Page 1

Summit Series

Electric Convection Ovens

Installation, Operation and Maintenance Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

models

SUME-100

SUME-200

SEM-100S1

SEM-100D1

SEM-200S1

SEM-200D1

Part Number 1955204 rev 3 4/15

SUME-100

Page 2

SAFETY NOTICES

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects or other

reproductive harm. Installation and servicing of this product could expose you to airborne particles of glass wool/

ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers is known to the state of California to cause

cancer.

Keep appliance area free and clear of combustibles.

PLEASE READ ALL SECTIONS OF THIS MANUAL

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

Power Failure

In the event of a power failure, no attempt should be

made to operate this oven.

Part Number 1955204 rev 3 2/152

Page 3

TABLE OF CONTENTS

SAFETY NOTICES. . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL INFORMATION . . . . . . . . . . . . . . . 5

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . .5

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

DIMENSIONS AND SPECIFICATIONS,

MODEL SUME 100/200 . . . . . . . . . . . . . . . . . 6

DIMENSIONS AND SPECIFICATIONS,

MODEL SEM 100/200. . . . . . . . . . . . . . . . . . . 7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 8

Entry Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Clearance . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation Of Ovens Equipped With Casters . . 8

Installation of Double Deck Models . . . . . . . . . . . 8

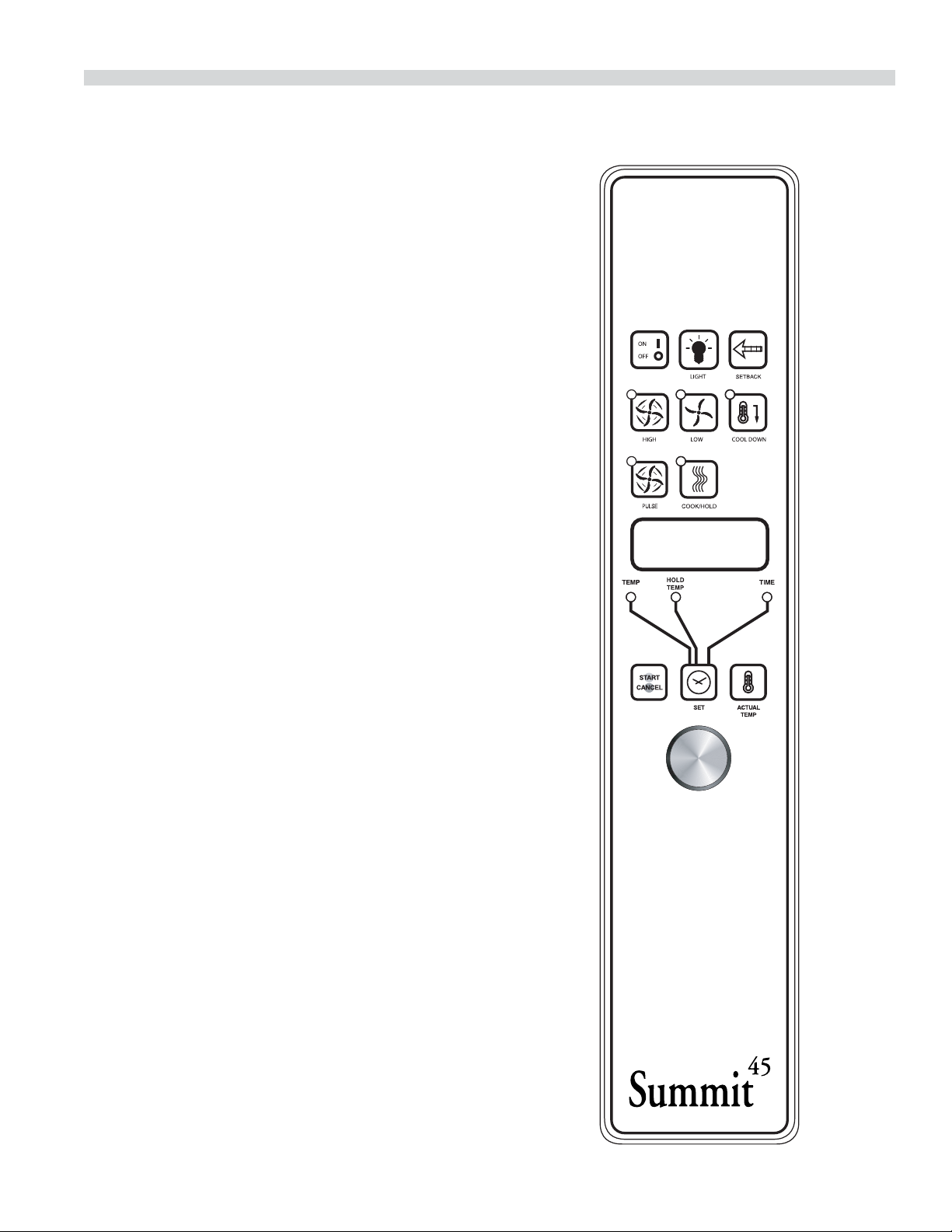

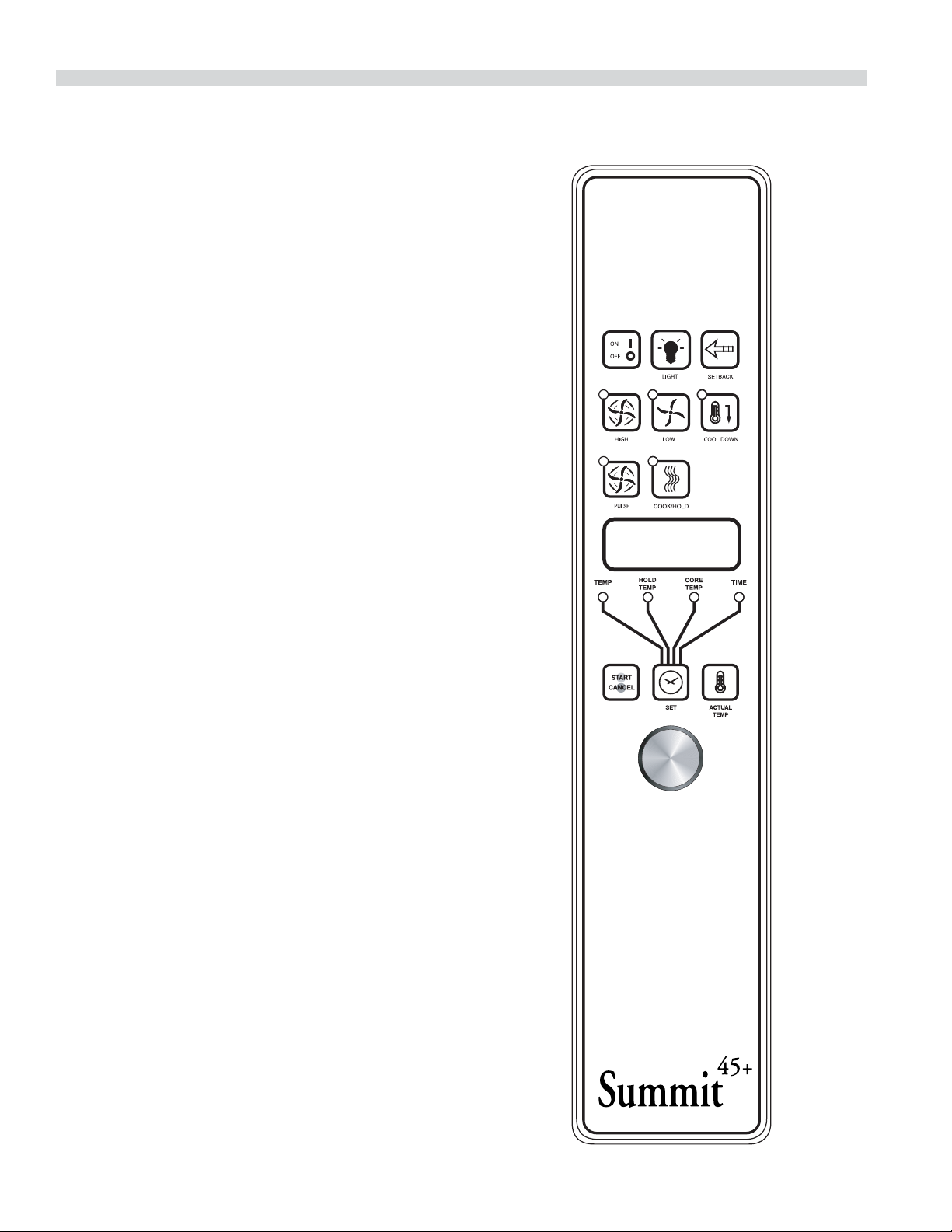

Summit 45 Electronic Control With Cook-NHold And Summit 45+ Electronic Control With

Cook-N-Hold & Core Probe (Models

Manufactured prior to June 2012) . . . . . . . . . . . . 11

In O Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

On Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controller Keys . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fahrenheit/Celsius. . . . . . . . . . . . . . . . . . . . . . . 12

Operating the Controls . . . . . . . . . . . . . . . . . . 12

Cook-N-Hold Operation . . . . . . . . . . . . . . . . . 13

Core Probe Operation . . . . . . . . . . . . . . . . . . . 13

Setting Setback Feature . . . . . . . . . . . . . . . . . 13

PERFORMANCE RECOMMENDATIONS . . 14

PROBLEM/SOLUTIONS . . . . . . . . . . . . . . . . 15

COOKING GUIDE. . . . . . . . . . . . . . . . . . . . . . 16

COOK AND HOLD . . . . . . . . . . . . . . . . . . . . . 17

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATING INSTRUCTIONS. . . . . . . . . . . . 10

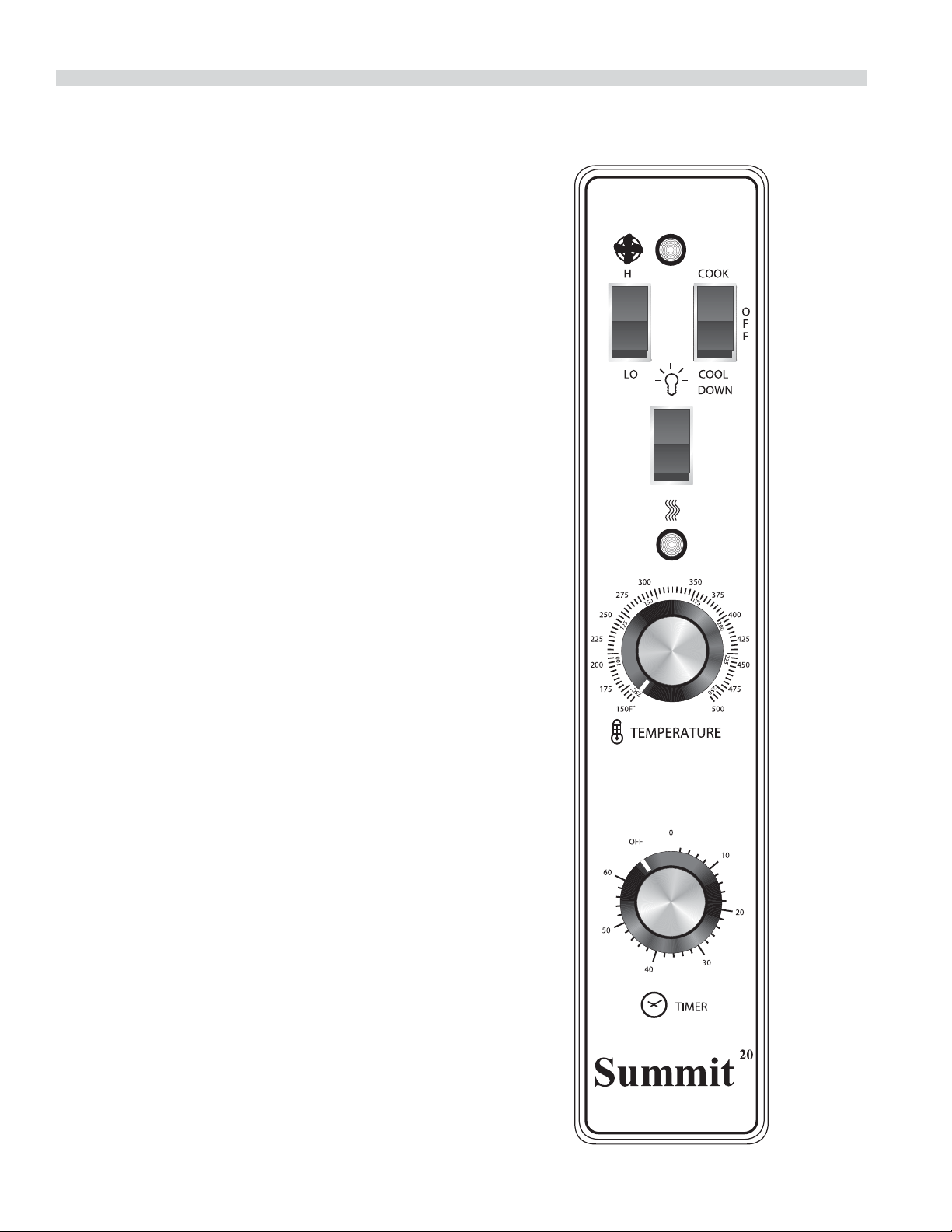

Summit 20 Solid State Control with

Electromechanical Timer . . . . . . . . . . . . . . . . . . .10

In O Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cool Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CLEANING AND MAINTENANCE . . . . . . . .18

Break-In Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Interior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fan Area Maintenance . . . . . . . . . . . . . . . . . . . . . .18

Motor Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Part Number 1955204 rev 3 2/15 3

Page 4

THIS PAGE INTENTIONALLY LEFT BLANK

Page 5

GENERAL INFORMATION

Model Numbers

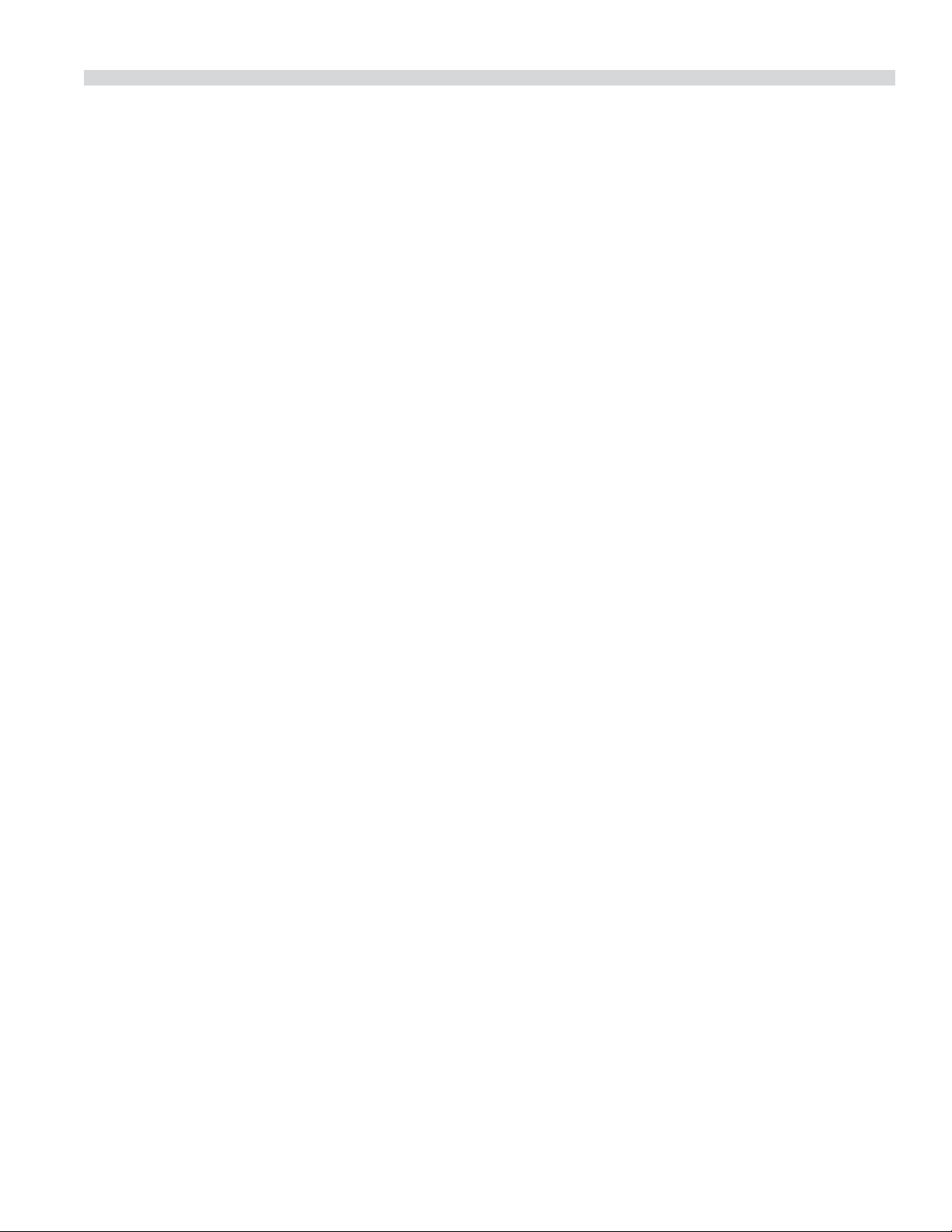

Model Standard

Depth

SUME-100

SUME-200

SEM-100S1*

SEM-100D1*

SEM-200S1*

SEM-200D1*

* Models discontinued (June, 2012)

Deep

Depth

Single

Deck

Double

Deck

Summit20

Control

Digital

Control

Warranty

Visit www.Garland-Group.com to view or download a copy of your

warranty.

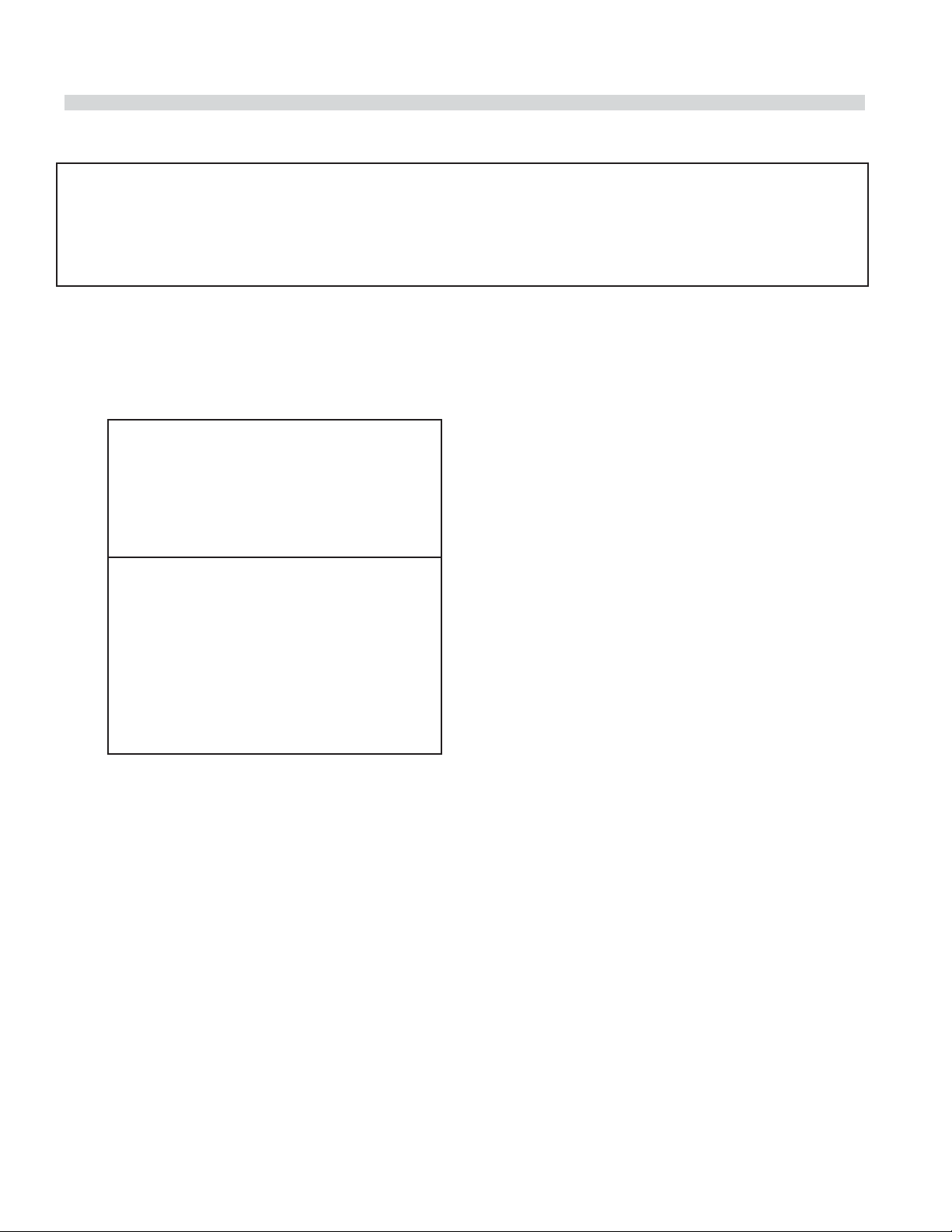

Accessories

• Stainless steel open base

with rack guides and shelf

(in lieu of 25-inch legs) for

extra rack/pan storage,

single deck oven only

• Swivel Casters (set of 4)

with front brakes

• Extra oven rack

• Removable stainless steel drip pan

Serial Plate Location

When corresponding with the factory or your local authorized

factory service center regarding service problems or replacement

parts, be sure to refer to the particular unit by the correct model

number (including the prefix and suffix letters and numbers) and

the warranty serial number.

Ovens Built prior to 31-MAR-2011

• The serial plate is affixed to the

inside of the lower front cover.

Ovens Built between 01-APR-2011

and 02-FEB-2015

• The serial plate is affixed to the

lower left corner of the left body

panel.

Ovens Built after 02-FEB-2015

• The serial plate is affixed to the

upper right corner of the left

body panel.

Part Number 1955204 rev 3 2/15 5

Page 6

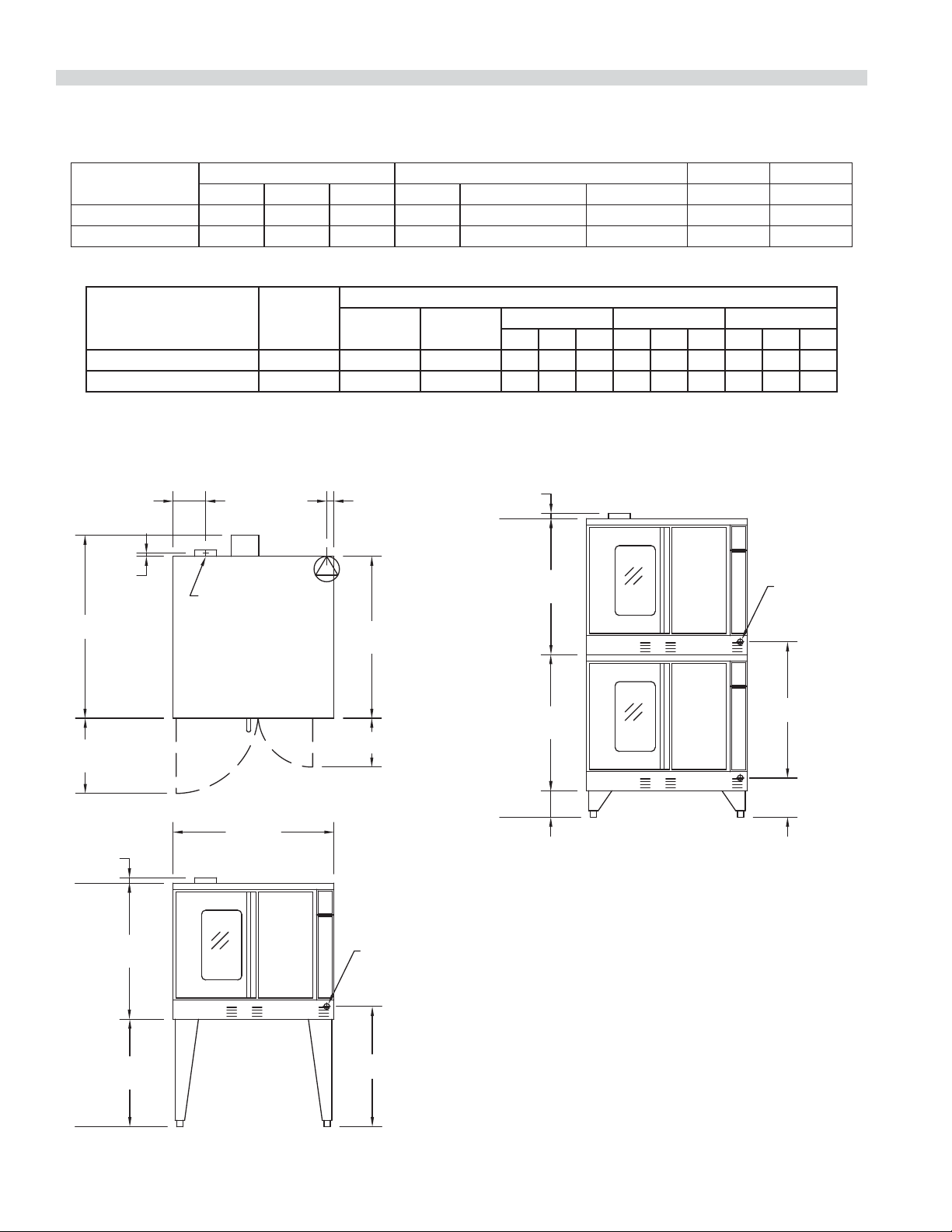

DIMENSIONS AND SPECIFICATIONS, MODEL SUME 100/200

Model

SUME-100 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 41-1/4 (1048)

SUME-200 29 (736) 24 (610) 24 (610) 38 (965) 70-1/2 (1791)** 41-1/4 (1048)

** Height with legs or with standard casters. Height with low profile casters (double deck) is 68-1/2” (1740mm).

Int. Dimensions :In (mm) Ext. Dimensions: In (mm) Ship Wt Ship Dim.

W H D W H D (w/motor) Lbs/kg Cubic Ft.

515 / 230 64

1030 / 465 128

Nominal Amperes Per Line, (includes 3/4 HP fan motor)

Model Total kW

208V/1Ph 240V/IPh

208V/3Ph 240V/3Ph 460V/3Ph

XYZXYZXYZ

Single Deck 10.4 50 43 30 30 28 26 26 24 14 14 13

Double Deck* each oven 10.4 50 43 30 30 28 26 26 24 14 14 13

* Double Deck Models are provided with individual power supply connections.

Electrical speci cations include motor requirements. 3/4 HP, 2-speed motor: 1725/1140 rpm, 60Hz; or 1440/950 rpm, 50Hz.

Please specify electrical characteristics when ordering.

7-3/4"

[197mm]

3/4"

[19mm]

"D" (includes

motor)

1-11/16"

[43mm]

FLUE: 2-3/8" x 5"

[60mm x 127mm]

38-1/4"

[972mm]

1-1/4"

[32mm]

32-1/8"

[816mm]

REAR CABLE

ENTRANCE

17-3/4"

[451mm]

1-1/4"

[32mm]

32-1/8"

[816mm]

25-3/8"

[645mm]

TOP VIEW

38"

[965mm]

SINGLE DECK

FRONT VIEW

11-1/2"

[292mm]

REAR CABLE

ENTRANCE

28-3/8"

[721mm]

32-1/8"

32-1/8"

[816mm]

6-1/4"

[159mm]

DOUBLE DECK

FRONT VIEW

[816mm]

9-1/4"

[235mm]

Many local codes exist and it is the responsibility of

the owner and installer to comply with those codes.

These appliances are intended for commercial use by

professionally trained personnel.

Part Number 1955204 rev 3 2/156

Page 7

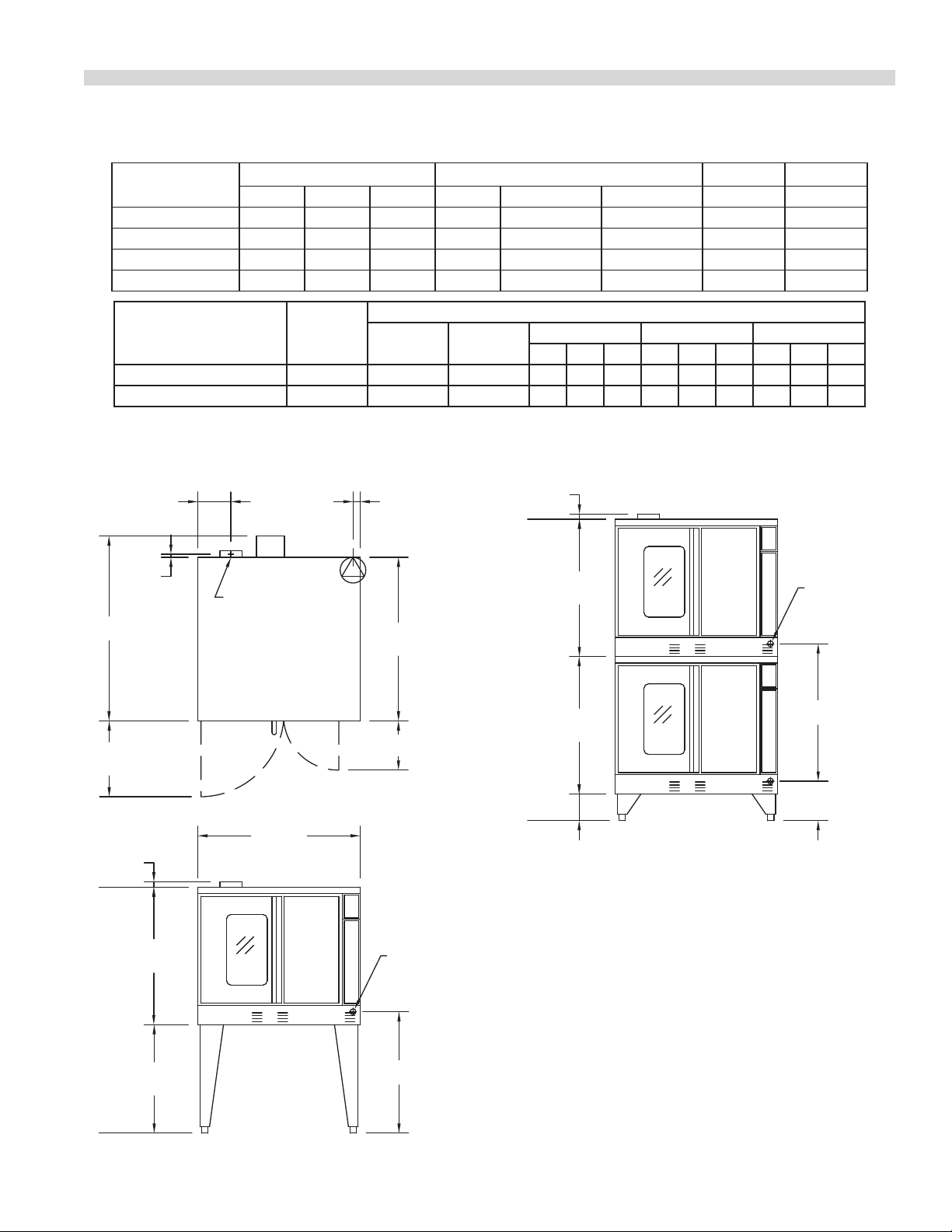

DIMENSIONS AND SPECIFICATIONS, MODEL SEM 100/200

(Models Discontinued, Manufactured Up To June 2012)

Model

Int. Dimensions :In (mm) Ext. Dimensions: In (mm) Ship Wt Ship Dim.

W H D W H D Lbs/kg Cubic Ft.

SEM-100S1 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 39-1/4(997) 510/232 42

SEM-100D1 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 43-1/4(1099) 510/232 42

SEM-200S1 29(736) 24(610) 24(610) 38(965) 70-1/2 (1791) 39-1/4(997) 1024/464 84

SEM-200D1 29(736) 24(610) 28 (711) 38(965) 70-1/2 (1791) 43-1/4(1099) 1024/464 84

Nominal Amperes Per Line, (includes 3/4 HP fan motor)

Model Total kW

208V/1Ph 240V/IPh

208V/3Ph 240V/3Ph 460V/3Ph

XYZXYZXYZ

Single Deck 10.4 50 43 30 30 28 26 26 24 14 14 13

Double Deck* each oven 10.4 50 43 30 30 28 26 26 24 14 14 13

* Double Deck Models are provided with individual power supply connections.

Electrical speci cations include motor requirements. 3/4, HP, 2-speed motor: 1725/1140 rpm, (60Hz); or 1440/950 rpm (50Hz)

Please specify electrical characteristics when ordering.

7-3/4"

[197mm]

3/4"

[19mm]

"D" (includes

motor)

1-11/16"

[43mm]

FLUE: 2-3/8" x 5"

[60mm x 127mm]

38-1/4"

[972mm]

1-1/4"

[32mm]

32-1/8"

[816mm]

REAR CABLE

ENTRANCE

17-3/4"

[451mm]

1-1/4"

[32mm]

32-1/8"

[816mm]

25-3/8"

[645mm]

TOP VIEW

38"

[965mm]

SINGLE DECK

FRONT VIEW

11-1/2"

[292mm]

REAR CABLE

ENTRANCE

28-3/8"

[721mm]

32-1/8"

32-1/8"

[816mm]

6-1/4"

[159mm]

DOUBLE DECK

FRONT VIEW

[816mm]

9-1/4"

[235mm]

Many local codes exist and it is the responsibility of

the owner and installer to comply with those codes.

These appliances are intended for commercial use by

professionally trained personnel.

Part Number 1955204 rev 3 2/15 7

Page 8

INSTALLATION

Entry Clearance

• Crated: 47” (1194mm)

• Uncrated: 32-1/2” (826mm)

Installation Clearance

NOTE: Always provide adequate clearance for maintenance

and operation.

• Installation adjacent to combustible and noncombustible wall, minimum clearance:

Left Side Control Side Rear

Single-Deck 1" (26 mm) 1" (26 mm) 3" (77 mm)

Double-Deck 1" (26 mm) 2" (51 mm) 3" (77 mm)

• Installation near high heat producing equipment,

minimum clearance:

Left Side Control Side Rear

Single-Deck 1" (26 mm) 6" (153 mm) 3" (77 mm)

Double-Deck 1" (26 mm) 6" (153 mm) 3" (77 mm)

Notice

Avoid installing ovens near equipment, such as charbroilers or fryers, which generate high heat and high

grease laden air.

Installation of Double Deck Models

A. Position insert in bottom leg opening and tap insert up

into leg until it seats at collar. Attach six inch (6”, 152mm)

legs to lower oven section. Raise unit or lay on its left side.

Place the front legs on the oven so as to line up with four

(4) attaching bolt holes. Secure leg to oven frame using

four (4) 3/8-16 x 3/4 bolts and washers provided. Repeat

at rear of unit.

B. Remove lower front cover of top deck (located under

oven doors). Raise top deck into place and line up body

sides and back of the unit. Fasten the rear of the units

together, with the stacking bracket, using (6) 1/4-20

machine screws, lock washers and nuts, (provided).

C. Install the interconnecting ue parts, carefully following

the instructions contained in the stacking kit. Pay

particular attention to the type of ovens you are stacking

and be sure to follow the corresponding instructions.

D. Check leveling of unit four (4) ways (using a common

carpenter’s level on the rack inside the oven).

E. Maintain clearance from combustibles.

• Clearance for Service (recommendation):

Control Side, minimum

Single-Deck 12" (305 mm)

Double-Deck 12" (305 mm)

NOTE: Install units with casters in very tight

locations for ease of service.

Installation Of Ovens Equipped With Casters

A. For an appliance equipped with casters, the installation

shall be made with a connector that complies with the

Standard for connectors for Movable Appliances, ANSI

Z21.69. Adequate means must be provided to limit the

movement of the appliance without depending on

connector wiring.

B. The front casters of the unit are equipped with brakes to

limit the movement of the oven without depending on

the connector wiring to limit the appliance movement.

C. The restraint can be attached to the unit near the

electrical inlet. If the restraint is disconnected, be sure to

reconnect the restraint after the oven has been returned

to its originally installed position.

Part Number 1955204 rev 3 2/158

Page 9

INSTALLATION Continued

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

Installation of the wiring must be made in accordance with

U.L. 197 Commercial Electric cooking Appliance Standards,

Local and/or National electrical Code, ANSI/NFPA 70-1990.

1. Switch panel size

2. Overload protection

3. Wire type

4. Wire size

5. Temperature limitations of the wires

6. Method of connection (Cable, Conduit, etc)

The service line will enter through the rear of the unit and is

to be connected to the terminal block (see diagram left). The

terminal block is accessed by removing the lower front cover.

Removal of the body side is not necessary.

Input voltage and phasing must match the units voltage

and phasing. Wiring diagram is attached to the main back of

each oven. Visually check all electrical connections. Energize

electric service to units.

The oven is wired per original factory order. If it is necessary

to change to single-phase or three-phase, please refer to kit

part number 4533009.

Service and unit voltage must agree.

Part Number 1955204 rev 3 2/15 9

Page 10

OPERATING INSTRUCTIONS

Summit 20 Solid State Control with

Electromechanical Timer

In O Mode

When the oven is o , there are no lights or indicators.

Start Up

Press the Cook/O /Cool Down rocker switch to the “Cook”

position. The green lamp will light indicating the oven is

powered in cook mode.

The oven will begin to heat to the temperature set on the

thermostat dial. The amber lamp will light indicating the heat

is active. As the heat cycles on and o to maintain the set

temperature this light will go on and o accordingly.

The door must be closed for the oven to operate in cook

mode. Opening the door will cause the heat to stop and the

motor and fan will shut o . This is a safety feature.

Fan Speed

The fan speed can be either high (1725 RPM) or low (1150

RPM). The fan speed is controlled by the left rocker switch

marked high and low.

Lights

The oven lights are activated by pressing the light switch

on the control panel. This is a momentary switch and the

lights will only stay lit as long as this button held in the on

position. Lights will work whenever there is electrical power

connected to the oven.

Cool Down

Pressing the Cook/O /Cool down rocker switch to the Cool

down position activates the fan and motor to cool the oven

cavity. The door must be open slightly for the fan and motor

to start. The heat is not active in this mode.

Optimal cool down will be achieved with the door open

slightly. Opening the door too far will shut the fan and motor

o . This is a patented safety feature.

Pressing the button to the OFF position cancels the cool

down and turns the oven o .

Temp era tu re

The temperature range is from 150° to 500°F (66°ºC to 250ºC)

is controlled by rotating the temperature dial and aligning

the indicator to the desired temperature.

Part Number 1955204 rev 3 2/1510

Page 11

OPERATING INSTRUCTIONS Continued

Timer

The timer is set by rotating the dial clockwise aligning the

indicator to the desired time cycle. The timer will count down

from 2 minutes to 60 minutes. At the end of the timing cycle

the buzzer will sound. The buzzer is turned o by rotating the

dial counter-clockwise to the o position as shown on the

control panel.

NOTE: The timer does not control heating.

Summit 45 Electronic Control With Cook-NHold And Summit 45+ Electronic Control With

Cook-N-Hold & Core Probe (Models

Manufactured prior to June 2012)

In O Mode

When the controller is o , the display will show “OFF”.

Pressing the ON/OFF key will activate the controller into

Start Up Mode.

On Start Up

In Start Up mode, the controller will heat to the last set

temperature, time and fan speed. The factory defaults are

350°F (177°C), 30 minutes and low fan speed. The display will

indicate “LO” when the oven is below the set temperature.

When the oven cavity reaches the set temperature and is

ready for operation the display will indicate “LOAD”.

NOTE: If the oven temperature goes above the requested

temperature the display will indicate “HI”. If the oven

temperature goes above 575°(302°C) the display will indicate

“HELP” and an audible signal will sound. This is a safety

feature.

If the door is opened during a Cooking mode, the fan and

heat will stop, and the display will indicate “DOOR” until the

door is closed. This is a patented safety feature.

Pressing the ACTUAL TEMP key will display the actual oven

temperature in 5° increments.

Controller Keys

Pressing the ON/OFF key will activate the oven.

Pressing the LIGHT key will turn the lights on for 30 seconds.

The lights will work if the controller is in the o mode. When

the door is opened, the light will come on and stay on for 30

seconds.

Pressing the FAN HIGH key will activate the lower fan speed

Part Number 1955204 rev 3 2/15 11

Page 12

OPERATING INSTRUCTIONS Continued

and light its LED.

Pressing the FAN LOW will activate the higher fan speed and

light its LED.

Pressing the FAN PULSE key the fan will be active the lower

fan speed and light its LED. The fan will be activated for 30

seconds then o for 30 seconds, and continues this cycle.

Pressing the SETBACK key will cool the oven cavity to

a preprogrammed temperature, see: Setting “Set-Back”

Feature. The oven will automatically go into Setback mode

after the pre-programmed non-usage time. The display will

indicate “SETB”. This is an energy-saving feature.

Pressing the COOL DOWN key will deactivate the heat, turn

the fan on high and light its LED. This display will indicate

“OPEN DOOR” if the door is closed, prompting the user

to open the door slightly. With the door open slightly the

display will indicate “COOL”. The Cool down will operate

when the door is closed or opened slightly. Optimal cool-

down will be achieved with the door open slightly. When

the door opens wider, the Cool Down mode will deactivate

and the display will indicate “DOOR”. This is a patented safety

feature. Pressing the COOL DOWN key again will turn the LED

o and stop this mode. Pressing the ON/OFF key will also

cancel Cool down. Cool Down is not active during a cook.

When the ON/OFF switch is pressed to turn the oven o and

the oven is above 200°F (93°C), the oven will go into an AUTO

COOL DOWN mode. In Auto cool Down, the oven will run the

fan on high until the oven cavity drops below 150°F (66°C).

During this time the display will indicate “AUTO”. When the

oven temperature drops below 150°F (66°C) the oven turns

o . This feature protects the oven motor from premature

failure. Optimal cool-down will be achieved with door open

slightly.

Fahrenheit/Celsius

Factory default is Fahrenheit (F). To change to Celsius (C),

press and hold in the “Phantom Key” located to the right of

“Cook/Hold” key. “F” appears in the display. Continue to hold

until “C” is displayed and then release the “Phantom key”

Operating the Controls

Setting the cook temperature and time are done in the same

manner. Pressing the SET key will light the TEMP LED. The

operator then sets the temperature by rotating the dial on

the controller until the desired temperature is shown on the

display. Pressing the SET key a second time lights the TIME

LED and allows the operator to select the desired cook time

Part Number 1955204 rev 3 2/1512

Page 13

OPERATING INSTRUCTIONS Continued

as shown on the display. Pressing the Set key a third time

ends the programming.

Pressing the START/CANCEL key will start the timing cycle.

The display will count down from the set time in minutes and

seconds (solid colon) or hours and minutes (blinking colon)

then minutes and seconds. When the cycle is completed,

pressing this key will also cancel the “DONE” prompt. To

cancel a timing cycle in progress, press and hold the START/

CANCEL.

Cook-N-Hold Operation

Pressing the COOK/HOLD (45 and 45+ Controllers Only) key

activates the Cook-N-Hold mode and lights is LED. To verify

the proper hold temperature has been selected, press the

SET key twice. The display will show the hold temperature.

At the end of the cook cycle, an audible alarm will sound, the

display will ash “DONE” and change to count “UP” the time

the oven is on hold. The oven will switch to the programmed

hold temperature.

Setting the cook temperature, hold temperature and time

are done in the same manner. Pressing the SET key will

light the TEMP LED. The operator then sets the temperature

by rotating the dial on the controller until the desired

temperature is shown on the display. Pressing the SET key a

second time will light the HOLD LED and allows the operator

to select the desired hold temperature as shown on the

display. Pressing the SET key a third time lights the TIME

LED and allows the operator to select the desired cook time

as shown on the display. Pressing the SET key a fourth time

ends the programming.

Pressing the START/CANCEL key will start the timing

cycle. When the cycle is completed, pressing the key will

also cancel the “DONE” prompt. To cancel a timing cycle

in progress press and hold the START/CANCEL key for 3

seconds.

Core Probe Operation

The Core Probe option (45+ Controller Only) is only active

when the core probe is plugged into its connector. To set the

core temperature, rst plug the core probe into its connector.

The display will indicate “100” and the CORE TEMP LED will

be on.

The operator then sets the temperature by rotating the dial

on the controller until the desired temperature is shown on

the display. Pressing the SET key stores the core temperature

and starts the cooking process.

To set the oven temperature, press the SET key again. The

TEMP LED will light and the oven temperature can be

set by rotating the dial on the controller until the desired

temperature is displayed. Pressing the Set key again will

light the HOLD LED allowing the operator to set the hold

temperature in the same manner.

NOTE: If the hold temperature is not set, the default

hold temperature is 150°F (66°C) or the last programmed

temperature. (Hold temperature range is 140°F (60°C) to

210°F (99°C).

When the core temperature is reached the display will sound

and ash “DONE” for 3 seconds. Automatically, the display

will switch to count “UP” the time the oven is on hold. To

end this cycle, the core probe must be removed from the

connector.

Setting Setback Feature

To set or change the setback settings, press and hold the

SETBACK key for two seconds. The TEMP LED will light and a

temperature will be displayed. Set the temperature using the

dial, then press the SET key. The TEMP LED will go out and

the TIME LED will light (“Time” is factory set at 0). Set the time

using the dial, then press the SET key. Press the SET key one

more time to exit programming.

Note: To disable the setback function, set the temperature to

250º F (121ºC) and the time to zero.

Part Number 1955204 rev 3 2/15 13

Page 14

PERFORMANCE RECOMMENDATIONS

1. Preheat oven thoroughly (approx. 20 minutes) before use.

2. As a general rule, temperature should be reduced 25°

to 50° from that used in a standard/conventional oven.

Cooking time may also be shorter, so we suggest closely

checking the rst batch of each product prepared.

3. Use the chart of suggested times and temperatures as

a guide. These will vary depending upon such factors

as size of load, temperature, and mixture of product

(particularly moisture) and density of product.

4. Keep a record of the times, temperature, and load sizes

you establish for various products. Once you have

determined these, they will be similar for succeeding

loads.

5. When practical, start cooking the lowest temperature

product rst and gradually work up to higher

temperatures.

6. If you nd that your previous temperature setting is more

than 10° higher than needed for succeeding loads, press

COOL DOWN to reach the desired temperature before

setting a new cooking temperature.

10. When baking, weigh or measure the product in each pan

to assure even cooking.

11. When cooking ve pans, use rack positions 1, 4, 6, 8, and

10 and, starting from the top.

12. Do not overload the oven. Five pans are suggested for

most items, i.e., cakes, cookies, rolls, etc. However, the

maximum (10 pans) may be used for sh sticks, chicken

nuggets and hamburgers. Cooking times will have to be

adjusted.

13. Mu n pans should be placed in the oven back to front

or with the short side of the pans facing the front. This

results in the most evenly baked product.

14. When re-thermalizing frozen casseroles, preheat the oven

100° over the suggested temperature. Return to cooking

temperature when the oven is loaded. This will help

compensate for the introduction of a large frozen mass

into the cavity.

15. Use pan extenders or two inch deep 18” x 26” pans for

batter type products which weigh more than eight

pounds, i.e., Pineapple Upside down Cake.

7. When loading oven, work as quickly as possible to

prevent loss of heat.

8. Oven will continue to heat even though the timer goes

o . Product should be removed from the oven as soon as

possible to avoid over cooking.

9. Center pans on racks and load each shelf evenly to allow

for proper air circulation within the cavity.

16. Never place anything directly on the bottom of the oven

cavity. This obstructs the air ow and will cause uneven

results.

NOTE: Moisture will escape around the doors when baking

products with heavy moisture content, such as chicken,

potatoes, etc. This is normal.

Part Number 1955204 rev 3 2/1514

Page 15

PROBLEM/SOLUTIONS

Problem Solution

Cakes are dark on the sides and not done in the center Lower oven temperature

Cakes edges are too brown Reduce number of pans or lower oven temperature

Cakes have light outer color Raise temperature

Cake settles slightly in the center Bake longer or raise oven temperature slightly.

Do not open doors too often or for long periods

Cake ripples Overloading pans or batter is too thin

Cakes are too coarse Lower oven Temperature

Pies have uneven color Reduce number of pies per rack

or eliminate use of bake pans

Cupcakes crack on top Lower oven temperature

Meats are browned and not done in center Lower temperature and roast longer.

Meats are well done and browned Reduce time. Limit amount of moisture

Meats develop hard crust Reduce temperature or place pan of water in oven.

Rolls have uneven color Reduce number or size of pans.

Part Number 1955204 rev 3 2/15 15

Page 16

COOKING GUIDE

The following suggested times and temperatures are provided as a starting guide. Elevation, atmospheric conditions, recipe,

cooking pans, and oven loading may a ect your actual results.

PRODUCT TEMPERATURE (°F) TIME

Cakes

White Sheet Cakes – 5 lbs 300° 20 min

White Sheet Cakes – 6 lbs 300° 22 min

Yellow Sheet Cake – 5 lbs 325° 15 min

Chocolate Layer Cake – 21 oz 300° 22 min

Angel Food Cake 375° 22 min

Brownies 350° 15 min

Breads

Soda Biscuits 400° 6 min

Yeast Rolls 325° 24 min

Sweet Bread 325° 24 min

Corn Bread 350° 22 min

Gingerbread 300° 24 min

Apple Turnovers 350° 25 min

Cream Pu s 300° 25 min

Sugar Cookies 325° 12 min

Chocolate Chip cookies 375° 8 min

Apple Pie (Fresh) 375° 25 min

Blueberry Pie (Fresh) 350° 30 min

Blueberry Pie (Frozen) 300° 50 min

Pumpkin Pie (Frozen 300° 50 min

Frozen Pizza 300° 6 min

Macaroni & Cheese 350° 15 min

Fish Sticks 350° 16 min

Stu ed Peppers 350° 45 min

Baked Potatoes 350° 60 min

Meats

Chick Parts 350° 45 min

Hamburger Patties-10/lb frozen 350° 8 min

Hamburger Patties - 10/lb fresh 350° 5 min

Hamburger Patties - 4/lb frozen 350° 12 min

Hamburger Patties – 4/lb fresh 350° 8 min

Meatloaf – 4lb 325° 45 min

Bacon 350° 10 min

Roast Beef 20lb 325° 3 hr 15 min

Prime Rib 10lb 300° 1 hr 45 min

Stu ed Port chops 350° 45 min

Lamb chops 375° 40 min

Boneless Veal Roast 300° 3 Hr

Part Number 1955204 rev 3 2/1516

Page 17

COOK AND HOLD

Please refer to the operating instructions to program the 450 and 455 control units for Cook and Hold feature. The times and

temperatures listed below are to be used as a starting guide. Your actual results may vary greatly depending on your elevation,

atmospheric conditions, and other items being cooked at the same time.

TIME IN HOURS

Weight in lbs

8 2.5 3.5 1.5 2 1.25 1.5

9 2.75 3.75 1.75 2.25 1.25 1.75

10 3 4.25 2 2.5 1.5 1.75

11 3.25 4.5 2 2.75 1.5 1.75

12 3.5 5 2.25 3 1.5 2

13 3.75 5 2.5 3.25 1.5 2.25

14 4 5.75 2.5 3.5 1.75 2.5

15 4.25 6 2.75 3.5 2 2.5

16 4.5 6.25 2.75 3.75 2 2.75

17 4.75 6.5 3 4 2.25 2.75

18 4.75 6.75 3.25 4.25 2.25 3

19 5 7.25 3.25 4.25 2.25 3

20 5.25 7.5 3.5 4.5 2.5 3.25

21 5.5 7.75 3.5 4.75 2.75 3.5

22 5.75 7.75 3.5 4.75 2.75 3.5

23 6 8.25 3.75 5 2.75 3.75

24 6 8.75 3.75 5 2.75 3.75

25 6.25 9 4.25 5.5 3 4

26 6.5 9.25 4.25 5.5 3.25 4.25

27 6.75 9.5 4.25 5.75 3.25 4.25

28 7 9.75 4.5 6 3.25 4.25

29 7.25 10 4.75 6.25 3.5 4.5

30 7.25 10.25 4.75 6.25 3.5 4.5

Temperature: 200°F Temperature: 250°F Temperature: 300°F

Rare Medium Rare Medium Rare Medium

Part Number 1955204 rev 3 2/15 17

Page 18

CLEANING AND MAINTENANCE

Note: Disconnect line cord from power supply before

cleaning or servicing.

Break-In Period

When oven is new, operate it for one hour at 375°F (191°C)

before you begin your normal cooking operation. After

cooling, wipe the interior, including the racks, with a clean

damp cloth.

Exterior Cleaning

Establish a regular schedule. Any spills should be wiped o

immediately.

1. The oven should always be allowed to cool su ciently

before any cleaning is attempted.

2. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

3. Stubborn stains may be removed by using a non-metallic

abrasive pad, rubbing in the direction of the metal’s grain.

If necessary, for particularly heavy deposits, you may mix

a thin paste of water and scouring powder, and apply

it with a sponge. Be careful to apply light pressure and

remember to rub only in the direction of the grain in the

metal.

4. The control panel surface is easily cleaned with hot water,

soap and a soft cloth. Do not use hard abrasives, solvent

type materials or metallic scouring pads since these will

scratch or cloud the surface.

5. Never spray the perforated areas or control panel with

steam or water, as this will allow moisture into the control

cavity, which could damage electrical components.

Interior Cleaning

Establish a regular cleaning schedule or wipe o , on the

same day when spill overs occur.

1. Cool down oven.

2. Remove oven racks.

3. Lift rack guides on either side of oven o of holders. Racks

and guides may be run through dishwasher while oven

cavity is being cleaned.

4. Clean with soap and water using a non-metallic scouring

pad, if necessary. If dirt and grease have accumulated, a

mild ammonia solution or commercial oven cleaner such

as Easy-O or Dow may be used.

5. To reinstall, reverse procedure. Place the bottom of the

rack guide against the cavity wall. Keeping the top pulled

away from the wall lift up. Push the top of the guide

against the wall and push down locking it into place.

Fan Area Maintenance

If aluminum foil is routinely used to wrap food or cooking

vessels during oven operation, the following preventive

maintenance must be performed:

1. Turn power switch to “O ” position.

2. Remove oven racks and rack guides.

3. Remove air ba e and clean any stains or deposits.

4. Check blower wheel and air ba e for particles of

aluminum foil or food deposits. Clean ns of blower

wheel. (Caution: edges of blower wheel ns may be

sharp).

5. Reinstall the air ba e, rack guides and oven racks.

This simple practice, if performed on a regular basis will keep

your U.S. Range oven operating at peak performance.

Part Number 1955204 rev 3 2/1518

Page 19

CLEANING AND MAINTENANCE Continued

Motor Care

The motor on your convection oven is maintenance free

since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions

to follow on the care of your motor. When the motor is

operating, it cools itself internally by air entering at the rear

of the motor case, provided proper clearance has been

allowed.

Since the blower wheel is in the oven cavity it is at the same

temperature as the oven. If the motor is stopped while the

oven is hot, the heat from the blower wheel is conducted

down the shaft and into the armature of the motor. This

action could shorten the life of the motor.

We recommend, at the end of the bake or roasting period,

when the oven will be idle for any period of time, or before

shutting down completely, that the doors be left open

slightly. On the 45 series controllers press the COOL DOWN

key on the control panel. The fan will continue to run until

the oven cools down to 150°F (66°C).

At the end of the day, press the ON/OFF key, for the 45 series

controllers to activate the Auto Cool Down feature. The fan

will run on high until the oven cavity drops below 150°F

(66°C). When the oven temperature drops below 150°F (66°C)

the oven turns o . This feature protects the oven motor

from pre-mature failure. On the 20 series controllers, push

the rocker switch to COOL position. Once cool set the rocker

switch to OFF.

NOTE: Optional cool-down will be achieved with the door

open slightly.

Part Number 1955204 rev 3 2/15 19

Page 20

US RANGE

1177 KAMATO ROAD, MISSISSAUGA, ONTARIO, CANADA. L4W 1X4

8884427526

WWW.GARLANDGROUP.COM

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

your operational needs from one restaurant to multiple locations.

StarCare – Warranty & lifetime service, certi ed OEM parts, global parts inventory, performance audited

ExtraCare — CareCode, 24/7 Support, online/mobile product information

LifeCare – Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

Talk with KitchenCare™ • 1-844-724-CARE • www.mtwkitchencare.com

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

©2014 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved. Continuing product improvement may necessitate change of speci cations without notice.

Part Number 1955204 rev 3 4/15

Page 21

Numéro de Pièce 1955204 rév 3 4/15

©2014 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved. Continuing product improvement may necessitate change of speci cations without notice.

www.manitowocfoodservice.com, then discover the regional or local resources available to you.

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

Talk with KitchenCare™ • 1-844-724-CARE • www.mtwkitchencare.com

LifeCare – Install & equipment orientation, planned maintenance, KitchenConnect™, MenuConnect

ExtraCare — CareCode, 24/7 Support, online/mobile product information

StarCare – Warranty & lifetime service, certi ed OEM parts, global parts inventory, performance audited

your operational needs from one restaurant to multiple locations.

Every new piece of Manitowoc Foodservice equipment comes with KitchenCare™ and you choose the level of service that meets

8884427526

WWW.GARLANDGROUP.COM

1177 KAMATO ROAD, MISSISSAUGA, ONTARIO, CANADA. L4W 1X4

US RANGE

Page 22

Numéro de Pièce 1955204 rév 3 4/15 19

est légèrement ouverte.

REMARQUE: Un refroidissement idéal sera obtenu si la porte

basculant à la position FERMER.

REFROIDISSEMENT. Une fois refroidi, réglez l'interrupteur

la série 20, appuyez sur l'interrupteur basculant à la position

du four des défaillances prématurées. Sur les contrôleurs de

(66°C), le four s'arrêtera. Cette fonction protège le moteur

(66°C). Lorsque la température sera en déça 1de 150°F

température de la cavité de celui-ci tombe en déça de 150°F

du four s'activera à la haute vitesse jusqu'à ce que la

la fonction de refroidissement automatique. Le ventilateur

45, appuyez sur la touche ALLUMER/ÉTEINDRE pour activer

À la n de la journée, sur les contrôleurs de la série Summit

atteinte 150°F (66°C).

fonctionner jusqu'au moment où la température du four est

sur le panneau de contrôle. Le ventilateur continuera de

série 45, appuyez sur la touche REFROIDISSEMENT située

soit entre ouverte légèrement. Sur les contrôleurs de la

temps, ou avant de l'arrêter complètement, que la porte

période de rôtissage, lorsque le four sera inactif pour un

Nous recommandons, à la n de la cuisson ou de la

raccourcir la durée de vie du moteur.

d'entraînement, dans l'armature du moteur. Ceci peut

provenant de la roue du ventilateur descend sur l'arbre

moteur est arrêté pendant que le four est chaud, la chaleur

celle-ci est à la même température que le four. Si le

Puisque la roue du ventilateur est dans la cavité du four,

moteur, si un dégagement approprié est maintenu.

lui-même par l'air entrant par la partie arrière du boîtier du

votre moteur. Lorsque le moteur fonctionne, il se refroidit

quelques suggestions à suivre concernant l'entretien de

celui-ci est entretenu de façon normale. Nous avons

lubri és. Il est conçu pour fonctionner longtemps lorsque

puisqu'il est fabriqué à l'aide de roulements à billes scellés

Le moteur de votre four à convection est sans entretien

Entretien du moteur

ENTRETIEN ET NETTOYAGE suite

Page 23

Numéro de Pièce 1955204 rév 3 4/1518

optimal.

gardera votre four U.S. Range selon un fonctionnement

Cette pratique simple, si e ectuée sur une base régulière,

les grilles du four.

5. Réinstallez la chicane d'air, les guides de grilles ainsi que

ventilateur peuvent être coupantes).

du ventilateur. (Avertissement: les bords de la roue du

papier d'aluminium. Nettoyez les ailettes de la roue

d'air pour des dépôts de particules d'aliments ou de

4. Véri ez la roue du ventilateur ainsi que la chicane

3. Enlevez la chicane d'air et nettoyez toute tache ou dépôt.

composants électriques.

la cavité du contrôleur ce qui peut endommager les

puisque ceci permet à l'humidité de pénétrer dans

le panneau de contrôle avec le la vapeur ou de l'eau,

5. Ne jamais vaporiser ou asperger la zone perforée ou

égratigner ou endommager la surface.

tampons à récurer en métal puisque ceux-ci peuvent

utiliser d'abrasifs, matériaux de types solvants ou de

à l'aide de savon, d'eau chaude et d'un chi on. Ne pas

4. La surface du panneau de contrôle est facile à nettoyer

2. Enlevez les grilles du four ainsi que les guides.

1. Mettre l'interrupteur à la position «FERMER».

l'entretien préventif suivant doit être fait:

envelopper les aliments ou comme récipient de cuisson,

Si du papier d'aluminium est constamment utilisé pour

Entretien du ventilateur

place.

contre le mur et poussez vers le bas pour le verrouiller en

dessus loin du mur soulever. Poussez le dessus du guide

du guide de la grille contre la cavité du mur. Gardez le

5. Pour réinstaller, faites la procédure inverse. Placez le fond

peut être utilisé.

ou un nettoyant pour four comme du Easy-O ou Dow

la graisse s'accumule, une solution d'ammoniaque douce

récurer non métallique, si nécessaire. Si de la saleté ou de

4. Nettoyez avec de l'eau et du savon ainsi qu'un tampon à

que la cavité du four est nettoyée.

peuvent être passés au lave-vaisselle en même temps

du four, de leur renfort. Les grilles ainsi que les guides

3. Soulevez les supports des grilles, situés de chaque côté

2. Retirez les grilles du four.

1. Laissez refroidir le four.

dans le sens du grain du métal.

légère pression et n'oubliez pas de frotter seulement

l'appliquer à l'aide d'une éponge. Veillez à appliquer une

que de la poudre récurrente, faire une pâte mince, et

de grosses tailles, vous pouvez mélanger de l'eau ainsi

sens du grain du métal. Si nécessaire, pour les dépôts

un tampon abrasif non métallique, en frottant dans le

3. Les tâches tenaces peuvent être enlevées en utilisant

propre.

métallique. Séchez complètement à l'aide du chi on

être enlevés à l'aide d'un tampon (doux) à récurer non

detergent and hot water. Les résidus tenaces peuvent

2. Wipe exposed, cleanable surface when cool with a mild

procédure de nettoyage puisse être entreprise.

1. Laisser le four refroidir su samment avant que toute

nettoyé immédiatement.

Établissez un horaire régulier. Tout déversement doit être

Nettoyage extérieur

chi on propre et humide.

refroidi, nettoyez l'intérieur, incluant les grilles, à l'aide d'un

fonctionnement de cuisson normal. Après que celui-ci est

une heure à 375°F (191°C) avant de commencer votre

Lorsque le four est neuf, faites fonctionner celui-ci pour

Période de rodage

nettoyage, la journée même où le déversement est survenu.

Établissez un horaire de nettoyage régulier ou procédez au

Nettoyage intérieur

de l'appareil.

prise électrique avant d'e ectuer l'entretien ou le nettoyage

REMARQUE: Déconnectez le cordon d'alimentation de la

ENTRETIEN ET NETTOYAGE

Page 24

Numéro de Pièce 1955204 rév 3 4/15 17

30 7.25 10.25 4.75 6.25 3.5 4.5

29 7.25 10 4.75 6.25 3.5 4.5

28 7 9.75 4.5 6 3.25 4.25

27 6.75 9.5 4.25 5.75 3.25 4.25

26 6.5 9.25 4.25 5.5 3.25 4.25

25 6.25 9 4.25 5.5 3 4

24 6 8.75 3.75 5 2.75 3.75

23 6 8.25 3.75 5 2.75 3.75

22 5.75 7.75 3.5 4.75 2.75 3.5

21 5.5 7.75 3.5 4.75 2.75 3.5

20 5.25 7.5 3.5 4.5 2.5 3.25

19 5 7.25 3.25 4.25 2.25 3

18 4.75 6.75 3.25 4.25 2.25 3

17 4.75 6.5 3 4 2.25 2.75

16 4.5 6.25 2.75 3.75 2 2.75

15 4.25 6 2.75 3.5 2 2.5

14 4 5.75 2.5 3.5 1.75 2.5

13 3.75 5 2.5 3.25 1.5 2.25

12 3.5 5 2.25 3 1.5 2

11 3.25 4.5 2 2.75 1.5 1.75

10 3 4.25 2 2.5 1.5 1.75

9 2.75 3.75 1.75 2.25 1.25 1.75

8 2.5 3.5 1.5 2 1.25 1.5

Saignant À point Saignant À point Saignant À point

Température: 200°F Température: 250°F Température: 300°F

livres

Poids en

TEMPS EN HEURES

variés grandement selon l'élévation, les conditions atmosphériques et si plusieurs articles di érents sont cuits en même temps.

maintien. Les temps et températures indiqués ci-dessous doivent être utilisés comme guide de départ. Les résultats peuvent

Veuillez vous référer aux directives d'utilisation pour programmer les appareils à contrôle 450 et 455, fonction de cuisson et

CUISSON ET MAINTIEN

Page 25

Numéro de Pièce 1955204 rév 3 4/1516

Rôti de veau sans os 300° 3h

Côtelettes d'agneau 375° 40min

Côtelettes porc farcies 350° 45min

Côte de boeuf 10lb 300° 1h 15

Rôti de boeuf 325° 3h 15

Bacon 350° 10min

Pain de viande 325° 45min

fraîches - 4/lb

350° 8min

350° 12min

350° 5min

350° 8min

Galettes de viande pour hamburger

congelé - 4/lb

Galettes de viande pour hamburger

fraîches - 10/lb

Galettes de viande pour hamburger

congelé - 10/lb

Galettes de viande pour hamburger

Poulet 350° 45min

Viandes

Patates au four 350° 60min

Poivrons farcis 350° 45min

Bâtonnets de poisson 350° 16min

Macaroni & au fromage 350° 15min

Pizza congelée 300° 6min

Tarte à la citrouille (congelé) 300° 50min

Tarte aux bleuets (congelé) 300° 50min

Tarte aux bleuets (fraîche) 350° 30min

Tarte aux pommes (fraîche) 375° 25min

Biscuits aux brisures de chocolat 375° 8min

Biscuits au sucre 325° 12min

Choux à la crème 300° 25min

Chaussons aux pommes 350° 25min

Pain d'épice 300° 24min

Pains de maïs 350° 22min

Pains sucrés 325° 24min

Petits pains à la levure 325° 24min

Biscuits soda 400° 6min

Pains

Carré au chocolat 350° 15min

Gâteau des anges 375° 22min

Gâteau étage au chocolat 300° 22min

Gâteau doré – 5 lb 325° 15min

Gâteau blanc en tranche – 6 lb 300° 22min

Gâteau blanc en tranche – 5 lb 300° 20min

Gâteaux

PRODUITS TEMPÉRATURE (°F) TEMPS

atmosphériques, les recettes, les moules de cuisson ainsi que les charges peuvent a ecter les résultats.

Les temps suivants et températures suivantes sont suggérés et fournis comme supports de départ. L'élévation, les conditions

GUIDE DE CUISSON

Page 26

Numéro de Pièce 1955204 rév 3 4/15 15

dans le four.

ou éliminer l'utilisation de moules de cuisson

périodes

N'ouvrez pas la porte trop fréquemment ou pour de longues

Réduire la température

Problème Solution

Les pains à mollets sont de couleur inégale Réduire le nombre ou la taille des moules.

Le dessus des viandes devient dur Réduire la température ou placer un moule avec de l'eau

Les viandes sont bien cuites et brunies Réduire le temps de cuisson Limiter la quantité d'humidité

Les viandes sont brunies, mais ne sont pas cuites à l'intérieur Réduire la température et rôtir plus longtemps.

Les petits gâteaux craquent sur le dessus Réduire la température

Les tartes sont de couleur inégale Réduire le nombre de tartes par grille

Les gâteaux sont trop gros Réduire la température

Ondulations dans le gâteau Surcharge des moules ou la pâte est trop mince

Le gâteau s'e ondre légèrement au centre Cuire plus longtemps ou élever la température légèrement.

Les gâteaux sont trop pâles Élever la température

Les côtés des gâteaux sont trop bruns Réduire le nombre de moules ainsi que la température

centre

Les gâteaux sont foncés sur les côtés, mais pas assez cuits au

PROBLÈMES/SOLUTIONS

Page 27

Numéro de Pièce 1955204 rév 3 4/1514

comme le poulet, les patates etc. Ceci est normal.

lors de la cuisson de produits à haute teneur en humidité,

REMARQUE: L'humidité s'échappera du pourtour de la porte

l'aire et entraînera une cuisson inégale.

fond de la cavité du four. Ceci entrave la circulation de

16. Ne jamais placer quoi que ce soit directement dans le

supérieur à 8livres exemple: un renversé aux ananas.

cm) pour les produits à base de pâte dont le poids est

2pouces (5,08cm) de profondeur x 26 pouces (66,04

15. Utilisez des allongeurs de moules ou des moules de

de produits congelés dans la cavité.

aidera à compenser à l'introduction d'une grande masse

la température de cuisson lorsque le four est chargé. Ceci

le four à 100°selon la température suggérée. Retournez à

14. Lors de la cuisson des casseroles congelées, préchau é

Ceci permet une cuisson égale du produit.

l'avant ou le côté restreint du moule vers l'avant du four.

13. Les moules à mu ns doivent être placés de l'arrière vers

de cuisson devront être ajustés.

poissons, croquettes de poulet et hamburgers. Les temps

de (10 moules) peut être utilisé pour les bâtonnets de

biscuits, pains mollets etc. Cependant, un maximum

moules pour la plupart des articles exemple: gâteaux,

12. Ne pas surcharger le four. Il est suggérer d'utiliser cinq

grilles 1, 4, 6 8 et 10 à commencer par le haut.

11. Lors de la cuisson de cinq moules, utilisez les positions de

chaque moule pour assurer une cuisson égale.

10. Lors de la cuisson, pesez et mesurez le produit versé dans

adéquate à l'intérieur de la cavité du four.

étage uniformément a n de permettre une circulation

9. Centrez les moules sur les grilles et chargez chaque

pour éviter que le produit ne soit trop cuit.

écoulé. Dès que possible, le four doit être retiré du four

8. Le four continuera de chau er même si le temps est

four.

possible pour empêcher une perte de chaleur dans le

7. Lors du chargement du four, travaillez aussi vite que

au réglage d'une nouvelle température de cuisson.

pour atteindre la température désirée avant de procéder

charges subséquentes, appuyez sur REFROIDISSEMENT

précédente est supérieur à 10° à celle nécessaire pour les

6. Si vous remarquez que le réglage de la température

plus élevées.

vers la cuisson des produits demandant des températures

la température la plus basse et progressez graduellement

5. Si possible, commencez par cuire le produit demandant

similaires pour les charges subséquentes.

fois que ces paramètres auront été déterminés, ils seront

des tailles des charges établies pour chaque produit. Une

4. Garder un registre des temps, des températures ainsi que

l'humidité) ainsi que selon la densité du produit.

ainsi que mélange de produit (particulièrement

des facteurs comme la taille de la charge, la température

températures suggérées. Ceux-ci varieront en fonction

3. Comme guide, utilisez le tableau des temps et des

constamment le premier lot préparé.

aussi être plus court, nous vous suggérons de véri er

conventionnel/standard. Le temps de cuisson peut

25° à 50°comparativement à la température d'un four

2. En règle générale, la température doit être réduite de

20minutes) avant l'utilisation.

1. Préchau ez le four complètement (approximativement

RECOMMANDATIONS DE PERFORMANCES

Page 28

Numéro de Pièce 1955204 rév 3 4/15 13

température à 250º F (121ºC) et le temps à zéro.

Remarque: Pour désactiver la fonction de retour, réglez la

la programmation.

Appuyez sur la touche RÉGLAGE une autre fois pour quitter

en utilisant le cadran puis, appuyez sur la touche RÉGLAGE.

(le «temps» est réglé à 0 en usine). Réglez la température

TEMPÉRATURE se fermera et le VOYANT TEMPS s'allumera

le cadran puis, appuyez sur la touche RÉGLAGE. Le VOYANT

température sera a chée. Réglez la température en utilisant

deux secondes. Le VOYANT TEMPÉRATURE s'allumera et la

retour, appuyez et maintenez la touche RETOUR pour

Pour régler ou changer les réglages de la fonction de

Réglage de la fonction de retour

la sonde centrale doit être débranchée du connecteur.

temps pour lequel le four est maintenu. Pour arrêter ce cycle,

l'a chage changera pour un comptage «PROGRESSIF» du

se fera entendre pour 3secondes. Automatiquement,

«TERMINER» s'a chera et clignotera et une alerte sonore

Lorsque la température centrale est atteinte, le message

maintien varie entre 140°F (60°C) à 210°F (99°C).

la dernière température programmée. (La température de

la température de maintien par défaut est de 150°F (66°C) ou

REMARQUE: Si la température de maintien n'est pas réglée,

quatrième fois, ceci termine la programmation.

démontré à l'écran. En appuyant sur la touche RÉGLAGE une

de faire la sélection du temps de cuisson désiré, comme

fois, ceci activera le VOYANT TEMPS et permet à l'utilisateur

l'écran. En appuyant sur la toucheRÉGLAGE une troisième

la température de maintien désirée, comme démontré à

MAINTIEN et permet à l'utilisateur de faire la sélection de

touche RÉGLAGE une seconde fois, ceci allumera le VOYANT

température désirée s'a che à l'écran. En appuyant sur la

rotation du cadran, situé sur le contrôleur, jusqu'à ce que la

la suite, l'utilisateur règle la température en faisant une

la touche RÉGLAGE , ceci allumera le VOYANT TEMP. Par

et du temps se font de la même façon. En appuyant sur

Le réglage de la température, de la température de maintien

Le four changera à la température de maintien programmée.

«PROGRESSIF» du temps pour lequel le four sera maintenu.

clignotera et la minuterie changera pour un comptage

se fera entendre, le message «TERMINER» s'a chera et

de maintien. À la n du cycle de cuisson, une alarme sonore

touche RÉGLAGE deux fois. L'écran a chera la température

de maintien sélectionnée est appropriée, appuyez sur la

N-Hold et le voyant s'allume. Pour véri er que la température

(Contrôleurs 45 et 45+ seulement), ceci active le mode CookEn appuyant sur la touche CUISSON/MAINTENIR

Fonctionnement de la fonction Cook-N-Hold

façon.

l'utilisateur de régler la température de maintien de la même

nouveau allumera le VOYANT MAINTIEN ce qui permet à

température désirée. Appuyer sur la touche de réglage à

une rotation du cadran, situé sur le contrôleur, jusqu'à la

et la température du four peut être réglée en e ectuant

RÉGLAGE à nouveau. Le VOYANT TEMPÉRATURE s'allumera

Pour régler la température du four, appuyez sur la touche

et démarre le processus de cuisson.

touche RÉGLAGE, ceci emmagasine la température centrale

température désirée s'a che à l'écran. En appuyant sur la

rotation du cadran, situé sur le contrôleur, jusqu'à ce que la

Par la suite, l'utilisateur règle la température en faisant une

CENTRALE s'allumera.

L'a chage indiquera «100» et le VOYANT TEMPÉRATURE

branchement, préalable, de la sonde centrale au connecteur.

Pour régler la température centrale, procédez au

activée seulement si celle-ci est branchée au connecteur.

L'option de la sonde centrale (contrôleur 45+ seulement) est

Fonctionnement de la sonde centrale

trois secondes.

appuyez et maintenant la touche DÉMARRAGE/ARRÊT pour

«TERMINER». Pour arrêter le cycle de temps en progression,

terminé, appuyer cette touche annulera le message

démarrera le cycle de la minuterie. Lorsque le cycle est

En appuyant sur la touche DÉMARRAGE/ARRÊT ceci

appuyez et maintenant la touche DÉMARRAGE/ARRÊT.

«TERMINER». Pour arrêter le cycle de temps en progression,

cycle est terminé, appuyer cette touche annulera le message

clignotante) puis en minutes et en secondes. Lorsque le

secondes (colonne solide) ou en heures et minutes (colonne

régressif s'a chera, à partir du temps réglé en minutes et en

démarrera le cycle de la minuterie. À l'écran, un comptage

En appuyant sur la touche DÉMARRAGE/ARRÊT ceci

fois, ceci termine la programmation.

l'écran. En appuyant sur la touche de réglage une troisième

la sélection du temps de cuisson désiré, comme démontré à

activera le VOYANT TEMPS et permet à l'utilisateur de faire

l'écran. En appuyant sur la toucheRÉGLAGE à nouveau, ceci

contrôleur, jusqu'à ce que la température désirée s'a che à

la température en faisant une rotation du cadran, situé sur le

ceci allumera le VOYANT TEMP. Par la suite, l'utilisateur règle

de la même manière. En appuyant sur la touche RÉGLAGE ,

Le réglage de la température et du temps de cuisson se fait

Fonctionnement des contrôles

s'a che puis relâchez la «clé fantôme».

l'écran. Continuez de maintenir jusqu'à ce que la lettre «C»

de la touche «Cuisson/En attente». La lettre «F» s'a che à

appuyez et maintenez la «clé fantôme» située à la droite

(F). Pour changer la lecture de la température en Celsius (C),

La lecture de la température par défaut est en Fahrenheit

Fahrenheit/Celsius

DIRECTIVES D'UTILISATION suite

Page 29

Numéro de Pièce 1955204 rév 3 4/1512

obtenu si la porte est légèrement ouverte.

four des défaillances prématurées. Un refroidissement idéal sera

50°F (66°C), le four s'arrêtera. Cette fonction protège le moteur du

s'a chera à l'écran. Lorsque la température sera en déça 1de

déça de 150°F (66°C). Pendant ce temps, le message «AUTO»

jusqu'à ce que la température de la cavité de celui-ci tombe en

refroidissement automatique, le ventilateur du four s'activera

entrera en mode REFROIDISSEMENT AUTOMATIQUE. En mode

arrêtera le four et si le four est à plus de 200°F (93°C), le four

Lorsque l'interrupteur ALLUMER/ÉTENDRE est enfoncé, ceci

fonction de refroidissement n'est pas activée lors de la cuisson.

ÉTEINDRE, ceci arrêtera la fonction de refroidissement. La

voyant et arrêtera ce mode. En appuyant sur la touche ALLUMER/

nouveau sur la touche REFROIDISSEMENT, ceci désactivera le

à l'écran. Il s'agit d'un dispositif de sécurité breveté. En appuyant de

refroidissement sera désactivé et le message «PORTE» s'a chera

ouverte. Lorsque la porte est complètement ouverte, le mode de

Un refroidissement idéal sera obtenu si la porte est légèrement

fonctionnera lorsque la porte sera fermée ou ouverte légèrement.

«FROID» s'a chera à l'écran La fonction de refroidissement

porte légèrement. Avec la porte légèrement ouverte, le message

l'écran si la porte est fermée, demandant à l'utilisateur d'ouvrir la

allumera le voyant. Un message «PORTE OUVERTE» s'a chera à

la fonction de chaleur, activera le ventilateur à haute vitesse et

En appuyant sur la touche REFROIDISSEMENT ceci désactivera

d'un dispositif d'économie d'énergie.

non utilisé. Le message «RETOUR» s'a chera à l'écran. Il s'agit

automatiquement en mode retour après le temps préprogrammé

Réglage de la fonction de «RETOUR». Le four retournera

la cavité du four à une température préprogrammée, voir:

En appuyant sur la touche RETOUR ceci permettra de refroidir

cycle.

s'arrêtera pour une période de 30secondes et continuera ce

Le ventilateur sera activé pour une période de 30secondes puis

activera le ventilateur à basse vitesse et le voyant sera allumée.

En appuyant sur la touche VENTILATEUR IMPULSION ceci

ventilateur à haute vitesse et le voyant sera allumé.

En appuyant sur la touche VENTILATEUR BAS ceci activera le

ventilateur à basse vitesse et le voyant sera allumé.

En appuyant sur la touche VENTILATEUR HAUT ceci activera le

voyant s'allumera et restera allumé pour 30secondes.

le contrôleur est en mode arrêt. Lorsque la porte est ouverte, le

pour une période de 30secondes. Les voyants fonctionneront si

En appuyant sur la touche VOYANT ceci allumera les voyants

four.

En appuyant sur la touche ALLUMER/ÉTEINDRE ceci activera le

Touches du contrôleur

DIRECTIVES D'UTILISATION suite

Page 30

Numéro de Pièce 1955204 rév 3 4/15 11

l'écran la température actuelle du four avec un incrément de 5°.

En appuyant sur la touche TEMP. ACTUELLE ceci a chera à

s'agit d'un dispositif de sécurité breveté.

«PORTE» s'a chera à l'écran jusqu'à ce que celle-ci soit fermée. Il

ainsi que la fonction de chaleur s'arrêteront et le message

Si la porte est ouverte lors du mode de cuisson, le ventilateur

d'un dispositif de sécurité.

s'a chera à l'écran et un signal sonore se fera entendre. Il s'agit

température du four excède 575°(302°C) le message «AIDE»

demandée, le message «HAUT» s'a chera à l'écran. Si la

REMARQUE:Si la température du four excède la température

message «CHARGE» s'a chera à l'écran.

température réglée et que celui-ci est prêt à l'utilisation, le

à la température réglée. Lorsque la cavité du four atteint la

indiquera «BAS» lorsque la température du four est inférieure

pour la minuterie et le ventilateur à basse vitesse. L'a chage

usine sont de 350°F (177°C) pour la température, 30minutes

vitesse du ventilateur utilisés. Les réglages par défaut réglés en

derniers réglages de la température, du temps ainsi que de la

En mode de démarrage, le contrôleur réchau era selon les

Au démarrage

activera le contrôleur en mode démarrage.

à l'écran. En appuyant sur la touche ALLUMER/ÉTEINDRE ceci

Lorsque le contrôleur est arrêté, le message «arrêt» s'a chera

En mode arrêt

avant juin2012)

Cook-N-Hold& Summit 45+ (modèle fabriqué

muni d'une sonde centrale

Cook-N-Hold Summit 45 et contrôle électronique

Contrôle électronique muni de la fonction de

REMARQUE: La minuterie ne contrôle pas la fonction de chaleur.

contrôle.

antihoraire à la position arrêt comme présenté sur le panneau de

être arrêté en e ectuant une rotation du cadran dans le sens

n du cycle, une alarme sonore se fera entendre. L'alarme peut

cadran de la minuterie varie entre 2minutes et 60minutes. À la

le sens horaire, en alignant l'indicateur selon le temps désiré. Le

La minuterie est réglée en e ectuant une rotation du cadran dans

Minuterie

ainsi qu'en alignant l'indicateur à la position désirée.

contrôlée en e ectuant une rotation du cadran de la température

La température varie entre 150° et 500°F (66°ºC à 250ºC) et est

Temp éra tu re

DIRECTIVES D'UTILISATION suite

Page 31

Numéro de Pièce 1955204 rév 3 4/1510

processus de refroidissement et arrêtera le four complètement.

En appuyant sur le bouton à la position arrêt interrompra le

breveté.

ventilateur ainsi que le moteur. Il s'agit d'un dispositif de sécurité

ouverte. Une trop grande ouverture de la porte arrêtera le

Un refroidissement idéal sera obtenu si la porte est légèrement

ce mode, la fonction de chaleur n'est pas activée.

ouverte pour que le ventilateur ainsi que le moteur démarrent. À

refroidissement de la cavité du four. La porte doit être légèrement

marche le ventilateur ainsi que le moteur pour permettre le

refroidissement à la position refroidissement, ceci met en

En appuyant sur l'interrupteur basculant cuisson/arrêt/

Refroidissement

électrique.

fonctionneront lorsque le four est branché à l'alimentation

que celui-ci sera maintenu en position ouvert. Les voyants

à rappel et ces voyants resteront allumés aussi longtemps

lampe situé sur le panneau de contrôle. Il s'agit d'un interrupteur

Les voyants du four sont activés en appuyant sur l'interrupteur de

Voyants

l'interrupteur basculant situé à gauche identi é par haut et bas.

ou basse (1150 T/M). La vitesse du ventilateur est contrôlée par

La vitesse du ventilateur peut être réglée à élever (1725 T/M)

Vitesse du ventilateur

d'un dispositif de sécurité.

chaleur et le moteur ainsi que le ventilateur s'arrêteront. Il s'agit

en mode cuisson. L'ouverture de la porte arrêtera la fonction de

La porte doit être fermée pour que le four puisse fonctionner

s'éteindra en conséquence.

maintenir le réglage de la température, ce voyant s'allumera et

Puisque le cycle de chaleur s'activera et se désactivera, pour

s'allumera vous indiquant que la fonction de chaleur est activée.

température réglée sur le cadran du thermostat. Le voyant jaune

La température du four augmentera pour atteindre la

vous indiquant que le four est en fonction en mode cuisson.

refroidissement à la position «cuisson» Le voyant vert s'allumera

Appuyez sur l'interrupteur basculant cuisson/arrêt/

Démarrage

indicateur d'allumés.

Lorsque le four est éteint, il n'y a aucun voyant ou aucun

En mode arrêt

électromécanique Summit 20

Panneau de contrôle rigide avec minuterie

DIRECTIVES D'UTILISATION

Page 32

Numéro de Pièce 1955204 rév 3 4/15 9

La tension ainsi que le raccordement doivent correspondre.

4533009.

ou triphasés, s’il vous plaît se référer à Numéro de Pièce

nécessaire le transformer pour une connexion monophasée

Le four est câblé par commande d’usine d’origine. S’il est

l'appareil sous tension.

une inspection visuelle des connexions électriques. Mettez

schéma électrique est situé à l'arrière de chaque four. Faites

correspondres à la tension et au phasage de l'appareil. Le

La tension d'entrée ainsi que de phasage doivent

pas nécessaire.

couvercle inférieur avant. Le retrait du panneau latéral n'est

gauche). Le bloc de jonction est accessible en enlevant le

et doit être reliée au bloc de jonction (voir le schéma de

La conduite de raccordement entrera à l'arrière de l'appareil

6. Mode de raccordement (câble, conduit, etc.)

5. Limitations de température des câbles

4. Grosseur du câble

3. Type de câblage

2. Protection contre la surcharge

1. Dimension du panneau de contrôle

Local and/or National electrical Code, ANSI/NFPA 70-1990.

U.L. 197 Commercial Electric cooking Appliance Standards,

L'installation du câblage doit être fait et conforme à la norme

d'alimentations électriques de l'appareil sont conformes.

pour s'assurer que les caractéristiques électriques et

véri cation de la plaque signalétique devrait être faite

Avant de procéder au raccordement électrique, une

Raccordements électriques.

INSTALLATION suite

Page 33

Numéro de Pièce 1955204 rév 3 4/158

du connecteur.

limiter le mouvement du four sans déranger le câblage

câblage du connecteur.

permettre à l'appareil d'être déplacé sans déranger le

Des moyens adéquats doivent être mis en place pour

d'appareils mobiles, doit être utilisé lors de l'installation.

à la norme ANSI Z21.69, norme pour les connecteurs

le service de réparation dans les endroits étroits.

NOTE : Installer l’appareil sur roues pour faciliter

Deux Sections

12 po (305 mm)

E. Maintenez le dégagement aux matières combustibles.

four).

12 po (305 mm)

Côté commande

utilisant un niveau à bulle, sur la grille à l'intérieur du

D. Véri ez le niveau de l'appareil aux quatre (4) côtés ( en

assurez-vous de suivre les directives correspondantes.

particulière aux types de fours que vous superposez et

l'ensemble de superposition. Portez une attention

suivant attentivement les directives contenues dans

C. Installez les pièces d'interconnecxions du conduit, en

que les écrous (fournis).

Avis

1 po (26 mm) 6 po (153mm) 3 po (77 mm)

1/4-20 (0,63cm - 50,80cm), les rondelles d'arrêts ainsi

de superposition, en utilisant six (6) vis mécaniques de

l'appareil. Fixez l'arrière de l'appareil, à l'aide du support

emplacement et alignez les côtés ainsi que l'arrière de

sous les portes du four). Levez le four supérieur à son

Arrière

commande

1 po (26 mm) 6 po (153mm) 3 po (77 mm)

Côtés Côté

B. Enlevez le couvercle inférieur avant du double four (situé

Modèles À

Une Section

Modèles À

(recommandation)

chaleur et de l’air chargé avec la graisse.

(comme les rôtissoires et friteuses) produisant de la

Éviter d’installer en plus d’autres equipements

Deux Sections

Modèles À

Une Section

Modèles À

d’equipements proximité produirant de chaleur élevée:

étape à l'arrière de l'appareil.

x 1,90cm) ainsi que les rondelles fournies. Répétez cette

utilisant quatre (4) boulons 3/8-16 x 3/4 (0,95cm - 40,64

1 po (26 mm) 2 po (51 mm) 3 po (77 mm)

boulons de xation. Sécurisez la patte au cadre du four en

façon à ce qu'elles s'alignent aux quatre (4) trous des

le sur le côté gauche. Placez les pattes avant du four de

la section inférieure du four. Levez l'appareil ou couchez-

Arrière

commande

1 po (26 mm) 1 po (26 mm) 3 po (77 mm)

Côtés Côté

Deux Sections

Modèles À

Une Section

Modèles À

des pattes de six pouces (6po, 15,24cm, 152mm) dans

combustibles et noncombustibles:

qu'elle s'insère dans la patte jusqu'au collet. Attachez

mur de

inférieure et donnez de petits coups sur celle-ci pour

A. Positionnez la pièce dans l'ouverture de la patte

Installation des modèles à four double

installation, d'origine.

celui-ci après avoir replacé le four à son emplacement,

est déconnecté, veuillez vous assurer de reconnecter

près de l'entrée électrique. Si le dispositif de retenue

C. Le dispositif de retenue peut être xé à l'appareil,

B. Les roues avant de l'appareil sont munies de freins pour

A. Pour un appareil sur roues, un connecteur conforme

Installation des fours sur roues

• Pour le service, espace de dégagement

• Espace de dégagement minimum d’installation à

• Espace de dégagement minimum d’installation près d’un

l’utilisation.

NOTE : Toujours garder un espace su sant pour l’entretien et

Conditions d’espace requises

• Déballé : 32 ½ po (826 mm)

• Emballé : 47 po (1194 mm)

Dégagement d’entrée

INSTALLATION

Page 34

DU FOUR SIMPLE

VUE DU DEVANT

Numéro de Pièce 1955204 rév 3 4/15 7

[235mm]

9-1/4"

[816mm]

32-1/8"

DU CÂBLE

ARRIÈRE

ENTRÉE

[159mm]

DU FOUR DOUBLE

VUE DU DEVANT

6-1/4"

32-1/8"

32-1/8"

formation.

commerciale par un personnel ayant reçu une

Ces appareils sont conçus pour une utilisation

conformes à ces codes.

responsabilité du propriétaire que ces appareils soient

Il existe de nombreux codes locaux et il est de la

[816mm]

[816mm]

[721mm]

28-3/8"

DU CÂBLE

ENTRÉE ARRIÈRE

[292mm]

11-1/2"

[972mm]

38-1/4"

[965mm]

38"

VUE DU HAUT

[645mm]

25-3/8"

[816mm]

32-1/8"

motor)

[60mm x 127mm]

TUYAU: 2-3/8" x 5"

3/4"

[32mm]

1-1/4"

[451mm]

17-3/4"

"D" (includes

[19mm]

Pied carré

livraison

à la

Dimension

livraison

[32mm]

1-1/4"

[43mm]

1-11/16"

[197mm]

7-3/4"

T/M (50Hz) veuillez préciser les caractéristiques électriques lors de la commande.

Caractéristiques électriques incluant les exigences du moteur. 3/4, HP, moteur 2 vitesses: 1725/1140 T/M, (60 Hz); ou 1440/950

* Les modèles à four double sont fournis avec des branchements électriques individuels

four

10.4 50 43 30 30 28 26 26 24 14 14 13

Chaque four *double

Four simple 10.4 50 43 30 30 28 26 26 24 14 14 13

XYZXYZXYZ

208V/3Ph 240V/3Ph 460V/3Ph

HP)

208V/1Ph 240V/IPh

Modèle kW total

Intensités nominales par lignes, (incluant un moteur de ventilateur 3/4

SEM-200D1 29(736) 24(610) 28 (711) 38(965) 70-1/2 (1791) 43-1/4(1099) 1024/464 84

SEM-200S1 29(736) 24(610) 24(610) 38(965) 70-1/2 (1791) 39-1/4(997) 1024/464 84

SEM-100D1 29 (736) 24 (610) 28 (711) 38 (965) 57-1/2 (1461) 43-1/4(1099) 510/232 42

SEM-100S1 29 (736) 24 (610) 24 (610) 38 (965) 57-1/2 (1461) 39-1/4(997) 510/232 42

kilogramme

W H D W H D Livres/

Modèle

(mm)

Extérieur Dimensions: En (mm) Poids à la

Intérieur Dimensions: en

(Modèles fabriqués avant juin2012)

DIMENSIONS ET CARACTÉRISTIQUES, MODÈLE SEM 100/200

Page 35

Numéro de Pièce 1955204 rév 3 4/156

DU FOUR SIMPLE

VUE DU DEVANT

formation.

commerciale par un personnel ayant reçu une

Ces appareils sont conçus pour une utilisation

[721mm]

28-3/8"

[645mm]

25-3/8"

conformes à ces codes.

responsabilité du propriétaire que ces appareils soient

Il existe de nombreux codes locaux et il est de la

[235mm]

9-1/4"

[816mm]

32-1/8"

DU CÂBLE

ARRIÈRE

ENTRÉE

[159mm]

DU FOUR DOUBLE

VUE DU DEVANT

6-1/4"

[816mm]

32-1/8"

[816mm]

32-1/8"

DU CÂBLE

ENTRÉE ARRIÈRE

[292mm]

11-1/2"

[972mm]

38-1/4"

[965mm]

38"

VUE DU HAUT

[816mm]

32-1/8"

motor)

[60mm x 127mm]

TUYAU: 2-3/8" x 5"

3/4"

[32mm]

1-1/4"

[451mm]

17-3/4"

"D" (includes

[19mm]

d’expédition

Volume

515 / 230 64

1030 / 465 128

d’expédition

HP)

[32mm]

1-1/4"

[43mm]

1-11/16"

[197mm]

7-3/4"

T/M, 50Hz veuillez préciser les caractéristiques électriques lors de la commande.

Caractéristiques électriques incluant les exigences du moteur. 3/4 HP, moteur 2 vitesses: 1725/1140 T/M, 60 Hz; ou 1440/950