Page 1

215S/216S

SATELLITE

PARTS MANUAL

035251

REV. 03/07/03

The information in this document is confidential and proprietary. No further disclosure shall be made without

permission from Gasboy International LLC. Gasboy International LLC believes that the information in this document

is accurate and reliable. However, we assume no responsibility for its use, nor for any infringements of patents or

other rights of third parties resulting from its use. We reserve the right to make changes at any time without notice.

Copyright 2003 by Gasboy International LLC All rights reserved.

GASBOY INTERNATIONAL LLC LANSDALE, PA

Page 2

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to th e enti re system. Instru ctions

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

IMPORTANT WARNINGS AND SAFEGUARDS

OF A FUEL SPILL.

DO NOT use Teflon tape for any pipe

threads in the product.

DO NOT use consumer pumps for

pumping fuel or additives into aircraft.

DO NOT use commercial pumps for

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT use where sanitary design is

required (for food products for human

consumption) or with water-based

liquids.

DO NOT smoke near the pump or when

using the pump.

DO NOT use near open flame or

electrical equipment which may ignite

fumes.

DO NOT permit the dispensing of

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT permit the dispensing of

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

includin g trucks. All contain ers must be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT block open the nozzle in any

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO ensure that the pump is equipped

with proper filters based on the product

being dispensed and its intended use.

DO wear safety goggles and protective

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO keep all parts of body and loose

clothing clear of belts, pulleys, and other

exposed moving parts at all times.

DO require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO provide a receptacle for catching

product from pump/meter when

servicing.

DO clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO insure pump is properly grounded.

DO insure hose is compatible with fluid

being dispensed.

DO inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

035282 Rev. 1267

GASBOY INTERNATIONAL LLC.

707 North Valley Forge Rd. Lansdale, PA, 19446 ● (215) 855-4631 ● FAX: (215) 855-0341

Page 3

CONTENTS

General .................................................................................................... 1

Final Assemblies

215S, Final Assembly - Front View .......................................................... 2

215S, Final Assembly - Side View ........................................................... 3

216S, 1" Nozzle Final Assembly - Front View .......................................... 4

216S, 1" Nozzle Final Assembly - Side View ........................................... 5

216S, 1-1/4" Nozzle Final Assembly - Front View .................................... 6

216S, 1-1/4" Nozzle Final Assembly - Side View ..................................... 7

Chassis Assemblies

215S Chassis - Front View ....................................................................... 8

215S Chassis - Side View ........................................................................ 9

216S Chassis - Front View ....................................................................... 10

216S Chassis - Side View ........................................................................ 11

Breakdown

Switch Housing and Wire Assembly.......................................................... 12

High Hose Retriever.................................................................................. 13

Warranty

03/07/03 Contents-1

Page 4

Page 5

PARTS LIST

GENERAL

This manual lists parts information for the Model 215S and 216S Satellites. Using par t numbers

when ordering will expedite your order and reduce the possibility of the wrong parts being shipped.

When ordering replacement parts, be sure to give the complete name and par t number as shown

in the appropriate parts lists. It is also helpful to supply the serial number of the equipment.

03/07/03 1

Page 6

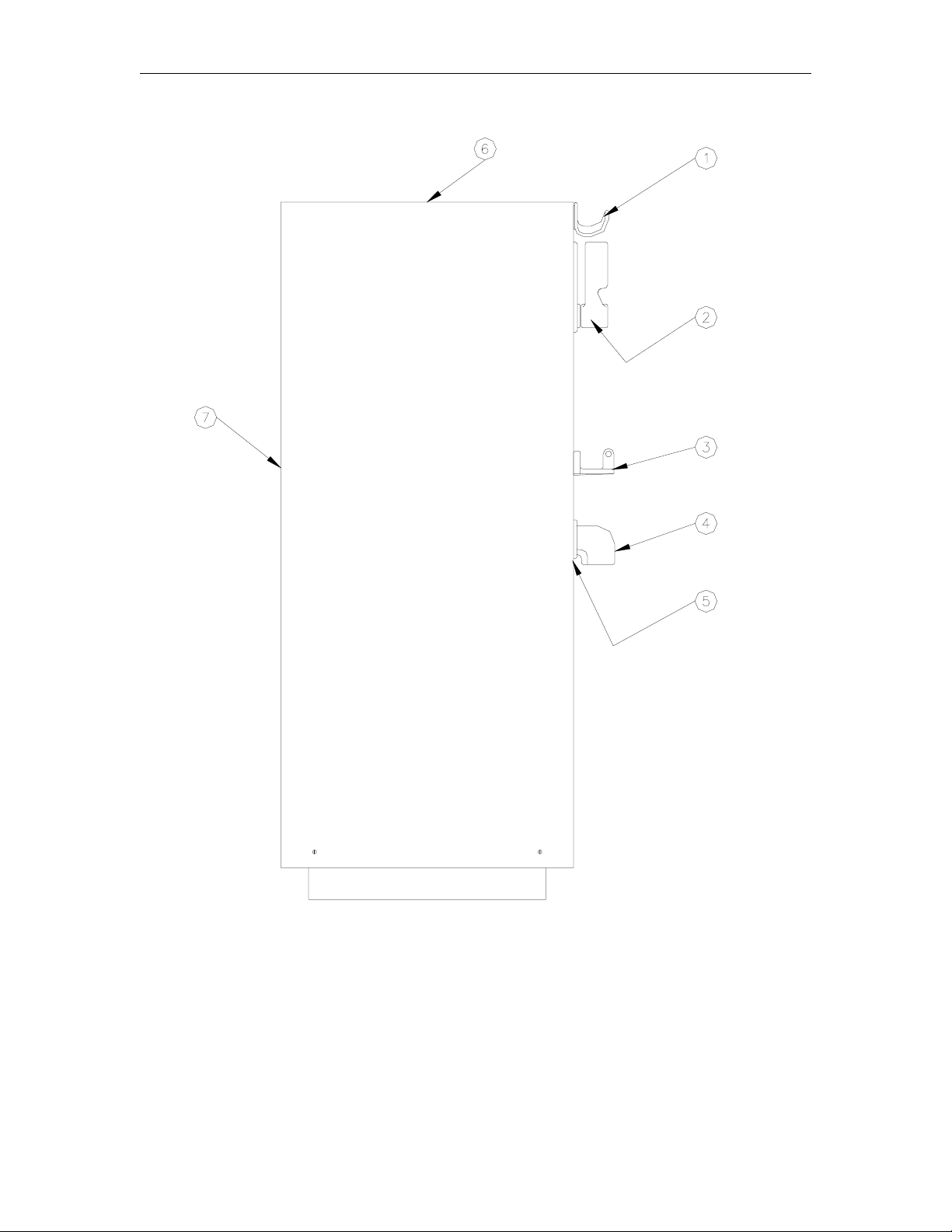

GASBOY 215S & 216S

215S, FINAL ASSEMBLY - FRONT VIEW

Item Part No. Description

1 003740 Hose Hanger

2 043105 Pin, Spirol, 3/16 x 1-1/4, CRS

3 003745 Hook, Nozzle

046011 Hook, Richards Nozzle

4 003620 Elbow, Discharge, 1"

5 028960 Grommet, Discharge, 1"

6 022119 Top Cover Weld Assy., CRS

022165 Top Cover Weld Assy., SS

7 040168 Panel, Left, CRS

040176 Panel, Left, SS

2 03/07/03

Page 7

Parts List

215S, FINAL ASSEMBLY - SIDE VIEW

Item Part No. Description Item Part No. Description

1 033825 Lever, Control 5 003745 Hook, Nozzle

2 003620 Elbow, Discharge, 1" 6 041951 Panel, Scuff, Rt

3 040601 Panel, Front & Rear, CRS 7 003332 Boot, Nozzle

040177 Panel, Front & Rear, SS 8 046300 Plate, Hose Hanger, Stiffener

4 040169 Panel, Right, CRS 9 047229 Plug

040178 Panel, Right, SS 10 046943 Plate, Nozzle Hook Backup

03/07/03 3

Page 8

GASBOY 215S & 216S

216S, 1" NOZZLE, FINAL ASSEMBLY - FRONT VIEW

Item Part No. Description

1 043105 Pin, Spirol, 3/16 x 1-1/4, CRS

2 056779 Spacer

3 003745 Hook, Nozzle

4 028975 Grommet, Discharge

5 040168 Panel, Left, CRS

040176 Panel, Left, SS

4 03/07/03

Page 9

Parts List

216S, 1" NOZZLE, FINAL ASSEMBLY - SIDE VIEW

Item Part No. Description Item Part No. Description

1 033831 Lever, Control 7 040160 Panel, Scuff, Right

2 024944 Elbow, Red, 1-1/2 x 1 x 90o 8 003817 Boot, Nozzle

3 040601 Panel, Front & Rear, CRS 9 003739 Hose Hanger

040177 Panel, Front & Rear, SS 10 022119 Top Cover Weld Assy., CRS

4 040161 Panel, Right, 216S, CRS 022165 Top Cover Weld Assy., SS

040193 Panel, Right, 216S, SS 11 047229 Plug

5 003745 Hook, Nozzle 12 046300 Plate, Hose Hanger Stiffener

6 046943 Plate, Nozzle Hanger Backup

03/07/03 5

Page 10

GASBOY 215S & 216S

216S, 1-1/4" NOZZLE, FINAL ASSEMBLY - FRONT VIEW

Item Part No. Description

1 043105 Pin, Spirol, 3/16 x 1-1/4, CRS

2 056779 Spacer

3 003319 Hook, Nozzle

4 028975 Grommet, Discharge

5 040168 Panel, Left, CRS

040176 Panel, Left, SS

6 03/07/03

Page 11

Parts List

216S, 1-1/4" NOZZLE, FINAL ASSEMBLY - SIDE VIEW

Item Part No. Description Item Part No. Description

1 033831 Lever, Control 7 040160 Panel, Scuff, Right

2 Z07941 Elbow, Red, 1-1/2 x 1-1/4 x 90o 8 003817 Boot, Nozzle

3 040601 Panel, Front & Rear, CRS 9 003739 Hose Hanger

040177 Panel, Front & Rear, SS 10 047229 Plug

4 040161 Panel, Right, CRS 11 022119 Top Cover Weld Assy., CRS

040193 Panel, Right, SS 022165 Top Cover Weld Assy., SS

5 003319 Hook, Nozzle 12 046300 Plate, Hose Hanger Stiffener

6 046943 Plate, Nozzle Hanger Backup

03/07/03 7

Page 12

GASBOY 215S & 216S

215S CHASSIS - FRONT VIEW

Item Part No. Description Item Part No. Description

1 017261 Bushing, Operating Shaft 11 024944 Elbow, Red, 1-1/2 x 1 x 90o

2 003185 Bearing, Start Shaft 12 026573 Frame, 215S

3 055648 Shaft, Start Assy. 13 011636 Base, 215S

4 015573 Bracket 14 044922 Pipe TBE, 1-1/2 x 18-1/8

5 064461 Switch Housing & Wire Assy. 15 031933 Nut, Lock, Conduit, 1-1/2

6 038050 Pipe TBE, 1/2 x 1-1/8 16 014752 Bracket, Junction Box

7 025045 Elbow, Conduit, 1/2 x 90o, M/F 17 025015 Elbow, Conduit, 1/2 x 45o

8 044555 Pipe TBE, 1 x 3-3/4 18 014113 Box, Junction, Red Dot, 19.3 ci

9 067034 VL Sol, 1" Skin, 2 Stg, Tp Cond 19 025030 Elbow, Conduit, 1/2 x 90o F/F

10 015437 Bracket, Pipe Support 20 021377 Conduit

8 03/07/03

Page 13

Parts List

215S CHASSIS - SIDE VIEW

Item Part No. Description

1 014942 Bracket, Control Shaft

2 021986 Conduit Coupling

3 025045 Elbow, Conduit, 1/2 x 90

4 012658 Block Stop Assembly

o

03/07/03 9

Page 14

GASBOY 215S & 216S

216S CHASSIS - FRONT VIEW

Item Part No. Description Item Part No. Description

1 017261 Bushing, Operating Shaft 11 Z03555 Elbow

2 003185 Bearing, Start Shaft 12 043809 Pipe TBE, 1-1/2 x 15-1/4

3 055653 Shaft, Start Assembly 13 039133 Nut, Lock

4 015573 Bracket

5 064461 Switch Hsg & Wire Assembly

6 021456 Conduit 15 015610 Bracket, Junction Box

7 045488 Pipe TBE, 1-1/2 x 3-1/2 16 025045 Elbow, Conduit, 1/2 x 90o, M/F

8 067028 VL Sol, 1-1/2", 2-stg, Top Cond 17 014113 Box, Junction, Red Dot, 19.3 ci

9 038005 Pipe TBE, 1-1/2 x 1-3/4 18 021345 Pipe TBE, 1/2 x 1-1/2

10 015609 Bracket 19 025030 Elbow, Conduit, 1/2 x 90o F/F

20 021294 Conduit

14 066400 1/2" UNY Explosion-Proof

Conduit Union

10 03/07/03

Page 15

Parts List

216S CHASSIS - SIDE VIEW

Item Part No. Description

1 014942 Bracket, Control Shaft

2 025030 Elbow, Conduit, 1/2 x 90

3 025045 Elbow, Conduit, 1/2 x 90

4 021337 Pipe TBE, 1/2 x 2

5 026605 Frame, 216S

6 011636 Base

7 012658 Block Stop Assembly

o

F/F

o

, M/F

03/07/03 11

Page 16

GASBOY 215S & 216S

SWITCH HOUSING AND WIRE ASSEMBLY

Item Part No. Description

1 003517 Cover, Switch

2 003773 Housing, Switch

3 064333 Switch, DPDT

4 063189 Stop, 4-wire

5 068606 Washer, SS, .328 x 19/32 x 1/1

6 049491 Retaining Ring, SS

7 038569 Nut, Adjusting Fin

8 042355 Pin, Cotter

9 054419 Shaft

10 057161 Spring

11 C01891 Term, Wire 1/4F QC Flag

12 03/07/03

Page 17

Parts List

HIGH HOSE RETRIEVER

032666 Kit, HHR, 5/8" & 3/4" Hardwall/Softwall 032669 Kit, HHR, 1" Hardwall (1-3/8 OD)

032667 Kit, HHR, 1" Softwall 032671 Kit, HHR, GY Prem Coax, Vapor Rec

032668 Kit, HHR, 1" Hardwall (Std. 1-7/16 OD) 032670 Kit, HHR, 1-1/4" Softwall

Item Part. No. Description Item Part. No. Description

1 030804 Reel Assy, 5/8" & 3/4"

Hardwall/Softwall; GY Prem Coax,

Vapor Recovery 4 017930 Caplug

1-1/4" Softwall 6 068080 Washer, 5/16 Pltd

020712 Clamp, 1" Softwall 9 056924 Spacer

020719 Clamp, 1" Hardwall (1-3/8 OD)

Recovery

020717 Clamp, 1-1/4" Softwall

3 063818 Support Bar Assy., 9152, 9153

063837 Support Bar Assy., 9150

5 051955 Bolt, 5/16-18 x 2 030805 Reel Assy, 1" Softwall, 1" Hardwall;

7 068875 Lockwasher, 5/16 Pltd 2 020714 Clamp, 5/8" & 3/4" Hardwall/Softwall

8 038605 Nut, 5/16-18 Hex Keps

10 047219 Plug Button, 7/8 020718 Clamp, 1" Hardwall (Std. 1-7/16 OD)

11 013250 Anchor

026732 Clamp, GY Prem Coax, Vapor

03/07/03 13

Page 18

GW01 - 6/04/02 Rev. 1

WARRANTY

General Statements:

Gasboy International LLC. warrants all new equipment manufactured by Gasboy against defective m aterial and/or workmanship, f or the warranty

period specified below, when the equipment i s installed in accordanc e with specifications prepared by Gasboy.

This warranty does not cover damage caused by acci dent, abuse, Acts of God, lack of surveillance of automatic recording system s, negligence,

mis-application, faulty installation, i mproper or unauthorized maintenance, i nstallation or use in violat i on of product manuals, i nstructions, or warnings.

Under no circumstanc e shall Gasboy be liable for any indirect, special, or cons equent i al damages, losses , or expenses to include, but not limited

to, loss of product, los s of profits, litigation fees , or the use, or inability to use, our product f or any f or any purpos e whatsoever.

Parts Only - During the warranty period, Gasboy will, at its option, repair or replace defective parts returned transportat i on prepaid to its factory.

On-Site Labor Included - Gasboy will also provide, within the Continental United States and during the warranty period, the services of an

Authorized Service Representati ve (A S R) for on-site repair or replacement of defective parts.

Replacement Parts - A ny system com ponents that are not part of the origi nal system order, incl udi ng Island Card Readers, Pump Cont rol Uni ts, etc.,

are considered replacement part s.

Equipment Term Coverage

Commercial Pumps and Dispensers

Full-Cabinet Consumer Pum ps

Small Transfer Pumps, Meters,

Pressure Regulators

Keytrol One year from date of instal l ation or 18 mos. from date of

Fuel Management Systems :

- CFN/ Profit Point

- Series 1000/Fleetkey

- TopKAT

- Fuel Point Readers

(sold with new systems)

Additional Fuel Point Items:

- Fuel Point Readers sold for

retrofitting existing systems.

- Fuel Point vehicle and dispenser

components.

Encoders, Embos sers, Modems,

CRTs, and Logger Printers

Air Diaphragm Pumps Three years from date of purchas e (for full warranty

Items not m anufactured by Gasboy

(ex. automatic nozzles, hoses, swivels,

etc.)

Replacement Parts One year from date of Gasboy International's invoice to the

To the extent permitted by law, this warranty is made in lieu of all other warranties , expressed or implied, incl udi ng warranties of freedom from pat ent

infringement, or merchant abilit y, or fitness for a particular purpos e, or arising from a course of dealing or usage of t rade. No one is authorized to

vary the terms of the warranty nor may anyone make any warranty of representation, or assume any liability other than that herein stated, in

connection with the sale desc ri bed herei n. The acceptance of any order by Gasboy I nt ernational is expressly made subj ect to the purchaser's

agreement to these condit i ons.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.- Excepting the Model 2020 Hand Pump, which

has a 90-day warranty from date of GASBOY International’s

invoice.

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first .- The basic warranty only applies to systems

which have been started up by a Gasboy Authorized Service

Representative (ASR).

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser,

whichever comes first.

Purchased with Fuel Management Syst em (Encoders,

Embossers only):

90 days from the date of s t art-up by a Gasboy ASR, or 180

days from date of Gasboy I nternational's invoice, whichever

occurs first.

Purchased with Fuel Management System

(Modems, CRTs, and Logger Printers only):

Matches system warranty.

Purchased Separately:

90 days from date of Gasboy International's

invoice to the purchaser.

description, see Price List).

Not warranted by Gasboy International (consul t original

manufacturer’s warranty).

purchaser.

Parts and Labor.

Parts Only.

Parts and Labor.

Parts and Labor.

Parts Only.

Purchased with System

(Encoders, Embos sers only):

Parts only.

Purchased with System (Modems,

CRTs, Logger Printers only):

Matches system warranty.

Purchased Separately:

Parts Only.

Parts Only.

Not Applicable.

Parts Only.

GASBOY INTERNATIONAL LLC

P.O. Box 309, Lansdale, PA 19446 ● (800) 444-5579 ● FAX: (800) 444-5569 ● www.gasboy.com

Loading...

Loading...