Garmin A-33, A33W Installation Manual

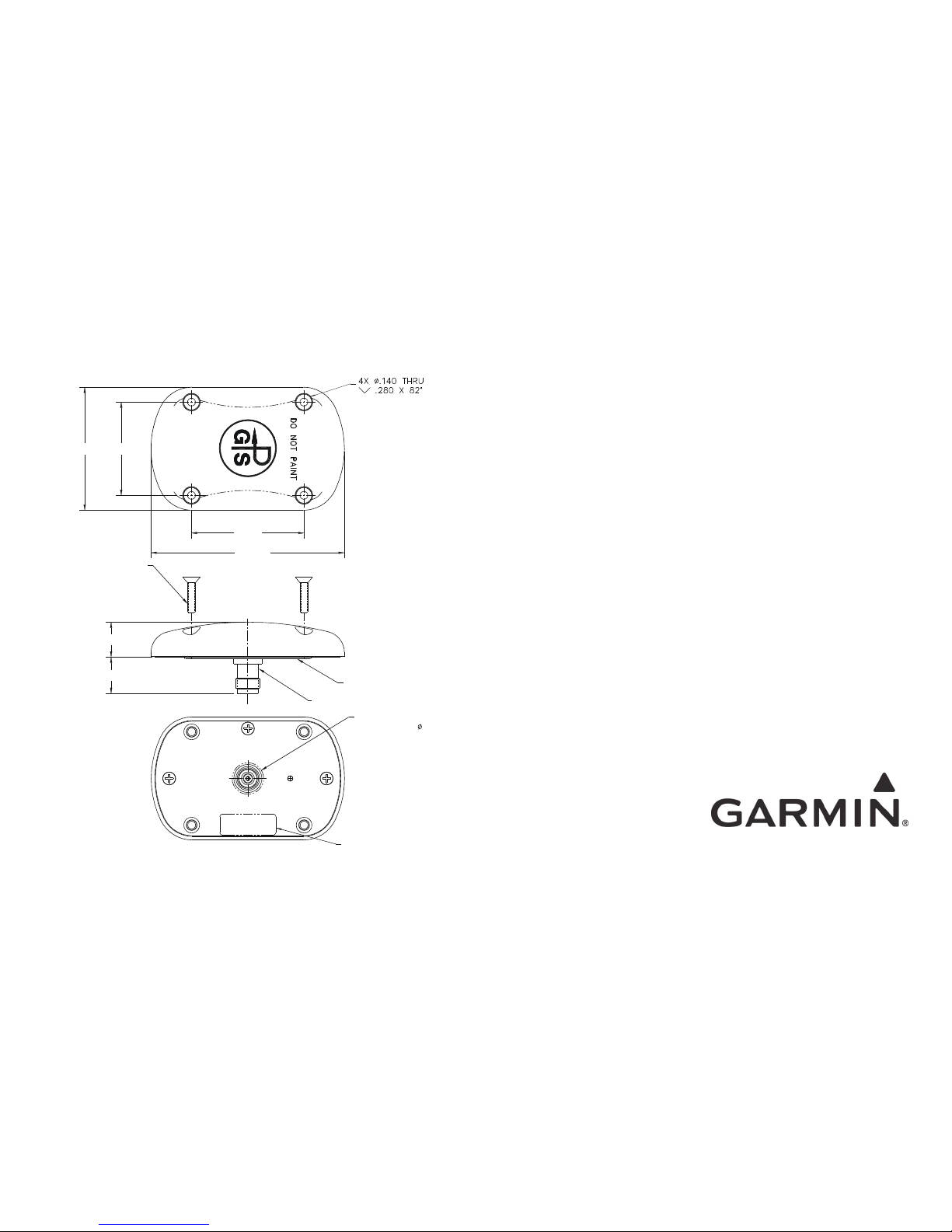

4X MOUNTING SCREW

6-32 UNC-2A

CROSS RECESSED

FLAT HEAD, SST

WIDTH

1.66

2.00

LENGTH

HEIGHT

.65

GASKET

TNCF CONNECTOR

CONNECTOR CLEARANCE

HOLE:

.63

TSO LABEL

Garmin A-33 and A33W

GPS Antenna

Installation Manual

August 2008

560-0949-01 Rev E

©2003 - 2008 by Garmin AT, Inc. Printed in the USA All Rights Reserved

Environmental Qualifications

The A-33 and A33W antennas have been tested in the following environmental categories per

procedures defined in RTCA DO-160D.

Environmental Qualification Form

Nomenclature: Patch Antenna

Model No.: A-33 A33W

Part No.: 575-9 (590-1104) 575-33 2G (013- 00261-00 )

Manufacturer:

Aero Antenna Technology

Chatsworth, CA USA

Conditions Section Description of Conducted Tests

Temperature and Altitude

In-flight Loss of Cooling

4.0

4.5.4

Equipment tested to Category F2

No cooling required

Temperature Variation 5.0 Equipment tested to Category A

Humidity 6.0 Equipment tested to Category B severe humidity

environment, (more stringent than Category C)

Shock

Operational

Crash Safety

7.0

7.2

7.3

Equipment tested to Category B and D

Vibration 8.0 Equipment tested without shock mounts to

Categories S (Curves C, L, M, and Y) and

U (Curves F and F1)

Explosion Proofness 9.0 Equipment tested to Category E

Waterproofness 10.0 Equipment tested to Category S

(Also DO-160E Category Y)

Fluids Susceptibility 11.0 Equipment spray tested to Category F, with

Trichloroethane (cleaning solvent), and Ethylene

Glycol (de-icing fluid)

Sand and Dust 12.0 Equipment identified as Category D, Blowing sand

and dust (Also DO-160E Category S)

Fungus Resistance 13.0 Equipment tested to Category F, severe fungus

resistance

Salt Spray 14.0 Equipment tested to Category S, normal salt

atmosphere

Magnetic Effect 15.0 Equipment is Class Z

Power Input 16.0 E quipmen t tested t o Catego ry A. Antenna power

supplied directly from GPS receiver

Voltage Spike 17.0 Equipment tested to Category A. Antenna power

supplied directly from GPS receiver

Audio Frequency Conducted Susceptibility- Power Input 18.0 Equipment tested to Category Z. Antenna power

supplied directly from GPS receiver

Induced Signal Susceptibility 19.0 Equipment tested to Category Z and C

Radio Frequency Susceptibility 20.0 Equipment tested to Category YYP

Emission of Radio Freq. Energy 21.0 Equipment is Category H

Lightning Induced Transient Susceptibility 22.0 Equipment tested to Category A4ZZ

Lightning Direct Effects 23.0 Equipment tested to Category 2A.

Icing 24.0 Equipment tested to Category C with an ice

thickness of 0.50 inch.

Electrostatic Discharge 25.0 Equipment tested to Category A

Specifications A-33 Both A33W

Frequency: 1575 MHz ±10MHz

Polarization: Right Hand Circular

Axial Ratio: 3 dB Max at bore site

Radiation Coverage:

Elevation Angle: Minimum Gain Minimum Gain

>15º -2.0 dBic -2.0 dBic

10º -3.0 dBic -3.0 dBic

5° -4.5 dBic -3.5 dBic

0° -7.5 dBic -7.5 dBic

Weight: 3.9 oz. (0.11 kg) 7.5 oz. (0.22 kg)

Height: 0.62 inches (1.55 cm) 0.85 Inches (2.16 cm)

Length: 3.44 inches (8.74 cm) 3.80 inches (9.65 cm)

Width: 2.19 inches (5.57 cm) 2.97 inches (7.54 cm)

Finish: Polyurethane Enamel

Operating Temperature: 55°C to +85°C

Operating Altitude: 55,000 feet (16,764m) max

Amplifier:

Noise Figure: 2.5 dB Max

Impedance: 50 ohms

VSWR (Dry):

∠

1.5:1

VSWR (Rain):

∠

2.0:1

Band Rejection: 35 dB

Power Handling: 1 Watt

Voltage: 5 VDC ±10%

Current: 35 mA nom., 40 max 40 mA nominal, 60 max.

TSO: TSO-C144, C129a TSO-C144

1. Antenna Installation Considerations:

a. GPS signals are received by line of sight. The location chosen on the aircraft for placement of the

GPS antenna will have a lot to do with the overall performance of the GPS sensor. The antenna

MUST be located on the top of the aircraft. Typically, the best location is centerline as high and far

forward as possible, just aft the windscreen.

b. Any ‘shadowing’ or signal shading from the aircraft will degrade the performance of the GPS

receiver. Ideally, the antenna should have an unobstructed view of the sky from the horizon up.

However, some shading is inevitable in most installations.

c. Choose a location to minimize the length of coax. Shorter coax length provides better signal

strength available to the receiver.

d. Avoid locations that would subject the antenna to build up of contamination from exhaust.

e. Install the antenna symmetrically on the airframe. This is especially important on metallic aircraft,

as this affects the gain pattern of the antenna.

f. Select location to minimize effect from other antennas. Mount at least 2 feet from VHF Com

transmitter antennas, at least 6 inches from other antennas emitting less than 25 watts, and at

least 2 feet from higher power radio transmitting antennas. Follow installation spacing guidelines

from other near by antennas.

g. Installation on helicopters can present unique installation problems. When selecting antenna

placement, avoid exhaust areas, consider shadowing. One method to select antenna location is to

compare signal strength between various locations by temporarily attaching antenna to various

locations and compare signal strength. It is important to check with the rotors turning, as they can

be a source of shadowing.

2. Coax Cable Selection Considerations

a. Because of high frequency and sensitivity to cable losses, use high quality coax and coax

connectors, and minimize quantity of connectors and splices.

b. The type of coaxial cable may be dependent on the length required for installation. Long runs may

require lower loss cable to meet the cable loss requirements (see receiver install manual).

3. Installation Procedures:

a. Follow good avionics installation practices per FAA Advisory Circulars AC 43.13-1B, AC 43.13-2A,

and AC 20-138, or later FAA approved revisions of these documents.

b. Supplies required for installation, but not provided:

(4) #6 flat washer

(4) #6-32 locking nuts (may be part of doubler plate or backing plate)

Silicone sealer or other aviation type sealer

c. Provide a stable mounting base for the antenna and provide clearance for the connector. Use a

backing plate or doubler plate as required by the installation.

d. Insure a continuous contact between the antenna O ring seal and aircraft skin.

e. Use silicone sealer between the antenna and the aircraft skin. Use supplied four #6 stainless

screws to secure antenna to aircraft, using silicone sealer to seal the screws.

f. When routing the coax, avoid sharp bends, kinking or placement near aircraft control, power DME,

transponder or radio communications cables. Careful attention must be given when securing the

coax to the airframe. Do not allow cable ties to crimp or crush the coax.

g. Check the antenna installation using the GPS receiver to insure adequate signal strength. Refer to

GPS receiver installation manual.

4. Maintenance and Cleaning:

a. Occasionally clean and inspect the antenna. No other maintenance is required. Use mild detergent

and water to clean antenna. Never use abrasive materials or harsh chemicals.

b. Do not apply paint to the antenna.

c. Occasionally inspect the antenna to ensure that the installation remains well sealed against

moisture and the TNC connector remains free of corrosion.

d. If antenna should sustain damage, it cannot be repaired. Replace the antenna.

5. Limitations:

The conditions and test required for TSO approval of this article are minimum performance standards. It is

the responsibility of those desiring to install this article either on or within a specific type or class of aircraft

to determine that the article, when installed, performs in accordance with the design specifications that

meet this TSO. The article may be installed only if further evaluation by the applicant documents an

acceptable installation and is approved by the Administrator.

Loading...

Loading...