Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND S680, SS680 &

SU680 SERIES RESTAURANT

RANGES AND SALAMANDERS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Part # P153 Rev 1 (02/21/08) © 2004 Garland Commercial Industries, Inc.

Part # P153 Rev 1 (02/21/08) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # P153 Rev 1 (02/21/08)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS,

MODELS S,SU & SS684 . . . . . . . . . . . . . . . . . 4

DIMENSIONS AND SPECIFICATIONS,

MODELS S,SU & SS686 . . . . . . . . . . . . . . . . . 5

DIMENSIONS AND SPECIFICATIONS,

RANGE MODELS . . . . . . . . . . . . . . . . . . . . . . . 6

DIMENSIONS AND SPECIFICATIONS,

MODELS SERC, SER-680 . . . . . . . . . . . . . . . . 7

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 8

Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rating Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 9

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Legs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilation Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation Of Range Mount Salamander . . . . . 9

Assembly of Backguard/High Shelf . . . . . . . . . . 10

Code Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Single And Three Phase Connection . . . . . . . . . 10

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

OPERATING INSTRUCTIONS. . . . . . . . . . . . 11

Operation of the Griddle: . . . . . . . . . . . . . . . . . . . . 11

Operating The Solid Hot Top . . . . . . . . . . . . . . . . 11

Operating The Sealed Hotplate

(SS/SU) Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Operation Of Standard Ovens . . . . . . . . . . . . . . . 12

Operation of the Convection Ovens. . . . . . . . . . 13

Operation of the Salamander . . . . . . . . . . . . . . . . 13

PRODUCT APPLICATION. . . . . . . . . . . . . . . 14

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Solid Hot Tops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Sealed Hotplate (SS/SU Models) . . . . . . . . . . . . .14

Standard Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

RC Convection Ovens . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE AND CLEANING . . . . . . . . 15

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Enameled Surfaces . . . . . . . . . . . . . . . . . . . . . . 15

Salamander . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

After Each Use . . . . . . . . . . . . . . . . . . . . . . . . . . 16

For Heavy Build Up . . . . . . . . . . . . . . . . . . . . . . 16

Griddle Do’s & Don’ts . . . . . . . . . . . . . . . . . . . . 16

Thermostat Calibration . . . . . . . . . . . . . . . . . . . . . . 16

Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

INITIAL OPERATION . . . . . . . . . . . . . . . . . . . 11

Preparing a New Griddle . . . . . . . . . . . . . . . . . . . . 11

Seasoning of the Griddle . . . . . . . . . . . . . . . . . . . 11

Part # P153 Rev 1 (02/21/08) Page 3

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Page 4

7-1/2"

[190mm]

REAR CABLE

ENTRANCE

3-1/2"

[829mm]

24-1/2"

[622mm]

34-1/4"

[870mm]

41"

[1041mm]

9-1/4"

[235mm]

31-3/4"

[806mm]

6"

[152mm]

60"

[1524mm]

REAR CABLE

ENTRANCE

15-1/4"

[387mm]

29"

[737mm]

3"

[76mm]

4-3/4"

[mm]

W/OPTIONAL

RC MOTOR

6"

[152mm]

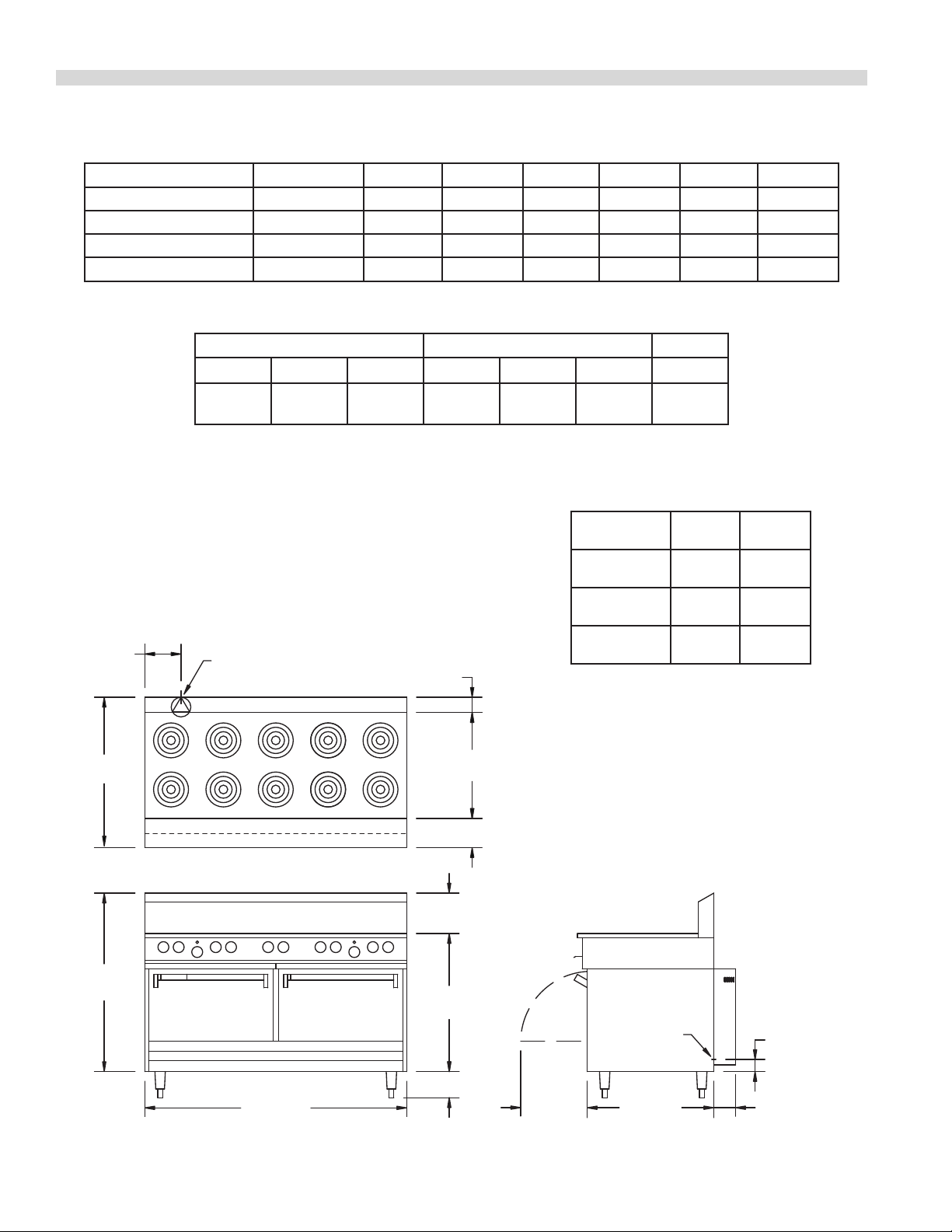

DIMENSIONS AND SPECIFICATIONS, MODELS S,SU & SS684

Model Total Kw Load 208V/1Ph 208V/3 Ph 240V/3 Ph 400 V/3N 415V/3N

S684* 27 127 76 110 66 — —

SU684** 33 157 97 136 84 60 58

SU684RC2*** 34 N/A 100 142 87 60 58

Salamander Broiler**** 7 34 23 29 20 4 4

*(all purpose tubular elements) **(Sealed -top elements, North American Model # SS684) *** Maximum on any 684 series range.

****Add when wired to range base (SER/SUER-680)

Exterior Dimensions Oven Interior Dimensions Weight

Height Width Depth Height Width Depth Lbs/Kg

47”

(1194mm)

Ratings:

Tubular Elements - Small 6-1/2” (165mm) - 1250 Watts. Large 8-1/2” (216mm) - 2100 Watts

Sealed High Performance Elements - Small 7” (180mm) - 2000 Watts. Large 8-5/8” (220mm) - 2600 Watts

Hot Top (per 12”/305mm section) - Front and Rear sections each 1675 Watts, (3350 Watts total)

Griddle (per 12”/305mm section) - 3350 Watts

Standard Oven - 4.85 kW

Convection Oven - 5.0 kW (plus 0.5kW fan motor, for 5.5kW total)

60”

(1524mm)

31-1/4”

(794mm)

13-1/2”

(343mm)

26-1/4”

(667mm)

NOTE: For ranges with convection oven(s),

(models with sux `RC’ or `RC2’), air circulation

is required for proper operation of fan motors.

These models must not be dais mounted or

installed without legs.

NOTE: Salamander can not be installed wired

from the range base on a S684 in 208/1/60.

Salamander must have a separate circuit.

NOTE: Many local codes exist, and it is the

responsibility of the Owner and the Installer to

comply with those codes.

22”

(559mm)

Installation

Clearances:

Range w/o

Salamander

Range w/

Salamander

Hot Sections

600/273

Side Back

3”

(76mm)

7”

(178mm)

10”

(254mm)

(51mm)

(51mm)

2”

2”

—

Part # P153 Rev 1 (02/21/08)Page 4

Page 5

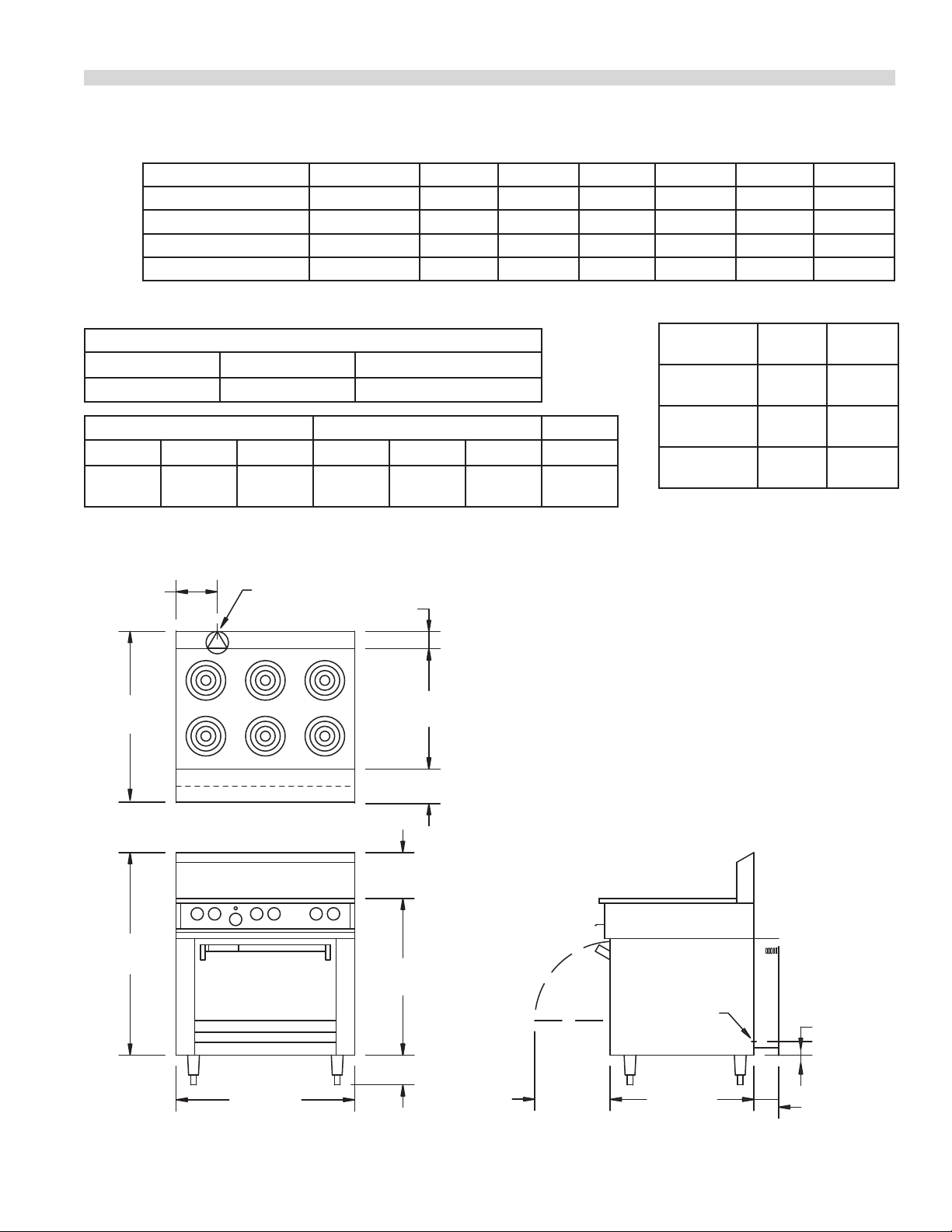

DIMENSIONS AND SPECIFICATIONS, MODELS S,SU & SS686

8-3/8"

[213mm]

34-1/4"

[870 mm]

3-1/2"

[89mm]

24-1/2"

[622mm]

REAR CABLE

ENTRANCE

41"

[1041mm]

9-1/4"

[235mm]

31-3/4"

[806mm]

6"

[152mm]

36"

[914mm]

15-1/4"

[387mm]

29"

[737mm]

3"

[76mm]

4-3/4"

[121mm]

W/OPTIONAL

RC MOTOR

REAR CABLE

ENTRANCE

6"

[152mm]

Model Total Kw Load 208V/1Ph 208V/3 Ph 240V/3 Ph 400 V/3N 415V/3N

S686* 15 72 48 62 42 — —

SU686** 19 90 59 78 52 40 38

SU686RC2*** 20 93 62 80 54 40 38

Salamander Broiler**** 7 34 19 29 16 4 4

*(All purpose tubular elements) **(Sealed -top elements, North American Model # SS686) *** Maximum on any 684 series range.

****Add when wired to range base (SER/SUER-680)

Entry Clearances

Crated Uncrated Uncrated “RC” Model

45” (1143mm) 35” (889mm) 40” (1016mm)

Exterior Dimensions Oven Interior Dimensions Weight

Height Width Depth Height Width Depth Lbs/ Kg

47”

(1194mm)

NOTE: Many local codes exist, and it is the responsibility of the Owner and the Installer to comply with those codes.

36”

(914mm)

31-1/4”

(794mm)

13-1/2”

(343mm)

26-1/4”

(667mm)

22”

(559mm)

360/190

Installation

Clearances:

Range w/o

Salamander

Range w/

Salamander

Hot Sections

Side Back

3”

(76mm)

7”

(178mm)

10”

(254mm)

(51mm)

(51mm)

2”

2”

—

Ratings:

Tubular Elements: 6-1/2” (165mm): 1250 Watts

8-1/2” (216mm): 2100 Watts

Sealed High Performance Elements: 7” (180mm): 2000 Watts

8-5/8” (220mm): 2600 Watts

Hot Top (per 12”/305mm section):

Front and Rear sections each 1675 Watts,

(3350 Watts total)

Griddle (per 12”/305mm section): 3350 Watts

Standard Oven: 4.85 kW

Convection Oven: 5.0 kW (+0.5kW fan motor; for 5.5kW total)

NOTE: For ranges with convection oven(s), (models with sux `RC’ or

`RC2’), air circulation is required for proper operation of fan motors.

These models must not be dais mounted or installed without legs.

Part # P153 Rev 1 (02/21/08) Page 5

Page 6

S/SS/SU 686/684 RC (2) -(1,2,3) (L,C,R) -(12,24,36) (L,C,R)

-12 = 12" (305 mm) wide griddle

-24 = 24" (610 mm) wide griddle

-36 = 36" (915 mm) wide griddle

- L = griddle on left hand side of range

- C = griddle in center of range

- R = griddle on right hand side of range

-1 = 12" (305mm) wide solid top

-2 = 24" (610mm) wide solid top

-3 = 36" (915mm) wide solid top

-L = Solid top on left hand side of range

-C = Solid top in center of range

-R = Solid top on right hand side of range

RC = Convection Oven

RC2 = Double convention oven base

686 = 36" (915mm) wide range

684 = 60" (1524mm) wide range

S = Sentry series range

SU = Sentry series range

CE marked design

SS = Sentry series range

with sealed top elements

DIMENSIONS AND SPECIFICATIONS, RANGE MODELS

Part # P153 Rev 1 (02/21/08)Page 6

Page 7

3"

[76mm]

REAR CABLE

ENTRANCE

34"

[864mm]

16-14"

[413mm]

1-1/8"

[29mm]

18"

[457mm]

34-1/4"

[870mm]

20-1/4"

[514mm]

36"

[914mm]

DIMENSIONS AND SPECIFICATIONS, MODELS SERC, SER-680

Model Total Kw Load

SERC, SER-680

wired independently

Installation Notes:

Clearances from combustible surfaces should be minimum 7” (178mm) from sides, 2” (51mm) from back.

Note: Salamander can not be installed wired from the range base on a S684 in 208/1/60. Salamander must have a separate

circuit.

KW Ratings

Total kW loading is 7.0 kW

7 34 29 29 25 15 15

208V/1Ph 208V/3 Ph 240V/1Ph 240V/3 Ph 400 V/3N 415V/3N

TOTAL AMPS

Model

S/SUERC 164 76

S/SUER-680 190 86

Weight

Pounds KG

Part # P153 Rev 1 (02/21/08) Page 7

Page 8

INTRODUCTION

This appliance should be given regular care and

maintenance. Periodic inspections by your dealer or a

qualied service agency are recommended.

NOTE: Many parts of the equipment are raw steel, i.e..,

griddle top and solid hot top and can react with moisture

forming rust. This is normal and not considered a defect. A

light coating of salt free oil may be applied to prevent further

rusting.

Uncrating

1. Check the crate for possible damage sustained during

transit. Carefully remove the unit from the crate and

again check for damage. Any damage to the appliance

must be reported to the carrier immediately.

2. All packing material must be removed from the unit. The

protective material covering the stainless steel must be

removed immediately, after the unit is installed.

3. All ranges are shipped from the factory with legs or

casters tted unless specially ordered without.

4. The splash back and high shelf is packed and ordered

separately.

5. Do not remove permanently axed labels, warnings

or data plates from the appliance, for this may void

approvals and create a safety hazard.

Rating Plate

The data plate is readily accessible, located behind the lower

panel on ranges & behind the drip tray on salamanders.

It contains all the pertinent information required by the

installer.

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

Safety Precautions

This manual pertains to ranges and salamanders. The reader/

operator must interpret its contents to applicable needs. If

there is any question of interpretation of any of the literature

pertaining to Garland ranges or salamanders, please contact

your authorized service agency, or our customer service

department at the phone number listed on the front of this

manual or on our web site: http://www.garland-group.com.

A qualied person must make the installation of these

products in accordance with the local codes of the country of

destination.

Always follow these safety precautions when operating the

range or salamander.

1. The Unit must only be operated by qualied persons. DO

NOT operate without reading this manual.

2. DO NOT operate the product unless it has been properly

installed and grounded.

3. DO NOT operate the product unless all service and access

panels are in place and fastened properly.

4 DO NOT attempt to repair or replace any part of this

product unless all main power supplies have been

disconnected.

WARNING: to avoid personal injury: Use Extreme caution

in setting up, operating and cleaning the product to avoid

coming in contact with the hot grill surfaces or hot grease.

Suitable protective clothing should be worn to prevent the

risk of burns.

NOTE Other Safety precautions are noted throughout this

manual, when applicable for specic operations.

Part # P153 Rev 1 (02/21/08)Page 8

Page 9

INSTALLATION

This equipment must be installed by a competent factory

trained, certied, licensed and / or authorized service

or installation person. Electrical work must be installed

by a qualied person as required by the local electrical

authorities.

WARNING: This appliance must be grounded.

CAUTION: Prior to installation check the electrical supply to

ensure the input voltage and phase match the equipment

voltage rating and phase as shown on the rating plate.

Clearances

The space in which the appliance is to be positioned must

include the minimum installation clearances to combustible

surfaces.

MINIMUM INSTALLATION CLEARANCES

Clearance To Combustible Material

Models

Location

Top * * *

Sides 3” (76mm) 10” (254mm) 7” (178mm)

Rear 2” (51mm) 2” (51mm) 2” (51mm)

* NOTE: Garland recommends equipment be installed under

a ventilation canopy

Ranges c/w Hot Top Combustible

IMPORTANT: For ranges with convention oven (models with

sux “RC”), air circulation is required for proper operation of

the fan motors. Allow 1” (25mm) rear clearance for ventilation

of the motor.

Adequate clearance must be provided for servicing,

ventilation and proper operation. The range must be kept

clear of combustible material.

Ranges

LOCATION

Models Type Of Floor Or Base

Ranges Combustible

Salamander Non-Combustible

Ranges

c/w Hot Top

Salamander

Positioning

The range should be installed on a rm, smooth and level

oor designed to withstand the weight of the fully laden

appliance.

Place the range or salamander in desired position and level

from side to side and back to front and diagonally. This

leveling must be done with the unit under the hood and in

it’s normal operating position. If the range is to be dais or

cove mounted, the base on which it is to be set should be

level. If it is not, the range must be shimmed to level.

Legs

All ranges are shipped from the factory with legs installed

unless otherwise specied. When the range is specied for

dais or cove base mounting, it is shipped less legs. Legs must

be adjusted to a minimum height of 6” (152mm) in order to

comply with NSF standards.

Casters

1. The front casters on the unit are equipped with brakes to

limit the movement of the range without depending on

the electrical connection to limit appliance movement.

2. A restraint can be attached to the unit near the electric

connection. If the restraint is disconnected, be sure to

reconnect it after the range has been returned to its

originally installed position.

Ventilation Air

The area in which the appliance is installed must be

adequately ventilated to provide air for removal of steam,

heat generated by the appliance, etc. These products are

recommended to be installed under a ventilation hood.

Proper operation of exhaust fans (proper speed, rotation and

adjustment) is essential. The hood, and the lters must be

cleaned on a regular bases and kept grease free.

Installation Of Range Mount Salamander

1. The rear of the range must be easily accessible.

2. Place the salamander in position on the range. Slide the

uprights into the opening at the oven rear. Secure the

salamander uprights to the range with the hex head bolts

provided.

3. Remove the terminal block access cover

4. Pass the wires though cable entrance hole.

5. Secure the cable connector

6. Terminate the salamander wire at the terminal block

provided (Red to L1, Black to L2 or N, Green to GRN or E).

Part # P153 Rev 1 (02/21/08) Page 9

Page 10

INSTALLATION Continued

NOTE: When mounting a salamander over an existing range

in the eld, an independent fussed connection must be

made though the knock out plate provided in the main back

of the salamander.

Assembly of Backguard/High Shelf

The back guard or high shelf will have been shipped

separately. To install, put the backguard/high self on the rear

of the range, slipping the uprights into the opening on each

burner box side. Fasten the upright to the burner box side

with four hex fasteners provided.

Code Requirements

The Garland S/SS680 series complies with the standards CSA

C22.2 no.109 – latest edition, the UL197 – latest edition and

the NSF#4 – latest edition. The installation and connection

of this appliance must comply with current codes. In Canada

– The Canadian Electrical Code Part 1 and in the USA – The

National Electrical Code.

The Garland SU680 series complies with the essential

requirements of the Directives 73/23/EEC, 89/336/EEC,

89/392/EEC, 93/68/EEC and the standards, EN60335,

IEC801.2, IEC801.3, IEC801.4, IEC801.5, IEC801.6 and

IEC801.11.

Electrical Supply

Before attempting the electrical connection, the rating plate

should be checked to ensure that the equipment’s electrical

characteristics and supply electrical characteristics agree. On

ranges and salamanders the supply entrance is located at the

rear or alternatively on the main bottom. The supply terminal

block is accessible from the front. The electrical supply must

be adequate for the voltage, phase, and current marked on

the rating plate.

NOTE: A means of disconnection from the supply having

a contact separation of at least 3 mm in all poles must be

incorporated in the xed wiring.

This equipment is intended to be installed with xed

permanent wiring.

WARNING: This appliance must be grounded.

Single And Three Phase Connection

Unless otherwise noted, all ranges are shipped from the

factory for three phase connection. Salamanders are shipped

from the factory for single phase connection. A wiring

diagram is attached to the rear of each appliance. Visually

check all electrical connections. The range is wired at the

factory as specied on the order. If it is necessary to change

the phasing refer to the wiring diagram.

Commissioning

Ensure all circuit breakers located in the lower compartment

are set to the ON (1) position

1. Ensure that all controls are in the OFF position and turn

on the main electrical supply.

2. Operate each section of the range or salamander in

accordance with the instructions given in the Operating

Instructions.

3. Check that the product functions correctly and that the

voltage supply to the unit does not drop more than 5%

when all sections are operated simultaneously.

Part # P153 Rev 1 (02/21/08)Page 10

Page 11

INITIAL OPERATION

4

5

0

4

0

0

3

5

0

3

0

0

2

5

0

2

0

0

1

5

0

1

0

0

2

1

3

8

8

0

0

˚

F

2

2

0

2

0

0

1

8

0

1

6

0

1

5

0

1

2

0

1

0

0

8

0

3

0

4

0

2

1

3

8

8

0

1

˚

C

2

3

0

Preparing a New Griddle

1. Remove the protective coating on the surface using mild

detergent.

2. Thoroughly rinse the griddle with vinegar and a water

solution (3/4-cup vinegar per quart of water) and dry.

Seasoning of the Griddle

1. Using a clean cloth, rub a thin and even layer of oil into

the griddle surface. Oil should be unsalted shortening or

high temperature cooking oil.

OPERATING INSTRUCTIONS

Operation of the Griddle:

The griddle must be seasoned before initial operation.

2. Set the griddle thermostat to 130°F (55°C) and heat

griddle surface until the oil begins to caramelize (turn

a golden brown color). Once this occurs, turn the

thermostat to OFF “ ”.

3. Scrape o the caramelized oil with a standard spatula.

4. Repeat step 1, and set the griddle thermostat to 275°F

(135°C).

5. Repeat steps 2 & 3. The griddle is now seasoned and

ready for use.

Griddle Operating Control Centigrade

NOTE: Ensure the electrical supply to the appliance is turned

on.

1. Set the thermostat to the desired temperature.

Shutting the griddle down:

1. Set the thermostat to the OFF ( ) position.

Griddle Operating Control Fahrenheit

Operating The Solid Hot Top

1. Set the control dial to the desired position from MIN

- 2,3,4,5,6, - MAX.

2. The recommended pre-heat time is minutes.

Part # P153 Rev 1 (02/21/08) Page 11

Shutting The Solid Hot Top Down

1. Set the control dial to the OFF ( ) Position.

Page 12

M

A

X

M

I

N

2

3

4

5

6

2

1

3

9

0

0

0

OPERATING INSTRUCTIONS Continued

1

2

3

4

5

6

2

1

3

9

1

0

0

5

5

0

5

0

0

4

5

0

4

0

0

3

5

0

3

0

0

2

5

0

2

0

0

1

5

0

2

6

8

5

9

0

0

˚

F

Solid Top/Open Top (Tubular) Operating Controls

Operating The Sealed Hotplate

(SS/SU) Models

1. Before using sealed hotplates for the rst time they

should be heated at setting 3 for ve (5) minutes. This will

harden and burn o the protective coating.

2. Set the six heat switch dial to the desired position for 1 to 6.

Shutting Down The Sealed Hot Plate:

1. Set dial to the OFF ( ) position

Sealed Hot Plate Operating Controls

Operation Of Standard Ovens

1. Set dial to desired temperature, preheat for at least 45

minutes after turning on the oven from cold.

3. Do not preheat.

SEALED HOT PLATE WATTAGES AND

APPLICATIONS

Application

Broiling,

Frying,

Braising

Simmering

Dial

Setting

6 2600 W 2000 W

5 1750 W 1400 W

4 1300 W 950 W

3 450 W 450 W

2 340 W 305 W

8 2/3”

(220mm)

7” (180mm)

Warming 1 240 W 200 W

Shutting down oven:

1. Set the dial to the OFF ( ) Position.

Oven Operating Controls Fahrenheit

Part # P153 Rev 1 (02/21/08)Page 12

Page 13

2

9

0

2

6

0

2

3

0

2

0

5

1

7

5

1

5

0

1

2

0

9

5

6

5

2

6

8

5

9

0

1

C

˚

OPERATING INSTRUCTIONS Continued

1

2

3

2

6

9

3

0

0

0

Oven Operating Controls Centigrade

Operation of the Convection Ovens

Starting the Oven:

1. Set the cook/cook switch to the “Heat” position.

2. Set Thermostat to the desired temperature.

3. Preheat the oven thoroughly before use (at least 30

minutes).

B. Since the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, the heat from the blower wheel is

conducted down the shaft and into the armature of the

motor. This action could shorten the motor life.

C. We recommend, at the end of the bake or roasting period

or before shutting down completely, that the doors

be left open. Set the fan switch to the “COOL DOWN”

position. The fan should run for at least 20 minutes. The

“FAN” should never be turned “OFF” when the oven is

“HOT”.

Operation of the Salamander

1. Set the three heat switch to the desired position from –

1 (MIN), 2, 3 (MAX).

2. Allow the salamander to preheat before adding product

Shutting the salamander down

1 Set the three heat switch to the OFF ( ) position.

2. Turn the switches to the o position when the unit is not

in use.

Shutting down:

1. Set the thermostat dial to the OFF ( ) position.

2. Open doo.r

3. Activate power to the cool down.

The motor on your range convection oven is maintenance

free since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions to

follow on the care of your motor.

A. When the motor is operating, it cools itself internally by

air entering the rear of the motor case, provided proper

clearance has been allowed.

Part # P153 Rev 1 (02/21/08) Page 13

Page 14

PRODUCT APPLICATION

The top of the range is designed for exibility and the

preparation of numerous types of products.

Griddles

Griddle tops are designed to have food cooked directly on

the surface. Do not put pots or pans on the griddle surface as

this will scratch or nick the surface and will result in improper

cooking or sticking of the product. Never salt food over the

griddle since this will build up gummy residue making it

dicult to clean.

Avoid hitting the surface of the griddle with the edge of a

spatula, since this will cause nicks. The most frequently used

temperatures are 300° F to 350° F (149° C to 177° C). After one

ring, the griddle plate will discolor. This is normal and will not

aect cooking performance.

Solid Hot Tops

Recommended where long term stock pot cooking is

required for soups, sauces, or stocks. Pots can be placed

anywhere on the hot top. The maximum recommended

stock pot size is 12” (305mm) diameter.

The recommended pre-heat time is 30 minutes. This will

thoroughly saturate the plate. Pots must have at bottoms

for maximum contact with the hot surface. Roasting pans

with straps should never be used on a hot top since only the

straps touch the surface and heat transfer will be minimal.

Preparation of soups, stocks, or sauces are done on the hot

top where slow even cooking is desirable. Heating larger

quantities of food can be done more eciently than heating

small quantities. Pots and pans should be covered whenever

possible to reduce the energy consumption.

High acid sauces, such as tomato should be cooked in

stainless steel vessels rather than aluminum since stainless

steel will not react chemically. Light colored sauces may be

discolored by the aluminum especially if stirred with a metal

spoon. Salty water may pit aluminum if used frequently.

Sealed Hotplate (SS/SU Models)

All-purpose sealed top elements provide and easy-clean top.

They are intended for broiling, sauté, and other range top

cooking.

Operation practices are very important for ecient use of

these elements:

1. Pot bottoms must be at. This increases the heat transfer

to the pot. Do not use pots with convex bottoms or

concave bottoms with more than 1/32” (1mm) concave.

2. Use pots with the same diameter as the element where

possible. This will reduce heat up time.

3. Do not preheat the element. Elements are protected with

a high limit, which will automatically reduce the element

to a lower power. It will increase heatup time if this

occurs.

4. Use a lid on pots when boiling water.

Standard Ovens

The temperature is automatically controlled by the

thermostat so satisfactory cooking can be repeated. For best

performance the following instructions should be followed:

Grid shelves: There are three shelf positions. The shelf

position is governed by the size of the product cooked.

Always push the shelf back into the oven until it pops making

contact with the rear of the oven.

Tray size: A cake tray may be used on each shelf. Single trays

or dishes must not be allowed to overhang the shelf in any

direction, since this will adversely aect the heat circulation.

Loading: Allow at least 45 minutes after turning the oven on

from cold, with the thermostat at the desired temperature

before loading the oven. Put the food in quickly and close

the oven door.

RC Convection Ovens

The forced air range oven improves heating eciencies by

circulating the heated air within the cooking chamber. This

reduces the temperature rise time and baking time. The oven

elements are interlocked with the door. When the fan switch

is in the heat position the elements will only operate when

the door is closed. When the fan switch is in the cool position

the fan will only operate when the door is open.

Operating suggestions for convection ovens:

1. As a general guide, set the oven temperature 25-50°

F (10-20° C) lower than temperature used in standard

ovens.

2. Cooking times may be 2% to 3% less.

Part # P153 Rev 1 (02/21/08)Page 14

Page 15

PRODUCT APPLICATION Continued

3. Keep a close check on any product being prepared for the

rst time. The size of the load, temperature of the product

going in, and moisture content are major factors that

inuence necessary cook times and temperatures.

4. Record successful times and temperatures for future

reference.

5. Preheat the oven thoroughly before use (at least 30

minutes).

6 Allow air circulation around the product. Center pans on

oven racks.

MAINTENANCE AND CLEANING

7. Never place pans directly on the oven bottom.

8 Do not use a deep pan for shallow cakes, cookies, etc. as

heat circulation across the top of these items is essential

for browning.

9. When rethermalizing frozen products, preheat oven to

50° F (10°C) higher than the cooking temperature to

compensate for heat loss before and after loading. Return

thermostat to the cooking temperature after loading.

General

Grease the door hinges and check for loose fasteners.

Tighten as necessary.

Cleaning

WARNING: this appliance must not be cleaned with a water jet.

Stainless Steel

Stainless steel should be cleaned using mild detergent, a soft

cloth and hot water. If it is necessary to use a non-metallic

scouring pad, always rub in the direction of the grain in the

metal to prevent scratching. Wash a small area at a time and

rinse the washed area with a clean sponge dipped into a

disinfectant and wipe dry with a clean soft cloth before it can

dry.

Use only stainless steel, wood, or plastic tools to scrape o

heavy deposits of grease or oil. Do not use ordinary steel

scrapers or knives as particles of iron may become imbedded

and rust. NEVER USE STEEL WOOL.

Enameled Surfaces

Establish a regular cleaning schedule. Any spills should be

wiped o immediately. The unit should be allowed to cool

down before cleaning any exterior surfaces. Wipe exposed

cleanable surfaces when cool with mild detergent and

hot water. Stubborn residue spots may be removed with a

scouring pad. Dry thoroughly with a clean cloth.

Salamander

1. Clean the salamander racks as soon as possible after

cooking with tomato or vinegar based products, which

have a high acid content. These foods can cause pitting of

the rack surface.

2. Drain and clean drip tray frequently. Excessive oil drain o

can cause spillover.

Ovens

Clean the oven racks and guides with hot soapy water and

dry thoroughly. Clean the oven interior with oven cleaner

following instructions.

Part # P153 Rev 1 (02/21/08) Page 15

Page 16

MAINTENANCE AND CLEANING Continued

Griddles

After Each Use

1. Using a traditional 2 1/2” – 3” (64mm –76mm) scraper

or spatula, scrape the griddle surface (to remove food

particles and oil residues) towards the grease trough

using even front to back strokes. Deposit debris into the

chute.

2. Pour shortening or oil onto the griddle surface using

straight front to back motion. Clean the griddle using a

griddle stone or grill screen. Always wipe with the grain

of the steel, never sideways.

3. Using a clean cloth, rub a thin and even layer of oil into

the griddle surface.

4. Remove the grease drawer, empty and wash thoroughly

with soap and water. Replace.

For Heavy Build Up

NOTE: After using cleaners and grease cutters, re-season the

griddle.

Apply to a warm griddle for best results.

1. Using a traditional 2 1/2” – 3” (64mm –76mm) scraper

or spatula scrape the griddle surface (to remove food

particles and oil residues) towards the grease trough

using even front to back strokes. Deposit debris into the

chute.

Griddle Do’s & Don’ts

Do’s

1. Season the griddle. This will prevent food from sticking

and make it easier to keep the surface clean.

2 Keep the surface clean. Scraping the surface thorough

out production to clear foods and oils prevents build up

and will make it easier to keep the surface clean.

3. Turn the temperature down during slow periods.

Reducing the temperature or turning sections o during

slow times will conserve energy and prevent the plate

from overheating.

Don’ts

1. Do not use salt to clean the griddle surface, Salt is

corrosive and can cause pitting of the griddle.

2 Do not allow metal utensils (Spatula, scraper, etc.) to

nick and/or dent the surface of the griddle. The edges of

these utensils are sharp and will create divots that oil can

collect and caramelize with will cause sticking.

3. Do not use the griddle as a hot top. A large pan or pot will

trap heat and can cause the griddle plate to warp.

4. Do not over heat the griddle to preheat faster. Preheating

only takes 15-20 minutes.

Thermostat Calibration

2. Apply griddle cleaner evenly over the griddle surface and

let sit as directed. Follow the procedures on the label of

the specic cleaning product.

3. Using a traditional scraper or spatula, slosh around the

griddle cleaner to remove the build up.

4. Scrape the griddle surface towards the grease trough

using even back to front stokes. Repeat step 2 if

necessary.

5. Using mild detergent, clean the surface and rinse

thoroughly with water and vinegar solution. Dry griddle.

6. Using a clean cloth rub a thin and even layer of oil into

the griddle surface.

7. Re-season the griddle as detailed in initial cleaning. The

griddle is now ready for use.

WARNING: Turn o the electrical mains before

commencing any service work.

Oven

It is normal for an electromechanical thermostat to cycle with

a 45°F - 50° F (25°C - 28°C) range when checking calibration

allow the thermostat to cycle a minimum of two times.

1. Place the thermocouple of the test instrument in the

center of the oven.

2. Turn the oven temperature control dial to 400° F (205°

C). In order to allow the oven temperature to stabilize,

the oven control must be allowed to cycle twice before

taking a test reading.

3. Check the temperature reading just when the control

cycles “OFF” as indicated by the cycling pilot lamp. If the

temperature does not read with in 15° F (8°C) of the dial

setting, recalibrate as follows:

Part # P153 Rev 1 (02/21/08)Page 16

Page 17

Dial Shaft

Calibration Screw Head

Calibration

Screw Head

Increase

Decrease

1/4" Turn

MAINTENANCE AND CLEANING Continued

4. Carefully remove the thermostat dial, not disturbing the

dial setting.

5. Hold the thermostat shaft steady with a small at blade

screw driver. Turn the calibration screw located inside the

shaft clockwise to decrease the temperature and counter

clockwise to increase the temperature. NOTE: each ¼ turn

of the screw will create a change of approximately 35° F

(20°C).

6. Replace the thermostat dial and repeat steps 1 though 3

to verify that the correct adjustment has been made.

Griddle

1. Use a test instrument with a special disc type

thermocouple or a reliable surface type pyrometer. NOTE:

a drop of oil on the face of the disc will provide better

contact with the plate.

2. Set all griddle thermostats to 350°F (177°C). In order

to allow the griddle temperature to stabilize, the

thermostats must be allowed to cycle twice before taking

a test reading.

3. Check the griddle temperature when the thermostat just

cycles “OFF” by placing the thermocouple rmly on the

griddle directly about the sensing bulb of the thermostat.

The reading should be between 335° F (168°C) and 365°

F and (185°C). If the reading is outside of these limits,

calibrate as follows:

4. Carefully remove the dial, not disturbing the shaft

position.

5. Hold the shaft steady and with a small at screw

driver turn the calibration screw located inside the

shaft clockwise to decrease temperature and counter

clockwise to increase temperature. NOTE: Each ¼ turn

of the screw will create a change of approximately 35° F

(20°C).

6. Replace the thermostat dial and repeat steps 1 through 3

verify that a correct adjustment has been made.

Part # P153 Rev 1 (02/21/08) Page 17

Page 18

SAFETY

It is essential that the instructions in this booklet are strictly

followed for the safe and economical operation of the

equipment. If it is know or suspected that a fault exists on the

appliance then it must not be used until the fault has been

rectied by a competent person.

Part # P153 Rev 1 (02/21/08)Page 18

Page 19

Part # P153 Rev 1 (02/21/08) Page 19

Page 20

Loading...

Loading...