Page 1

Introduction

This manual provides installation instructions for the Gasboy Automatic Temperature

Compensation (ATC) Kits:

Contents

Section Page ...

Introduction 1

Important Safety Information 6

Installation 8

Appendix: Totalizer Display Information 25

MDE-4351A

Gasboy ATC Kits 039086 and 039087

Installation Manual

February 2006

• 039086 for Twin 9800 Unit

• 039087 for Single 9800 Unit

Required Reading 1

Required Tools 1

Abbreviations and Acronyms 2

Parts Lists 3

Installing the 039086 ATC Kit in Single Unit 8

Installing the 039087 ATC Kit in T win Unit 16

Required Reading

Before installing a kit, the installer m ust read, understand, and follow:

• This manual

• NFPA 30A, The Automotive and Marine Service Station Code

• NFPA 70, The National Electric Code

• Applicable federal, state and local codes and regulations

Failure to do so may adversely affect the safe use and operation of the equipment.

Note: This kit must be installed by a Gasboy Authorized Service Contractor (ASC) to ensure

warranty.

Required Tools

The following tools are needed to install the ATC Kits:

• Open end wrench set

• Flat-tip s crewdriver

• Cross-tip screwdriver

•Allen

MDE-4351A Gasboy ATC K its 039086 and 039087 Installation Manual • February 2006 Page 1

®

wrench set

Page 2

Introduction

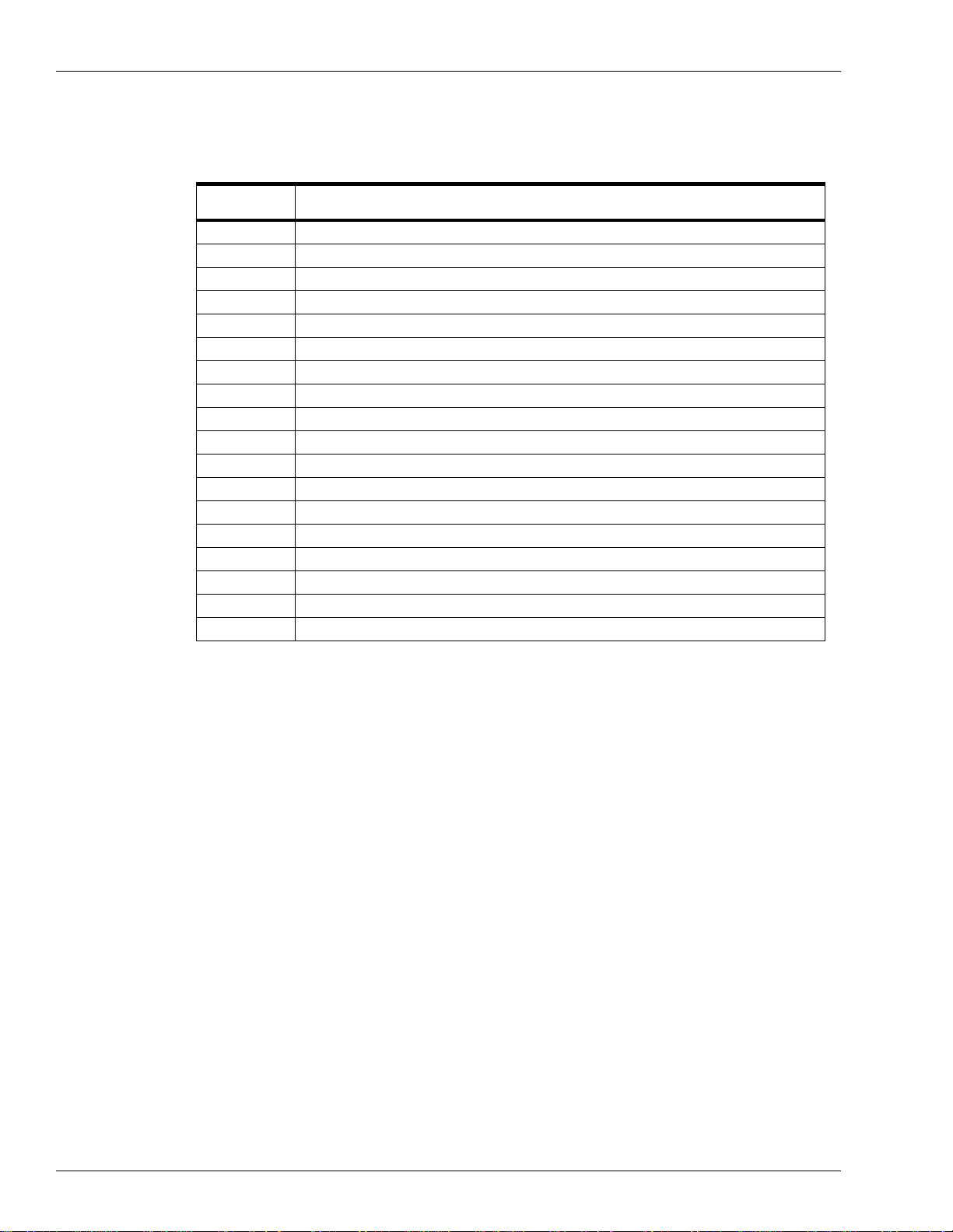

Abbreviations and Acronyms

The following are abbreviations and acronyms used in this document.

Abbreviation

or Acronym Expansion

ATC Automatic Temperature Compensation

ASC Authorized Service Contractor

AWG American Wire Gauge

CFR Code of Federal Regulations

CPU Central Processing Unit

DIP Dual Inline Package

ESD Electrostatic Discharge

I.D. Inside Diameter

IS Intrinsic Safety

LCD Liquid Crystal Display

LPM Liters Per Minute

NEC National Electrical Code

NFPA National Fire Protection Association (http://www.nfpa.org/Home/index.asp)

NPT National Pipe Thread

OSHA Occupational Safety & Health Administration (http://www.osha.gov/)

PCB Printed Circuit Board

STP Submerged Turbine Pump

®

TPS Teflon

Pipe Sealant

Page 2 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 3

Introduction

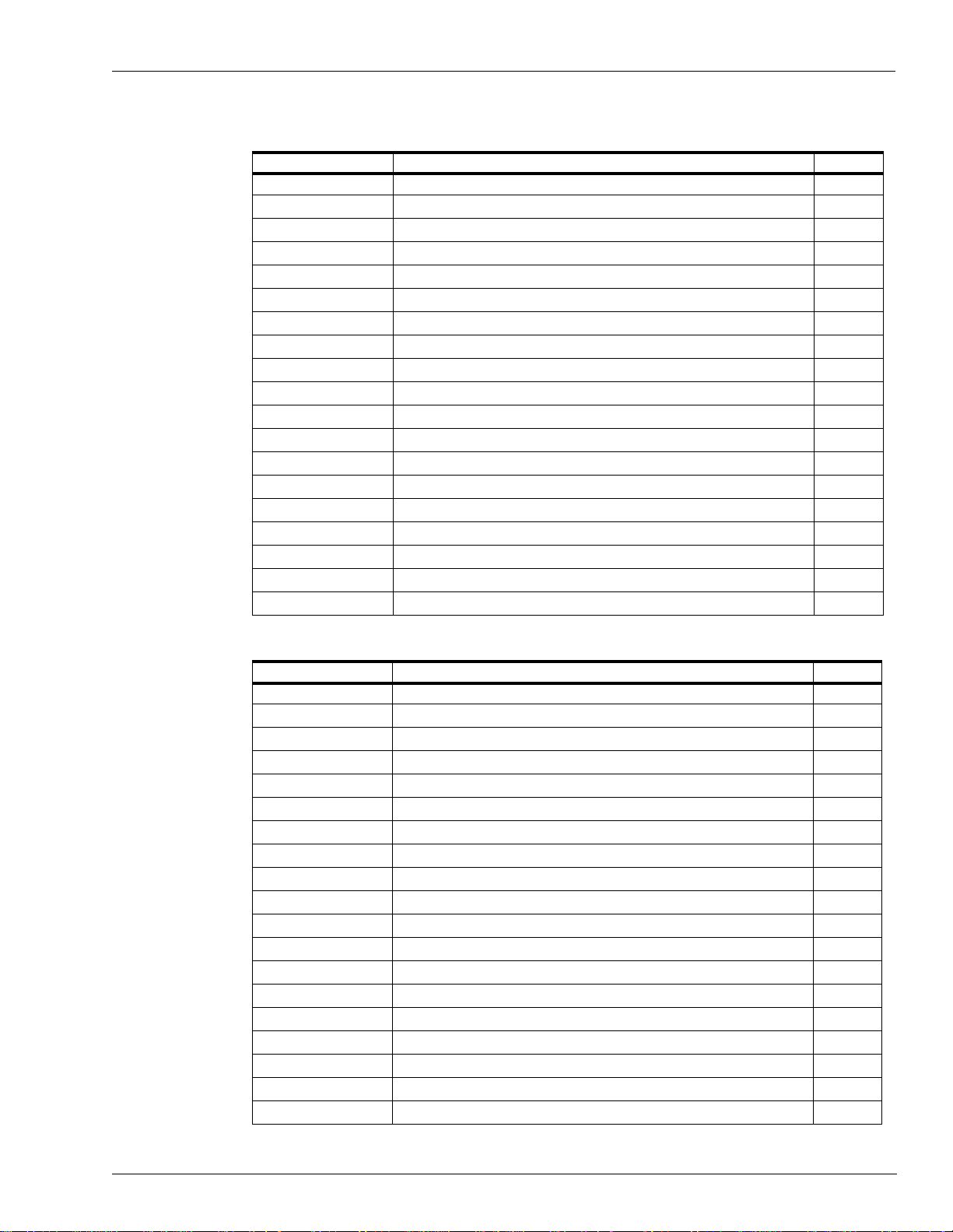

Parts Lists

039086 - ATC Kit for Twin Unit

Kraus Part Number Description Quantity

®

SK449C PCB Assembly in LP-70 Polycase

SK460 ATC Display Adapter Board (460A4 in Figure 1)1

SK461 Pulser/Handle Adapter Board (461A2 in Figure 1)1

218AY00 Dual Intrinsic Safety Barrier 1

- 5/16-inch Flat Washer (part of 218AY00) 2

- 5/16-inch Hex Nut (part of 218AY00) 1

212AY05 Dual Probe Connector Assembly 1

W172 3-Wire Harness for Intrinsic Safety Barrier 1

W199 Probe Assembly 2

BC407 Thermowell 2

235-C Thermowell plug 2

122-B 1/8-inch NPT X 1-inch Coupling 2

BC546 120-B 1/8-inch NPT Adapters Drilled to 17/64-inch I.D. 2

103-B 1/8-inch NPT Couplings 2

W283 Display Adapter Harness 1

W284 Pulser/Handle Ribbon Cable 2

- 18-22 AWG Crimp Splices 10

DC256W White “Volume Corrected to 15° C” Label 4

BC1380 Serialized AV-2322 Nameplate 1

Box and BC1379 Mounting Sponge 1

039087 - ATC Kit for Single Unit

Kraus Part Number Descri ption Quantity

SK449C PCB Assembly in LP-70 Polycase Box and BC1379 Mounting Sponge 1

SK460 ATC Display Adapter Board (460A4 in Figure 1)1

SK461 Pulser/Handle Adapter Board (461A2 in Figure 1)1

218AY00 Dual Intrinsic Safety Barrier 1

- 5/16-inch Flat Washer (part of 218AY00) 2

- 5/16-inch Hex Nut (part of 218AY00) 1

212AY04 Single Probe Connector Assembly 1

W171 2-Wire Harness for Intrinsic Safety Barrier 1

W199 Probe Assembly 1

BC407 Thermowell 1

235-C Thermowell plug 1

122-B 1/8-inch NPT Coupling 1

BC546 120-B 1/8-inch NPT Adapters Drilled to 17/64-inch I.D. 1

103-B 1/8-inch NPT Couplings 1

W283 Display Adapter Harness 1

W284 Pulser/Handle Ribbon Cable 1

- 18-22 AWG Crimp Splices 10

DC256W White “Volume Corrected to 15° C” Label 2

BC1380 Serialized AV-2322 Nameplate 1

MDE-4351A Gasboy ATC K its 039086 and 039087 Installation Manual • February 2006 Page 3

Page 4

Introduction

Parts Identification

Figure 1 and Figure 2 provide an identification of the parts in the 039086 and 039087 kits.

Figure 1: The 039086 and 039087 Kits Parts Identification

W199 Probe Assembly

212AY04 Single Probe/

W284 Pulser/

Handle Ribbon

Cable

W283 Display

Adapter Harness

W172 3-Wire Harness

(For Twin Unit)

~ OR ~

W171-2 Wire Harness

(For Single Unit)

212AY05 Dual Probe

Connector Assembly

Crimp Splices

103B Couplings

122-B Nipples

235C Thermowell Plugs

BC546 120-B Adapters

BC407 Thermowells

218AY00 Dual Intrinsic Safety

Barrier (Newer Version)

460A4 Display

Adapter Board

218A Y00 Dual Intrinsic

Safety Barrier (Older

Version)

461A2 Pulser/Handle

Adapter Board

BC256W Label

BC1380 Nameplate

Note: If your kit is for a single unit, you will have only one of some of these items.

Page 4 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 5

Introduction

Figure 2: SK449C LP-70 Polycase Box and Cover (Part of 039086 and 039087 Kits)

Cover

LP-70 Polycase

Box

SK449C PCB

Assembly

MDE-4351A Gasboy ATC K its 039086 and 039087 Installation Manual • February 2006 Page 5

Page 6

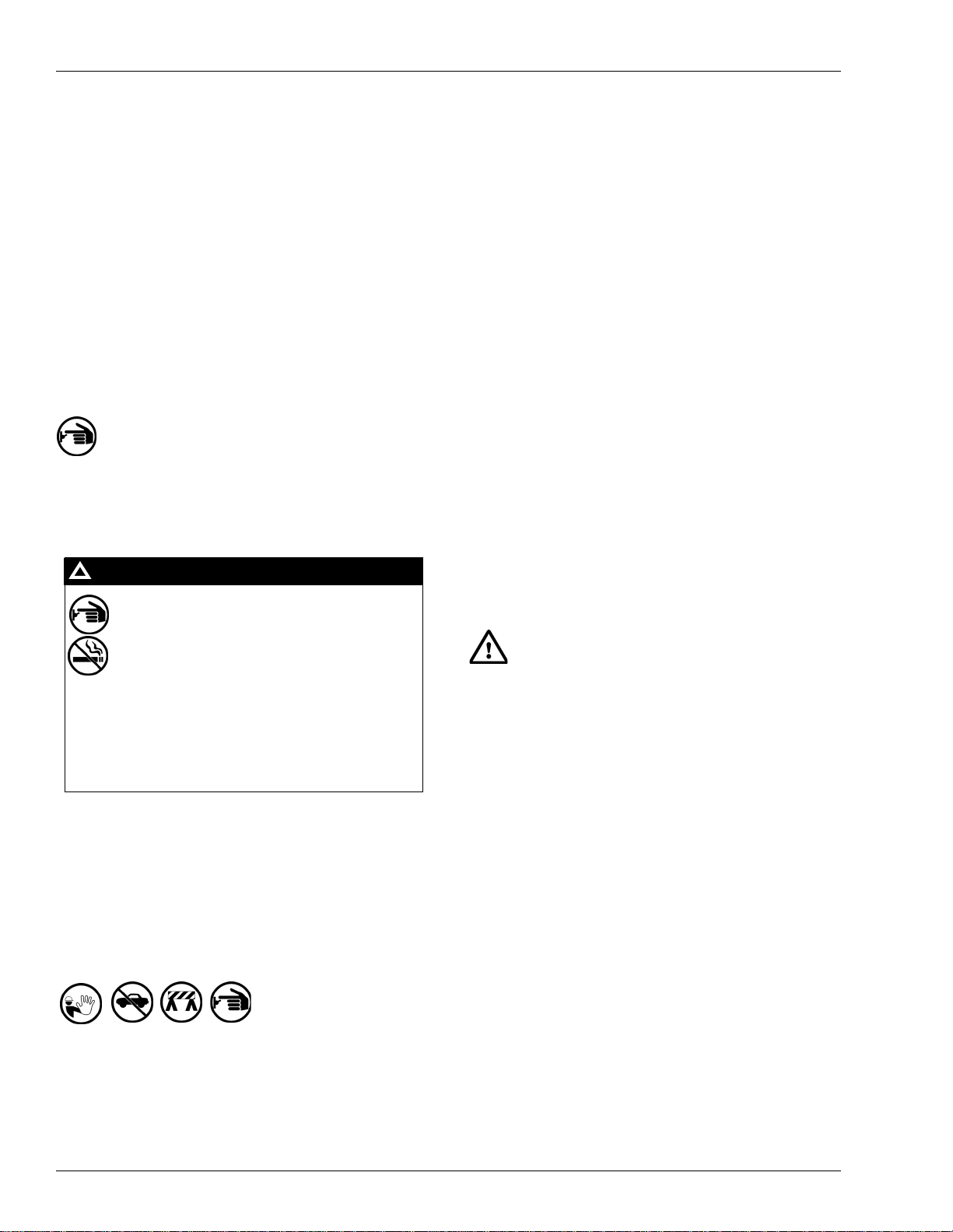

Important Safety Information

The EMERGENCY STOP, ALL STOP, and

PUMP STOP buttons at the cashier’s station

WILL NOT shut off electrical power to the

pump/dispenser.

This means that even if you activate these

stops, fuel may continue to flow uncontrolled.

You must use the TOTAL ELECTRICAL SHUTOFF in the case of an emergency and not only

these cashier station “stops.”

!

WARNING

!

Important Safety Information

This section introduces the hazards and safety precautions

associated with inst alling , inspecting, main tainin g or servicing

this product. Before performin g any t ask on this pro duct, read

this safety information and the applicable sections in this

manual, where additional hazards and safety precautions for

your task will be found. Fire, explosion, electrical shock or

pressure release could occur and cause death or serious

injury if these safe service procedures are not followed.

Preliminary Precautions

You are working in a potentially dangerous environment of

flammable fuels, vapors, and high voltage or pressures. Only

trained or authorized indiv iduals know ledgeable in the related

procedures should install, inspect, maintain or service this

equipment.

Read the Manual

Read, understand and follow this manual and any other

labels or related mate rials suppli ed with this eq uipment. If y ou

do not understand a procedure, call a Gasboy Authorized

Service Contractor or call the Ga sb oy Serv ic e Center at 1800-444-5529. It is imp erative to y our safety and the sa fety of

others to understand the procedures before beginning work.

Follow the Regulations

There is applicable information in NFPA 30A; Automotive and

Marine Service Code, NFPA 70; National Electrical Code (NEC),

OSHA regulations and federal, state, and local codes which

must be followed. Failure to install, inspect, maintain or

service this equipment in accordance with these codes,

regulations and standards may lead to legal citations with

penalties or affect the safe use and operation of the

equipment.

Emergency Total Electrical Shut-Off

The first and most impo rtant information you mus t know is

how to stop all fuel flow to the pump and island. Locate the

switch or circuit breakers that shut-off all power to all fueling

equipment, dispensing devices, and submerged turbine

pumps (STPs).

Total Electrical Shut-Off Before Access

Any procedure requiring access to electrical components or

the electronics of the dispenser requires total electrical shutoff of that unit. Know the function and location of this switch

or circuit breaker before in sp ect ing , installing, maintaining, or

servicing Gasboy equipment.

Evacuation, Barricading and Shut-Off

Any procedures requiring accessing the pump/dispenser or

STPs requires the following three actions:

- An evacua tion of all unauthorized persons and vehicles

using safety tape, cones or barricades to the effected units

- A total electrical shut-off of that unit

Replacement Parts

Use only genuine Gasboy replacement parts and retrofit kits

on your pump/dispenser. Using parts other than genuine

Gasboy replacement parts could create a safety hazard and

violate loc al regulations.

Safety Symbols and Warning Words

This section provides important informati on about warning

symbols and boxes.

Alert Symbol

This safety alert symbol is used in this manual and on

warning labels to alert you to a precaution whi c h m ust be

followed to prevent potential personal safety hazards. Obey

safety directives that follow this symbol to avoid possible

injury or death.

Signal Words

These signal words used in this manual and on warning labels

tell you the seriousness of particular safety hazards. The

precautions that follow must be followed t o pre vent death,

injury or damage to the equipment

DANGER - This signal word is used to alert you to a

hazard to unsafe practice which will resul t in deat h or

serious injury

WARNING - This alerts you to a hazard or unsafe

practice that could result in death or serious injury.

CAUTION with Alert symbol - This signal word

designates a hazard or unsafe practice which may

result in minor injur y.

CAUTION without Alert symbol - When used by itself,

CAUTION designates a hazard or unsafe practice

which may result in property or equipment damage.

Working With Fuels and Electrical Energy

Prevent Explosions and Fires

Fuels and their vapors will become explosive if ignited. Spilled

or leaking fuels cause vapors. Even filling custom er tanks will

cause explosive vapors in the vicinity of dispe nser or island.

Page 6 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 7

Important Safety Information

No Open Flames

Open flames from matches, lighters, welding torches

or other sources can ignite fuels and their vapors.

No Sparks - No Smoking

Sparks from starting vehicles, starting or using power tools,

burning cigarettes, cigars or pipes can also ignite fuels and

their vapors. Static electricity, including an electrostatic

charge on your body, can cause a spark sufficient to ignite

fuels and thei r vapo rs. Aft er gett ing ou t of a veh icle, touch the

metal of your vehicle to discharge any electrostatic charge

before you approach the dispenser island.

Working Alone

It is highly recommended that someone who is capable of

rendering first aid be present during servicing. Be familiar

with Cardiopulmonary Resuscitation (CPR) methods if you

are working with or around high voltages. This information is

available from the American Red Cross. Always advise the

station personnel about where you will be working, and

caution them not to activate power while you are working on

the equipment. Use the OSHA tag out and lock out

procedures. If you are not fam iliar wit h this require ment, ref er

to information in the service manual and OSHA

documentation.

Working With Electricity Safely

Be sure to use sa fe an d established pra ct ice s in w ork in g with

electrical devices. Poorly wired devices may cause a fire,

explosion or electrica l sh ock . Be su re grou nding connections

are properly made. Make sure that sealing devices and

compounds are in place. Be sure not to pinch wires when

replacing covers. Follow OSHA Lock-Out and Tag-Out

requirements. Station employees and service contractors

need to underst and and comply wit h th is pro gra m c om pl ete ly

to ensure safety while the equipment is down.

Emergency First Aid

Informing Emergency Personnel

Compile the following information for emergency personnel:

Location of accident (for example, address, front/back of

building, and so on.)

Nature of accident (for example, possible heart attack, run

over by car, burns, and so on.)

Age of victim (for example, baby, teenager, middle-age,

elderly.)

Whether or not victim has received first aid (for example,

stopped bleeding by pressu re, and so on.)

Whether or not a victim has vomited (for example, if

swallowed or inhaled something, and so on.)

WARNING

!

Gasoline ingeste d may c ause unc onsciou sness

and burns to internal organs.

Do not induce vomiting.

Keep airway open.

Oxygen may be needed at scene.

Seek medical advice immediately.

WARNING

!

Gasoline inhaled may cause unconsciou sness

and burns to lips, mouth and lungs.

Keep airway open.

Seek medical advice immediately.

WARNING

!

Gasoline spilled in ey es may cause bur ns to eye

tissue.

Irrigate eyes with water for approximately 15

minutes.

Seek medical advice immediately

Hazardous Materials

Some materials present inside electronic enclosures may

present a health hazard if not handled correctly. Be sure to

clean hands after handling equipment. Do not place any

equipment in mouth.

!

WARNING

This area contains a chemical known to the State of

California to cause cancer.

WARNING

!

Gasoline spilled on skin may cause burns.

Wash area thoroughly with clear/water.

Seek medical advice immediately.

IMPORTANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

Lockout/Tagout

WARNING

!

This area contains a chemical known to the State of

California to cause birth defects or other reproductive

harm.

Lockout/Tagout covers servicing and maintenance of

machines and equipment in which the unexpected

energization or start up of the machine(s) or equipment or

release of stored energy could cause injury to employees or

personnel. Lockout/Tagout applies to all mechanical,

hydraulic, chemical or other energy, but does not cover

electrical hazards. Referenc e Sub part S of 2 9 CFR Pa rt 1910

IMPORT ANT: Oxygen may be needed at scene if gasoline

has been ingested or inhaled. Seek medical advice

immediately.

- Electrical Hazards, 29 CFR Part 1910.333 contains specific

Lockout/Tagout provision for electrical hazards.

MDE-4351A Gasboy ATC K its 039086 and 039087 Installation Manual • February 2006 Page 7

Page 8

Installation

Installation

Preparation

1 Request permission from the manager/owner to remove power from the unit and then remove

2 Make sure you have the proper kit for the model dispenser to be retrofitted.

3 Using the proper key for the unit, unlock and remove the doors from both sides of the unit.

4 Using a cross-tip screwdriver, at side 1 of the unit, loosen the two screws (one on each side of

Use electrostatic discharge (ESD) precautions to place yourself at a neutral

static-free potential by touching an unpainted metal surface and by using a wrist

strap connected to a grounded metal frame or chassis.

power using normal procedures. Observe the lockout/tagout safety procedures.

Place doors in a safe place to prevent damage or scratches.

the display cove r), s pring the s crew ho lders and scre ws out from t he dis pl ay cove r and pull the

display cover forward. The cover will pivot down in a horizontal position allowing access to

the electronics section of the unit.

Installing the 039086 ATC Kit in Single Unit

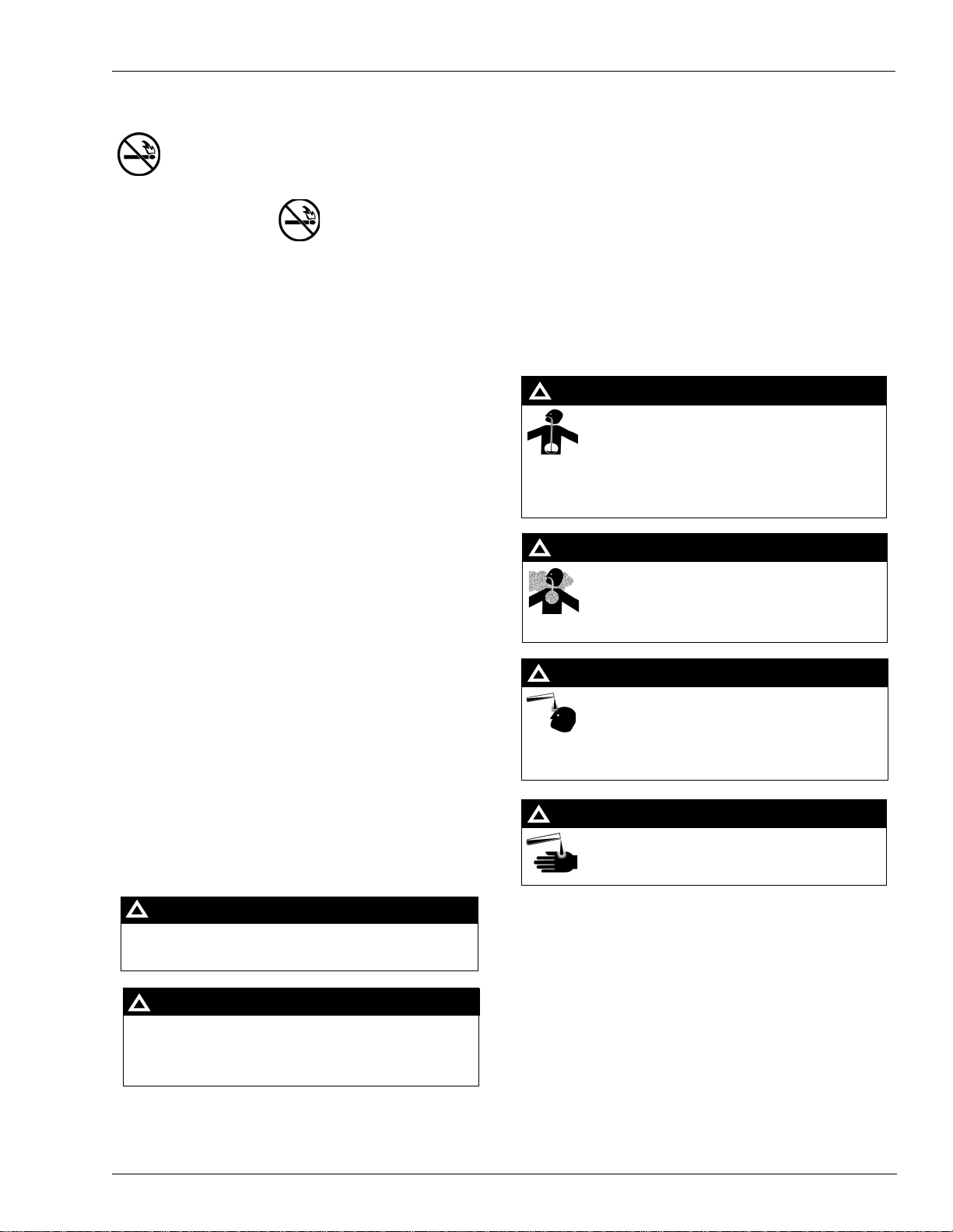

1 In the kit, locate the LP-70 Poly case box wit h SK449C PCB mounted insid e. Remove the four

mounting screws securing the cover and remove the cover from the box. Save screws and

cover for reinstalling later.

2 Peel the protective cover from the mounting sponge (on the back of the polycase box) and

mount the box as shown in Figure 3. Mount approximately 1/2-inch up from shelf (1/2-inch

clearance underneath shelf).

Figure 3: Mounting the LP-70 Polycase Box

Approximately 1/2-inch

Clearance

Page 8 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 9

Installation

3 In the kit, locate the 218AY00 single intrinsic safety (IS) barrier and 212AY04 single probe

connector assembly. Remove the nut and washer from the mounti ng stud on the IS barrier a nd

slide them off the wires. Save for reuse.

4 Feed the wires extending from the IS barrier mounting stud through the hole in the shelf as

shown in Figure 4 and place the mounting stud through the hole.

Figure 4: Mounting the IS Barrier on the Shelf

Notch in Shelf

IS Barrier

Probe Connector

Assembly

5

Place the wires extending from the mounting stud through the mounting hole in the single

probe connector assembly and place the connector assembly up on the stud (underneath the

shelf).

CAUTION

If your kit contains the newer version of the 218Y00 IS Barrier (see Figure 1 for

identification) and your unit does NOT have the notch in the shelf (Figure 4), the IS

barrier will not mount. DO NOT try to mount the IS barrier if the shelf does not have

the notch.

6 Place the washer and nut over the wires and turn nut onto the stud securing the IS barrier and

probe connector. Tighten snugly but do not overtighten.

7 Place the wires extending from the top of the IS barrier up through the grommet in the upper

shelf as sho wn in Figure 5.

Note: Figure 5 shows tw o pair s of wires (for a twin unit inst allat io n). The re is only one pai r of

wires in this single unit instal lation.

MDE-4351A Gasboy ATC K its 039086 and 039087 Installation Manual • February 2006 Page 9

Page 10

Installation

Figure 5: Wires from IS Barrier Extending Through Shelf

Wires from IS Barrier

Grommet

8

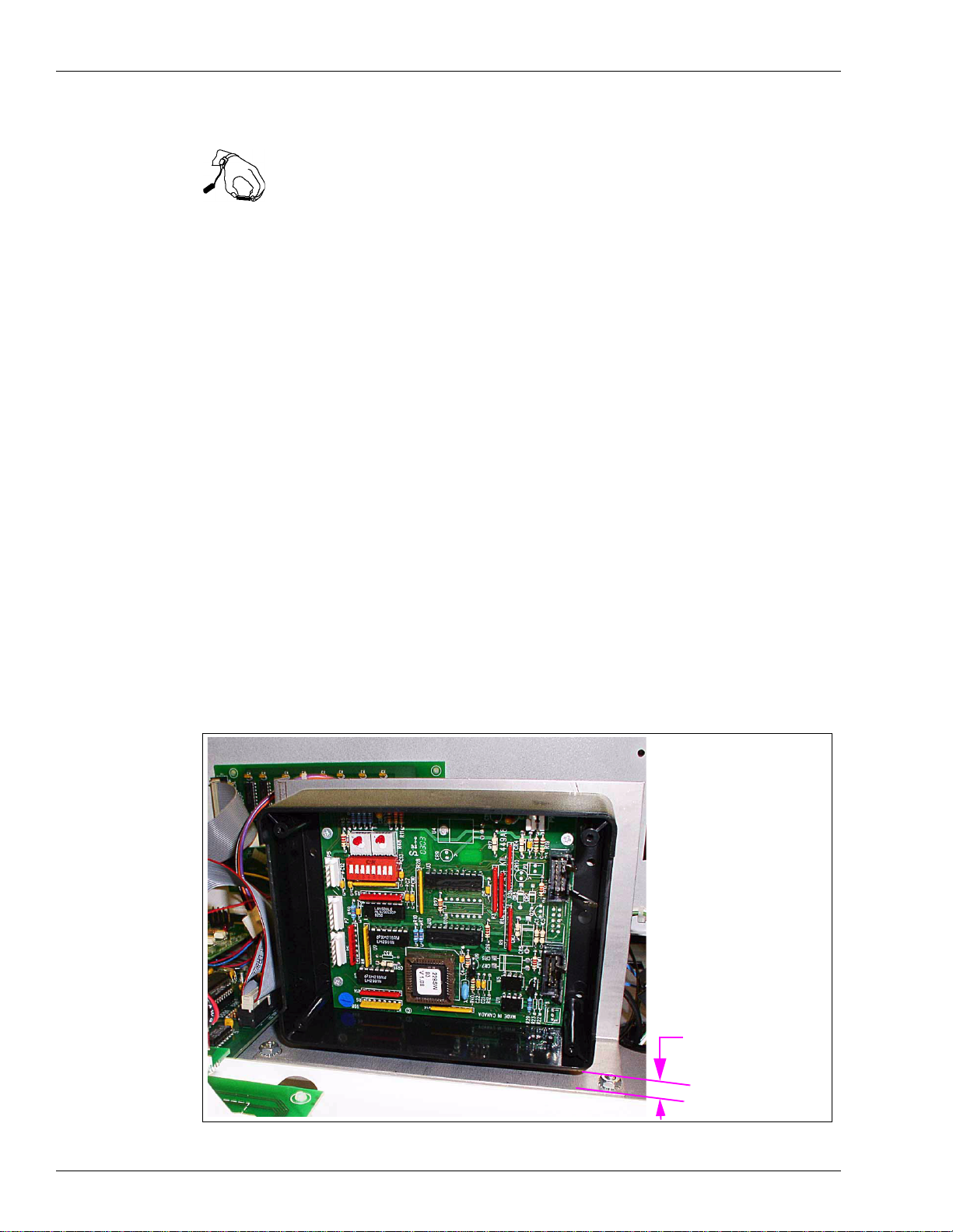

At the C06391 9800 CPU P rinted Ci rcuit Board Assembl y (Fig ure 6 and Figure 7), disc onnect

the connectors connected to the Pulser 1 and Handles jacks.

9 In the kit, locate the 461A2 Circuit Board Assembly (see Figure 1 for identity). Connect the

assembly to the jacks labeled Pulser 1, Handles, and Pulser 2 on the 9800 CPU PCB.

10 Reconnect the connector removed in Step 8 to the 461A2 Circuit Board Assembly (directly

above the Pulser 1 and Handles connectors).

11 At the 9800 CPU PCB Assembly (Fi gure 6 and Figure 7), disconnect the connector connected

to the LCD Display jack.

12 In the kit, locate the 460A4 Circuit Board Assembly (see Figure 1 for identity). Connect the

assembly to the jack labeled LCD Display on the 9800 CPU PCB.

13 Reconnect the connect or remov ed in S tep 1 1 t o th e 460A4 Cir cuit Boa rd Assembly jack J 1 (in

center of board).

Page 10 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 11

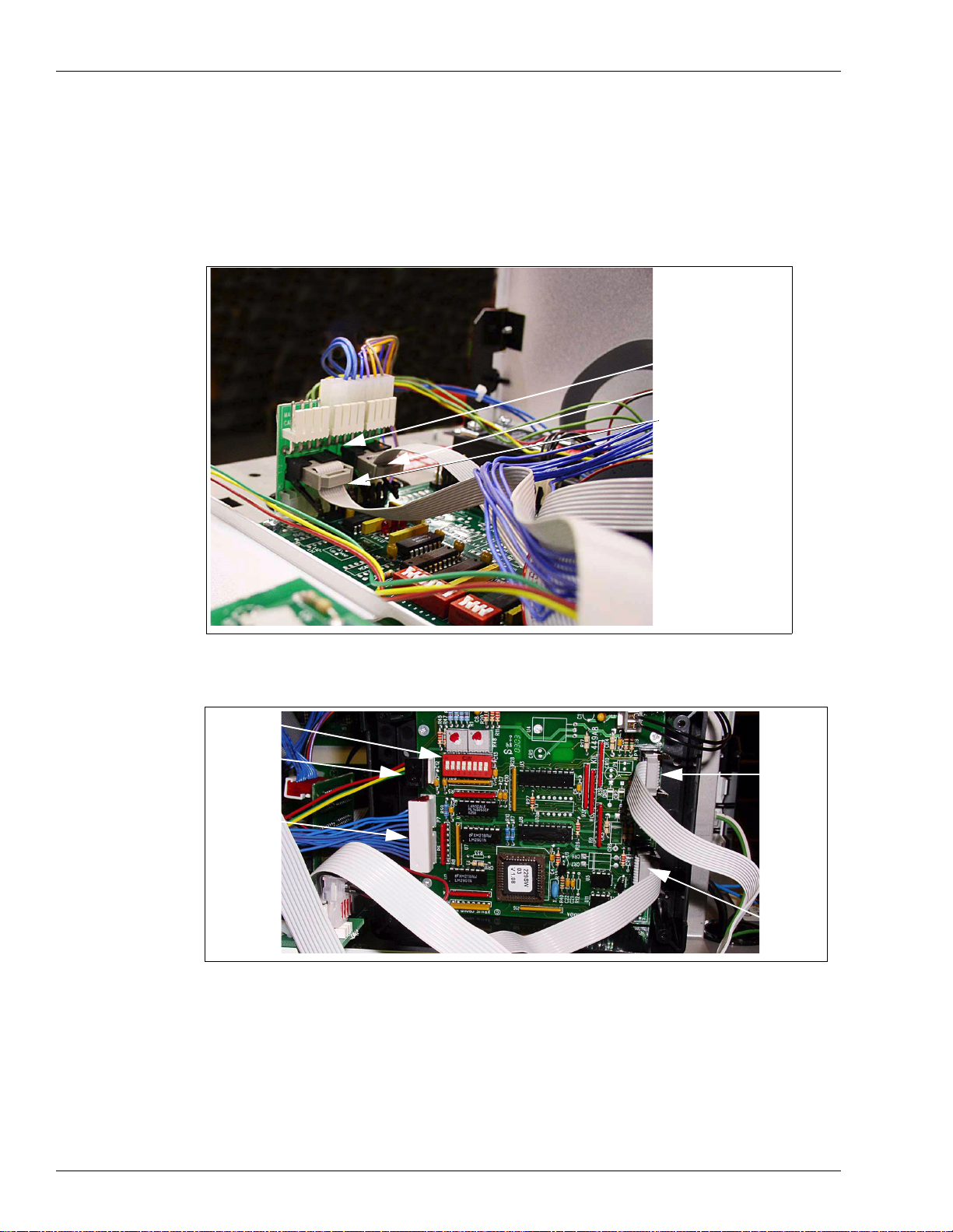

Figure 6: C06391 9800 CPU Printed Circuit Board (Photograph)

Pulser 1 and

Handles Jac ks

Installation

Pulser 1 and

Handles Ja cks

Pulser 2 J ack

Pulser 2 Jack

Figure 7: C06391 9800 CPU Printed Circuit Board (Drawing)

LCD

Display

Jack

LCD

Display

Jack

14

In the kit, locate the W284 Pulser/Handle Ribbon Cable (see Figure 1 for identity).

15 Connect one end of the W284 cable to P1 on the 461A2 board (Figure 8) and the other end to

P2 in the LP-70 Polycase box (Figure 9).

16 Connect one end of the second W284 cable to P8 o n t he 4 61A2 b oard (Figure 8) and the other

end to P3 in th e LP-70 Polyc ase box (Figure 9).

Note: Be sure the cables are connected to the connectors as follows:

P1 of 461A2 to P2 of LP-70 Polycase box

P8 of 461A2 to P3 of LP-70 Polycase box

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 11

Page 12

Installation

Figure 8: 461A2 Circuit Board in Place with Connections Made

461A2 PCB

P1

P8

Figure 9: LP-70 Polycase Box Showing Connections

DIP

Switches

P5

P6/P7

17

In the kit, locate the W283 Display Adapter Harness (see Figure 1 for identification).

P3

P2

18 Connect one connector on the harness (both are the same) to J4 on the 460A4 Circuit Board

Assembly (Figure 10) and the other connector to P6/P7 in the LP-70 Polycase box (Figure 9).

Page 12 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 13

Figure 10: 460A4 Circuit Board in Place with Connections Made

J4

460A4 Circuit

Board Assembly

W283 Display Adapter

Connector on J4

Installation

19

In the kit, loc ate the W171 2-wire harness for IS Barrier.

20 Place the connector on the harness on P5 of the LP-70 Polycase box (Figure 9).

21 Using two of the crimp splices, connect the wires of the harness to the wires extending from

the top of th e IS barrier. Match co lor codes.

22 Using an OM0205 cap or an appropriate size wire nut (OM0205 cap or wire nut is not part or

the kit), cap the end of the green wire from the IS barrier.

23 Connect the ground wire (wire with eyelet connector) to the nearest true ground.

24 Disconnect cable going to P6 connector of the Pump CPU board.

25 Connect the cable that was disconnected in previous step to P9 connector in the LP-70

Polycase box.

26 If the user wants to be able to display electronic totals, a second cable (C06003) must be

installed and connected to the P6 connector on the Pump CPU board.

27 In the LP-70 Polyca se box, locate the DIP switches shown in Figure 9 and set the switches for

the proper unit as shown in the following table:

DIP Switch Settings

Switch

Number Switch Function Settings

1 Product 1 ON for Diesel, OFF for Gasoline

2 Product 2 ON for Diesel, OFF for Gasoline

3Not used

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 13

Page 14

Installation

DIP Switch Settings

Switch

Number Switch Function Settings

4Not used

5 Pulser Multiplier ON for 9850, OFF for 9852/9853

6 Number of Probes ON for two (2) probes, OFF for one (1) probe

7 Pulser Adder ON for 9840

8 ATC ON for ATC ON, OFF for ATC OFF

28 Remount the LP-70 Polycase box cover removed in step 1.

29 Using two of the crimp spl ices, conne ct the two ye llow wires extending from the bot tom of the

IS barrier mounti ng st ud to t he two blue wi res a ttac hed to the singl e pro be conn ector as sembly.

30 Using two OM0205 caps or suitable-size wire nuts (OM0205 caps or wire nuts are not part of

the kit.), cap the end of the two green wires extending from the bottom of the IS barrier.

31 In the kit, locate the foll owing: (See Figure 1 for parts identity)

• W199 probe assembly

• BC407 Thermowell

• 235-C Thermowell Plug

• BC546 Adapter

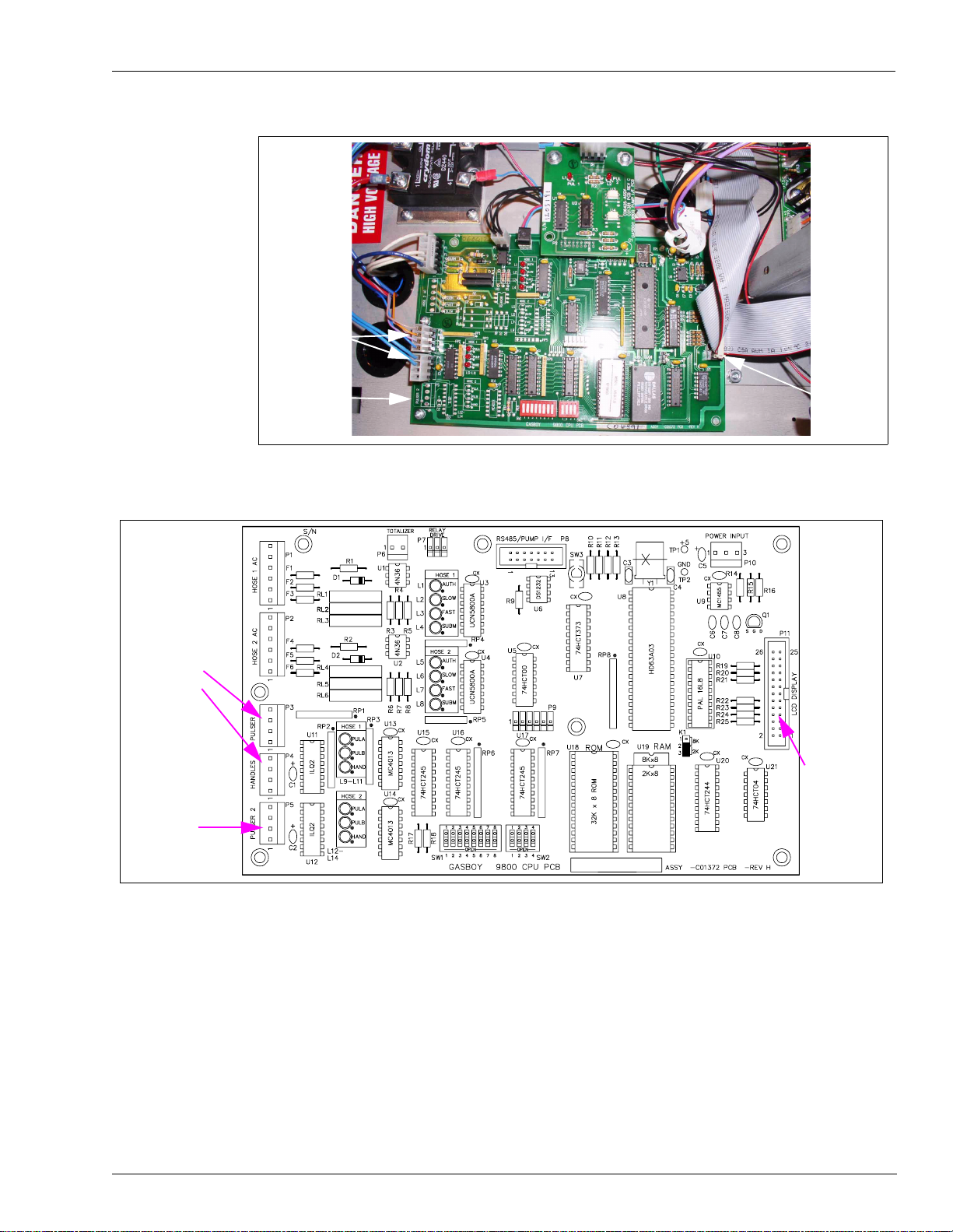

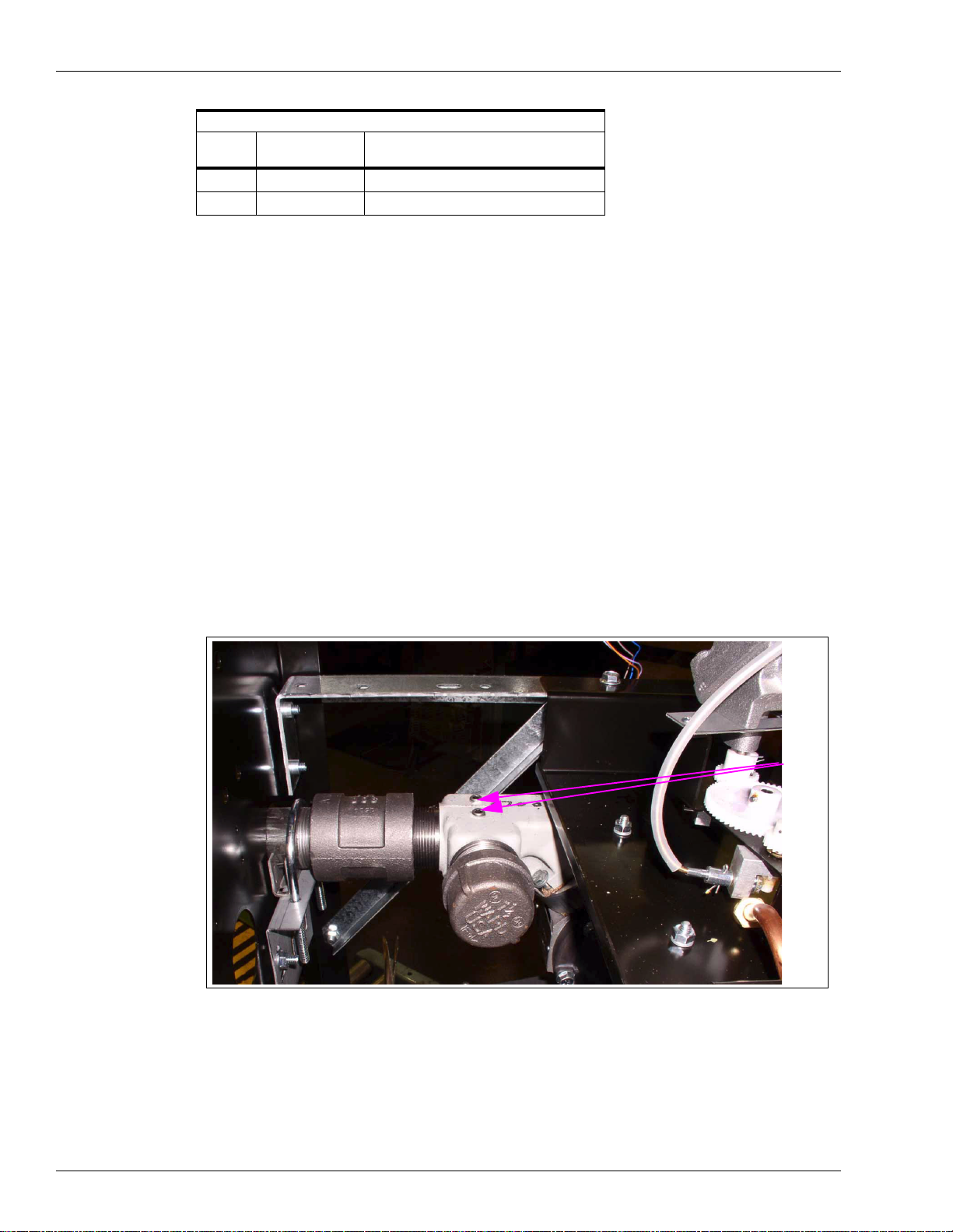

32 Underneath the shelf (where the IS barrier is mounted), locate the two plugs in the hydraulic

coupling (Figure 11).

Figure 11: Probe Assembly Mounting Location

Plugs

Using the appropriate size Allen wrench, remove the two plugs.

33

Page 14 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 15

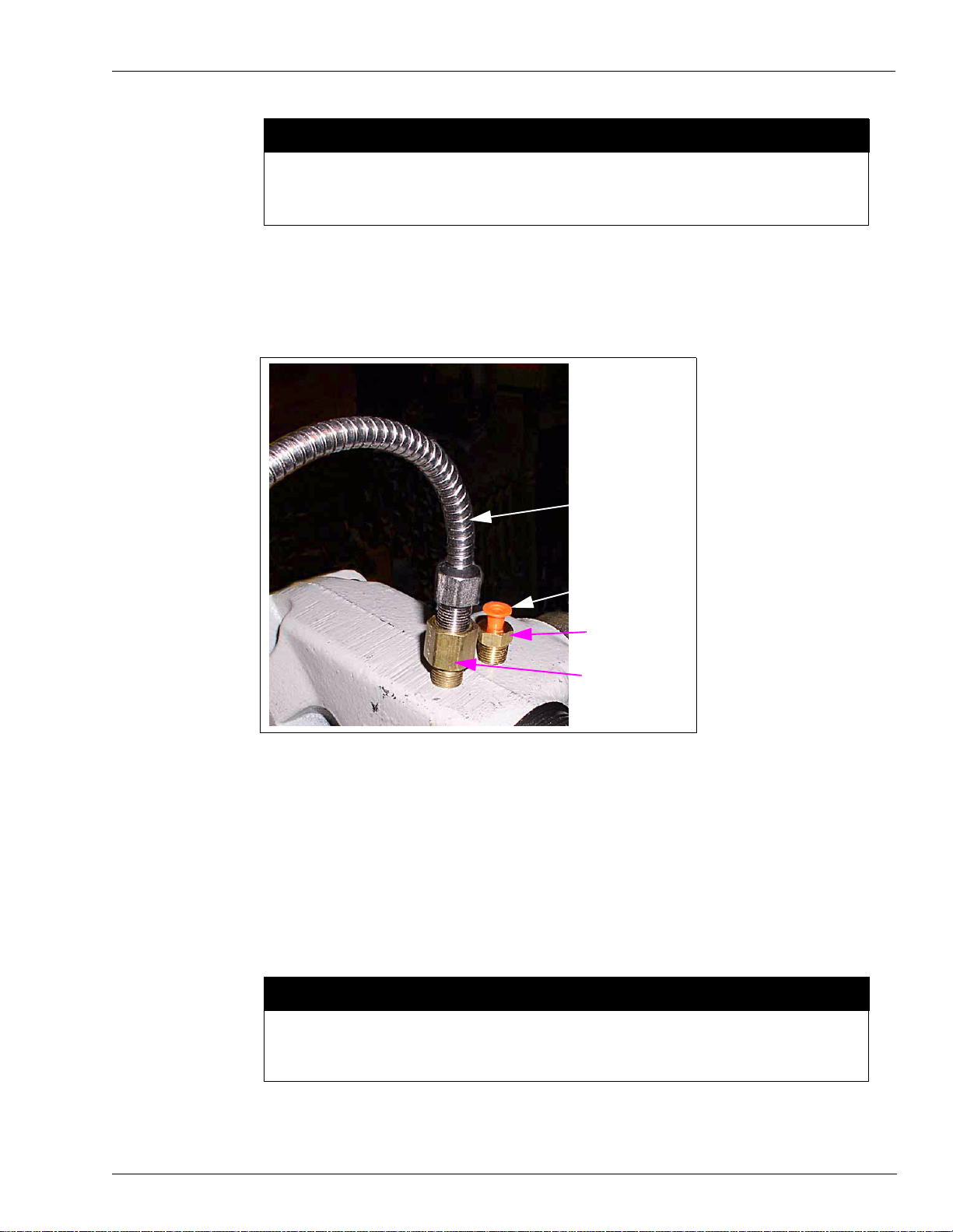

CAUTION

Installation

When applying

hole first free of sealant to prevent the sealant from entering, and possibly damaging or

inhibiting proper operation of, the unit.

34 Using SAF-T-LOK TPS sealant, coat the BC407 Thermowell threads and thread into one of

SAF-T-LOK® TPS sealant on threads, leave the two threads that enter the

the holes where the plugs were removed in the previous step (Figure 12).

Figure 12: Thermowell and Probe Assembly Connections

Probe Assembly

Thermowell Plug

Thermowell

Adapter

35

Using a proper size wrenc h, tig hten th e ther mowell and pl ace the 235-C Ther mowell p lug int o

the thermow ell.

36 Coat the threads of the BC546 Adapte r with SAF-T-LOK TPS sealant and turn it into th e other

hole where the plugs were removed in step 33 (see Figure 12).

37 Coat the threads of the W199 Probe Assembly with SAF-T-LOK TPS sealant and turn it into

the BC546 a dapter mounted in the previous step.

38 Using the proper size wrench, tighten both the adapter and probe.

CAUTION

Be sure the threads on the thermowell, adapter, and probe assembly are properly

coated with the SAF-T-LOK TPS sealant and tightened properly to prevent leaks

.

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 15

Page 16

Installation

39 Connect the other end of th e probe to Probe Connector Asse mbly in the conne ctor labe led “1”.

(See Figure 4 for Probe Connector Assembly location.)

40 Go to “Completing Installation” on page 24 in this manual.

Installing the 039087 ATC Kit in Twin Unit

1 In the kit, locate the LP-70 Poly case box wit h SK449C PCB mounted insid e. Remove the four

mounting screws securing the cover and remove the cover from the box. Save screws and

cover for reinstalling later.

2 Peel the protective cover from the mounting sponge (on the back of the polycase box) and

mount the box as shown in Figure 13. Mount approximately 1/2-inch up from shelf.

Figure 13: Mounting the LP-70 Polycase Box

Approximately

1/2-inch

Clearance

3

In the kit, locate the 218AY00 single IS barrier and 212AY05 dual probe connector assembly.

Remove the nut and washer from the mounting stud on the IS barrier and slide them off the

wires. Save for reuse.

4 Feed the wires extending from the IS barrier mounting stud through the hole in the shelf as

shown in Figure 14 and place the mounting stud through the hole.

Page 16 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 17

Figure 14: Mounting the IS Barrier on the Shelf

Notch in Shelf

Installation

IS Barrier

Probe Connector

Assembly

5

Place the wires exte nding fr om the moun ting s tud th rough t he mounting hole i n the dual p robe

connector assembly and place the connector assembly up on the stud (underneath the shelf).

CAUTION

If your kit contains the newer version of the 218Y00 IS Barrier (see Figure 1 for

identification) and your unit does NOT have the notch in the shelf (Figure 14), the IS

barrier will not mount. DO NO T try to mount the IS barrier if the shelf does not have the

notch.

6 Place the washer and nut over the wires and turn nut onto the stud securing the IS barrier and

probe connector. Tighten snugly but do not overtighten.

7 Place the wires extending from the top of the IS barrier up through the grommet in the upper

shelf as sho wn in Figure 15.

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 17

Page 18

Installation

Figure 15: Wires from IS Barrier Extending Through Shelf

Wires from IS Barrier

Grommet

8

At the C06392 9800 CPU Printed Circuit Board Assembly (Figure 16 and Figure 17),

disconnect the connector connected to the Pulser 1, Handles, and Pulser 2 jacks.

9 In the kit, locate the 461A2 Circuit Board Assembly (see Figure 1 for identity). Connect the

assembly to the jacks labeled Pulser 1, Handles, and Pulser 2 on the 9800 CPU PCB.

10 Reconnect the connector removed in Step 8 to the 461A2 Circuit Board Assembly (directly

above the Pulser 1, Handles and Pulser 2 connectors).

11 At the 9800 CPU PCB Assembly (Figure 16 and Figure 17), disconnect the connector

connected to the LCD Display jack.

Page 18 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 19

Installation

12 In the kit, locate the 460A4 Circuit Board Assembly (see Figure 1 for identity). Connect the

assembly to the jack labeled LCD Display on the 9800 CPU PCB.

13 Reconnect the connector remov ed in S tep 1 1 t o the 460 A4 Cir cuit Boa rd Assembly j ack J1 (i n

center of board).

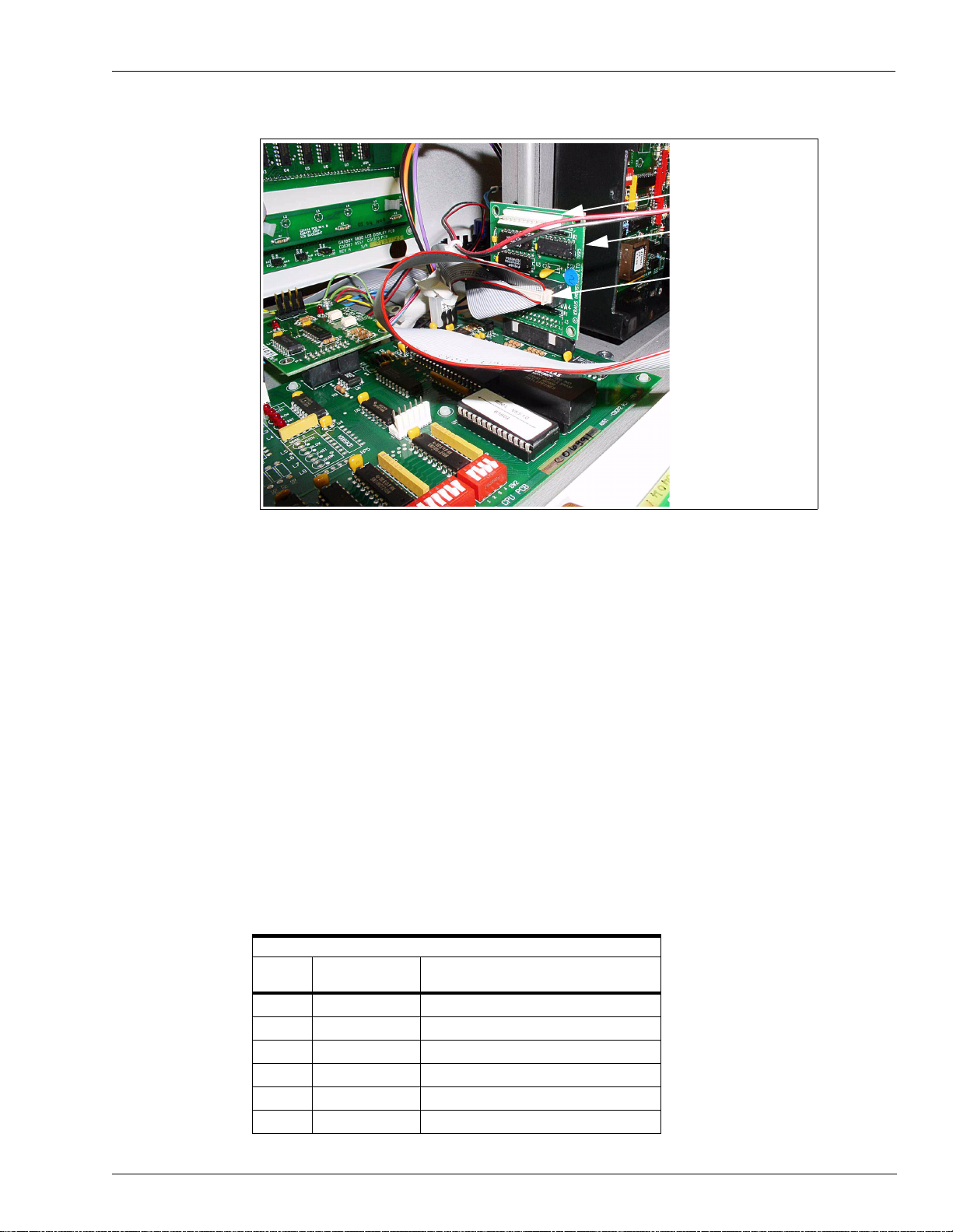

Figure 16: C06392 9800 CPU Printed Circuit Board (Photograph)

Pulser 1 and

Handles Jacks

Pulser 1 and

Handles Ja cks

Pulser 2 J ack

Pulser 2 Jack

Figure 17: C06392 9800 CPU Printed Circuit Board (Drawing)

LCD

Display

Jack

LCD

Display

Jack

14

In the kit, locate the two W284 Pulser/Handle Ribbon Cables (see Figure 1 for identity).

15 Connect one end of one W284 cable to P 1 on the 461A2 b oard (Figure 18) and the other end to

P2 in the LP-70 Polycase box (Figure 19).

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 19

Page 20

Installation

16 Connect one end of the second W284 cable to P8 on the 461A2 board (Figure 18) and the

other end to P3 in the LP-70 Polycase box (Figure 19).

Note: Be sure the cables are connected to the connectors as follows:

P1 of 461A2 to P2 of LP-70 Polycase box

P8 of 461A2 to P3 of LP-70 Polycase box

Figure 18: 461A2 Circuit Board in Place with Connections Made

461A2 PCB

P1

P8

Figure 19: LP-70 Polycase Box Showing Connections

DIP

Switches

P5

P6/P7

17

In the kit, locate the W283 Display Adapter harness (see Figure 1 for identification).

P3

P2

18 Connect one connector on the harness (both are the same) to J4 on the 460A4 Circuit Board

Assembly (Figure 20) and the other connect or to P6/P7 in the LP-70 Polyc ase box (Fi gure 19).

Page 20 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 21

Figure 20: 460A4 Circuit Board in Place with Connections Made

J4

460A4 Circuit

Board Assembly

W283 Display Adapter

Connector on J4

Installation

19

In the kit, loc ate the W172 3-wire harness for IS Barrier.

20 Place the connector on the harness on P5 of the LP-70 Polycase box (Figure 19).

21 Using three of the crimp splices, connect the wires of the harness to the wires extending from

the top of th e IS barrier. Match co lor codes.

22 Connect the ground wire (wire with eyelet connector) to the nearest true ground.

23 Disconnect cable going to P6 connector of the Pump CPU board.

24 Connect the cable that was disconnected in previous step to P9 connector in the LP-70

Polycase box.

25 If the user wants to be able to display electronic totals, a second cable (C06003) must be

installed and connected to the P6 connector on the Pump CPU board.

26 In the LP-70 Polycase box, locate the DIP switches shown in Figure 19 and set the switches

for the proper unit as shown in the following table:

DIP Switch Settings

Switch

Number Switch Function Settings

1 Product 1 ON for Diesel, OFF for Gasoline

2 Product 2 ON for Diesel, OFF for Gasoline

3 Not used N/A

4 Not used N/A

5 Pulser Multiplier ON for 9850, OFF for 9852/9853

6 Number of Probes ON for two (2) probes, OFF for one (1) probe

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 21

Page 22

Installation

DIP Switch Settings

Switch

Number Switch Function Settings

7 Pulser Adder ON for 9840

8 ATC ON for ATC ON, OFF for ATC OFF

27 Remount the LP-70 Polycase box cover removed in step 1.

28 Using two of the crimp splices, connect the two green wires extending from the bottom of the

IS barrier mounting stud to the two green wi res attac hed to the dual probe conn ector assembly.

29 Using two of the crimp spl ices, conne ct the two ye llow wires extending from the bot tom of the

IS barrier mounting stud to the two yellow wires attached to the dual probe connector

assembly.

30 In the kit, locate the foll owing: (See Figure 1 for parts identity)

• W199 probe assemblies (2)

• BC407 Thermowells (2)

• 235-C Thermowell Plugs (2)

• BC546 Adapters (2)

31 Underneath the shelf (where the IS barrier is mounted), locate the two plugs in the hydraulic

coupling toward the right side of the unit (Figure 21).

Figure 21: Probe Assembly Mounting Location

Plugs

32

Using the appropriate size Allen wrench, remove the two plugs.

Page 22 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 23

CAUTION

Installation

When applying

first free of sealant to prevent the sealant from entering, and possibly damaging or inhibiting

proper operation of, the unit.

33 Using SAF-T-LOK TPS sealant, coat the BC407 Thermowell threads and thread into one of

SAF-T-LO K TPS sealant on threads, leave the two thre ads that enter the hole

the holes where the plugs were removed in the previous step (Figure 22).

Figure 22: Thermowell and Probe Assembly Connections

Probe Assembly

Thermowell Plug

Thermowell

Adapter

34

Using a proper size wrenc h, tig hten th e ther mowell and pl ace the 235-C Ther mowell p lug int o

the thermow ell.

35 Coat the threads of the BC546 Adapte r with SAF-T-LOK TPS sealant and turn it into th e other

hole where the plugs were removed in step 32 (see Figure 22).

36 Coat the threads of the W199 Probe Assembly with SAF-T-LOK TPS sealant and turn it into

the BC546 a dapter mounted in the previous step.

37 Using the proper size wrench, tighten both the adapter and probe.

CAUTION

Be sure the threads on the thermowell, adapter, and probe assembly are properly

coated with the SAF-T-LOK TPS sealant and tightened properly to prevent leaks

.

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 23

Page 24

Installation

38 Connect the other end (connector) of the probe to probe connector assembly in the connector

labeled “1”.

39 Locate the other two plugs in the hydraulic coupling toward the left side of the unit (Figure

21).

40 Repeat Steps 29 through 34 to mount the second probe assembly.

41 Connect the connector end of the second probe to probe connector assembly in the connector

labeled “2”.

42 Go to “Completing Installation” on page 24 in this manual.

Completing Installation

1 Dress the cabling by placing them in existing cable ties. Be sure the cables do not create any

obstruction to operation, access or servicing.

2 Test the ATCs to determine that they are functioning properly.

This will involve r unning transactions and using the totalizer display (see Appendix: Totalizer

Display Info rmation).

3 After determining that the ATCs are functioning properly, remount the doors on both sides of

the unit and secure with the keylocks.

4 Inform the manager/owner that the unit can be returned to service.

Page 24 MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Page 25

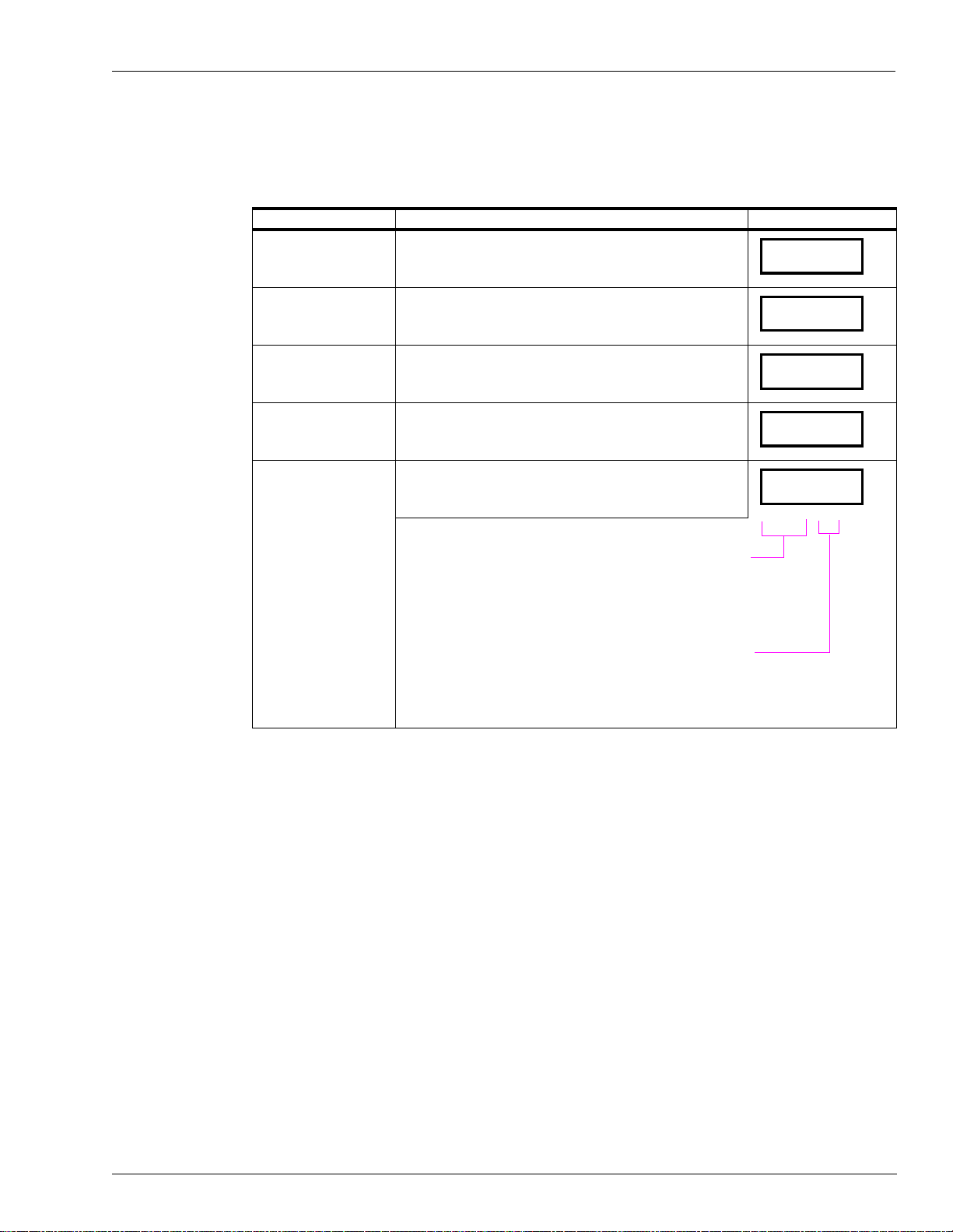

Appendix: Totalizer Display Information

By activating the magnet located at the opposite side of the totalizer, various information will

appear on the display as follows:

Information Type Definition Example of Display

Volume Displays uncompensated volume

Appendix: Totalizer Display Information

0023.43

Probe Temperature Displays probe temperature (in Celsius only)

Flow Rate Displays flow rate (in LPM only)

Software Version Displays software version number

ATC Status Displays ATC status

Leftmost digits (842) are error indicators which are blank when

the corresponding error condition is not active.

8 = temperature probe fault detected

4 = pulser error occured

2 = exceptional reset detected

Rightmost digit (2) indicates whether temperature compensation

is enabled, and if so, what product is being dispensed.

0 = temperature compensation disabled

1 = product is gasoline and compensation enabled

2 = product is diesel and compensation enabled

0 23.2

189.2

1.30

842 .2

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006 Page 25

Page 26

Appendix: Totalizer Display Information

Allen® is a registered trademark of Industrial Fasteners, Inc.

®

Polycase

SAF-T-LOK

Teflon

is a registered trademark of ECP Corporation.

®

is a registered trademark of SAF-T-LOK Chemical Corporation.

®

is a registered trademark of E.I. DuPont de Nemou rs and Company.

© 2006 GASBOY

7300 West Friendly Avenue • Post Office Box 22087

Greensboro, North Carolina 27420

Phone (800) 444-5529 • http://www.gasboy.com • Printed in the U.S.A.

MDE-4351A Gasboy ATC Kits 039086 and 039087 Installation Manual • February 2006

Loading...

Loading...