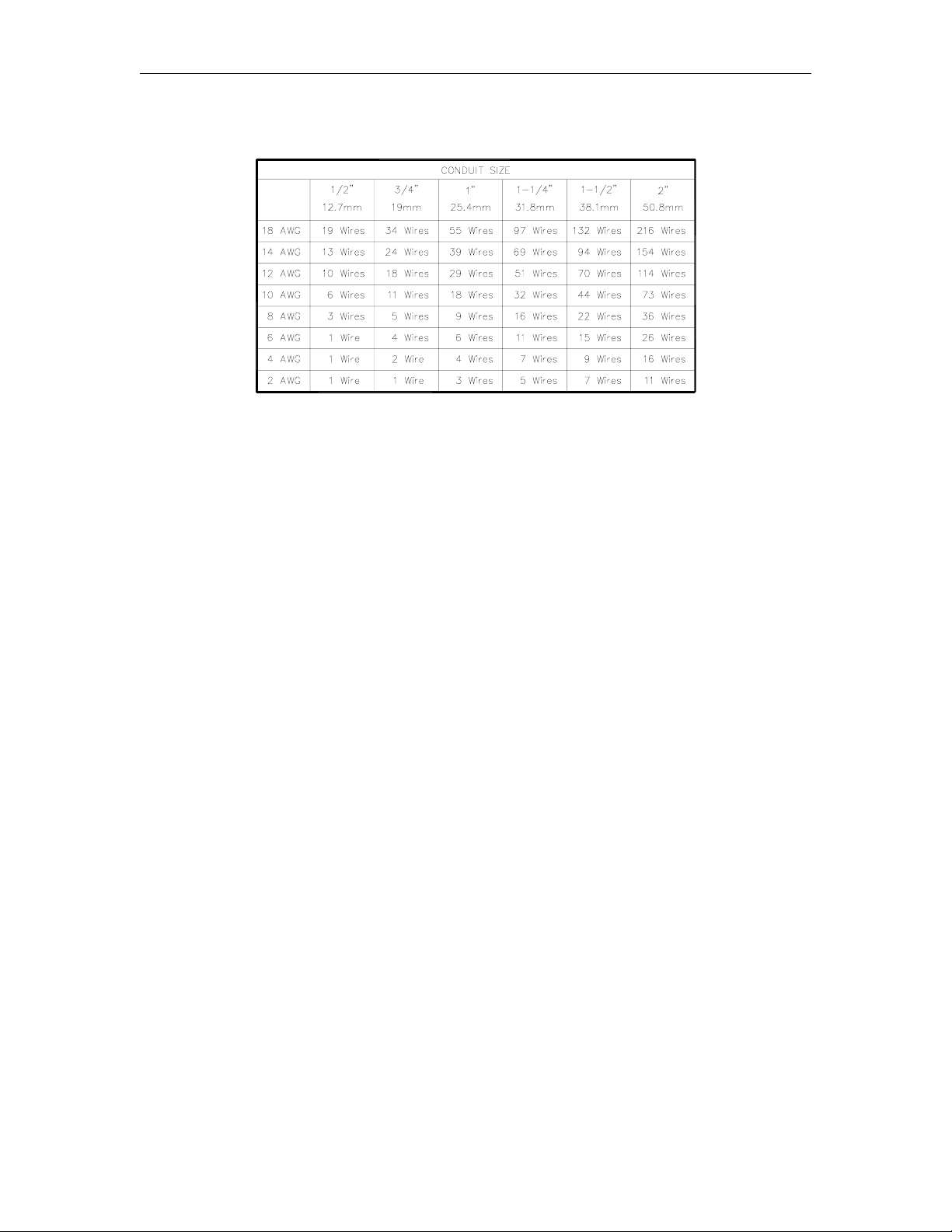

The table that follows shows conduit capacity for rigid, metal conduit with a 50% fill of gas- and

oil-resistant wire. Use this chart as a guideline to determine the proper conduit sizes for the

Gasboy 550A Series dispensing units. When planning the orientation of the wiring runs, follow the

applicable wiring diagram and consider the layout of the components at the site. Long runs or a

large number of bends may require you to increase conduit size over what is listed.

03/07/03 3-3

Page 16

GASBOY 552A/553A Commercial Pumps

Conduit Size

To connect the rigid conduit for the motor, start at the electrical connection box in pedestal of

pump, and take necessary measurements for pipe between motor and switchboard in building.

The conduit must be connected to make it water-and vapor-tight. Do not use flexible conduit.

When pulling wires through conduits, be careful not to damage insulation or break wires. To

connect wires, ends of wires must have insulation removed. Splice them tightly together, apply

solder, and follow with an application of electrical tape equal in thickness to insulation of wire

leads.

WIRING NOTES

1. All wiring and conduit runs must conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, and Automotive and Marine

Service Station Code (NFPA 30A) codes and regulations.

2. The brown wire (Switch Detect) is shipped capped from the factory. When used, it connects

to a solenoid valve or fuel management system. Do not connect this wire without first

checking the ON voltage of this line to ascertain compatibility with the equipment being

connected.

3. All wiring must be installed according to the requirements outlined in this section.

3-4 03/07/03

Page 17

Wiring

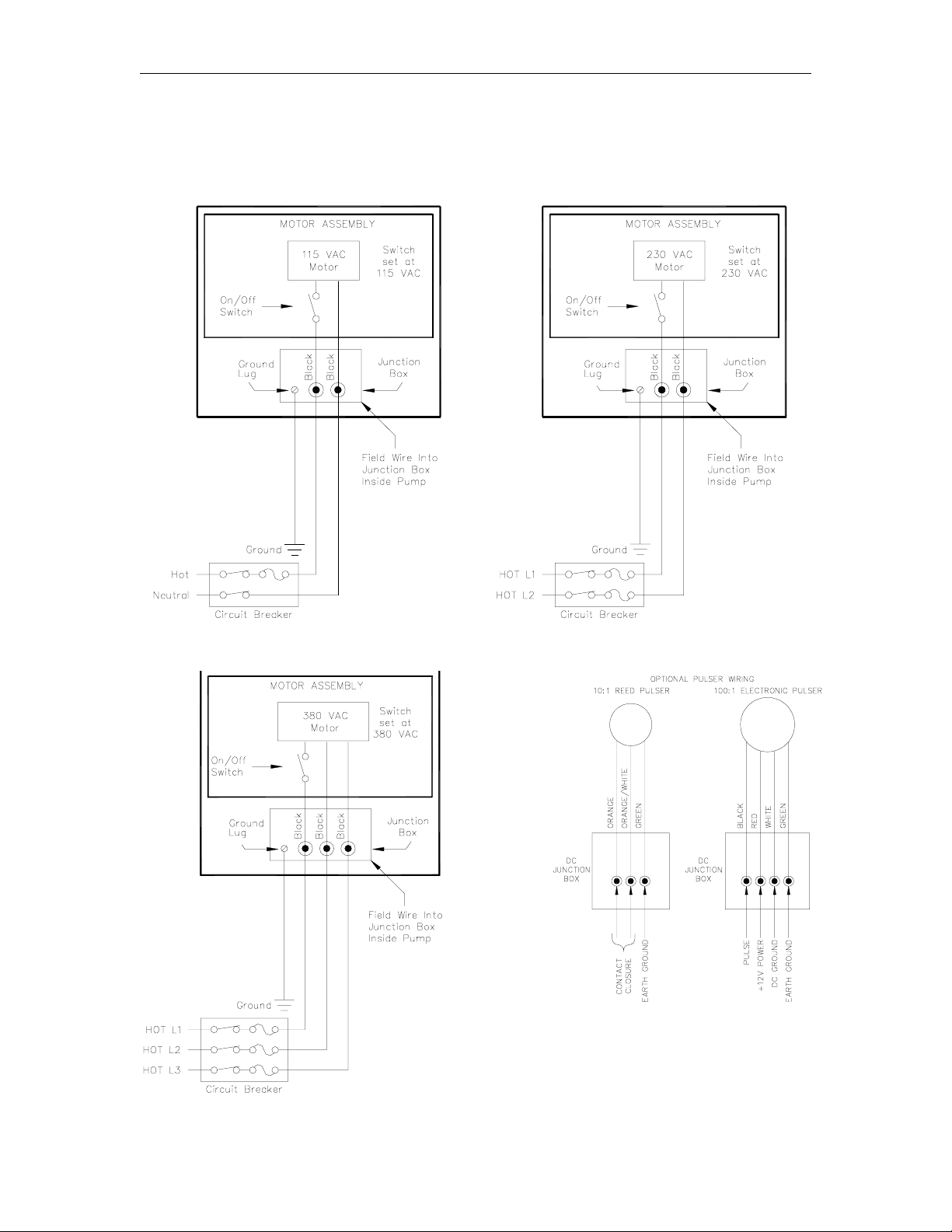

WIRING DIAGRAM - 024206

115 VAC Wiring 230 VAC Wiring

380 VAC Wiring Pulser Wiring

03/07/03 3-5

Page 18

Page 19

Section 4

TESTING AND OPERATION

TESTING THE INSTALLATION

Before placing the pump into full operation, you should first test the installation.

1. Place a small quantity of product in storage tank, but do not cover tank or pipe line

connections until pump is operated several times to make certain the system is fully primed

with product.

2. Operate pump several times, following instructions below, until gasoline is discharged from

hose nozzle. This will fill suction line and pump with gasoline.

3. Make a final inspection of all pipe lines to insure that connections are absolutely tight.

NOTE: If necessary for more than one pump to be connected to a single outlet from storage tank,

OPERATING INSTRUCTIONS

1. Reset register assembly to zero by turning instrument knob (located on left side panel) in a

CAUTION: On units equipped with a built-in interlock, failure to reset register before

2. Remove nozzle from nozzle hook.

3. Pull out switch rod and knob assembly (on right side panel). This will turn on motor and

4. Place nozzle into receiving vehicle and dispense desired quantity of product into vehicle.

5. Upon completion of delivery, push switch r od and knob assembly in. This will turn the motor

6. Replace nozzle on nozzle hook.

it is imperative that high grade check valves be used in each line to pumps, and must be

placed as close as possible to the connection into main supply line from tank. This is to

prevent a partial vacuum being created in suction lines, causing pumps to operate in a

pulsating manner.

counterclockwise direction.

attempting to turn dispenser on may result in damage to reset mechanism.

activate the pump.

NOTE: Nozzle must be manually held open at all times.

and pump off.

03/07/03 4-1

Page 20

Page 21

Section 5

MAINTENANCE AND TROUBLESHOOTING

GENERAL

GASBOY pumps are designed and constructed to give many years of uninterrupted service. In

fact, hundreds of operators report years of trouble-free operation with absolutely no service

expense. Yet, certain parts of a pump are bound to wear, and GASBOY therefore recommends a

periodic inspection, at least twice a year, for such things as fuel leaks, belt tension and condition,

lubrication and strainer cleanliness. If such a procedure is followed, any small adjustments that

are necessary can be made before expensive, annoying breakdowns occur. The result of this

sound approach is continuous, profitable service from all of your GASBOY equipment.

Procedures requiring disassembly of portions of the pump should be performed by

qualified service personnel.

WARNING:

To reduce the risk of electrical shock when servicing, turn off and lock out all

power to the pump. Always turn off and lock out all power to the pump at the

master panel before performing any maintenance or service, including the

changing of any fuel filters or strainers. Also block islands so no vehicles can pull

up to the pump while it is being worked on.

Where to Get Help: If your pump should stop or fail to operate properly, GASBOY has a

distributor network which services fuel dispensing and management systems in every section of

the country.

Use Authorized Parts: Parts needing replacement should be replaced only with GASBOY new

authorized service parts. This will ensur e the best results and the continuity of the Underwriters’

Label on your pump. Incorrect or substandard parts can result in unsatisfactory pump operation.

Always use new gaskets or seals when servicing or rebuilding GASBOY equipment; do not re-use

old ones.

EXTERIOR MAINTENANCE

The urethane finish on GASBOY pump housings is similar to that used on automobiles. Keep

your pump looking like new by thoroughly cleaning its exterior with a high grade automobile polish

and then protecting it with a coat of paste wax. Do not use abrasive cleaners or polish. Do not

use high pressure spraying equipment.

03/07/03 5-1

Page 22

GASBOY 552A/553A Commercial Pumps

LUBRICATING THE PUMP’S COMPONENTS

The following illustration shows the lubrication locations for your 550A Series pump.

Linkage Apply one drop of oil (SAE 10) at each pivot point of linkage every six months.

Register Every six months, or after each 100,000 gallons delivered, clean the register with

compressed air, and wipe all accessible parts (such as figure wheels) with a clean cloth. Use a

light, non-acid type oil (SAE 10), applying one drop between each figure wheel. Never use

solvents such as gasoline or kerosene, as they can become trapped in many of the inaccessible

bearings and dissolve the new lubricant when applied.

Motor Every three months, the oil the motor with 3 drops of high grade light oil (SAE 10) . Avoid

over-lubrication; more motors are damaged by too much, rather than too little, oil.

Rotary Pump & Air Separator Assembly O nce every six months, lubricate the felt with 1 oz. of

high grade light oil (SAE 10).

Meter Do not disassemble the meter for lubrication.

Gear Train Do not lubricate the gear train. It is permanently lubricated at the time of

manufacture.

5-2 03/07/03

Page 23

Maintenance and Troubleshooting

CLEANING THE STRAINER

Once every three months, remove strainer cap using the correct wrench and turning in

counterclockwise direction. Remove the strainer screen and clean it with compr essed air or by

rinsing in solvent.

NOTE: Always wear protective safety goggles or glasses when using compressed air.

Replace the gasket after cleaning the strainer screen and before reinstalling strainer cap. Be sure

strainer cap is drawn up tight after reinstalling, as a leak will prevent proper operation of pump.

CALIBRATING THE METER

All GASBOY pumps and dispensers are adjusted for accurate measure at the factor y. However,

since the conditions of the installation can affect pump accuracy, it is the responsibility of the

installer to check the pump for accuracy and make any needed adjustments. Where required, it is

the owner’s responsibility to report this device to the local Weights and Measures officials for their

inspection before the unit is put into service. Calibration methods are given in gallons. When

calibrating liter pumps, use the same procedure, but convert gallons to liters (1 gallon = 3.78

liters).

The adjustment of measurement is

accomplished by breaking the seal wire and

removing the Seal Pin. This will permit the

Index Disc, to be turned either

counterclockwise (-), decreasing the

measurement, or clockwise (+), increasing the

measurement. A variation of approximately

one cubic inch in measurement is obtained by

turning the Index Disc five holes. After

measurement has been properly adjusted, the

Seal Pin and seal wire should be replaced.

CORRECTING METER DRIVE SHAFT LEAK

If a leak develops around the meter drive shaft, it can be corrected as follows:

1. Remove screws and lockwashers securing gear train assembly and remove gear train

assembly.

2. Remove following items by lifting from meter cover packing cavity: upper bearing assembly,

washer, seal, o-ring, seal retaining ring, seal, o-ring, and seal retaining ring.

3. Reseal meter drive shaft by using the following new parts: seal, o-ring, seal retaining ring,

seal, o-ring, and seal retaining ring.

NOTE: Seals are to be formed to meter shaft size by rotating seals on a smooth 3/8" dia.

tapered punch or pencil. Be careful not to damage the seals in the forming

4. Reinstall parts in reverse order of disassembly.

Replacement of meter is recommended if the above procedures do not correct the

problem.

process or when inserting into packing cavity.

0124 5-3

Page 24

GASBOY 552A/553A Commercial Pumps

ADJUSTING THE BELTS

A loose belt reduces pump output due to slippage, and results in excessive wear. Once every six

months, check for proper V-belt tension. V- belt tension is proper when the back side of the belt

can be depressed approximately 3/8" (9.5mm). If adjustment is required, loosen cap screws and

pivot idler arm either upward or downward to obtain proper tension. Cap screws must be retightened before belt tension can be checked.

5-4 03/07/03

Page 25

Maintenance and Troubleshooting

TROUBLESHOOTING

Possible Cause Checks Corrective Action

Failure of bypass valve causes

pump to stall completely

Failure of regulating valve to

open prevents gasoline from

flowing to meter.

Failure of regulating valve to

close.

Failure of float needle valve to

open causes gasoline to be

discharged from air vent tube.

Presence of foreign material in

pump may cause bypass valve

to become stuck in its seat or

valve cylinder. Condition may

develop when a pump has

been idle for some time; when

water is present; or when ice

has formed.

Foreign matter may be lodged

in valve cylinder.

Insufficient pressure in supply

chamber due to break in

suction pipe, empty

underground storage tank,

clogged strainer screen, stuck

foot valve, needle valve,

extreme wear of parts or

excessive end play in rotary

pump head assembly, or ice

formation during cold weather,

if water is present in gasoline.

Valve may be held off its seat

by small particles of foreign

matter. Effect on normal pump

operation is not noticeable;

however, when the pump is

standing idle, even a slight

leak will permit gasoline to

drop down in the system.

May be caused by float being

clogged with gasoline, or by

corrosion of small pins (float

lever and valve pin) of needle

valve mechanism.

Float may be filled with product

caused by leak or puncture in

float.

Remove by-pass valve, clean

all parts, and reinstall the

valve.

Clean all parts and reinstall

valve.

Check list of possible causes

and perform appropriate

remedy.

Remove regulating valve and

clean dirt from poppet and

seat; reinstall.

If cork disc of regulating valve

is badly pitted or worn, replace

it with a new regulating valve.

Replace a damaged float with

a new one. Clean or replace

corroded parts.

Replace with new float

assembly.

0124 5-5

Page 26

GASBOY 552A/553A Commercial Pumps

PREPARING USED PUMPS FOR STORAGE

Special care should be taken when pumps are removed from service prior to storage. Gasoline,

moisture, and foreign material that is left in the pumps will do extensive damage to the internal

working parts. This damage can be prevented, if entire pump is drained of gasoline, moisture, and

foreign material before it is put into storage.

1. Remove drain plugs in r otary pump and separator body and in the top of meter cover. Then

lay pump on its side and elevate bottom of pump.

2. Apply compressed air (no gr eater that 50 pounds [3.5barr]) through suction inlet to force out

all gasoline, moisture, and foreign material that may be trapped in the inaccessible cavities.

Be sure to wear safety glasses when using compressed air.

3. Oil interior working parts by using a spray gun filled with light oil (free from gum content). The

oil may be blown in through the suction inlet.

4. Shellac drain plugs and reinstate them in their pr oper positions. Use a cloth bag or wooden

plug to cover the suction inlet and discharge outlet to prevent dirt from entering interior.

5-6 03/07/03

Page 27

Section 6

PARTS LIST

GENERAL

This section lists parts information for the 550A Series pumps. Using part numbers when order ing

will expedite your order and reduce the possibility of the wrong parts being shipped.

Procedures requiring disassembly of portions of the pump should be performed by competent

service personnel. Do not depend upon the repair service of a general mechanic unless he is

thoroughly familiar with the mechanism. GASBOY has a distributor network which services fuel

dispensing and management systems in every section of the country.

WARNING:

To reduce the risk of electrical shock when servicing, turn off and lock out all power to the pump.

Always turn off and lock out all power to the pumps at the master panel before performing

maintenance or service, including the changing of any fuel filters or strainers. Also block islands

so no vehicles can pull up to the pump while it is being worked on.

03/07/03 6-1

Page 28

GASBOY 552A/553A Series Commercial Pumps

PANELS AND TRIM DIAGRAM

6-2 03/07/03

Page 29

Parts List

PANELS AND TRIM PARTS

Item Part No. Description

1 Dial Enclosure Assembly (See Dial Enclosure breakdown)

2 035903 Dial Mask

3 024895 Elbow, 1” x 90°

4 017278 Bushing, reducer, ¾ x 1 (552A)

5 056913 Spacer

6 015104 Deflector

7 028960 Grommet, 1”

8 024544 Dome Assembly

9 038550 Nozzle Boot

10 035000 Right Side Panel

11 030847 Rear Panel

12 024518 Front Door Panel

024563 Front Door Panel for units with Hand Crank Option

13 015890 Hose Support Hook

14 017005 Nozzle Hook

15 033007 Switch Rod and Knob Assembly

16 045805 Latch Plate

17 058021 Grommet

18 045804 Plate

19 035002 Left Side Panel

20 032714 Reset Knob

21 057402 Spring Clip

22 027073 Gasket, 2”

23 027073 Cushion, 38-3/8

24 027072 Cushion, 30-1/2

NOTE: Specify standard color (black, white, red). If not a standard color, specify serial

number of pump/dispenser.

(See Note)

(See Note)

(See Note)

(See Note)

(See Note)

1212 6-3

Page 30

GASBOY 552A/553A Series Commercial Pumps

CHASSIS ASSEMBLY - FRONT AND REAR VIEW DIAGRAM

6-4 03/07/03

Page 31

Parts List

CHASSIS ASSEMBLY - FRONT AND REAR VIEW PARTS

Item Part No. Description

1 Register Assy. w/start-stop l inkage

Register Assy. w/Int erlock

(See breakdown for your model)

2 045774 Counter Support Plate

3 047511 Corner Post, Right Front

4 044016 Discharge Pipe

5 026071 Meter flange

6 027004 O-Ring

7 063969 Meter Support

8 Meter Assembly (See breakdown for your model)

11 012148 V-Belt 4L330

12 Motor Assembly (See breakdown for your model)

13 047510 Corner Post, Rear

14 Pump Assembly (See breakdown for your model)

16 011902 Base

17 Flange Assembly (See Meter Assembly breakdown)

18 047512 Corner Post, Left Front

19 Pulser Assembly (See Pulser Assembly breakdown)

20 Hand Crank Assembly (See Hand Crank breakdown)

03/07/03 6-5

5

Page 32

GASBOY 552A/553A Series Commercial Pumps

ADAPTER ASSEMBLY

Item Part No. Description

1 003612 Adapter

2 011065 Bearing Insert

3 027447 Drive Gear

4 043031 Roll Pin, 1/16 Dia x 3/8 Lg.

5 068041 Washer

6 043246 Spirol Pin, .039 x 1/2 Lg.

7 043032 Roll Pin, 1/16 Dia. X 1/2 Lg.

8 027446 Driven Gear

9 068016 Thrust Washer

10 054437 Shaft

11 048629 Truarc Retaining Ring

12 054444 Shaft

13 043227 Spirol Pin, 3/32 Dia. X 3/4 Lg.

14 049406 Retaining Ring

15 054829 Shaft, Drive

16 S00146 Bevel Drive Gear

6-6 03/07/03

Page 33

Parts List

DIAL ENCLOSURE ASSEMBLY

Item Part No. Description

1 026333 Dial Enclosure Assembly, Complete

This assembly includes all items listed below. When ordering a complete dial enclosure

assembly, you must also specify either 025689 (Gallons silkscreen) or 026161 (Litres

silkscreen). For other customized silkscreens, include the serial number of your dispenser

with your order. Standard silkscreens have a white background with black text.

2 025689 Dial Glass, Gallons

026161 Dial Glass, Litres

For all other applications, specify the serial number of the pump.

3 025935 Frame, Dial

4 023871 Dial Enclosure

5 057403 Spring Clip

6 020819 Clip Dial Glass Assembly

03/07/03 6-7

Page 34

GASBOY 552A/553A Series Commercial Pumps

METER ASSEMBLY DIAGRAM

6-8 03/07/03

Page 35

Parts List

METER ASSEMBLY PARTS

Item Part No. Description

1 035589 Meter Assembly, Gallons

035588 Meter Assembly, Imperial Gallons

035556 Meter Assembly, Liters

2 027038 Meter Transfer Body Gasket

3 035514 Meter Transfer Body

4 003613 Inlet Connection

5 S00162 Gasket

6 021950 Coupling

7 026079 Flange

8 051950 Screw, HHC, 5/16-18 x 1-3/4

9 068005 Washer, 1/4

10 068875 Lockwasher, 5/16

11 049014 O-Ring

M49014 O-Ring, Methanol

12 027797 Gasket

13 042130 Pin

03/07/03 6-7

Page 36

GASBOY 552A/553A Series Commercial Pumps

METER ASSEMBLY BREAKDOWN DIAGRAM

6-8 03/07/03

Page 37

Parts List

METER ASSEMBLY BREAKDOWN PARTS

035589 Meter Assy., Gallon

035588 Meter Assy., Imp. Gallon

035556 Meter Assy., Liter

Item Part No. Description

1 S00466 Packing Gland Plate

2 S00467 Seal Pin

3 S00469 Compensator Screw Spring

4 S00473 Drive Shaft

5 069080 Seal & Seal Wire

6 S00475 Special Screw

7 S00476 Drive Shaft Pin

8 S00477 1/2" Ball

9 S00480 Plunger Cup Support

10 S00481 Plunger Disc

11 S00482 Washer

12 S00483 Washer

13 S00484 Upper Bearing Assembly

14 S00485 Bearing Assembly

15 S00487 Compensator Index Disc

16 S00488 Seal Half

17 S00489 Seal Wedge

18 S00490 Washer

19 S00492 Packing Spring

20 S00493 Seal

23 S00494 Bearing Retainer

24 S00495 Seal (black)

25 S00491 Seal Retaining Ring

26 S00478 Compensator Pinion

27 S00512 Screw

28 S00498 Main Pivot Bracket Assembly

w/ Pins

29 S00032 Plunger Cup Kit (Set of 3

Cups)

30 S00501 Valve

31 S00502 Wobble Plate w/ Slack Roller

Post

32 S00503 Connector

33 S00504 Bearing Seat

35 S00505 Slack Roller Assembly

36 S00506 Slack Spring Assembly

37 S00496 Drive Shaft Gear - Gal

S00115 Drive Shaft Gear - Ltr

Item Part No. Description

38 S00499 Counter Drive Gear Complete -

Gal

S00114 Counter Drive Gear Complete -

Ltr

39 S00497 Compensator Shaft

40 S00500 Bracket & Pin Assembly

41 S00468 Index Plate

42 S00479 Pivot & Ball Assembly

43 S00470 Meter Body Gasket

44 S00471 O-Ring (.362 Dia.)

45 S00472 O-Ring (.487 Dia)

46 S00486 Meter Cover w/ Center Gear

Post, Index Plate, Pipe Plug &

Retaining Ring

47 S00509 Mach. Screw, 10-32 x 3/8 Lg.

Rd. Hd.

48 S00507 Mach. Screw, #12-24 x 1/2 Lg.

Rd. Hd.

49 S00508 Mach. Screw, 1/4-20 x 3/4 Lg.

Rd. Hd.

50 S00511 Hex Nut, 1/4-20

51 S00510 Hex Nut, 5/16-18

52 S00520 Lockwasher, 1/4

53 S00513 Lockwasher, #1212

54 S00514 Lockwasher, #1114

55 S00515 Pipe Plug, 1/8 Sq. Hd.

56 S00516 Sems Fastener, #10-32 x 3/8

Lg. Rd. Hd.

57 S00517 Cotter Pin, 1/16 x 1/4 Lg.

58 S00518 Truarc Retaining Ring

59 S00519 Truarc "E" Retaining Ring

60 S00521 Plunger Assy. w/ Bearing

Retainer, Bearing Seat & Sems

Fastener

61 S00522 Body & Seat Assembly w/Pins

62 S00523 Meter Drive Shaft Kit

63 S00130 Shaft-Seal Kit

03/07/03 6-11

Page 38

GASBOY 552A/553A Series Commercial Pumps

MOTOR ASSEMBLY DIAGRAM

6-12 03/07/03

Page 39

Parts List

MOTOR ASSEMBLY PARTS

Item Part No. Description

1 F37630 Motor, ½ HP, 552A, 115V/230V, 50Hz./60Hz.

F37609 Motor, ¾ HP, 553AMC, 115V/230V, 50Hz./60Hz.

F37320 Motor, ¾ HP, 553AMC, 380V/50Hz., 3 Ph

F37323 Motor, ¾ HP, 553AMC, 115V/230V, 50Hz./60Hz. For tropical environments.

2 031315 Key

3 047005 Pulley, 5/8 Bore 2.4, 552A

047023 Pulley, 5/8 Bore, 3-1/4, 553AMC

4 038050 Pipe TBE, 1/2 x 1-1/8

5 014165 J-Box, 550

6 014164 Conn. Box Cover

7 063967 Bracket, Motor Right

8 051925 Screw, 5/16-18 x 1-1/4 HHC Pl

9 068080 Washer, 5/16 Pltd.

10 067735 Washer, Cup

11 037884 Mount, Rubber

12 068620 Washer, 5/16 x 1 x 3/64

13 037885 Mount, Rubber

14 038920 Nut, Lock, 5/16-18 Hex

15 021030 Conduit Conn.

03/07/03 6-13

Page 40

GASBOY 552A/553A Series Commercial Pumps

PUMPING UNIT ASSEMBLY DIAGRAM

6-14 03/07/03

Page 41

Parts List

PUMPING UNIT ASSEMBLY PARTS

Item Part No. Description

1 021935 Coupling, Nipple

2 047009 Pulley, Idler

3 026038 Fitting, Ell, ¼ x 3/8

4 056605 Sleeve, Compression

5 038555 Nut, Compression

6 063633 Tube, Vent

7 047029 Idler Arm

8 048424 Pumping Unit, 553AMC

048227 Pumping Unit, 552A

9 031315 Key

10 047598 Pulley, 3/4 bore, 4, 553AMC, 60Hz.

047597 Pulley, 3/4 bore, 3-1/2, 553AMC, 50 Hz.

047015 Pulley, 3/4 bore, 5-1/4, 552A, 50 Hz./60Hz.

11 063968 Bracket, Pump Left

12 066385 Union, 1-1/2 #150 Stockham

13 044907 Pipe TBE, 1-1/2 x 2-1/4

14 063966 Bracket, Motor Left

15 067735 Washer, Cup

16 037884 Mount, Rubber

17 037885 Mount, Rubber

18 068875 Washer, Std. Spring Lock, 5/16

19 051925 Screw, 5/16-18 x 1-1/4 HHC

20 063965 Pump Support, Right

03/07/03 6-15

Page 42

GASBOY 552A/553A Series Commercial Pumps

PUMPING UNIT ASSEMBLY BREAKDOWN DIAGRAM

6-16 03/07/03

Page 43

Parts List

PUMPING UNIT ASSEMBLY BREAKDOWN PARTS

048227 Pumping Unit Assy., 552A

048424 Pumping Unit Assy., 553AMC

Item Part No. Description

1 S00117 Gasket

2 S00456 Float Lever Pin

3 S00066 Valve Pin

4 S00067 Guide Plate

5 S00068 Spring Plate

6 S00069 Plunger Head

7 S00072 Plunger Plate

8 S00073 Plunger Follower

9 S00074 Valve Cylinder

10 S00075 Cylinder Head

11 S00076 Clamp Plate

12 S00077 Float Valve Body

13 S00078 By-Pass Valve Spring (#34 to

35-1/2# spring)

S00079 By-Pass Valve Spring (44-1/2#

Spring)

14 S00080 Vent Screw

15 S00062 Valve Cylinder Gasket

16 S00081 Vent Screw Guard

17 S00082 Float Valve Needle

18 S00083 Float Valve Gasket

19 S00128 Pump Rotor Shaft Assembly

20 S00119 Bottom Head Gasket

21 S00084 Separator Cover

22 S00120 Cover Gasket

23 S00085 Retainer

24 S00121 Bearing

25 S00086 Regulating Poppet Assy

26 S00124 Oil Well Felt

27 S00061 Float Assembly

29 S00087 Gasket

30 063312 Suction Screen (Gasoline)

063313 Suction Screen (Diesel)

31 S00088 Regulating Valve Spring

32 S00089 By-pass Valve Poppet

33 S00056 Packing Gland

34 S00090 Packing Spring

35 S00091 Rotary Pump & Separator

Body w/Gasket, Bearing,

Screws & Spring

36 S00092 Regulating Valve Seat

37 S00093 Valve Seat Guide

38 S00094 By-pass Valve Seat

39 S00448 Check Valve Cap

41 S00447 Poppet Spring

43 S00116 "V" Packing

44 S00095 Plunger Guide

Item Part No. Description

45 S00096 Plunger Disc

46 S00097 Plunger Spacer

47 S00122 Drive Shaft Bearing

48 S00129 Rotary Pump Idler

50 S00098 Poppet Disc. & Relief Valve

Assy

52 S00427 Suction Strainer Cap

53 S00125 By-pass Valve Assembly (34#

to 35-1/2# spring), 552A

S00126 By-pass Valve Assembly (44-

1/2# spring), 553AMC

54 S00127 Regulating Valve Assembly

55 S00123 Gasket

56 S00451 1/4-20 x 7/8 Lg. Rd. Hd. Mach

Screw

57 S00452 1/4-20 x 1/2 Lg. Hex Hd. Cap

Screw

58 S00453 5/16-18 x 7/8 Lg. Hex. Hd. Cap

Screw

59 S00454 3/8-16 x 2-3/4 Lg. Hex. Hd.

Cap Screw

60 S00455 3/8-16 x 1-1/8 Lg. Hex. Hd.

Cap Screw.

61 S00458 3/8 Lockwasher

62 S00457 1/16 x 1/2 Lg. Cotter Pin

63 S00459 1/4 Sq. Hd. Pipe Plug

64 S00460 1/4 Countersunk Pipe Plug

65 S00461 1/4 - 28 Hex. Nut

67 S00462 Lower Pump Head w/Valve

Seat Guides, Regulating Valve

Seat & By-pass Valve Seat

68 S00057 Rotary Pump Head Assembly

03/07/03 6-17

Page 44

GASBOY 552A/553A Series Commercial Pumps

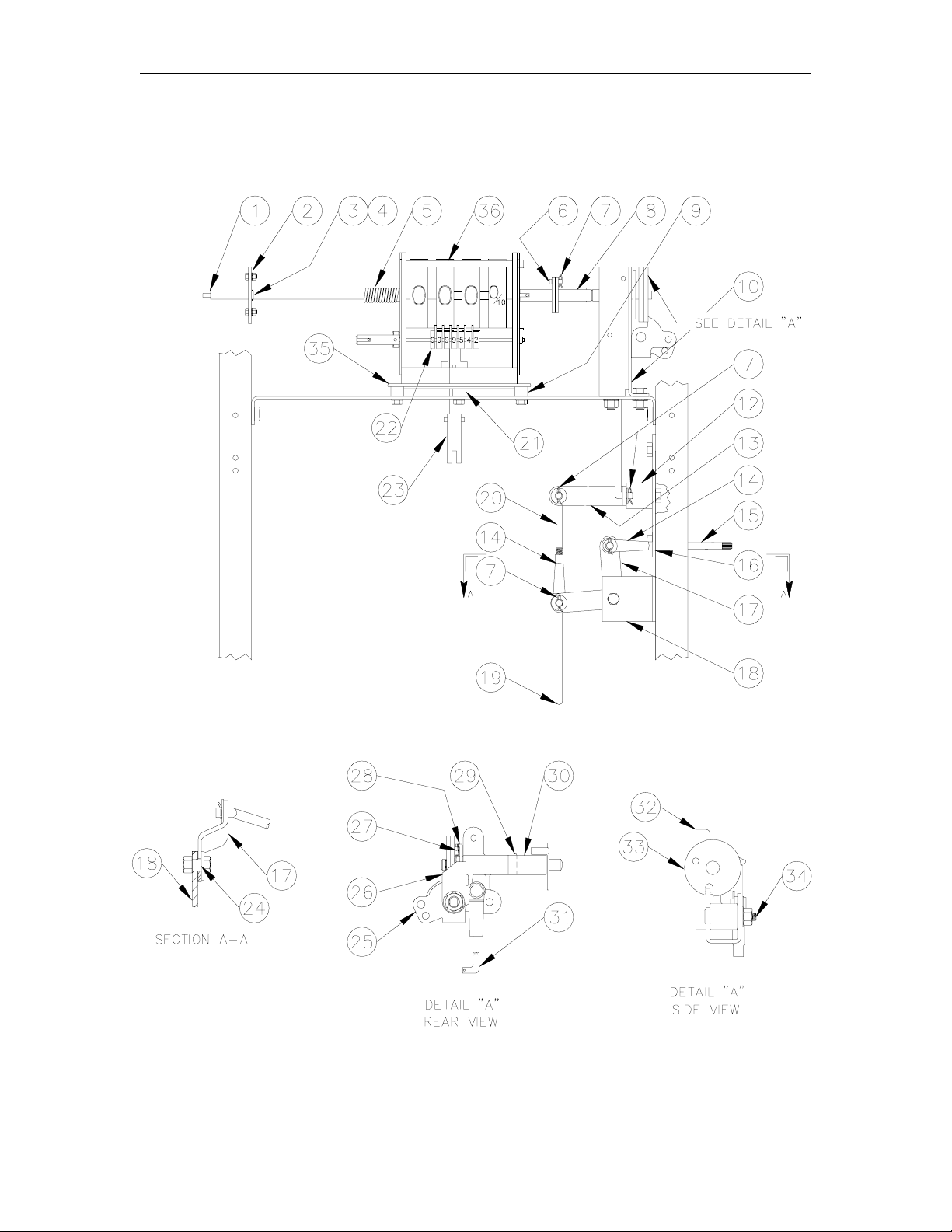

REGISTER ASSEMBLY WITH START-STOP LINKAGE DIAGRAM

6-18 03/07/03

Page 45

Parts List

REGISTER ASSEMBLY WITH START-STOP LINKAGE PARTS

Item Part No. Description

1 051211 Reset Rod

2 063964 Support Rod

3 049425 E-Ring

4 068042 Thrust Washer, 9/16OD x .382ID

5 022011 Coupling, Reset

6 022997 Coupling Kit

7 056917 Spacer, 7/32ID x 1/2OD x 13/32

8 050250 Rod End

10 017002 Switch, Arm

11 017001 Bracket, Support

12 051215 Rod, Switch

13 042430 Pin, Cotter, 1/16 x 1/2

14 056915 Spacer, .314ID x .434 OD x .145

15 S00173 Totalizer Assembly

16 056916 Spacer, 7/32ID x 1/2OD x 3/16

17 010070 Adapter Assembly (See breakdown)

18 048456 Register and adapter assembly (includes item 15, totalizer assembly)

*048456 Register (subcomponent of 048456)

03/07/03 6-19

Page 46

GASBOY 552A/553A Series Commercial Pumps

REGISTER ASSEMBLY WITH INTERLOCK DIAGRAM

6-20 03/07/03

Page 47

Parts List

REGISTER ASSEMBLY WITH INTERLOCK PARTS

Item Part No. Description

1 051213 Rod, Reset

2 063964 Rod, Support

3 049425 E-Ring

4 068042 Washer, Thrust, 9/16OD x .382ID

5 022011 Coupling, Reset, 550

6 043016 Pin, Seal, Special

7 042430 Pin, Cotter

8 021918 Coupling and Disc Assembly

9 056917 Spacer, 7/32ID x 1/2OD x 13/32

10 017003 Bracket, Interlock Support

12 056912 Spacer, Interlock

13 017008 Arm, 550

14 050250 Rod, End

15 051209 Rod, Switch Handle

16 015748 Support Bracket

17 017002 Switch Arm

18 017001 Support Bracket

19 051215 Rod, Switch

20 050022 Rod, Interlock

21 056916 Spacer, 7/32ID x 1/2OD x 3/16

22 S00173 Totalizer Assembly

23 022997 Coupling Kit

24 056915 Spacer, .314ID x .434OD x .145

25 017519 Cam, Reset Locking

26 057132 Spring, Interlock Cam

27 057131 Spring, Blocking Cam

28 012525 Block, Switch lever

29 043035 Pin, Roll 1/8 x ¾

30 021880 Coupling and Pin Assembly

31 050021 Rod, Interlock

32 017006 Support Interlock

33 048504 Reset and Shaft Assembly

34 054441 Shaft, Interlock

35 010070 Adapter Assembly (See breakdown)

36 048454 Register and Adapter assembly (includes item 22, totalizer assembly)

*048562 Register (subcomponent of 048454)

03/07/03 6-21

Page 48

GASBOY 552A/553A Series Commercial Pumps

HAND CRANK ASSEMBLY DIAGRAM

6-22 03/07/03

Page 49

Parts List

HAND CRANK ASSEMBLY PARTS

Item Part No. Description

1 038605 Nut, 5/16-18 Hex Keps

2 030803 Bearing-Pltd Assy.

3 030024 Housing/Bearing Assy.

4 055004 Shaft, Drive

5 048710 Pulley, 5-1/2 x .5 bore

6 053731 Screw, 1/4-20 x 5/8 Sq. Hd Set Cad Case Hardened

7 017130 Bushing, Hand Crank

8 014835 Bracket, Pulley

9 012166 Belt, 4L230, A21

10 051895 Screw, 5/16-18-3/4 HHC Pl

11 068875 Washer, Std. Spring Lock, 5/16

12 068080 Washer, 5/16-18 x 1/2

13 012168 Belt, 4L520-A50

14 048709 Pulley, 2" x 5" Bore

15 052010 Screw, Set 5/16-18 x 1/2

16 055005 Shaft, Drive

17 023139 Handcrank Assy.

18 068040 Washer, .505ID x .880OD, .058T

19 030025 Housing/Bearing Assy. (dbl)

20 049403 Retaining Ring, .396 Dia. (units built after 3/99)

048612 Retaining Ring, Truarc, .468 Dia.

21 043030 Pin, Roll, 3/16 x 1

03/07/03 6-23

Page 50

GASBOY 552A/553A Series Commercial Pumps

PULSER ASSEMBLY DIAGRAM

6-24 03/07/03

Page 51

Parts List

PULSER ASSEMBLY PARTS

Item Part No. Description

1 021788 Pulser, 10:1

047648 Pulser, 100:1

2 011954 Bearing, Nyliner

3 042100 Pin, Driv-Lok, 3/32 x 5/8 Type E

4 042280 Pin, Driv-Lok, 3/32 x 5/8 Type A

5 053471 Screw, Set, Soc. Hd, 6-32 x 3/16

6 043221 Pin-Spirol, 1/16 x 3/4 CRS

7 068037 Washer, SS, .260 x .500 x .010

8 051790 Screw, 1/4-20 x 1/2 HHC

9 068155 Washer, 1/4’ Int. Tooth

10 054551 Shaft, Pulser

11 028415 Gear, Miter Pulser

12 015917 Bracket, Pulser

13 023006 Coupling, Pulser

14 021058 Cond. Fitting, 90

15 003345 Junction Box, Mchng

16 003515 Junction Box Cover, Mchng

17 028422 Gear, Miter 24T

18 052285 Screw, 5/16-18 x 5/8 HHC

19 038605 Nut, 5/16-18 Hex Keps

20 023069 Conduit, Pulser

21 C08125 Conduit Fit, 1/2’ Union FF

22 023007 Conduit, Pulser, Lower

23 020745 Clamp, Junction Box

24 051805 Screw, 1/4-20 x 5/8 HHC

25 038740 Nut, 1/4-20 Hex Hd. Jam

26 068005 Washer, 1/4 Pltd

27 068860 Washer, Std. Spring-Lock

28 014641 Bracket

o

MF

0220 6-25

Page 52

GASBOY 552A/553A Series Commercial Pumps

ACCESSORIES AND FIELD KITS

Drip Tray

011982 Directs fuel from an internal leak to the outside of the cabinet to minimize ground

contamination. Installed between island and dispenser.

Filter Kits and Elements

External standard speed filter kits, designed for flow up to 15 GPM. Typically used on Model 552A.

Methanol fuels require special methanol element listed below.

032115 External Standard Speed Filter Kit (includes adapter, standard speed particulate filter

element and pipe fittings)

032116 External Standard Speed Hydrosorb Filter Kit (includes adapter, standard speed

Hydrosorb filter element and pipe fittings)

Replacement Elements

026005 Standard (removes particulates only)

026042 Hydrosorb (removes water and particulates)

025909 Methanol (particulate removal in methanol and methanol blends where content exceeds

15%)

External High Flow Filter Kits

Typically used on Model 553AMC. Components in high flow kits are not designed for use with Methanol or

Methanol blends.

032754 External Single Element High Flow Kit (includes adapter, one high flow particulate filter

element and pipe fittings)

032755 External Single Element High Flow Hydrosorb Kit (includes adapter, one high flow

Hydrosorb filter element and pipe fittings)

Replacement Elements

025900 Standard (removes particulates only)

025901 Hydrosorb (removes water and particulates)

Pulser Kits

050003 1:1 Pulser (one pulse per unit of measure)

050002 10:1 Pulser (10 pulses per unit of measure)

050004 100:1 Pulser (100 pulses per unit of measure). Recommended for most applications.

6-26 03/07/03

Page 53

GW01 - 6/04/02 Rev. 1

WARRANTY

General Statements:

Gasboy International LLC. warrants all new equipment manufactured by Gasboy against defective m aterial and/or workmanship, f or the warranty

period specified below, when the equipment i s installed in accordanc e with specifications prepared by Gasboy.

This warranty does not cover damage caused by acci dent, abuse, Acts of God, lack of surveillance of automatic recording system s, negligence,

mis-application, faulty installation, i mproper or unauthorized maintenance, i nstallation or use in violat i on of product manuals, i nstructions, or warnings.

Under no circumstanc e shall Gasboy be liable for any indirect, special, or cons equent i al damages, losses , or expenses to include, but not limited

to, loss of product, los s of profits, litigation fees , or the use, or inability to use, our product f or any f or any purpos e whatsoever.

Parts Only - During the warranty period, Gasboy will, at its option, repair or replace defective parts returned transportat i on prepaid to its factory.

On-Site Labor Included - Gasboy will also provide, within the Continental United States and during the warranty period, the services of an

Authorized Service Representati ve (A S R) for on-site repair or replacement of defective parts.

Replacement Parts - A ny system com ponents that are not part of the origi nal system order, incl udi ng Island Card Readers, Pump Cont rol Uni ts, etc.,

are considered replacement part s.

Equipment Term Coverage

Commercial Pumps and Dispensers

Full-Cabinet Consumer Pum ps

Small Transfer Pumps, Meters,

Pressure Regulators

Keytrol One year from date of instal l ation or 18 mos. from date of

Fuel Management Systems :

- CFN/ Profit Point

- Series 1000/Fleetkey

- TopKAT

- Fuel Point Readers

(sold with new systems)

Additional Fuel Point Items:

- Fuel Point Readers sold for

retrofitting existing systems.

- Fuel Point vehicle and dispenser

components.

Encoders, Embos sers, Modems,

CRTs, and Logger Printers

Air Diaphragm Pumps Three years from date of purchas e (for full warranty

Items not m anufactured by Gasboy

(ex. automatic nozzles, hoses, swivels,

etc.)

Replacement Parts One year from date of Gasboy International's invoice to the

To the extent permitted by law, this warranty is made in lieu of all other warranties , expressed or implied, incl udi ng warranties of freedom from pat ent

infringement, or merchant abilit y, or fitness for a particular purpos e, or arising from a course of dealing or usage of t rade. No one is authorized to

vary the terms of the warranty nor may anyone make any warranty of representation, or assume any liability other than that herein stated, in

connection with the sale desc ri bed herei n. The acceptance of any order by Gasboy I nt ernational is expressly made subj ect to the purchaser's

agreement to these condit i ons.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.- Excepting the Model 2020 Hand Pump, which

has a 90-day warranty from date of GASBOY International’s

invoice.

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first .- The basic warranty only applies to systems

which have been started up by a Gasboy Authorized Service

Representative (ASR).

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser,

whichever comes first.

Purchased with Fuel Management Syst em (Encoders,

Embossers only):

90 days from the date of s t art-up by a Gasboy ASR, or 180

days from date of Gasboy I nternational's invoice, whichever

occurs first.

Purchased with Fuel Management System

(Modems, CRTs, and Logger Printers only):

Matches system warranty.

Purchased Separately:

90 days from date of Gasboy International's

invoice to the purchaser.

description, see Price List).

Not warranted by Gasboy International (consul t original

manufacturer’s warranty).

purchaser.

GASBOY INTERNATIONAL LLC

P.O. Box 309, Lansdale, PA 19446 ● (800) 444-5579 ● FAX: (800) 444-5569 ● www.gasboy.com

Parts and Labor.

Parts Only.

Parts and Labor.

Parts and Labor.

Parts Only.

Purchased with System

(Encoders, Embos sers only):

Parts only.

Purchased with System (Modems,

CRTs, Logger Printers only):

Matches system warranty.

Purchased Separately:

Parts Only.

Parts Only.

Not Applicable.

Parts Only.

Loading...

Loading...