Page 1

Model 52 Pressure Regulator Valve

Installation/Parts Manual

MDE-4645A

(formerly 035340)

Page 2

Computer Programs and Documentation

Federal Communications Commission (FCC) Warning

All Gasboy computer programs (including software on diskettes and within memory chips) and documentation are copyrighted by, and shall remain the property of, Gasboy. Such

computer programs and documents may also contain trade secret information. The duplication, disclosure, modification, or unauthorized use of computer programs or

documentation is strictly prohibited, unless otherwise licensed by Gasboy.

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be re quired to correct the inte rference at his own exp ense. Changes or modifications not expressly approved by

the manufacturer could void the user’s authority to operate this equipment.

Approvals

Gasboy, Greensboro, is an ISO 9001:2000 registered facility.

Underwriters Laboratories (UL):

UL File# Products listed with UL

MH4314

MH6418

MH7404

MH10581 Key con t r o l u n i t , M o d e l G K E - B S e r i e s

All dispensers and self-contained pumping

units

Power operated Transfer Pump Models 25,

25C, 26, 27, 28, 72, 72S, 72SP , 72X, 73 and

1820

Hand operated Transfer Pump Models 1230

Series, 1243 Series, 1520 and 1720 Series

Card reader terminals, Models 1000, 1000P

Site controller, Model 2000S CFN Series

Data entry terminals, Model TPK-900 Series

Fuel Point Reader System

New York City Fire Department (NYFD):

NYFD C of A # Product

4823 9100A, 9140A, 9152A, 9153A,

4997 9822A, 9823A

5046 9100Q, 9140Q, 9152Q, 9153Q,

5087 8753K, 8853K, 9153K, 9853K

9800A, 9840A, 9850A, 9852A,

9853A, 9140

9800Q, 9840Q, 9852Q, 9853Q

(restricted to diesel and nonretail gasoline sales)

National Conference of Weights and Measures (NCWM) - Certificate of Compliance (CoC):

Gasboy pumps and dispensers are evaluated by NCWM under the National Type Evaluation Program (NTEP). NCWM has issued the following CoC:

CoC# Product Model # CoC# Product Model # CoC# Product Model #

95-179A2 Dispenser

95-136A5 Dispenser 9800 Series 91-057A3 Controller

9100 Retail Series, 8700

Series, 9700 Series

91-019A2 Dispenser

9100 Commercial

Series

1000 Series FMS,

2000S-CFN Series

California Air Resources Board (CARB):

Executive Order # Product

G-70-52-AM Balance Vapor Recovery

G-70-150-AE VaporVac

Patents

Gasboy products are manufactured or sold under one or more of the following US patents:

Dispensers

5,257,720

Point of Sale/Back Office Equipment

D335,673

Trademarks

Non-registered trademarks

Atlas™

Consola™

Infinity™

Registered trademarks

ASTRA

Fuel Point

Gasboy

Keytrol

Slimline

Additional US and foreign patents pending.

®

®

®

®

®

Additional US and foreign trademarks pending.

Other brand or product names shown may be

trademarks or registered trademarks of their

respective holders.

This document is subject to change without notice.

E-mail: literature@gasboy.com · Internet: http://www.gasboy.com

© 2009 GASBOY. All Rights Reserved

Page 3

Table of Contents

1 – Introduction 1

Purpose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Abbreviations and Acronyms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2 – Important Safety Information 3

3 – Installation 7

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Valve Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 – Parts 11

Model 52 Pressure Regulator Valve Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page i

Page 4

This page is intentionally left blank.

Page ii MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009

Page 5

Purpose Introduction

1 – Introduction

Purpose

The Model 52 Pressure Regulator Valve Installation/Parts Manual is provided to assist the

installer in installing and operating the unit and should be provided to the installer prior to the

installation of conduit. Faulty installations are the major cause for unit malfunctions. The

Model 52 Pressure Regulator Valve must be installed and operated as described in this manual.

Ensure that you leave this manual with the owner after the installation is complete.

Note: Customers and installers who have queries pertaining to the installation should contact

their Gasboy

The Model 52 Pressure Regulator Valve is a unique control valve developed for use with

suction-type island dispensers. The Model 52 Pressure Regulator can be used for

Aboveground Storage Tank (AST) installations or in booster systems with a submersible pump

in an Underground Storage Tank (UST).

The standard Model 52 Pressure Regulator Valve can be used in temperatures between -13 °F

to 130 °F (-25 °C to 54 °C). The Model 52 is not for use with methanol/ethanol applications.

®

distributor.

Abbreviations and Acronyms

Term Description

AST Aboveground Storage Tank

NEC National Electrical Code

NFPA National Fire Protection Association

PSI Pounds per Square Inch

UST Underground Storage Tank

Warranty

For information on warranty, refer to MDE-4255 Gasboy’ s Warranty Policy Statement. If you

have any warranty-related questions, contact Gasboy’s Warranty Department at its Greensboro

location.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page 1

Page 6

Introduction Warranty

This page is intentionally left blank.

Page 2 MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009

Page 7

2 – Important Safety Information

Important Safety Information

This section introduces the hazards and safety precautions

associated with installing, inspecting, maintaining or servicing

this product. Before performing any task on this product, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury, if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized individuals knowledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Emergency Total Electrical Shut-Off

The first and most important information you must know is

how to stop all fuel flow to the pump/dispenser and island.

Locate the switch or circuit breakers that shut off all power to

all fueling equipment, dispensing devices, and Submerged

Turbine Pumps (STPs).

!

WARNING

!

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical po wer to th e pump/

dispenser. This means that even if you activate

these stops, fuel may continue to flow

uncontrolled.

Read the Manual

Read, understand and follow this manual and any other

labels or related materials supplied with this equipment. If you

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Gasboy Service Center at 1800-444-5529. It is imperative to your safety and the safety of

others to understand the procedures before beginning work.

Follow the Regulations

Applicable information is available in National Fire Protection

Association (NFPA) 30A; Code for Motor Fuel Dispensing

Facilities and Repair Garages, NFPA 70; National Electrical

Code (NEC), Occupational Safety and Hazard Association

(OSHA) regulations and federal, state, and local codes. All

these regulations must be followed. Failure to install, inspect,

maintain or service this equipment in accordance with these

codes, regulations and standards may lead to legal citations

with penalties or affect the safe use and operation of the

equipment.

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate local regulations.

Safety Symbols and Warning Words

This section provides important information about warning

symbols and boxes.

Alert Symbol

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not the

console’s ALL STOP and PUMP STOP or

similar keys.

Total Electrical Shut-Off Before Access

Any procedure that requires access to electrical components

or the electronics of the dispenser requires total electrical

shut off of that unit. Understand the function and location of

this switch or circuit breaker before inspecting, installing,

maintaining, or servicing Gasboy equipment.

Evacuating, Barricading and Shutting Off

Any procedure that requires access to the pump/dispenser or

STPs requires the following actions:

• An evacuation of all unauthorized persons and vehicles

from the work area

• Use of safety tape, cones or barricades at the affected

unit (s)

• A total electrical shut-off of the affected unit (s)

This safety alert symbol is used in this manual and

on warning labels to alert you to a precaution which must be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning

labels tell you the seriousness of particular safety hazards.

The precautions below must be followed to prevent death,

injury or damage to the equipment:

DANGER: Alerts you to a hazard or unsafe practice

!

which will result in death or serious injury.

WARNING: Alerts you to a hazard or unsafe practice

!

that could result in death or serious injury.

CAUTION with Alert symbol: Designates a hazard or

!

unsafe practice which may result in minor inju ry.

CAUTION without Alert symbol: Designates a hazard

or unsafe practice which may result in property or

equipment damage

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will explode or burn, if ignited. Spilled

or leaking fuels cause vapors. Even filling customer tanks will

cause potentially dangerous vapors in the vicinity of the

dispenser or island.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page 3

Page 8

Important Safety Information

No Open Fire

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity , including an electrostatic charge

on your body, can cause a spark suffi c ien t to ig nite fuel

vapors. Every time you get out of a vehicle, touch the metal of

your vehicle, to discharge any electrostatic charge before you

approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Familiarize

yourself with Cardiopulmonary Resuscitation (CPR) methods,

if you work with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA Lockout/ Tagout procedures. If

you are not familiar with this requirement, refer to this

information in the service manual and OSHA documentation.

Working With Electricity Safely

Ensure that you use safe and established practices in working

with electrical devices. Poorly wired devices may cause a fire,

explosion or electrical shock. Ensure that grounding

connections are properly made. Take care that sealing

devices and compounds are in place. Ensure that you do not

pinch wires when replacing covers. Follow OSHA Lockout/

Tagout requirements. Station employees and service

contractors need to understand and comply with this program

completely to ensure safety while the equipment is down.

In an Emergency

Inform Emergency Personnel

Compile the following information and inform emergency

personnel:

• Location of accident (for example, address, front/back of

building, and so on)

• Nature of accident (for example, possible heart attack, run

over by car, burns, and so on)

• Age of victim (for example, baby, teenager, middle-age,

elderly)

• Whether or not victim has received first aid (for example,

stopped bleeding by pressure, and so on)

• Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on)

WARNING

!

Gasoline ingested may cause unconsciousness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciousness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in eyes may cause burns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately.

Hazardous Materials

WARNING

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Ensure that

you clean hands after handling equipment. Do not place any

equipment in the mouth.

!

WARNING

The pump/dispenser contains a chemical known to the

State of California to cause cancer.

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

Lockout/Tagout covers servicing and maintenance of

machines and equipment in which the unexpected

The pump/dispenser contains a chemical known to the

State of California to cause birth defects or ot her

reproductive harm.

energization or start-up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Subpart S of 29 CFR Part 1910 - Electrical

Hazards, 29 CFR Part 1910.333 contains specific Lockout/

Tagout provision for electrical hazards.

Page 4 MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009

Page 9

Hazards and Actions

Important Safety Information

!

WARNING

Spilled fuels, accidents involving pumps/dispensers, or uncontrolled fuel flow create a

serious hazard.

Fire or explosion may result, causing serious injury or death.

Follow established emergency procedures.

The following actions are recommended regarding these hazards:

Collision of a Vehicle with Unit Fire at Island Fuel Spill

• Do not go near a fuel spill or allow anyone else in the area.

• Use station EMERGENCY CUTOFF immediately. T urn of f all system circuit br eakers to the island(s).

• Do not use console E-STOP, ALL STOP and PUMP STOP to shut off power. These keys do not

remove AC power and do not always stop product flow.

• Take precautions to avoid igniting fuel. Do not allow starting of vehicles in the area. Do not allow

open flames, smoking or power tools in the area.

• Do not expose yourself to hazardous conditions such as fire, spilled fuel or exposed wiring.

• Call emergency numbers.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page 5

Page 10

Important Safety Information

This page is intentionally left blank.

Page 6 MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009

Page 11

Installation Precautions Installation

3 – Installation

Installation Precautions

All tanks and installations must conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code (NFPA 70), NFPA 30, Automotive and Marine Service

Station Code (NFPA 30A), and NFPA 395 codes and regulations.

Plan your installation carefully. Dispensing troubles, which seem to be pump-related, are

frequently traced to faulty installation. Review the following list of installation DOs and

DO NOTs to avoid potential problems:

• DO read the “Important Safety Information” on page 3. It contains important information

regarding the safe use of fuel dispensing equipment.

• DO have the valve installed by a qualified installer.

• DO remove the shipping plug from the vent opening for proper operation of valve.

• DO NOT experiment with fuel dispensing equipment if you are not sure whether the

installation is correct.

• DO NOT install any underground piping without proper swing joints. Always use

shoulder nipples, never close nipples.

• DO NOT cover any lines until they have been both air and liquid-tested.

• DO NOT back-fill the tank or supply line with cinders or ashes. Back-fill with clean sand,

crushed rock, or pea gravel.

• DO NOT use black iron pipe or fittings for underground installations. Use only new

galvanized or fiberglass* pipe and fittings.

* Install all fiberglass pipe and fittings according to manufacturer’s specifications and

requirements.

• DO NOT install the fill pipe to a tank where it can be submerged with standing water.

• DO NOT use the Gasboy fuel dispensing equipment to remove water ballast from the

storage tank.

• DO NOT use gaskets on covers of explosion-proof type boxes. The sealing compound

found at various locations within conduit is a requirement of the National Electrical Code

and should not be disturbed. Tighten the Junction Box covers before replacing panels.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page 7

Page 12

Installation Valve Requirements

Valve Requirements

The requirements of the Model 52 Pressure Regulator Valve are as follows:

• It must conform with all building/fire codes, all Federal, State, and Local codes, National

Electrical Code (NFPA 70), NFPA 30, Automotive and Marine Service Station Code

(NFPA 30A), and NFPA 395 codes and regulations.

• It is designed to operate in fueling systems that have a maximum pressure of 50 psi.

• Installation must include thermal expansion relief valves. Thermal expansion can cause

pressures in the system greater than 50 psi and can result in failure of the valve and loss of

product to the environment.

• Installation must include a solenoid valve positioned adjacent to the shutoff valve at the

tank. Its purpose is to prevent loss due to failure of the downstream piping or the system.

CAUTION

When a 52 valve is installed at the pump, never install a vacuum anti-siphon valve

at the top of a tank. An electric solenoid valve is required.

• Installation must locate the shear groove at the same level as the top of the concrete island

+1/2-inch (13 mm).

• Installation must include shutoff or gate valve to close the system and prevent product loss

when the equipment utilized in the fueling system downstream from the AST is being

serviced or replaced.

Refer to Figure 3-1 on page 9, Figure 3-2 on page 9, Figure 3-3 on page 10, and Figure 3-4 on

page 10 for additional requirements.

Troubleshooting

Refer to the parts drawing Figure 4-1 on page 12 for item references.

Problem Possible Cause

Product leaking out valve vent and/or pumping unit

vent.

No delivery when pump is turned on. • Failed Diaphragm (11).

• Diaphragm (11) has failed and an obstruction in the valve is

holding open the poppet complete (12).

• Gasket (7) and Diaphragm (11) have failed.

• Pressure Relief Valve assembly (4) and Diaphragm (11)

have failed.

• Valve vent blocked or shipping plug never removed.

Page 8 MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009

Page 13

Troubleshooting Installation

Figure 3-1: Flow Chart Model 52 Pressure Regulator

U

O

T

S

C

I

E

N

:

N

P

U

T

T

T

O

U

E

L

T

O

U

S

C

O

U

N

T

I

P

P

M

N

V

E

T

T

O

O

T

P

F

O

T

G

O

E

R

S

A

K

A

T

N

O

N

T

P

V

T

O

F

E

O

T

T

G

O

E

K

R

N

T

A

S

A

O

N

C

,

A

L

U

U

M

V

E

A

V

O

U

E

T

A

V

T

L

A

C

R

A

V

O

T

N

S

I

P

E

A

S

S

P

T

E

O

P

P

L

Y

B

M

L

V

E

V

A

O

T

I

P

L

H

O

T

U

R

E

E

R

L

D

:

O

E

N

T

B

S

L

G

A

N

C

I

O

U

E

R

S

D

S

E

R

A

E

H

P

Y

O

T

R

A

L

C

O

T

E

H

P

C

O

T

N

R

H

N

E

W

R

A

E

P

O

U

T

S

M

D

S

I

E

P

F

.

N

A

K

T

E

G

P

E

S

O

D

S

I

T

I

F

O

H

T

E

U

E

P

R

S

O

L

O

H

E

W

T

F

O

O

L

N

I

D

L

W

E

T

H

A

L

I

T

S

H

F

T

O

E

O

N

T

I

A

V

P

E

O

B

F

O

E

B

N

E

R

.

R

N

E

S

N

T

O

I

O

E

P

I

S

L

S

D

O

Q

I

U

L

N

O

D

O

M

F

R

O

P

E

O

V

L

E

I

V

R

P

E

D

A

R

N

E

H

D

I

E

O

I

V

L

5

E

2

E

R

T

D

C

U

T

S

E

R

D

H

A

S

R

H

D

A

Y

D

O

U

T

C

C

E

S

U

G

R

H

T

U

N

A

I

T

G

V

N

A

L

V

A

I

L

T

U

E

S

H

O

T

G

U

H

C

T

I

O

N

G

T

A

K

S

O

R

O

R

L

C

I

F

B

E

A

H

.

T

E

L

A

L

T

V

I

O

P

L

H

T

W

O

R

U

H

O

T

G

V

N

L

W

I

L

O

N

O

P

E

T

S

T

A

E

C

N

S

I

R

E

R

R

C

L

A

E

N

D

E

R

E

U

G

C

L

E

N

A

R

A

E

N

S

D

T

R

P

E

O

E

V

N

R

C

T

T

S

F

N

I

E

S

T

R

I

T

S

R

B

E

F

O

E

R

R

E

L

P

A

C

T

O

L

W

F

D

I

U

Q

I

O

E

A

L

N

S

P

D

I

D

S

I

N

E

T

O

O

S

T

Y

S

E

S

R

E

V

U

H

E

S

O

C

S

I

N

I

T

L

T

H

O

E

P

E

T

N

N

I

G

F

R

N

E

S

.

M

S

L

N

D

A

O

S

R

N

O

E

P

E

T

P

O

A

O

R

E

H

T

S

U

P

R

S

R

N

I

E

E

S

T

S

E

A

P

P

O

P

E

L

B

M

L

R

N

O

S

A

L

W

A

P

D

T

A

T

P

O

O

H

M

E

O

A

E

N

V

I

V

L

A

U

M

O

T

N

O

F

R

O

P

D

T

S

H

S

O

R

G

U

H

A

O

P

E

N

R

V

G

T

N

I

E

T

E

H

R

N

T

O

T

H

S

E

U

C

T

H

R

E

A

T

R

O

H

S

G

N

R

I

U

N

I

G

N

N

S

E

H

P

D

S

I

E

H

T

I

P

E

A

V

L

E

V

O

L

T

D

E

O

P

I

T

S

O

F

T

E

H

W

,

U

N

H

Y

T

I

N

R

I

H

C

U

D

C

L

H

F

T

O

W

T

O

T

S

N

N

O

L

Y

E

N

O

E

P

U

A

O

I

U

U

Y

R

C

Q

I

E

E

D

T

R

B

U

T

C

T

E

H

S

I

O

N

I

S

R

A

T

R

S

E

F

O

R

A

P

I

I

S

L

N

N

D

S

P

D

E

I

A

S

C

T

H

E

L

V

Y

R

B

Z

E

Z

L

E

O

N

A

C

L

E

N

A

D

A

U

B

N

S

T

T

O

P

T

S

N

I

P

E

R

O

N

I

A

G

P

,

O

N

A

T

N

V

H

I

A

M

E

S

E

R

U

H

H

T

Y

S

O

E

G

M

S

E

T

T

G

O

A

L

L

O

H

W

T

E

H

S

H

T

E

I

D

N

N

I

G

E

S

N

O

P

N

H

T

R

E

,

E

S

P

D

D

S

L

N

I

A

R

O

M

R

L

E

F

O

V

W

O

N

I

G

R

E

S

N

O

R

E

A

O

T

I

S

P

N

I

I

H

P

D

A

I

V

L

A

O

L

T

I

V

P

R

N

S

P

I

A

V

L

E

V

N

I

A

M

O

T

N

P

P

O

P

P

S

I

E

B

S

M

A

S

E

L

I

P

E

N

M

U

S

B

T

E

L

A

R

L

Y

.

U

O

S

E

L

V

S

E

F

O

T

R

B

S

U

H

.

U

H

S

G

C

N

S

I

E

R

N

E

E

R

A

R

N

I

S

R

C

E

N

I

N

E

L

A

V

B

I

N

T

N

I

O

E

V

G

E

R

E

N

E

E

H

E

L

V

.

Z

Z

L

E

U

S

W

H

T

H

E

R

E

N

.

O

1

R

O

R

"

O

M

H

Y

T

F

S

E

E

A

S

A

R

O

.

I

N

S

E

T

C

R

G

M

A

E

G

T

L

Y

V

O

L

A

V

E

T

T

E

I

L

:

N

O

E

N

T

T

N

T

O

C

P

A

O

.

Y

D

R

D

H

A

R

O

F

E

O

M

V

E

A

K

O

N

G

O

R

T

E

A

T

R

S

B

O

M

E

T

S

O

Y

R

S

E

S

T

P

N

E

O

P

S

U

I

D

S

T

I

H

C

D

T

E

E

A

R

M

Y

L

B

E

A

S

S

N

L

O

Z

S

I

E

Z

S

R

P

E

T

E

H

E

P

O

T

H

E

R

E

L

Z

Q

A

I

U

E

C

L

O

E

A

N

S

S

T

Y

S

T

E

H

T

E

A

U

R

P

T

C

M

E

M

S

C

U

F

A

U

O

M

E

V

O

T

.

E

V

L

A

N

V

E

P

O

.

N

O

I

S

O

T

I

E

O

T

T

H

T

O

E

H

N

B

H

Y

T

C

L

E

S

O

R

O

U

E

S

P

N

I

G

T

A

,

D

W

H

C

I

D

S

P

T

O

M

.

E

L

R

P

E

A

T

R

N

I

E

E

F

D

F

I

E

O

P

E

R

N

E

O

Z

,

D

H

T

E

O

N

T

B

N

O

T

S

I

H

A

L

L

T

E

F

H

S

E

U

S

R

G

A

N

I

T

L

.

W

Z

E

O

L

I

P

H

S

I

E

D

P

O

P

T

S

W

O

L

O

W

O

T

E

O

T

N

P

P

O

S

P

I

P

T

H

N

E

H

E

S

G

N

I

E

P

I

D

N

S

E

W

V

L

I

L

T

A

V

S

O

F

T

S

A

E

P

H

E

M

A

F

O

R

P

N

E

L

L

C

A

S

D

O

S

L

S

M

Y

I

B

E

E

T

L

N

A

V

O

I

V

D

C

U

H

T

T

R

U

G

O

H

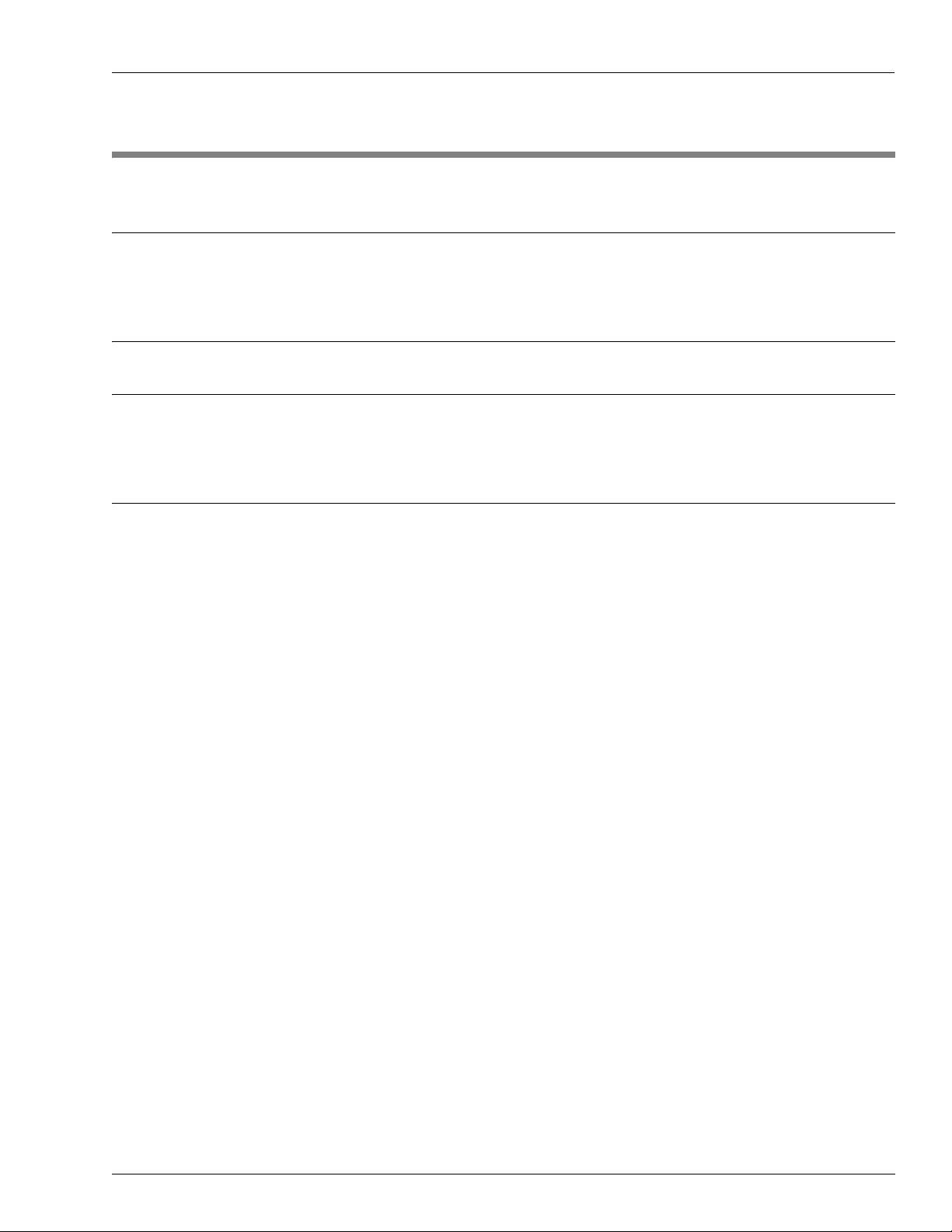

Figure 3-2: Schematic Piping Diagram

F

S

H

U

A

T

F

V

O

V

R

E

E

Q

L

R

B

D

Y

U

E

N

F

P

A

0

P

3

A

O

O

B

A

E

V

R

O

G

U

D

N

S

R

G

A

O

T

R

O

F

S

C

O

N

E

S

N

:

T

O

E

A

N

I

F

O

S

R

R

E

G

B

E

T

W

F

O

R

M

I

N

.

U

S

E

W

A

L

L

V

R

E

G

L

V

V

A

S

D

P

E

I

L

G

A

L

V

A

L

T

O

R

U

K

A

E

N

E

T

N

O

N

T

N

E

W

I

S

F

O

0

1

0

R

'

R

O

I

P

2

"

/

2

1

-

.

P

E

A

R

N

G

N

I

A

L

V

T

N

I

E

S

A

T

U

L

O

M

R

U

E

S

.

C

E

N

S

E

N

I

R

V

&

I

H

S

O

E

P

A

L

N

P

G

I

I

,

L

S

U

O

N

I

U

M

C

T

P

E

N

G

L

P

R

O

D

U

L

T

C

E

S

S

B

E

T

E

W

E

P

T

N

P

E

G

I

I

T

O

E

B

Q

P

U

E

P

I

E

E

K

N

A

T

N

E

R

A

T

G

O

A

T

T

S

R

E

D

T

E

N

F

A

P

O

R

U

M

S

T

P

.

O

V

T

S

U

C

T

N

A

N

H

T

E

O

T

I

D

W

H

K

N

O

I

U

T

C

L

I

A

A

0

A

P

3

N

L

M

D

O

T

G

I

E

N

B

E1-

E

R

O

T

I

K

&

K

H

E

T

H

.

O

U

5

P

R

2

E

S

S

1

O

F

0

R

0

N

.

M

I

1

2

"

/

B

U

"

0

T

0

1

N

M

P

P

U

,

U

P

O

.

M

P

S

M

M

D

O

I

E

R

A

M

L

E

E

R

O

'

U

N

D

E

3

0

R

0

U

S

'

A

L

P

L

M

U

N

I

G

P

I

1

V

E

0

R

0

B

U

'

T

R

L

5

E

S

S

P

2

U

R

X

S

A

N

P

R

E

N

O

L

I

S

F

N

R

E

L

E

S

S

P

E

.

I

P

2

"

E

2

B

S

T

"

E

U

N

D

3

0

E

R

0

'

E

E

F

I

I

R

1

7

2

2

.

-

.

A

E

L

N

D

I

O

V

E

L

V

A

P

A

3

0

P

A

R

2

A

-

V

M

V

A

E

L

A

N

C

H

O

R

M

B

I

E

D

D

E

H

P

P

R

E

L

L

E

A

N

K

G

I

P

I

N

N

P

I

G

I

A

C

D

C

I

E

N

W

I

M

B

Y

R

R

E

E

U

I

Q

D

7

1

.

S

B

U

T

S

E

E

C

U

R

E

L

E

D

T

N

I

D

E

V

E

N

F

R

O

E

H

T

T

.

R

I

E

O

S

P

O

T

O

Y

T

S

A

B

U

B

L

R

A

E

O

A

I

C

T

H

C

E

O

T

D

AMA

M

U

N

D

E

E

V

E

N

T

S

S

O

O

L

E

O

N

N

L

R

S

U

I

R

E

N

C

R

E

T

T

O

E

A

G

N

D

E

R

G

U

O

N

D

A

N

F

O

1

1

-

E

/

2

R

"

S

I

R

V

A

L

D

E

NOI

E

V

P

U

M

H

W

E

P

N

Y

N

I

G

.

N

N

S

U

C

T

I

P

O

U

N

P

M

S

H

E

A

R

S

E

C

O

T

I

E

V

N

E

H

T

T

I

H

W

P

F

O

U

M

P

P

P

I

E

V

E

N

T

O

F

S

T

R

O

A

G

T

C

O

O

I

A

L

F

O

T

N

O

P

R

2

E

5

S

S

N

T

R

A

W

O

U

.

O

O

E

N

T

I

F

R

K

H

E

I

M

O

M

D

E

L

A

G

T

U

L

O

R

U

M

D

A

N

I

D

L

S

T

I

E

H

T

H

L

E

E

A

T

S

F

0

7

N

N

F

P

,

A

P

N

B

O

T

E

T

O

M

E

B

A

.

S

T

O

T

O

P

A

E

N

K

.

T

M

O

K

M

D

E

H

E

I

L

R

E

A

T

R

L

O

E

G

.

U

5

S

P

R

2

S

U

E

R

E

N

S

T

A

I

L

T

B

S

E

L

E

C

C

O

T

R

A

3

D

R

D

A

N

C

E

E

M

N

R

E

U

I

Q

T

S

E

N

F

3

P

&

0

A

0

A

.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page 9

Page 14

Installation Troubleshooting

Figure 3-3: Booster System with Model 52 Pressure Regulators

S

U

C

T

O

P

I

U

N

M

P

S

S

T

F

S

Y

H

E

E

A

H

E

W

N

A

P

P

L

T

H

R

E

S

H

E

A

R

B

O

C

N

O

C

R

R

T

O

E

&

Y

L

A

S

E

R

C

E

V

I

E

X

F

L

I

S

A

E

R

C

I

.

T

N

O

A

S

S

Y

S

H

A

D

S

T

T

E

T

B

L

F

L

O

U

L

W

N

,

A

E

I

M

B

A

L

G

Y

W

R

E

N

E

A

R

B

E

I

N

G

E

C

O

T

I

O

F

M

O

I

E

S

L

A

N

N

I

E

E

E

X

B

L

I

R

T

P

E

S

C

H

B

T

W

N

E

E

E

S

E

C

O

T

I

A

N

N

D

G

E

T

I

H

T

N

E

D

.

E

T

N

E

N

H

I

V

W

P

U

P

M

B

A

S

E

.

C

L

A

P

M

O

M

5

D

E

L

N

.

O

2

P

R

S

E

U

R

R

E

E

S

G

U

L

A

T

R

N

D

P

I

P

R

E

E

E

P

I

D

O

N

O

T

U

V

A

L

V

W

E

P

R

E

U

R

S

S

D

A

A

M

E

G

O

P

A

M

C

T

S

I

E

T

M

I

H

O

D

5

E

L

2

U

R

E

E

L

G

A

O

T

R

A

M

-

C

O

U

C

Y

R

.

P

I

E

V

E

P

N

T

T

O

T

O

S

O

F

D

S

P

I

E

N

S

E

P

T

O

R

A

A

T

E

N

G

K

S

P

U

R

M

E

R

S

P

P

I

I

"

R

2

1

1

-

/

E

E

U

T

C

O

P

L

I

G

N

M

1

N

I

/

I

U

M

M

R

8

"

S

E

P

E

T

A

N

K

S

P

U

M

I

F

R

O

R

O

O

F

T

U

N

s

a

n

t

I

1

)

n

m

u

o

a

s

l

i

t

o

c

n

t

l

7

n

0

d

a

i

p

a

l

p

e

r

q

u

r

i

e

m

e

n

s

t

)

2

n

g

i

t

t

i

f

,

n

g

i

P

p

i

r

u

b

n

s

e

i

f

h

e

d

3

)

a

W

!

r

n

n

i

g

e

v

h

e

h

e

t

n

w

t

i

o

o

f

r

t

m

N

F

3

P

0

A

,

3

0

A

c

a

a

o

n

i

a

t

n

s

a

t

,

l

e

l

b

.

s

e

s

a

v

s

l

,

,

v

a

l

e

s

b

!

,

c

y

u

s

o

e

t

.

m

r

S

e

s

y

a

t

f

h

e

a

r

s

o

f

m

o

o

t

t

b

p

u

h

e

t

,

o

c

l

&

e

t

c

a

o

d

l

e

o

t

s

e

u

c

p

.

t

m

s

,

e

c

i

u

t

o

n

m

s

t

b

e

s

b

m

p

a

e

.

9

0

°

L

B

E

E

O

W

Figure 3-4: Approximate Overall Dimensions of Model 52 Pressure Regulator

9”

1-15/16

1-1/8”

5”

1-1/2”

9-1/4”

3”

3”

Page 10 MDE-4645A Model 52 Pressure Reg ulator Valve Installation/Parts Manual · Ap ril 2009

Page 15

4 – Parts

Parts

Using part numbers when you place an order will expedite your order and reduce the

possibility of the wrong parts being shipped. When ordering replacement parts, ensure that

you give the complete name and part number as shown in the appropriate parts lists.

Procedures that require the disassembly of portions of the fueling installation should be

performed by qualified service personnel. Do not depend upon the repair service of a general

mechanic unless he is thoroughly familiar with the mechanism. Gasboy has a distributor

network which services fuel dispensing equipment and management systems in every section

of the country.

WARNING

To reduce the risk of electrical shock when servicing, turn off and lock out all power to the

fuel dispensing system.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page 11

Page 16

Parts

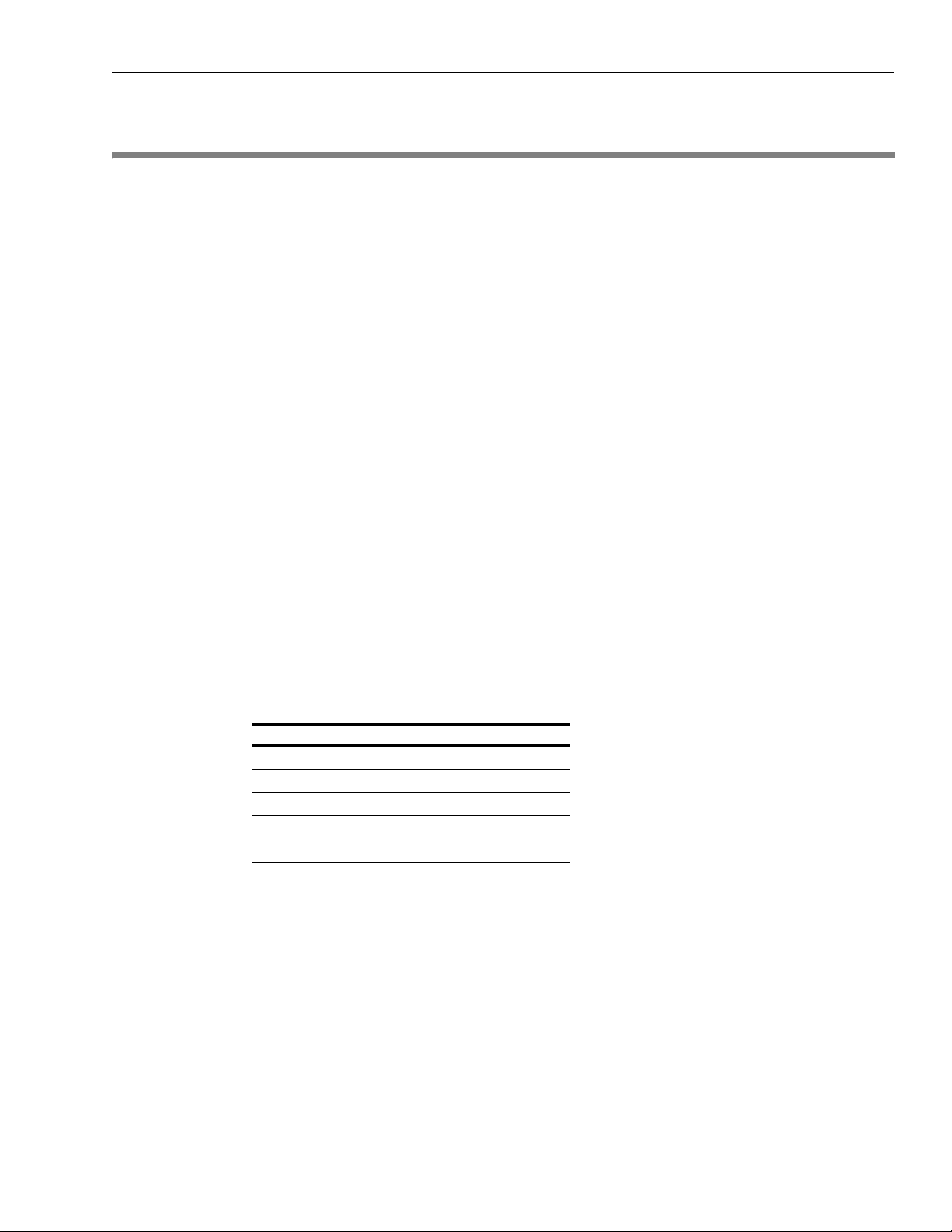

Figure 4-1: Model 52 Pressure Regulator Valve

Page 12 MDE-4645A Model 52 Pressure Reg ulator Valve Installation/Parts Manual · Ap ril 2009

Page 17

Model 52 Pressure Regulator Valve Parts List Parts

Model 52 Pressure Regulator Valve Parts List

Note: For the complete Model 52 Valve Assembly, order Gasboy Part Number 048577PG8.

Item Part Number Description

1 026768 Square Ring

2 014273 Square Ring

3 014274 Valve Cover

4 014319 Pressure Relief Valve Assembly

5 063312 Suction Screen Complete, Gas

063313 Suction Screen Complete, Diesel

6 014262 Pilot Valve Spring

7 014318 Gasket

8 014277 Valve Spring

9 063203 Suction Strainer Cap

10 014267 Safety Shear Section

11 014317 Diaphragm (for Model 52)

12 014276 Poppet Complete

13 014280 Poppet Assembly

14 014263 Valve Actuator

15 014320 Valve Body Assembly, Model 52

Note: When replacing this assembly on a Model 52, the Model 52

Diaphragm is also required.

16 014282 Diaphragm Cover

17 003433 Screen Adapter Coupling

18 K43625 1/4-20 X 3/4" Long Hex Head Cap Screw

19 K01914-75 7/16-14 X 1-1/4" Long Hex Head Cap Screw

20 K08674

21 K02278 1/8” Plug Pipe

22 K78953-30 1/4” Plug, Protective Closure

°

90

Street Elbow

Note: Gasboy has redesigned the Model 52 Pressur e Regulator Valve eliminating the need for

a “cold weather” version of the valve. A new Diaphragm and standardized diesel

strainer are now included with the standard valve making it appropriate for warm and

cold weather conditions.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009 Page 13

Page 18

Parts Model 52 Pressure Regulator Valve Parts List

© 2009 GASBOY

7300 West Friendly Avenue · Post Office Box 22087

Greensboro, North Carolina 27420

Phone 1-800-444-5529 · http://www.gasboy.com · Printed in the U.S.A.

MDE-4645A Model 52 Pressure Regulator Valve Installation/Parts Manual · April 2009

Loading...

Loading...