Page 1

SERIES 4860

METER-REGISTER

INSTALLATION/OPERATION/PARTS

MANUAL

035352

Rev. 03/07/03

INSTALLERS - IMPORTANT

In addition to installation information, this manual contains warnings, safeguards

and procedures on the use and care of the Series 4860 Meter-Register. Please

leave this manual with the meter owner after the installation is complete.

Copyright 2003 by Gasboy International LLC All rights reserved.

The information in this document is confidential and proprietary. No further disclosure shall be made without

permission from Gasboy International LLC Gasboy International LLC believes that the information in this document

is accurate and reliable. However, we assume no responsibility for its use, nor for any infringements of patents or

other rights of third parties resulting from its use. We reserve the right to make changes at any time without notice.

GASBOY INTERNATIONAL LLC LANSDALE, PA

Page 2

IMPORTANT WARNINGS AND SAFEGUARDS

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

OF A FUEL SPILL.

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to th e en tir e syste m. Instr ucti ons

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

DO NOT use Teflon tape for any pipe

threads in the product.

DO NOT use consumer pumps for

pumping fuel or additives into aircraft.

DO NOT use commercial pumps for

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT use where sanitary design is

required (for food products for human

consumption) or with water-based

liquids.

DO NOT smoke near the pump or when

using the pump.

DO NOT use near open flame or

electrical equipment which may ignite

fumes.

DO NOT permit the dispensing of

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT permit the dispensing of

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

including tru cks. All co ntai ners must be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT block open the nozzle in any

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO ensure that the pump is equipped

with proper filters based on the product

being dispensed and its intended use.

DO wear safety goggles and protective

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO keep all parts of body and loose

clothing clear of belts, pulleys, and

other exposed moving parts at all times.

DO require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO provide a receptacle for catching

product from pump/meter when

servicing.

DO clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO insure pump is properly grounded.

DO insure hose is compatible with fluid

being dispensed.

DO inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

035282 Rev. 1267

GASBOY INTERNATIONAL LLC

707 North Valley Forge Rd. Lansdale, PA, 19446 ● (215) 855-4631 ● FAX: (215) 855-0341

Page 3

INSTALLATION/OPERATION/PARTS

INSTALLATION

The 4860 meter can be installed either vertically or horizontally in a piping system. The inlet and

outlet are 90

strainer in the meter inlet to prevent jamming from foreign material. A 40 mesh or finer basket is

required.

o

apart and can be rotated in relation to the register by 90o increments. Install a

OPERATING CHARACTERISTICS

The 4860 meter uses a nutating disc type measuring chamber and can be calibrated using an

adjusting screw. The pushbutton register records in gallons or liters up to 999 9/10. The totalizer

is a 7-wheel counter which records up to 999,999.9 gallons or liters. Pushing in the reset button

resets the four-wheel register to zero. Change gears permit the meter to be US gallons or liter

measure. The 4860 meter will accurately measure liquids with viscosities of less than 120 SSU

o

(60

F) (16oC) at flow rates fr om 4 to 15 G PM or 15 to 57 LPM. Although designed specifically for

petroleum products, the 4860 meter can be used in applications where the materials are

compatible with recommendations of the manufacturer of the chemical or substance under

consideration.

CALIBRATION

NOTES: This meter was redesigned causing the calibration procedure to be different depending

on the age of your meter. Meters made after May 10,1995 are referred to as new style

meters; meters made before that date are referred to as old style.

This meter is for consumer use only and not for re-sale. It is not sealable by Weights

and Measures.

All GASBOY meters are adjusted for accurate measure for diesel within +

factory. However, since the conditions of the installation can affect pump accuracy, it is the

responsibility of the installer to check the pump for accuracy and make any needed adjustments.

Choose the flow rate at which the meter will be used most often for the zero calibration point. For

example, if the pump is being used with an automatic nozzle, calibrate with the nozzle set on the

middle or top notch position, whichever is used most frequently.

Use a certified five-gallon measure with a sight glass and scale showing cubic inches over or

under an exact five gallons. Fill and drain the test measure to completely wet the interior surfaces.

Reset the register to zer o and deliver an exact measured five gallons into the test measur e at the

selected flow. Read the level of the liquid in the sight glass on the scale in +

03/07/03 1

.05 gallons at the

cubic inches.

Page 4

GASBOY Model 4860 Meter

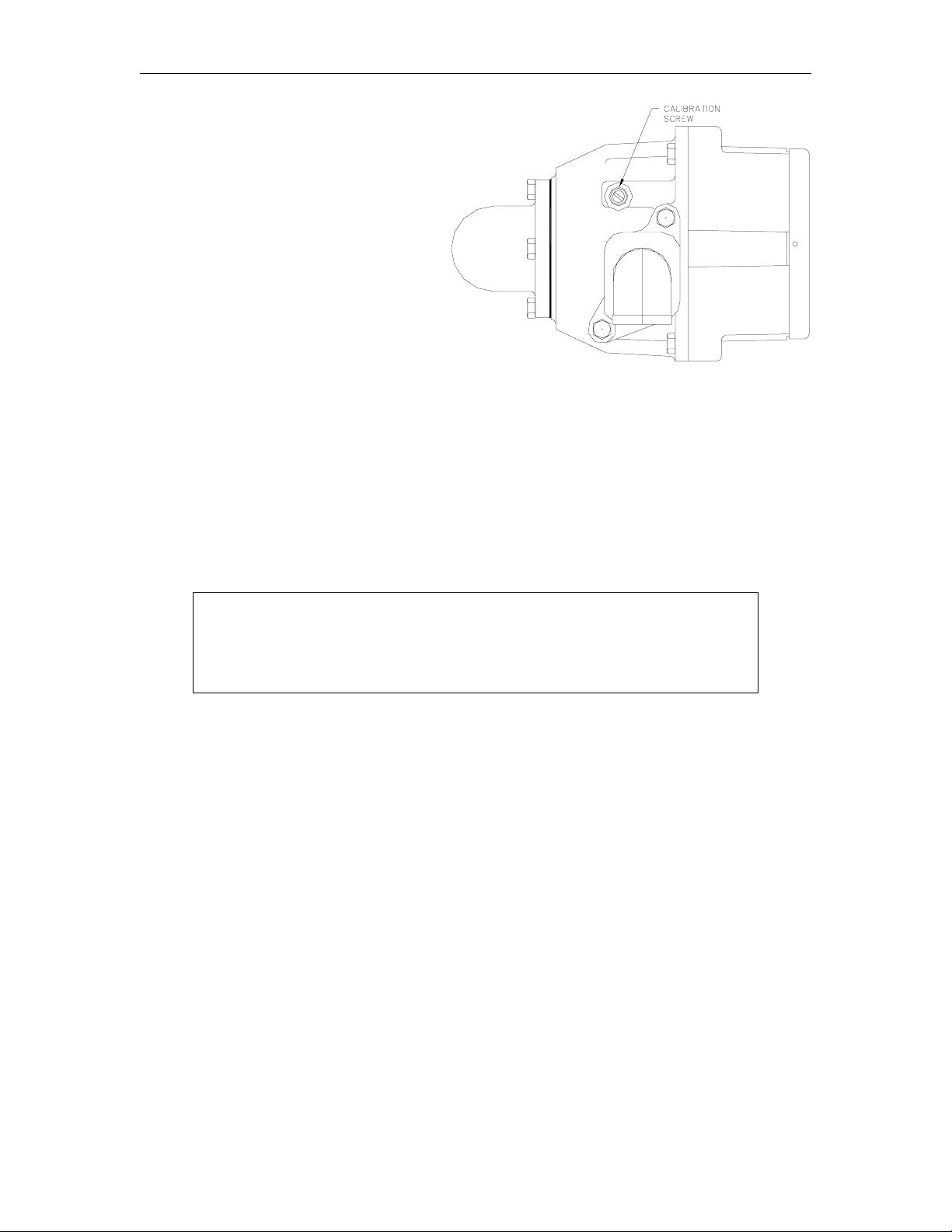

For old style meters only, remove cap

screw, exposing the slotted head

calibration screw. Use a narrow blade

screw driver to turn the calibration screw

clockwise to correct for plus cubic inches

or counterclockwise for minus cubic inches

in the test measure.

Count the number of full turns and

fractional turns each time for reference in

judging the number and direction of any

additional turns required to calibrate the

meter to exact zero.

For new style meters, start with the screw turned all the way in clockwise. For gasoline

calibration, turn the screw approximately two full turns counter-clockwise. For diesel, turn the

screw approximately two additional full turns counter-clockwise.

Replace the cap screw (old style only) . Deliver about 1/2 gallon thr ough the meter before r esetting

to zero and retesting. Allow a ten second drain period each time the test measure is emptied to

assure accurate measure. Adjust and retest until register is zeroed at desired flow.

SERVICE

WARNING:

To reduce the risk of electrical shock when servicing, turn off and lock out all

power to the meter/pump.

NOTE: Numbers in parentheses correspond to the numbers shown on the parts illustration and

To service the pushbutton register, remove two (one on each side) screws (2) from bezel (1).

Remove bezel (1), gasket (3), and dial mask (4). Reset button (5) and spring (6) are released

when dial mask is removed. Remove screws (7), reset bearing (8 ) and screws (11) and lift out

register assembly. Drive shaft assembly (12) may be removed by taking out four bearing screws.

Replacing Bearing and Seal Assembly (Item 16, Old Style)

To replace the shaft seal or service the gear train on back of register housing (18), remove

housing from meter body by taking out four screws. NOTE: The meter housing will be full of liquid

so some means should be available to catch what drains from the case and lines. To remove

gears (22-25), remove three retaining rings (20) and dr ive key (21). Withdraw the drive shaft and

gear (14), spacer (15), meter stuffing box (16), and O-ring (17). Slide new O-ring over new

bearing seal like you would slide a ring on your finger. Insert shaft (14) through spacer (15) and

bearing (16) as shown in the exploded view. Press entire assembled shaft and seal through

housing and seat the square of the bearing firmly into the recess in the register housing (18).

Reassemble the balance of the register in reverse order of disassembly.

parts list on pages 4 and 5.

2 03/07/03

2

Page 5

Installation/Operation/Parts

Replacing Bearing and Seal Assembly (Item 48, New Style)

To replace the bearing and shaft seal assembly (48), or service the gear train on back of register

housing (18), remove housing from meter by taking out four screws. NOTE: The meter housing

will be full of liquid so some means should be available to catch what drains from the case and

lines. To remove gears (22-25), remove three r etaining rings (20) and drive key (21). Withdraw

the drive shaft and gear (14), spacer (15), and all parts of bearing and seal assembly (48).

Remove the nylon washer from item 48 and note its location. Remove both oilite bearings and

both O-rings from bore in register housing. Using new parts, which consist of a new nylon washer,

2 oilite bearings, and 2 O-rings, reassembly parts in reverse order. Be sur e to lubricate both Orings with an O-ring lubricant before assembling.

Reassemble Gear Train

Reassemble gear train as follows: gear (24), key (21) , cluster gear (25) , r etaining ring (20) , contr ol

block (22), and retaining ring (20).

B-SIZE MEASURING CHAMBER DISASSEMBLY

The B-size measuring chamber can be r emoved for cleaning by taking out the four meter body

screws (33) and lifting off the register housing (18). Remove the three measuring chamber screws

(26). After separating the two halves and cleaning, reassemble, making sure the metal baffle (30)

is seated in the groove in the two halves and through the slot in the measuring disk (29). Do not

sharply strike or drop the phenolic parts while handling. Rotate the disk ( 29) to make sure it turn s

freely and replace in the meter body (32). Do not overtighten the screws. A torque of 20-25

pounds is sufficient. When reassembling the register to the old meter body, use a new O-ring

(19).

PARTS LIST

This manual lists parts information for the Model 4860 Meter. Using part numbers when ordering

will expedite your order and reduce the possibility of the wrong parts being shipped. When

ordering replacement parts, be sure to give the complete name and part number as shown in the

appropriate parts lists.

Procedures requiring disassembly of portions of the meter should be performed by competent

service personnel. Do not depend upon the repair service of a general mechanic unless he is

thoroughly familiar with the mechanism. GASBOY has a distributor network which services fuel

dispensing equipment and management systems in every section of the country.

WARNING:

To reduce the risk of electrical shock when servicing, turn off and lock out all

power to the meter/pump.

03/07/03 3

Page 6

GASBOY Model 4860 Meter

NEW STYLE

(Mfr. after May 10,1995)

4 03/07/03

4

Page 7

Installation/Operation/Parts

NEW STYLE METER - MANUFACTURED AFTER 5-1 0-95

036341 Meter Register, US Gallons

036343 Meter Register, Liters

036400 Register Assy., US Gallons (Consists of items 1-18, 20-25)

036404 Register Assy., Liters (Consists of items 1-18, 20-25)

Item Part No. Description

1 012236 Bezel

2 052693 Bezel Screw

4 035309 Dial Mask, U.S. & Imperial

035313 Dial Mask, Liter Measure

5 017269 Reset Button

6 057985 Reset Button Spring

7 053737 Reset Bearing Screw

8 011816 Reset Bearing

9 028736 Dial Glass

10 S00758 Register and Glass Assembly

11 053901 Register Screws

12 054513 Drive Shaft Assembly

13 053626 Drive Shaft Assembly Screw

14 054522 Drive Shaft and Gear

15 056791 Spacer

16 014095 Bearing & Seal Assy. (old

style) Use item 48 if Rev G is

cast onto rear of housing.

17 048865 O-ring

18 031020 Register Housing Assembly

19 049075 O-ring

20 049390 Retaining Ring

21 031345 Drive Key

22 -25 See Change Gears below

26 025851 Screw, phenolic chamber

052750 Screw, bronze chamber

27 019016 Measuring Chamber, phenolic

(Standard, sold as assembly

only. Consists of items 28-31)

019015 Measuring Chamber, Bronze

(Optional)

28 Measuring Chamber, Top

29 Measuring disk

30 Baffle

31 Measuring Chamber, bottom

32 012790 Meter Body

33 051835 Meter Body Screw

34 027055 Gasket

37 053081 Adjusting Screw

38 048895 O-ring

39 003560 Discharge Flange, 1"

40 052090 Discharge Flange Screw

Item Part No. Description

41 063400 Inlet Flange & Strainer

Assembly, 1"

42 051880 Strainer Cover Screw

43 022915 Strainer Cover

44 027355 Strainer Cover Gasket

45 063295 Strainer

46 003305 Strainer Body, 1", 60

47 051985 Inlet Flange Screw

48 036995 Bearing & Seal Assy. (new

style)

NOTE: New style assy. used

on meters made after mid-

1993. Use items 16 & 17 if no

Rev is cast onto rear of

housing.

CHANGE GEARS

US - Gas and Diesel

22 012491 Control Block, 12T

012490 Control Block, Bronze, 12T

23 028168 Cluster Gear, 12T-39T

24 028448 Drive Gear, 36T

25 028172 Cluster Gear, 15T-38T

Liters - Gas and Diesel

22 012491 Control Block, 12T

012490 Control Block, Bronze, 12T

23 028172 Cluster Gear, 15T-38T

24 028151 Drive Gear, 25T

25 028175 Cluster Gear, 29T-36T

Imperial - Gas and Diesel

22 012491 Control Block, 12T

012490 Control Block, Bronze, 12T

23 028168 Cluster Gear, 12T-39T

24 028449 Gear, 37T

25 028174 Cluster Gear, 13-39T

o

03/07/03 5

Page 8

GASBOY Model 4860 Meter

OLD STYLE

(Mfr. before May 10,1995)

6 03/07/03

6

Page 9

Installation/Operation/Parts

036341 Meter Register, US Gas

036342 Meter Register, US Diesel

036343 Meter Register, Liter Gas

036400 Register Assy., US Gasoline (Consists of items 1-18, 20-25)

036401 Register Assy., US Diesel (Consists of items 1-18, 20-25)

036404 Register Assy., Liter Gas (Consists of items 1-18, 20-25)

036405 Register Assy., Liter Diesel (Consists of items 1-18, 20-25)

Item Part No. Description

1 012236 Bezel

2 052693 Bezel Screw

3 026786 Gasket

4 035309 Dial Mask, U.S. & Imperial

035313 Dial Mask, Liter Measure

5 017269 Reset Button

6 057985 Reset Button Spring

7 053737 Reset Bearing Screw

8 011816 Reset Bearing

9 028736 Dial Glass

10 S00758 Register and Glass Assembly

11 053901 Register Screws

12 054513 Drive Shaft Assembly

13 053626 Drive Shaft Assembly Screw

14 054522 Drive Shaft and Gear

15 056791 Spacer

16 014095 Bearing & Seal Assy. (old

style) Use item 48 if Rev G is

cast onto rear of housing.

17 048865 O-ring

18 031020 Register Housing Assembly

19 049075 O-ring

20 049390 Retaining Ring

21 031345 Drive Key

22 -25 See Change Gears below

26 025851 Screw, phenolic chamber

052750 Screw, bronze chamber

27 019016 Measuring Chamber, phenolic

(Standard, sold as assembly

only. Consists of items 28-31)

019015 Measuring Chamber, Bronze

(Optional)

28 Measuring Chamber, Top

29 Measuring disk

30 Baffle

31 Measuring Chamber, bottom

32 012790 Meter Body

33 051835 Meter Body Screw

34 027055 Gasket

35 053080 Adjusting Screw

36 048865 O-ring

37 052195 Adjusting Screw Cap

38 048895 O-ring

39 003560 Discharge Flange, 1"

40 052090 Discharge Flange Screw

036344 Meter Register, Liter Diesel

036345 Meter Register, Imperial Gas

036346 Meter Register, Imperial Diesel

Item Part No. Description

41 063400 Inlet Flange & Strainer

42 051880 Strainer Cover Screw

43 022915 Strainer Cover

44 027355 Strainer Cover Gasket

45 063295 Strainer

46 003305 Strainer Body, 1", 60

47 051985 Inlet Flange Screw

48 036995 Bearing & Seal Assy. (new

CHANGE GEARS - U.S. GALLONS

22 012491 Control Block, 12T

012490 Control Block, Bronze, 12T

23 028168 Cluster Gear, 12T-39T

24 028450 Drive Gear, 37T, Gas

028465 Drive Gear, 38T, Diesel

25 028172 Cluster Gear, 15T-38T, Gas

028173 Cluster Gear, 15T-39T, Diesel

CHANGE GEARS - LITERS, TENTHS (99.9)

22 012491 Control Block, 12T

012490 Control Block, Bronze, 12T

23 028172 Cluster Gear, 15T-38T, Gas

028173 Cluster Gear, 15T-39T, Diesel

24 028151 Drive Gear, 25T, Gas

028171 Drive Gear, 26T, Diesel

25 028175 Cluster Gear, 29T-36T

CHANGE GEARS - IMPERIAL GALLONS

22 012491 Control Block, 12T

012490 Control Block, Bronze, 12T

23 028168 Cluster Gear, 12T-39T

24 028449 Drive Gear, 37T, Gas

028163 Drive Gear, 39T, Diesel

25 028174 Cluster Gear, 13-39T

Assembly, 1"

o

style)

NOTE: New style assy. used

on meters made after mid-

1993. Use items 16 & 17 if no

Rev is cast onto rear of

housing.

03/07/03 7

Page 10

GASBOY Model 4860 Meter

SPECIFIC METER MODEL CONFIGURATIONS

All flanged castings are interchangeable and can be mixed to match special requirements. Please

consult the nearest Gasboy representative for special applications. All configurations shown on

this page and the next page use the following parts list.

Item Part No. Description

1 052000 Inlet Flange Screw

2 027055 Gasket

3 003597 Inlet Flange, 3/4", 15

4 052105 Discharge Flange Screw

5 003542 Discharge, 3/4", Vac. breaker

6 003235 Hose Drain Valve Body

7 066570 Vacuum Breaker

o

Item Part No. Description

8 052105 Discharge Screw

9 030205 Nozzle Hook

10 052090 Body & Nozzle Hook Screw

11 003650 Inlet Flange, 1"

12 052112 Inlet Flange Screw

13 003560 Discharge Flange, 1"

035867 Model 4860-7A

For Hand Pump Applications

Hose drain valve body equipped with vacuum breaker to

permit easy draining of hose and prevent siphoning on

aboveground tank applications. Nozzle boot and hook

provided to hang up hand pump nozzle. 1" NPT inlet; 3/4"

NPT outlet.

035882 Model 4860-4D

For Straight Piping Applications

Register can be oriented to any of four 90

o

positions for

proper reading to conform to vertical or horizontal straight

piping requirements. 1" NPT inlet and outlet.

8 03/07/03

8

Page 11

Installation/Operation/Parts

035888 Model 4860-4E

o

For 90

Register can be oriented to any of four 90

Turn Piping Applications

o

positions for

proper reading to conform to piping requirements. 1" NPT

inlet and outlet.

035936 Model 4860-4F

For Electric Pump Applications

Inlet flange offset to tip register back 15

o

from vertical

for convenient reading. Discharge flange angled at

o

30

to prevent hose kink at coupling. 3/4" NPT inlet

and outlet.

033026 REPAIR KIT, 4860 METER

Item Part No. Description

1 S00758 Register and Glass Assembly

2 036995 Meter Parts-Stuffing Box

3 027055 Gasket, Inlet-Outlet

4 027355 Gasket, Strainer Cover

5 031345 Key, Spring

6 057985 Setback Spring

7 048895 O-RIng, 5/16 x 7/16

8 049075 O-RIng, 4-5/8 x 4-7/8

9 049390 E-Ring, 5-33-15

10 011816 Bearing

11 017269 Reset Button

12 014095 Bearing, Seal-Stuffing Box

13 018074 O-Ring, 5/32 x 9/32

03/07/03 9

Page 12

GASBOY Model 4860 Meter

METER BREAKDOWN/FILTER

Item Part No. Description

1 044512 Pipe, 1 x 1-3/4”

2 003044 Filter Adapter, 1”

3 026005 Filter, 7 Micron, Particulate only

026015 Filter, 30 Micron, Water and Particulate

026042 Filter, 10 Micron, Water and Particulate

025909 Filter, 1 Micron, Particulate only, Methanol

10 03/07/03

10

Page 13

GW01 - 6/04/02 Rev. 1

WARRANTY

General Statements:

Gasboy International LLC warrants all new equipm ent manufactured by Gasboy against defective material and/ or workmanship, for the warranty

period specified below, when the equipment i s installed in accordance with specifications prepared by Gas boy.

This warranty does not cover damage caused by ac cident, abuse, Acts of God, lack of surveillance of automatic recording systems, negligence,

mis-application, faulty installation, i mproper or unauthorized maintenance, i nstallation or use in violati on of product manuals , i nstructions, or warnings.

Under no circumstanc e shall Gasboy be liable for any indirect , special, or consequenti al damages, losses, or expenses to include, but not limited

to, loss of product, loss of profits, litigation f ees, or the use, or inability to use, our product for any for any purpose whatsoever.

Parts Only - During the warranty period, Gasboy will, at its option, repair or replace defective parts returned transportation prepaid to i ts factory.

On-Site Labor Included - Gasboy will also provide, within the Continental Unit ed States and during the warranty period, the services of an

Authorized Service Representati ve (ASR) for on-site repair or replacement of defective parts.

Replacement Parts - Any system com ponents that are not part of the origi nal system order, includi ng I sland Card Readers, Pump Control Uni ts, etc.,

re considered replacement parts.a

Equipment Term Coverage

Commercial Pumps and Dispensers

Full-Cabinet Consumer Pumps

Small Transfer Pumps, Meters,

Pressure Regulators

Keytrol One year from date of instal l ation or 18 mos. from dat e of

Fuel Management Systems :

- CFN/ Profit Point

- Series 1000/Fleetkey

- TopKAT

- Fuel Point Readers

(sold with new systems)

Additional Fuel Point Items:

- Fuel Point Readers sold for

retrofitting existing sys tems.

- Fuel Point vehicle and dispenser

components.

Encoders, Embos sers, Modems,

CRTs, and Logger Printers

One year from date of instal l at i on or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of instal l at i on or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first . - E xcept i ng t he Model 2020 Hand Pump, which

has a 90-day warranty from date of GASBOY International’s

invoice.

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of start -up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first .- The basic warranty only applies to sys tems

which have been started up by a Gasboy Authorized Servi ce

Representative (ASR).

One year from date of start -up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser,

whichever comes first.

Purchased with Fuel Management Syst em (Encoders,

Embossers only):

90 days from the date of s tart-up by a Gasboy ASR, or 180

days from date of Gasboy I nternational's invoice, whichever

occurs first.

Parts and Labor.

Parts Only.

Parts and Labor.

Parts and Labor.

Parts Only.

Purchased with System

(Encoders, Embos sers only):

Parts only.

Purchased with Fuel Management System

(Modems, CRTs, and Logger Print ers only):

Matches system warranty.

Purchased Separately:

90 days from date of Gasboy I nternational's

invoice to the purchaser.

Air Diaphragm Pumps Three years from date of purchas e (for full warranty

Items not m anufactured by Gasboy

(ex. automatic nozzles, hoses, swivels,

etc.)

Replacement Parts One year from date of Gasboy Int ernational's invoice to the

To the extent permitted by law, this warranty is made in lieu of all other warranties, expressed or implied, inc l udi ng warranties of freedom from patent

infringement, or merchantability, or fitness for a part i c ular purpose, or arising from a course of dealing or us age of trade. No one is authorized to

vary the terms of the warranty nor may anyone make any warranty of representation, or assume any liability other than that herein stated, in

connection with the sale described herein. The acceptance of any order by Gasboy International is expressly made subject to the purchaser's

greement to these conditions.a

description, see Price List).

Not warranted by Gasboy International (consul t original

manufacturer’s warranty).

purchaser.

Purchased with System (Modems,

CRTs, Logger Printers only):

Matches system warranty.

Purchased Separately:

Parts Only.

Parts Only.

Not Applicable.

Parts Only.

GASBOY INTERNATIONAL LLC

P.O. Box 309, Lansdale, PA 19446 ● (800) 444-5579 ● FAX: (800) 444-5569 ● www.gasboy.com

Loading...

Loading...