Page 1

MODELS 2150A, 5200A, 5300A

PARTS MANUAL

035293

REV. 03/07/03

The information in this document is confidential and proprietary. No further disclosure shall be made without

permission from Gasboy International LLC. Gasboy International LLC believes that the information in this document

is accurate and reliable. However, we assume no responsibility for its use, nor for any infringements of patents or

other rights of third parties resulting from its use. We reserve the right to make changes at any time without notice.

Copyright 2003 by Gasboy International LLC All rights reserved.

GASBOY INTERNATIONAL LLC LANSDALE, PA

Page 2

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to th e e nti re syst em. Inst ruct ion s

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

IMPORTANT WARNINGS AND SAFEGUARDS

OF A FUEL SPILL.

DO NOT use Teflon tape for any pipe

threads in the product.

DO NOT use consumer pumps for

pumping fuel or additives into aircraft.

DO NOT use commercial pumps for

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT use where sanitary design is

required (for food products for human

consumption) or with water-based

liquids.

DO NOT smoke near the pump or when

using the pump.

DO NOT use near open flame or

electrical equipment which may ignite

fumes.

DO NOT permit the dispensing of

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT permit the dispensing of

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

includin g tru cks. All conta iner s must be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT block open the nozzle in any

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO ensure that the pump is equipped

with proper filters based on the product

being dispensed and its intended use.

DO wear safety goggles and protective

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO keep all parts of body and loose

clothing clear of belts, pulleys, and

other exposed moving parts at all times.

DO require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO provide a receptacle for catching

product from pump/meter when

servicing.

DO clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO insure pump is properly grounded.

DO insure hose is compatible with fluid

being dispensed.

DO inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

035282 Rev. 1267

GASBOY INTERNATIONAL, LLC.

707 North Valley Forge Rd. Lansdale, PA, 19446 ● (215) 855-4631 ● FAX: (215) 855-0341

Page 3

CONTENTS

Warnings and Safeguards

General..................................................................................................................................... 1

2150A, 5200A, 5300A Final Assembly - Front View ................................................................ 2

2150A, 5200A, 5300A Final Assembly - Side View.................................................................. 4

2150ARDX-1 Chassis - Front View.......................................................................................... 6

2150ARDX-1 Chassis - Side View........................................................................................... 8

2150ARDX-2 Chassis - Front View.......................................................................................... 10

2150ARDX-2 Chassis - Side View........................................................................................... 12

5200A-2, 5300A-2 Chassis - Front View.................................................................................. 14

5200A-2, 5300A-2 Chassis - Side View ................................................................................... 16

2150A Discharge Assembly - 024379...................................................................................... 18

2150A Satellite Discharge Assembly - 045641 ........................................................................ 18

5200A Discharge Assembly - 024375; 5300A Discharge Assembly - 024376 ........................ 19

5200A-1 & 5300A-1 Inlet Manifold Assembly - 035194............................................................ 19

Flange Assembly...................................................................................................................... 20

Electric Reset - S00206............................................................................................................ 21

Pumping Unit Assembly Breakdown........................................................................................ 22

Meter Assembly Breakdown..................................................................................................... 24

Motor Mount Detail................................................................................................................... 26

Strainer Body Assembly........................................................................................................... 26

03/07/03 Contents-1

Page 4

Page 5

PARTS LIST

GENERAL

This manual lists parts information for the Model 2150A, 5200A and 5300A pumps and

dispensers. Using part numbers when ordering will expedite your order and reduce the possibility

of the wrong parts being shipped. When ordering r eplacement parts, be sure to give the complete

name and part number as shown in the appropriate parts lists. It is also helpful to supply the serial

number of the equipment.

This manual is arranged from general to specific, presenting the complete unit first, then the

chassis breakdowns, then further breakdowns of the individual components. If you can’t find the

part you need from the chassis drawing, be sure to check the appropriate parts breakdown for

your model.

03/07/03 1

Page 6

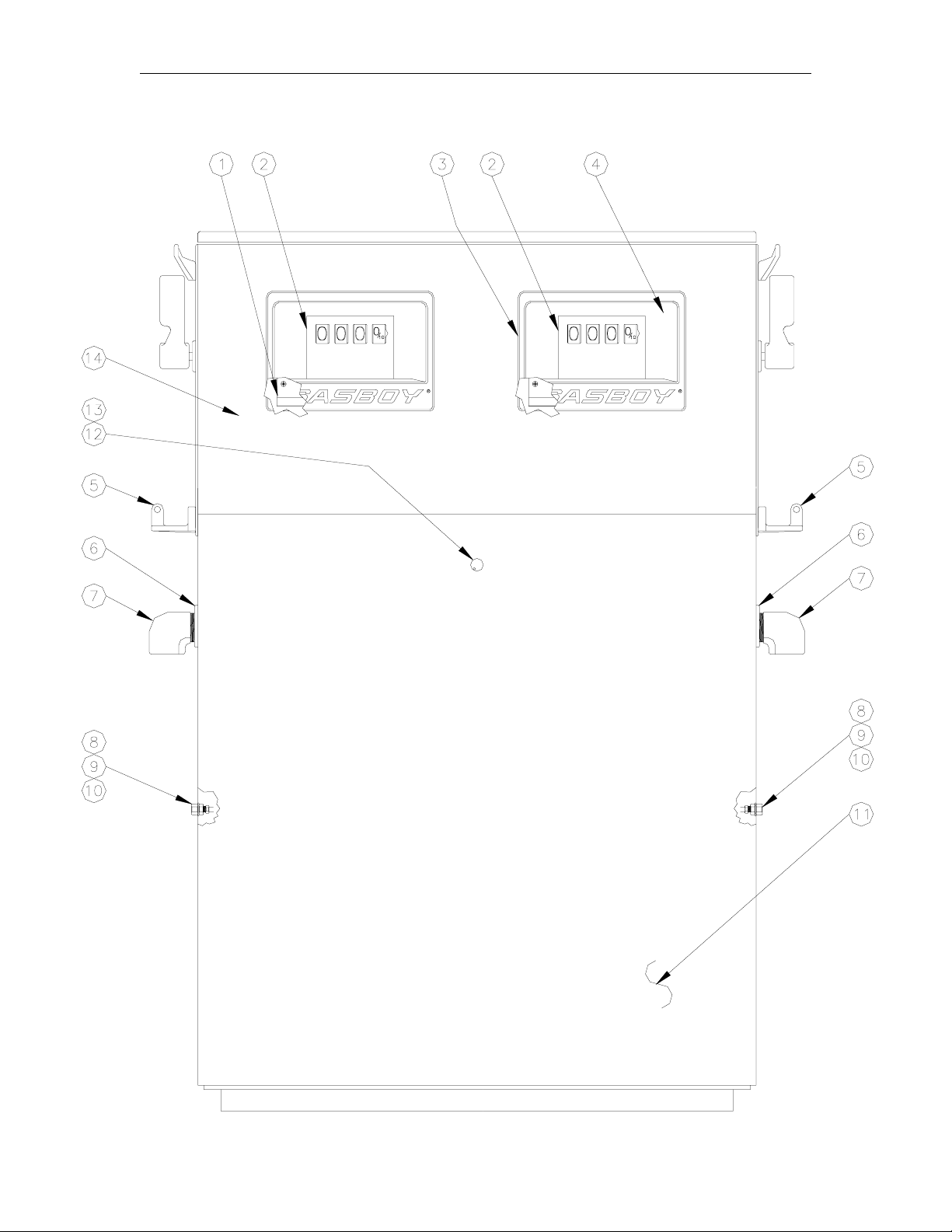

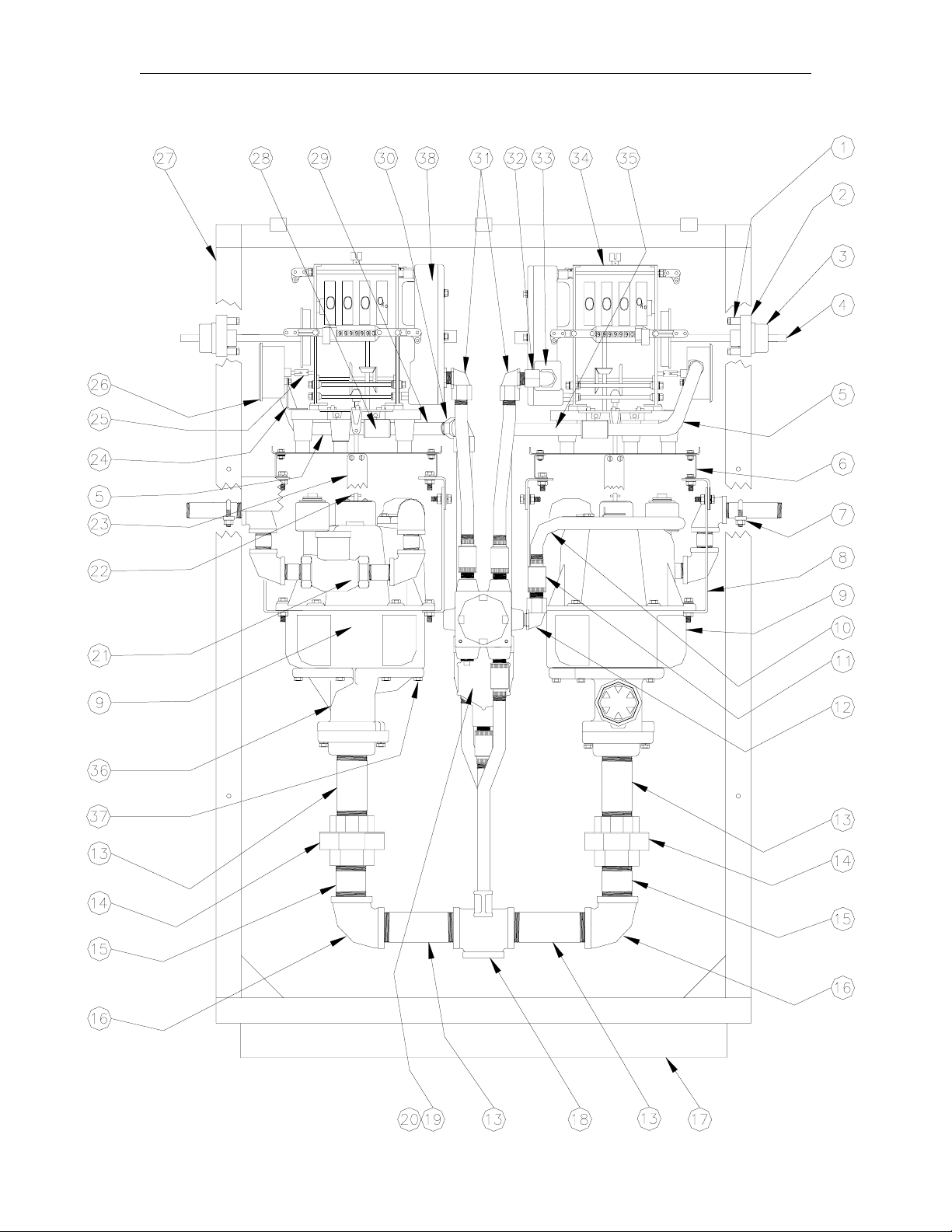

GASBOY Series 2150A, 5200A & 5300A

2150A, 5200A, 5300A FINAL ASSEMBLY - FRONT VIEW

2 03/07/03

Page 7

Parts

2150A, 5200A, 5300A FINAL ASSEMBLY - FRONT VIEW

Item Part No. Description

1 025527 Dial Face, Non-Totalizer

025542 Dial Face, Total Gallons

2 Dial Enclosure (Part no longer available)

3 012252 Bezel Assy.

4 069050 Window Glass

5 003745 Nozzle Hook

6 028960 Grommet

7 003620 Elbow, Discharge

8 026047 Fitting, 3/8 Ct Conn Inv Fl

9 067885 Washer, Fiber, 1/2 x 3/4 x 1/16

10 017921 Cap, Vent

11 Lower Panel Assy., CRS (Part no longer available)

Lower Panel Assy., SS (Part no longer available)

12 026799 Gasket, Lock

13 035012 Lock, Door

14 Upper Panel Assy., CRS (Part no longer available)

Upper Panel Assy., SS (Part no longer available)

03/07/03 3

Page 8

GASBOY Series 2150A, 5200A & 5300A

2150, 5200A, 5300A FINAL ASSEMBLY - SIDE VIEW

4 03/07/03

Page 9

Parts

2150, 5200A, 5300A FINAL ASSEMBLY - SIDE VIEW

Item Part No. Description

1 003744 Hose Hook

2 033831 Control Lever

3 043105 Pin

4 Scuff Panel (Part no longer available)

5 Side Panel Weld Assy., CRS (Part no longer available)

Side Panel Weld Assy., SS (Part no longer available)

Side Panel Assy., Int. Retriever, CRS (Part no longer available)

Side Panel Assy., Int. Retriever, SS (Part no longer available)

6 046765 Plate, Nozzle Backup

7 003332 Boot, Nozzle

8 Top Cover Assy., CRS (Part no longer available)

Top Cover Assy., SS (Part no longer available)

NOTE: Pumps equipped with internal retrievers use the following parts (not shown):

Internal Retriever Parts - 047946

Item Part No. Description

1 040035 Cable Guide, Internal Hose Retriever

2 020712 Clamp, 1" Hose

3 048369 Reel and Cable

4 015022 Bracket, Internal Hose Retriever

03/07/03 5

Page 10

GASBOY Series 2150A, 5200A & 5300A

2150ARDX-1 CHASSIS - FRONT VIEW

6 03/07/03

Page 11

Parts

2150ARDX-1 CHASSIS - FRONT VIEW

Item Part No. Description

1 063215 Stop, Operating Shaft

2 015546 Bracket & Spring Assy.

3 003185 Bearing, Start Shaft

4 055675 Shaft, Start Assy.

5 021651 Conduit, Pulser

6 063963 Support, Computer

7 013295 U-Bolt, 1-3/8 ID

8 015043 Bracket, Meter Support, Non-Computer

9 035517 Meter, Gallons

035576 Meter, Liters

10 021648 Conduit, 1" ITT Valve

11 066400 Union, Explosion-Proof Conduit

12 025045 Elbow

13 044933 Pipe, TBE, 1-1/2 x 4-3/4

14 066385 Union, 1-1/2 Stockham #150

15 038005 Pipe, TBE, 1-1/2 x 1-3/4

16 Z03555 Elbow, 1-1/2 x 90

17 011680 Base Assy.

18 064811 Tee, Reducing 1-1/2 x 1-1/2 x 2

19 003337 Box, Junction

20 003461 Cover, Junction Box

21 024379 Discharge Pipe/Valve Assy.(See Breakdown)

045641 Satellite Piping Assembly (See Breakdown)

22 042595 Pin, Drive-Lock, 1/8 x 5/8

23 021978 Coupling Half

24 015431 Bracket, Pulser, Gallon

25 021941 Coupling, Pulser

26 021788 Pulser, 10:1

047648 Pulser, 100:1

27 026656 Frame

28 021986 Coupling, 1/2 Conduit

29 021652 Conduit, Pulser

30 025030 Elbow, Conduit 1/2 x 90

31 021685 Conduit & Electrical

32 024917 Potted Elbow

33 048370 Reducer, Conduit

34 021222 Non-Computer Assy., Electric Reset, w/o Top Drive, Gallons

*020996 Non-Computer Assy. w/o Electric Reset

021107 Non-Computer Assy., Electric Reset, w/o Top Drive, Liters

35 021650 Conduit, Pulser

36 Strainer Body Assy. (See breakdown Strainer Body Assembly)

37 052020 Screw, 3/8-16 x 1-1/4, HHC, GR-5

38 Electric Reset only (See Breakdown)

*Denotes this is a subpart used in the preceding assembly

o

o

F/F

03/07/03 7

Page 12

GASBOY Series 2150A, 5200A & 5300A

2150ARDX-1 CHASSIS - SIDE VIEW

8 03/07/03

Page 13

Parts

2150ARDX-1 CHASSIS - SIDE VIEW

Item Part No. Description

1 015000 Bracket, Junction Box

2 021685 Conduit & Electrical

3 066400 Union, Explosion-Proof Conduit

4 027038 Gasket

5 003344 Junction Box

6 022140 Junction Box Cover Assy.

7 Check Valve Assy. (See breakdown Strainer Body Assembly)

8 048138 Valve Housing

9 021162 Conduit

10 021986 Conduit Coupling

11 021380 Conduit, 1/2 x 7-1/2

03/07/03 9

Page 14

GASBOY Series 2150A, 5200A & 5300A

2150ARDX-2 CHASSIS - FRONT VIEW

10 03/07/03

Page 15

Parts

2150ARDX-2 CHASSIS - FRONT VIEW

Item Part No. Description

1 063215 Stop, Operating Shaft

2 015546 Bracket & Spring Assy.

3 003185 Bearing, Start Shaft

4 055675 Shaft, Start Assy.

5 021651 Conduit, Pulser

6 063963 Support, Computer

7 013295 U-Bolt, 1-3/8 ID

8 015043 Bracket, Meter Support, Non-Computer

9 035517 Meter, Gallons

035576 Meter, Liters

10 021648 Conduit, 1" ITT Valve

11 066400 Union, Explosion-Proof Conduit

12 025045 Elbow

13 044903 Pipe, TBE 1-1/2 x 9-1/4

14 066385 Union, 1-1/2 Stockham #150

15 003337 Box, Junction

16 003461 Cover, Junction Box

17 024379 Discharge Pipe/Valve Assy.(See Breakdown)

045641 Satellite Piping Assembly (See Breakdown)

18 042595 Pin, Drive-Lock, 1/8 x 5/8

19 021978 Coupling Half

20 015431 Bracket, Pulser, Gallon

21 021941 Coupling, Pulser

22 021788 Pulser, 10:1

047648 Pulser, 100:1

23 026656 Frame

24 021986 Conduit Coupling

25 021652 Conduit, Pulser

26 025030 Elbow, Conduit 1/2 x 90

27 021685 Conduit & Electrical

28 024917 Potted Elbow

29 048370 Reducer, Conduit

30 021222 Non-Computer Assy., ERS, w/o Top Drive, Gallons

*020996 Non-Computer Assy. w/o Electric Reset

021107 Non-Computer Assy., ERS, w/o Top Drive, Liters

31 021650 Conduit, Pulser

32 Strainer Body Assy. (See breakdown Strainer Body Assembly)

33 052020 Screw, 3/8-16 x 1-1/4, HHC, GR-5

34 Electric Reset only (See Breakdown)

*Denotes this is a subpart used in the preceding assembly

o

F/F

03/07/03 11

Page 16

GASBOY Series 2150A, 5200A & 5300A

2150ARDX-2 CHASSIS - SIDE VIEW

12 03/07/03

Page 17

Parts

2150ARDX-2 CHASSIS - SIDE VIEW

Item Part No. Description

1 015000 Bracket, Junction Box

2 021685 Conduit & Electrical

3 066400 Union, Explosion-Proof Conduit

4 027038 Gasket

5 003344 Junction Box

6 022140 Junction Box Cover Assy.

7 Check Valve Assy. (See breakdown Strainer Body Assembly)

8 048138 Valve Housing

9 021162 Conduit

10 021986 Conduit Coupling

11 021380 Conduit, 1/2 x 7-1/2

03/07/03 13

Page 18

GASBOY Series 2150A, 5200A & 5300A

5200A-2, 5300A-2 CHASSIS - FRONT VIEW

14 03/07/03

Page 19

Parts

5200A-2, 5300A-2 CHASSIS - FRONT VIEW

Item Part No. Description

1 021222 Non-Computer Assy., ERS,

w/o Top Drive, Gallons

*020996 Non-Computer Assy. w/o

Electric Reset

021107 Non-Computer Assy., ERS,

w/o Top Drive, Liters

2 021651 Conduit, Pulser

3 021986 Conduit Coupling

4 025030 Elbow, Conduit 1/2 x 90o F/F

5 025045 Elbow

6 021685 Conduit & Electrical

7 024917 Potted Elbow

8 048370 Reducer, Conduit

9 021650 Conduit, Pulser

10 021788 Pulser, 10:1

047648 Pulser, 100:1

11 063215 Stop, Operating Shaft

12 015546 Bracket & Spring Assy.

13 003185 Bearing, Start Shaft

14 055675 Shaft, Start Assy.

15 063963 Support, Computer

16 013295 U-Bolt, 1-3/8 ID

17 024375 Discharge Piping Assy., 3/4"

Twin Pump, 5200

024376 Discharge Piping Assy., 1"

Pump Twin, 5300

18 015043 Bracket, Meter Support, Non-

Computer

19 035528 Meter Assy., Gallons

*035517 Meter, Gallons

*035513 Meter Transfer Body

*027038 Gasket

*052020 Screw, 3/8-16 x 1-1/4 HHC,

GR-5

035535 Meter Assy., Liters

*035576 Meter, Liters

*035513 Meter Transfer Body

*027038 Gasket

*052020 Screw, 3/8-16 x 1-1/4 HHC,

GR-5

Item Part No. Description

20 065830 Tube Assy, Vent

21 021972 Coupling Nipple

22 047680 Pulley, Variable Pitch

23 012143 Belt, Vee 30 4L300

24 031315 Key

25 047598 Pump, Pulley

26 066385 Union, 1-1/2 Stockham #150

27 038005 Pipe, TBE 1-1/2 x 1-3/4 Close

28 047075 Platform, Motor

29 025015 Elbow, Conduit, 1/2 x 45o M/F

30 014141 Box, Junction

31 022196 Cover, Junction Box

32 021666 Conduit

33 066400 Union, Explosion-Proof

Conduit

34 003337 Box, Junction

35 003461 Cover, Junction Box

36 037667 Motor, 1/3 HP, 60 Hz. w/o

switch, 5200

037692 Motor, 3/4 HP, 60 Hz.w/o

switch, 5300

NOTE: Motor must be A.O. Smith;

Franklin cannot be substituted.

37 048028 Pumping Unit, 5200

048022 Pumping Unit, 5300

(See Breakdown)

38 Flange Assy. (See Breakdown)

39 021377 Conduit, 1/2 x 6

40 021518 Conduit, 1/2 x 11-1/2

41 021652 Conduit, Pulser

42 021977 Coupling Half

43 015431 Bracket, Pulser, Gallon

44 021941 Coupling, Pulser

45 026652 Frame

46 Electric Reset only (See

Breakdown)

*Denotes this is a subpart used in the preceding

assembly

03/07/03 15

Page 20

GASBOY Series 2150A, 5200A & 5300A

5200A-2, 5300A-2 CHASSIS - SIDE VIEW

16 03/07/03

Page 21

Parts

5200A-2, 5300A-2 CHASSIS - SIDE VIEW

Item Part No. Description

1 066400 Union, Explosion-Proof Conduit

2 021986 Coupling, 1/2 Conduit

3 021364 Conduit, 1/2 x 3-1/2

4 038050 Conduit, 1/2 x 1-3/16 Close

5 025030 Elbow, Conduit 1/2 x 90

6 021664 Conduit, Bent, 3-7/8 x 3-7/8

7 021456 Conduit, 1/2 x 4-1/4

8 025045 Elbow

9 038050 Conduit, 1/2 x 1-3/16 Close

10 C08125 Conduit, Fitting 1/2 Union F/F

11 021663 Conduit

12 021345 Conduit, 1/2 x 1-1/2

13 021294 Conduit, 1/2 x 8

14 064840 Tee, Conduit

15 048370 Reducer, Conduit

o

F/F

03/07/03 17

Page 22

GASBOY Series 2150A, 5200A & 5300A

2150A DISCHARGE ASSEMBLY - 024379

Item Part No. Description

1 003582 Elbow, Flanged Meter Discharge

2 024941 Elbow, 1 x 90

3 038035 Pipe, TBE, 1 x 1-1/2 Close Nip

4 024895 Elbow, 1 x 90

5 067035 Valve, Solenoid, 1" Skinner

NOTE: This part replaces part 067021

which is no longer available. It

requires field modification of

conduit for installation.

6 044550 Pipe, TBE, 1 x 3-1/2

o

, Street

o

, Std.

2150A SATELLITE DISCHARGE ASSEMBLY - 045641

Item Part No. Description

1 003582 Elbow, Flanged Meter Dschg

2 024941 Elbow, 1 x 90o, Street

3 038035 Pipe, TBE, 1 x 1-1/2 Close Nip

4 064796 Tee, 1 x 1 x 1

5 044665 Pipe, TBE 1 x 12

6 021984 Pipe Coupling, Reducer, 1-1/2 x 1

7 044921 Pipe, TBE, 1-1/2 x 7

8 066385 Union, 1-1/2 Stockham #150

9 067035 Valve, Solenoid, 1" Skinner

(See NOTE above)

10 024895 Elbow, 1 x 90o, Std.

11 044550 Pipe, TBE, 1 x 3-1/2

18 03/07/03

Page 23

Parts

5200A DISCHARGE ASSEMBLY - 024375

5300A DISCHARGE ASSEMBLY - 024376

Item Part No. Description

1 044159 Pipe, TBE, 3/4 x 15-1/2, 5200

044664 Pipe TBE, 1 x 11-7/8, 5300

2 003581 Elbow, Flanged Meter Discharge, 5200

003582 Elbow, Flanged Meter Discharge, 5300

3 024940 Elbow, Street, 3/4 x 9 Obl, 5200

024941 Elbow, 1 x 90

o

, Street, 5300

5200A-1 & 5300A-1 INLET MANIFOLD ASSEMBLY - 035194

Item Part No. Description

1 064797 Tee, 1-1/2

2 045487 Pipe TOE, 1-1/2 x 3-3/8

3 022046 Ell, Dresser, 1-1/2 x 90

4 066804 Check Valve Assy.

5 044910 Pipe, TBE, 1-1/2 x 2-1/2

6 024926 Pipe Return Bend 1-1/2

7 038005 Pipe, TBE, 1-1/2 x 1-3/4

8 066385 Union, 1-1/2 Stockham #150

NOTE: Items 5 and 6 must be ordered separately. They are not part of assembly 035194.

o

03/07/03 19

Page 24

GASBOY Series 2150A, 5200A & 5300A

FLANGE ASSEMBLY

Item Part No. Description

1 049014 O-Ring

M49014 O-Ring, Methanol/Ethanol

2 026079 Flange

3 051950 5/16-18 x 1-3/4 HHC Screw

4 068005 1/4 Washer

5 068875 Lockwasher, 5/16

6 027797 Gasket

7 021950 Coupling

20 03/07/03

Page 25

Parts

ELECTRIC RESET - S00206

Item Part No. Description

1 S00211 Reset Motor, 115V

S00212 Reset Motor, 220V

2 S00208 Electric Reset Motor Switch

3 S55321 Shaft, Ctr, Non-Computer (not visible on illustration)

4 S00213 Cam Group, Clockwise

5 S00210 Switch, DPDT, Robertshaw

03/07/03 21

Page 26

GASBOY Series 2150A, 5200A & 5300A

PUMPING UNIT ASSEMBLY BREAKDOWN

22 03/07/03

Page 27

Parts

PUMPING UNIT ASSEMBLY BREAKDOWN

Item Part No. Description

1 S00117 Gasket

2 S00456 Float Lever Pin

3 S00066 Valve Pin

4 S00067 Guide Plate

5 S00068 Spring Plate

6 S00069 Plunger Head

7 S00072 Plunger Plate

8 S00073 Plunger Follower

9 S00074 Valve Cylinder

10 S00075 Cylinder Head

11 S00076 Clamp Plate

12 S00077 Float Valve Body

13 S00078 By-Pass Valve Spring (#34 to

S00079 By-Pass Valve Spring (44-1/2#

14 S00080 Vent Screw

15 S00062 Valve Cylinder Gasket

16 S00081 Vent Screw Guard

17 S00082 Float Valve Needle

18 S00083 Float Valve Gasket

19 S00128 Pump Rotor Shaft Assembly

20 S00119 Bottom Head Gasket

21 S00084 Separator Cover

22 S00120 Cover Gasket

23 S00085 Retainer

24 S00121 Bearing

25 S00086 Regulating Poppet Assy

26 S00124 Oil Well Felt

27 S00061 Float Assembly

29 S00718 Gasket

30 063312 Suction Screen (Gasoline, 100

063313 Suction Screen (Diesel, 40

31 S00088 Regulating Valve Spring

32 S00089 By-pass Valve Poppet

33 S00056 Packing Gland

34 S00090 Packing Spring

35 S00091 Rotary Pump & Separator

36 S00092 Regulating Valve Seat

37 S00093 Valve Seat Guide

38 S00094 By-pass Valve Seat

39 S00717 Check Valve Cap

41 S00447 Poppet Spring

43 S00116 "V" Packing

44 S00095 Plunger Guide

45 S00096 Plunger Disc

46 S00097 Plunger Spacer

47 S00122 Drive Shaft Bearing

48 S00129 Rotary Pump Idler

50 S00098 Poppet Disc. & Relief Valve

52 063261 Suction Strainer Cap

35-1/2# spring (52)

Spring (53)

mesh)

mesh)

Body w/Gasket, Bearing,

Screws & Spring

Assy

Item Part No. Description

53 S00125 By-pass Valve Assembly (34#

to 35-1/2# spring (52)

S00126 By-pass Valve Assembly (44-

1/2# spring (53)

54 S00127 Regulating Valve Assembly

55 026768 Gasket

56 S00451 1/4-20 x 7/8 Lg. Rd. Hd. Mach

Screw

57 S00452 1/4-20 x 1/2 Lg. Hex Hd. Cap

Screw

58 S00453 5/16-18 x 7/8 Lg. Hex. Hd. Cap

Screw

59 S00454 3/8-16 x 2-3/4 Lg. Hex. Hd.

Cap Screw

60 S00455 3/8-16 x 1-1/8 Lg. Hex. Hd.

Cap Screw

62 S00457 1/16 x 1/2 Lg. Cotter Pin

63 S00459 1/4 Sq. Hd. Pipe Plug

65 S00461 1/4 - 28 Hex. Nut

67 S01135 Lower Pump Head w/Valve

Seat Guides, Regulating Valve

Seat & By-pass Valve Seat

68 S00057 Rotary Pump Head Assembly

03/07/03 23

Page 28

GASBOY Series 2150A, 5200A & 5300A

METER ASSEMBLY BREAKDOWN

24 03/07/03

Page 29

Parts

METER ASSEMBLY BREAKDOWN

Item Part No. Description

1 S00466 Packing Gland Plate

2 S00467 Seal Pin

3 S00469 Compensator Screw Spring

4 S00473 Drive Shaft

5 069080 Seal & Seal Wire

6 S00475 Special Screw

7 S00476 Drive Shaft Pin

8 S00477 1/2" Ball

9 S00480 Plunger Cup Support

10 S00481 Plunger Disc

11 S00182 Washer

12 S00183 Washer

13 S00484 Upper Bearing Assembly

14 S00485 Bearing Assembly

15 S00487 Compensator Index Disc

16 S00488 Seal Half

17 S00489 Seal Wedge

18 S00490 Washer

19 S00492 Packing Spring

20 S00493 Seal

23 S00494 Bearing Retainer

24 S00495 Seal (black)

25 S00491 Seal Retaining Ring

26 S00478 Compensator Pinion

27 S00512 Screw

28 S00498 Main Pivot Bracket Assembly

w/ Pins

29 S00032 Plunger Cup Kit (Set of 3

Cups)

30 S00501 Valve

31 S00502 Wobble Plate w/ Slack Roller

Post

32 S00503 Connector

33 S00504 Bearing Seat

35 S00505 Slack Roller Assembly

36 S00506 Slack Spring Assembly

37 S00496 Drive Shaft Gear - Gal

S00115 Drive Shaft Gear - Ltr

Item Part No. Description

38 S00499 Counter Drive Gear Complete -

Gal

S00114 Counter Drive Gear Complete -

Ltr

39 S00497 Compensator Shaft

40 S00500 Bracket & Pin Assembly

41 S00468 Index Plate

42 S00479 Pivot & Ball Assembly

43 S00470 Meter Body Gasket

44 S00471 "O" Ring (.362 Dia.)

45 S00472 "O" Ring (.487 Dia)

46 S00486 Meter Cover w/ Center Gear

Post, Index Plate, Pipe Plug &

Retaining Ring

47 S00509 #10-32 x 3/8 Lg. Rd. Hd. Mach.

Screw

48 S00507 #12-24 x 1/2 Lg. Rd. Hd. Mach.

Screw

49 S00508 1/4-20 x 3/4 Lg. Rd. Hd. Mach.

Screw

50 S00511 1/4-20 Hex Nut

51 S00510 5/16-18 Hex Nut

52 S00520 1/4 Lockwasher

53 S00513 #1212 Lockwasher

54 S00514 #1114 Lockwasher

55 S00515 1/8 Sq. Hd. Pipe Plug

56 S00516 #10-32 x 3/8 Lg. Rd. Hd. Sems

Fastener

57 S00517 1/16 x 1/4 Lg. Cotter Pin

58 S00518 Truarc Retaining Ring

59 S00519 Truarc "E" Retaining Ring

60 S00521 Plunger Assy. w/ Bearing

Retainer, Bearing Seat & Sems

Fastener

61 S00522 Body & Seat Assembly w/ Pins

03/07/03 25

Page 30

GASBOY Series 2150A, 5200A & 5300A

MOTOR MOUNT DETAIL

Item Part No. Description

1 051940 5/16-18 x 1-1/2 HHC Screw

2 068080 5/16 Washer

3 067735 Cup Washer

4 068620 Washer

5 038920 5/16-18 ESNA Nut

6 037885 Rubber Mount

STRAINER BODY ASSEMBLY

Item Part No. Description

1 063261 Strainer Cap

2 063312 Gasoline Strainer (100 mesh)

063313 Diesel Strainer (40 mesh)

3 S00524 Strainer Body

4 026768 O-Ring

5 027005 Gasket

6 035319 Check Valve Assy.

26 03/07/03

Page 31

GW01 - 6/04/02 Rev. 1

WARRANTY

General Statements:

Gasboy International LLC. warrants all new equipment manufactured by Gasboy against defective material and/or workmanship, for the warranty

period specified below, when the equipment i s installed in accordance with specifications prepared by Gasboy.

This warranty does not cover damage caused by acci dent, abuse, Acts of God, lack of surveillance of automatic recording systems, negl i gence,

mis-application, faulty installation, i mproper or unauthorized maintenance, i nstallation or use in violati on of product manuals, instructions, or warnings.

Under no circumstanc e shall Gasboy be liable for any indirect , special, or consequential damages, losses, or expenses t o i nclude, but not limit ed

to, loss of product, los s of profits, litigation fees, or the use, or inability to use, our product f or any f or any purpos e whatsoever.

Parts Only - During the warranty period, Gasboy will, at its option, repair or replace defective parts returned transportati on prepai d to its factory.

On-Site Labor Included - Gasboy will also provide, within the Continental United States and during the warranty period, the services of an

Authorized Service Representati ve (A S R) for on-site repair or replacement of defective parts.

Replacement Parts - A ny system component s that are not part of the original system order, including Island Card Readers, Pump Control Uni ts, etc.,

are considered replacement part s.

Equipment Term Coverage

Commercial Pumps and Dispensers

Full-Cabinet Consumer Pum ps

Small Transfer Pumps, Meters,

Pressure Regulators

Keytrol One year from date of instal l ation or 18 mos. from date of

Fuel Management Systems :

- CFN/ Profit Point

- Series 1000/Fleetkey

- TopKAT

- Fuel Point Readers

(sold with new systems)

Additional Fuel Point Items:

- Fuel Point Readers sold for

retrofitting existing systems.

- Fuel Point vehicle and dispenser

components.

Encoders, Embos sers, Modems,

CRTs, and Logger Printers

Air Diaphragm Pumps Three years from date of purchas e (for full warranty

Items not m anufactured by Gasboy

(ex. automatic nozzles, hoses, swivels,

etc.)

Replacement Parts One year from date of Gasboy International's invoice to the

To the extent permitted by law, this warranty is made in lieu of all other warranties, expressed or implied, includi ng warranties of freedom from patent

infringement, or merchant abilit y, or fitness for a particular purpose, or arising from a course of dealing or usage of t rade. No one i s authorized to

vary the terms of the warranty nor may anyone make any warranty of representation, or assum e any liabilit y ot her t han that herein stated, in

connection with the sale desc ri bed herei n. The acceptance of any order by Gasboy Int ernational is expressly made subject to the purchaser's

agreement to these condit i ons.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of install ation or 18 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first.- Excepting the Model 2020 Hand Pump, which

has a 90-day warranty from date of GASBOY International’s

invoice.

Gasboy International’s invoi ce to the purchaser, whichever

comes first.

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser, whichever

comes first .- The basic warranty only applies to sys tems

which have been started up by a Gasboy Authorized Service

Representative (ASR).

One year from date of start-up or 15 mos. from date of

Gasboy International’s invoi ce to the purchaser,

whichever comes first.

Purchased with Fuel Management Syst em (Encoders,

Embossers only):

90 days from the date of s t art-up by a Gasboy ASR, or 180

days from date of Gasboy I nternational's invoice, whichever

occurs first.

Purchased with Fuel Management System

(Modems, CRTs, and Logger Printers only):

Matches system warranty.

Purchased Separately:

90 days from date of Gasboy International's

invoice to the purchaser.

description, see Price List).

Not warranted by Gasboy International (consul t original

manufacturer’s warranty).

purchaser.

Parts and Labor.

Parts Only.

Parts and Labor.

Parts and Labor.

Parts Only.

Purchased with System

(Encoders, Embos sers only):

Parts only.

Purchased with System (Modems,

CRTs, Logger Printers only):

Matches system warranty.

Purchased Separately:

Parts Only.

Parts Only.

Not Applicable.

Parts Only.

GASBOY INTERNATIONAL LLC

P.O. Box 309, Lansdale, PA 19446 ● (800) 444-5579 ● FAX: (800) 444-5569 ● www.gasboy.com

Loading...

Loading...