Page 1

400 SERIES

INSTALLATION MANUAL

GPS 400, GNC TM 420 (A), and GNS TM 430 (A)

GNC and GNS are trademarks of Garmin Ltd. or its subsidiaries

and may not be used without the express permission of Garmin.

(GNS 430 Shown)

Garmin International, Inc.

1200 E. 151

Olathe, KS 66062 USA

190-00140-02, Revision L

December 2002

st

Street

£

Page 2

© Copyright 1998 - 2002

Garmin Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted, disseminated,

downloaded or stored in any storage medium, for any purpose without the express prior written consent of Garmin.

Garmin hereby grants permission to download a single copy of this manual and of any revision to this manual onto a

hard drive or other electronic storage medium to be viewed and to print one copy of this manual or of any revision

hereto, provided that such electronic or printed copy of this manual or revision must contain the complete text of this

copyright notice and provided further that any unauthorized commercial distribution of this manual or any revision

hereto is strictly prohibited.

Garmin International, Inc.

1200 E. 151

Olathe, KS 66062 USA

st

Street

Telephone: 913-397-8200

Aviation Panel-Mount Technical Support Line (Toll Free): 1-888-606-5482

Web Site Address: www.garmin.com

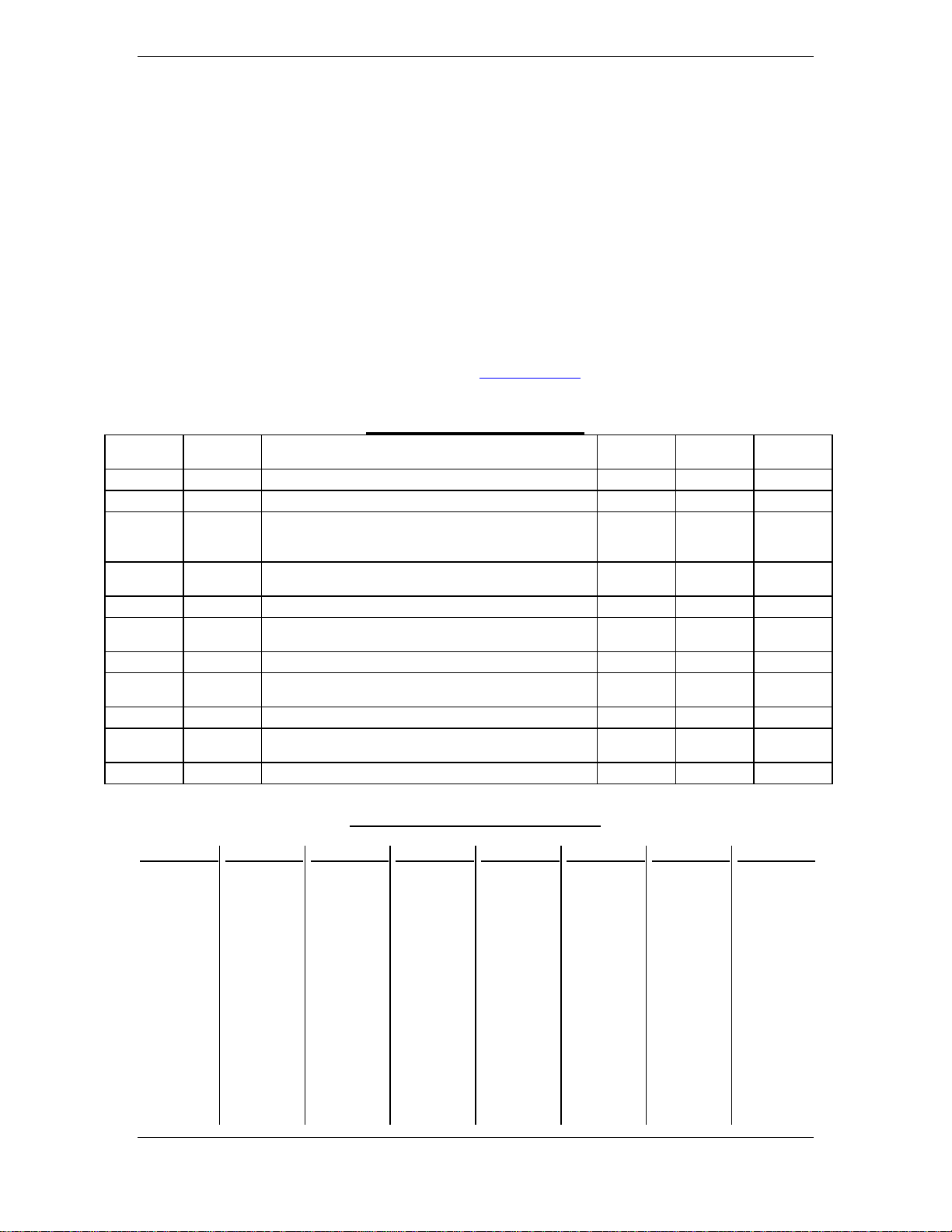

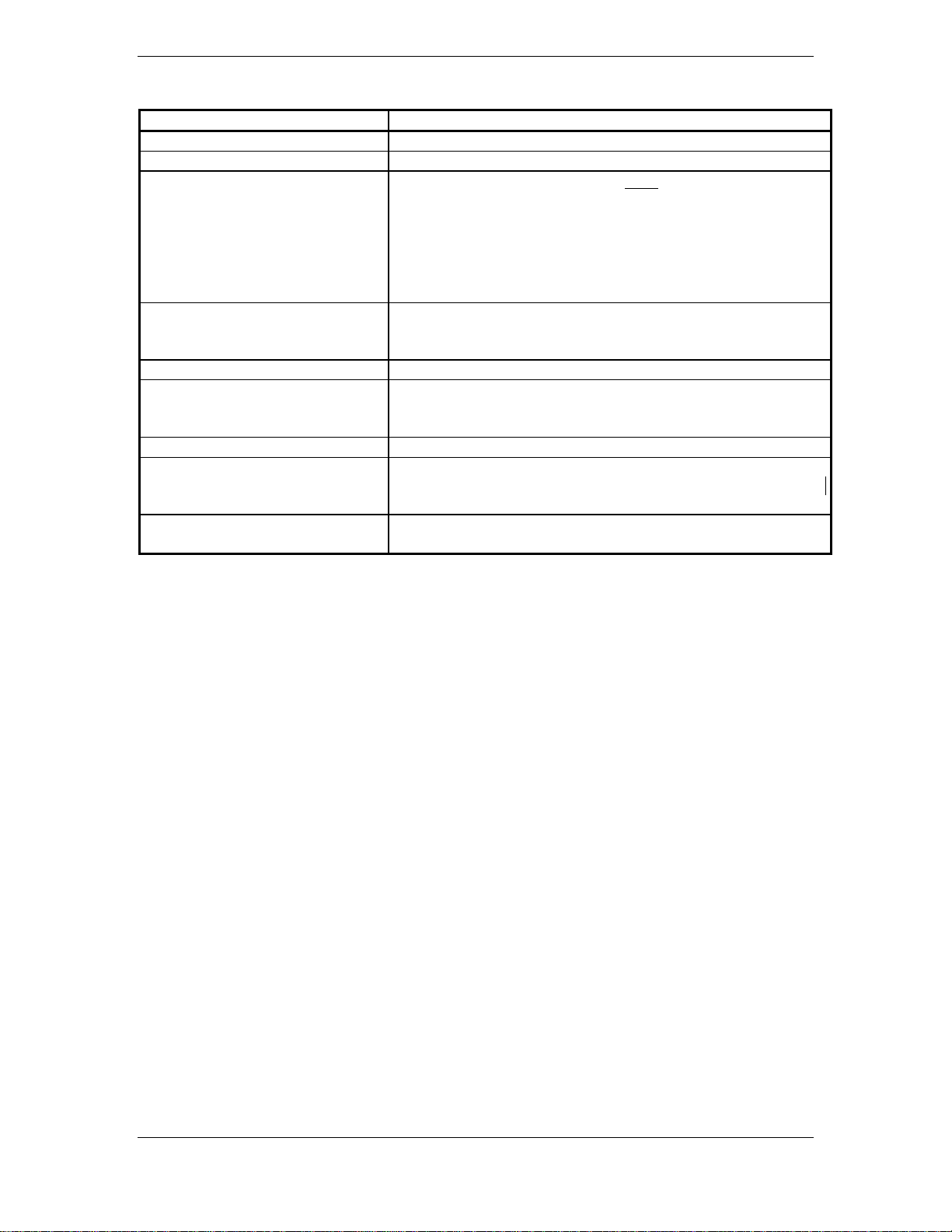

RECORD OF REVISIONS

Revision Revision

Date

A 6/19/98 Initial Release ----

B 10/22/98 General update 9891

C 11/11/98 Add 18 AWG pin positioner and insertion/extraction

tools. Add King Serial DME tuning interface

description.

D 3/18/99 Add GNC 420, GPS 400, ARINC 429, GPS King Serial

OBI, RS-232 Fuel/Air Data Inputs

E 6/25/99 Reflect changes to configuration pages, Misc corrections 11243

F 10/13/99 Add interface to BF Goodrich Stormscope and Skywatch

and Ryan TCAD

G 4/27/00 Update installation accessory kits 13205

H 9/1/00 Add unit versions with 14/28 volt transmitter. Update

configuration pages.

J 2/22/01 Update configuration pages. 15207

K 5/22/02 Add gray unit and 16 watt “A” versions. Update

configuration pages.

L 12/13/02 Add Fault Detection and Exclusion 19779

Description ECO # Insertion

By

Date

10008

10665

11871

14026

18149

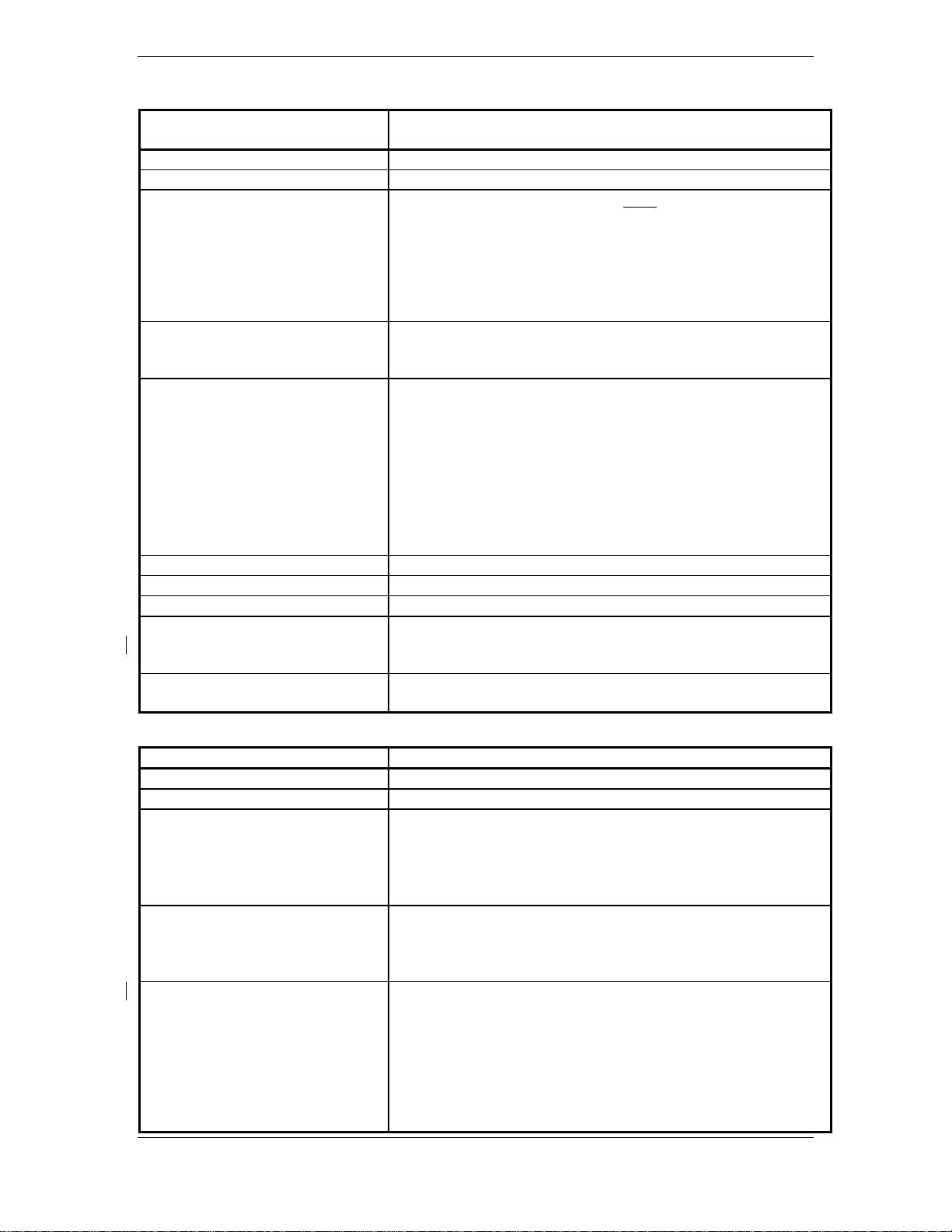

LIST OF EFFECTIVE PAGES

Page Rev.

A ................L

i..................L

ii.................L

iii................L

iv................L

v .................L

vi................L

1-1..............L

1-2..............L

1-3..............L

1-4..............L

1-5..............L

1-6..............L

1-7..............L

1-8 L

2-1..............L

Page Rev.

2-2..............L

2-3..............L

2-4..............L

3-1..............L

3-2..............L

3-3..............L

3-4..............L

3-5..............L

3-6..............L

3-7..............L

3-8..............L

3-9..............L

3-11............L

3-13............L

3-15............L

3-17............L

Page A 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page ...... Rev.

3-19............L

3-21............L

3-23............L

4-1..............L

4-2..............L

4-3..............L

4-4..............L

4-5..............L

4-6..............L

4-7..............L

4-8..............L

4-9..............L

4-10............L

4-11............L

4-12............L

4-13............L

Page Rev.

4-14............L

4-15............L

4-16............L

4-17............L

4-18............L

4-19............L

4-20............L

4-21............L

4-23............L

4-25............L

4-27............L

4-29............L

4-31............L

4-33............L

4-35............L

4-37............L

Page Rev.

4-39 ...........L

4-41 ...........L

4-43 ...........L

4-45 ...........L

4-47 ...........L

4-49 ...........L

4-51 ...........L

4-53 ...........L

4-55 ...........L

4-57 ...........L

4-59 ...........L

4-61 ...........L

4-63 ...........L

4-65 ...........L

4-67 ...........L

4-69 ...........L

Page Rev.

4-71 ...........L

5-1 .............L

5-2 .............L

5-3 .............L

5-4 .............L

5-5 .............L

5-6 .............L

5-7 .............L

5-8 .............L

5-9 .............L

5-10 ...........L

5-11 ...........L

5-12 ...........L

5-13 ...........L

5-14 ...........L

5-15 ...........L

Page Rev.

5-16 ...........L

5-17 ...........L

5-18 ...........L

A-1 ............ L

A-2 ............ L

A-3 ............ L

A-4 ............ L

A-5 ............ L

A-6 ............ L

B-1............. L

B-2............. L

B-3............. L

B-4............. L

B-5............. L

B-6............. L

B-7............. L

Page Rev.

B-8............. L

C-1............. L

C-2............. L

C-3............. L

C-4............. L

D-1 ............ L

D-2 ............ L

D-3 ............ L

D-4 ............ L

E-1............. L

E-2............. L

Page 3

This manual is written for software version 3.00, and is not suitable for earlier software versions.

Information in this document is subject to change without notice. Visit the Garmin web site

(www.garmin.com) for current updates and supplemental information concerning the operation of

this and other Garmin products.

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration

Regulations ("EAR") issued by the United States Department of Commerce (15 CFR, Chapter

VII, Subchapter C) and which may not be exported, released, or disclosed to foreign nationals

inside or outside of the United States without first obtaining an export license. A violation of the

EAR may be subject to a penalty of up to 10 years imprisonment and a fine of up to $1,000,000

under Section 2410 of the Export Administration Act of 1979. Include this notice with any

reproduced portion of this document.

WARNING

This product, its packaging, and its components contain chemicals known to the State of

California to cause cancer, birth defects, or reproductive harm. This Notice is being provided in

accordance with California's Proposition 65. If you have any questions or would like additional

information, please refer to our web site at www.garmin.com/prop65.

400 SERIES INSTALLATION MANUAL Page i

P/N 190-00140-02 Page Rev L

Page 4

TABLE OF CONTENTS

1. GENERAL DESCRIPTION

1.1 INTRODUCTION .........................................................................................................................................1-1

1.2 EQUIPMENT DESCRIPTION......................................................................................................................1-1

1.3 TECHNICAL SPECIFICATIONS.................................................................................................................1-2

1.4 LICENSE REQUIREMENTS .......................................................................................................................1-7

1.5 CERTIFICATION .........................................................................................................................................1-7

1.6 FAULT DETECTION AND EXCLUSION (FDE) ......................................................................................1-7

1.7 LIMITED WARRANTY ...............................................................................................................................1-8

2. INSTALLATION

2.1 INTRODUCTION .........................................................................................................................................2-1

2.2 ANTENNA CONSIDERATIONS .................................................................................................................2-1

2.3 RACK CONSIDERATIONS .........................................................................................................................2-3

2.4 CABLING AND WIRING ............................................................................................................................2-3

2.5 COOLING AIR..............................................................................................................................................2-3

2.6 MINIMUM INSTALLATION REQUIREMENTS .......................................................................................2-3

3. INSTALLATION PROCEDURE

3.1 UNIT AND ACCESSORIES.........................................................................................................................3-1

3.2 DATA BASE OPTIONS................................................................................................................................3-4

3.3 MISCELLANEOUS OPTIONS.....................................................................................................................3-4

3.4 INSTALLATION ACCESSORIES REQUIRED BUT NOT PROVIDED ...................................................3-4

3.5 ANTENNA INSTALLATION ......................................................................................................................3-4

3.6 CABLE INSTALLATION.............................................................................................................................3-5

3.7 RACK INSTALLATION...............................................................................................................................3-6

3.8 400 SERIES UNIT INSERTION AND REMOVAL.....................................................................................3-7

3.9 COM ANTENNA INSTALLATION CHECK (GNC 420 AND GNS 430)..................................................3-7

3.10 GA 56 ANTENNA INSTALLATION DRAWING.....................................................................................3-9

3.11 MOUNTING RACK DIMENSIONS...........................................................................................................3-11

3.12 MOUNTING RACK INSTALLATION ......................................................................................................3-17

3.13 RECOMMENDED PANEL CUTOUT DIMENSIONS ..............................................................................3-23

4. SYSTEM INTERCONNECTS

4.1 PIN FUNCTION LIST...................................................................................................................................4-1

4.2 POWER, LIGHTING, AND ANTENNAS....................................................................................................4-5

4.3 ALTIMETER.................................................................................................................................................4-6

4.4 MAIN INDICATOR......................................................................................................................................4-7

4.5 ANNUNCIATORS/SWITCHES ...................................................................................................................4-9

4.6 SERIAL DATA .............................................................................................................................................4-11

4.7 COM/VOR/ILS AUDIO (GNC 420 AND GNS 430 ONLY)........................................................................4-14

4.8 VOR/ILS INDICATOR (GNS 430 ONLY)...................................................................................................4-16

4.9 RMI/OBI........................................................................................................................................................4-18

4.10 DME TUNING (GNS 430 ONLY)..............................................................................................................4-19

4.11 400 SERIES INTERCONNECTS................................................................................................................4-21

5. POST INSTALLATION CONFIGURATION & CHECKOUT PROCEDURE

5.1 CONFIGURATION MODE OPERATIONS.................................................................................................5-1

5.2 INSTALLATION CONFIGURATION PAGES............................................................................................5-1

5.3 ADDITIONAL GROUND TESTS ................................................................................................................5-16

Appendix A. CERTIFICATION DOCUMENTS

A.1 CONTINUED AIRWORTHINESS..............................................................................................................A-1

A.2 ENVIRONMENTAL QUALIFICATION FORM—GNS 430......................................................................A-3

A.3 ENVIRONMENTAL QUALIFICATION FORM—GNC 420 .....................................................................A-4

A.4 ENVIRONMENTAL QUALIFICATION FORM—GPS 400 ......................................................................A-5

A.5 ENVIRONMENTAL QUALIFICATION FORM—GA 56..........................................................................A-6

Appendix B. STC PERMISSION ................................................................................................................................B-1

Appendix C. 400 SERIES RS-232 AVIATION DATA FORMAT .............................................................................C-1

Appendix D. 400 SERIES RS-232 FUEL/AIR DATA INPUT FORMAT..................................................................D-1

Appendix E. 400 SERIES LRU INTERFACE OVERVIEW ......................................................................................E-1

Note: Throughout this document references made to GNS 430 and GNC 420 shall equally apply to

the GNS 430A and GNC 420A except where specifically noted.

Page ii 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 5

LIST OF FIGURES

FIGURE 2-1. GPS ANTENNA AND UNIT INSTALLATION CONSIDERATIONS .............................................2-2

FIGURE 3-1. COAXIAL CABLE INSTALLATION ................................................................................................3-5

FIGURE 3-2. GA 56 ANTENNA INSTALLATION DRAWING .............................................................................3-9

FIGURE 3-3. GNS 430 MOUNTING RACK DIMENSIONS ...................................................................................3-11

FIGURE 3-4. GNC 420 MOUNTING RACK DIMENSIONS...................................................................................3-13

FIGURE 3-5. GPS 400 MOUNTING RACK DIMENSIONS....................................................................................3-15

FIGURE 3-6. GNS 430 MOUNTING RACK INSTALLATION...............................................................................3-17

FIGURE 3-7. GNC 420 MOUNTING RACK INSTALLATION ..............................................................................3-19

FIGURE 3-8. GPS 400 MOUNTING RACK INSTALLATION ...............................................................................3-21

FIGURE 3-9. 400 SERIES RECOMMENDED PANEL CUTOUT DIMENSIONS..................................................3-23

FIGURE 4-1. 400 SERIES SYSTEM INTERFACE DIAGRAM ..............................................................................4-21

FIGURE 4-2. GNS 430 TYPICAL INSTALLATION ...............................................................................................4-23

FIGURE 4-3. GNC 420 TYPICAL INSTALLATION...............................................................................................4-25

FIGURE 4-4. GPS 400 TYPICAL INSTALLATION................................................................................................4-27

FIGURE 4-5. POWER, LIGHTING, AND ANTENNAS INTERCONNECT...........................................................4-29

FIGURE 4-6. ALTIMETER INTERCONNECT........................................................................................................4-31

FIGURE 4-7. MAIN INDICATOR INTERCONNECT .............................................................................................4-33

FIGURE 4-8. KI 209A MAIN INDICATOR INTERCONNECT ..............................................................................4-35

FIGURE 4-9. KI 208A MAIN INDICATOR INTERCONNECT ..............................................................................4-37

FIGURE 4-10. ANNUNCIATORS/SWITCHES INTERCONNECT ........................................................................4-39

FIGURE 4-11. RS-232 SERIAL DATA INTERCONNECT .....................................................................................4-41

FIGURE 4-12. ARINC 429 EFIS INTERCONNECT................................................................................................4-43

FIGURE 4-13. ARINC 429 SANDEL EHSI INTERCONN. (1 400 SERIES UNIT, 1 SANDEL SN3308)..............4-45

FIGURE 4-14. ARINC 429 SANDEL EHSI INTERCONNECT (2 GNS 430, 1 SANDEL SN3308).......................4-47

FIGURE 4-15. ARINC 429 SANDEL EHSI INTERCONNECT (2 GNS 430, 2 SANDEL SN3308).......................4-49

FIGURE 4-16. ARINC 429 AIR DATA/IRU/AHRS INTERCONNECT..................................................................4-51

FIGURE 4-17. ARINC 429 FLIGHT CONTROL INTERCONNECT ......................................................................4-53

FIGURE 4-18. TRAFFIC ADVISORY SYSTEM INTERCONNECT ......................................................................4-55

FIGURE 4-19. WEATHER AND TERRAIN INTERCONNECT .............................................................................4-57

FIGURE 4-20. AUDIO PANEL INTERCONNECT..................................................................................................4-59

FIGURE 4-21. VOR/ILS INDICATOR INTERCONNECT ......................................................................................4-61

FIGURE 4-22. RMI/OBI INTERCONNECT.............................................................................................................4-63

FIGURE 4-23. KING SERIAL PANEL DME TUNING INTERCONNECT ............................................................4-65

FIGURE 4-24. KING SERIAL REMOTE DME TUNING INTERCONNECT.........................................................4-67

FIGURE 4-25. PARALLEL 2 OF 5 DME TUNING INTERCONNECT ..................................................................4-69

FIGURE 4-26. PARALLEL BCD/SLIP CODE DME TUNING INTERCONNECT ................................................4-71

Note: Throughout this document references made to GNS 430 and GNC 420 shall equally apply to

the GNS 430A and GNC 420A except where specifically noted.

400 SERIES INSTALLATION MANUAL Page iii

P/N 190-00140-02 Page Rev L

Page 6

LIST OF FIGURES - CONTINUED

FIGURE 5-1. MAIN ARINC 429 CONFIG PAGE....................................................................................................5-1

FIGURE 5-2. MAIN RS232 CONFIG PAGE ............................................................................................................5-3

FIGURE 5-3. MAIN INPUTS 1 PAGE......................................................................................................................5-4

FIGURE 5-4. MAIN INPUTS 2 PAGE......................................................................................................................5-4

FIGURE 5-5. INSTRUMENT PANEL SELF TEST PAGE ......................................................................................5-5

FIGURE 5-6. MAIN LIGHTING PAGE....................................................................................................................5-5

FIGURE 5-7. MAIN LIGHTING PAGE (DISPLAY LIGHTING FROM LIGHTING BUS) ...................................5-6

FIGURE 5-8. DISPLAY PAGE (AUX GROUP) .......................................................................................................5-6

FIGURE 5-9. DATE/TIME SETUP PAGE................................................................................................................5-6

FIGURE 5-10. MAIN DISCRETE INPUTS PAGE...................................................................................................5-6

FIGURE 5-11. MAIN DISCRETE OUTPUTS PAGE ...............................................................................................5-7

FIGURE 5-12. MAIN CDI/OBS CONFIG PAGE......................................................................................................5-7

FIGURE 5-13. COM SETUP PAGE (GNC 420 AND GNS 430 ONLY) ..................................................................5-9

FIGURE 5-14. VOR DISCRETE INPUTS PAGE (GNS 430 ONLY).......................................................................5-10

FIGURE 5-15. VOR/LOC/GS CDI PAGE (GNS 430 ONLY)...................................................................................5-10

FIGURE 5-16. VOR/LOC/GS ARINC 429 CONFIG PAGE (GNS 430 ONLY).......................................................5-11

FIGURE 5-17. STORMSCOPE CONFIG PAGE.......................................................................................................5-12

FIGURE 5-18. STORMSCOPE TEST PAGE............................................................................................................5-12

FIGURE 5-19. STORMSCOPE DOWNLOAD DATA PAGE ..................................................................................5-12

FIGURE 5-20. TRAFFIC PAGE (SKYWATCH)......................................................................................................5-13

FIGURE 5-21. TRAFFIC PAGE (TCAD)..................................................................................................................5-13

FIGURE 5-22. RYAN TCAD CONFIG PAGE..........................................................................................................5-13

FIGURE 5-23. GAD 42 CONFIG PAGE ...................................................................................................................5-13

FIGURE 5-24. DATA LINK PAGE...........................................................................................................................5-14

Note: Throughout this document references made to GNS 430 and GNC 420 shall equally apply to

the GNS 430A and GNC 420A except where specifically noted.

Page iv 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 7

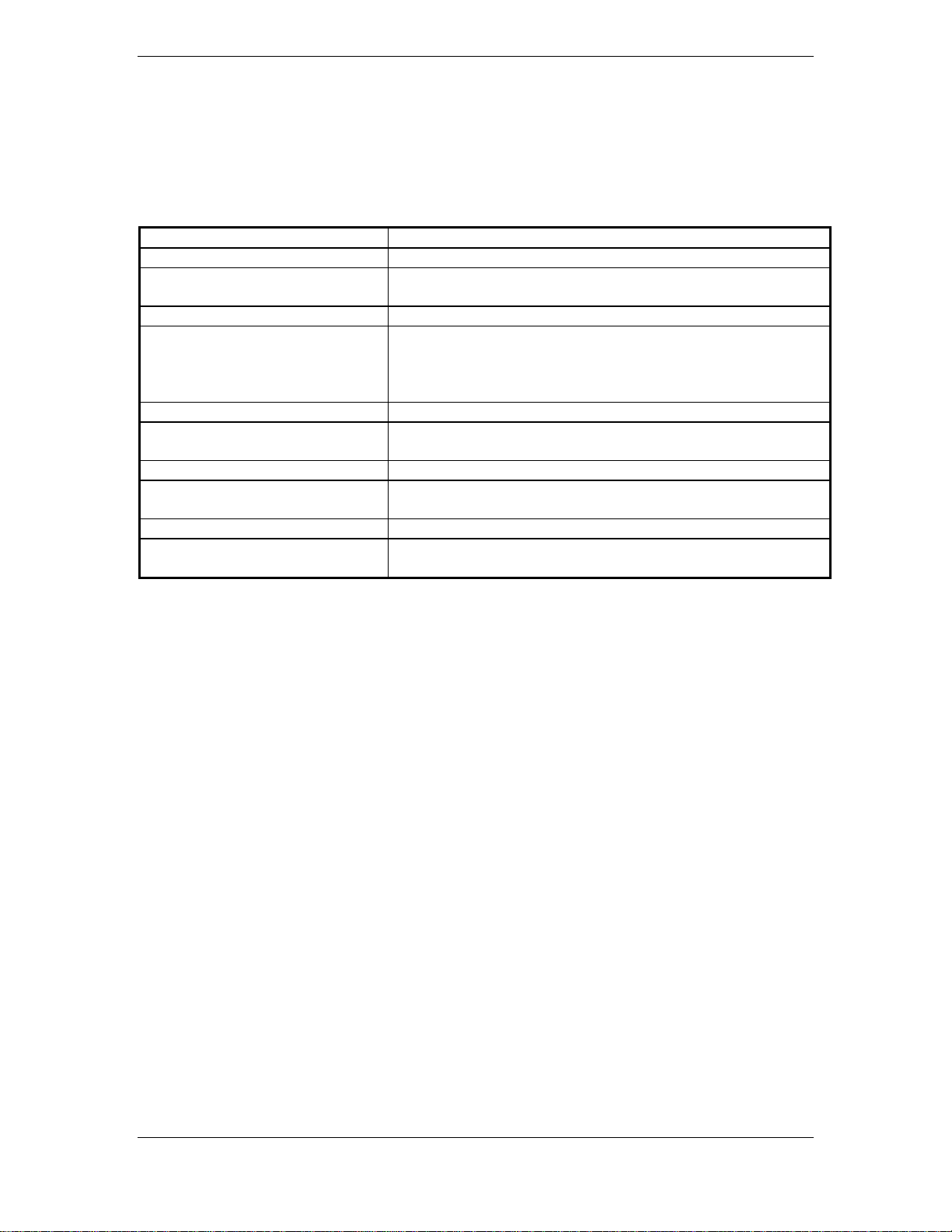

400 SERIES HARDWARE MOD LEVEL HISTORY

The following table identifies hardware modification (Mod) Levels for the GPS 400, GNC 420 and

GNS 430. Mod Levels are listed with the associated service bulletin number, service bulletin date, and

the purpose of the modification. The table is current at the time of publication of this manual (see date on

front cover) and is subject to change without notice. Authorized Garmin Sales and Service Centers are

encouraged to access the most up-to-date bulletin and advisory information on the Garmin Dealer Resource

web site at www.garmin.com using their Garmin -provided user name and password.

MOD

LEVEL

1 9905 9/17/99 CDI/HSI deviation error; GNS 430, P/N 011-

1 0019 11/07/00 Replace fuse in COM circuit with a resistor;

2 0101 2/16/01 Remote COM transfer

3 0203, Rv B 8/12/02 Improve receiver audio compressor

4 0207 4/2/02 Remove excess solder from COM board

5 0211 6/4/02 Reduce input transients from Audio Panel

SERVICE

BULLETIN

NUMBER

SERVICE

BULLETIN

DATE

PURPOSE OF MODIFICATION

00280-00, GNC 420, P/N 011-00506-00, GPS

400, P/N 011-00504-00

GNS 430, P/N 011-00280-10, GNC 420, P/N

011-00506-10, GNS 530, P/N 011-00550-10

performance

Note: Throughout this document references made to GNS 430 and GNC 420 shall equally apply to

the GNS 430A and GNC 420A except where specifically noted.

400 SERIES INSTALLATION MANUAL Page v

P/N 190-00140-02 Page Rev L

Page 8

This page intentionally left blank

Page vi 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 9

1. GENERAL DESCRIPTION

1.1 INTRODUCTION

This manual describes the physical, mechanical, and electrical characteristics and the installation

requirements for the 400 Series (GPS 400, GNC 420, and GNS 430) Panel-mounted units. After

installation of the 400 Series system, FAA Form 337 must be completed by an appropriately certificated

agency to return the aircraft to service.

1.2 EQUIPMENT DESCRIPTION

The 400 Series units are mark width (6.25” wide) units, and 2.66” high. The display is a 128 by 240 pixel

color LCD. The units include two removable data cards, one with a Jeppesen database, and the second

being an optional custom data card.

The GPS 400 is a GPS receiver certifiable for IFR en route, terminal, and non-precision approach

operations.

The GNC 420/ (A) includes all the features of the GPS 400, and also includes an IFR certified airborne

VHF communications transceiver. The (A) model is a 28 Vdc unit with a 16 Watt COM transmitter.

The GNS 430/ (A) includes all the features of the GNC 420, and also includes IFR certified airborne

VOR/Localizer and Glideslope receivers. The (A) model is a 28 Vdc unit with a 16 Watt COM transmitter.

GPS signals are received by Garmin's low profile GA 56 antenna (P/N 010-10040-0X).

CAUTION

The 400 Series product lens is coated with a special anti-reflective coating which is very

sensitive to skin oils, waxes and abrasive cleaners. It is very important to clean the lens

using an eyeglass lens cleaner which is specified as safe for anti-reflective coatings (one

suitable product is Wal-Mart

®

Lens Cleaner) and a clean, lint-free cloth.

CAUTION

The use of cellular telephones while aircraft are airborne is prohibited by FCC rules. Due

to potential interference with onboard systems, the use of cell phones while the aircraft is

on the ground is subject to FAA regulations (Part 91.21).

FCC regulation 47 CFR Ch.1 (Section 22.925) prohibits airborne operation of cellular

telephones installed in or carried aboard aircraft. Cellular telephones must not be operated

while aircraft are off the ground. When any aircraft leaves the ground, all cellular

telephones on board that aircraft must be turned off.

Cell phones that are on, even in a monitoring state, can disrupt GPS performance.

400 SERIES INSTALLATION MANUAL Page 1-1

P/N 190-00140-02 Page Rev L

Page 10

1.3 TECHNICAL SPECIFICATIONS

The conditions and tests required for TSO approval of the 400 Series are minimum performance standards.

It is the responsibility of those desiring to install this article either on or within a specific type or class of

aircraft to determine that the aircraft installation conditions are within the TSO standards. The article may

be installed only if further evaluation by the applicant documents an acceptable installation and is approved

by the administrator. For TSO Compliance, see Appendix A.

1.3.1 Physical Characteristics

Bezel Height 2.66 in. (67 mm)

Bezel Width 6.25 in. (159 mm)

Rack Height (Dimple-todimple)

Rack Width 6.32 in. (160 mm)

Depth Behind Panel with

Connectors (Measured from

face of aircraft panel to rear of

connector backshells)

GPS 400 Weight (Unit only) 3.8 lbs. (1.7 kg)

GPS 400 Weight (Installed with

rack and connectors)

GNC 420 Weight (Unit only) 4.5 lbs. (2.0 kg)

GNC 420 Weight (Installed with

rack and connectors)

GNS 430 Weight (Unit only) 5.1 lbs. (2.3 kg)

GNS 430 Weight (Installed with

rack and connectors)

2.69 in. (68 mm)

11.00 in. (279 mm)

4.9 lbs. (2.2 kg)

5.8 lbs. (2.6 kg)

6.5 lbs. (2.9 kg)

Page 1-2 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 11

1.3.2 General Specifications

Operating Temperature Range

-20°C to +55°C. For more details see Environmental

Qualification Form.

Humidity 95% non-condensing

Altitude Range -1,500 ft to 50,000 ft

Input Voltage Range (GPS 400) 11 to 33 V

Input Voltage Range

22 to 33 V

DC

DC

GNS 430 (011-00280-00) and

GNC 420 (011-00506-00)

Input Voltage Range

11 to 33 V

DC

GNS 430 (011-00280-10, -30)

GNC 420 (011-00506-10, -30)

GNS 430 (A) (011-00836-00,-10)

28 V

DC

GNC 420 (A) (011-00837-00,-10)

Power Requirements—P4001

(GPS 400 Main Connector)

Power Requirements—P4001

0.72 A @ 27.5 VDC________or

1.44 A @ 13.75 V

DC

1.5 A @ 27.5 VDC (maximum)

(GNC 420 Main Connector)

Power Requirements—P4001

1.5 A @ 27.5 VDC (maximum)

(GNS 430 Main Connector)

Power Requirements—P4002

(COM Connector)

15 mA @ 27.5 VDC (not transmitting);

3.0 A @ 27.5 V

(transmitting)

DC

GNS 430 (011-00280-00)

GNS 430A (011-00836-00, -10)

and

GNC 420 (011-00506-00)

GNC 420A (011-00837-00, -10)

Power Requirements—P4002

(COM Connector)

GNS 430 (011-00280-10, -30)

and GNC 420 (011-00506-10)

15 mA @ 27.5 VDC (not transmitting);

3.0 A @ 27.5 V

10 mA @ 13.75 V

6.0 A @ 13.75 V

(transmitting)_______or

DC

(not transmitting);

DC

(transmitting)

DC

Superflag Power Requirements 500 mA max. per superflag output @ 27.5 V

1.0 A max. @ 27.5 VDC on P4001 (Main Superflags).

1.0 A max. @ 27.5 V

on P4006 (VOR/LOC, G/S

DC

Superflags).

Software RTCA DO-178B level C

Environmental Testing RTCA DO-160C.

For more details see Environmental Qualification Forms.

DC.

1.3.3 GPS Specifications

Regulatory Compliance TSO C129a, RTCA DO-208

Acquisition Time a) Search-the-Sky (without almanac, without initial position

or time): 5 minutes

b) AutoLocate™ (with almanac, without initial position or

time): 5 minutes

c) Cold Start (position known to 300 nm, time known to 10

minutes, with valid almanac): 45 seconds

d) Warm Start (position known to 10 nm, time known to 10

minutes, with valid almanac and ephemeris): 15 seconds

Max Velocity 1000 kts.

Dynamics 6 g

400 SERIES INSTALLATION MANUAL Page 1-3

P/N 190-00140-02 Page Rev L

Page 12

1.3.4 COM Transceiver Specifications (GNC 420 and GNS 430 Only) **

Regulatory Compliance TSO-C37d Class 4 & 6* (3 & 5 for “A” models), TSO-C38d

Class C & E, JTSO-2C37e, JTSO-2C38e, RTCA DO-186a

ICAO Annex 10 Volume III (Part II – Voice Communications

Systems) Par. 2.3.3

Audio Output

100 mW minimum into a 500 Ω load.

Audio Response Less than 6 dB of variation between 350 and 2500 Hz.

Audio Distortion The distortion in the receiver audio output shall not exceed

15% at all levels up to 100 mW.

AGC Characteristics The audio output shall not vary by more than 6 dB when the

level of the RF input signal, modulated 30% at 1000 Hz, is

varied from 5 µV to 450,000 µV.

Sensitivity (S+N)/N on all channels shall be greater than 6 dB when the

RF level is 2 µV (hard) modulated 30% at 1000 Hz at rated

audio.

Squelch

2 µv ±6 dB for 25 kHz channels.

3 µv ±6 dB for 8.33 kHz channels.

Selectivity

6 dB BW is greater than ±8 kHz for 25 kHz channeling.

60 dB BW is less than ±25 kHz for 25 kHz channeling.

6 dB BW is greater than ±2.778 kHz for 8.33 kHz channeling.

60 dB BW is less than ±7.37 kHz for 8.33 kHz channeling.

Spurious Response Greater than 85 dB.

Transmitter Power At Least 10 watts, 16 watts for “A” models

Transmitter Duty Cycle Recommended 10% maximum.

Modulation Capability The modulation shall not be less than 70% and not greater

than 98% with a standard modulator signal applied to the

transmitter.

Carrier Noise Level Shall be at least 45 dB (S+N)/N.

Frequency Stability 0.0005%

Demodulated Audio Distortion Less than 10% distortion when the transmitter is modulated

at least 70%.

Sidetone

1.4 V

into a 500 Ω load when the transmitter is modulated

RMS

at least 70%.

Demodulated Audio Response Shall be less than 6 dB when the audio input frequency is

varied from 350 to 2500 Hz.

* C37d Class 4 & 6 may not provide suitable COM transmit range for some high-altitude aircraft.

** Specifications shown apply at nominal input voltages of 13.75 Vdc or 27.5 Vdc, as applicable, and with

a nominal 50 ohm resistive load at the antenna connector.

Page 1-4 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 13

1.3.5 VOR Specifications (GNS 430 Only)

Regulatory Compliance TSO C40c, JTSO-2C40c, RTCA DO-196, EuroCAE ED-22B

Receiver Audio Sensitivity At -103.5 dBm (S+N)/N shall not be less than 6 dB.

Course Deviation Sensitivity -103.5 dBm or less for 60% of standard deflection.

Flag The VOR Course Deviation Flag must be flagged:

a) in the absence of an RF signal.

b) in the absence of the 9960 Hz modulation.

c) in the absence of either one of the two 30 Hz

modulations.

d) When the level of a standard VOR deviation test signal

produces less than a 50% of standard deflection.

AGC Characteristics From -99 dBm to -13 dBm input of a Standard VOR Audio

Test Signal, audio output levels shall not vary more than 3

dB.

Spurious Response Greater than 80 dB.

VOR OBS Bearing Accuracy The bearing information as presented to the pilot shall not

have an error in excess of 2.7° as specified by RTCA DO-196

and EuroCAE ED-22B.

Audio Output

A minimum 100 mW into a 500 Ω load.

Audio Response Less than 6 dB of variation between 350 and 2500 Hz.

Except the 1020 Hz Ident Tone is at least 20 dB down in

voice mode.

Audio Distortion The distortion in the receiver audio output shall not exceed

10% at all levels up to 100 mW.

400 SERIES INSTALLATION MANUAL Page 1-5

P/N 190-00140-02 Page Rev L

Page 14

1.3.6 LOC Specifications (GNS 430 Only)

Regulatory Compliance TSO C36e, JTSO-C36e, RTCA DO-195 CLASS A, EuroCAE

ED-46B

Receiver Audio Sensitivity At -103.5 dBm (S+N)/N shall not be less than 6 dB.

Course Deviation Sensitivity -103.5 dBm or less for 60% of standard deflection.

Flag The LOC Course Deviation Flag must be flagged:

a) in the absence of an RF signal.

b) When either the 90 or 150 Hz modulating signals is

removed and the other is maintained at its normal 20%.

c) In the absence of both 90 and 150 Hz modulation.

d) When the level of a standard localizer deviation test

signal produces less than a 50% of standard deflection.

AGC Characteristics From -86 dBm and -33 dBm input of a Standard VOR Audio

Test Signal, audio output levels shall not vary more than 3

dB.

Selectivity Nose Bandwidth: The input signal level required to produce

the reference AGC voltage shall not vary more than 6 dB

over the input signal frequency range of ± 9 kHz from the

assigned channel frequency.

Skirt Bandwidth: The input signal level required to produce

reference AGC voltage shall be at least 70 dB greater than

the level required to produce reference AGC voltage at the

assigned channel frequency at ± 36 kHz from the assigned

channel frequency.

Spurious Response Greater than 80 dB.

Centering Accuracy

Audio Output

Typical 0 ± 3 mV (Max error 9.9 mV per RTCA DO-195).

A minimum 100 mW into a 500 Ω load.

Audio Response Less than 6 dB of Variation between 350 and 2500 Hz.

Except the 1020 Hz Ident Tone is at least 20 dB down in

voice mode.

Audio Distortion The distortion in the receiver audio output shall not exceed

10% at all levels up to 100 mW.

1.3.7 Glideslope Specifications (GNS 430 Only)

Regulatory Compliance TSO C34e, JTSO-C34e, RTCA DO-192, EuroCAE ED-47B

Sensitivity -87 dBm or less for 60% of standard deflection.

Centering Accuracy

Selectivity

0 ± .0091 ddm or 0 ± 7.8 mV

The course deviation shall be 0 ddm ± .0091ddm when using

the Glideslope Centering Test Signal as the RF frequency is

varied ±17 kHz from the assigned channel.

At frequencies displaced by ±132 kHz or greater, the input

signal shall be at least 60 dB down.

Standard deflection a) With a standard deflection ‘FLY DOWN’ condition (90 Hz

dominant), the output shall be -78 mV ± 7.8 mV.

b) With a standard deflection ‘FLY UP’ condition (150 Hz

dominant), the output shall be +78 mV ± 7.8 mV.

Flag The unit Flags:

a) When the level of a standard deviation test signal

produces 50% or less of standard deflection of the deviation

indicator.

b) In the absence of 150 Hz modulation.

c) In the absence of 90 Hz modulation.

d) In the absence of both 90 Hz and 150 Hz modulation.

e) In the absence of RF.

Page 1-6 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 15

1.4 LICENSE REQUIREMENTS

The following guidance is provided to help ensure the proper licensing of the GNC 420/GNS 430 COM:

1. The Telecommunications Act of 1996 effective February 8, 1996 provides the FCC discretion to

eliminate radio station license requirements for aircraft. At present, an individual license to operate

the 400 Series aboard a private aircraft is not needed in many circumstances. Please see FCC Fact

Sheet PR5000 or contact the FCC at 1-800-322-1117 for more information.

2. No license change is required for an aircraft which already has a station license per FCC 404

Instructions dated 1994.

3. If an aircraft license is required or desired, contact the FCC at 1-800-322-1117 to request FCC Form

404, “Application for Aircraft Radio Station License,” to apply for FCC authorization. The FCC also

has a “Fax on Demand” service to provide forms by FAX at 202-418-0177.

This equipment has been type accepted by the FCC. The bandwidth/emission designator is 6K00 A3E.

CAUTION

THE VHF TRANSMITTER IN THIS EQUIPMENT IS GUARANTEED TO MEET FEDERAL

COMMUNICATIONS COMMISSION ACCEPTANCE OVER THE OPERATING

TEMPERATURE RANGE. MODIFICATIONS NOT EXPRESSLY APPROVED BY GARMIN

COULD INVALIDATE THE LICENSE AND MAKE IT UNLAWFUL TO OPERATE THE

EQUIPMENT.

1.5 CERTIFICATION

The GPS receivers in the 400 Series units are certified for IFR enroute, terminal, and non-precision

approaches. The 400 Series initial certification was accomplished via STC’s by Garmin in a Piper PA32.

See Appendix B for copies of the STC’s.

The 400 Series units have been qualified to RTCA/DO-160 Section 22 lightning requirements. Special

installation considerations are required, refer to the Environmental Qualification Forms in Appendix A.

1.6 FAULT DETECTION AND EXCLUSION (FDE)

NOTE

The 400 Series equipment as installed has been found to comply with the requirements for GPS

primary means of navigation in oceanic and remote airspace, when used in conjunction with the

400 Series Trainer Program incorporating the FDE Prediction Program. This does not constitute

an operational approval.

The Garmin 400 Series Main and GPS Software version 3.00 and higher incorporate Fault Detection and

Exclusion (FDE) display interface and control, satisfying the requirements for GPS as a Primary Means of

Navigation for Oceanic/Remote Operations per FAA Notice N8110.60.

Fault Detection and Exclusion consists of two parts. The fault detection function detects a satellite failure

that can affect navigation. The exclusion function refers to the capability of excluding one or more failed

satellites and preventing them from affecting navigation.

FDE is provided for Oceanic and Remote Operations, non-precision approaches, en route and terminal

phases of flight. FDE for non-oceanic flight phases adhere to the same missed alert probability, false alert

probability, and failed exclusion probability specified by N8110.60.

400 SERIES INSTALLATION MANUAL Page 1-7

P/N 190-00140-02 Page Rev L

Page 16

The FDE function is built into the GPS 400/GNC 420/GNS 430 and does not require pilot interaction. In

contrast, the FDE Prediction Program does require pilot interaction and must be used prior to

oceanic/remote area flights to predict FDE availability.

The 400 Series Trainer software (Garmin Part Number 190-00176-00) includes an FDE Prediction

Program to meet the requirements for GPS as a primary means of navigation for oceanic/remote operations

per N8110.60. The oceanic flight phase occurs on the GPS 400/GNC 420/GNS 430 when more than 200

nautical miles from the nearest airport.

All operators using the GPS 400/GNC 420/GNS 430 as primary means of navigation in oceanic/remote

areas under FAR parts 91, 121, 125 and 135 must utilize the FDE Prediction Program prior to conducting a

flight in these areas.

1.7 LIMITED WARRANTY

This Garmin product is warranted to be free from defects in materials or workmanship for one year from

the date of purchase. Within this period, Garmin will at its sole option, repair or replace any components

that fail in normal use. Such repairs or replacement will be made at no charge to the customer for parts or

labor, provided that the customer shall be responsible for any transportation cost. This warranty does not

cover failures due to abuse, misuse, accident or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES EXPRESS OR IMPLIED OR STATUTORY, INCLUDING ANY

LIABILITY ARISING UNDER ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, WHICH MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL GARMIN BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE, OR

INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT. Some states do not

allow the exclusion of incidental or consequential damages, so the above limitations may not apply to you.

Garmin retains the exclusive right to repair or replace the unit or software or offer a full refund of the

purchase price at its sole discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE

REMEDY FOR ANY BREACH OF WARRANTY.

To obtain warranty service, contact your local Garmin Authorized Service Center. For assistance in

locating a Service Center near you, call Garmin Customer Service at one of the numbers shown below.

Garmin International, Inc. Garmin (Europe) Ltd.

1200 East 151

st

Street Unit 4, The Quadrangle, Abbey Park Industrial Estate

Olathe, Kansas 66062, U.S.A. Romsey, SO51 9DL, U.K.

Phone: 913/397.8200 Phone: 44/1794.519944

FAX: 913/397.0836 FAX: 44/1794.519222

Page 1-8 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 17

2. INSTALLATION

2.1 INTRODUCTION

Careful planning and consideration of the suggestions in this section are required to achieve the desired

performance and reliability from the 400 Series unit. Any deviations from the installation instructions

prescribed in this document shall be accomplished in accordance with the requirements set forth in FAA

AC 43.13-2A, and 14 CFR Part 43 Maintenance, Preventive Maintenance, Rebuilding, and Alteration.

2.2 ANTENNA CONSIDERATIONS

Antenna installations on pressurized cabin aircraft require FAA approved installation design and

engineering substantiation data whenever such antenna installations incorporate alteration (penetration) of

the cabin pressure vessel by connector holes and/or mounting arrangements. For needed engineering

support pertaining to the design and approval of such pressurized aircraft antenna installations, it is

recommended that the installer proceed according to any of the following listed alternatives:

1. Obtain approved antenna installation design data from the aircraft manufacturer.

2. Obtain an FAA approved STC, pertaining to, and valid for the antenna installation.

3. Contact the FAA Aircraft Certification Office in the appropriate Region and request identification of

FAA Designated Engineering Representatives (DERs) who are authorized to prepare and approve the

required antenna installation engineering data.

4. Obtain FAA Advisory Circular AC-183C and identify a DER from the roster of individuals in it.

5. Contact an aviation industry organization such as the Aircraft Electronics Association for assistance.

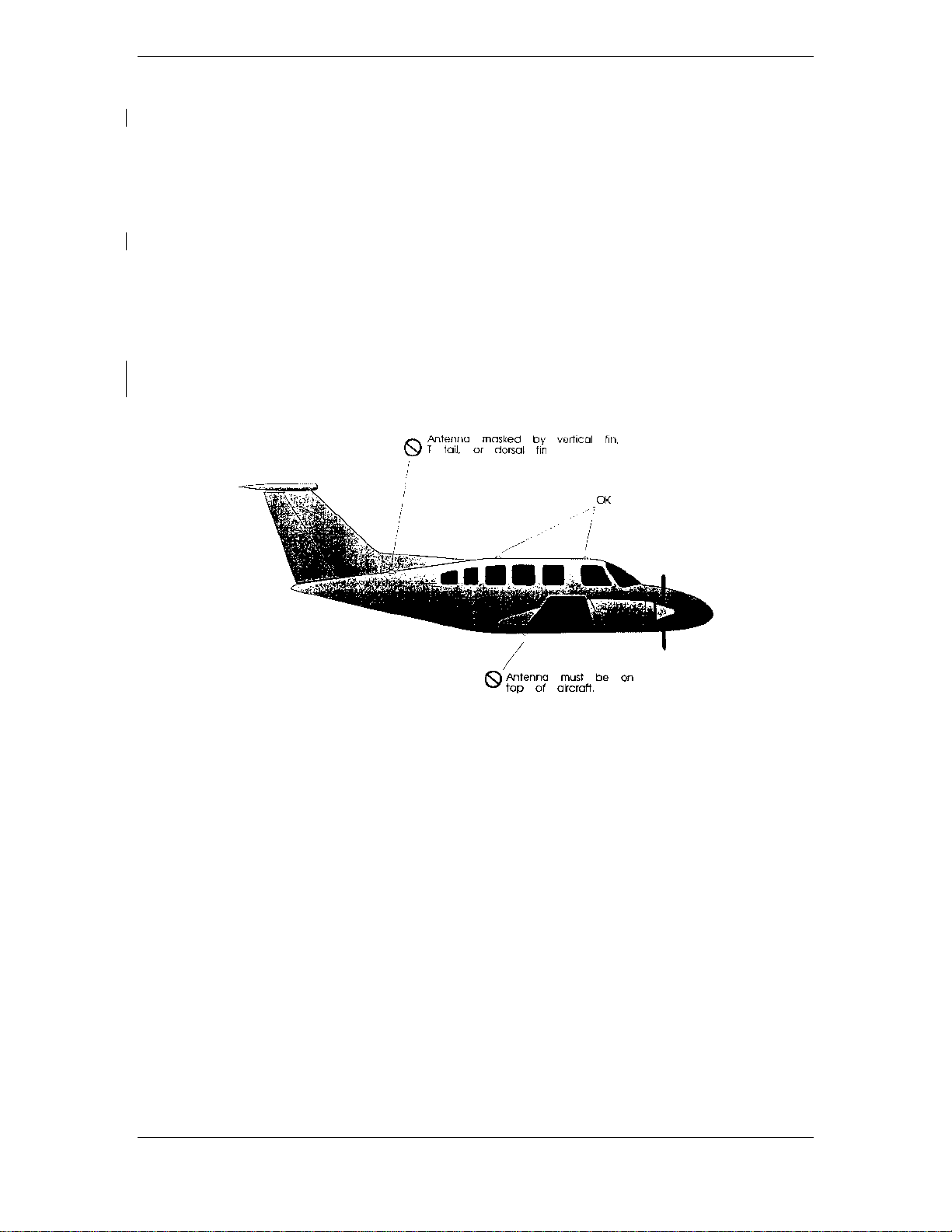

2.2.1 GPS ANTENNA LOCATION

The GA 56 Antenna must be mounted on top of the aircraft. For best performance, select a location with

an unobstructed view of the sky above the aircraft when in level flight. Figure 2-1 illustrates a typical GPS

antenna installation. The antenna should be located at least three feet from transmitting antennas such as

VHF COM, HF transmitter, DME, Transponder and Radar.

For rotorcraft, locate the GA 56 Antenna as far as possible from the main rotor hub. This reduces the

percentage of time the blade blocks the antenna. Also mount it as far below the blade surface as possible if

installing the antenna under the blade. This reduces signal distortion caused by the blades.

2.2.2 COM ANTENNA LOCATION

The GNC 420 or GNS 430 COM antenna should be well removed from all projections, engines and

propellers. The ground plane surface directly below the antenna should be a flat plane over as large an area

as possible (18 inches square, minimum). The antenna should be mounted a minimum of six feet from any

DME or other COM antennas, four feet from any ADF sense antennas, and three feet from the 400 Series

and its GPS antenna.

If simultaneous use of two COM transceivers is desired (spit- COM or simulcomm), use of the TX

interlock function is mandatory. In addition, the COM antennas should be spaced for maximum isolation.

A configuration of one topside antenna and one bottom side antenna is recommended.

2.2.3 VOR/LOC ANTENNA LOCATION

The GNS 430 VOR/LOC antenna should be well removed from all projections, engines and propellers. It

should have a clear line of sight if possible. The antenna must be mounted along the centerline of the

aircraft, minimizing the lateral offset.

2.2.4 GLIDESLOPE ANTENNA LOCATION

The GNS 430 Glideslope antenna should be well removed from all projections, engines and propellers. It

should have a clear line of sight if possible.

2.2.5 ELECTRICAL BONDING

No special precautions need to be taken to provide a bonding path between the GPS antenna and the

aircraft structure. Follow the manufacturers’ instructions for the COM, VOR/LOC and Glideslope

antennas.

400 SERIES INSTALLATION MANUAL Page 2-1

P/N 190-00140-02 Page Rev L

Page 18

2.2.6 ANTENNA LIMITATIONS

Garmin’s GA 56 Antennas are recommended for installations where the airspeed of the aircraft is subsonic.

In such installations, GA 56—Mod 1 or later—must be used. See the COM, VOR/LOC, and Glideslope

antenna specifications for their limitations.

2.2.7 VHF COM INTERFERENCE OF GPS

On many panel-mounted installations, VHF COM transceivers can radiate strong harmonics from the

transceiver and its antenna. The 400 Series COM does not interfere with its own GPS section. However,

placement of the GA 56 GPS antenna relative to a COM transceiver and COM antenna, including the GNC

420 or GNS 430 COM antenna, is critical.

Use the following guidelines, in addition to others in this document, when locating the 400 Series unit and

its antennas.

• GPS Antenna—Locate as far as possible from all COM antennas and all COM transceivers

(including the 400 Series COM). The GPS antenna is less susceptible to harmonic interference

if a 1.57542 GHz notch filter is installed on the COM transceiver antenna output.

• Locate the 400 Series unit as far as possible from all COM antennas.

Figure 2-1. GPS Antenna and Unit Installation Considerations

If a COM antenna is found to be the problem, a 1.57542 GHz notch filter (Garmin P/N 330-00067-00) may

be installed in the VHF COM coax, as close to the COM as possible. This filter is not required for the

GNC 420 and GNS 430 transmitters.

If a COM is found to be radiating, the following can be done:

1. Replace or clean the VHF COM rack connector to ensure good coax ground.

2. Place grounding straps between the 400 Series unit, VHF COM and a good ground.

3. Shield the VHF COM wiring harness.

Page 2-2 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 19

2.2.8 COM, VOR/LOC, and Glideslope Antenna Installation Instructions

Install the COM, VOR/LOC, and Glideslope antennas according to the manufacturer’s recommendations.

Avoid running other wires and coaxial cables near the VOR/LOC antenna cable.

2.3 RACK CONSIDERATIONS

Plan a location which gives the pilot complete and comfortable access to the entire keypad and which is

plainly visible from the pilot’s perspective. Installation of remote switches and annunciators may not be

required if the 400 Series unit is installed in the pilot’s normal field of view (refer to the FAA letter in

Appendix B).

Check that there is adequate depth for the rack in the instrument panel. A location away from heating

vents or other sources of heat generation is optimal.

2.4 CABLING AND WIRING

Coaxial cable with 50 Ω nominal impedance and meeting applicable aviation regulations should be used

for the installation. A typical maximum cable length for the GPS antenna is 40 feet. The installer should

insure that the attenuation does not exceed 10 dB at 1.5 GHz for the specific installation.

Check that there is ample space for the cabling and mating connectors. Avoid sharp bends in cabling,

particularly the COM antenna cable, and routing near aircraft control cables. Cabling for the 400 Series

unit should not be routed near components or cabling which are sources of electrical noise. Do not route

the COM antenna coax near any ADF antenna cables. Route the GPS, VOR/LOC, and Glideslope antenna

cables as far as possible away from all COM transceivers and antenna cables.

2.5 COOLING AIR

The 400 Series units meet all TSO requirements without external cooling. However, as with all electronic

equipment, lower operating temperatures extend equipment life. On the average, reducing the operating

temperature by 15-20 °C (25 to 35 °F) doubles the mean time between failure (MTBF). Recommended

airflow rating is 1 CFM (cubic foot per minute) at a pressure equivalent to 0.1 inches of water. Potential

damage to your 400 Series unit may occur by using outside forced air to cool the equipment. Therefore, it

is recommended that an electric forced air fan be installed, of the indicated rating, to cool this equipment.

Units tightly packed in the avionics stack heat each other through radiation, convection, and sometimes by

direct conduction. Even a single unit operates at a much higher temperature in still air than in moving air.

Fans or some other means of moving the air around electronic equipment are usually a worthwhile

investment. A 5/8” diameter air fitting is provided on the rear of the mounting rack for the purpose of

admitting cooling air under such conditions. If a form of forced air cooling is installed, make certain that

rainwater cannot enter and be sprayed on the equipment.

2.6 MINIMUM INSTALLATION REQUIREMENTS

Below is a list of required devices for TSO C129a category A1 and A2 certification. For a specific list of

equipment used in the initial STC, obtain a copy of “GNS 430 in Piper PA32 Documented Installation”

(P/N 190-00140-06). The FAA or the governing organization should approve deviations from that set of

equipment.

Pressure Altitude Device

This device delivers pressure altitude data to the 400 Series unit. This data can come from a parallel

encoding altimeter, blind encoder, serializer, or an air data system.

Manual Course Device (Required for GNS 430 Only)

This device delivers the manual course select to the 400 Series unit, which is required for the GNS 430

VOR receiver, and optional for the 400/420/430 GPS receiver. Course information can come from an

analog resolver, or from an EFIS/EHSI via ARINC 429 serial data.

HSI/CDI Indicator or EFIS

This device displays Nav Flag, Left/Right, To/From, Glideslope Flag, and Up/Down. The indicator(s)

used in conjunction with the GNS 430 VOR/ILS receivers shall be TSO'd.

400 SERIES INSTALLATION MANUAL Page 2-3

P/N 190-00140-02 Page Rev L

Page 20

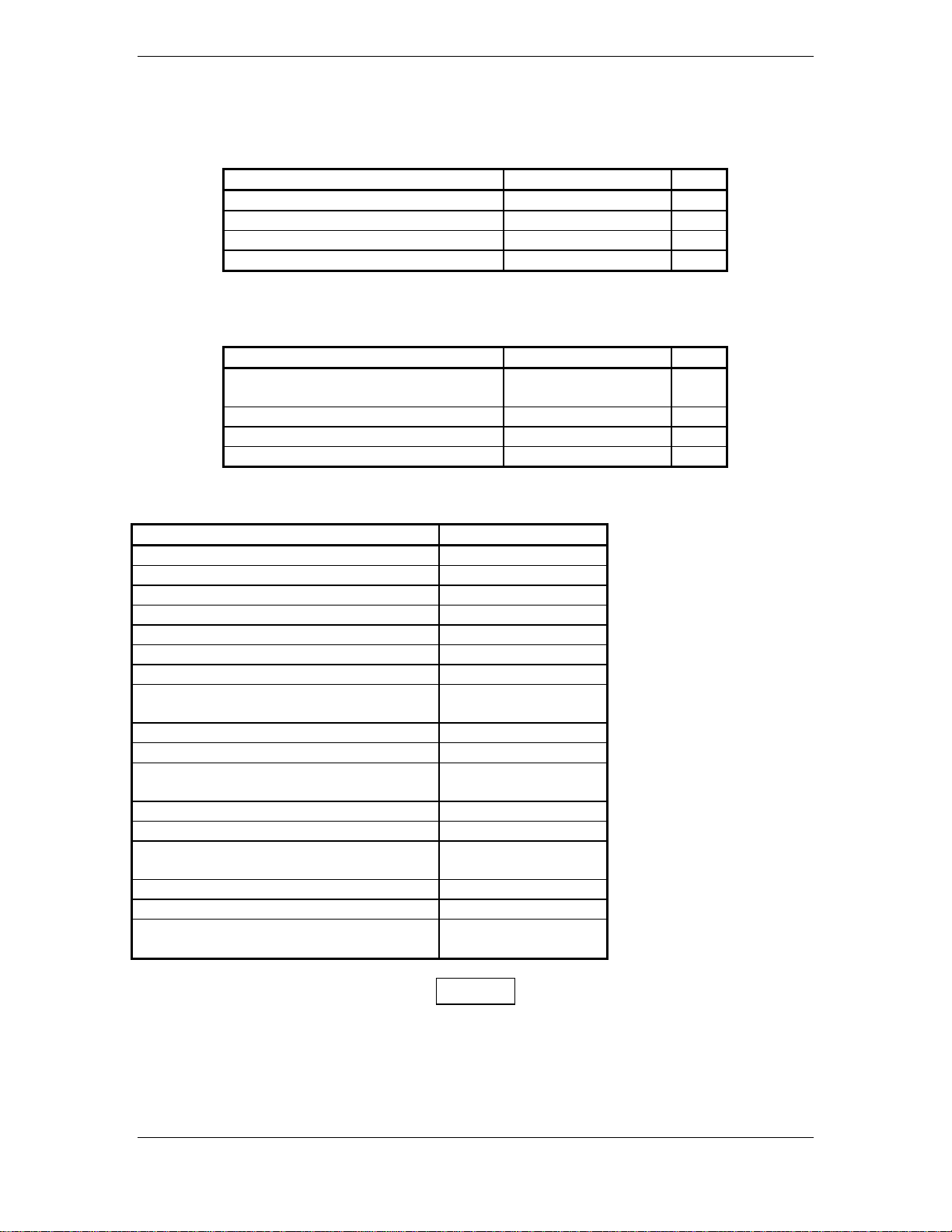

Qualified GPS Antenna

This antenna must be one of those listed in the accessories list, or meet the following requirements:

1. DO-160C Environmental Conditions

The antenna shall meet the environmental conditions listed below and shall conform to the test

requirements of RTCA DO-160C.

Environmental Condition Category Description

Temperature (operating) F2 -55 to +70oC

(ground survival) F2 -55 to +85

Altitude F2 55,000 feet

Temperature Variation A 10

o

Humidity C 95% at +55

o

C

C per minute

o

C

Vibration CLMY Turbo/Reciprocating/Helicopter

Waterproofness S Continuous Stream

Fluids F Deicing Fluid

Lightning 2A Direct Effects

Icing C 0.15” thick

2. Electrical Characteristics

LNA Supply voltage 4.5 ± 0.5 V

DC

LNA Supply Current 20 mA Maximum

LNA Operating Frequency 1575.42 ± 2.00 MHz

LNA Gain 20 dB Maximum, 12dB Minimum

LNA Noise Figure 3.0 dB Maximum

LNA Output VSWR (50 Ω)2:1 Maximum

LNA Input power at -1 dB Gain Compression -6 dB Minimum

LNA Bandwidth

(-3 dB) 40 MHz Maximum

(-20 dB) 100 MHz Maximum

(-40 dB) 250 MHz Maximum

3. Radiation Characteristics

Polarization RHCP

Operating Frequency 1575.42 ± 2.00 MHz

Gain (on axis) 2.0 dBic Minimum

(at 160

o

beam width) -6.0 dBic Minimum

Cross Pole Gain (LHCP)

(on axis) -8 dBic Maximum

o

(at 160

beam width) -9 dBic Maximum

4. Mounting Requirements

Cable connection BNC Female

Mounting studs Four 8-32 UNC-2A studs 0.50” long

Page 2-4 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 21

3. INSTALLATION PROCEDURE

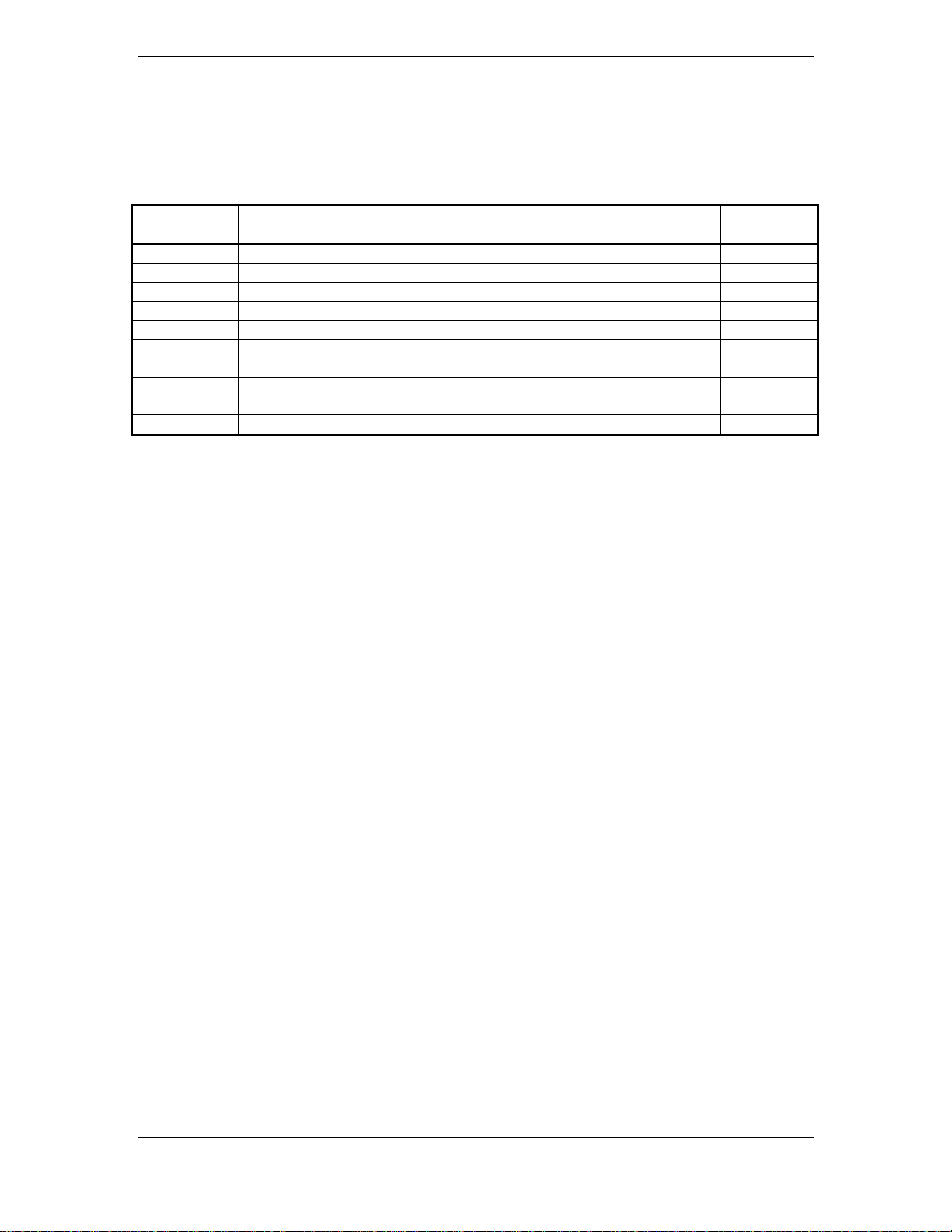

3.1 UNIT AND ACCESSORIES

The 400 Series units are available under the following part numbers:

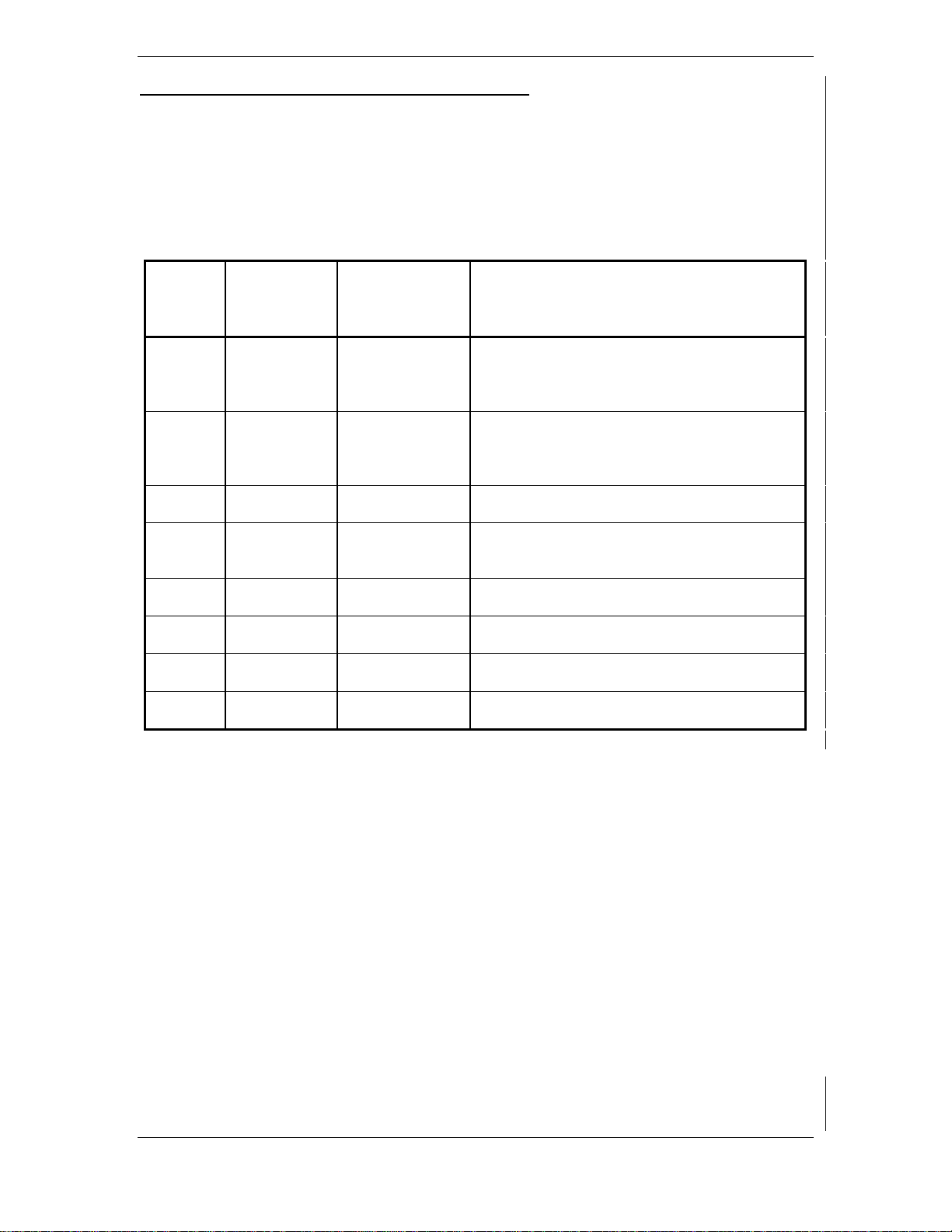

3.1.1 GNS 430 (A)

CATALOG

P/N

010-00139-00 011-00280-00 N N BLACK 28 10 W

010-00139-01 011-00280-00 N Y BLACK 28 10 W

010-00139-10 011-00280-10 N N BLACK 14 or 28 Vdc 10 W

010-00139-11 011-00280-10 N Y BLACK 14 or 28 Vdc 10 W

010-00139-30 011-00280-30 N N GRAY 14 or 28 V (2) 10 W

010-00139-31 011-00280-30 N Y GRAY 14 or 28 V (2) 10 W

010-00286-00 011-00836-00 Y N BLACK 28 Vdc 16 W

010-00286-01 011-00836-00 Y Y BLACK 28 Vdc 16 W

010-00286-10 011-00836-10 Y N GRAY 28 Vdc (2) 16 W

010-00286-11 011-00836-10 Y Y GRAY 28 Vdc (2) 16 W

1) The following accessories are included with the GNS 430 (A) for those indicated with a “Y” above:

MOUNTING RACK (115-00243-00)

CONNECTOR KIT (011-00351-00)

BACK PLATE ASSEMBLY (011-00676-00)

GNS 430 PRODUCT INFO KIT (K00-00055-00)

UNIT

P/N

GNS

430A

ACCESSORIES

(1)

COLOR OPERATING

VOLTAGE

MINIMUM

XMIT PWR

2) Denotes alternate (secondary) power input available, (review installation drawing).

400 SERIES INSTALLATION MANUAL Page 3-1

P/N 190-00140-02 Page Rev L

Page 22

3.1.2 GNC 420 (A)

CATALOG

P/N

UNIT

P/N

GNC

420A

ACCESSORIES

(1)

COLOR OPERATING

VOLTAGE

MINIMUM

XMIT PWR

010-00173-00 011-00506-00 N N BLACK 28 10 W

010-00173-01 011-00506-00 N Y BLACK 28 10 W

010-00173-10 011-00506-10 N N BLACK 14 or 28 Vdc 10 W

010-00173-11 011-00506-10 N Y BLACK 14 or 28 Vdc 10 W

010-00173-30 011-00506-30 N N GRAY 14 or 28 V (2) 10 W

010-00173-31 011-00506-30 N Y GRAY 14 or 28 V (2) 10 W

010-00287-00 011-00837-00 Y N BLACK 28 Vdc 16 W

010-00287-01 011-00837-00 Y Y BLACK 28 Vdc 16 W

010-00287-10 011-00837-10 Y N GRAY 28 Vdc (2) 16 W

010-00287-11 011-00837-10 Y Y GRAY 28 Vdc (2) 16 W

1) The following accessories are included with the GNS 420 (A) for those indicated with a “Y” above:

MOUNTING RACK (115-00243-00)

CONNECTOR KIT (011-00351-01)

BACK PLATE ASSEMBLY (011-00676-01)

GNC 420 PRODUCT INFO KIT (K00-00057-00)

2) Denotes alternate (secondary) power input available, (review installation drawing).

3.1.3 GPS 400

CATALOG

P/N

UNIT

P/N

ACCESSORIES

(1)

COLOR ALT PWR

AVAILABL

E

010-00171-00 011-00504-00 N BLACK N

010-00171-01 011-00504-00 Y BLACK N

010-00171-10 011-00504-10 N GRAY Y

010-00171-11 011-00504-10 Y GRAY Y

1) The following accessories are included with the GPS 400 for those indicated with a “Y” above:

MOUNTING RACK (115-00243-00)

CONNECTOR KIT (011-00351-03)

BACK PLATE ASSEMBLY (011-00676-03)

GPS 400 PRODUCT INFO KIT (K00-00056-00)

Alternate (secondary) power input available (review installation drawing).

Page 3-2 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 23

The following installation accessories are available:

1. GPS Antenna Options:

• GA 56 Antenna Kit, without cable (Mod 1 or later, Garmin P/N 010-10040-01). This kit

contains the following items:

ITEM GARMIN P/N QTY

GA 56 ANTENNA SUB-ASSEMBLY 011-00134-00 1

BACKING PLATE 115-00031-00 1

NUT, SELF-LOCKING, #8-32 210-10004-09 4

ANTENNA GASKET 253-00002-00 1

• GA 56 Flange Mount Antenna Kit (Mod 1 or later, Garmin P/N 010-10040-02). This kit

contains the following items:

ITEM GARMIN P/N QTY

FLANGE MOUNT GA 56 ANTENNA

SUB-ASSEMBLY

NUT PLATE 115-00080-00 1

SCREW, #10-32 x 5/8” 211-62212-14 4

ANTENNA GASKET 253-00011-00 1

2. Other accessories include the following:

ITEM GARMIN P/N

MOUNTING RACK, 400/420/430 115-00243-00

GPS 400 BACK PLATE ASSEMBLY 011-00676-03

GPS 400 CONNECTOR KIT 011-00351-03

GNC 420 BACK PLATE ASSEMBLY 011-00676-01

GNC 420 CONNECTOR KIT 011-00351-01

GNS 430 BACK PLATE ASSEMBLY 011-00676-00

GNS 430 CONNECTOR KIT 011-00351-00

400 SERIES ADDENDUM FOR TRAFFIC

& WEATHER INTERFACES

GPS 400 PILOT’S GUIDE 190-00140-60

GPS 400 QUICK REFERENCE GUIDE 190-00140-61

GPS 400 SAMPLE AIRPLANE FLIGHT

MANUAL SUPPLEMENT

GNC 420 PILOT’S GUIDE 190-00140-20

GNC 420 QUICK REFERENCE GUIDE 190-00140-21

GNC 420 SAMPLE AIRPLANE FLIGHT

MANUAL SUPPLEMENT

GNS 430 PILOT’S GUIDE 190-00140-00

GNS 430 QUICK REFERENCE GUIDE 190-00140-01

GNS 430 SAMPLE AIRPLANE FLIGHT

MANUAL SUPPLEMENT

190-00140-10

190-00140-64

190-00140-24

190-00140-04

011-00147-00 1

NOTE

A mounting rack is required for approved installations. The following hardware is

required for installation of the mounting rack, but is not provided--#6-32 Flat Head

Screw (6 ea.), #6-32 Self-locking Nut (6 ea.).

400 SERIES INSTALLATION MANUAL Page 3-3

P/N 190-00140-02 Page Rev L

Page 24

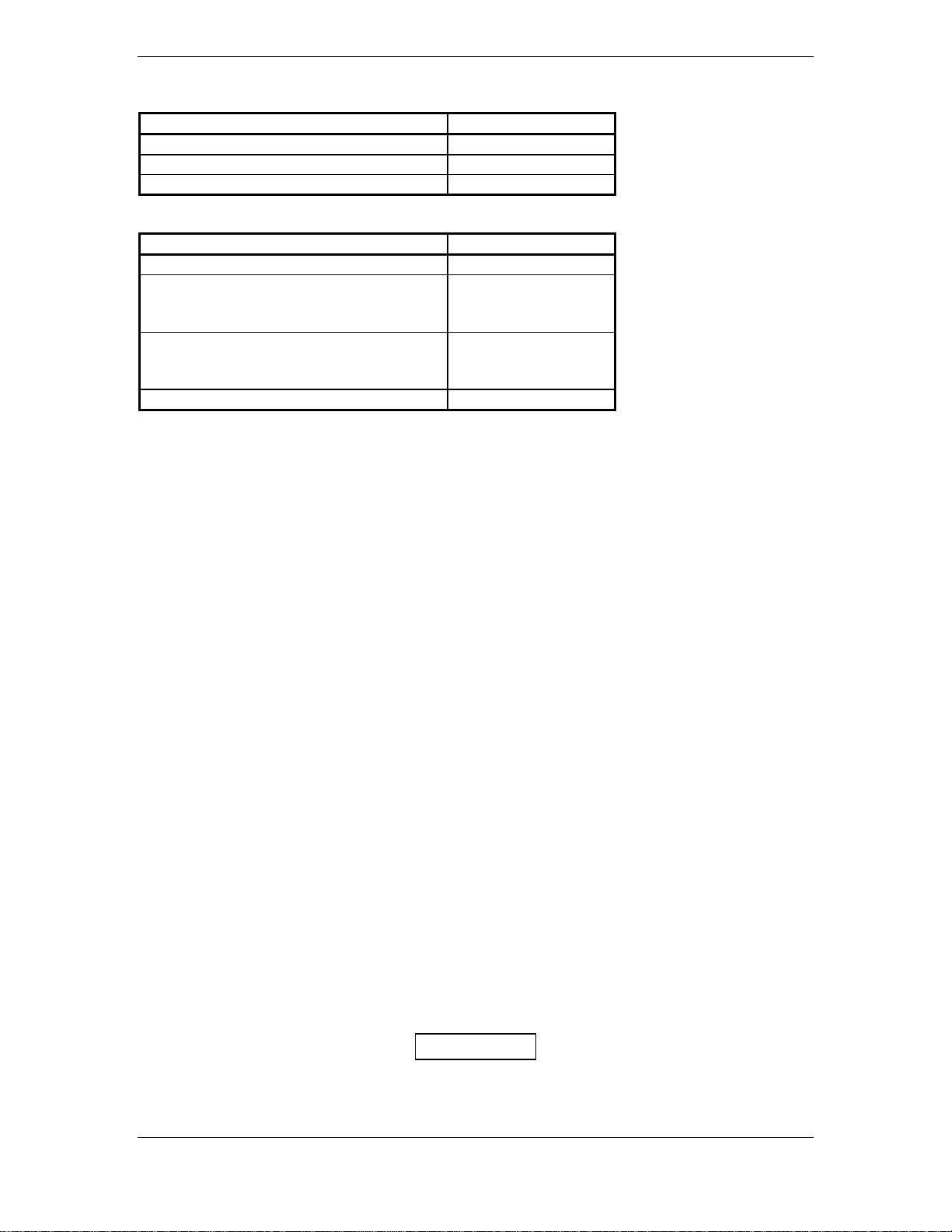

3.2 DATA BASE OPTIONS

ITEM GARMIN P/N

DATA CARD, WORLD WIDE 010-10201-00

DATA CARD, AMERICAS 010-10201-01

DATA CARD, INTERNATIONAL 010-10201-02

3.3 MISCELLANEOUS OPTIONS

ITEM GARMIN P/N

CONNECTOR, BNC, MALE, CLAMP 330-00087-00

LOW-LOSS AVIATION ANTENNA

EXTENSION CABLE WITH RIGHT

ANGLE BNC CONNECTOR, 15 FT.

LOW-LOSS AVIATION ANTENNA

EXTENSION CABLE WITH RIGHT

ANGLE BNC CONNECTOR, 30 FT.

GPS 1.57542 GHz NOTCH FILTER 330-00067-00

320-00003-00

320-00003-02

3.4 INSTALLATION ACCESSORIES REQUIRED BUT NOT PROVIDED

The following installation accessories are required but not provided:

COM Antenna: (GNC 420 and GNS 430 Only) Shall meet TSO C37() and C38(). Broad band, 50

Ω, vertically polarized with coaxial cable

VOR/LOC Antenna: (GNS 430 Only) Shall meet TSO C40() and C36(). Broad band, 50 Ω,

horizontally polarized with coaxial cable

Glideslope Antenna: (GNS 430 Only) Shall meet TSO C34(). Broad band, 50 Ω, horizontally polarized

with coaxial cable or low-loss splitter used with the VOR/LOC antenna

Headphones: (GNC 420 and GNS 430 Only) 500 Ω nominal impedance

Microphone: (GNC 420 and GNS 430 Only) Low impedance, carbon or dynamic, with

transistorized pre-amp

3.5 ANTENNA INSTALLATION

For the COM, VOR/LOC, and Glideslope antennas, follow the manufacturers’ instructions.

The remainder of this section applies to the GPS antenna. The GA 56 antenna outline and footprint

dimensions are shown in Figure 3-2, page 3-9. Also refer to 190-00094-00 GA 56 Antenna Installation

Instructions.

1. Using the backing plate as a template, mark the location of the mounting holes and the through

hole for coaxial cable. Drill or punch the holes.

2. The antenna installation must provide adequate support for the antenna, considering a

maximum drag load of 5 lbs. for the GA 56 antennas (at subsonic speed). Install a doubler

plate to reinforce thin-skinned aircraft. Observe guidelines for acceptable installation practices

as outlined in AC 43.13-2A.

Seal the antenna and gasket to the fuselage using a good quality electrical grade sealant. Use caution to

insure that the antenna connector is not contaminated with sealant. Insure that the mounting screws are

fully tightened and that the antenna base is well seated against the gasket.

CAUTION

Do not use construction grade RTV sealant or sealants containing acetic acid. These

sealants may damage the electrical connections to the antenna. Use of these type sealants

may void the antenna warranty.

Page 3-4 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 25

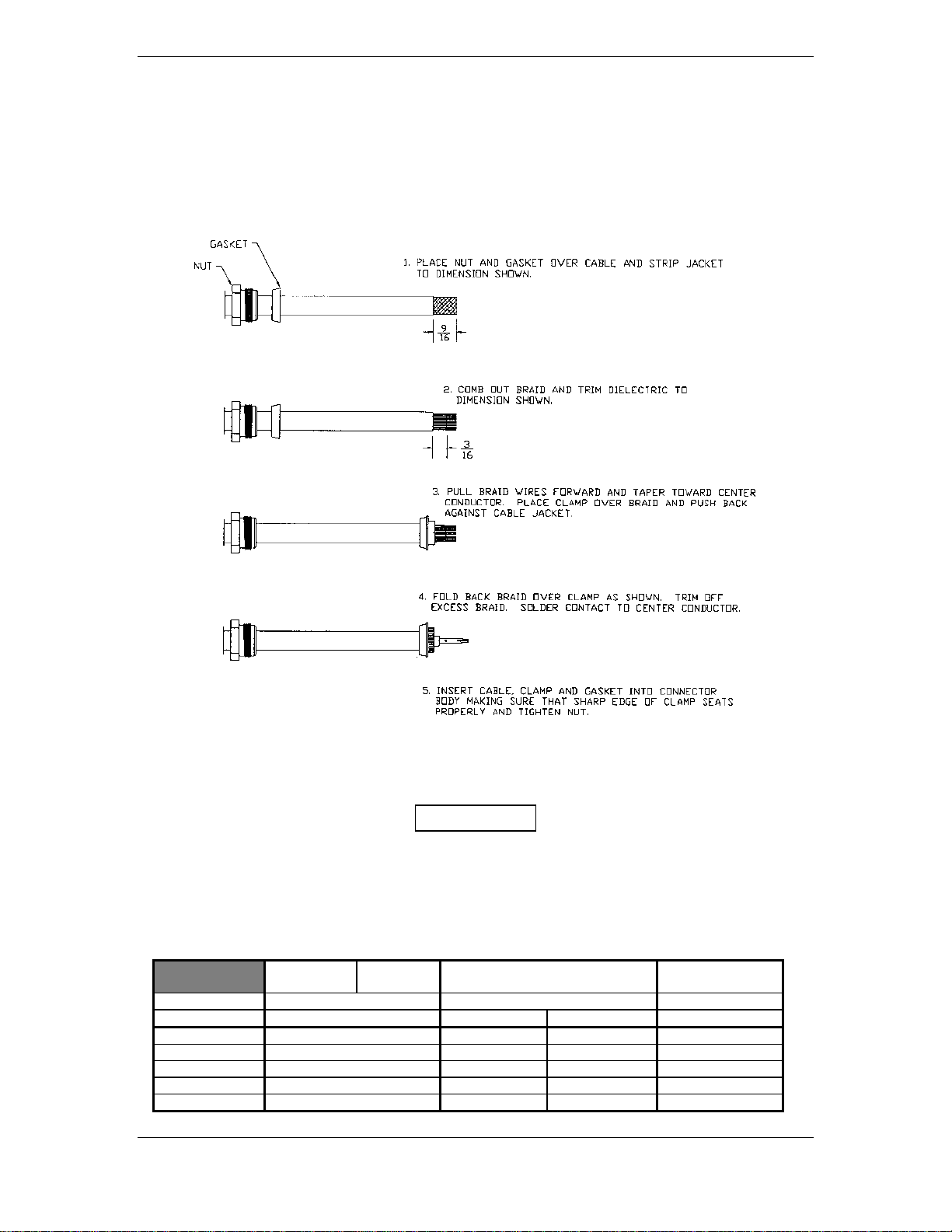

3.6 CABLE INSTALLATION

1. Route the coaxial cable to the rack location keeping in mind the recommendations of Section 2.

Secure the cable in accordance with good aviation practice.

2. Trim the coaxial cable to the desired length and install the BNC connector (330-00087-00) per

the cabling instructions on Figure 3-1. If the connector is provided by the installer, follow the

connector manufacturer’s instructions for cable preparation.

Figure 3-1. Coaxial Cable Installation

3. The card-edge connector may be used to terminate shield grounds to the 400 Series back plate.

CAUTION

4. Feed wires through the connector backshells before insertion into the 78, 44, and 25 pin connectors.

5. Contacts for the 78, 44 and 25 pin connectors must be crimped onto the individual wires of the aircraft

wiring harness. The following tables list contact part numbers (for reference) and recommended crimp

tools:

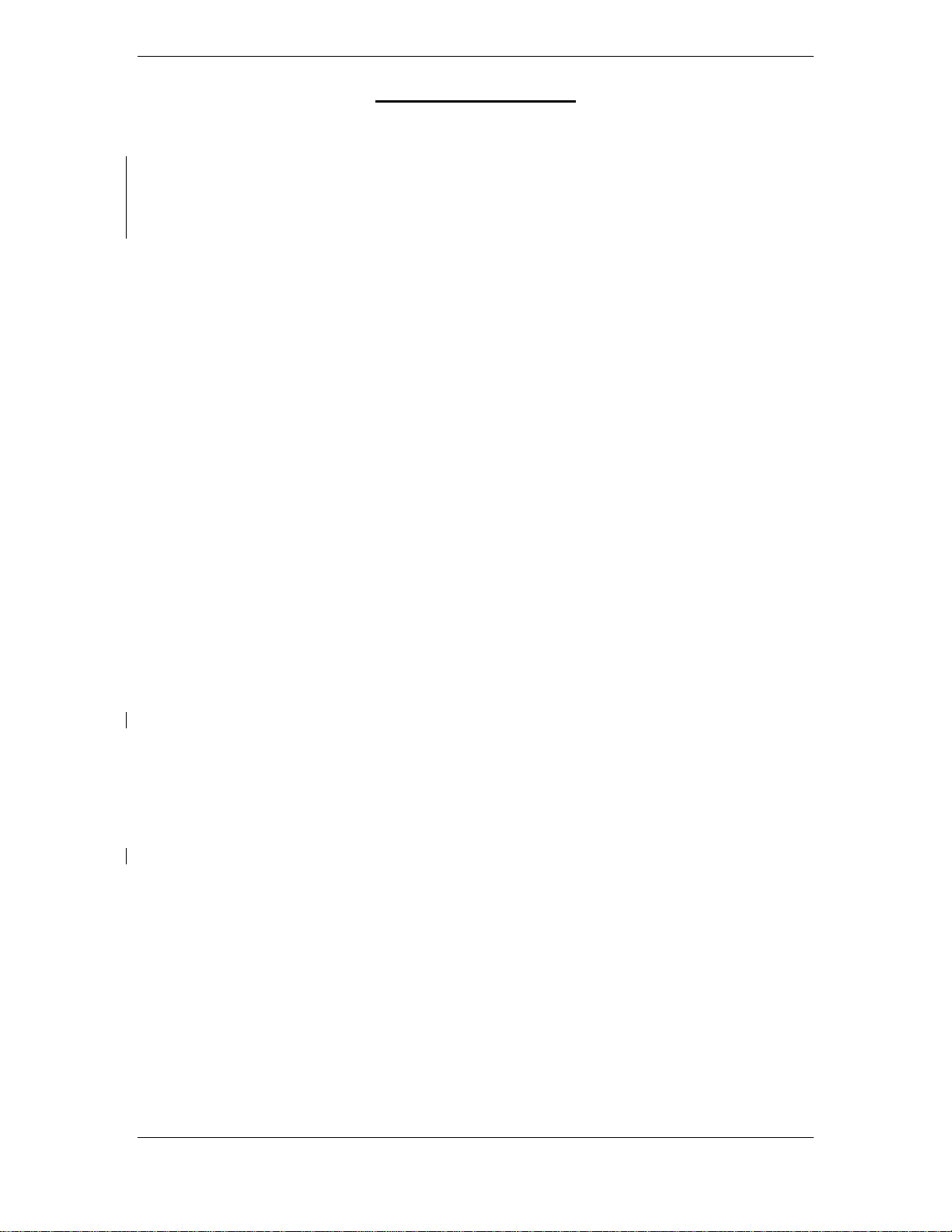

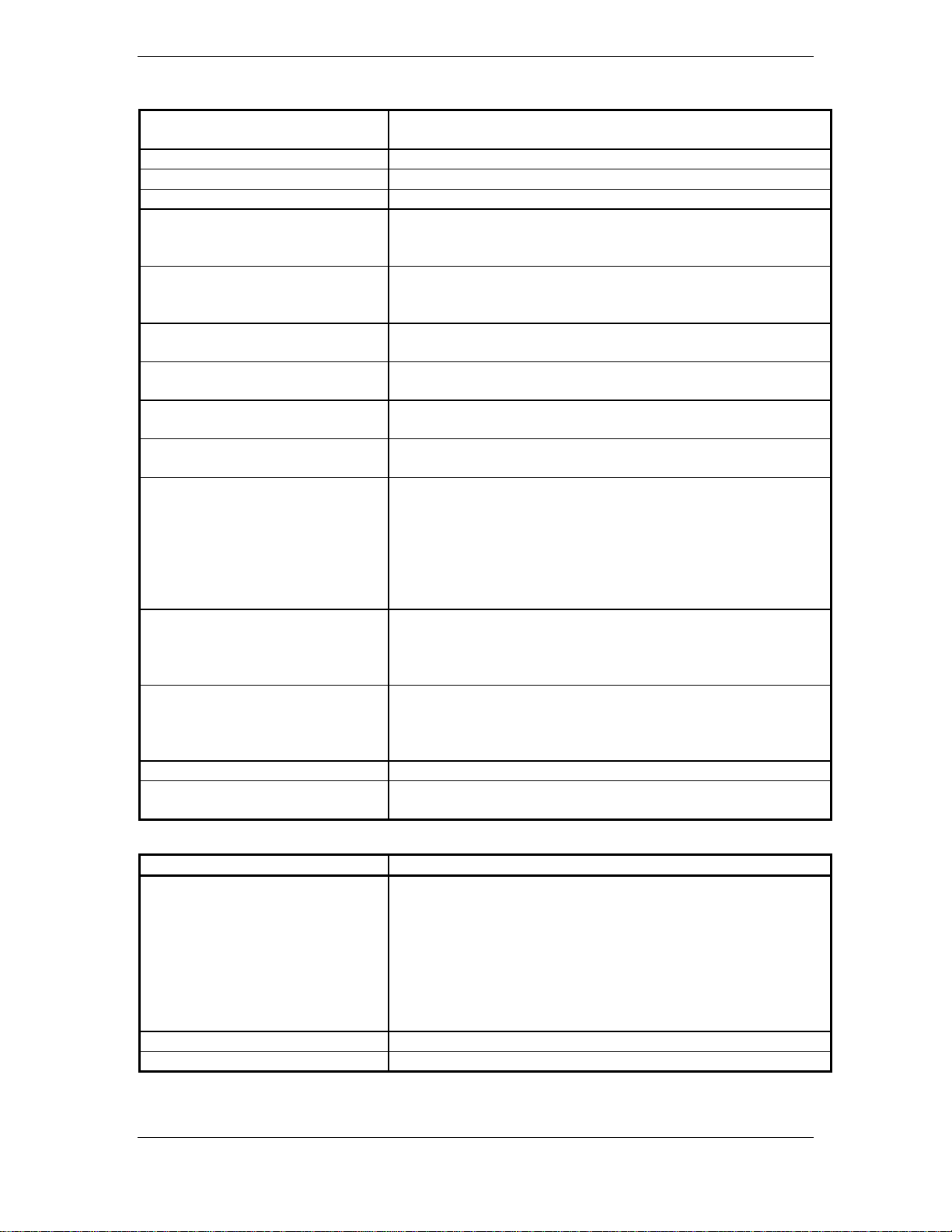

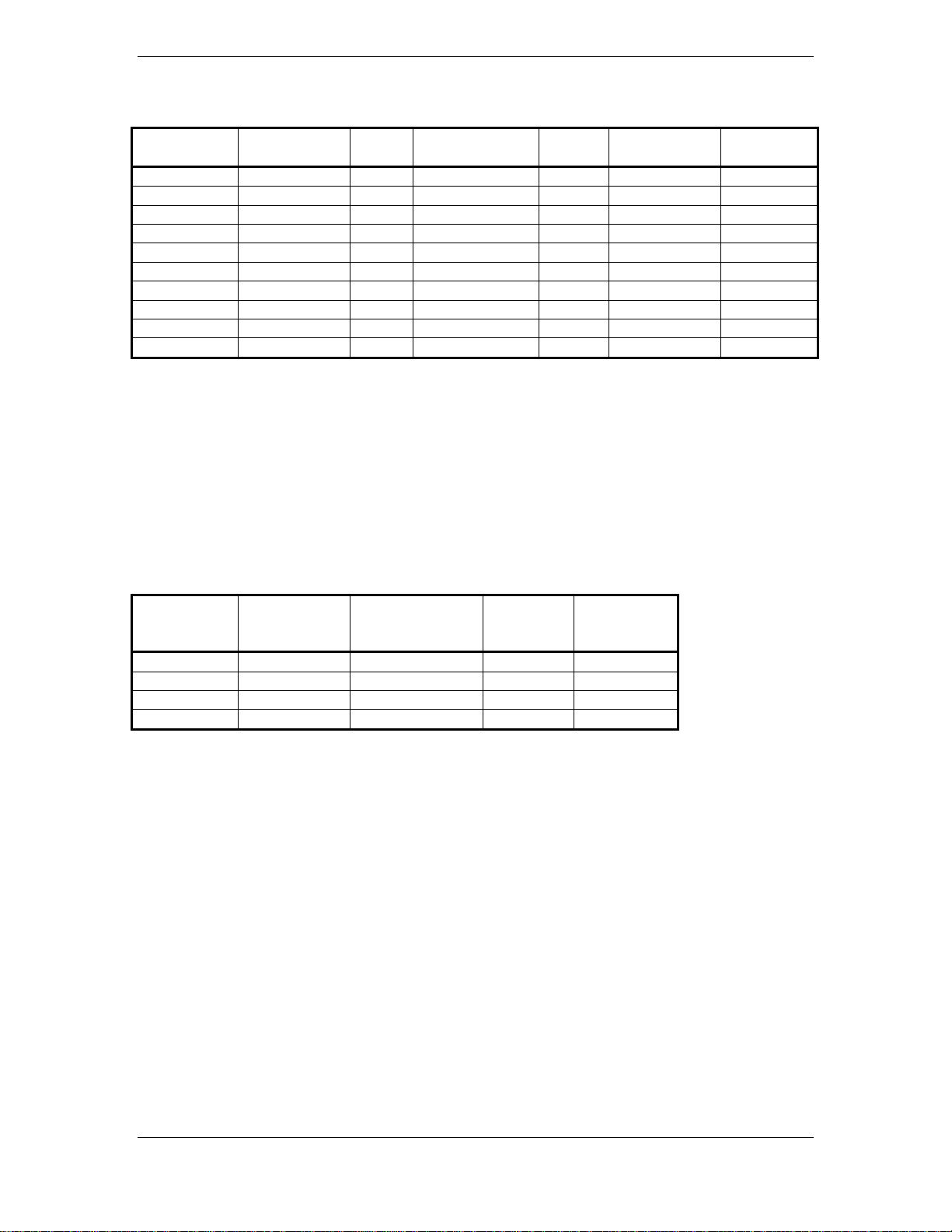

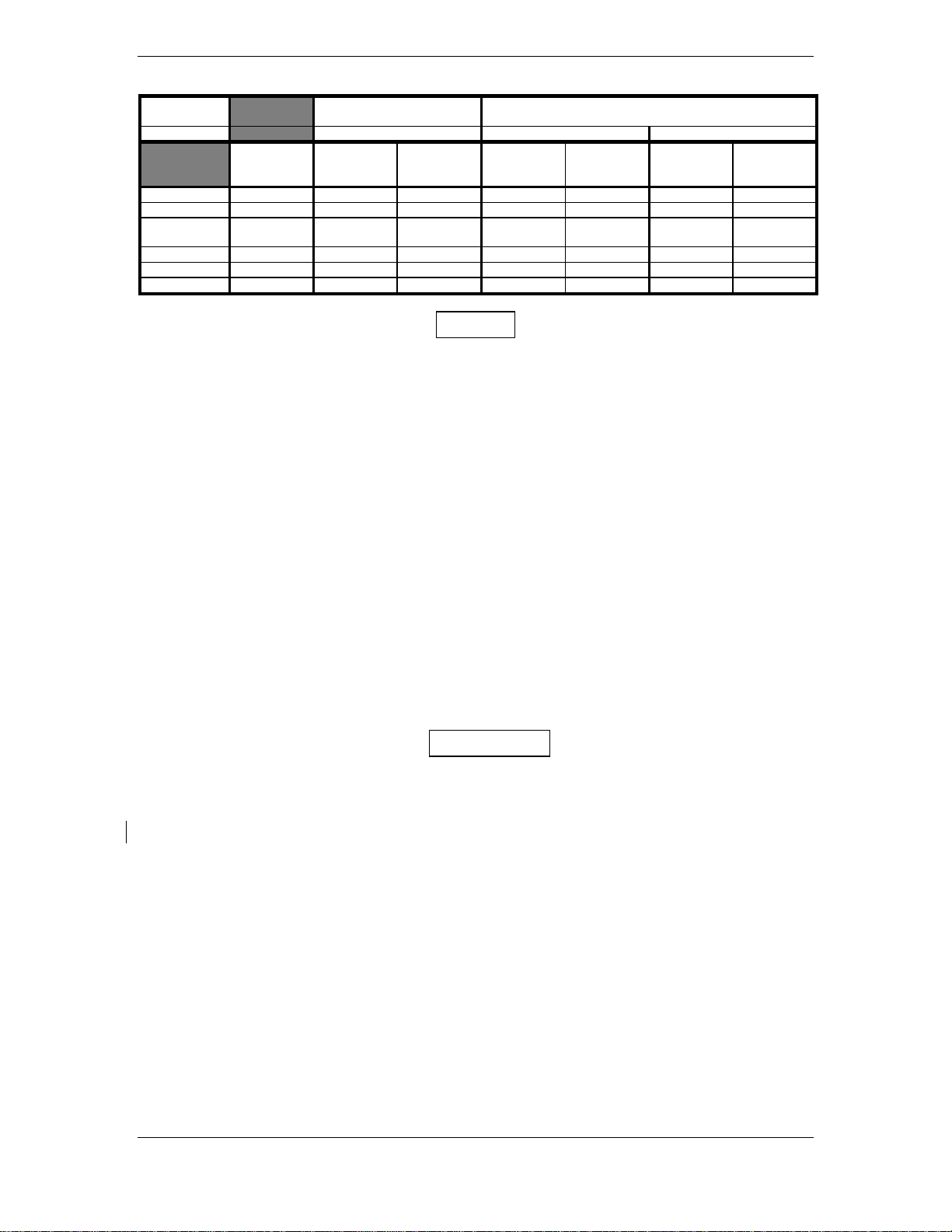

Table 3-1. Pin Contact Part Numbers

78 pin conn

(P4001)

Connector Type High Density Pin Contact Standard Density Socket Contact .1” Pitch Card-edge

Wire Gauge 22-28 AWG 18 AWG 20-24 AWG 20-24 AWG

Garmin P/N 336-00021-00 336-00023-00 336-00022-00 336-00029-00

Military P/N M39029/58-360 N/A M39029/63-368 N/A

AMP 204370-2 N/A 205090-1 583853-4

Positronic M39029/58-360 FC6018D M39029/63-368 N/A

ITT Cannon 030-2042-000 See Note 3 031-1007-042 N/A

400 SERIES INSTALLATION MANUAL Page 3-5

P/N 190-00140-02 Page Rev L

44 pin conn

(P4006)

25 pin connector (P4002) Shield ground

connector

Page 26

Table 3-2. Recommended Crimp Tools (or equivalent)

Connector

Type

Wire Gauge 22-28 AWG 18 AWG 20-24 AWG

Hand

Crimping

Tool

Military P/N M22520/2-01 M22520/2-09 M81969/1-04 N/A M81969/1-02 M22520/2-08 M81969/1-02

Positronic 9507 9502-3 M81969/1-04 9502-11 M81969/1-02 9502-5 M81969/1-02

ITT Cannon 995-0001-

584

AMP 601966-1 601966-6 91067-1 N/A N/A 601966-5 91067-2

Daniels AFM8 K42 M81969/1-04 K774 M81969/1-02 K13-1 M81969/1-02

Astro 615717 615725 M81969/1-04 N/A M81969/1-02 615724 M81969/1-02

High Density Standard Density

Positioner Insertion/

995-0001-

739

Extraction

Tool

N/A N/A N/A 995-0001-

Positioner Insertion/

Extraction

Tool

Positioner Insertion/

604

Extraction

Tool

980-2000-

426

NOTES

1. Insertion/extraction tools from ITT Cannon are all plastic; others are plastic with metal tip.

2. Non-Garmin part numbers shown are not maintained by Garmin and consequently are subject

to change without notice.

3. Alternate contacts for 18 AWG wire: As an alternative to the Positronic contacts listed (and

provided in the installation kit), the installer may use contacts made by ITT Cannon under P/N

031-1007-001. These contacts require the use of a different crimp tool positioner than shown

in the table, with the part numbers as follows: Daniels P/N K250, Astro P/N 616245, or ITT

Cannon P/N 980-0005-722.

4. For the card-edge connector pin contacts, use AMP part number 90272-1 or equivalent

crimping tool.

3.7 RACK INSTALLATION

1. The back plate of the rack may optionally be removed for ease of mounting in the aircraft

panel. To do so, remove the two #4-40 screws, tilt the back plate away from the tray, and then

slide the back plate to the side.

2. Figures 3-3, 3-4 and 3-5, starting on pages 3-11, 3-13, and 3-15, show outline dimensions for

the aviation rack for the various 400 Series units. Install the rack in a rectangular 6.320” x

2.700” hole (or gap between units) in the instrument panel (refer to Figure 3-9, page 3-23).

The lower-front lip of the rack should be flush with, or extend slightly beyond, the finished

aircraft panel.

CAUTION

If the front lip of the mounting rack is behind the surface of the aircraft panel,

the 400 Series unit connectors may not fully engage.

Make sure that no screw heads or other obstructions prevent the unit from fully engaging in the

rack (refer to the “Connector Engagement Test,” section 5.3.1, page 5-15). Exercise caution

when installing the rack into the instrument panel. The rack is designed to facilitate removal of

the 400 Series for use in Demo Mode outside the aircraft. Deformation of the rack may make it

difficult to install and remove the 400 Series unit.

3. Install the rack in the aircraft panel using six #6-32 flat head screws and six self-locking nuts.

The screws are inserted from the inside through the holes in the sides of the rack.

4. If the back plate was previously removed (see step #1), replace the back plate by positioning

the tabs on the back plate in the slots of the left side of the rack (viewing it from the cockpit)

and attaching it by replacing the two #4-40 screws.

Page 3-6 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 27

3.8 400 SERIES UNIT INSERTION AND REMOVAL

The 400 Series unit is installed in the rack by sliding it straight in until it stops, about 1 inch short of the

final position. A 3/32“ hex drive tool is then inserted into the access hole at the bottom of the unit face.

Rotate the hex tool clockwise while pressing on the left side of the bezel until the unit is firmly seated in

the rack. It may be necessary to insert the hex drive tool into the access hole and rotate the mechanism 90°

counterclockwise to insure correct position prior to placing the unit in the rack.

To remove the unit from the rack, insert the hex drive tool into the access hole on the unit face and rotate

counterclockwise until the unit is forced out about 3/8 ” and can be freely pulled from the rack.

Be sure not to over tighten the unit into the rack. The application of hex drive tool torque exceeding

15 in•lbs can damage the locking mechanism.

3.9 COM ANTENNA INSTALLATION CHECK (GNC 420 AND GNS 430)

Check for insertion loss and VSWR (voltage standing wave ratio). VSWR should be checked with an inline type VSWR/wattmeter inserted in the coaxial transmission line between the transceiver and the

antenna. The VSWR should be inserted as close to the transceiver as possible. When rack and harness

buildup is performed in the shop, the coax termination may be provisioned by using a 6” inline BNC

connection. This would be an acceptable place to insert the VSWR. Any problem with the antenna

installation is most likely seen as high reflected power. A VSWR of 3:1 may result in up to a 50% loss in

transmit power.

400 SERIES INSTALLATION MANUAL Page 3-7

P/N 190-00140-02 Page Rev L

Page 28

This page intentionally left blank.

Page 3-8 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 29

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-9 (Page 3-10 blank)

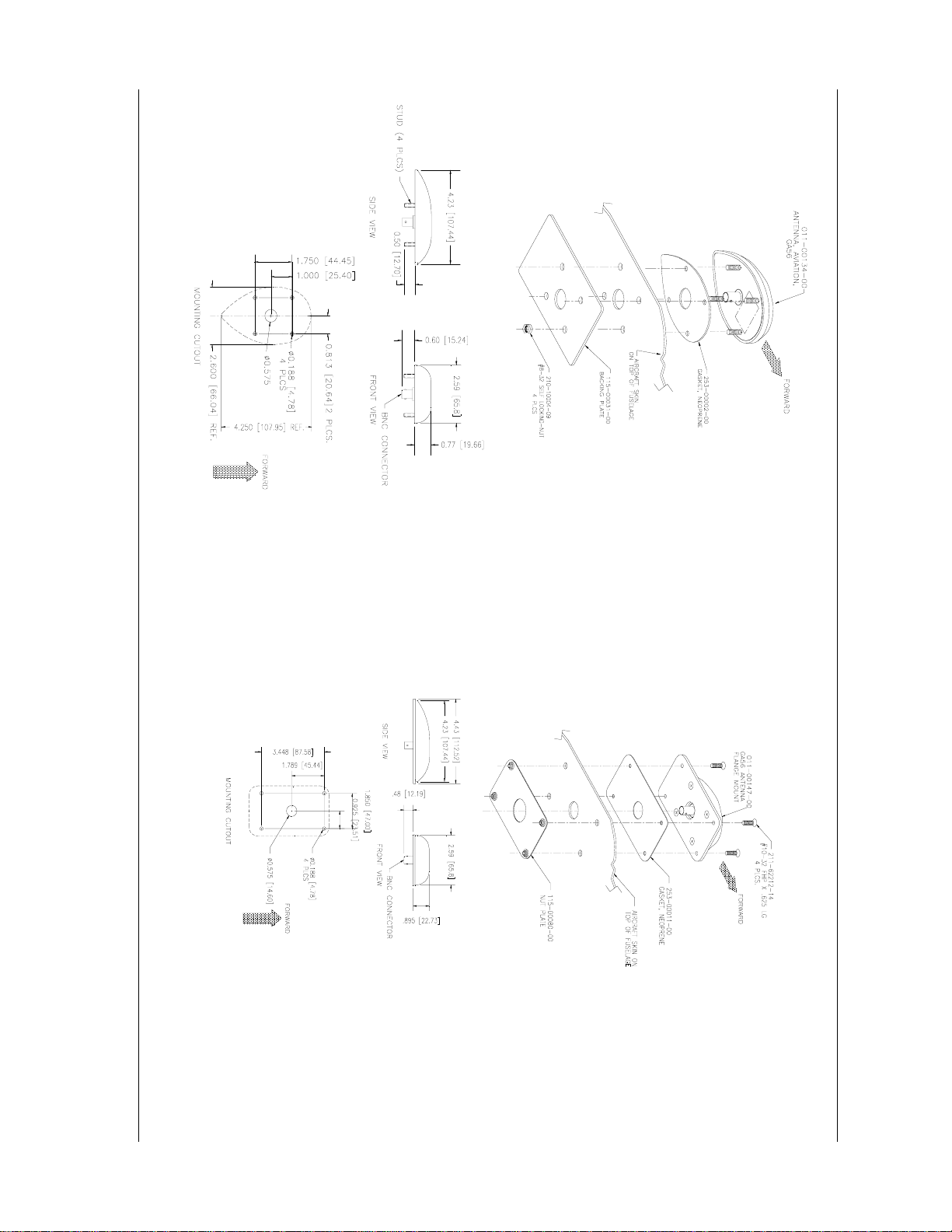

3.10 GA 56 Antenna Installation Drawing

Figure 3-2. GA 56 Antenna Installation Drawing

Page 30

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-11 (Page 3-12 blank)

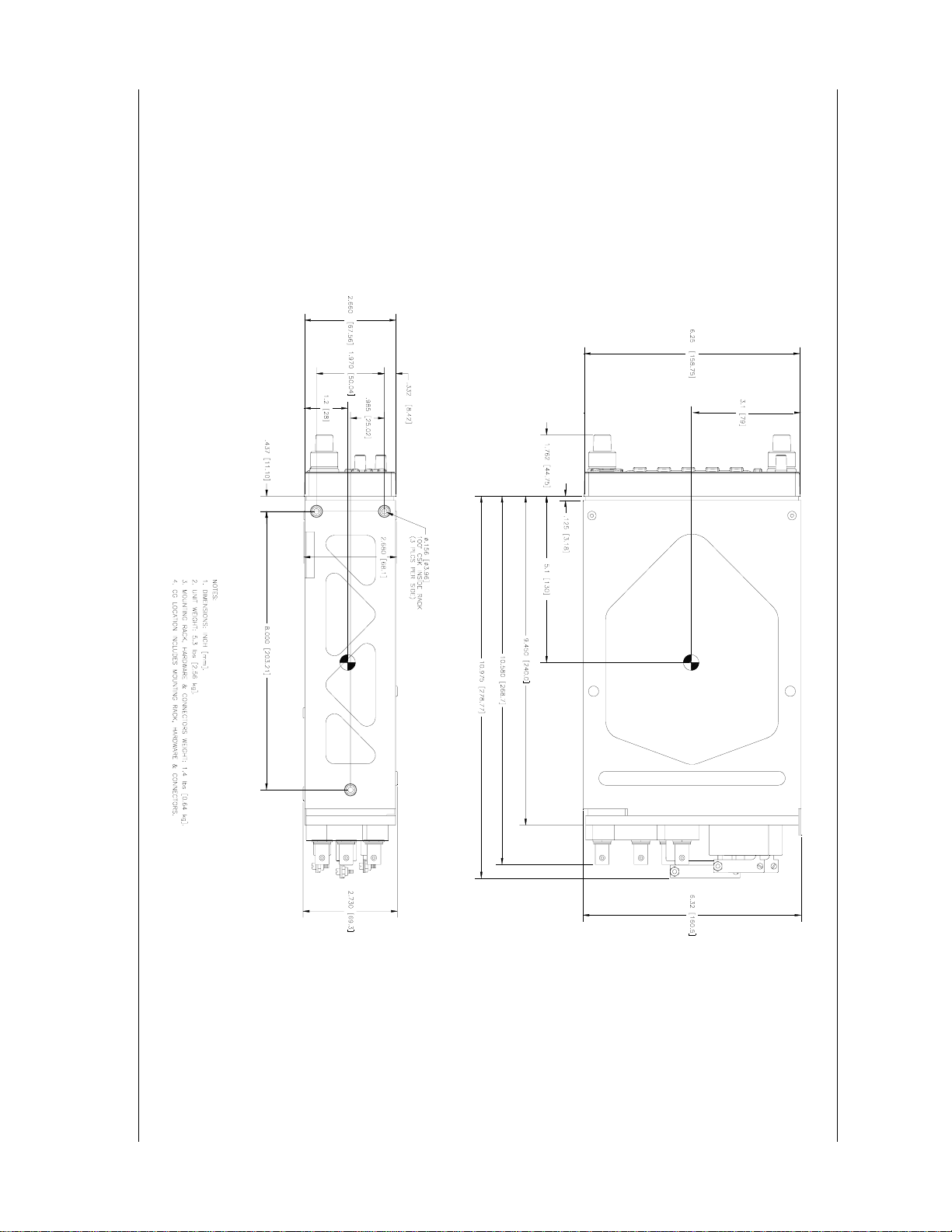

3.11 Mounting Rack Dimensions

Figure 3-3. GNS 430 Mounting Rack Dimensions

Page 31

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-13 (Page 3-14 blank)

Figure 3-4. GNC 420 Mounting Rack Dimensions

Page 32

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-15 (Page 3-16 blank)

Figure 3-5. GPS 400 Mounting Rack Dimensions

Page 33

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-17 (Page 3-18 blank)

3.12 Mounting Rack Installation

Figure 3-6. GNS 430 Mounting Rack Installation

Page 34

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-19 (Page 3-20 blank)

Figure 3-7. GNC 420 Mounting Rack Installation

Page 35

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-21 (Page 3-22 blank)

Figure 3-8. GPS 400 Mounting Rack Installation

Page 36

P/N 190-00140-02 Page Rev L

400 SERIES INSTALLATION MANUAL Page 3-23 (Page 3-24 blank)

3.13 Recommended Panel Cutout Dimensions

Figure 3-9. 400 Series Recommended Panel Cutout Dimensions

Page 37

4. SYSTEM INTERCONNECTS

4.1 PIN FUNCTION LIST

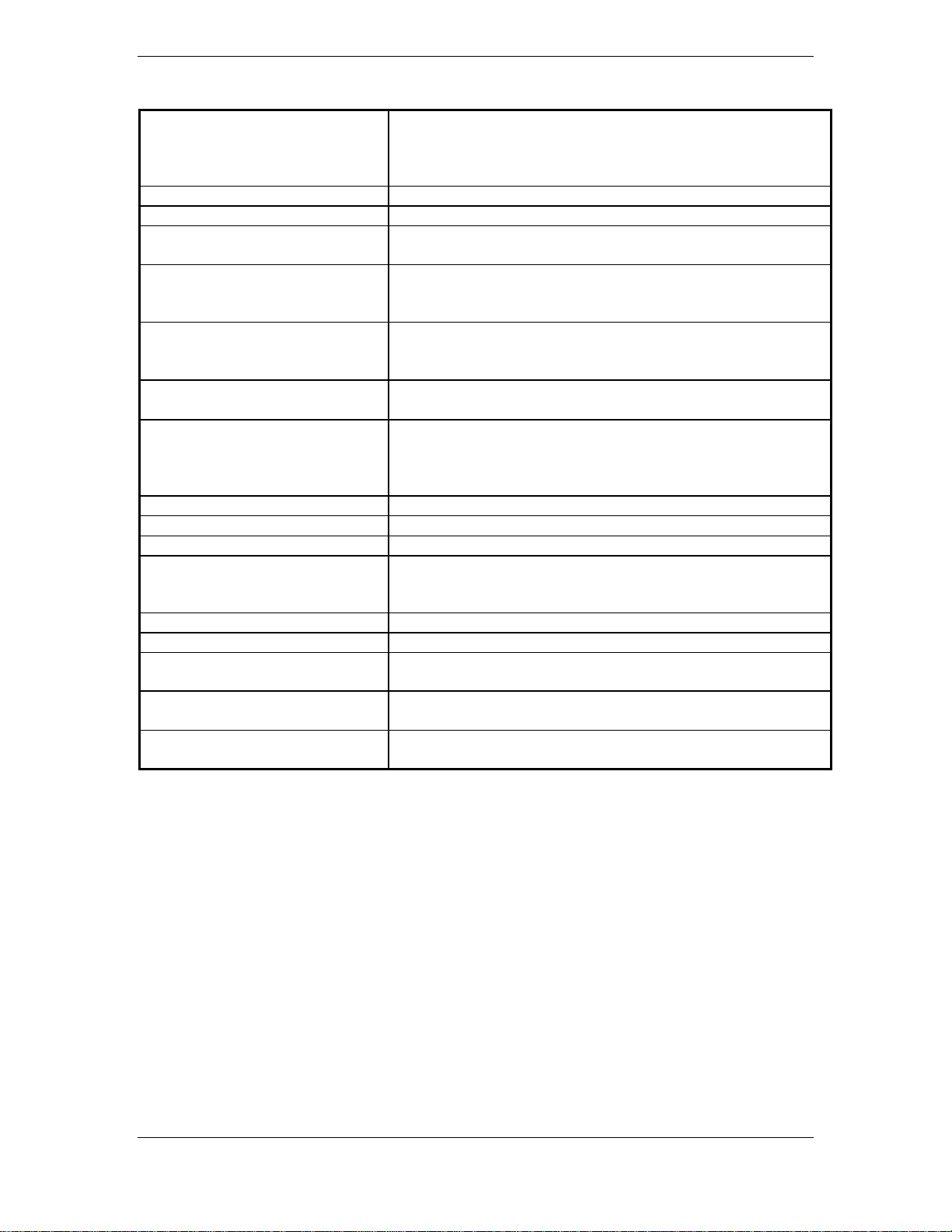

4.1.1 P4001

View of J4001 connector from back of unit

60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78

40

21 22 23 24 25 26 27

1 2 3 4 5 6 7 8 9 10 111213 14151617181920

Pin Pin Name I/O

1 VLOC ANNUNCIATE Out

2 GPS ANNUNCIATE Out

3 WAYPOINT ANNUNCIATE Out

4 TERMINAL ANNUNCIATE Out

5 APPROACH ANNUNCIATE Out

6 MESSAGE ANNUNCIATE Out

7 OBS ANNUNCIATE Out

8 AUTO ANNUNCIATE Out

9 INTEGRITY ANNUNCIATE Out

10 ANNUNCIATE D Out

11 ANNUNCIATE E Out

12 ALTITUDE ALARM ANNUNCIATE (Not implemented at time of publication) Out

13 ANNUNCIATE F (Not implemented at time of publication) Out

14 ILS/GPS APPROACH Out

15 AIRCRAFT POWER 2* In

16 TIME MARK OUT Out

17 MAIN LATERAL SUPERFLAG Out

18 MAIN VERTICAL SUPERFLAG Out

19 AIRCRAFT POWER 1 In

20 AIRCRAFT POWER 1 In

21 MAIN +LEFT Out

22 MAIN +RIGHT (2.5V COMMON) Out

23 MAIN LATERAL +FLAG Out

24 MAIN LATERAL -FLAG (2.5V COMMON) Out

25 MAIN +TO Out

26 MAIN +FROM (2.5V COMMON) Out

27 MAIN +UP Out

28 MAIN +DOWN (2.5V COMMON) Out

29 MAIN VERTICAL +FLAG Out

30 MAIN VERTICAL -FLAG (2.5V COMMON) Out

31 MAIN OBS ROTOR C Out

32 MAIN OBS ROTOR H (GROUND) Out

33 MAIN OBS STATOR D In

34 MAIN OBS STATOR E (2.5V COMMON OBS) Out

35 MAIN OBS STATOR F In

36 MAIN OBS STATOR G (2.5V COMMON OBS) Out

43 44 45 46 47 48 49 50 51 52 53 54 55 565758 59

41 42

30 31 32 33 34 35 36 37 38 39

28 29

* Applies only to part numbers 011-00280-30 (GNS 430), 011-00836-10 (GNS 430A), 011-00506-30

(GNC 420), 011-00837-10 (GNC 420A) and 011-00504-10 (GPS 400). For applications requiring

secondary or alternate power bus input.

400 SERIES INSTALLATION MANUAL Page 4-1

P/N 190-00140-02 Page Rev L

Page 38

Connector P4001, continued

Pin Pin Name I/O

37 ALTITUDE ALARM AUDIO HI (Not implemented at time of publication) Out

38 ALTITUDE ALARM AUDIO LO (Not implemented at time of publication) Out

39 LIGHTING BUS HI In

40 LIGHTING BUS LO In

41 GPS RS 232 OUT 3 In

42 GPS RS 232 IN 3 Out

43 MAIN OBI CLOCK Out

44 MAIN OBI DATA Out

45 MAIN OBI SYNC Out

46 GPS ARINC 429 OUT A Out

47 GPS ARINC 429 OUT B Out

48 GPS ARINC 429 IN 1 A In

49 GPS ARINC 429 IN 1 B In

50 GPS ARINC 429 IN 2 A In

51 GPS ARINC 429 IN 2 B In

52 RESERVED -53 RESERVED -54 GPS RS 232 OUT 4 Out

55 GPS RS 232 IN 4 In

56 GPS RS 232 OUT 1 Out

57 GPS RS 232 IN 1 In

58 GPS RS 232 OUT 2 Out

59 GPS RS 232 IN 2 In

60 ALTITUDE COMMON (GROUND) Out

61 ALTITUDE C4 In

62 ALTITUDE C2 In

63 ALTITUDE C1 In

64 ALTITUDE B4 In

65 ALTITUDE B2 In

66 ALTITUDE B1 In

67 ALTITUDE A4 In

68 ALTITUDE A2 In

69 ALTITUDE A1 In

70 ALTITUDE D4 In

71 OBS MODE SELECT In

72 AIRCRAFT POWER 2* In

73 CDI SOURCE SELECT In

74 RESERVED -75 DEMO MODE SELECT In

76 RESERVED -77 AIRCRAFT GROUND -78 AIRCRAFT GROUND --

* Applies only to part numbers 011-00280-30 (GNS 430), 011-00836-10 (GNS 430A), 011-00506-30

(GNC 420), 011-00837-10 (GNC 420A) and 011-00504-10 (GPS 400). For applications requiring

secondary or alternate power bus input.

Page 4-2 400 SERIES INSTALLATION MANUAL

Page Rev L P/N 190-00140-02

Page 39

4.1.2 P4002 (GNC 420 and GNS 430 Only)

View of J4002 connector from back of unit

4321

161514

12111098765

13

25

23222120191817

24

Pin Pin Name I/O

1 RESERVED --

2 RESERVED --

3 RESERVED --

4 COM MIC KEY In

5 INTERCOM MIC HI In

6 COM MIC AUDIO HI In

7

500Ω COM AUDIO HI

8 RESERVED -9 RESERVED --

10 RESERVED -11 AIRCRAFT POWER In

12 AIRCRAFT POWER In

13 RESERVED -14 TRANSMIT INTERLOCK In

15 COM REMOTE TRANSFER In

16 SPARE -17 INTERCOM MIC LO In

18 COM MIC AUDIO LO In

19

500Ω COM AUDIO LO

20 RESERVED -21 AIRCRAFT GROUND -22 AIRCRAFT GROUND -23 RESERVED -24 RESERVED -25 RESERVED --

Out

Out

400 SERIES INSTALLATION MANUAL Page 4-3

P/N 190-00140-02 Page Rev L

Page 40

4.1.3 P4006 (GNS 430 Only)

View of J4006 connector from back of unit

123456789101112131415

161718192021222324252627282930

43

44

404142

313233343536373839

Pin Pin Name I/O

1 VOR/LOC +TO Out

2 VOR/LOC +FROM (VOR/LOC COMMON) Out

3 VOR/LOC +FLAG Out

4 VOR/LOC -FLAG (VOR/LOC COMMON) Out

5 VOR/LOC +LEFT Out

6 VOR/LOC +RIGHT (VOR/LOC COMMON) Out

7 RESERVED -8 VOR/LOC COMPOSITE OUT Out

9 VOR OBS ROTOR C Out

10 VOR OBS ROTOR H (GROUND) Out

11 VOR OBS STATOR E/G (VOR/LOC COMMON) In

12 VOR OBS STATOR F In

13 VOR OBS STATOR D In

14 PARALLEL DME - 8MHZ Out

15 VOR/LOC SUPERFLAG Out

16

500Ω VOR/ILS AUDIO HI

17

500Ω VOR/ILS AUDIO LO

18 SERIAL DME CLOCK Out

19 SERIAL DME DATA Out

20 SER DME - CHAN REQ/PAR DME - 4MHZ I/O

21 SER DME - RNAV MODE/PAR DME - 2MHZ I/O

22 DME COMMON In

23 VOR/ILS ARINC 429 OUT B Out

24 VOR/ILS ARINC 429 OUT A Out

25 VOR OBI CLOCK Out