Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND INDUCTION

BUILT-IN LINE

DUAL-ZONE COOKERS

with RTCSmp TECHNOLOGY

Real-time Temperature Control System

multi-point sensing

CE models comply with the latest European

Norms:

EN 60335-1, EN 60335-2-36, EN 62233 (EMC/EMV)

North American models: ETL listed in compliance

with UL 197, CSA C22.2 No.109, NSF-4

Complies with FCC part 18, ICES-001

WARNING

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY, OR DEATH.

READ THE INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT

Models:

SH DU IN 7000 (2x3500 / 7kW)

SH DU IN 10000 (2x5000 / 10kW)

PLEASE READ ALL SECTIONS OF THIS MANUAL AND

RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND MUST BE

INSTALLED BY PROFESSIONAL PERSONNEL AS

SPECIFIED

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES IN YOUR

REGIION:

IN CANADA – THE CANADIAN ELECTRICAL CODE

PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE ANSI /

NFPA – CURRENT EDITION.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER APPLIANCE

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent using only

genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been improperly

installed, adjusted, operated or not maintained in accordance with national and local codes and/or installation instructions

provided with the product or any product that has its serial number defaced, obliterated or removed, and/or which has been

modified or repaired using unauthorized parts or by unauthorized service agents. For a list of authorized service agents

and/or genuine replacement parts, please visit our website at www.garland-group.com (USA and Canadian customers) or

www.manitowocfoodservice.com (international customers). The information contained herein, including design and part

specifications, may be superseded and is subject to change without notice.

Visit our Video Gallery at

Part # 4532285 Rev 4 (4/29/14) © 2013 Garland Commercial Ranges Limited

www.Garland-Group.com

Page 2

Installation and Operation Manual RTCSmp Induction Built-In Line Dual Zone Cookers

T

WARRANTY

Our warranty statements for induction products are available on-line. Please visit our

website at www.garland-group.com/minisite/service to download the latest revision. If you

might have any questions, please contact Garland.

USING THIS MANUAL

This manual contains important information regarding safety, installation, operation,

maintenance, and troubleshooting. They must be read entirely and carefully by the

installers and operators before the equipment is installed and taken into operation. This

manual must always be available for reference at the place of operation.

Throughout this manual, the induction unit type “RTCSmp Dual Install-Line” is referred to as

“induction unit”.

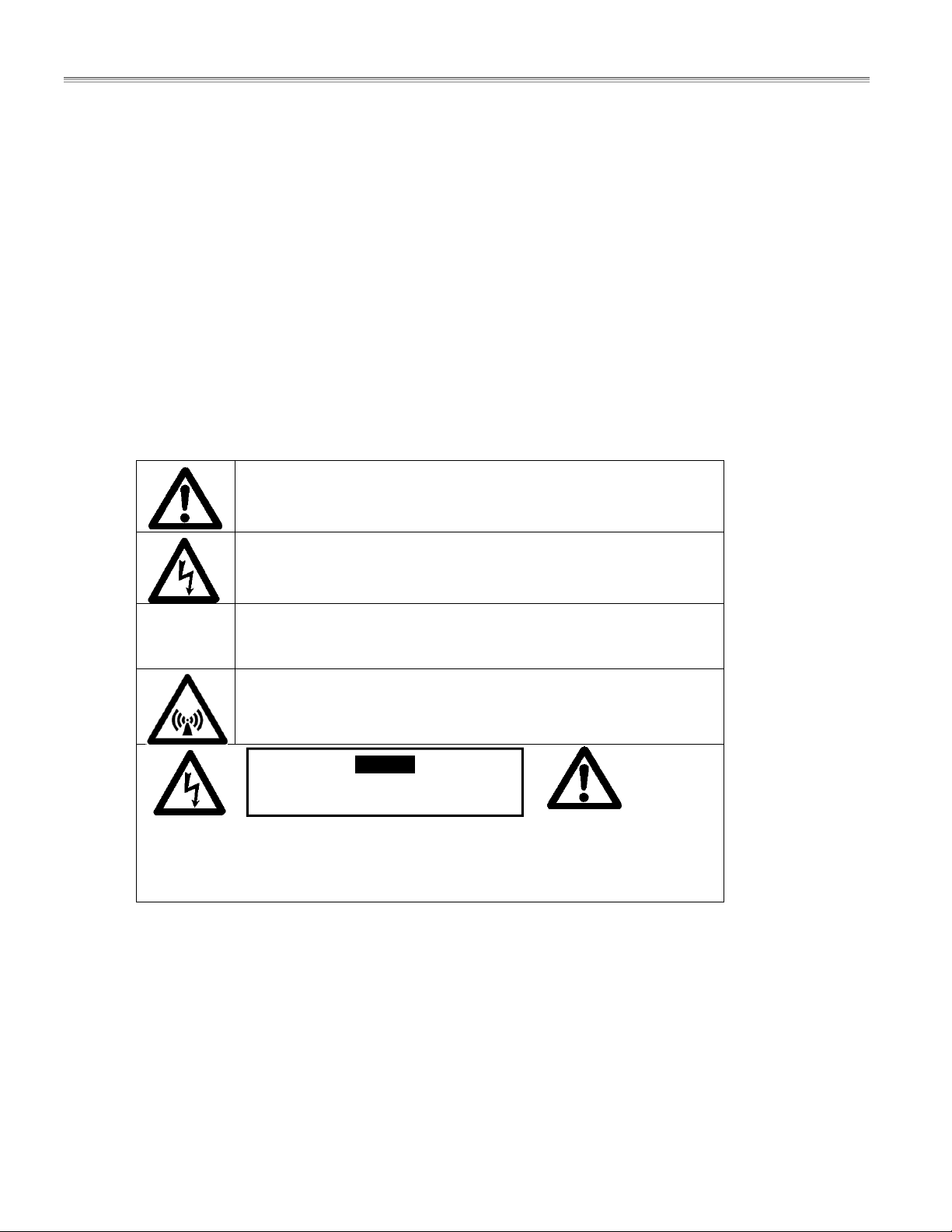

DESCRIPTION OF WARNING SYMBOLS

This symbol alerts you to a hazardous situation that WILL or COULD

cause serious bodily harm or death. Be alert and implement relevant

safety precautions.

CAUTION

CONTACTS

Garland Commercial Ranges Ltd.

1177 Kamato Road, Mississauga, Ontario, Canada. L4W 1X4

T: 1-905-624-0260 | F: 1-905-624-5669 | www.garland-group.com

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-7526

Canada or USA Parts/Service 1-800-427-6668

International Sales and Service www.ManitowocFoodservice.com

This dangerous voltage warning symbol indicates a risk of electric shock

and hazards from dangerous voltage.

his symbol alerts a hazardous situation, which if not avoided, COULD

cause minor to moderate personal injury or property damage. The

relevant safety precautions MUST be implemented at all times.

Electromagnetic field.

Risk of fire or electric shock

To reduce the risk of fire or electric shock,

do not remove or open cover.

No user serviceable parts inside.

Refer servicing to qualified personnel.

Warning

Do not open

2 Part # 4532285 Rev 4 (4/29/14)

Page 3

Installation and Operation Manual RTCSmp Induction Built-In Line Dual Zone Cookers

CONTENTS

WARRANTY ....................................................................................................................................................... 2

USING THIS MANUAL ....................................................................................................................................... 2

DESCRIPTION OF WARNING SYMBOLS ........................................................................................................... 2

CONTACTS ......................................................................................................................................................... 2

1 Safety Requirements .............................................................................................................. 4

1.1 Risk Involved By Disregarding Safety Information ............................................................................................. 4

1.2 Safety Instructions for Operator ............................................................................................................................... 4

1.3 Improper Use of the Equipment ............................................................................................................................... 5

1.4 Unauthorized Modification and Use of Spare Parts ........................................................................................... 5

1.5 Pan Detection ................................................................................................................................................................. 5

1.6 Cooking Zone Monitoring .......................................................................................................................................... 5

2 Components and Features ..................................................................................................... 6

2.1 Application ...................................................................................................................................................................... 6

2.2 Components Included ................................................................................................................................................. 6

2.3 Features ............................................................................................................................................................................ 6

3 Dimensions and Technical Specifications ............................................................................. 7

3.1 Rating Plate ...................................................................................................................................................................... 7

3.2 Nomenclature and Models ......................................................................................................................................... 7

3.3 Dimensions and Weights ............................................................................................................................................ 7

3.4 Electrical Specifications ............................................................................................................................................... 7

3.5 Operating Conditions .................................................................................................................................................. 7

3.6 Compliances .................................................................................................................................................................... 7

4 Installation .............................................................................................................................. 8

4.1 Location ............................................................................................................................................................................ 8

4.2 Ventilation ........................................................................................................................................................................ 8

4.3 Dimensions and Installation ...................................................................................................................................... 9

4.3.1 Built-In Induction Unit Installation .............................................................................................................. 9

4.3.1.1 Dimensions: Dual Zone RTCSmp Built-In SHDUIN7000 /10000 9

4.3.1.2 Top-Mount / Flush-Mount and Dimensions 9

4.3.1.3 Compartment Protection and Clearance 10

4.3.1.4 Parallel Installation and Clearance 10

4.3.1.5 Installation Steps 11

4.3.2 Control Unit Installation ............................................................................................................................... 12

4.3.2.1 Front-Mount 12

4.3.2.2 Back-Mount 12

4.3.2.3 Dimensions: Control Unit RTCSmp Built-In SHDUIN 13

4.3.3 Air Intake Kit Installation .............................................................................................................................. 13

4.3.3.1 Components 13

4.3.3.2 Installation Steps 14

4.4 Electrical Installation ................................................................................................................................................... 15

5 Function Test ......................................................................................................................... 16

6 Operating Instructions ......................................................................................................... 17

6.1 Proper Induction Cookware ..................................................................................................................................... 17

6.2 Proper Placement of Cookware on Dual Hobs .................................................................................................. 18

6.3 Power Control ............................................................................................................................................................... 18

6.4 No Pan No Heat ............................................................................................................................................................ 19

6.5 When Unit is Not In Use ............................................................................................................................................. 19

7 Cleaning ................................................................................................................................. 20

8 Maintenance .......................................................................................................................... 21

9 Important Rules .................................................................................................................... 21

10 Troubleshooting ................................................................................................................... 22

10.1 Common causes for induction unit failure ......................................................................................................... 22

10.2 Problems and Possible Causes ................................................................................................................................ 23

10.3 Indicator Lamp Flashes at Intervals (for Operators) ......................................................................................... 24

10.4 Troubleshooting with Error Codes (for Service Technicians) ........................................................................ 25

Part # 4532285 Rev 4 (4/29/14) 3

Page 4

Safety Requirements RTCSmp Induction Built-In Line Dual Zone Cookers

T

1 Safety Requirements

WARNING This product contains chemicals known to the State of California to cause cancer.

Installation and servicing of this product could expose you to airborne particles of glass

wool / ceramic fibers. Inhalation of airborne particles of glass wool / ceramic fibers is

known to the State of California to cause cancer.

IMPORTANT Warning labels mounted directly on the induction unit must be observed at all times and

kept in a fully legible condition.

IMPORTANT To ensure your work environment is safe, you must follow all of the safety instructions

contained in this manual, the existing national regulations for accident prevention with

electrical systems, as well as any relevant company-specific safety instructions.

he induction unit should only be used if and only if the

installation of the electrical system is fitted by an approved

installation contractor in accordance with specific national and

local regulations.

1.1 Risk Involved By Disregarding Safety Information

Disregarding the safety instructions may cause harm to people, the surroundings, and the induction unit. Garland

is not responsible for any damages or personal injury caused by failure to observe the safety requirements. Risks

involved when disregarding safety precautions may include:

Death or injury caused by electric shock.

Injury due to burns from contacting overheated cooking surface, cookware, or oil and grease.

Damage to the induction unit caused by using unsuitable cookware.

1.2 Safety Instructions for Operator

Please follow the following rules to avoid personal injuries and property damages:

When the unit is in use, heat transfers from cookware to the glass-top; the glass-top can become hot. To

avoid burn injuries, do not touch the heating area when the unit is in use.

The induction unit heats up cookware and cooks food quickly. Do not leave an empty pan on the unit and do

not leave the unit unattended during operation.

If the glass-top is cracked or broken, switch off the induction unit immediately and if possible and safe,

disconnect it from the power supply. Do not touch any parts inside the induction unit.

Persons with cardiac pacemakers should consult their doctors whether they are safe near an induction unit.

If the power cord is damaged, have it replaced immediately by an approved service technician.

Ensure no liquid can enter into the induction unit. Do not let water or food overflow the cooking area. Do not

use hoses to clean or power wash the induction unit or its vicinity.

Do not put any other items on the glass-top except non-empty induction cookware.

o Do not leave any object such as paper, cardboard, or cloth between the cookware and the cooking

surface, as this might start a fire.

o Metallic objects are heated up very quickly when placed on the induction unit when the unit is in

use. Do not place any objects such as closed cans, aluminum foil, cutlery, jewelry, or watches on the

induction unit when the unit is in operation.

4 Part # 4532285 Rev 4 (4/29/14)

Page 5

Safety Requirements RTCSmp Induction Built-In Line Dual Zone Cookers

T

o Do not place credit cards, phone cards, tapes, or any objects sensitive to magnetism on the cooking

surface.

o Do not place any vessels made of aluminum or plastics on the glass-top.

The induction unit has an internal air-cooling system. Do not block the air intake and exhaust openings with

objects such as cleaning cloths or containers. Any obstruction to the air intake and exhaust could cause the

unit to overheat and to switch off.

Switch the unit OFF if you take the cookware away for a while. This will prevent the heating process to start

automatically and unintentionally when a pan is placed back on the heating area. If any person needs to use

the induction unit, he/she will have to turn the unit ON intentionally.

A dirty air intake filter blocks the fresh air intake. Clean the air intake filter at least once a week or as often as

necessary. Garland’s Air Intake Filter, included in the Air Intake Kit, is dishwasher-safe.

Use only induction suitable cookware with proper sizes and made of proper material. The induction suitable

cookware should also be in good condition without any uneven, arched or partially detached bottoms.

1.3 Improper Use of the Equipment

The reliability of the induction unit can only be guaranteed when it is used properly. The induction unit must

always be operated within the limits provided in the technical specifications. Please also refer to chapter 9

Important Rules for using induction equipment.

1.4 Unauthorized Modification and Use of Spare Parts

Please contact Garland if you intend to make any changes on the induction unit. For safety reasons, always use

genuine parts and accessories approved by Garland. Any unauthorized modification as well as any installation of

unapproved components will void all warranty.

1.5 Pan Detection

Energy is transferred to cookware when the induction system detects a suitable pan on the heating area. The

green indicator light signals to communicate the Pan Detection process:

When the unit is ON without any pan on the hob, the green indicator light flashes; the unit is in pan

detection mode.

As soon as a pan is put on the hob, the heating process is engaged and the indicator light stops flashing

and remains bright. However, the indicator light will keep flashing if the unit is not detecting any pan or

an unsuitable pan is placed on the hob.

NOTE: Pan with a bottom diameter smaller than 5”(12 cm) is not detected by the system.

1.6 Cooking Zone Monitoring

Each cooking zone is monitored by multiple temperature sensors beneath the glass-top. The sensors can detect

overheated empty pans or overheated oil and grease. When this occurs, the system stops the energy supply to

the pan. You must turn the unit off and let it cool down before restarting it.

o avoid burn injuries, do not touch the unit when a pan is

CAUTION

Part # 4532285 Rev 4 (4/29/14) 5

overheated and take all the necessary precautions when

removing the overheated pan.

Page 6

Components and Features RTCSmp Induction Built-In Line Dual Zone Cookers

2 Components and Features

2.1 Application

The RTCSmp Dual Install-Line units are specially engineered as built-in cooking equipment for closed counters.

The cookers can be used for many applications such as cooking, warming, flambéing, and brazing. To guarantee

the reliability and performance of the induction equipment, please observe all safety, installation, and operation

requirements mentioned in this manual.

2.2 Components Included

1 Induction Generator with Built-in Frame and Ceran Glass-Top.

2 Control Units and 2 RJ-45 cables, each cable is 36” (914mm) long.

1 Air Intake Kit (part number 95000020 for dual models)

Installation and Operation Manual.

2.3 Features

Garland offers two power ratings— 7kW and 10kW— for the RTCSmp Dual Install-Line induction units. Built with a

robust construction, the induction units are compact and powerful with the revolutionary RTCSmp-Technology

(Realtime Temperature Control System with Multi-Point sensing). The RTCSmp Technology monitors the energy

supply, the state of the induction coil, power board, CPU, and the cooking zones in realtime. The essential features

are:

Drop-in, flush mounted design with CrNi-Steel body below counter.

High impact Ceran glass-top.

Control units are mounted separately from the built-in unit. Easy to connect with the RJ-45 cables (provided).

Integrated cooling fan keeps electronics cool.

Compact and flat profile with powerful electronics.

Thermostatically controlled overheat sensors shut off the unit preventing damage from pans cooking dry.

Instant energy transmission to the cookware only, not to the surrounding air.

Electronic output limitation continually monitors the energy transfer to the cookware, ensuring the most

efficient energy transfer possible.

Easy to install.

Simple to operate. Adjust cooking power level simply by turning the knob.

6 Part # 4532285 Rev 4 (4/29/14)

Page 7

Dimensions and Technical Specifications RTCSmp Induction Built-In Line Dual Zone Cookers

T

/

3 Dimensions and Technical Specifications

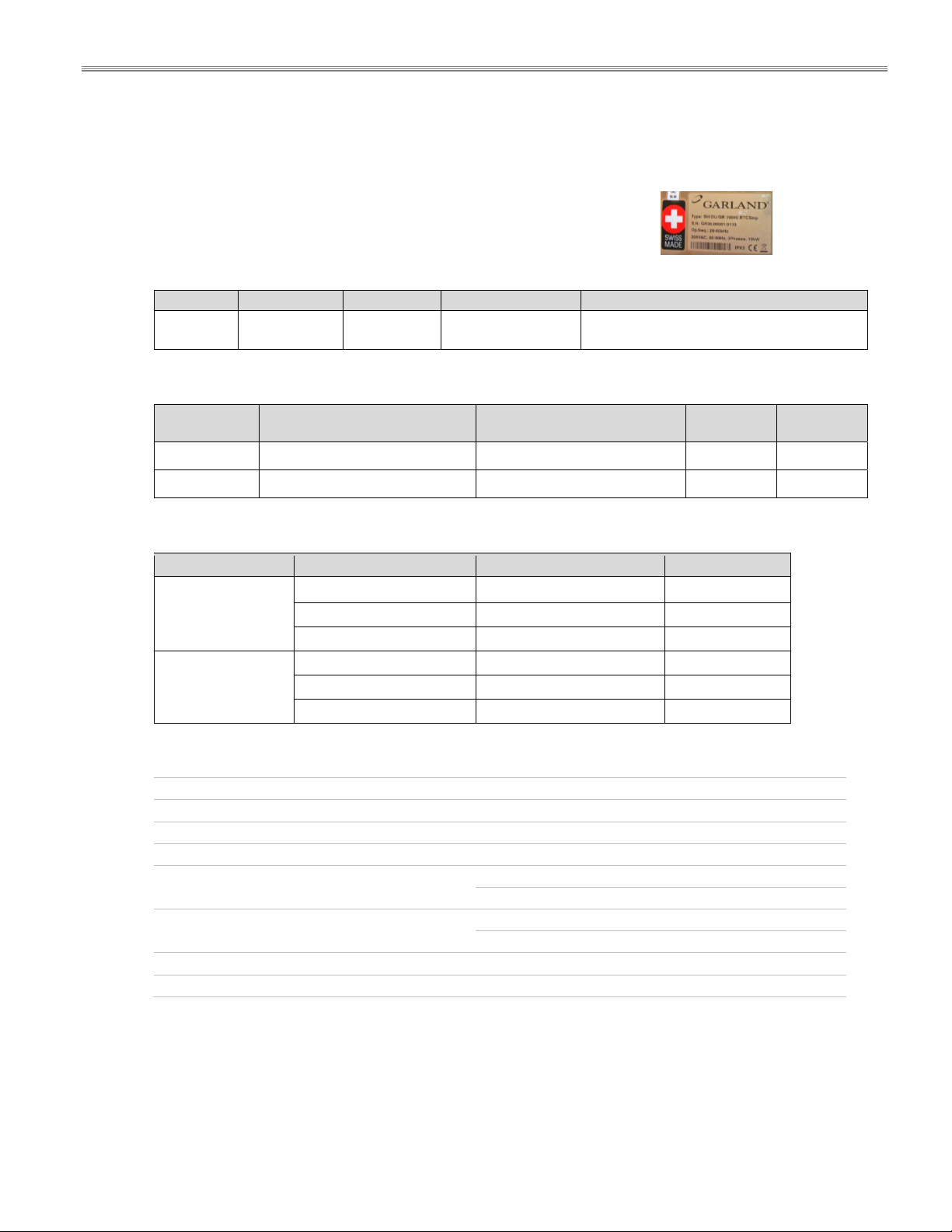

3.1 Rating Plate

he rating plate specifies important information such as the model number,

serial number, and electrical specifications. The rating plate is affixed to the

unit’s housing, close to the mains power connection on the unit.

3.2 Nomenclature and Models

Series Dual Hobs Built-In Power (Watt) Models

SH =

Slim Hob

DU

IN =

Built-In Line

3.3 Dimensions and Weights

7kW Model

10kW Model

Glass Area Only

(width x depth)

12.60” x 22.83” (320 x 580 mm) 15.12” x 25.35” (384 x 644 mm)

12.60” x 22.83” (320 x 580 mm) 15.12” x 25.35” (384 x 644 mm)

7000 (2x 3500)

10000 (2x 5000)

Glass-Top with Frame

(width x depth)

SH DU IN 7000 (2x 3500 / 7kW)

SH DU IN 10000 (2x 5000 / 10kW)

Shipping

Weight

25kg/55.1lb 23kg/50.7lb

27kg/59.5lb 25kg/55.1lb

Net

Weight

3.4 Electrical Specifications

Voltage Power Conductor Size

208 V AC / 3Ph / 60Hz 7000 W (2x 3500W) / 22A

7kW Model

10kW Model

400 V AC / 3Ph / 50Hz 7000 W (2x 3500W) / 11A 1.5mm2

440 V AC / 3Ph / 50Hz 7000 W (2x 3500W) / 10A 1.5mm2

208 V AC / 3Ph / 60Hz 10000 W (2x 5000W) / 30A AWG 8

400 V AC / 3Ph / 50Hz 10000 W (2x 5000W) / 16A 2.5mm2

440 V AC / 3Ph / 50Hz 10000 W (2x 5000W) / 15A 2.5mm2

3.5 Operating Conditions

Max. Tolerance of Nominal Supply Voltage +6 /-10 %

Supply frequency 50/60 Hz

Ingress Protection class IP X0

Minimal Diameter of Induction Pan 5” (12cm)

Maximum Ambient Temperature In Storage > -4°F to +158°F (-20°C to +70°C)

Maximum Relative Air Humidity In Storage > 10% to 90%

Clearance from Materials Min. 1.18” / 30mm

Maximum air flow: 70.63cfm/120m3per hour and min. opening: 10.075in

AWG 10

In Operation >+ 41°F to +104°F (+5°C to +40°C)

In Operation > 30% to 90%

2

6500mm2 is required.

3.6 Compliances

North American models:

ETL listed in compliance with UL 197, CSA C22.2 No.109, NSF-4. Complies with FCC part 18, ICES-001

CE models comply with the latest European Norms:

EN 60335-1, EN 60335-2-36, EN 62233 (EMC/EMV)

Part # 4532285 Rev 4 (4/29/14) 7

Page 8

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

4 Installation

IMPORTANT

Kitchen designers and installation contractors are responsible for designing and installing correctly the

appropriate support structures and ventilation system for the cooking equipment.

When designing kitchen cabinets for the induction equipment, please take into account all installation

requirements, including factors such as: ease of electrical installation, size of the power conductor, and

length of the wires.

The installation, including electrical installation, must be carried out by registered installation contractors

only. The contractors are responsible for interpreting all instructions correctly and performing the

installation in compliance with national and local regulations. The warning signs and rating plates on the

cooking equipment must strictly be followed.

Read ALL SECTIONS carefully, comply with all requirements listed and ensure all inspection is done by

qualified personnel.

Refer to the technical data given in chapter 3 Dimensions and Technical Specifications.

Induction equipment that is not installed correctly will have warranty voided. See Warranty, p.2.

4.1 Location

The induction unit must be installed securely in closed counters. IMPORTANT: Allow easy access to the

unit, the air intake filter, and the cable connections for maintenance and service.

The induction unit must be installed securely on a leveled and even counter surface.

Do not place the induction unit on or near a hot surface or any heat producing equipment such as an

oven or a deep fryer.

Protect the induction unit from steam if the unit is placed next to high steam emitting equipment such as

pasta cookers, steamers, and water bath.

Allow easy access to the control knobs and ensure the LED lights are not obstructed.

Keep the induction unit away from combustible materials, vapors or liquids.

4.2 Ventilation

Proper cool air intake and ventilation is essential to the reliability and functioning of the induction unit. Please

ensure all requirements listed below are met:

This induction unit is equipped with an internal air cooling system. Ensure the air supply and air exhaust

outlets are not blocked. CLEARANCE: minimum 1.18” (30mm).

The maximum air flow is 70.63cfm (120m

inches (6500 mm

An optimal air intake must not be restricted by the installation.

When installing the built-in unit, ensure the intake air and exhaust air are conducted separately. The in-

take air and exhaust air must not mix. To avoid build-up of hot exhaust air inside the cabinet, draw the

exhaust air out of the cabinet. Build up of hot exhaust air will cause the induction unit to reduce power

or to switch-off.

Ensure the Air Intake Kit is installed properly to guarantee cool air supply to the induction unit.

Ensure the induction unit does not take in hot ambient air from other surrounding units and appliances,

especially when the unit is installed close to heat generating equipment such as fryers or ovens.

The air intake temperature must not exceed 104F (40C).

2

) is required.

3

per hour) and therefore a minimal opening of 10.075 square

8 Part # 4532285 Rev 4 (4/29/14)

Page 9

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

T

It is highly recommended that an exhaust fan be installed into the cabinet at an appropriate location.

This will force hot air out the cabinet and away from the induction unit. Consult an electrical or

installation expert for the most appropriate location to install a cabinet exhaust fan.

4.3 Dimensions and Installation

4.3.1 Built-In Induction Unit Installation

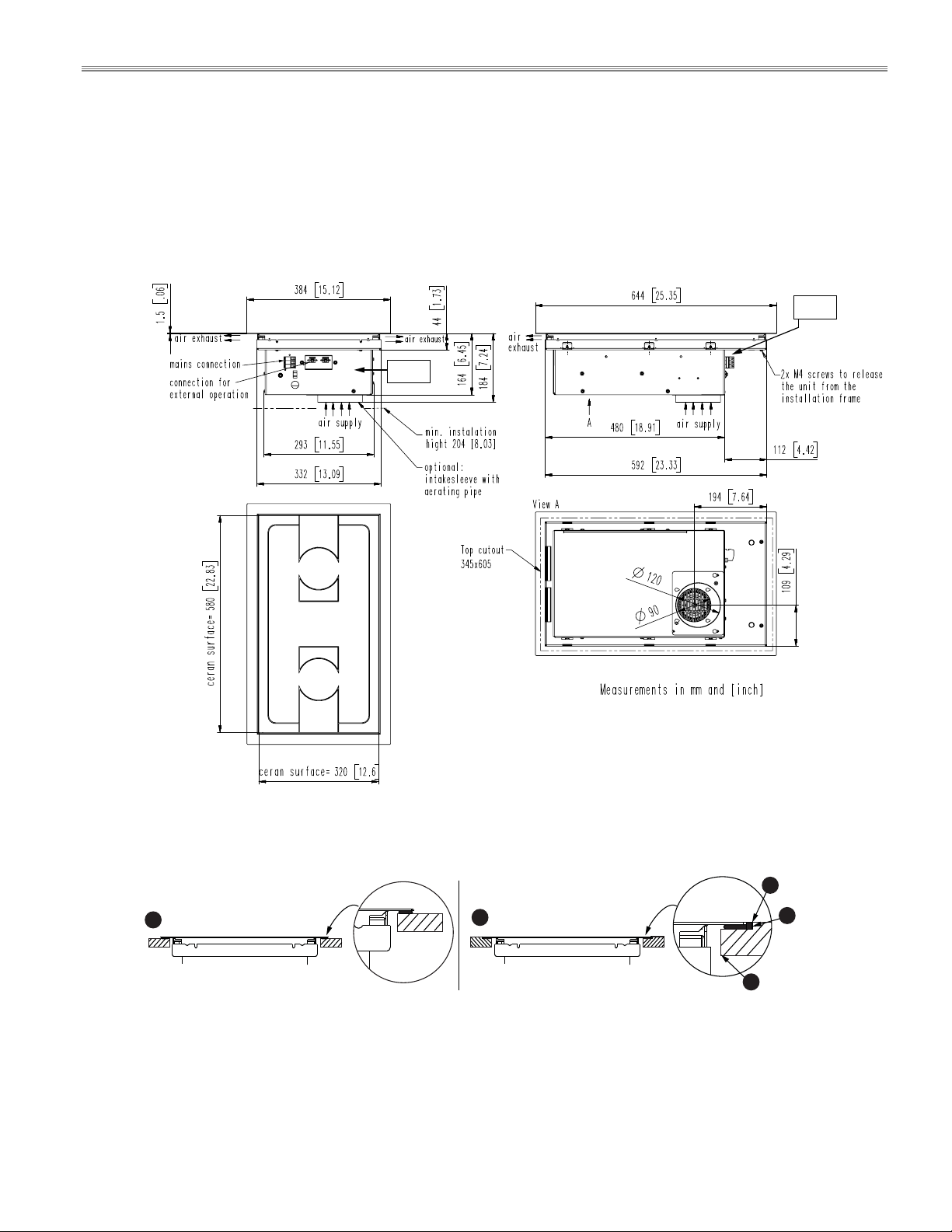

4.3.1.1 Dimensions: Dual Zone RTCSmp Built-In SH DU IN 7kW / 10kW

FRONT

FRONT

4.3.1.2 Top-Mount / Flush-Mount and Dimensions

There are two methods to install the built-in unit—top-mount (A) or flush-mount (B). The counter surface cut-out

dimensions are different for these two methods.

i

A

B

OP-MOUNT — cut-out dimensions on the

counter surface:

345 x 605mm [13.58” x 23.82”]

FLUSH-MOUNT — cut-out dimensions:

(i) Opening for flange:

minimum– 384.5 x 644.5mm [15.14 “ x 25.37”]

ii

iii

maximum– 385.6 x 645.6mm [15.18” x 25.41”]

(ii) Depth for flange: 2mm [0.079”]

(iii) Body clearance: 345 x 605mm [13.58” x 23.82”]

Part # 4532285 Rev 4 (4/29/14) 9

Page 10

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

4.3.1.3 Compartment Protection and Clearance

To protect the induction unit, the terminal block and the wire connections, we recommend isolating the unit and

the wires in a separate electrical compartment inside the cabinet.

The illustrations below show two installation versions. In Figure A, the unit is installed in one compartment and

the wires are exposed. In Figure B, the interior space of the cabinet is divided and the unit and the wires are

protected inside the upper compartment. Extra storage space is also created below the electrical compartment.

Figure

Figure

A

B

FRONT

H

F

G

F

FRONT

E

C

H

G

H H

FF

E

D

C

The call-outs in the illustrations indicate:

(C) Two methods to connect the Air Intake Kit. The duct can be connected from the unit to the bottom or to

the side of the cabinet.

(D) If there is no direct path to install the air intake duct, make an opening on an inner shelf or wall for the

duct to pass through.

(E)

IMPORTANT Minimum clearance below the counter-surface for the unit:

204mm[8.03”] (height) x 393mm[15.47”] (width) x 653mm[25.71”] (depth).

(F) Hot air exhaust from the induction unit.

(G) Air exhaust opening installed on the cabinet.

(H) Fresh air supply through the intake duct.

4.3.1.4 Parallel Installation and Clearance

For parallel installation of multiple RTCSmp SHDUIN units, a gap of minimum 12.7mm (0.5”), from flange to

flange, must be maintained between units. This minimum distance ensures proper air exhaust ventilation.

However, always leave enough space around the units in the cabinet for maintenance and service.

minimum

12.7 mm / 0.5”

FRONT

FRONT FRONT

minimum

12.7 mm / 0.5”

minimum

12.7 mm / 0.5”

FRONT

FRONT

10 Part # 4532285 Rev 4 (4/29/14)

Page 11

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

4.3.1.5 Installation Steps

NOTE Please pay attention to the orientation of the unit. All the electrical connectors are located at the

front of the unit. For parallel installation of multiple RTCSmp SH DU IN units, the units can be

installed side-to-side and front-to-back. Refer to section 4.3.1.3 Parallel Installation and

Clearance.

IMPORTANT To protect the induction unit from water penetration, you must apply and bond the silicone

adhesive properly to create a water-tight seal. Before you begin the installation, it is very

important to use isopropyl alcohol (minimum 70%) or equivalent to clean the flange and

the counter surfaces where the silicone adhesive will be applied.

To install the built-in unit:

1. Apply silicone adhesive PACTAN (Part#: 70000015, provided with the Air Intake Kit) to:

(A) TOP-MOUNT: The top of the counter surface where the built-in frame will sit.

(B) FLUSH-MOUNT: The top of the support step where the built-in frame will sit.

A

B

2. Carefully lower the induction unit into the opening and press the frame into the silicone, allowing a

complete water tight seal between the unit and the counter.

3. Ensure the countertop and the hob(s) are leveled.

4. FLUSH-MOUNT ONLY. Apply

silicone adhesive to fill the gap

completely around between the

flange and the counter surface.

Carefully wipe up any excess

silicone.

Part # 4532285 Rev 4 (4/29/14) 11

Page 12

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

4.3.2 Control Unit Installation

The induction unit comes with two complete control units — one for the front cooking zone and one for the rear

zone. Each control comes with a 36” (914mm) RJ-45 cable.

NOTE Install the control units VERTICALLY on the cabinet panel. There are two methods to install a control

unit: front-mount or back-mount onto the panel.

Installers are responsible for choosing the appropriate fasteners for the installation.

4.3.2.1 Front-Mount

To mount the control unit

onto the front of the panel:

1. Drill holes and make the

cut-out using the

dimensions and the

actual unit provided.

2. Secure the control unit to

the panel with fasteners.

Front Panel

Illustration: Measurements in

mm and [inch].

4.3.2.2 Back-Mount

NOTE For this type of installation, the maximum thickness of the panel must not exceed 1.5mm or 16 gauge.

This restriction ensures a proper grip on the knob and the LED light will not be obstructed.

10.11 [ .398]

11.91 [ .469]

12 [ .474]

maximum

1.5 [0.06]

Front Panel

To mount the control unit

onto the back of the panel:

1. Drill holes on the panel using

the dimensions provided.

2. Remove the plastic knob

from the control unit and

attach the control unit to the

panel with fasteners as

shown. NOTE: DO NOT

remove or loosen any

screws on the control unit.

Illustration: Measurements in mm

and [inch].

12 Part # 4532285 Rev 4 (4/29/14)

Page 13

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

4.3.2.3 Dimensions: Control Unit RTCSmp Built-In SHDUIN

(measurements in mm and [inch])

4.3.3 Air Intake Kit Installation

4.3.3.1 Components

An Air Intake Kit (Part Number 95000020)

is provided. The illustration shows the

components included in the kit.

To operate effectively, the induction unit

requires adequate cool air intake. See 4.1

Location and 4.2 Ventilation .

An example of an Air Intake Kit connected to a built-in induction unit:

B

I I

G

H

D

A

B

C

A

A. Cut Out Opening

E

A. Air Intake Filter

B. Air Filter Holder

C. Air Duct Holder

D. Clamp (x2)

F

E. Flex Aluminum Air Duct

F. Silicone Adhesive (PACTAN)

G

G. Caulking Gun

B. Silicone Adhesive (PACTAN)

C. Air Exhaust Opening close to the top

D. Duct mounted to the unit

C

D

E

F

E. Flex Aluminum Air Duct (max. length 244cm [96”] )

F. Air Duct Holder, Air Duct and Hose Clamp.

G. Removable Air Intake Filter and Filter Holder Mounted

onto the Cabinet

H. Fresh Air Supply

I. Hot Air Exhaust from the Induction Unit

Part # 4532285 Rev 4 (4/29/14) 13

Page 14

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

4.3.3.2 Installation Steps

1. Cut-out dimension: 9.25” x 6.50” (235mm x 165mm).

(4x)

3/16" [4.5mm]

FRONT

BACK

9" [288.6 mm]

8 3/16" [208 mm]

11" [279.4mm]

10 3/16" [258.8mm]

Cut-Out:

9.25" x 6.50"

[235 x 165 mm]

2. Mount the Air Filter Holder onto the cabinet. Then connect the Duct Holder and the Flex Duct.

NOTE: The maximum length of the air duct must not exceed 96”(244cm).

3. The Air Filter Holder is fitted with a removable Air Intake Filter. Ensure the filter is visible and easily

accessible. Please label the Air Filter or its location for the kitchen staff.

IMPORTANT The Air Intake Filter (Grease Filter) should be in visible view, easily accessible, and

4. To allow hot exhaust air to escape, install in the cabinet an air exhaust opening such as a louvered air

duct, which must be at least 1.5 times or greater than the air intake opening. Depending on the air path

and the amount of natural air movement, it is highly recommended that an exhaust fan be installed into

the cabinet to pull hot air out.

IMPORTANT Failure to provide adequate ventilation for the unit will result in the unit

labeled. A blocked filter can cause electronic damage to the induction unit. Refer

to chapter 7 Cleaning.

overheating, nuisance shutdown, and potential failure of the unit.

14 Part # 4532285 Rev 4 (4/29/14)

Page 15

Installation RTCSmp Induction Built-In Line Dual Zone Cookers

4.4 Electrical Installation

IMPORTANT

Refer to the electrical specifications in chapter 3 Dimensions and Technical Specifications AND the

markings/instruction labels on the unit. If the information differs between the data listed in the

manual and the markings on the unit, always follow the markings on the unit.

Ensure the supply voltage and the line current match the specifications given on the rating plate. A

stable mains supply must be provided.

CAUTION

The electrical connections must satisfy the national and local electrical codes.

If ground fault current protective switches are used, they must be provided with selective activation and

designed for a minimum fault current of 30mA. Multiple generators with a mains connection must not be

connected to a single fault current protective switch.

To setup the unit for operation:

1. Ensure the control knob is at the 0 (OFF) position.

2. Remove all objects from the glass-top and check that the glass-top is neither cracked nor broken.

Wrong voltage will damage the induction unit. Follow

strictly the specifications on the rating plate.

ON-Position

Any position where

“0” is not pointing to

the LED light. The

light is on.

OFF-Position

“0” is pointing to the

LED light. The light is

off.

CAUTION

Contact an authorized service agency for assistance.

3. Connecting the components:

A. Use the RJ-45 cables provided to connect the

control units to the built-in induction

generator. The black solid circle on the sticker

Do not continue if the glass-top is cracked or broken.

indicates the active zone.

B

B. The control unit connected to the LEFT

connector will control the FRONT heating

zone.

C. The control unit connected to the RIGHT

FRONT

connector will control the REAR heating zone.

D. Connect the generator to an electrical power

D

cable (G, LI, L2, L3).

4. Connect the unit to the power supply.

5. After the installation is complete, perform the Function Test. See chapter 5 Function Test.

C

FRONT

A

Part # 4532285 Rev 4 (4/29/14) 15

Page 16

Function Test RTCSmp Induction Built-In Line Dual Zone Cookers

5 Function Test

IMPORTANT

When the unit is in use, the cookware will warm up the glass-top. To

CAUTION

Remove all objects from the glass-top and verify that the glass-top is not cracked or broken.

CAUTION

Before carrying out the function test, the user must understand how to operate the unit.

Always use a pan suitable for induction cooking, having a bottom diameter of at least 5”(12cm). See 6.1

Proper Induction Cookware and 6.2 Proper Placement of Cookware on Dual Hobs.

NEVER LEAVE AN EMPTY PAN ON AN INDUCTION HOB.

To perform a function test:

1. Put some water in the pan and place it in the center of the hob.

2. Turn the control knob to a position between 1 and 12. The LED indicator lamp lights up and the water is

heated.

3. Take the pan away from the hob. Power transmission stops and the indicator lamp starts to blink.

4. Place the pan back on the heating area. The LED indicator lamp lights up continuously again and the

heating process resumes.

5. Turn the control knob to the OFF/“0”-position. The heating process stops; the indicator lamp goes off.

avoid burn injuries, do not touch the glass-top.

Do not continue if the glass-top is cracked or broken. Immediately

switch off the unit and if possible and safe, disconnect it from the

power outlet. Contact a Factory Authorized Service agency.

ON-Position

Any position where

“0” is not pointing to

the LED light. The

light is on.

OFF-Position

“0” is pointing to the

LED light. The light is

off.

NOTE: The green indicator lamp illuminates continuously when energy is being transferred to the pan.

If the indicator lamp remains off, check:

Is the induction unit connected to the power supply?

Is the control knob in an ON-Position?

If the indicator lamp keeps blinking and a pan is placed in the heating zone:

Are you using a suitable pan? See chapter 6.1 Proper Induction Cookware.

Is the pan placed in the center of the hob? See chapter 6.2 Proper Placement of Cookware on Dual

Hobs.

For further assistance, see chapter 10 Troubleshooting or call a Factory Authorized Service agency.

16 Part # 4532285 Rev 4 (4/29/14)

Page 17

Operating Instructions RTCSmp Induction Built-In Line Dual Zone Cookers

6 Operating Instructions

IMPORTANT

Induction units are more powerful, heat up pans quicker, and cook food faster than conventional cooking

equipment. Your induction unit will require different use and care than other conventional equipment. Do

not operate the induction equipment without reading this manual and follow all safety requirements. Refer

to chapter 1 Safety Requirements.

This appliance is for professional use and shall be used only by qualified personnel.

Do not put any empty cookware on the heating area when the induction unit is

ON. The induction unit heats up empty pans very quickly. Overheated empty pan

CAUTION

Induction unit offers short cooking time. When you turn the power level up, the temperature of the pan and

its contents is changed quickly. Therefore especially when you heat up oil or grease, check the cooking

process frequently to prevent the oil or grease from overheating and burning.

can cause personal injury and damages to cookware and the induction unit. See

Warranty, p.2.

To avoid overheating, always put food products or oil into the pan before turning

the induction unit on.

BROIL-DRY PROTECTION

The RTCSmp electronic temperature control monitors overheating at the pan base. When an overheated pan

(overheated oil, empty pan) is detected, energy transfer from the generator to the pan will be stopped

immediately. You must turn the unit off, let it cool down before re-starting the unit.

6.1 Proper Induction Cookware

IMPORTANT Using unsuitable cookware on the induction unit can cause the unit to fail prematurely, void

your warranty, or incur high service costs. Refer to Warranty, p.2.

IMPORTANT: CONDITION OF COOKWARE

Pans with layer separation (outward and inward bubbles), arching or partially detached bottoms must be

replaced. When these pans are used, the sensors under the glass-top cannot detect temperature correctly.

These pans will overheat the sensors below and eventually will damage them. Illustration below shows

examples of good and bad pans in cross-sections.

Material

Use cookware made of conductive and magnetic materials. If the pan bottom attracts a magnet,

the pan is suitable for induction cooking. Look for cookware that is labeled “suitable for induction”

or has an induction compatible symbol on the pan bottom.

Part # 4532285 Rev 4 (4/29/14) 17

Page 18

Operating Instructions RTCSmp Induction Built-In Line Dual Zone Cookers

Size

Minimum size: The bottom of the cookware must have a diameter of at least 5” (12cm). Otherwise, the

sensors will not detect the pan properly.

Do not use oversized pans on the induction unit. The bottom of the pan must fit the glass. When a hot,

oversized pan covers the flange and the silicone joint underneath, the heat from the pan may dry out the

silicone overtime and cause this water tight seal to break. The induction unit may fail eventually due to

penetration of liquid through the broken silicone seal.

6.2 Proper Placement of Cookware on Dual Hobs

The RTCSmp Dual Install model has two cook zones (dual hobs). Each cook-zone is equipped with the latest

RTCSmp sensor technology which enables temperature controls in realtime. To obtain the optimal results from

the sensors, you must always place the pan in the center of the hob, which is indicated by the markings on the

glass.

Pans and pots must not cover more than one cook

CAUTION

A

C

zone. Otherwise, electronic components of the

induction unit can be damaged.

B

DO NOT

(A): Place one pan over two cook-zones.

(B): Place multiple pans on a single cook-zone.

D

DO

(C) and (D): Place one pan on each hob, and each

pan is placed in the center of the hob.

6.3 Power Control

Set the desired power level by turning the control knob and the unit is immediately ready for operation. When

the green indicator lamp lights up, energy is being transferred to the cookware.

ON-Position

Any position where

“0” is not pointing to

the LED indicator

light. The LED is on.

Set and adjust the power level by turning the control knob:

Position (1) indicates minimum power.

Position (12) indicates maximum power.

18 Part # 4532285 Rev 4 (4/29/14)

OFF-Position

“0” is pointing to the

LED indicator light. The

LED is off.

Page 19

Operating Instructions RTCSmp Induction Built-In Line Dual Zone Cookers

The following Power Diagram indicates that when you increase the power level, the power output does not

increase linearly. The difference in power output between two higher power levels is much larger than that

between two lower power levels.

POWER

OUTPUT

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0123456789101112

P O W E R D I A G R A M

P O W E R LEVEL

6.4 No Pan No Heat

Energy is transferred to cookware when the induction system detects a suitable pan on the heating area. The

green indicator light signals to communicate the Pan Detection process:

When the unit is ON without any pan on the glass-top, the green indicator light flashes; the unit is in pan

detection mode.

As soon as an induction pan is put on the glass-top, the heating process is engaged and the indicator

light stops flashing and remains bright. However, the indicator light will keep flashing if the unit is not

detecting any pan or an unsuitable pan is placed on the glass-top.

When you remove the pan from the heating area, power transfer to the pan is stopped immediately.

NOTE: Pan with a bottom diameter smaller than 5”(12 cm) is not detected by the system.

6.5 When Unit is Not In Use

Best Practice: If the induction unit is not in use, ensure the control knob is in the 0 (OFF) position.

Switch the unit OFF if you take the cookware away for a while. This will prevent the heating process to

start automatically and unintentionally when a pan is placed back on the heating area. If any person

needs to use the induction unit, he/she will have to turn the unit ON intentionally.

Part # 4532285 Rev 4 (4/29/14) 19

Page 20

Cleaning RTCSmp Induction Built-In Line Dual Zone Cookers

7 Cleaning

The cleaning of the Ceran glass is identical to cleaning other similar

glass surfaces. You may use any regular glass cleaning products

available from a hardware store.

ENSURE NO LIQUID CAN ENTER into the induction

CAUTION

IMPORTANT

DO NOT USE: corrosive or abrasive cleaning agents, such as grill sprays, oven sprays, stain removers, rust

removers, scouring powder, and rough sponges.

Let the Ceran glass-top cool down before cleaning.

Ensure to remove all residues of cleaning agents from the glass-top. Use a clean moist cloth to wipe off

any such residues.

IMPORTANT Air Intake Filter

unit. Do not let water or food overflow the cooking

area. Do not use hoses to clean or power wash the

induction unit or its vicinity.

A dirty, blocked air intake filter can cause electronic damage to the induction unit. Ensure to clean the

filter at least once a week or as often as required. Garland’s Air Intake Filter is dishwasher-safe. Wipe the filter

dry before inserting it back into the Filter Holder.

Air Intake Filter

Filter Holder

PRESSPRESS

The filter is pressure fitted into the

Air Filter Holder installed onto the

cabinet.

The filter pops out when you press down on its

corners as shown. If it doesn’t move, try the opposite

corners.

Glass and Body Cleaning

1. Use razor blade scraper or non-scratching sponge to remove all residues on the glass.

When scraping, ensure you angle

your razor blade scraper at about

o

20

to 30o from the glass.

2.

Wipe the glass clean with a damp cloth.

3.

To clean the stainless steel rim, use regular stainless steel cleaners available from a hardware store.

20o - 30

o

Visual Inspection of Silicone Seal

Check the silicone seal around the glass and the flange. Call service as soon as possible if you notice:

Cracks on the silicone seal.

The silicone seal comes away from the glass or moves when you press down on the seal.

When the silicone seal is broken, water penetration can cause the induction unit to fail, and the malfunction

can cause personal harm.

20 Part # 4532285 Rev 4 (4/29/14)

Page 21

Maintenance RTCSmp Induction Built-In Line Dual Zone Cookers

8 Maintenance

Maintenance and servicing work other than cleaning

CAUTION

A good maintenance of the induction unit requires regular cleaning, care and servicing. The operator has to

ensure all components relevant for safety are in perfect working order at all times.

Best Practice: Have the induction unit examined once a year by an authorized technician.

as described in this manual must be done by an

authorized service personnel.

Do not open the induction unit – dangerous

electric voltage inside!

The induction unit may only be opened by an

authorized service personnel.

9 Important Rules

Six Simple rules to ensure reliable and repeatable performance of your induction unit:

Keep kitchen temperature below 105°F (40°C).

Never place your induction units next to any grease generating or heat generating equipment.

Clean the intake filter at least once a week or as often as required.

Use only pans that fits the glass, do not use oversized pans.

Never pre-heat the pan. Place the pan on the cooking area only when you are ready to cook.

Do not use dented pans; it will cause damages to the electronics.

Part # 4532285 Rev 4 (4/29/14) 21

Page 22

Troubleshooting RTCSmp Induction Built-In Line Dual Zone Cookers

10 Troubleshooting

Do not open the induction unit – dangerous electric

voltage inside!

The induction unit may only be opened by an

CAUTION

10.1 Common causes for induction unit failure

One or more of the following conditions may affect the function or contribute to the failure of an induction unit:

Using unsuitable cookware such as non-induction pans, oversized pans, or damaged pans.

High ambient temperature.

Inadequate ventilation causing hot air to re-enter through the air intake slots.

Dirty air intake filter.

Empty pan is left on the hob when the unit is ON.

authorized service personnel.

STOP and DO NOT USE the induction unit if any part

of the unit is cracked or broken. Turn off the

induction unit immediately and if possible and safe,

disconnect the unit from the power supply. Do not

touch any parts inside the unit.

Symptoms

When a malfunction occurs, the induction unit may be in one of the following states:

The induction unit stops working immediately.

The induction unit continues to work in a power reduction mode.

The induction unit continues to work as usual.

The green indicator light may also blink at regular intervals.

Corrective steps

Use the following sections to locate the problem area(s) and to take only the corrective action(s) indicated. Ensure

you exercise safety precautions at all time.

Only an authorized service technician would have the training and correct tools to diagnose the internal

components accurately and thoroughly. Contact a Factory Authorized Service agency for assistance. For a list of

Garland authorized service agencies, please visit our websites at www.Garland-Group.com (USA/Canadian

customers) or www.ManitowocFoodservice.com (international customers).

22 Part # 4532285 Rev 4 (4/29/14)

Page 23

Troubleshooting RTCSmp Induction Built-In Line Dual Zone Cookers

T

10.2 Problems and Possible Causes

Problem Possible Causes Action To Take By Operator

Pan does not heat, green

LED lamp is OFF (dark)

Pan does not heat, green

LED lamp is blinking.

If LED lamp blinks at

intervals, see next section.

Poor heating, green LED

lamp is ON (shining)

Unit does not react to

control knob positions

Power/heating level seems

to be reduced, fan is

working

Power/heating level seems

to be reduced, fan does

not work

After a longer permanent

operating time,

Power/heating level seems

to be reduced

Small metallic objects (e.g.

spoon) are heated up on

the cooking area.

No power supply. Check the electrical supply, e.g. power cable

plugged into the wall socket.

Check primary fuses.

Control knob is in OFF-position.

Defective induction unit. Ensure knob is in OFF-position and if possible

Pan is too small. Use a suitable pan with bottom diameter larger

Pan is not placed in the center of the

heating zone; pan is not detected by

sensor.

Unsuitable pan. Select a pan recommended for the induction

Defective induction unit. Ensure knob is in OFF-position and if possible

Air-cooling system obstructed. Verify that air inlet and outlet are not

Unsuitable pan. Use a pan recommended for the induction unit.

Ambient temperature is too high;

the cooling system is not able to

keep the induction unit in normal

operating conditions.

One phase is missing (for units with

three phase supply only).

Defective induction unit. Ensure knob is in OFF-position and if possible

Defective control switch. Ensure knob is in OFF-position and if possible

Air-cooling system is blocked.

Internal fan is dirty.

Defective fan or fan control. Ensure knob is in OFF-position and if possible

Overheated induction coil; cooking

area is too hot.

Overheated oil in pan.

Pan is empty.

Pan detection circuit is defective. Ensure knob is in OFF-position and if possible

urn control knob to an ON-position.

and safe, disconnect the unit from the power

supply. Contact your authorized service agency.

than 5” (12cm).

Move the pan to the center of the heating zone.

unit.

and safe, disconnect the unit from the power

supply. Contact your authorized service agency.

obstructed. Ensure the Intake Air Filter is clean.

Then compare the results.

Verify that no hot air is sucked in by the fan.

Reduce the ambient temperature. The intake air

temperature must be lower than 104°F (40°C).

Check primary fuses.

and safe, disconnect the unit from the power

supply. Contact your authorized service agency.

and safe, disconnect the unit from the power

supply. Contact your authorized service agency.

Verify that air inlet and outlet are not

obstructed. Ensure the Intake Air Filter is clean.

Contact your authorized service agency.

and safe, disconnect the unit from the power

supply. Contact your authorized service agency.

Switch the unit off. Safely remove pan. Wait

until the heating zone has cooled down before

turning the unit ON again.

and safe, disconnect the unit from the power

supply. Contact your authorized service agency.

Part # 4532285 Rev 4 (4/29/14) 23

Page 24

Troubleshooting RTCSmp Induction Built-In Line Dual Zone Cookers

NOTE: The fan starts when the ambient temperature in the control area exceeds 131ºF/55ºC. At heat temperatures

higher than 158ºF/70ºC, the controller automatically reduces the power to keep the unit in normal operating

conditions. The cooker runs in a non-continuous mode. This mode can be heard.

10.3 Indicator Lamp Flashes at Intervals (for Operators)

The indicator lamp flashes to signal a specific problem area. Counting the number of short flashes after each long

flash will give the possible causes. Example: “— …. — ….” The LED gives a long flash for 0.6 seconds. Then it

gives 4 short flashes (indicated by the dots in the example). The sequence repeats unit the error is cancelled.

# of Flashes Possible Causes Action To Take By Operator

1 Unsuitable induction cooking pan. Cooking

pan is not placed in the center of the heating

zone. Internal wiring/coil connection

malfunction. (3)

2 Unsuitable induction cooking pan. Internal

software overcurrent. (3)

3 Air-cooling system obstructed. Internal heat

sink overheated.

(1)

4 Overheated cooking zone. Sensor unit failure.

(1)

Overheated or defective sensor.

1

5 Error on rotary power switch. (1) Contact your authorized service agency.

6 Ambient temperature too high (the cooling

system is not able to keep the induction unit in

normal operating conditions). Internal

component overheated. (1)

Check pan material.

Check pan placement on cooking area.

Contact your authorized service agency.

Check pan material.

Contact your authorized service agency.

Let unit cool down.

Verify that air inlet and outlet are not obstructed.

Check and clean air filter.

Contact your authorized service agency.

Let unit cool down.

Verify that air inlet and outlet are not obstructed.

Check and clean air filter.

Contact your authorized service agency.

Let unit cool down.

Verify that air inlet and outlet slots are not block.

Check and clean air filter.

Verified that no hot air is sucked in by the fan.

Reduce the ambient temperature. The intake air

temperature must be lower than 104°F (40°C).

Contact your authorized service agency.

7 Warning from cooking empty sensor or coil

connection failed. (1)

Check food in the pan or empty pan.

Contact your authorized service agency.

8 Sensor error, internal board or heat sink. (1) Contact your authorized service agency.

10 Internal electronic failure. (1) Contact your authorized service agency.

(1) The induction unit stops working immediately.

(2) The induction unit continues to work in power reduction mode.

(3) The induction unit continues to work as usual.

24 Part # 4532285 Rev 4 (4/29/14)

Page 25

Troubleshooting RTCSmp Induction Built-In Line Dual Zone Cookers

10.4 Troubleshooting with Error Codes (for Service Technicians)

The indicator lamp flashes to signal a specific problem area. Counting the number of short flashes after each long

flash will give the possible causes. Example: “— …. — ….” The LED gives a long flash for 0.6 seconds. Then it

gives 4 short flashes (indicated by the dots in the example). The sequence repeats unit the error is cancelled.

To obtain the internal data and error code for troubleshooting, you need an IR Adapter, proper connectors, and

software. The table below is a reference guide. For further information and assistance, please contact Garland

Technical Service.

Error

Code

E01 1 Hardware overcurrent. Induction coil

E02 2 High coil current. Software overcurrent.

E03 3 Heat sink (KK) temperature too high.

E04 4 Cook zone temperature too high.

E05 5 Rotary power switch error. Defective

E06 6 Internal temperature too high

E10 10 Communication BUS error. (1) Check all wiring.

E12 No Flash High heat sink (KK) temperature. (2) Check installation/air flow (supply of cool air).

E20 No Flash High internal temperature. (2) Check installation/air flow (supply of cool air).

E21 8 Heat sink (KK) temperature sensor

E24 8 Board sensor error. (1) Check temperature sensor. Contact Garland.

E29 7 Coil connection error. Empty pan

E30 6 CPU temperature too high. (1) Check installation/air flow (supply of cool air).

E41 4 Sensor 1 overheated or defect. (1) Check cook zone (coil) sensor 1.

E42 4 Sensor 2 overheated or defect. (1) Check cook zone (coil) sensor 2.

E43 4 Sensor 3 overheated or defect. (1) Check cook zone (coil) sensor 3.

E44 4 Sensor 4 overheated or defect. (1) Check cook zone (coil) sensor 4.

E45 4 Sensor 5 overheated or defect. (1) Check cook zone (coil) sensor 5.

E46 4 Sensor 6 overheated or defect. (1) Check cook zone (coil) sensor 6.

#Flashes Reason Things To Check

Check cooking pan material.

not detected. (3)

Check pan placement on cooking zone.

Check wiring and connection on induction coil.

Check cooking pan material.

(3)

Check installation/air flow (supply of cool air).

(1)

Check fan operation.

Check sensor unit.

Failure of sensor unit or sensor unit not

Pan empty.

connected. (1)

Check potentiometer and its wiring.

potentiometer or broken cable. (1)

Check installation/air flow (supply of cool air).

“generator”. (1)

Check fan operation.

Check wiring. Check heat sink sensor.

error. (1)

Contact Garland.

Check cooking pan. Check sensors.

detected or sensor error. (1)

(1) The induction unit stops working immediately.

(2) The induction unit continues to work in power reduction mode.

(3) The induction unit continues to work as usual.

Part # 4532285 Rev 4 (4/29/14) 25

Page 26

Troubleshooting RTCSmp Induction Built-In Line Dual Zone Cookers

NOTES

26 Part # 4532285 Rev 4 (4/29/14)

Page 27

Installation and Operation Manual RTCSmp Induction Built-In Line Dual Zone Cookers

CORRECT DISPOSAL OF THIS PRODUCT

This marking shown on the product indicates that the

product should not be disposed as household waste or regular

commercial waste. Instead it shall be handed over to the

applicable collection point for the recycling of electrical and

electronic equipment. By ensuring this product is disposed

correctly, you will help prevent potential harm to the environment

or human health, which could otherwise be caused by

inappropriate waste handling of this product.

For more detailled information regarding recycling of the product,

please contact your local city office, your waste disposal service or

your equipment dealer.

IMPORTANT Induction units, sent for disposal, can be

brought back into operation and their use should be avoided.

NOTE The unit is built with common electrical,

electromechanical, and electronic parts. No batteries are used.

NOTE The owner and operator are responsible for the proper

and safe disposal of the induction unit.

Part # 4532285 Rev 4 (4/29/14) Page 27

Page 28

Installation & Operation Manual

GARLAND INDUCTION BUILT-IN LINE DUAL-ZONE COOKERS with RTCSmp TECHNOLOGY

Garland Commercial Ranges Ltd.

1177 Kamato Road, Mississauga,

Ontario, CANADA L4W 1X4

T. 1-905-624-0260

F. 1-905-624-5669

www.garland-group.com

USA Sales, Parts and Service 1-800-424-2411

Canadian Sales 1-888-442-7526

Canada or USA Parts/Service 1-800-427-6668

Loading...

Loading...