Page 1

INSTALLATION AND

OPERATION MANUAL

STARFIRE AND STARFIRE SENTRY

SERIES GAS OPERATED RESTAURANT

RANGES, FRYERS & BROILERS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1382683 (01/08) © 2005 Garland Commercial Industries, Inc.

Part # 138683 (01/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 1382683 (01/08)Page 2

Page 3

Part # 138683 (01/08) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION................... 2

SPECIFICATIONS............................. 4

Gas Input Information................................4

Gas Connections – All Models.........................4

Installation Clearances................................4

INTRODUCTION.............................. 5

General Information..................................5

Rating Plate..........................................5

INSTALLATION............................... 5

Gas Supply...........................................5

Appliances Equipped with Casters ....................6

Appliances Equipped with Legs.......................6

Ventilation and Air Supply............................6

Mounting Instructions for Backguards,

Low Prole Backguards, Single-Deck High Shelves,

Double Deck High Shelves, Salamanders and

Cheesmelters.........................................6

Testing and Adjustments .............................7

Electrical Connection.................................7

Installation of a Common Front Rail & Backguard ......7

Assembly of Broiler...................................8

Sanitary Countertop Seal.............................8

Assembly of Optional Stands.........................8

OPERATING INSTRUCTIONS .................. 9

Starre Ranges.......................................9

Open top burners..................................9

Hot Top Sections...................................9

Thermostat Controlled Griddles....................9

Valve Controlled Griddles ..........................9

Griddle/Broiler (Models H281, 282, 283, 285) ........9

Griddle/Broiler (Model ST283).....................10

Oven, (Standard)..................................10

“RC” Convection Ovens............................10

Starre Sentry Ranges...............................11

General Notes ....................................11

Open Type Hot Plate..............................11

Solid Hot Tops....................................12

Oven (Standard) ..................................13

“RC” Convection Ovens............................13

Fryers and Broilers...................................13

Range-Match Broilers.............................13

Range-Match Fryers...............................14

Fryer Burner ......................................14

PRODUCT APPLICATION INFORMATION...... 15

General.............................................15

Open Burners.......................................15

Hot Tops............................................15

Griddle Tops ........................................16

Oven (Standard).....................................16

Range Base Convection Oven........................16

ADJUSTMENTS.............................. 17

Pilot Burner Adjustment.............................17

“Minimum” Flame Setting ...........................17

Burner Gas / Air Adjustment .........................18

FDO Heavy Duty Oven control.......................18

BJWA Griddle Thermostat ...........................19

MAINTENANCE AND CLEANING..............20

Seasoning...........................................20

Griddle...........................................20

Cast Iron top Grates...............................20

Cleaning............................................20

Painted Finishes...................................20

Fryer Thermostat....................................20

Stainless Steel.....................................21

Oven Interior (Porcelain Enamel)...................21

Oven Interior – Optional Continuous Clean ........21

Griddle...........................................22

Open Top Burners.................................22

Cast Iron Top and Ring Grates .....................22

Porcelain Top and Ring Grates .....................22

Hot tops..........................................22

TROUBLESHOOTING ........................23

Oven (Standard & Convection).......................23

Convection Ovens Only..............................24

Open Burner – Models not Equipped with

Flame Supervision Device ...........................24

Open Burner – Models Equipped with

Flame Supervision Device ...........................25

Hot Top / Griddle / Broiler............................26

Fryers...............................................27

WIRING DIAGRAMS.........................28

Page 4

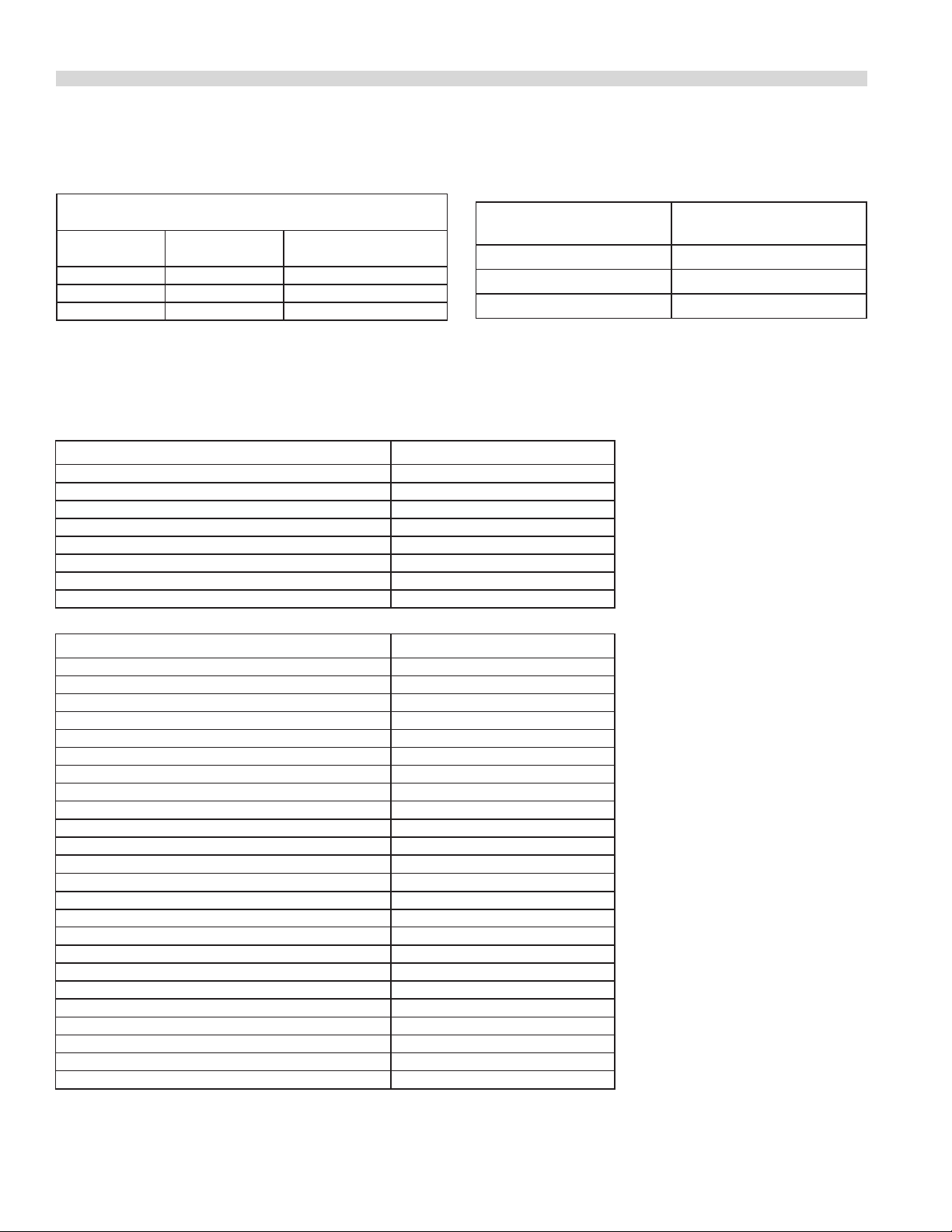

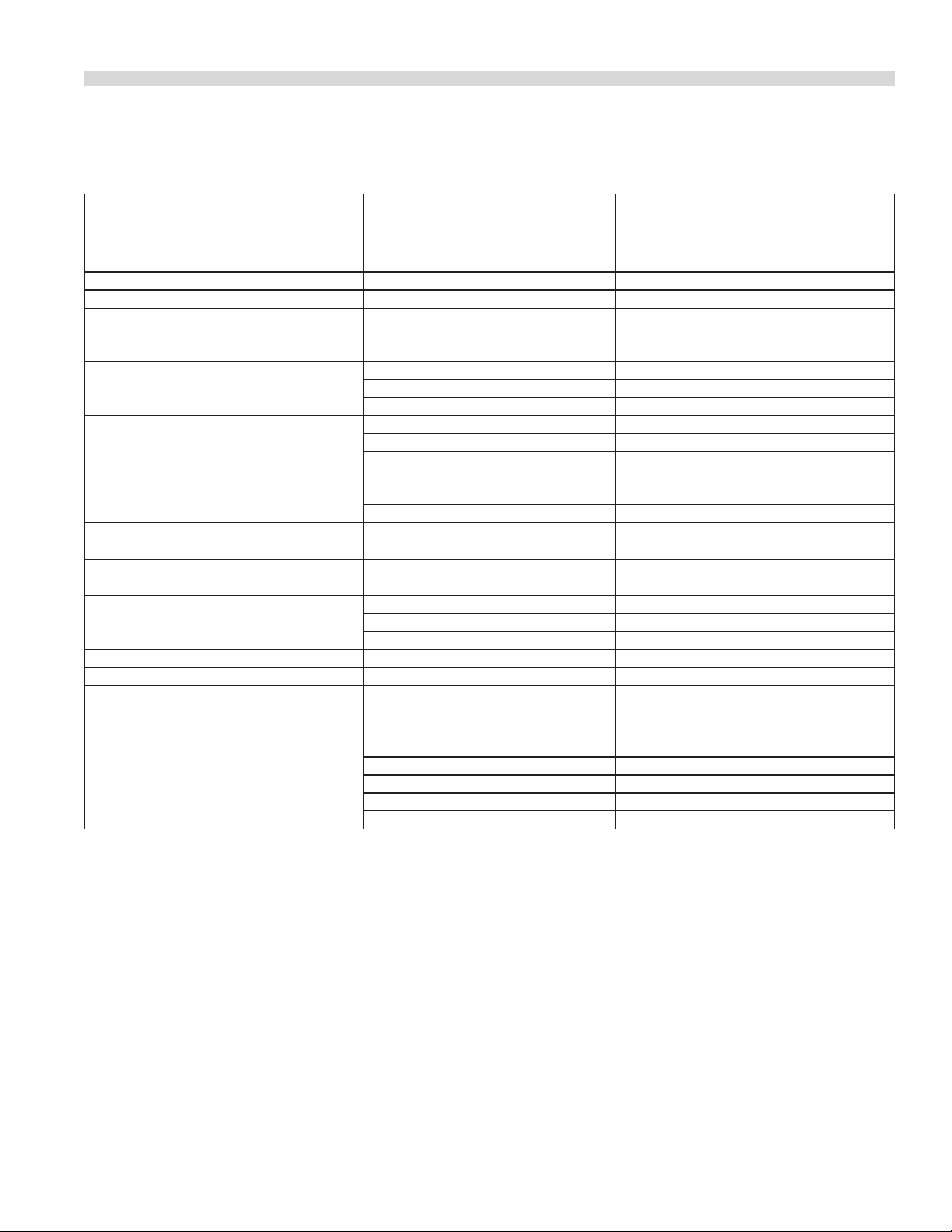

SPECIFICATIONS

Installation Clearances

Minimum Installation Clearance To Adjacent

Combustible Walls &Type Of Floor Or Base.

TYPE OF

EQUIPMENT

Ranges 6” (152mm) Combustible

Fryers 6” (152mm) Combustible

Broilers** 0” Non-combustible

**For installation in non-combustible locations only

SIDES AND

REAR

TYPE OF

FLOOR/BASE

Gas Connections – All Models

TYPE OF

EQUIPMENT

Ranges 3/4 inch N.P.T.

Fryers 1/2 inch N.P.T.

Broilers 3/4 inch N.P.T.

Gas Input Information

BURNER TYPE B.T.U.’S/HOUR-

Oven – Standard or “RC” 30,000

Space Saver Oven 25,000

Open Burner 24,000,(Nat) / 20,000,(Pro)

Hot Top, (in lieu of two open burners) 18,000

Griddle, (in lieu of two open burners) 18,000

Hot top, Front Fired 37,000

Broiler 15,000

Raised Griddle/Broiler (H/S/ST283) 13,000

MANIFOLD

INLET SIZE

BASIC MODEL NUMBER TOTAL B.T.U.’S/HOUR

H28 (-E) / ST28 (-E) 121,000

H28S/28S (-E)/ST28S(-E) 96,000

G30A 85,000

G30A-T 50,000

(S,ST) 286 (-E) H286 H286RC/ (S,ST ) 286RC(-E) 174,000

(S,ST)286S (-E)/H286S 144,000

(S,ST) 288 (-E)/H288 242,000

(S,ST)288S (-E)/H288S 222,000

(S,ST)284 (RC,RC2)/H284 (RC,RC2) 300,000

H287 (RC) 270,000

H282 (RC) 222,500

(H/S/ST)283 (RC,RC2) 257,500

H281 (RC) 203,000

H285 (RC) 238,000

H289 (RC,RC2) 358,000

H289S (RC) 323,000

(S,ST,H) 280-18B 45,000

(S,ST,H)280-24B 60,000

(S,ST,H)280-30B 75,000

(S,ST,H)280-36B 90,000

(S,H)35-280(ST,SD,SC) 110,000

ST280-45R 104,000

ST280-45(S,T) 74,000

ST24GS 39,000

Part # 1382683 (01/08)Page 4

Page 5

Part # 138683 (01/08) Page 5

INTRODUCTION

General Information

1. Damage check: Check carton or crate for possible

damage incurred in shipping. After carefully uncrating,

check for “concealed” damage. Report any damage

immediately to your carrier.

2. The correct type of gas for which the unit was

manufactured is noted on the rating plate, and only this

type of gas must be used.

3. The gas pressure must be checked when the unit is

installed to ensure that the operating gas pressure is the

same as that specied on the rating plate. If necessary,

pressure adjustments may be made at the pressure

regulator, supplied on each appliance.

4. Have a qualied gas technician check the gas pressure

to make certain that the existing gas facilities, (meter,

piping, etc.), will deliver the volume, (BTU’s), of gas

required for proper operation with no more than 0.50”

water column pressure drop. When checking pressure, be

sure that all the equipment on the same gas line is turned

to the “ON” position.

5. Make certain that new piping, joints and connections

have been made in a clean manner, and have been

purged, so that the piping compound, chips, etc., will

not clog pilots, valves, and/or controls. Use pipe joint

sealant that is approved for use with natural and liqueed

petroleum gases.

6. WARNING: Check gas connections for leaks using soap

solutions or similar mean. DO NOT CHECK WITH AN OPEN

FLAME.

Rating Plate

All burner input ratings are shown on the rating plate of each

unit which can be located as follows:

Ranges – Remove lower front panel, (located on main

bottom).

Broilers – Remove upper front panel, (located on the top left

corner).

Fryers - Open fryer door, (located on inside of fryer door.)

When corresponding with the factory or your local

authorized service agency regarding service or parts, be sure

to refer to the particular unit by the correct model number

(including prex and sux letters and numbers) and the

serial or code number. The rating plate axed to the unit

contains this information.

INSTALLATION

Gas Supply

Before assembly and connection, check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the rating plate, (refer to “Rating Plate “above).

Connect a unit stamped “NAT” only to natural gas, and a

unit stamped “PRO” only to propane.

B. In a new installation, have the gas authorities check

meter size and piping to ensure that the gas supply will

deliver sucient pressure to operate the unit properly.

C. When adding or replacing equipment, have gas

authorities check gas pressure to ensure that the existing

meter and piping will supply fuel to the appliance with

no more than 1/2 “ water column pressure drop during

operating.

D. Before turning on the main gas supply, check the unit to

be certain that all the valves are in the “OFF” position.

E. When checking gas pressure, be sure that all other

equipment on the same gas line is turned “ON.” A preset

gas pressure regulator is supplied with GARLAND

Restaurant Series Equipment. It may be necessary to

adjust the regulator to deliver fuel at the pressure shown

on the rating plate.

Page 6

INSTALLATION Continued

F. In Canada, the installation must comply with local codes,

or in the absence of local codes, with the Installation

codes for Gas Burning Appliances and Equipment CAN/

CGA-B149.1 and B149.2, (or latest edition), and with the

Canadian Electrical Code (C22.1)(latest edition).

In the United States the installation must conrm with

the National Fuel Gas Code ANSI Z223.1, (or latest

edition). NFPA No. 54, (or latest edition), and the National

Electrical Code ANSI/NFPA 70, (latest edition), and/or

local codes to ensure a safe and ecient operation.

G. The appliance and its individual shut-o (supplied by

others) must be disconnected from the gas supply piping

system during any pressure testing of that system at

pressures in excess of 1/2 PSIG (3.45 KPA). The appliance

must be isolated from the gas supply piping by closing

its individual manual shut-o (supplied by others) during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 PSIG (3.45 KPA).

H. Adequate clearance must be provided for servicing and

proper operation.

Appliances Equipped with Casters

Ventilation and Air Supply

Proper ventilation is highly essential for optimum

performance. The ideal method of ventilating open-top

equipment is the use of a properly designed canopy which

should extend six inches, (152mm), beyond all sides of the

appliance(s) and six feet, six inches, (1981mm), above the

oor.

A strong exhaust will create a vacuum in the room. For an

exhaust vent to work properly, replace air must enter the

room. The amount of air that enters must equal the amount

exhausted.

All gas burners and pilots need sucient air to operate. Large

objects should not be placed in front of the appliance(s)

which would obstruct the ow of air into the front.

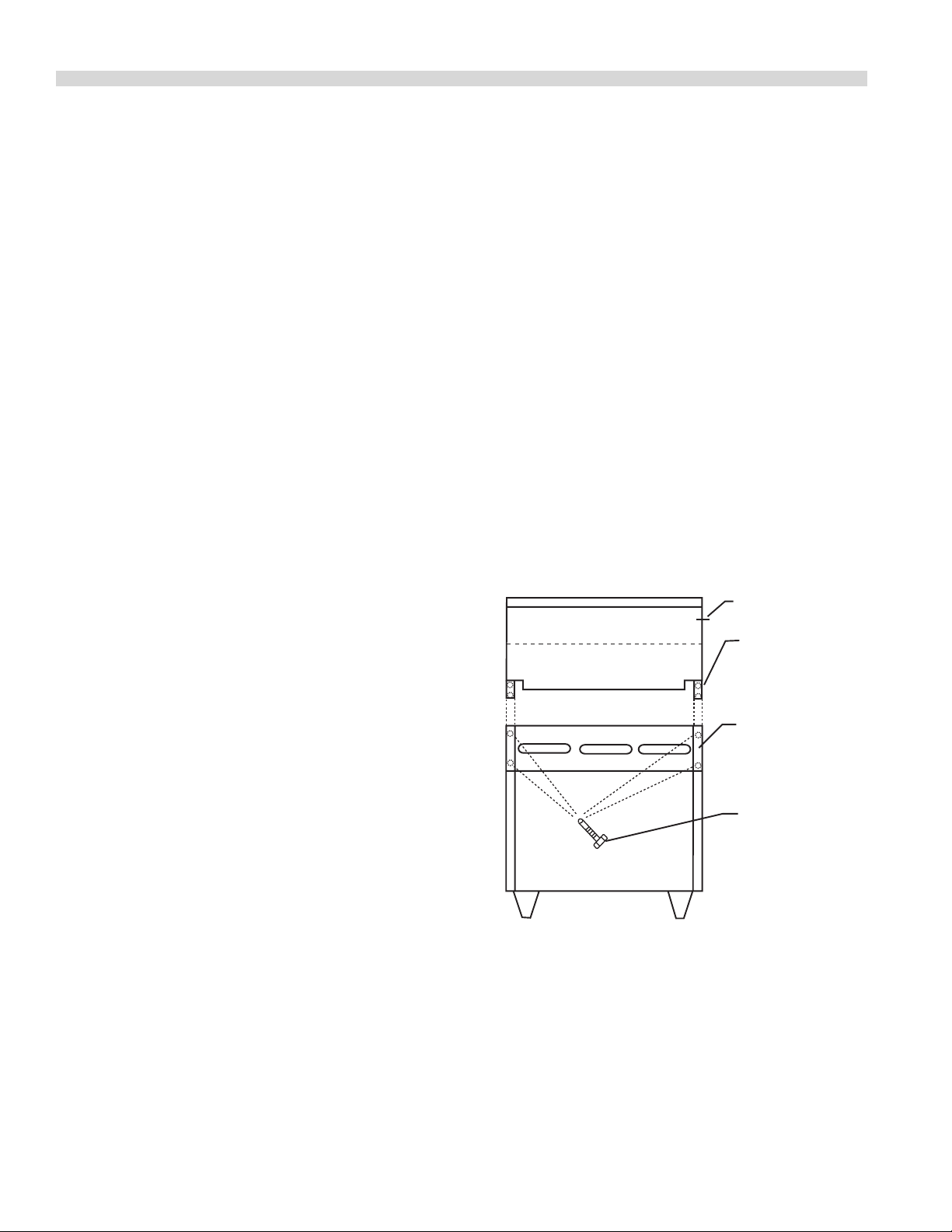

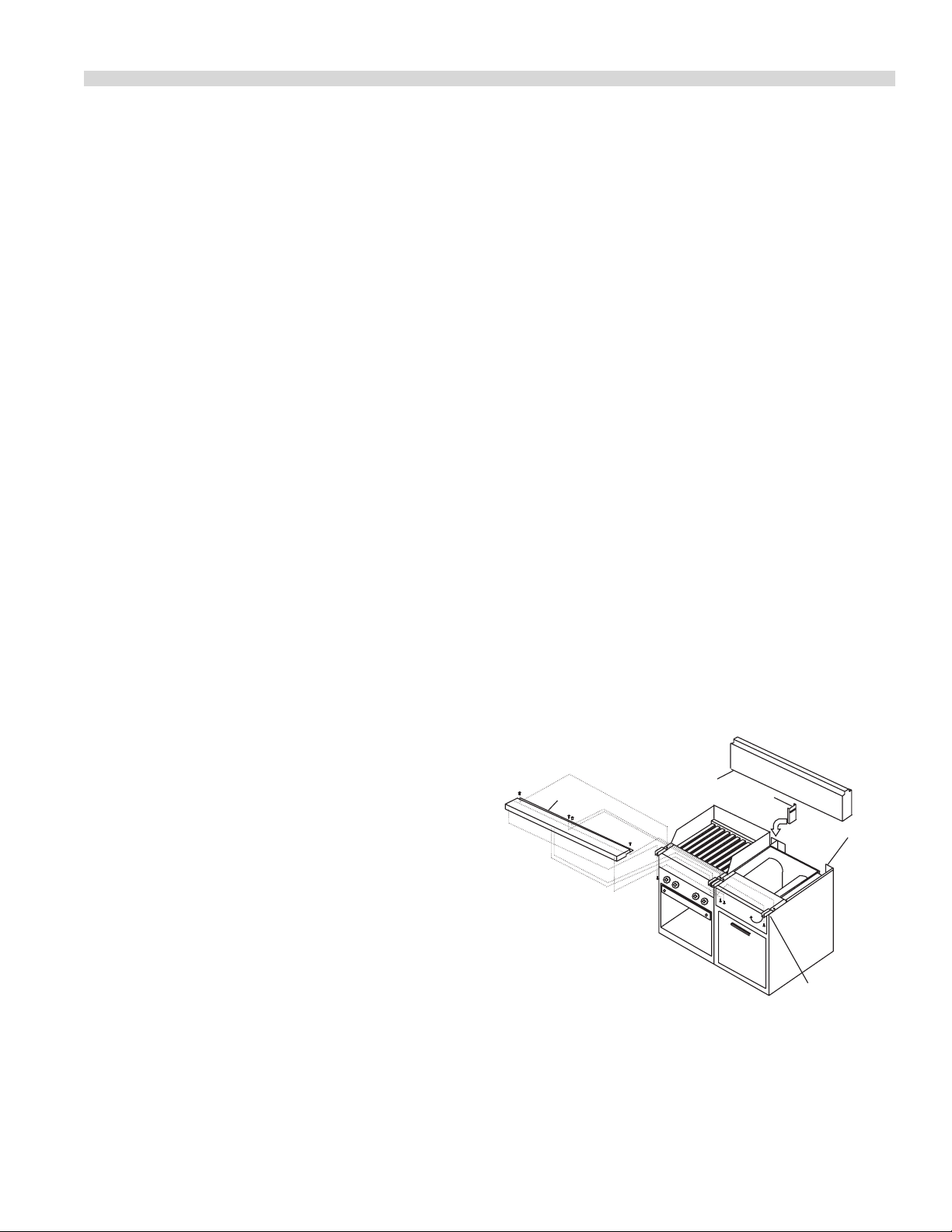

Mounting Instructions for Backguards, Low

Prole Backguards, Single-Deck High Shelves,

Double Deck High Shelves, Salamanders and

Cheesmelters.

Bolt "A"

A. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69/CSA 6.16, Addenda Z21.69B2006/CSA 6.16B-2006 (or latest edition), and a quickdisconnect device that complies with the Standard for

Quick Disconnects for Use with Gas Fuel, ANSI Z21.41/

CSA 6.9, Addenda Z21.41A-2005/CSA 6.16A-2005 (or

latest edition).

B. The front casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick disconnect

device or its associated piping.

C. Please be aware: required restraint is attached to a

bracket, (which is located on the rear caster closest to

the gas connection), and if disconnection of the restraint

is necessary, be sure to reconnect the device after the

appliance has been returned to its original position.

Appliances Equipped with Legs

Raise the front of the appliance and block. Do not lay the

appliance on its back. Position a leg insert in leg retainer

opening and tap upward until the insert seats at the collar

ange. Repeat leg insert installation for the other three

legs and adjust all four legs to the same height. Legs can be

further adjusted to level the appliance and to compensate

for uneven ooring.

Upright

Burner Box

Side

1/4" x 3/4"

Type "B"

Washer Hex

Head SMS

4 Req'd

A. Rear of range must be easily accessible.

B. Remove the at-head bolt “A” from each side of the

backguard only when the unit will be placed against

another appliance with a backguard, shelf, or broiler.

C. Place the backguard, high shelf, salamander, or

cheesmelter on the rear of the range, slipping the

support brackets into the openings in the burner box

side.

Part # 1382683 (01/08)Page 6

Page 7

Part # 138683 (01/08) Page 7

INSTALLATION Continued

D. Securely fasten the support brackets to the burner box

sides with (4) 1/4-20 x 3/4 slot truss head machine screws,

or (4) #10B x 1/2 Phillips sheet metal screws. (Hardware

package is supplied).

E. Remove front panel.

F. If the appliance is banked with others that have

backguards installed, replace the at head bolts removed

in Step B so that the upright of the backguard is fastened

to upright of the adjacent backguard.

G. Replace the front panel(s).

Testing and Adjustments

All ttings and pipe connections must be tested for

leaks. Use approved gas leak detectors, soap solution or

equivalent, checking over and around all the ttings and

pipe connections. DO NOT USE A FLAME! Accessibility to

all gas lines and ttings require that valve panel(s) lower

front panel(s), and/or oven rack(s) be removed. It may be

necessary to remove, or at least raise and securely prop

griddle(s), hot top(s), and /or top grate(s). All parts removed,

(including fasteners), should be stored safely for reinstallation.

1. Be sure that all valves and thermostats are in the “OFF”

position.

2. Turn on the main gas supply valve. Light all pilots.

3. Leak test all valves and ttings as described above.

Correct any leaks as required and recheck.

4. Shut o all valves and set thermostat dials to “OFF” or

lowest position.

For ease of attaching the supply line, there is a removable

cover on the terminal box.

Permanent connection to the electrical service must comply

with local codes, or in the absence of local codes, with the

national electrical code.

A wiring diagram is attached to the rear of each appliance

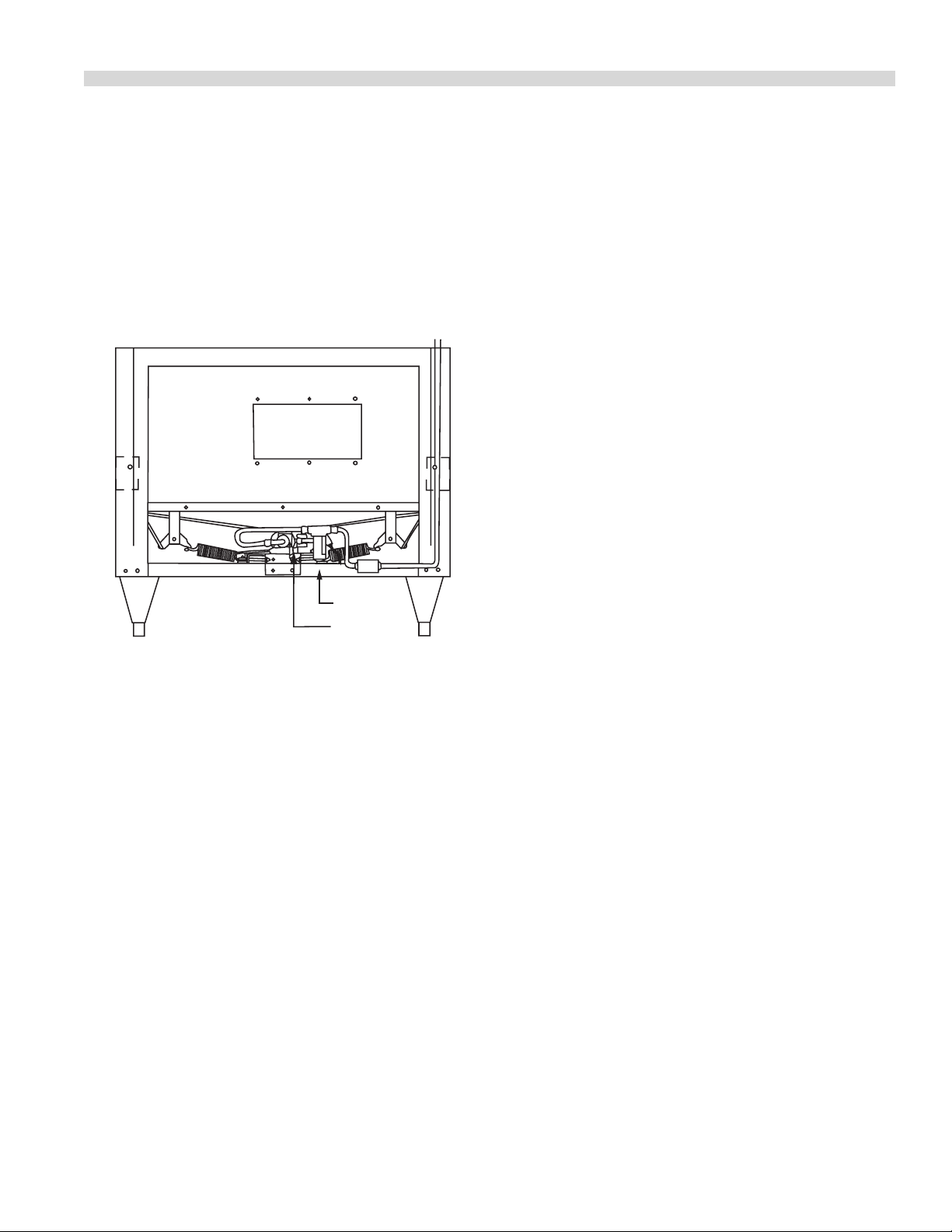

Installation of a Common

Front Rail & Backguard

1. All units must be properly aligned and leveled.

2. Remove the control panels on fryers and preparation

tops. Loosen the main top to allow the rail ange to t

between the main top and the frame.

3. The rail ange must be tucked under all the main tops

and fastened to the framework.

4. The front rail is anchored at the front using spacers and

screws provided.

5. Install connecting brackets between each pair of units to

receive backguard and pull the units together.

6. Install bayonet backguard by sliding it down over the rear

outer anges.

NOTE: Open burner top grates and preparation tops have

rear return ange which is placed inside the rear backguard.

BACKGUARD

RAIL FLANGE

CONNECTING BRACKETS

All units are tested and adjusted at the factory, however,

REAR OUTER FLANGE

burners and pilots should be checked upon installation and

adjusted if necessary.

Electrical Connection

IMPORTANT – This appliance must be electrically grounded

in accordance with local codes, or, in the absence of local

codes, with the national Electrical code.

When the appliance is ordered and equipped for 220/240

volt operation, the supply line must be connected to the

wiring terminations located inside the terminal box at the

rear of the appliance.

BROILER AND FRYER

REPRESENT TYPICAL UNITS

CHANNEL BRACKETS

SWING IN FOR

SHIPPING

Page 8

INSTALLATION Continued

Assembly of Broiler

Steel Grate Rods

Each broiler is supplied with (14) 15”/381mm, (-18B),

21”/533mm, (-24B), 26” /660mm, (-30B), or 31”/787mm, (-36B)

long steel rods. These rods are to be installed in the grooves

on the support brackets, which are atop the burners.

Briquettes

For best cooking results, it is recommended that the correct

amount of briquettes are installed in the broiler. Refer to

the table and drawing below for the proper arrangement

of briquettes. When all the briquettes have been placed as

instructed, install the top grate sections.

MODEL -18B -25B -30B -36B

Rows front to rear 7777

Rows left to right 7 11 14 17

Sanitary Countertop Seal

When the broiler is installed on a countertop, the National

Sanitation Foundation, (NSF), International recommends

that it be sealed in accordance with NSF standards per the

following instructions:

1. Unit should be located on a non-combustible, level

countertop surface.

2. Thoroughly clean the bottom perimeter of the broiler and

the countertop around the bottom of the broiler.

3. Apply a generous bead of silicone sealant around the

entire outside perimeter of the broiler bottom.

4. The broiler can be secured to the countertop by inserting

the 3/8-inch diameter crating bolts through the counter

from the bottom, (via predrilled 1/2” diameter holes), and

threading them into the nut inserts in the bottom of the

nit.

5. Smooth the silicone sealant with a nger or tool to

provide a cover seal.

Assembly of Optional Stands

Space briquettes evenly on rods in number of rows and

columns specied for your particular model.

1. Fit stand ends together.

2. Secure stand together with (8) 10-24 machine screws,

lock washers and 10-24 hex nuts, (provided). Use only the

front and back pieces.

3. If the stand exceeds a four, (4), foot length, use the

optional cross member. Optional cross member

mounting brackets are secured with ten, (10) each of the

following, (provided): 10-24 machine screws, 1/4-inch

lock washers, and 10-24 hex nuts.

4. Position a square foot insert in the bottom of one of the

legs, and use a light hammer to tap the insert upward

into the leg until it seats at the collar ange.

5. Repeat step 4 for each.

Part # 1382683 (01/08)Page 8

Page 9

Part # 138683 (01/08) Page 9

OPERATING INSTRUCTIONS

Starre Ranges

Open top burners

1. Remove top grates and ring grates.

2. Check ash tubes to see that they are properly positioned

on burner charge ports.

3. Light pilots.

4. Replace top grates and ring grates.

5. Turn valve completely on. Burner ame should be

1/2”, (13mm), stable blue ame, and should impinge on

the bottom of a pot placed on the ring.

CAUTION: Should burner ignition fail within 5 seconds, turn

the burner valve o and repeat steps 1 through 5. If ignition

continues to fail, consult your factory authorized service

agency.

Shut Down

1. Turn all valves to the “OFF” position.

2. If the unit is to be shut down for an extended period of

time, close the in-line gas valve.

Hot Top Sections

1. Raise or remove hot top sections. Each burner has one

pilot located at the front right side of the burner.

2. Light pilots. The pilot burner should be adjusted to

provide for rapid ignition of the burner.

3. Turn the burner valve on. A sharp blue ame should be

approximately 1/4”, (6mm), high.

4. Replace hot top sections.

Thermostat Controlled Griddles

See griddle seasoning before use.

1. Raise griddle at front and securely block.

2. Light pilots located at the front right side of each burner

3. The sensing bulbs must be fully inserted into their

individual holders, which are located on the underside of

the griddle.

4. Set the thermostat to its maximum setting. The burner

should have a 5/16”, (8mm), stable blue ame.

5. Lower the griddle carefully into position, being very

careful not to leave any part of the capillary tube in the

burner compartment.

Valve Controlled Griddles

See griddle seasoning before use.

1. Raise griddle at front and securely block.

2. Light pilots located at the front right side of each burner.

3. Turn burner valves completely on. Burners should have

1/2” to 5/8”, (13mm to 16mm), stable blue ame.

4. Lower griddle carefully into position.

Griddle/Broiler

(Models H, , , )

See griddle seasoning before use.

Before turning on main gas supply, be sure all burner valves

are in the “OFF” position.

1. Eight (8) ceramic bricks are supplied with each range.

These ceramics are to be placed in the burner section of

the griddle / broiler before it is put into operation.

2. Each burner has a ange on each side which will serve

as a rest for a pair of ceramics. Position two ceramics

between each pair of burners with the projections facing

downward. Place two ceramics between the outside

burner on each side, using the side lining ledges as the

outer support.

3. Light the pilots located in the broiler section.

4. Turn the burner valves completely on. Burners should

exhibit a 5/16” stable blue ame.

CAUTION: Gas will ow to the top burners even if the pilots

are not lit. Gas will not be interrupted. It is the responsibility

of the installer to check the ignition of all burners and ensure

that it is proper. SHOULD IGNITION FAIL AFTER 10 SECONDS,

TURN THE BURNER VALVE OFF, WAIT 5 MINUTES AND TRY

AGAIN.

Page 10

OPERATING INSTRUCTIONS Continued

Griddle/Broiler (Model ST)

See griddle seasoning before use.

1. One pilot serves three burners via a lighter burner.

2. Push in the valve knob and turn counter-clockwise to the

ignition position.

3. While holding the knob fully in, depress the ignitor

button and visually conrm that the pilot lights. If the

pilot does not light, repeatedly press the ignitor button

until ignition is achieved.

4. After the pilot is lit, continue to hold the valve knob in for

at least 20 seconds, then release it. If the pilot goes out,

wait ve, (5), minutes, then repeat the procedure.

5. When the pilot is established, push in the valve knob

again and turn it counter-clockwise to the full ame

position, igniting the main burner.

6. For low ame or simmer, push in the valve knob and turn

it to the low ame position.

7. To turn the burner o, push in and turn the valve knob to

the circular “OFF” symbol.

Shut down

1. Turn all gas valves o.

2. If the unit is to be shut down for an extended period of

time, turn the in-line service valve to the “OFF” position,

(this valve is not factory supplied).

Oven, (Standard)

Lighting

1. Remove oven bottom(s).

2. Depress and hold the red reset button, located at the

lower front of the oven, (beneath the oven door), while

lighting the oven pilot. Continue to hold the reset button

for at least 60 seconds after the pilot is lit. Release the

button. If the pilot does not stay lit, wait ve, (5) minutes,

then repeat the procedure.

LIGHT BURNER THRU INSIDE OF OVEN

RESET BUTTON ON SAFETY

Shut Down

1. Turn all valves and thermostats to the “OFF” position, or

lowest setting.

2. If the range is to be shut down for an extended period of

time, close the in-line gas valve.

Relighting

1. Turn all gas valves o.

2. Wait ve, (5), minutes.

3. Follow procedure under “LIGHTING” at left.

W/MATCH

“RC” Convection Ovens

For 115v usage, a cord and plug is provided but connection

to the electrical service must comply with local codes; or in

the absence of local codes, with the Canadian Electrical Code

C22.1, (or latest edition), or with the National Electrical Code,

ANSI/NFPA No. 70 (or latest edition).

WARNING: Electrical Grounding Instructions.

The appliance is equipped with a three pronged (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-pronged

receptacle. Do not cut or remove the grounding prong from

this plug.

Part # 1382683 (01/08)Page 10

Page 11

Part # 138683 (01/08) Page 11

OPERATING INSTRUCTIONS Continued

POWER FAILURE NOTE: In the event of a power failure, no

attempt should be made to operate this oven. This oven is

gas operated but has electrical features, motor and door

switches.

A wiring diagram is attached to the rear of this unit and a

copy is included in this manual for your use.

Lighting Instructions

REST

BUTTON

ON SAFETY

PILOT

IGNITOR

BUTTON

1. Using the access through the louver panel hold the reset

button (RED) located on the oven safety valve. (See prior)

2. Using the access hole located below the louver in the

panel, push the RED IGNITOR BUTTON continuously until

the oven pilot ignites. (See prior)

3. If the pilot does not stay lit after you release the reset

button, wait 5 minutes and repeat Step 2 and hold the

reset button approximately 60 seconds.

Start Up

The motor on your range convection oven is maintenance

free since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions to

follow on the care of your motor.

A. When the motor is operating, it cools itself internally by

air entering the rear of the motor case, provided proper

clearance has been allowed.

B. Since the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, the heat from the blower wheel is

conducted down the shaft and into the armature of the

motor. This action could shorten motor life.

C. We recommend, at the end of the bake or roasting

period, when the oven will be idle for any period of time

or before shutting down completely, that the doors

be left open, and by use of the cool-down position on

the fan switch, the fan continues to run for at least 20

minutes. The “FAN” should never be turned “OFF” when

the oven it “HOT”.

Starre Sentry Ranges

General Notes

NOTE: Models with sux “E” are equipped with an electric

spark ignition module for pilot burner ignition.

WARNING: If the pilot is extinguished either intentionally

or accidentally, no attempt should be made to relight for at

least ve, (5) minutes.

Open Type Hot Plate

All burners are equally rated, and may be used for either

fast boiling or simmering. The pan supports will safely

accommodate pans from 5”, (125mm), in diameter. It is,

however recommended that pans larger than 12 “, (300mm),

be placed only on the rear burners.

1. Activate the power switch to cook position.

2. Turn oven valve on.

3. Turn thermostat to desired setting.

Cool Down

1. Turn thermostat and oven valve o.

2. Open door.

3. Activate power to the cool down position.

NOTE: For maximum eciency and stability, use at bottom

utensils and center them over the burner head.

Lighting

(Models equipped with ame supervision devices):

1. Push in the valve knob, and turn it counter clockwise to

the ignition position.

2. While holding the valve knob fully in, light the pilot

burner with a match.

Page 12

OPERATING INSTRUCTIONS Continued

NOTE: On ranges equipped with electric spark ignitors, press

the ignitor button and observe that the pilot lights. If it does

not, repeatedly depress the ignitor button until it does.

3. When the pilot is lit continue to hold the valve knob fully

in for at least 30 seconds, then release it. If the pilot goes

out, wait for ve (5), minutes, then repeat from step 1.

4. When the pilot has been established, push the valve knob

in again and turn it counter-clockwise to the desired

ame setting position, lighting the burner.

5. To turn the burner o, turn the dial to the circular “OFF”

symbol. The safety device will disengage within 60

seconds.

(Models not equipped with ame supervision devices):

1. Push in the pilot valve knob and turn it counter clockwise

to the ignition position, (see caution below).

2. Light all pilots with a match.

3. When all pilots are lit, push the burner valve knob in

and turn counter-clockwise to the desired ame height

setting.

4. To turn the burner o, turn the dial to the circular “OFF”

symbol.

5. To turn o all pilots, turn the pilot dial to the circular “OFF”

symbol.

CAUTION: Gas will ow to the top burners even if the pilots

are not lit. Gas will not be interrupted. It is the responsibility

of the installer to check the ignition of all burners and ensure

that it is proper. SHOULD IGNITION FAIL AFTER 10 SECONDS,

TURN THE BURNER VALVE OFF, WAIT 5 MINUTES AND TRY

AGAIN.

Solid Hot Tops

Recommended preheat time is 30 minutes. This will ensure

that the casting is thoroughly saturated with heat. Pots

should have at bottoms for maximum surface contact.

Warped or dented pots will not transfer heat evenly, wasting

energy and resulting in uneven cooking patterns. During

slow periods, it is advisable to lower the burner setting to

conserve energy.

Lighting

1. Push in the valve knob, and turn it counter-clockwise to

the ignition position.

2. While holding the valve knob fully in, press the ignitor

button and observe that the pilot lights. If it does not,

repeatedly depress the ignitor button until it does.

3. When the pilot is lit, continue to hold the valve knob fully

in for at least 30 seconds, then release it. If the pilot goes

out, wait for ve, (5), minutes, then repeat from step 1.

4. When the pilot has been established, push the valve knob

in again and turn it counter-clockwise to the desired

ame setting position, lighting the burner.

5. For low ame or simmer push in the valve knob and turn

it counter-clockwise to the low ame position.

6. To turn the burner o, turn the dial to the circular “OFF”

symbol. The safety device will disengage within 60

seconds.

Griddles

NOTE: All burners are controlled by a ame supervision

device.

Griddle tops are designed to have food cooked directly on

the surface. Do not put pots or pans on the griddle surface.

This will scratch or nick the surface and result in poor

cooking performance and sticking of product.

NOTE: All burners are controlled by a ame supervision

device.

Use of the solid hot tops is recommended where long-term

stock pot cooking is required for soups, sauces or stock. Pots

can be placed anywhere on the hot top.

Check the grease container and empty frequently during

heavy use to prevent overow.

Lighting

Refer to the section titled “SOLID HOT TOPS’ on the previous

page for detailed instructions.

Part # 1382683 (01/08)Page 12

Page 13

Part # 138683 (01/08) Page 13

OPERATING INSTRUCTIONS Continued

Oven (Standard)

Lighting

1. Push in the valve knob, and turn it counter-clockwise to

the ignition position.

2. While holding the valve knob fully in, press the ignitor

button and observe that the pilot lights. If it does not,

repeatedly depress the ignitor button until it does.

3. When the pilot is lit, continue to hold the valve knob fully

in for at least 30 seconds, then release it. If the pilot goes

out, wait for ve (5), minutes, then repeat from step 1.

4. When the pilot has been established, push the valve

knob in again and turn it counter-clockwise to the oven

ame position, then set the thermostat to the desired

temperature.

5. To turn the burner o, turn the dial to the circular “OFF”

symbol. The safety device will disengage within 60

seconds.

“RC” Convection Ovens

The forced air range oven consists of a food preparation

chamber completely sealed from the combustion area.

This eliminates the possibility of contamination from ue

products and permits an ecient method of circulating the

heated air within the cooking chamber.

During the cooking process in a conventional oven, a vapor

barrier and a layer of “cool” air covers the exposed area of

the product. In a forced air oven, the fan pushes the heated

air over and around the product, sweeping away the vapor

barrier and cool air, permitting faster heat penetration. This

action permits the use of lower temperatures and shorter

cooking times.

The rule of thumb for determining the cooking temperature

is to reduce the set temperature by approximately 80°F,

(28°C), from that which you would use in a conventional

oven, and that the product be checked at a point midway in

the time required in a conventional oven.

Lighting

Refer to the section titled ‘STANDARD OVEN’ on the previous

page for detailed instructions.

Start Up

3. Turn the thermostat to the desired setting.

Cool down

1. Turn the oven valve knob to the circular “OFF” symbol.

2. Turn the thermostat to its lower setting.

3. Open the oven door.

4. Set the power switch to the “COOL DOWN” position.

Shut Down

1. Turn the oven valve knob to the circular “OFF” symbol.

2. Turn the thermostat to its lowest setting.

3. Set the power switch to the “OFF” position.

Operating Suggestions

The motor on your range convection oven is maintenance

free since it is constructed with self-lubricating sealed ball

bearings. It is designed to proved durable service when

treated with ordinary care. We have a few suggestions to

follow on the car of your motor.

A. When the motor is operating, it cools itself internally by

air entering the rear of the motor case, provided proper

clearance has been allowed.

B. Since the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, the heat from the blower wheel is

conducted down the shaft and into the armature of the

motor. This action could shorten motor life.

C. We recommend, at the end of the bake or roasting

period, when the oven will be idle for any period of time

or before shutting down completely, that the doors

be left open, and by use of the cool-down position on

the fan switch, the fan continues to run for at least 20

minutes. The “FAN” should never be turned “OFF” when

the oven is “HOT”.

Fryers and Broilers

Range-Match Broilers

To ensure long life and service, it is imperative that the

cooking surface be carefully broken in or “seasoned” in the

follow manner:

1. Set the power switch to the” COOK” position.

2. Turn the oven valve knob to the “ame” symbol.

1. Remove all factory applied protective material by

washing with hot water and a mild detergent or soap

solution. Rinse and dry thoroughly.

Page 14

OPERATING INSTRUCTIONS Continued

2. Apply a light coat of cooking oil to the cooking surface.

Wipe away the excess.

3. Turn all the valves to a low setting and allow the grids to

heat slowly for 30 minutes. Allow the oil to remain on the

cooking surface for an additional 3 to 4 minutes, then

wipe o.

4. Reset valves to your desired operating temperature and

apply a second coat of oil.

Allow the broiler to reach the set temperature, wait an

additional 2 to 3 minutes, then wipe away the excess oil.

The broiler is now ready for use.

NOTE: Unless your products contain a sucient amount of

fat, the grid racks may require re-seasoning before use to

prevent sticking. Grid racks must be re-seasoned after every

cleaning.

Lighting Instructions

Model (H,S)280 – (18,24,30,36)B

1. One pilot serves two burners and is located between

those burners.

2. Push red spark buttons several times to ignite pilot

burners.

3. Ensure pilots are lit by viewing through pilot view hole on

front of unit.

Model ST280 – (18,24,30,36)B

1. Push in the valve knob and turn counter-clockwise to the

ignition position.

2. While holding the knob fully in, depress the ignitor

button and visually conrm that the pilot lights. If the

pilot does not light, repeatedly press the ignitor button

until ignition is achieved.

3. After the pilot is lit, continue to hold the valve knob in for

at least 20 seconds, then release it. If the pilot goes out,

wait ve, (5), minutes, then repeat the procedure.

6. To turn the burner o, push in and turn the valve knob to

the circular “OFF” symbol.

Shut down

1. Turn all gas valves o.

2. If the unit is to be shut down for an extended period of

time, turn the in-line service valve to the “OFF” position,

(this valve is not factory supplied).

Range-Match Fryers

Before Operating the Fryer

1. Before leaving the factory, the fryer was tested, and the

thermostat calibrated with oil in the fry tank; therefore it

is necessary to clean the fry tank before lling with frying

compound. Use detergent or other cleaning agents with

hot water. Thoroughly rinse and dry.

2. Never operate the pilot or burner with an empty fry tank.

It will only take a few minutes to ruin the tank and void

the warranty.

3. If the fryer is equipped with a cold-rolled steel fry tank,

and is not to be lled immediately after cleaning, coat

the entire tank surface with shortening or cooking oil to

prevent rusting.

Fryer Burner

The burner used in Starre Range-Match Series Fryers

is a patented design which requires no primary air; so

adjustment of primary air is not possible. When the proper

gas is supplied at the proper pressure, and the ceramic

targets are properly adjusted, combustion will begin about

even with the bottom of the ceramics. The characteristic

sound is a low roar, similar to a blow-torch.

NEVER throttle down the incoming gas in an eort to make

the ame burn directly on the orice.

Lighting Instructions

1. Before lighting the pilot, ll the fry tank with frying

compound.

4. When the pilot is established, push in the valve knob

again and turn it counter-clockwise to the full ame

position, igniting the main burner.

5. For low ame or simmer, push in the valve knob and turn

it to the low ame position.

2. Turn the thermostat to the “OFF” position. Depress and

turn the gas control knob to the “OFF” position. Wait ve

(5) minutes.

3. Turn the control knob to the “PILOT” position.

4. Push the control knob in and press the piezo ignitor.

Continue to hold the control knob in for about 60

seconds after the pilot is lit.

Part # 1382683 (01/08)Page 14

Page 15

Part # 138683 (01/08) Page 15

OPERATING INSTRUCTIONS Continued

5. If liquid frying compound is used., Turn the gas control

knob to the “ON” position, and set the thermostat to the

desired temperature.

6. If a hydrogenated, (solid), frying compound is used,

pack the fry tank with the compound and turn the gas

control knob to the “ON” position for approximately ve,

(5) seconds, then turn it “OFF” for approximately ten,

(10), seconds. Repeat turning the control knob “ON,” then

“OFF” until the frying compound is melted. If smoking

occurs during this process, the heat is being applied too

fast, scorching the frying compound. If the process is

continued in this way, permanent damage to the fry tank

may occur.

7. If the pilot goes out during this process, repeat the

procedure from step 2.

Shut down

For complete shut down, turn both the thermostat and the

gas control knob to the “OFF” position.

PRODUCT APPLICATION INFORMATION

General

The range is the workhorse of the kitchen because of its

versatility. Most frequently used in small applications, such as

cafes, schools, church kitchens, rehouses, and small nursing

homes where demands are less taxing. As a general rule of

thumb, one four to six burner range with a hot top will be

adequate for a restaurant seating 30 to 35.

The top of the range is designed for exibility and the

preparation of numerous dierent types of products. It may

be equipped with two, or even three dierent types of tops

and burners, depending on the menu needs. An operation

that cooks to order, or uses the range primarily as back-up

will nd that open burners will suit most of their needs.

Preparation of soups, stocks, or sauces is done on a hot top

where slow, even cooking is desirable.

Open Burners

The most traditional uses of open burners are sautéing, pan

frying, and small stock pot work. Short-term cooking is the

most ecient use for the open burner. Pans should cover

as much of the grate as possible to minimize heat loss. The

maximum stock pot size to be used on an open burner is 11

inches, (279mm), diameter. Open burners should be turned

o when not in use to conserve energy. Leaving a ame

burning is of no advantage since the heat is instantaneous.

Hot Tops

Hot tops are recommended where long-term stock pot

cooking is required for soups, sauces or stocks. Pots can be

placed anywhere on the hot top, rather than in one specic

position, as on an open burner. The maximum stock pot size

to be used on the hot top is 12 inches, (305mm), in diameter.

Heating larger quantities of food can be done more

eciently than heating small quantities. Pots and pans

should be covered whenever possible to reduce energy

consumption.

High acid sauces, such as tomato should be cooked in

stainless steel rather than aluminum to avoid chemical

reaction. Light colored sauces such as Alfredo may be

discolored by the use of aluminum, especially if stirred with

a metal spoon or whip. Saltwater shellsh may pit aluminum

pots if they are frequently used for this purpose

Recommended preheat time for a 12-inch, (305mm), hot top

section is 30 minutes. This will thoroughly saturate the metal

with heat. Hot tops are evenly heated, and have a smooth

surface so that pots may be moved easily to any position.

Pots must have a at bottom for maximum contact with

the hot top surface. Warped or dented pots will not transfer

heat evenly or eciently, wasting energy and resulting in

uneven cooking patterns. Roasting pans with straps should

not be used on a hot top because only the straps will touch

the heated surface and transfer will be minimal. During slow

times, group pots on one hot top section and turn o the

other section(s). This will conserve energy. If needed, the

other section(s). Will preheat in 10 to 15 minutes due to the

retained heat in the metal.

Page 16

PRODUCT APPLICATION INFORMATION Continued

Griddle Tops

Griddle tops are designed to have food cooked directly on

the surface, for example hamburgers, eggs, pancakes, has

browns, etc. Do not put pots or pans on the griddle surface.

This will scratch or nick the surface, resulting in sticking and

scorching of product. Never salt food on a griddle because

this will cause a gummy residue to build up, making the

griddle more dicult to clean. Avoid hitting the griddle plate

with a spatula, as this will also nick the surface. The most

frequently used temperature range for griddles is 325° to

350°F, (163° to 177°C). Check and drain the grease drawer

frequently during heavy use to prevent overowing. Over

a period of time, some discoloration of the steel griddle

plate will occur. This will not aect performance. For best

cooking results, keep the griddle surface as clean and shiny

as possible.

Oven (Standard)

The temperature is automatically controlled by the

thermostat, so satisfactory results can be obtained with

condence again and again.

For best performance, these instructions should be followed:

A. Grid Shelves There are two shelf positions. The correct

shelf position should be decided by the size of the

product to be cooked. When the best position has been

determined, push the shelf fully into the oven until

contact with the back wall stops its movement.

B. Tray Size One cake tray up to 24 x 22 inches,

(610 x 560mm), can be placed on each shelf. Single trays

or dishes should be centered on the shelf. Trays must not

be allowed to overhand the shelf on any side, since this

will inhibit proper heat circulation.

Range Base Convection Oven

Generally, a temperature 25° to 50°F (-4° to 10°C), lower than

that specied in recipes for standard ovens should be used.

Cooking time may be reduced, depending on the product.

A 2% to 5% reduction in cook time is a general rule. Keep a

close check on any product being prepared for the rst time.

The size of the load, temperature of the product going in,

and moisture content are the major factors that inuence

necessary cook times and temperatures. Successfully

prepared products should be recorded with their times and

temperatures for future reference.

Preheat the oven thoroughly before loading. It will take

approximately 15 minutes for the oven to reach 350ºF, 177ºC.

Best results will be attained when the oven is allowed to

preheat for 30 minutes or more for thorough heat saturation.

Center the load on the oven racks to allow for proper heat

circulation around the sides. The oven will hold three, (3),

18” x 26”, (457mm x 660mm), sheet pans, six, (6), 12” x 20” x

2.5”, (305mm x 508mm x 64mm), steam table pans, or one,

(1) 17.75” x 25.75”, (451mm x 654mm), roast pan. Never place

pans directly on the oven bottom. Always use the lowest rack

position that will allow the heated air to circulate within the

oven cavity. Load and unload food as quickly as possible to

prevent excessive temperature drop. For even baking, avoid

using warped pans.

Do not use a deep pan for shallow cakes, cookies, etc., as heat

circulation across the top of these items is essential for even

browning. To prevent excessive shrinkage, roast meats at a low

temperature; 250°F, (121° to 163° C), When rethermalizing frozen

products, preheat the oven 50°F, (10°C), higher than the cooking

temperature to compensate for heat loss during and after

loading. Return the thermostat to the cooking temperature after

loading.

C. Preheat time Allow at least 45 minutes after turning on

the cold oven, with the thermostat set at the desired

temperature before loading with food. Load product

quickly and immediately close the door.

D. Thermostat The thermostat automatically controls the

heat to maintain the selected temperature.

To conserve energy, turn the oven o when not in use. If you

cover pans with aluminum foil, be sure to crimp it tightly

around the edges to prevent the foil from blowing o in the

oven. Any food or other matter which becomes lodged in the

fan must be removed as soon as the oven is cool.

Part # 1382683 (01/08)Page 16

Page 17

Part # 138683 (01/08) Page 17

ADJUSTMENTS

The top and oven orices are xed and cannot be adjusted.

Proper rate will be attained if the gas supply pressure is

correct. Pressure may be checked by using the 1/8” NPT

manifold pressure tap. A properly adjusted air shutter will

provide for a distinct blue ame over the entire port area of

the burner when at full rate.

Pilot Burner Adjustment

Set all pilots so that the ame envelopes the tip of the

thermocouple.

Open Burners Safety Device, (ST & STE Series)

Pilot Adjustment is made by turning the screw on the

adjusting valve located at the pilot outlet of the valve body

clockwise to decrease, or counter-clockwise to increase.

Open burners without Flame

Safety Device, (S Series)

Pilot adjustment is made at the adjusting valve located at the

pilot block(s) underneath the top grate by turning the screw

clockwise to decrease, or counter-clockwise to increase.

Griddles and Hot tops

Pilot adjustment is made at he adjusting screw located on

the valve body by turning the screw clockwise to decrease,

or counter-clockwise to increase.

“Minimum” Flame Setting

Griddle

Minimum ame setting is adjusted at the screw located on

the valve body, by turning the valve to the “MIN” position,

and turning the screw clockwise to decrease the ame size,

or counter-clockwise to increase the ame size. Set to the

lowest stable blue ame along the entire burner length.

Range Match Broiler

(280 Series & S280 Series)

Broilers are equipped with “HI/LO” valves which fracture an

adjustable low ame setting. To adjust:

1. Burner must be cold.

2. Pilot ames should be lit and properly adjusted.

3. Turn the dial to the “LOW” or “MIN” position and remove.

4. With a screwdriver, turn the small adjusting screw inside

the valve stem until the burner ame is at the desired

low setting, (minimum 3/16”/5mm ame along the entire

burner).

5. Replace the dial and return to the “OFF” position.

(ST280 Series)

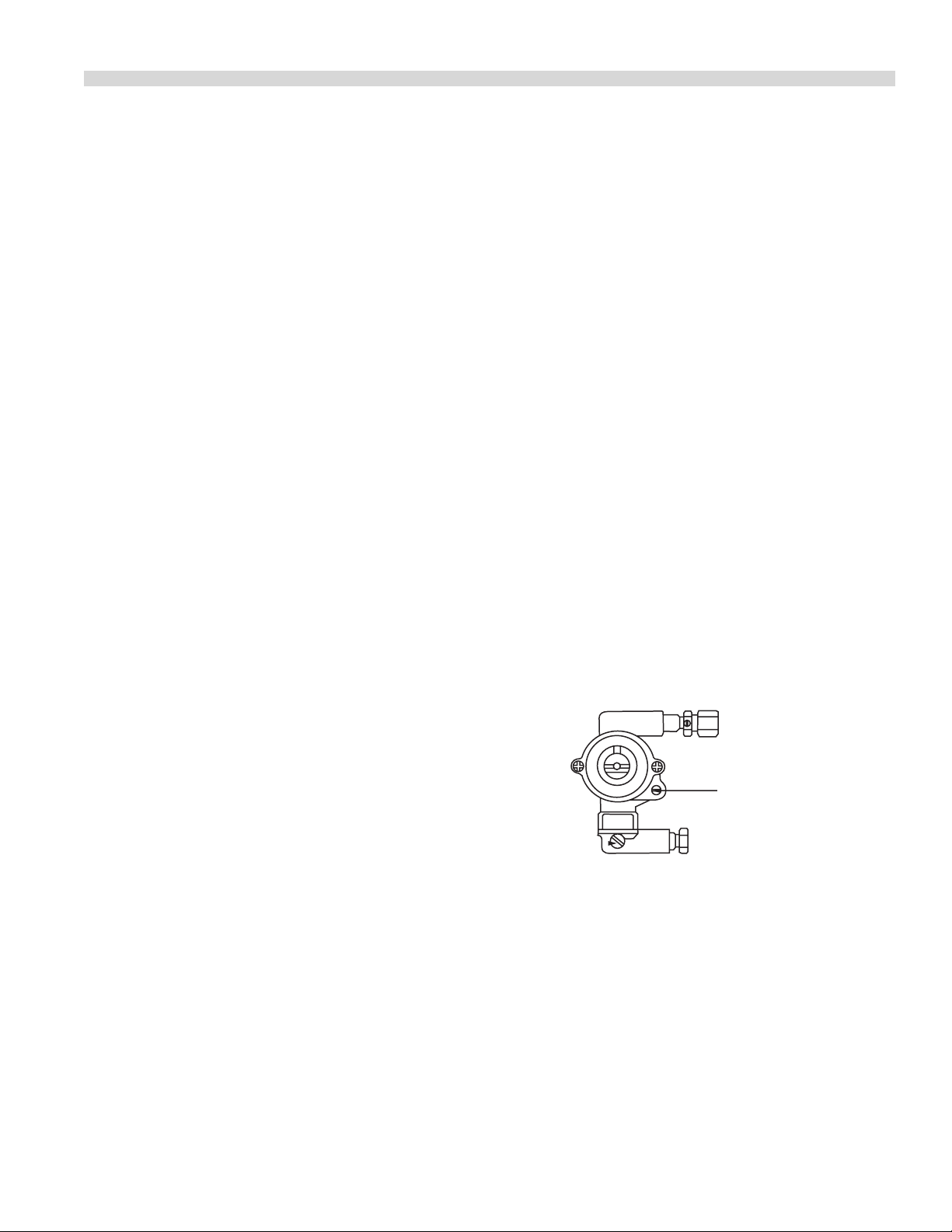

Oven, (Standard and ‘RC’)

Pilot adjustment is made by turning the screw on the

adjusting valve located at the pilot outlet of the valve body

clockwise to decrease, or counter-clockwise to increase.

Range Match Broilers

1. The pilot adjusting valves are located on the manifold.

2. With the valve panel in place, the pilots can be adjusted

with a long, thin-bladed screwdriver inserted through the

small hole in the valve panel to obtain a 1 5/8”, (41mm),

ame.

Minimum Flame

Adjuster

1. Set gas tap to low position.

2. Connect a U-gauge manometer to the test nipple located

down-stream of the gas tap.

3. The manometer should read 1.8” WC for natural gas, or

8”WC for propane.

4. If the reading on the manometer does not agree with

the pressure specied in step 3, adjust by turning the

adjusting screw clockwise to reduce the pressure, or

counter-clockwise to increase.

Page 18

ADJUSTMENTS Continued

Burner Gas / Air Adjustment

Variation in eld condition and/ or rough handling of the

equipment in transit may create the need for adjustment to

the primary burner air. Check operation and adjust as below

to provide a sharp blue ame at full rate, (valve open fully, or

thermostat calling for maximum gas ow).

On the burner, locate the air shutter, (at the end where the

burner orice enters). Loosen the locknut so that the air

shutter turns freely. Turn on the gas to the burner. Rotate the

air shutter to obtain the following:

a. Open, (Star), Burner – 1/2”, (13mm, stable, sharp inner

blue cones.

b. Hot tops & Griddles – 5/16”, (8mm) stable, sharp inner

blue cones.

c. Oven Burners – If the ames are soft, unstable, or

show yellow tipping, increase the amount of air by

opening the air shutter.

NOTE: The ame safety valve is a protective device which

allow gas to ow to the burner only when the pilot is burning,

(used on all models except H/P 280 Series)

A too loose or too tight connection of the thermocouple nut

to the automatic pilot valve can prevent the thermocouple

from activating the valve. The nut should be drawn up nger

tight, then tightened an additional 1/4-turn ONLY with a

wrench.

It is recommended that an automatic pilot test kit be used

to check the thermocouple and hood assembly of the safety

valve. A visual examination of the thermocouple lead should

be made to conrm that there are no cracks.

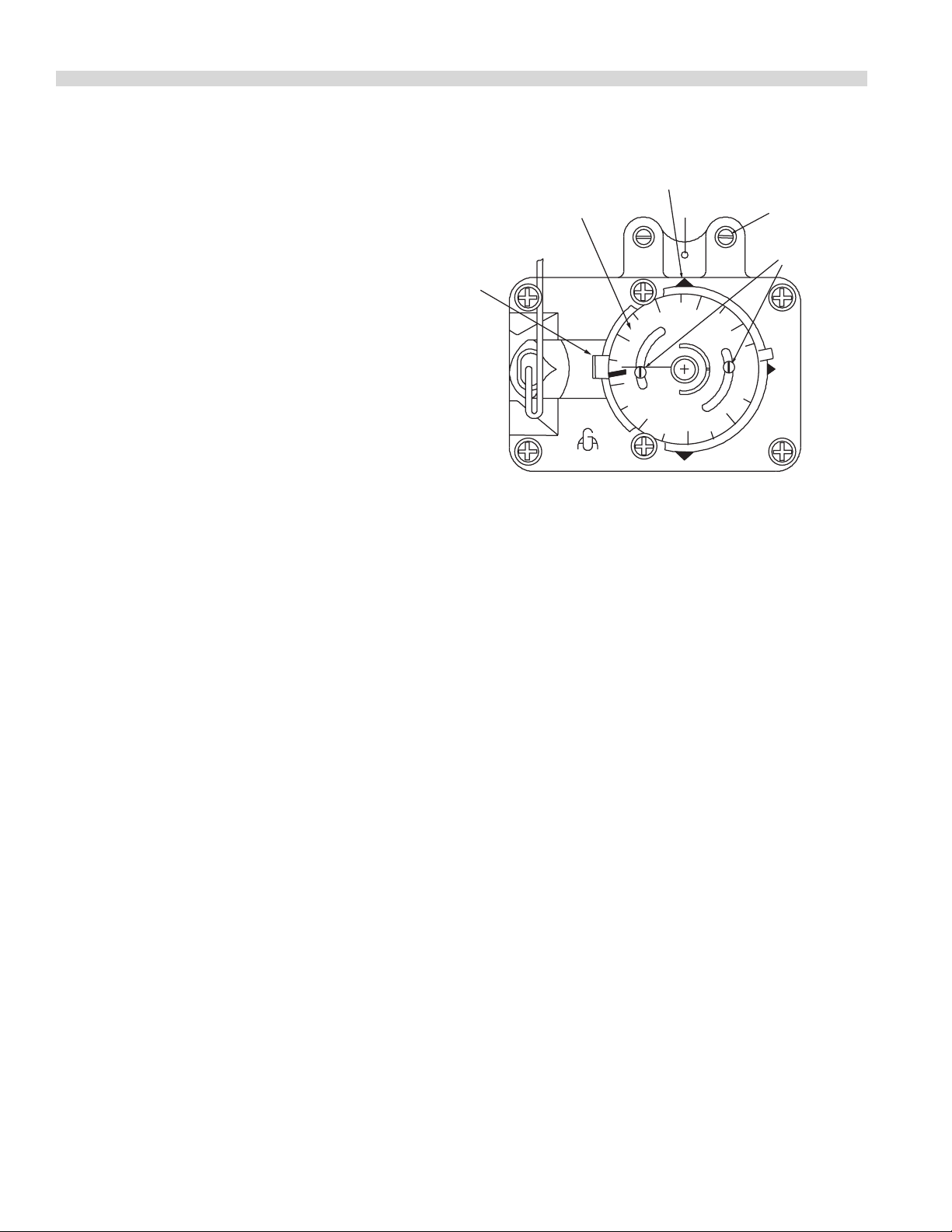

FDO Heavy Duty Oven control

The model FDO oven thermostat is a precision-made

instrument, carefully set at the factory to accurately control

oven temperatures from 150° to 500°F, (66° to 260°C). All

adjustments are accessible from the front of the appliance

after moving the dial. To remove the dial, grasp the outer

edges and pull straight out.

By-Pass Adjustment

The Robertshaw FDO snap/throttle thermostat requires that

the by-pass ame be properly adjusted. To adjust proceed as

follows:

Calibration

Plate

Dial

Stop

MODEL

FDO

Indicator Mark

0

5

4

0

0

4

0

5

3

0

0

3

0

5

2

By-pass Flame

Adjuster

Calibration

Lock Screws

5

0

0

5

5

0

1

5

0

3

0

0

1. Ensure pilot ame is lit and adjusted.

2. Turn oven temperature control to 200°F, (93°C), and allow

the oven to heat for three minutes.

3. Turn, the oven temperature control to the lowest

position, then turn slowly counter-clockwise until the

audible “click” is heard.

4. Making sure the oven temperature control dial is not

disturbed, turn the by-pass ame adjusting screw

clockwise to decrease, or counter-clockwise to increase

the ame on the burner to the lowest possible stable

ame. When properly adjusted, the by-pass ames will

cover the entire length of the burner.

Calibration Instructions

Field calibration is seldom necessary and should not

be resorted to unless experience with cooking results

undoubtedly indicate that the control is not maintaining

the temperature for which the dial is set. To check oven

temperatures when calibrating, use only a reliable mercury

thermometer, or preferably an oven pyrometer. To check

calibration, proceed as follows:

1. Place the thermocouple of the test instrument or reliable

mercury thermometer in the center of the oven.

2. Turn the oven temperature control knob to 400°F, (204°C),

and allow the oven to cycle at least three times.

Part # 1382683 (01/08)Page 18

Page 19

Part # 138683 (01/08) Page 19

ADJUSTMENTS Continued

3. Continue to monitor the oven temperature, recording

the readings at 5 minute intervals until three successive

readings are within 5°F, (2°C), of each other.

If the temperature does not read within 15°F, (8°C), of the dial

setting, recalibrate as follows.

1. Remove the oven temperature control dial, making sure

the setting is not disturbed.

2. Hold the calibration plate, (located directly behind the

control dial), and loosen the two calibration lock screws

until the plate can be rotated independently of the

control.

3. Turn the calibration plate until the temperature indicated

on the plate corresponds with the reading on the test

instrument. Hold the plate in place and tighten the

screws rmly.

4. Repeat step 3 in the previous section, checking the

temperature to ensure the adjustment has been made

properly.

5. Replace the temperature control dial.

NOTE: If adjustment of the calibration plate is prevented by

the position of the lock screws, the screws can be moved to

other holes that have been tapped for them.

BJWA Griddle Thermostat

(H/P 280 Series Only)

When the griddle surface reaches the temperature for which

the dial is set the control cuts down the ow of gas to the

amount required to keep the griddle at that temperature.

The control must be adjusted to pass enough gas to keep the

entire burner ignited. To properly adjust the by-pass setting,

proceed as follows:

1. Light the burner by turning the dial fully “ON.”

2. After 5 minutes, turn the dial clockwise to a point slightly

past, (to the right of), the rst mark on the dial.

CALIBRATION

SCREW

BY-PASS

ADJUSTMENT

SCREW

ROBERTSHAW BJWA

THERMOSTAT

Calibration

1. Use a Robertshaw test instrument with a disc-type

thermocouple, or a reliable “surface” type thermometer.

(NOTE: A drop of oil on the face of the disc will provide for

better contact.)

2. Turn ALL griddle control dials to 400°F, (240°C). allow the

temperature to stabilize by waiting for the thermostat(s)

to cycle three times before taking a temperature reading.

3. Check the temperature reading when the control cuts

down to by-pass, by placing the sensor rmly on the

griddle surface directly above the sensing bulb of the

control. Test instrument should read from 350° to 410°F,

(196° to 213°C). If the dial setting does not agree with

the test instrument reading within the above limits,

recalibrate.

NOTE: NO ATTEMPT SHOULD BE MADE TO RECALIBRATE

THE GRIDDLE CONTROL WITHIN THE WARRANTY PERIOD IF

THE TEMPERATURE IS WITHIN ±20°F OF THE DIAL SETTING.

RECALIBRATION SHOULD BE PERFORMED IF THE CONTROL IS

FOUND TO BE INACCURATE BY MORE THAN ±20°F, AND LESS

THAN ±50°F. IF THE CONTROL IS FOUND TO BE INACCURATE

BY MORE THAN ±50°F DURING THE WARRANTY PERIOD, THE

CONTROL WILL BE REPLACED UNDER WARRANTY.

3. Remove the dial by pulling it straight o.

4. With a screwdriver, turn the by-pass adjustment screw

counter-clockwise to decrease the ame, or clockwise to

increase the ame, until there is a minimum ame along

the entire burner.

To recalibrate:

1. Remove the dial and push out the center metal insert.

2. Replace the dial without the insert.

3. Holding the dial rmly in place, insert a screwdriver

through the center of the dial and seat it in the slot in

the calibration screw. DO NOT TURN THIS SCREW! Exert

pressure on the screwdriver to push the calibration stem

inward.

Page 20

ADJUSTMENTS Continued

4. While holding the calibration stem pushed inward with

the screwdriver, turn the control DIAL to the temperature

indicated on the test instrument. Release pressure on the

calibration stem.

5. Remove the dial from the control, replace the dial insert,

and reinstall the dial on the control.

6. Set the dial to 450° F, (232° C). Check temperature

as before. If the temperature is not now within the

acceptable ±20°F, (4°C), range, the sensing element is

inoperative and the control should be replaced.

MAINTENANCE AND CLEANING

Seasoning

Griddle

A. Remove all factory applied protective material by

washing with hot water, mild detergent or soap solution.

B. Apply a thin coat of cooking oil to the griddle surface,

about one ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

C. Light all burners, set a lowest possible setting. Some

discoloration will occur when heat is applied to steel.

D. Heat the griddle slowly for 15 to 20 minutes. Then wipe

away oil. Repeat the procedure 2 to 3 times until the

griddle has a slick, mirror like nish. Do this until you have

reached the desired cooking temperature.

IMPORTANT: Do not attain high (on valve control or 450° (on

thermostat control) during “break-in” period.

NOTE: Steel griddle surface will tone (blue discoloration)

from heat. This toning will not diminish function or operation

is not a defect.

Fryer Thermostat

Calibration

Field calibration is seldom necessary and should not

be resorted to unless experience with cooking results

undoubtedly indicate that the control is not maintaining

the temperature for which the dial is set. To check fryer

temperature for calibration, use a pyrometer.

1. Suspend the thermocouple in the center of the fry tank

approximately 3 inches, (756mm), deep.

2. Allow the burner to cycle at least four times.

3. The fourth time the burner cycles OFF, compare your

instrument reading with the thermostat setting.

The griddle will not require reseasoning if it is used properly.

If the griddle is over heated and product begins to stick to

the surface it may be necessary to repeat the seasoning

process again. If the griddle is cleaned with soap and water it

will be necessary to reseason the griddle surface.

Cast Iron top Grates

First, remove the cast iron top grates from the range. Wash

the cast iron top grates thoroughly with a mild soap and

warm water. Dry the cast-iron top grates thoroughly with a

clean cloth. Immediately after drying, season the top grates

lightly with a non-toxic oil, (Liquid vegetable oil or Pam spray

oil) WARNING; DO NOT SEASON THE TOP GRATES WHILE ON

THE RANGE TOP! Seasoning grates on the range top over an

open ame could cause a ash re. After seasoning, replace

the top grates onto the range. Turn all the range top sections

“ON LOW”. Allow the top sections to burn in this manner

for at least 20 minutes before using pots or pans on the top

grates. SEASONING OF THE TOP GRATES WILL BE REQUIRED

WHENEVER THEY HAVE BEEN CLEANED. FAILURE TO SEASON

GRATES WILL CAUSE RUSTING.

Cleaning

Painted Finishes

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

Part # 1382683 (01/08)Page 20

Page 21

Part # 138683 (01/08) Page 21

MAINTENANCE AND CLEANING Continued

The oven should be permitted to cool down before cleaning

exterior surfaces.

1. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a light weight non metallic scouring pad.

Dry thoroughly with a clean cloth.

2. Stainless steel should be cleaned using a mild detergent,

a soft cloth and hot water.

If necessary to use a nonmetallic scouring pad, always rub in

the direction of the grain in the metal to prevent scratching.

Use a water based stainless cleaner (Drackett Twinkle), if you

want a high shine.

Stainless Steel

For routine cleaning just wash with a hot water and

detergent solution. Wash just a small area at a time or the

water will evaporate leaving the chemicals behind causing

streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with a soft clean cloth

before it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

To prevent ngerprints there are several stainless steel

polishes on the market that leave an oily or waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste. Use only stainless steel, wool or plastic tools if

necessary to scrape o heavy deposits of grease and oil. Do

not use ordinary steel scraper soft knives as particles of the

iron may become imbedded and ruse. STEEL WOOL SHOULD

NEVER BE USED.

Either a typical bleach solution or hot water can be used to

sanitize stainless steel with out harm.

Oven Interior (Porcelain Enamel)

NOTE: Disconnect line cord (if applicable from power supply

before cleaning or servicing.

1. Before cleaning oven interior, remove all oven racks

and guides (if “RC” base). Oven racks and guides can be

cleaned with a mild soap and warm water or run through

dish washer.

2. The porcelain interior can be cleaned with oven cleaners

such as “Easy-O, or “Dow Oven Cleaner”.

Follow product manufacturer’s instructions for proper use.

Oven Interior – Optional Continuous Clean

NOTE: Disconnect line cord (if applicable ) from power supply

before cleaning or servicing.

1. “Break-In-Period” – When the oven is new, operate the

oven for at least two hours at high heat, with the oven

empty, before normal cooking operation. Continue

preheating the oven for two hours prior to use during

the rst two weeks. During this break-In-Period. It is

important that the oven surfaces be kept clean of

excessive soiling due to spillage.

2. How to put “continuous cleaning” action to work: Each

day, after baking and roasting operations have ceased,

empty the oven turn the temperature control up to high

heat (500°). This high heat will accelerate the cleaning

action and reduce the time required to eectively clean

the oven. Usually the cleaning operation will take about

45 to 60 minutes.

3. Heavy Staining – When the oven appears soiled, due to

heavy staining. We suggest pre-heating the empty oven

each day for 1 or 2 hours (depending on the condition of

the oven) for eective results. Also, ordinary household

ammonia has proven to be eective in removing baked

on “soil” build-up, and has the benecial eect at keeping

the microscopic “pores” of the coating open and free to

perform its cleaning action. An occasional light swabbing

with household ammonia while the oven is at room

temperature will prove extremely benecial.

WARNING – Abrasives and Oven cleaners should not be used

– in order to maintain continuous cleaning action, it is very

important to avoid the use of abrasive materials such as steel

wool scouring pads, abrasive or sharp implements which can

cause permanent damage to the surface coating. In addition,

oven cleaners such as “Easy-O” or “Dow Oven Cleaner will

clog the “PORES” of the special coating and will retard the

cleaning action.

4. High temperature cleaning causes grease and food

residue to be reduced to a ne powder. After oven has

cooled, the powder should be brushed from the oven

cavity.

5. Period “Tune-Up” – Although the oven appears clean, we

recommend operating the oven at high heat for 2 hours

approximately once each month. This will insure against

build-up of solids in the pores of the coating.

Page 22

MAINTENANCE AND CLEANING Continued

Griddle

To produce evenly cooked, browned griddle products, keep

griddle free from carbonized grease. Carbonized grease on

the surface hinders the transfer of heat from the griddle

surface to food product. This results in uneven browning

and loss of cooking eciency, and worst of all, carbonized

grease tends to cling to grilled foods, giving them a highly

unsatisfactory and unappetizing appearance. To keep the

griddle clean and operating at peak performance, follow

these simple instructions:

A. AFTER EACH USE clean griddle thoroughly with a grill

scraper or spatula. Wipe o any excess debris left from

cooking process.

B. ONCE A DAY clean griddle surface with a grill brick and

grill pad. Remove grease container and clean thoroughly,

in same manner as any ordinary cooking utensil.

C. ONCE A WEEK clean griddle surface thoroughly. If

necessary, use a grill stone or grill pad over the griddle

surface. Rub with grain of the metal while still warm.

A detergent may be used on the plate surface to help

clean it, but care must be taken to be sure it is thoroughly

removed. After removal of detergent, the surface of the

plate should be covered with a thin lm of oil to prevent

rusting. To remove discolorations, use a non-abrasive

cleaner. Before re-using, the griddle must be reseasoned.

Keep griddle drain tube to grease container clear at all

times on those models without grease container.

CAUTION This griddle plate is steel, but the surface is

relatively soft and can be scored or dented by careless use of

spatula.

Be careful not to dent, scratch, or gouge the plate surface.

This will cause food to stick in those areas. Also, note, since

this is a steel griddle if a light coating of oil is not always

present rust will develop on exposed and uncoated areas.

Open Top Burners

Cleaning of the range top burner is a simple procedure and,

if done at regular intervals will prolong the life of the range

and ensure good ame characteristics.

The most common problem with open burner ranges is

spillage. Once the burner ports are partially plugged with

food, the air-to-gas mixture is disturbed and results in an

inecient burner.

Wipe any spills as they occur.

Grids and trays should be removed daily, washed, rinsed and

dried thoroughly.

Use a wire brush to clean the ports of the burners. Ignite and

check for clogged holes.

If any clogged holes are apparent, the burner should be

lifted out and brushed inside and out with a small venture

brush. Each port on the burner itself should be cleaned with

a properly sized wire or thumb drill. Wash with soap and hot

water if grease is observed on the burners. Dry thoroughly.

Reinstall and check the ame pattern. Readjust the air

shutter if necessary.

If a yellow ame appears around the edges instead of being

uniformly blue, it is usually a sign of grease and dirt in the

throat of the burner. Remove and clean the burner and

readjust the air shutter.

Cast Iron Top and Ring Grates

Cast iron top and ring grate(s) can be cleaned with mild soap

and warm water. For baked on material, a wire brush can

be used. Dry thoroughly. Lightly coat with vegetable oil to

help prevent rust from forming. At the rear of the cast iron

top grate there are spills shields. These should be removed

and cleaned. Replace after cleaning to prevent grease and

spillovers dripping down the back of range.

Porcelain Top and Ring Grates

Porcelain top and ring grate(s) should be removed from

the range before cleaning. Clean with warm water, dish

detergent with degreaser and a soft cloth. DO NOT USE

ABRASIVES which will damage the porcelain surface. For

baked on material use of a ber pad or plastic scrubber

and standard oven cleaner is acceptable. Follow the

manufacturers directions for “cold Oven” cleaning method.

Porcelain tops and ring grates can also be processed through

a commercial dish water. Dry thoroughly and handle with

care.

Hot tops

While the surface is still slightly warm, wipe down with a

clean burlap cloth. Burnt on spillage should be scraped o. If

necessary, remove the plate and wash in a sink with soap and

hot water. Dry thoroughly. In damp climates, wipe down with

a light coating of oil to prevent rusting. Avoid excessive use

of water at this could damage the surface and the controls

below.

NOTE: Steel griddle and hot top surface will “tone” (blue/

brown discoloration) from heat. This toning will not diminish

function or operation and is not a defect.

Part # 1382683 (01/08)Page 22

Page 23

Part # 138683 (01/08) Page 23

TROUBLESHOOTING

Oven (Standard & Convection)

Problem Possible Cause Solution

Oven too hot or not hot enough Thermostat out of calibration Check calibration

Burner ame shuts o when oven is at

the required temperature.

Burner ame soft-lazy yellow tip Insucient primary air Check aeration shutter setting