Garland SRW286A Installation & Operating Instructions Manual

INSTALLATION & OPERATING

INSTRUCTIONS FOR THE

GARLAND® STARFIRE SENTRY COMBINATION

RANGE,

MODEL STW286A

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

KEEP APPLIANCE AREA FREE AND CLEAR

FROM COMBUSTIBLES.

WARNING: ELECTRICAL GROUNDING INSTRUCTIONS

THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG (GROUNDING) PLUG FOR YOUR PROTECTION

AGAINST SHOCK HAZARD. IT SHOULD BE PLUGGED DIRECTLY INTO A PROPERLY GROUNDED THREE-

PRONG RECEPTACLE. DO NOT CUT OR REMOVE THE GROUNDING PRONG FROM THIS PLUG

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR TO THIS APPLIANCE.

PLEASE READ ALL SECTIONS OF THIS MANUAL AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS COMMERCIAL COOKING EQUIPMENT AND MUST BE INSTALLED BY

PROFESSIONAL PERSONNEL AS SPECIFIED.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING

WARNING:

THIS EQUIPMENT.

For Your Safety:

Post in a prominent location, instructions to be followed in the event the user smells gas.

This information shall be obtained by consulting your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent using genuine

Garland replacement parts. Garland will have no obligation with respect to any product that has been improperly installed,

adjusted, operated or not maintained in accordance with national and local codes or installation instructions provided

with the product, or any product that has its serial number defaced, obliterated or removed, or which has been modified

or repaired using unauthorized parts or by unauthorized service agents. For a list of authorized service agents, please refer

to the Garland web site at http://www.garland-group.com. e information contained herein, (including design and parts

specifications), may be superseded and is subject to change without notice.

Continuous product improvement is a Garland policy, therefore design and specifications are subject to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

4517957 Rev. 2 (06/05) Page 1

4517957 Rev. 2 (06/05) © 2005 Garland Commercial Industries, Inc.

GARLAND COMMERCIAL RANGES,

LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallowfield Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

4517957 Rev. 2 (06/05)Page 2

TABLE OF CONTENTS

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Rating Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product Usage . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . 6

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Appliances Equipped with Casters. . . . . . . . . . . 7

Ventilation & Air Supply. . . . . . . . . . . . . . . . . . 7

Gas Connection: . . . . . . . . . . . . . . . . . . . . . . . . 8

Commissioning: . . . . . . . . . . . . . . . . . . . . . . . . 9

Burner Adjustments: . . . . . . . . . . . . . . . . . . . . . 9

Griddle /Solid Hot Top Burner . . . . . . . . . . 9

Hot Top Minimum Flame Setting . . . . . . . 9

Oven Burner . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety concerns . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation Controls . . . . . . . . . . . . . . . . . . . . . 10

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preparing A New Griddle . . . . . . . . . . . . . 10

Lighting e Griddle. . . . . . . . . . . . . . . . . 11

Seasoning e Griddle . . . . . . . . . . . . . . . 11

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . 11

Solid Hot Tops (STW286A) . . . . . . . . . . . . . . 11

Lighting e Solid Hot Top . . . . . . . . . . . 11

Oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Convection Oven . . . . . . . . . . . . . . . . . . . 12

Lighting the Oven. . . . . . . . . . . . . . . . . . . 12

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . 12

Operating Suggestions. . . . . . . . . . . . . . . . . . . 12

MAINTENANCE & CLEANING . . . . . . . . . . . 12

Stainless steel. . . . . . . . . . . . . . . . . . . . . . . . . . 12

Exhaust Filter . . . . . . . . . . . . . . . . . . . . . . . . . 13

Enameled/Painted Surfaces . . . . . . . . . . . . . . . 13

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleaning instructions (After each use). . . . 13

Cleaning Instructions

(For Heavy Build Up) . . . . . . . . . . . . . . . . 13

Griddle Do’s & Don’ts . . . . . . . . . . . . . . . 13

Cleaning Burners . . . . . . . . . . . . . . . . . . . . . . 14

Griddle / Solid Hot Plate. . . . . . . . . . . . . . 14

Convection Oven . . . . . . . . . . . . . . . . . . . 14

Pilot Burner Cleaning . . . . . . . . . . . . . . . . 14

Gas Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ermostat Calibration . . . . . . . . . . . . . . . . . . 14

Oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . 16

CONVERSION INSTRUCTIONS . . . . . . . . . . 16

FAULT FINDING. . . . . . . . . . . . . . . . . . . . . . . . 17

REPLACEMENT OF PARTS . . . . . . . . . . . . . . . 18

Gas Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Door Switch . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Control Panel Rocker Switches . . . . . . . . . . . . 18

ermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Heat-On Lamp . . . . . . . . . . . . . . . . . . . . . . . . 18

Gas Control Valve. . . . . . . . . . . . . . . . . . . . . . 18

Front Cooling Fan. . . . . . . . . . . . . . . . . . . . . . 19

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ignition Control . . . . . . . . . . . . . . . . . . . . . . . 19

Hot Top Ignition Momentary Switch . . . . . . . 19

Hot Top Spark Generator . . . . . . . . . . . . . . . . 19

REPLACEMENT PARTS

IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . 20

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . 28

4517957 Rev. 2 (06/05) Page 3

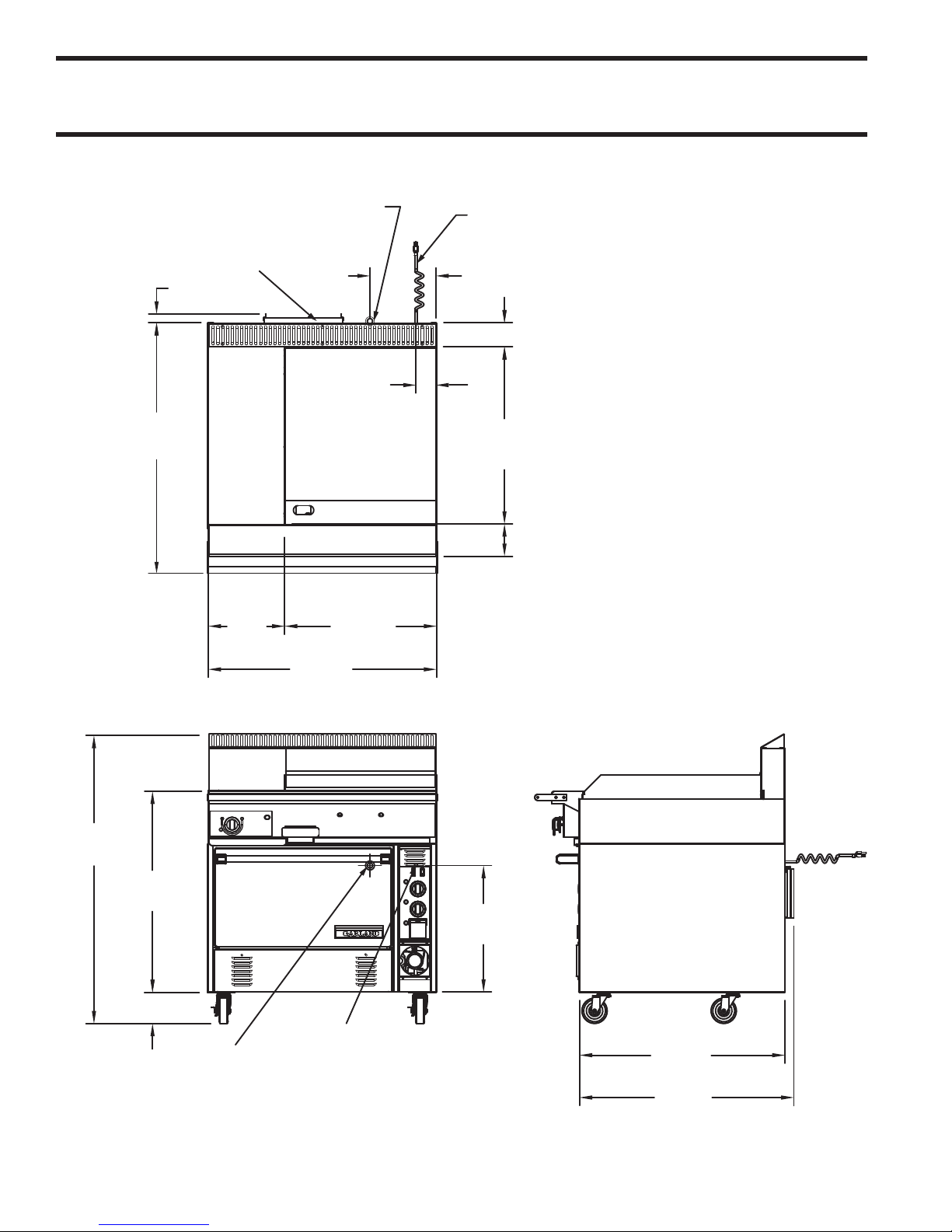

DIMENSIONS

3/4" NPT REAR

GAS INLET

10' POWER CORD

AT REAR [120V]

FAN

GUARD

10 1/2"

[267mm]

1 1/2"

[38mm]

3 3/4" [95mm]

3 1/2"

[83mm]

39 1/2"

[1003mm]

28"

[711mm]

5"

[127mm]

12"

[305mm]

24"

[610mm]

36"

[915mm]

45 1/2"

[1156mm]

31 3/4"

[806mm]

5"

[127mm]

20 1/2"

[521mm]

3/4" NPT REAR

GAS INLET

10' POWER CORD

AT REAR

32 1/2"

[825mm]

34"

[864mm]

4517957 Rev. 2 (06/05)Page 4

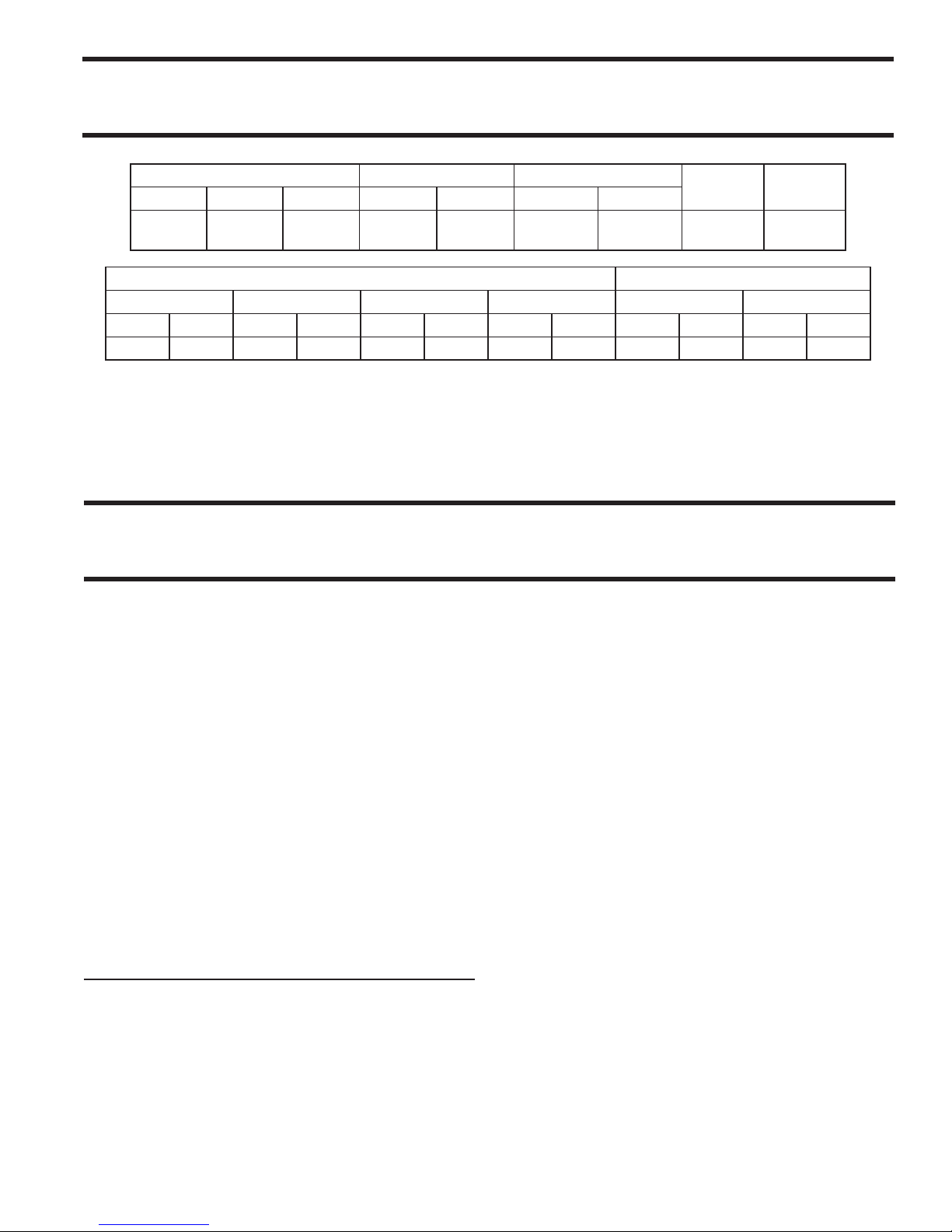

SPECIFICATIONS

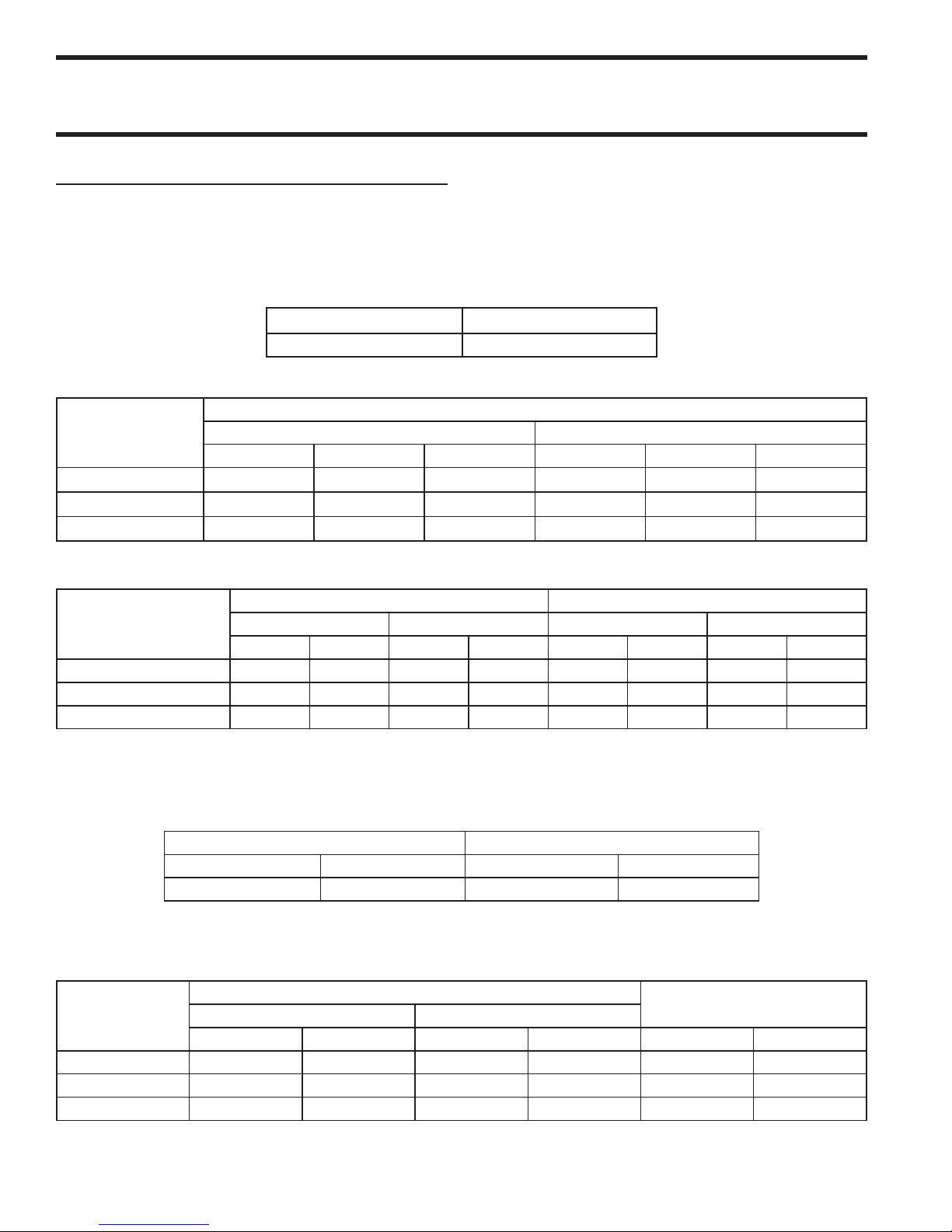

Oven Interior Dimensions Entry Clearance Installation Clearances

Height Width Depth Crated Uncrated Sides Rear

13-12"

(343mm)

Hot Top Griddle Oven Total Natural Propane

BTU kW BTU kW BTU kW BTU KW "WC mbar "WC mbar

25,000 7.32 50,000 14.65 30,000 8.79 105,000 30.76 4.5 11 10 25

NOTE: Installation clearance reductions are applicable only where local codes permit.

is product is not approved for residential use.

Commercial cooking equipment requires an adequate ventilation system. For additional information, refer to the National Fire Protection Association's standard NFPA96.

26-1/4"

(667mm)

22"

(559mm)

Input Ratings Operating Pressure

43"

(1105mm)

37-7/8"

(648mm)7"(178mm)6"(152mm)

Shipping

Weight

584lbs.

(265kg)

INTRODUCTION

is equipment must be installed and adjusted by a

competent person in accordance with the law. Failure

to install appliances correctly could lead to prosecution.

It is in your own interests and that of safety to ensure

that the law is complied with. Your Garland Dealer is

well qualified to provide this service.

is appliance should be given regular care and

maintenance. Periodic inspections by the dealer or a

qualified service company are recommended to check

temperature, burner adjustments and to ensure moving

parts are operative. Wherever possible avoid overheating

idle equipment as this is the primary cause of increased

service cost.

“Regular maintenance ensures peak performance.”

Unpacking:

1. Check crate for possible damage sustained during

transit. Carefully remove unit from crate and again

check for damage. Any damage to the appliance

must be reported to the carrier immediately.

2. e wires for retaining the burners and other

packing material must be removed from units. Any

protective material covering stainless steel parts

must also be removed.

3. All ranges are shipped from the factory with casters

fitted.

4. e type of gas and the supply pressure that the

equipment was set up for at the factory is noted on

the data plate and on the packaging. is type of

gas supply must be used.

5. Do not remove permanently affixed labels, warnings

or data plates from the appliance, for this may

invalidate the manufacturer’s warranty.

NOTE: Many parts of the equipment are raw steel i.e

griddle top and solid hot top and can react with moisture

forming rust. is is normal and not considered a defect.

Clean with a stainless steel fiber pad. A light coating of

salt free oil may be applied to prevent further rusting.

Manifold

Inlet Size

3/4" NPT

Female

4517957 Rev. 2 (06/05) Page 5

INTRODUCTION continued

Rating Plate

All burner input ratings are shown on the name/rating

plate of each range which can be located behind the lower

front kick panel, (located below oven door). To access,

remove two () fasteners securing the panel shut.

For proper operation, the fuel information on the data

plate of your new equipment must match your fuel

supply.

When corresponding with the factory or equipment

dealer regarding service problems or replacement parts,

be sure to refer to the particular unit by the correct

model number, including prefix and suffix letters and

numbers and serial number. e rating plate affixed to

the unit contains this information.

Safety

It is essential that the instructions in this booklet are

strictly followed for the safe and economical operation

of the equipment. If it is known or suspected that a fault

exists on the appliance then it must not be used until

the fault is rectified by a competent person.

Power Failure Note: In the event of a power failure, no

attempt should be made to operate the oven. e oven

is gas operated but has electrical features, motor and

door switches.

Product Usage

e top of the range is designed for flexibility and the

preparation of numerous types of products.

Preparation of soups, stocks and sauces are done on a

hot top where slow even cooking is desirable. Heating

larger quantities of food can be done more efficiently than

heating small quantities. Pots and pans should be covered

whenever possible to reduce energy consumption.

High acid sauces, such as tomato should be cooked in

stainless steel vessels rather than aluminum since stainless

will not react chemically. Light coloured sauces may be

dicoloured by the aluminum especially if stirred with

a metal spoon. Salty water may pit aluminum vessels if

used frequently.

INSTALLATION

General Information

Before assembly and connection, check gas supply.

• e type of gas for which the unit is equipped is

stamped on the name/rating plate. Connect a unit

stamped “NAT” only to natural gas, and a unit

stamped “PRO” only to propane.

• In a new installation, have the gas authorities check

meter size and piping to ensure that the gas supply

will deliver sufficient pressure to operate the unit

properly.

• When adding or replacing equipment, have gas

authorities check gas pressure to ensure that the

existing meter and piping will supply fuel to the

appliance with no more than 0.5 inch water column

pressure drop during operation

• Before turning on the main gas supply, check the

unit to be certain that all the controls are in the

“OFF” position.

• When checking gas pressure, be sure that all other

equipment on the same gas line is turned “ON.”

A preset gas pressure regulator is supplied with

GARLAND Restaurant Series Equipment. It may

be necessary to adjust the regulator to deliver fuel at

the pressure shown on the rating plate.

4517957 Rev. 2 (06/05)Page 6

INSTALLATION continued

• In Canada, the installation must comply with local

codes, or in the absence of local codes, with the

Installation Codes for Gas Burning Appliances and

Equipment CAN/CGA-B149.1 and CAN/CGA

B149.2, (latest edition), and with the Canadian

Electrical Code C22.1 (latest edition).

In the United States the installation must comply

with the National Fuel Gas Code ANSI Z223.1,

(latest edition), NFPA No. 54, (latest edition), and

the National Electrical Code ANSI/NFPA 70,

(latest edition), and/or local codes to ensure a safe

and efficient operation.

• is equipment must be electrically grounded in

accordance with local codes, or in the absence of

local codes, with National Electrical Code, ANSI/

NFPA 70, or the Canadian Electrical Code, CSA

C22.2, as applicable.

• e appliance and its individual shut-off (supplied

by others) must be disconnected from the gas

supply piping system during any pressure testing of

the system at pressures in excess of 1/2 PSIG (3.45

KPA). e appliance must be isolated from the gas

supply piping by closing its individual manual shutoff (supplied by others) during any pressure testing

of the gas supply piping system at test pressures equal

to or less than 1/2 PSIG (3.45 KPA).

• Adequate clearance must be provided for servicing

and proper operation.

Clearances

Minimum installation clearance to adjacent combustible

walls and type of floor or base:

MINIMUM CLEARANCES STW286A

LOCATION CLEARANCE

Left Hand Side 7" (178mm)

Right Hand Side 7" (178mm)

Rear 6" (152mm)

TYPE OF FLOOR OR BASE

Combustible

Location

e range should be installed on a firm, smooth and

level floor designed to withstand the weight of the fully

laden appliance. Any openings in the wall beside the

appliance should be sealed.

Appliances Equipped with Casters

• e installation shall be made with a connector

that complies with the Standard for Connectors

for Moveable Gas Appliances, ANSI Z21.69/CGA

6.16, (latest edition), addenda Z21.69a-1989, and

a quick-disconnect device that complies with the

Standard for Quick Disconnects for Use with Gas

Fuel, ANSI Z21.41/CAN1 6.9, (latest edition).

• e front casters on the appliance are equipped

with brakes to limit the movement of the appliance

without placing any strain on the connector or

quick disconnect device or its associated piping.

• Be aware; required restraint is attached to a bracket,

which is located on the rear caster closest to the

gas connection. If disconnection of the restraint is

necessary, be sure to reconnect the device after the

appliance is returned to its original position.

Ventilation & Air Supply

e area in which the appliance is installed must be

adequately ventilated to provide air for combustion,

removal of products of combustion and removal of

steam, etc. Proper ventilation is essential for optimum

performance.

e ideal method of ventilating equipment is the use

of a properly designed canopy which should extend six

inches, (mm), beyond all sides of the appliance(s) and

six feet, six inches, (mm), above the floor.

A strong exhaust will create a vacuum in the room. For

an exhaust vent to work properly, replacement air must

enter the room. e amount of air that enters must equal

the amount exhausted. All gas burners and pilots need

sufficient air to operate. Large objects should not be

placed in front of the appliance(s) which would obstruct

the flow of air into the front.

4517957 Rev. 2 (06/05) Page 7

INSTALLATION continued

Gas Connection:

e gas pipe connection is made at the rear right hand

side of the equipment. e size of the pipe work supplying

the appliance must not be less than the inlet connection

TABLE A. Gas Flow Rate (total)

NATURAL GAS ( ft3/h ) PROPANE GAS (ft3/h )

105 42

TABLE B. Heat Input Per Burner

BURNER

GRIDDLE

HOT TOP

OVEN

kW BTU/HR MJ/HR kW BTU/HR MJ/HR

7.32 25,000 26.37 7.32 25,000

7.32 25,000 26.37 7.32 25,000

8.79 30,000 31.65 8.79 30,000

NATURAL GAS PROPANE

TABLE C. Manifold Pressure / Injector Size

NATURAL GAS PROPANE

BURNER

GRIDDLE

HOT TOP

OVEN

Manifold Pressure Injector Size Manifold Pressure Injector Size

mbar "W.C. DMS mm mbar "W.C. DMS mm

11.2 4.5 42 2.4 25 10 53 1.51

11.2 4.5 41 2.45 25 10 — 1.5

11.2 4.5 35 2.8 25 10 51 1.7

which is /” NPT. An isolating valve is recommended

to be close to the appliance to allow shut down during

an emergency or routine servicing. After installation, the

complete pipe work must be checked for soundness.

NOMINAL HEAT INPUT

26.37

26.37

31.65

NOTE: e pressure must be measured at the pressure test nipple located on the main manifold, located at the

left hand front of the range where the hot top valve is situated, with all burners lit.

TABLE D. Adjustment Pressure for “MIN” Valve Position (Hot Top section)

NATURAL GAS PROPANE

mbar "w.c. mbar "w.c.

2.0 0.8 4.5 1.8

NOTE: e pressure must be measured at the test nipple located downstream of the gas valve.

TABLE E. Aeration Shutter Setting / Pilot Flame Length

BURNER

OVEN

GRIDDLE

HOT TOP

SHUTTER OPENING

NATURAL GAS PROPANE

mm Ins. mm Ins. mm Ins.

19 0.750 19 0.750 25.4 1

41.3 1.625 41.3 1.625 25.4 1

41.3 1.625 41.3 1.625 12.5 0.5

PILOT FLAME LENGTH

4517957 Rev. 2 (06/05)Page 8

INSTALLATION continued

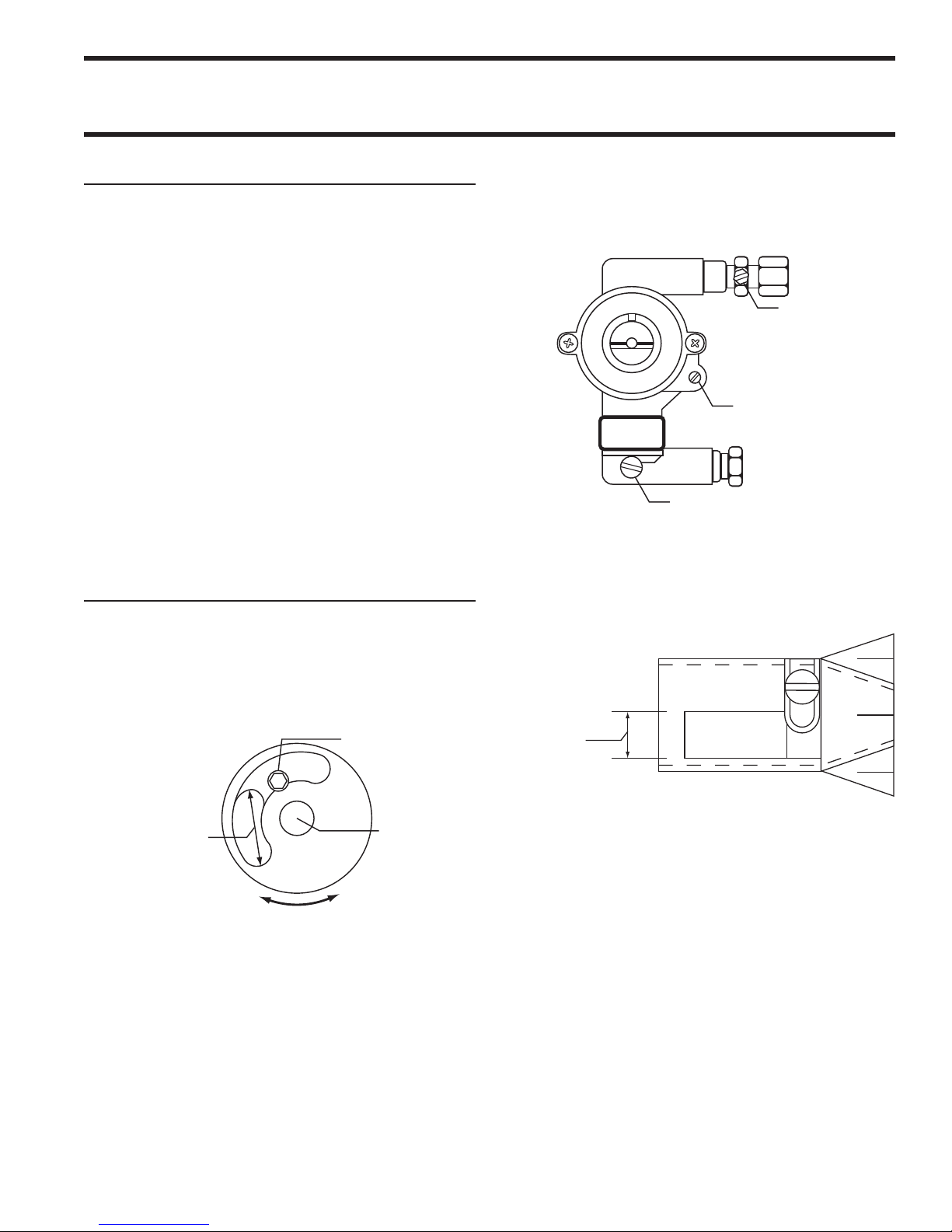

FIXING SCREW

SHUTTER

OPENING

MEASUREMENT

INJECTOR

LOCATION

TEST POINT

LOW FLAME

ADJUSTER

PILOT

ADJUSTER

SHUTTER

OPENING

MEASUREMENT

Commissioning:

e whole of the gas installation, including the meter,

should be inspected, purged and tested for leakage in

accordance with local codes.

1. Ensure that all controls are in the off position and

turn on the main gas supply and electrical mains.

2. Remove the screws securing the front fascia and

connect a U-gauge manometer to the pressure test

point on the main manifold. Operate the main

burners in accordance with the instructions given

in the User’s manual.

3. Check that the setting pressure is correct per

TABLE C on the previous page. If necessary, adjust

the pressure governor located at the rear of the

range, downstream of the shut-off valve, to give the

required setting.

Burner Adjustments:

Griddle /Solid Hot Top Burner

3. With a flat screwdriver, turn the adjuster on the

body of the tap clockwise to reduce the pressure or

anti-clockwise to increase pressure. Set the pressure

to correspond with table D.

Oven Burner

1. Check that the aeration shutter is set to the required

opening per table E. Adjust if necessary.

Check that the aeration shutter is set to provide the

required opening per table E on the previous page. Adjust

if necessary.

Hot Top Minimum Flame Setting

1. Set the gas tap to the MIN position.

2. Connect a U-gauge manometer to the pressure test

nipple located downstream of the gas tap.

When all the settings have been checked, remove the Ugauge manometer, replace the pressure test point screw

and the lower front panel.

Instruct the user or purchaser in the efficient and safe

operation of the appliance.

Tell the user of the location of the gas isolation cock

for use in an emergency. Leave this User Installation

and Servicing Instruction Manual with the user or

purchaser.

4517957 Rev. 2 (06/05) Page 9

OPERATION

OFF

IGNITION

FULL FLAME

LOW FLAME

SOLID TOP (STW286A)

5

0

0

4

5

0

4

0

0

3

5

0

3

0

0

2

5

0

2

0

0

1

5

0

2

6

2

1

4

4

0

°

F

O

F

F

OVEN/GRIDDLE TOP

Safety concerns

It is the responsibility of the supervisor or equivalent

person to ensure that users of this equipment wear

suitable protective clothing and draw attention to the

fact that some parts will by necessity become very hot

and will cause burns if touched accidentally.

Operation Controls

Griddles

Griddle tops are designed to have food cooked directly

on the surface. Do not put pots or pans on the griddle

surface as this will scratch or nick the surface and will

result in improper cooking or sticking of the product.

Never salt food over the griddle since this will build up

a gummy residue making it difficult to clean.

Avoid hitting the surface of the griddle with the edge of

a spatula since this will cause nicks. e most frequently

used temperatures are ° F (°C) to °(°C).

After one firing, the griddle plate will discolour, this is

normal and will not affect cooking performance.

Check the grease container and drain frequently during

heavy use to prevent overflow.

Preparing A New Griddle

1. Remove the protective coating on the surface using

a mild detergent.

2. oroughly rinse the griddle with vinegar and a

water solution (3/4 cup vinegar per quart of water)

and dry.

4517957 Rev. 2 (06/05)Page 10

Loading...

Loading...