Page 1

INSTALLATION AND

OPERATION MANUAL

PERFORMER S SERIES GAS

RESTAURANT RANGES

All 24, 36, 48, & 60-inch wide models.

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4500195 (02/20/08) © 2005 Garland Commercial Industries, Inc.

Part # 4500195 (02/20/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # 4500195 (02/20/08)Page 2

Page 3

Part # 4500195 (02/20/08) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION.............2

SPECIFICATIONS.......................4

Gas Pressure.................................4

Electrical Supply .............................4

Individual Burner Input Ratings...............4

Model Designations..........................4

INTRODUCTION........................6

INSTALLATION.........................7

Siting........................................7

Appliances Equipped With Legs ..............7

Appliances Equipped With Casters............7

Installing Shelf to Backguard .................7

Installing The Backguard Or Shelf.............7

Statutory Regulations........................8

Installation Notes............................8

PRODUCT APPLICATION INFORMATION 12

General.....................................12

Open Burners...............................12

Hot Tops....................................12

Griddles....................................12

Convection Ovens..........................12

CARE & CLEANING ....................13

Painted Finish...............................13

Stainless Steel ..............................13

Oven Interior (Porcelain Enamel).............13

Open Top Burners ..........................14

Cast Iron Top & Ring Grates..................14

Griddle.....................................14

Hot Tops....................................14

WIRING DIAGRAMS ...................15

Gas Connection..............................8

Electrical Connection ........................8

Ventilation Air ...............................8

TESTING & ADJUSTMENT...............9

Griddle Seasoning ...........................9

OPERATION...........................10

Open Top Burners ..........................10

Hot Top Sections............................10

Thermostat Controlled Griddles .............10

Valve Controlled Griddles ...................10

Raised Broiler / Griddles.....................10

Standard Ovens.............................11

Convection Ovens (RC)......................11

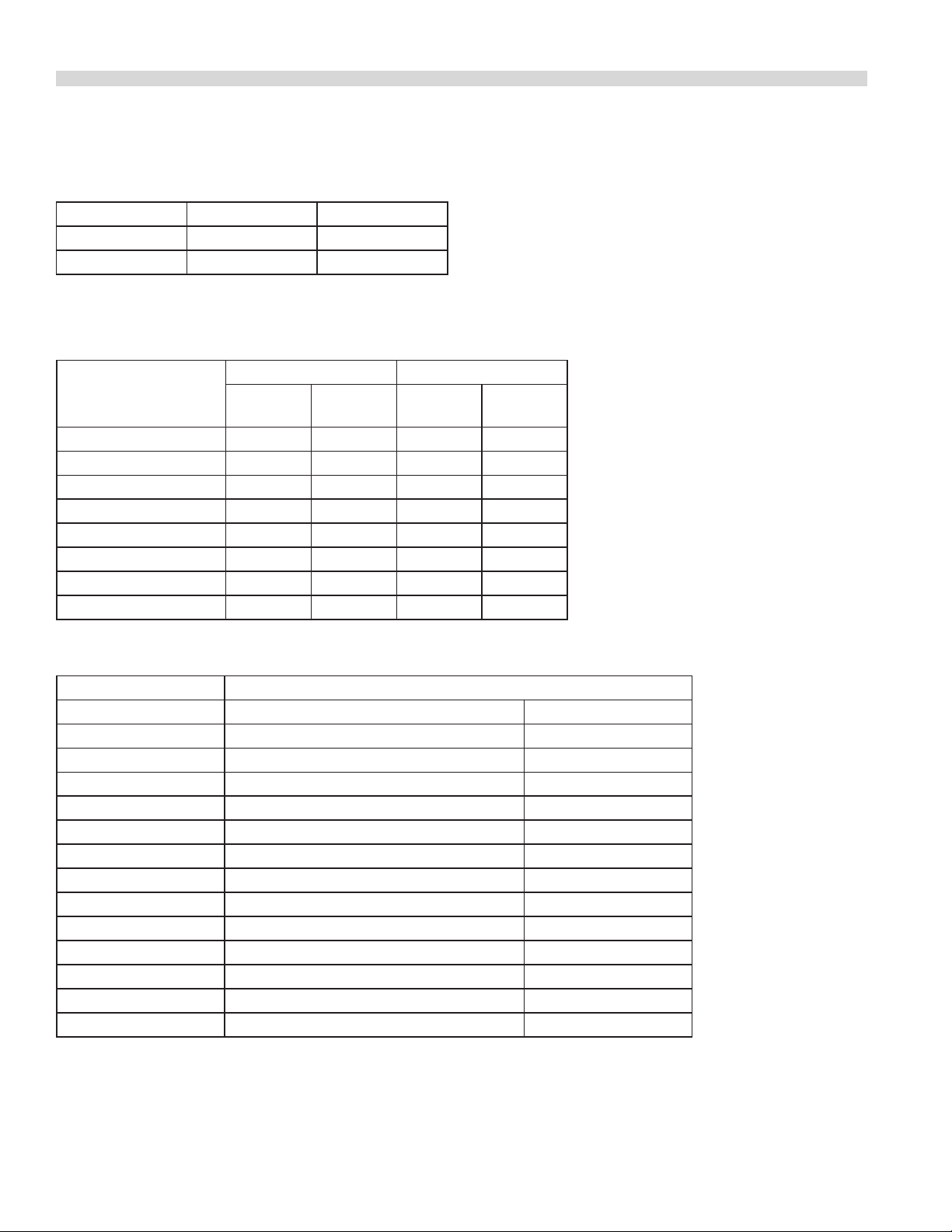

Page 4

SPECIFICATIONS

Gas Pressure

Gas Supply (Min.) Operating

Natural 7” w.c. 4.5 w.c

Propane 11” w.c. 10” w.c.

Electrical Supply

Models with sux “RC”: 115V 60Hz, 5 amps per

convection oven

Individual Burner Input Ratings

Natural Gas Propane

Burner

Open Burner 32,000 #37 28,000 1.5 mm

Hot Top 20,000 # 45 20,000 # 54

12” Griddle 20,000 # 45 20,000 # 54

Broiler/Griddle 14,000 # 52 13,500 # 57

Char-Broiler 15,000 # 50 15,000 # 56

26” Oven – Standard 35,000 # 31 30,000 # 51

26” Oven – Convection 30,000 # 36 30,000 # 51

20” Oven 25,000 # 40 25,000 # 54

Input

Btu/h

Orice

Size DMS

Input

Btu/h

Orice

Size DMS

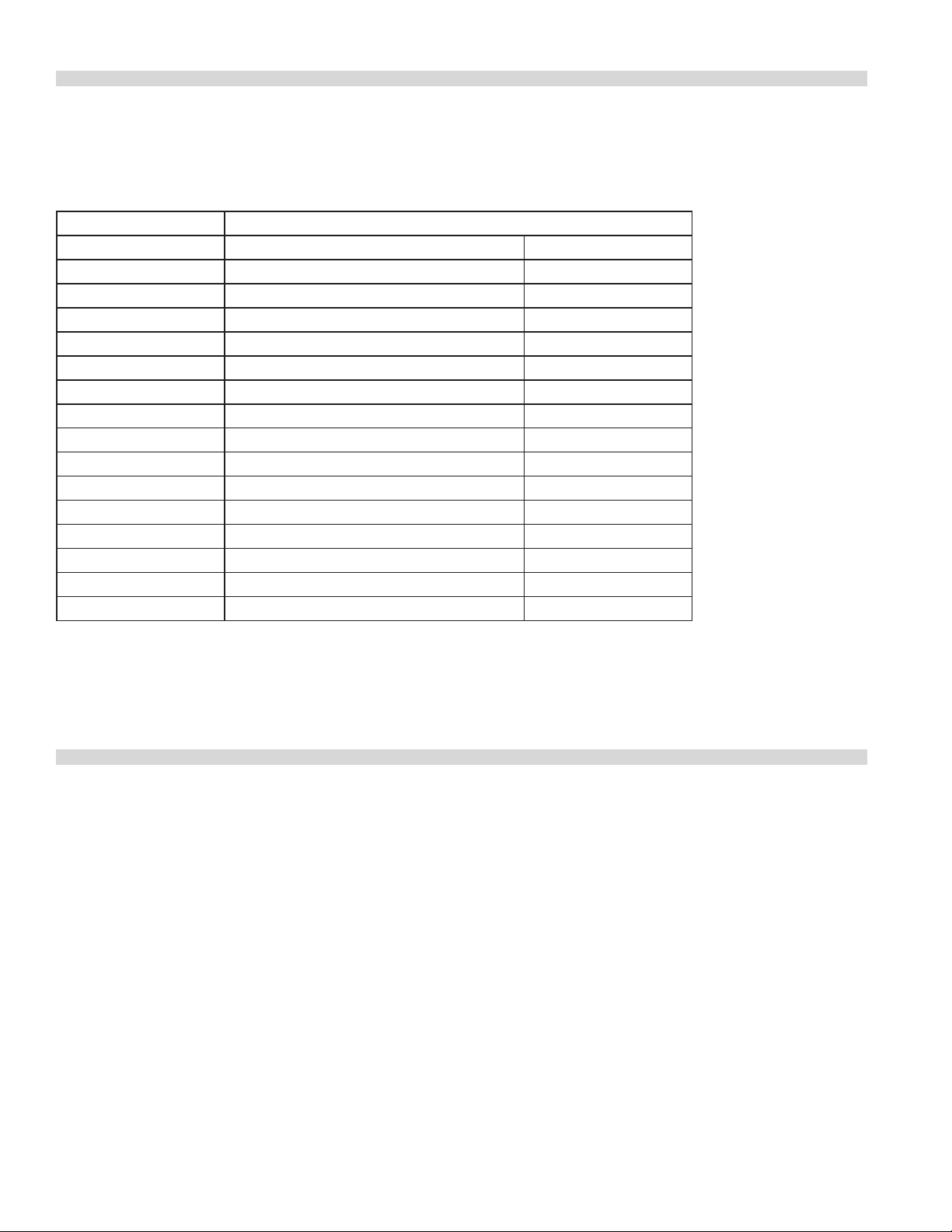

Model Designations

Model Number Description

PS-4-20 Four Open Burners w/Oven

PS-4 Four Open Burners w/o Oven

PS-12G-2-20 12” Griddle, 2 Open Burners w/ Oven

PS-12G-2 12” Griddle, 2 Open Burners w/o Oven

PS-24G-20 24” Griddle w/Oven

PS-24G 24” Griddle w/o Oven

PS-6-26 Six Open Burners w/Oven

PS-6 Six Open Burners w/o Oven

PS-12G-4-26 12” Griddle, Four Open Burners w/Oven

PS-12G-4 12” Griddle, Four w/o Oven

PS-24G-2-26 24” Griddle, Two Open Burners w/Oven

PS-24G-2 24” Griddle, Two Open Burners w/o Oven

PS-36G-26 36” Griddle w/Oven

PS-36G 36” Griddle w/o Oven

Part # 4500195 (02/20/08)Page 4

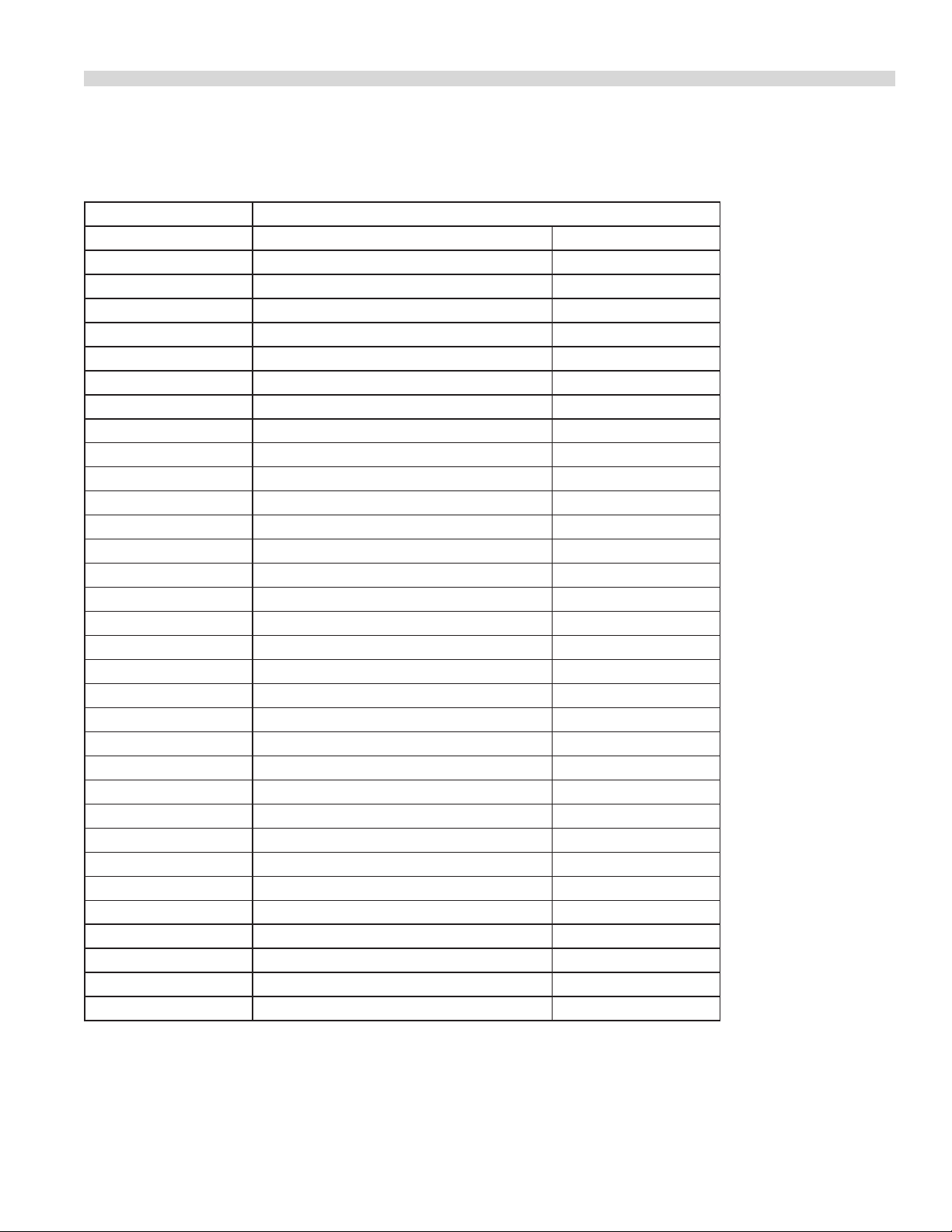

Page 5

Part # 4500195 (02/20/08) Page 5

SPECIFICATIONS Continued

Model Designations Continued

Model Number Description

PS-8-2020 Eight Open Burners w/(2) 20” Ovens

PS-8-26 Eight Open Burners w/(1) 26” Oven

PS-8 Eight Open Burners w/o Oven

PS-12G-6-2020 12” Griddle, Six Open Burners w/(2) 20” Ovens

PS-12G-6-26 12” Griddle, Six Open Burners w/(1) 26” Oven

PS-12G-6 12” Griddle, Six Open Burners w/o Oven

PS-24G-4-2020 24” Griddle, Four Open Burners w/(2) 20” Ovens

PS-24G-4-26 24” Griddle, Four Open Burners w/(1) 26” Oven

PS-24G-4 24” Griddle, Four Open Burners w/o Oven

PS-36G-2-2020 36” Griddle, Two Open Burners w/(2) 20” Ovens

PS-36G-2-26 36” Griddle, Two Open Burners w/(1) 26” Oven

PS-36G-2 36” Griddle, Two Open Burners w/o Oven

PS-48G-2020 48” Griddle w/(2) 20” Ovens

PS-48G-26 48” Griddle w/(1) 26” Oven

PS-48G 48” Griddle w/o Oven

PS-10-2626 Ten Open Burners w (2) Ovens

PS-10-26 Ten Open Burners w (1) Oven

PS-10 Ten Open Burners w (1) Oven

PS-12G-8-2626 12” Griddle, Eight Open Burners w (2) Ovens

PS-12G-8-26 12” Griddle, Eight Open Burners w (1) Oven

PS-12G-8 12” Griddle, Eight Open Burners w/o Oven

PS-24G-6-2626 24” Griddle, Six Open Burners w (2) Ovens

PS-24G-6-26 24” Griddle, Six Open Burners w (1) Oven

PS-24G-6 24” Griddle, Six Open Burners w/o Oven

PS-36G-4-2626 36” Griddle, Four Open Burners w (2) Ovens

PS-36-4-26 36” Griddle, Four Open Burners w (1) Oven

PS-36G-4 36” Griddle, Four Open Burners w/o Oven

PS-48G-2-2626 48” Griddle, Two Open Burners w (2) Ovens

PS-48G-2-26 48” Griddle, Two Open Burners w (1) Oven

PS-48G-2 48” Griddle, Two Open Burners w/o Oven

PS-60G-26 60” Griddle w (1) Oven

PS-60G 60” Griddle w/o Oven

PS-60G-2626 60” Griddle w (2) Ovens

Page 6

SPECIFICATIONS Continued

Model Designations Continued

Model Number Description

PS-12-2626 Twelve Open Burners w (2) Ovens

PS-12-26 Twelve Open Burners w (1) Oven

PS-12G-10-2626 12” Griddle, Ten Open Burners w (2) Ovens

PS-12G-10-26 12” Griddle, Ten Open Burners w (1) Oven

PS-24G-8-2626 24” Griddle, Eight Open Burners w (2) Ovens

PS-24G-8-26 24” Griddle, Eight Open Burners w (1) Oven

PS-36G-6-2626 36” Griddle, Six Open Burners w (2) Ovens

PS-36G-6-26 36” Griddle, Six Open Burners w (1) Oven

PS-48G-4-2626 48” Griddle, Four Open Burners w (2) Ovens

PS-4-12BG-26 Four Open Burners, 12” Broiler/Griddle w/26” Oven

PS-4-24BG-2020 Four Open Burners, 24” Broiler/Griddle w (2) 20” Ovens

PS-4-24BG Four Open Burners, 24” Broiler/Griddle w/o Oven

PS-6-24BG-26 Six Open Burners, 24” Broiler/Griddle w/26” Oven

PS-6-24BG-2626 Six Open Burners, 24” Broiler/Griddle w (2) 26” Ovens

PS-36-RB-26 36” Char-Broiler w/Oven

PS-36-PMA 36” Char-Broiler w/o Oven

Units with a 26” oven are available with a convection oven option. These models come with a sux RC in the model number

INTRODUCTION

1. Check crate for possible damage sustained during transit.

Carefully remove unit from crate and again check for

damage. Any damage to the appliance must be reported

to the carrier immediately.

2. The wires for retaining the burners and other packing

material must be removed from units. Any protective

material covering stainless steel parts must also be

removed.

3. All equipment is shipped from the factory with legs

tted, unless otherwise specied. Where the range is to

be mounted on a dais or cove base, it is shipped without

legs. Legs must be tted to the oven where it is installed

on a combustible oor.

4. The type of gas and supply pressure that the equipment

was set-up for at the factory is noted on the data plate

and on the packaging. This type of gas supply must be

used.

5. Do not remove permanently axed labels, warnings or

data plates from the appliance, for this may invalidate the

manufacturer’s warranty.

Part # 4500195 (02/20/08)Page 6

Page 7

Part # 4500195 (02/20/08) Page 7

INSTALLATION

Siting

The oor on which the appliance is to be sited must be

capable of adequately supporting the weight of the

appliance and any ancillary equipment.

Units with ovens must be tted with legs if installed on a

combustible oor.

Appliances Equipped With Legs

1 Raise the front of the appliance an block. Do not lay the

appliance on its back.

2. Position leg insert in leg retainer opening and tap upward

until the insert seats at the collar ange.

3 Repeat leg insert installation for the other legs and adjust

all four legs to the same height.

4. Legs can be further adjusted to level the appliance and to

compensate for uneven ooring.

Appliances Equipped With Casters

1. The installation shall be made with a connector that

complies with the Standard for Connectors for Movable

Gas Appliances, ANSI Z21.69 /CSA 6.16, and a quickdisconnect device that complies with the Standard for

Quick-Disconnect Devices for Use With Gas Fuel, ANSI

Z21.41 / CSA 6.9.

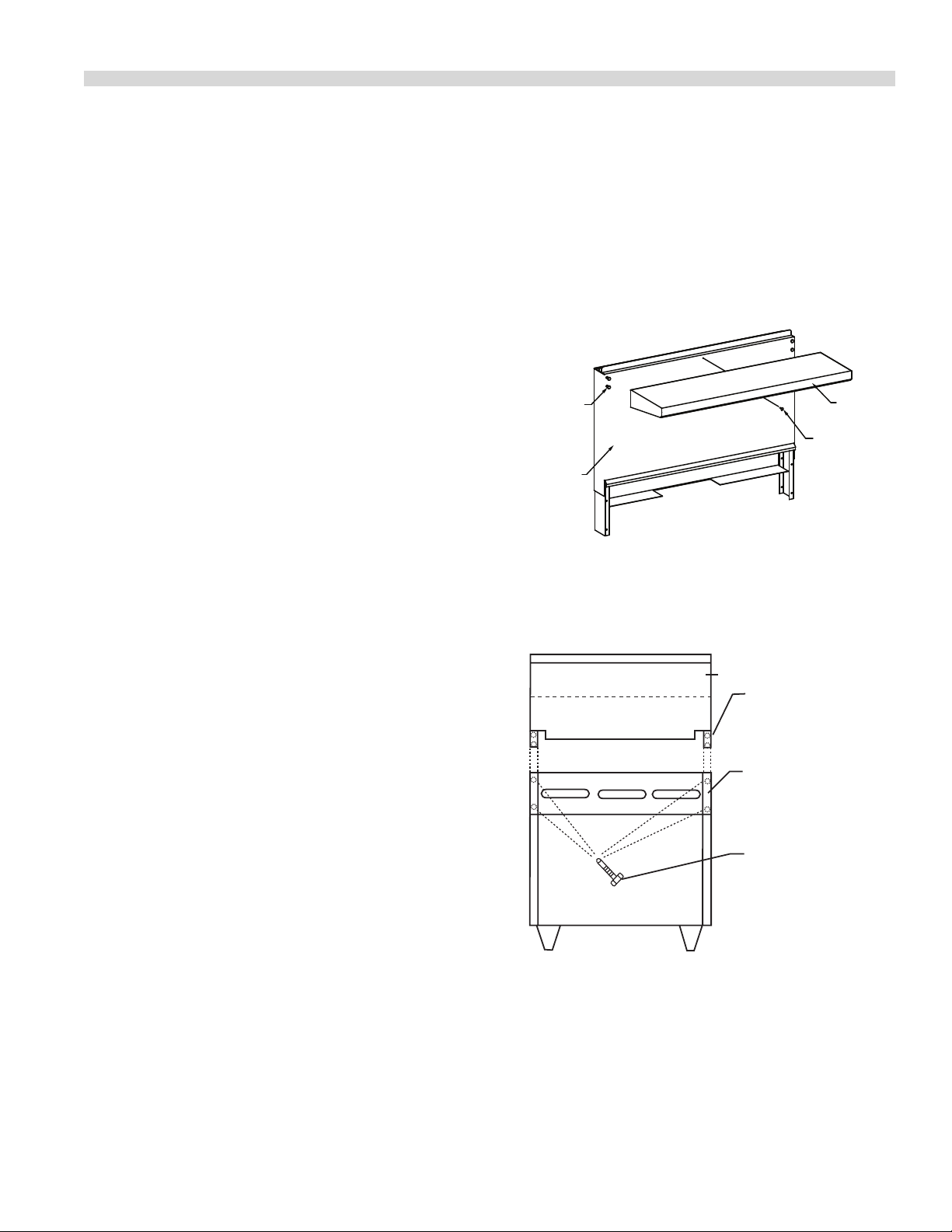

3. Slide the shelf downward until the 4 bolts are engaged in

the slotted portion of the keyhole.

4. Tighten the 4 bolts to secure shelf.

5 On 60” and 72” units only, install a sheet metal screw

though the hole in the underside of the shelf into the

backguard and tighten.

MOUNTING

BOLTS

BACKGUARD

SHELF

SHEETMETAL

SCREW

Installing The Backguard Or Shelf

Drawing 1

Upright

2. The front casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick-disconnect

device or its associated piping.

3. Please be aware; required restraint is attached to a

bracket (which is located on the rear caster closest to the

gas connection), and if disconnection of the restraint

is necessary; be sure to reconnect the device after the

appliance has been returned to its original position.

Installing Shelf to Backguard

Note: Shelf may be installed before or after installing the

backguard to the range.

1. Loosen 4 bolts on the front of the backguard

approximately 1/4” (6mm).

2. Align the 4 holes on the back of the shelf with the 4 bolts

on the backguard.

Burner Box

Side

#14 x 5/8"

Type "B"

Hex Head

Tapping Screw

4 Req'd

1. Rear of range must be easily accessible.

2. Place the backguard, high shelf, salamander, or

cheesemelter on the rear of the range, slipping the

support brackets into the openings in the burner box

sides.

Page 8

INSTALLATION Continued

3. Securely fasten the support brackets to the burner box

sides with (4) #14 x 5/8” Hex washer head, type B tapping

screws. (Hardware package is supplied).

Statutory Regulations

The installation of this appliance must be carried out by

a competent person and in accordance with the relevant

regulations, codes of practice and the related publications of

the country and destination.

The installation must conform to the National Fuel Gas Code

ANSI Z223.1-1998 or latest edition, NFPA No. 54 – latest

edition and National Electrical Code ANSI/NFPA 70-1990 or

latest edition and/or local code to assure safe and ecient

operation. In Canada, the installation must comply with

CSA B149.1 and local codes where applicable

In Canada, electrical connection must comply with

applicable sections of the Canadian Electrical Code,

C22.1 - 1990, latest edition, “Safety Standard for Installation,

Part 1” and C22.2- No. O-M 1982 latest edition , “General

Requirements, Part 2”.

Installation Notes

Before assembly and connection check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located behind the lower front panel.

Connect a unit stamped “NAT” only to natural gas;

connect one stamped “PRO” only to propane gas.

B. If it is a new installation have the gas authorities check

meter size and piping to assure that the unit is supplied

with necessary amount of gas pressure required to

operate the unit.

THIS APPLIANCE IS NOT RECOMMENDED FOR RESIDENTIAL

INSTALLATION.

Gas Connection

The local gas authority should be consulted at the

installation planning stage in order to establish the

availability of an adequate supply of gas and to ensure

that the meter is adequate for the required ow rate. The

pipe work from the meter to the appliances must be of an

appropriate size.

All xed (non-mobile) appliances MUST be tted with a

manual gas-cock upstream of the appliance to provide a

means of isolation for servicing or cleaning purposes. A

union or similar means of disconnection must be provided

between the gas-cock and the appliance.

A manually operable valve must be tted to the gas supply

to the kitchen to enable it to be isolated in an emergency.

Wherever practical, this shall be located either outside the

kitchen or near to an exit in a readily accessible position.

Where it is not practical to do this, an automatic isolation

valve system shall be tted which can be operated from a

readily accessible position near to the exit.

At locations where the manual isolation valve is tted or

the automatic system can be reset a notice MUST be tted

stating:

“ALL DOWNSTREAM BURNER AND PILOT VALVES MUST

BE TURNED OFF PRIOR TO ATTEMPTING TO RESTORE THE

SUPPLY. AFTER EXTENDED SHUT OFF, PURGE BEFORE

RESTORING GAS.”

Electrical Connection

C. If it is additional or replacement equipment have the gas

authorities check pressure to make certain that existing

meter and piping will supply fuel to the unit with not

more than 1/2” water column pressure drop.

NOTE: When checking gas pressure, be sure that all other

equipment on the same gas line is on.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system pressures in excess of

1/2 PSIG (3.45kPa).

Adequate clearance must be provided for servicing and

proper operation.

Models with sux “RC”

IMPORTANT – This appliance must be electrically grounded

in accordance with local codes.

Ventilation Air

The following notes are intended to give general guidance.

For detailed recommendations, refer to the applicable

code(s) in the country of destination.

Proper ventilation is highly essential for optimum

performance. The ideal method of ventilating open-top

equipment is the use of a properly designed canopy which

should extend six inches (152mm), beyond all sides of the

appliance(s) and six feet, six inches (1981mm) above the oor.

Part # 4500195 (02/20/08)Page 8

Page 9

Part # 4500195 (02/20/08) Page 9

INSTALLATION Continued

A strong exhaust will create a vacuum in the room. For an

exhaust vent to work properly, replacement air must enter

the room. The amount of air that enters must be equal to the

amount exhausted.

TESTING & ADJUSTMENT

All ttings and pipe connections must be tested for

leaks. Use approved gas leak detectors, soap solution or

equivalent, checking over and around all the ttings and

pipe connections. DO NOT USE A FLAME! Accessibility to

all gas lines and ttings require that valve panel(s), lower

front panel(s), and/or oven rack(s) be removed. It may be

necessary to remove, or at least raise and securely prop

griddles, hot top, and/or top grates. All parts removed,

(including fasteners), should be stored safely for reinstallation.

1. Be sure that all valves and thermostats are in the “OFF”

position.

All gas burners and pilots need sucient air to operate. Large

objects should not be placed in front of the appliance(s),

which would obstruct the ow of air into the front.

7. Shut o all valves and set thermostat dials to “OFF” or

lowest position.

All units are tested and adjusted at the factory, however,

burners and pilots should be checked upon installation and

adjusted if necessary.

CAUTION: Gas will ow to the top section burners even if

top section pilots are not lit. Gas will not be interrupted. It

is the responsibility of the operator to conrm the proper

ignition of each burner as it is turned on. Should ignition

fail to occur 5 seconds after turning a burner on, turn the

burner o, wait 5 minutes, and try again.

2 Turn on the main gas supply valve. Light all top section

pilots.

3. Leak test all valves and ttings as described at the

beginning of this section. Correct any leaks as required

and recheck.

4. Light the oven pilot.

5. If the range is equipped with an oven on/o valve

separate from the thermostat, turn this valve on. If

the oven thermostat dial has an “OFF” position the

thermostat is its own on/o valve.

6. In either case, now set the thermostat to 500°F (260°C).

Leak test all valves and ttings as described at the

beginning of this section. Correct any leaks as required

and recheck.

Griddle Seasoning

1. Remove all factory applied protective material by

washing with hot water, mild detergent or soap solution.

2. Apply a thin coat of cooking oil to the griddle surface,

about one-ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

3. Light burners, set at lowest possible setting. Some

discoloration will occur when heat is applied to steel.

4. Heat griddle slowly for 15 to 20 minutes. Then wipe away

oil. Repeat the procedure 2 to 3 times until the griddle

has a slick, mirror-like nish. Do this until you have

reached the desire cooking temperature.

IMPORTANT: Do not attain high (on valve control) or 450°F

(on thermostat control) during “break-in” period.

Page 10

TESTING & ADJUSTMENT Continued

NOTE: The steel griddle surface will tone (blue discoloration)

from the heat. This toning will not diminish function or

operation and is not a defect.

OPERATION

Open Top Burners

Lighting:

1. Light pilots.

2. Turn valve completely on. Burner ame should be 1/2

inch (13mm), stable blue ame, and should impinge on

the bottom of a pot placed on the ring grate.

Shut-Down:

1. Turn all valves to the “OFF” position.

2. If the unit is to be shut down for an extended period of

time, close the in-line gas valve.

CAUTION: Should burner ignition fail within 5 seconds,

turn the burner valve o and repeat steps 1 through 5. If

ignition continues to fail, consult your factory authorized

service agency.

The griddle will not require re-seasoning if it is used properly.

If the griddle is over heated and product begins to stick to

the surface it may be necessary to repeat the seasoning

process again. If the griddle is cleaned with soap and water it

will be necessary to re-season the griddle surface.

Thermostat Controlled Griddles

See section on Griddle Seasoning before initial operation.

1. Raise the griddle at the front and securely block.

2. Light the pilots located at the front right side of each

burner.

3. The sensing bulbs must be fully inserted into their

individual holders, which are located on the underside of

the griddle.

4. Set the thermostat to its maximum setting. The burner

should have a 5/16 inch (8mm) stable blue ame.

5. Lower the griddle carefully into position, taking care

not to leave any part of the capillary tube in the burner

compartment.

Valve Controlled Griddles

Hot Top Sections

1 Raise or remove the hot top sections. Each burner has

one pilot located at the front left side of the burner.

2 Light pilots. The pilot burner should be adjusted to

provide for rapid ignition of the burner.

3. Turn the burner valve on. A sharp blue ame should be

approximately 1/4 inch (6mm) high.

4. Replace hot top sections.

See section on Griddle Seasoning before initial operation.

1 Raise the griddle at the front and securely block.

2. Light the pilots located at the front left side of each

burner.

3. Turn the burner valves completely on. Burners should

have 1/2 inch to 5/8 inch (13mm to 16mm), stable blue

ame.

4. Lower griddle carefully into position.

Raised Broiler / Griddles

1. Light the pilots located in the broiler section.

2. Turn the burner valves completely on. The burners should

exhibit a 5/16 inch blue ame.

Part # 4500195 (02/20/08)Page 10

Page 11

Part # 4500195 (02/20/08) Page 11

OPERATION Continued

CAUTION: Gas will ow to the top section burners even if

top section pilots are not lit. Gas will not be interrupted. It

is the responsibility of the operator to conrm the proper

ignition of each burner as it is turned on. Should ignition

fail to occur 5 seconds after turning a burner on, turn the

burner o, wait 5 minutes, and try again.

Standard Ovens

Lighting:

1. Remove oven bottom(s).

2. Depress and hold the red reset button, located on the

safety valve behind the kick panel below the oven door,

while lighting the oven pilot. Continue to hold the reset

button for at least 60 seconds after the pilot is lit. Release

the button. If the pilot does not stay lit, wait ve minutes,

then repeat the procedure.

Shut-Down:

1. Turn all valves and thermostats to the “OFF” position, or

lowest setting.

2. If the range is to be shut down for an extended period of

time, close the in-line gas valve.

Re-Lighting:

1. Turn all gas valves o.

2. Wait ve minutes.

3. Follow procedure under “Lighting” above.

3. If the pilot does not stay lit after you release the reset

button, wait 5 minutes and repeat steps 1 and 2, holding

the reset button for approximately 60 seconds.

Start-Up:

1. Activate the power switch to cook position.

2. Turn oven valve on.

3. Turn thermostat to desired setting.

Cool Down:

1. Turn thermostat and oven valve o.

2. Open door.

3. Activate power to the cool down position.

The motor on your range convection oven is maintenance

free since it is constructed with self-lubricating sealed ball

bearings. It is designed to provide durable service when

treated with ordinary care. We have a few suggestions to

follow on the care of your motor.

A. When the motor is operating, it cools itself internally by

air entering the rear of the motor case, provided proper

clearance has been allowed.

B. Since the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, the heat from the blower wheel is

conducted down the shaft and into the armature of the

motor. This action could shorten the motor life.

Convection Ovens (RC)

Lighting:

1. Drop down the lower front panel below the door; hold

the reset button (RED) located on the oven safety valve

(See prior).

2. Push the red igniter button repeatedly until the oven

pilot lights. (Igniter button located next to the safety

valve.)

C. We recommend, at the end of the bake or roasting

period, when the oven will be idle for any period of time

or before shutting down completely, that the doors be

left open, and by use of the cool down position on the fan

switch, the fan continues to run for at least 20 minutes.

The “FAN” should never be turned “OFF” when the oven is

“HOT”.

Page 12

PRODUCT APPLICATION INFORMATION

General

The range is the workhorse of the kitchen because of its

versatility. Most frequently used in small applications, such as

cafes, schools, church kitchens, rehouses, and small nursing

homes where demands are less taxing.

The top of the range is designed for exibility and the

preparation of numerous dierent types of products. It may

be equipped with two, or even three dierent types of top

burners, depending on the menu needs. An operation that

cooks to order, or uses the range primarily as back-up will

nd that open burners will suit most of their needs.

Preparation of soups, stocks, or sauces is done on a hot top

where slow even cooking is desirable.

Heating larger quantities of food can be done more

eciently than heating small quantities. Pots and pans

should be covered whenever possible to reduce energy

consumption.

High acid sauces, such as tomato should be cooked in

stainless steel rather than aluminum to avoid a chemical

reaction. Light colored sauces such as Alfredo may be

discolored by the use of aluminum, especially if stirred with a

metal spoon or whisk. Saltwater shellsh may pit aluminum

pots if they are frequently used for this purpose.

NOTE: Many parts of the commercial range are raw steel.

Hot tops, griddles, springs, door hooks, etc., can react with

moisture, forming rust. This occurrence is normal and not

considered a defect. Clean with a stainless steel or ber pad.

A light coating of cooking oil may be applied.

Recommended preheat times for a 12 inch hot top section is

30 minutes. This will thoroughly saturate the metal with heat.

Hot tops are evenly heated and have a smooth surface so

that pots may be moved easily to any position.

Pots must have a at bottom for maximum contact with

the hot top surface. Warped or dented pots will not transfer

heat evenly or eciently, wasting energy and resulting in

uneven cooking patterns. Roasting pans with straps should

not be used on a hot top because only the straps will touch

the heated surface and transfer will be minimal. During slow

times, group pots on one hot top section and turn o the

other sections. This will conserve energy. If needed, the other

sections will preheat in 10 to 15 minutes due to the retained

heat in the material.

Griddles

Griddle tops are designed to have food cooked directly on

the surface, for example hamburgers, eggs, pancakes, hash

browns, etc. Do not put pots or pans on the griddle surface.

This will scratch or nick the surface, resulting in sticking and

scorching of product. Never salt food on a griddle because

this will cause a gummy residue to build up, making the

griddle more dicult to clean. Avoid hitting the griddle plate

with a spatula, as this will also nick the surface. The most

frequently used temperature range for griddles is 325°F to

350°F (163°C to 177°C). Check and drain the grease drawer

frequently during heavy use to prevent overowing. Over

a period of time, some discoloration of the steel griddle

plate will occur, this will not eect performance. For best

cooking results, keep the griddle surface as clean and shiny

as possible.

Open Burners

The most traditional uses of open burners are sautéing, pan

frying, and small stock pot work. Short-term cooking is the

most ecient use for the open burner. Pans should cover

as much of the grate as possible to minimize heat loss. The

maximum stockpot size to be used on an open burner is 11

inches (279mm) diameter. Open burners should be turned

o when not in use to conserve energy. Leaving a ame

burning is of no advantage since the heat is instantaneous.

Hot Tops

Hot tops are recommended where long-term stockpot

cooking is required for soups, sauces or stocks. Pots can be

placed anywhere on the hot top, rather than in one specic

position as on an open burner. The maximum stockpot size

to be used on the hot top is 12 inches (305mm) in diameter.

Convection Ovens

Generally, a temperature 25°F to 50°F (-4°C to 10°C) lower

than that specied in recipes for standard ovens should

be used. Cooking time may be reduced, depending on the

product. A 2% to 5% reduction in cook time is a general

rule. Keep a close check on any product being prepared

for the rst time. The size of the load, temperature of the

product going in and moisture content are the major factors

that inuence necessary cook times and temperatures.

Successfully prepared products should be recorded with

their times and temperatures for future reference.

Preheat the oven thoroughly before loading. It will take

approximately 15 minutes for the oven to reach 350°F

(177°C). Best results will be attained when the oven is

allowed to preheat for 30 minutes or more thorough heat

saturation.

Part # 4500195 (02/20/08)Page 12

Page 13

Part # 4500195 (02/20/08) Page 13

PRODUCT APPLICATION INFORMATION Continued

Center the load on the oven racks to allow for proper heat

circulation around the sides. The oven will hold three, 18” x

26” (457mm x 660mm) sheet pans, six 12” x 20” x 2.5” (305mm

x 508mm x 64mm) steam table pans, or one 17.75”x 25.75”

(451mm x 654mm), roast pan. Never place pans directly

on the oven bottom. Always use the lowest rack position

that will allow air to circulate within the oven cavity. Load

and unload food as quickly as possible to prevent excessive

temperature drop. For even baking avoid using warped pans.

Do not use a deep pan for shallow cakes, cookies, etc., as

heat circulation across the top of these items is essential for

browning. To prevent excessive shrinkage, roast meat at a

low temperature; 250°F to 325°F (121°C to 163°C).

CARE & CLEANING

Painted Finish

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

The oven should be permitted to cool down before cleaning

exterior surfaces.

When rethermalizing frozen products, preheat the oven 50°F

(10°C), higher than the cooking temperature to compensate

heat loss during and after loading. Return the thermostat to

the cooking temperature after loading.

To conserve energy, turn the oven o when not in use. If you

cover pans with aluminum foil, be sure to crimp it tightly

around the edges to prevent the foil from blowing o in

the oven. Any food or other or other matter that becomes

lodged in the fan must be removed as soon as the oven is

cool.

To prevent ngerprints there are several stainless steel

polishes on the market the leave and oily waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste.

1 Wipe exposed cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a lightweight non-metallic scouring pad.

Dry thoroughly with a clean cloth.

2. Stainless steel should be cleaned using a mild detergent,

a soft cloth and hot water. If necessary to use a nonmetallic scouring pad, always rub in the direction of the

grain in the metal to prevent scratching. Use a water

based stainless cleaner if you want a high shine.

Stainless Steel

For routine cleaning just wash with hot water and detergent

solution. Wash just a small area at a time or the water will

evaporate leaving the chemicals behind causing streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with soft clean cloth before

it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

Use only stainless steel, wood or plastic tools if necessary

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers or knives, as particles of the iron may

become imbedded and rust. STEEL WOOL SHOULD NEVER BE

USED.

Oven Interior (Porcelain Enamel)

NOTE: Disconnect line cord (if applicable) from power

supply before cleaning or servicing.

1. Before cleaning oven interior, remove all oven racks and

guides. Oven racks and guides can be cleaned with a mild

soap and warm water or run through a dishwasher.

2. The porcelain interior can be cleaned with oven cleaners

such as “Easy-O” or “Dow Oven Cleaner”. Follow product

manufacturer’s instructions for proper use.

Page 14

CARE & CLEANING Continued

Open Top Burners

Cleaning of the range top burner is a simple procedure, if

done at regular intervals will prolong the life of the range

and ensure good ame characteristics.

1 The most common problem with open burner range is

spillage. Once the burner ports are partially plugged with

food, the air-to-gas mixture is disturbed and results in an

inecient burner.

2. Wipe any spills as they occur.

3. Grids and trays should be removed daily, washed, rinsed

and dried thoroughly.

4. Use a wire brush to clean the ports of the burners. Ignite

and check for clogged holes.

5 If any clogged holes are apparent, the burner should be

lifted out and brushed inside and out with a small Venturi

brush. Each port on the burner itself should be cleaned

with a properly sized wire or thumb drill. Wash with soap

and hot water if grease is observed on the burners. Dry

thoroughly.

6. Reinstall and check the ame pattern. Readjust the air

shutter if necessary.

7. If a yellow ame appears around the edges instead of

being uniformly blue, it is usually a sign of grease and dirt

in the throat of the burner. Remove and clean the burner

and readjust the air shutter.

Cast Iron Top & Ring Grates

Cast iron top and ring grate(s) can be cleaned with mild soap

and warm water. For baked on material, a wire brush can be

used. Dry thoroughly and lightly coat with vegetable oil to

help prevent rust from forming.

Griddle

To produce evenly cooked, browned griddle products,

keep the griddle free from carbonized grease. Carbonized

grease on the surface hinders the transfer of heat from the

griddle surface to the food product. This results in uneven

browning and loss of cooking eciency, and carbonized

grease tends to adhere to grilled foods, giving them a highly

unsatisfactory and unappetizing appearance. To keep the

griddle clean and operating at peak performance, follow

these simple instructions.

After Each Use clean the griddle thoroughly with a grill

scraper or spatula. Wipe o any debris left from the cooking

process.

Once a Day clean the griddle surface with a grill brick and

grill pad. Remove grease container and clean thoroughly, in

same manner as any ordinary cooking utensil.

Once a Week clean the griddle surface thoroughly. If

necessary, use a grill brick or a grill pad over the griddle

surface. Rub with the grain of metal while still warm. A

detergent may be used on the plate surface to help clean it,

but care must be taken to be sure it is thoroughly removed.

After removal of detergent, the surface of the plate should be

covered with a thin lm of oil to prevent rusting. To remove

discoloration’s, use a nonabrasive cleaner. Before reusing

the griddle must be reseasond. Keep the griddle drain tube

chute to grease container clear at all times on those models

without a side grease container.

CAUTION: This griddle plate is steel, the surface is relatively

soft and can be scored or dented by careless use of a spatula.

Be careful not to dent, scratch, or gouge the plate surface.

This will cause food to stick in those areas. Also note, since

this is a steel griddle it should be lightly coated with oil to

prevent rust developing.

Hot Tops

While the surface is still slightly warm, wipe down with a

clean burlap cloth. Burnt-on spillage should be scraped o.

If necessary, remove the plate and wash in a sink with soap

and hot water and dry thoroughly. In damp climates, wipe

down with a light coating of oil to prevent rusting. Avoid

excessive use of water as this could damage the surface and

the controls below.

NOTE: Steel griddle and hot top surfaces will tone with

blue/brown discoloration from the heat. This toning will not

diminish function or operation and is not a defect.

Part # 4500195 (02/20/08)Page 14

Page 15

Part # 4500195 (02/20/08) Page 15

WIRING DIAGRAMS

13.4

PHASE

AMPS

ELECTRICAL RATING

120

VOLTS

35,000

BTU'S/HR

PER OVEN

GAS INPUT

MODELS

PS/SUNFIRE

120 VOLT

INPUT

APPR.

DATE

DR.

ALL DIMENSIONS ARE IN INCHES

REVISIONS

±2°

ANG.

(EXCEPT AS NOTED)

DESCRIPTION

±.031

TOLERANCES

REV

:

DATE

:

SCALE

APPR.

:

DR.

NOV 17/02

N/A

V.C .

TITLE:

PS/SUN 120V

4514771

W/D PS/SUN LEFT RC OVEN

1

SHT OF

COMMERCIAL RANGES LIMITED

MISSISSAUGA, ONTARIO, CANADA

LEFT RC OVEN SECTION

BLK

WHITE OR BLUE

BLACK OR BROWN

MOTOR

FROM FRONT

SWITCH VIEWED

GRN

14 13

11

GND

16

15

C

SWITCH

13

NCNO

14

DESCRIPTIONITEM PART NUMBER REV

W/D PS/SUN LEFT RC OVEN1 4514771 0

OVEN DOOR

Page 16

WIRING DIAGRAMS Continued

13.4

PHASE

AMPS

ELECTRICAL RATING

120

VOLTS

35,000

BTU'S/HR

PER OVEN

GAS INPUT

MODELS

PS/SUNFIRE

120 VOLT

INPUT

APPR.

DATE

DR.

ALL DIMENSIONS ARE IN INCHES

REVISIONS

±2°

ANG.

(EXCEPT AS NOTED)

DESCRIPTION

±.031

TOLERANCES

REV

:

DATE

:

SCALE

APPR.

:

DR.

NOV 17/02

N/A

V.C .

TITLE:

PS/SUN 120V

4514772

W/D RIGHT (SINGLE) RC OVEN

1

SHT OF

COMMERCIAL RANGES LIMITED

MISSISSAUGA, ONTARIO, CANADA

RIGHT (SINGLE) RC OVEN SECTION

BLK

MOTOR

WHITE OR BLUE

FROM FRONT

SWITCH VIEWED

BLACK OR BROWN

GRN

29 28

11

GND

26

27

C

SWITCH

28

NCNO

29

OVEN DOOR

DESCRIPTIONITEM PART NUMBER REV

W/D PS/SUN RIGHT RC OVEN1 4514772 0

Part # 4500195 (02/20/08)Page 16

Page 17

Part # 4500195 (02/20/08) Page 17

WIRING DIAGRAMS Continued

1

PHASE

3.4

6.8

AMPS

ELECTRICAL RATING

GAS INPUT

VOLTS

BTU'S/HR

120

35,000

70,000

APPR.

DATE

DR.

ALL DIMENSIONS ARE IN INCHES

REVISIONS

±2°

ANG.

(EXCEPT AS NOTED)

DESCRIPTION

±.031

TOLERANCES

REV

:

DATE

:

SCALE

APPR.

:

DR.

NOV 17/02

N/A

V.C .

TITLE:

PS/SUN 120V

W/D PS/SUN TWO RC OVENS

1

SHT OF

4514773

COMMERCIAL RANGES LIMITED

MISSISSAUGA, ONTARIO, CANADA

MODELS

PS/SUNFIRE

RIGHT RC OVEN SECTION

PER OVEN

TOTAL

INPUT

120 VOLT

MOTOR

BLK

FROM FRONT

SWITCH VIEWED

29 28

27

26

25

C

SWITCH

29

28

NCNO

OVEN DOOR

WHITE OR BLUE

BLACK OR BROWN

MOTOR

BLK

FROM FRONT

SWITCH VIEWED

GRN

14 13

11

GND

DESCRIPTIONITEM PART NUMBER REV

LEFT RC OVEN SECTION

16

15

C

SWITCH

13

NCNO

14

W/D PS/SUN TWO RC OVENS1 4514773 0

OVEN DOOR

Page 18

Part # 4500195 (02/20/08) Page 19

OVEN DOOR

14

NCNO

SWITCH

C

DESCRIPTIONITEM PART NUMBER REV

13

W/D PS/SUN TWO RC OVENS1 4514773 0

15

16

LEFT RC OVEN SECTION

GND

11

14 13

GRN

SWITCH VIEWED

FROM FRONT

BLK

MOTOR

WHITE OR BLUE

BLACK OR BROWN

OVEN DOOR

NCNO

SWITCH

C

28

29

25

26

27

RIGHT RC OVEN SECTION

29 28

SWITCH VIEWED

FROM FRONT

BLK

MOTOR

TITLE:

W/D PS/SUN TWO RC OVENS

MISSISSAUGA, ONTARIO, CANADA

COMMERCIAL RANGES LIMITED

4514773

SHT OF

1

PS/SUN 120V

TOLERANCES

DR.

±.031

:

V.C .

APPR.

(EXCEPT AS NOTED)

ANG.

±2°

SCALE

REVISIONS

N/A

:

ALL DIMENSIONS ARE IN INCHES

DATE

NOV 17/02

:

REV

DESCRIPTION

DR.

DATE

APPR.

120 VOLT

INPUT

TOTAL

70,000

120

6.8

1

PS/SUNFIRE

PER OVEN

35,000

VOLTS

AMPS

3.4

PHASE

MODELS

GAS INPUT

BTU'S/HR

ELECTRICAL RATING

SCHÉMAS DE CÂBLAGE suite

Page 19

DESCRIPTIONITEM PART NUMBER REV

Part # 4500195 (02/20/08)Page 18

W/D PS/SUN RIGHT RC OVEN1 4514772 0

OVEN DOOR

29

NCNO

SWITCH

C

TITLE:

W/D RIGHT (SINGLE) RC OVEN

MISSISSAUGA, ONTARIO, CANADA

COMMERCIAL RANGES LIMITED

4514772

SHT OF

1

PS/SUN 120V

GND

TOLERANCES

DR.

±.031

:

V.C .

APPR.

(EXCEPT AS NOTED)

ANG.

±2°

SCALE

REVISIONS

N/A

:

ALL DIMENSIONS ARE IN INCHES

DATE

NOV 17/02

:

GRN

WHITE OR BLUE

REV

DESCRIPTION

DR.

DATE

APPR.

28

27

RIGHT (SINGLE) RC OVEN SECTION

26

11

29 28

SWITCH VIEWED

BLACK OR BROWN

FROM FRONT

BLK

MOTOR

120 VOLT

INPUT

PS/SUNFIRE

MODELS

GAS INPUT

PER OVEN

BTU'S/HR

35,000

VOLTS

120

ELECTRICAL RATING

AMPS

PHASE

13.4

SCHÉMAS DE CÂBLAGE suite

Page 20

Part # 4500195 (02/20/08) Page 17

OVEN DOOR

14

NCNO

SWITCH

C

DESCRIPTIONITEM PART NUMBER REV

13

W/D PS/SUN LEFT RC OVEN1 4514771 0

15

16

LEFT RC OVEN SECTION

GND

11

14 13

GRN

SWITCH VIEWED

FROM FRONT

BLK

MOTOR

WHITE OR BLUE

BLACK OR BROWN

TITLE:

W/D PS/SUN LEFT RC OVEN

MISSISSAUGA, ONTARIO, CANADA

COMMERCIAL RANGES LIMITED

4514771

SHT OF

1

PS/SUN 120V

TOLERANCES

DR.

±.031

:

V.C .

APPR.

(EXCEPT AS NOTED)

ANG.

±2°

SCALE

REVISIONS

N/A

:

ALL DIMENSIONS ARE IN INCHES

DATE

NOV 17/02

:

REV

DESCRIPTION

DR.

DATE

APPR.

120 VOLT

INPUT

PS/SUNFIRE

MODELS

PER OVEN

BTU'S/HR

35,000

VOLTS

120

AMPS

PHASE

13.4

GAS INPUT

ELECTRICAL RATING

SCHÉMAS DE CÂBLAGE

Page 21

Part # 4500195 (02/20/08)Page 16

et ne constitue pas un défaut.

décoloration ne réduira pas les qualités ni le fonctionnement

prendra une teinte bleue/brune à cause de la chaleur. Cette

NOTA : La surface en acier des grils et des plaques de cuisson

et les commandes en dessous.

d’utiliser trop d’eau car cela pourrait endommager la surface

couche d’huile pour empêcher la formation de rouille. Éviter

sécher. Dans les climats humides, appliquer une légère

laver dans un évier avec du savon et de l’eau chaude. Bien

devront être grattés. Si nécessaire, retirer la plaque et la

avec un chi on en toile propre. Les déversements brûlés

Pendant que la surface est encore légèrement tiède, essuyer

Plaques De Cuisson

mince couche d’huile pour éviter la formation de rouille.

qu’il s’agit d’un gril en acier, celui-ci doit être recouvert d’une

parties correspondantes. Noter également qu’étant donné

sous peine de provoquer l’adhérence des aliments dans les

de ne pas entailler, rayer ou creuser la surface de la plaque,

suite d’une mauvaise utilisation d’une spatule. Prendre soin

est relativement tendre et peut être rayée ou entaillée par

ATTENTION : Cette plaque de gril est en acier, mais la surface

les modèles sans contenant à graisse latéral.

Maintenir le tube de vidange de graisse propre surtout sur

Avant de réutiliser le gril, celui-ci doit être apprêté à nouveau.

décoloration, utiliser un produit de nettoyage non-abrasif.

lm d’huile pour l’empêcher de rouiller. Pour éliminer la

détergent, la surface du gril doit être couvercle d’un mince

veiller à bien en éliminer les résidus. Après élimination du

détergent pour nettoyer la surface du gril. Cependant il faut

grain du métal encore tiède. Il est possible d’utiliser un

à gril pour nettoyer la surface. Frotter dans le sens du

du gril. Si nécessaire, utiliser une pierre à gril ou un tampon

Une fois par semaine, nettoyer soigneusement la surface

ENTRETIEN ET NETTOYAGE Suite

Page 22

Part # 4500195 (02/20/08) Page 15

des brûleurs. Allumer et véri er si les trous sont bouchés.

4. Utiliser une brosse métallique pour nettoyer les ori ces

lavés, rincés et séchés soigneusement.

bien le nettoyer comme tout autre outil de cuisson.

à gril et un tampon à gril. Retirer le contenant à graisse et

Une fois par jour, nettoyer la surface du gril avec une brique

débris laissé après le processus de cuisson.

du gril avec un raclette à gril ou une spatula. Essuyer tout

Après chaque utilisation, nettoyer soigneusement la surface

fonctionnement, suivre ces instructions simples.

inappétant. Pour maintenir le gril propre et en bon état de

aux aliments et leur donnent un aspect insatisfaisant et

et surtout ces graisses carbonisées ont tendance à coller

coloration inégale et une perte d’e cacité de la cuisson

de la chaleur du gril vers les aliments, ce qui provoque une

carbonisées sur la surface de cuisson empêchent le transfert

éliminer toute trace de graisses carbonisées. Les graisses

Pour obtenir des aliments uniformément cuits et dorés,

Gril

empêcher les grilles de rouiller.

sécher et appliquer une légère couche d’huile végétale pour

recuits dessus, on peut utiliser une brosse métallique. Bien

de l’eau tiède et du savon doux. Pour déloger les aliments

Les grilles supérieures en fonte peuvent être nettoyées avec

3. Les grilles et les plateaux devront être retirés chaque jour,

2. Essuyer tout déversement dès qu’il se produit.

est modi é et le brûleur n’assure pas un bon rendement.

bouchés par de la nourriture, le mélange d’air et de gaz

fois que les ori ces des brûleurs sont partiellement

brûleur ouvert est constitué par les déversements. Une

1. Le problème le plus commun avec les cuisinières à

d’excellentes caractéristiques de la amme.

prolongera la durée de vie de la cuisinière et assurera

procédure simple qui, si elle est faite à intervalles réguliers,

Le nettoyage du brûleur supérieur de la cuisinière est une

Brûleurs Supérieurs Ouverts

correcte.

instructions du fabricant du produit pour une utilisation

comme le “Easy-O ” ou “DOW Oven Cleaner”. Suivre les

nettoyées avec du produit de nettoyage pour fours

2. Les surfaces intérieures en émail vitri é peuvent être

savonneuse ou être mises dans le lave-vaisselle.

Ces pièces peuvent être nettoyées avec de l’eau tiède

et guides du four (en cas de base “four à convection”).

1. Avant de nettoyer l’intérieur du four, enlever les grilles

Les Grilles Supérieures En Fonte

procéder au nettoyage ou à l’entretien.

nouveau l’obturateur d’air.

du brûleur. Retirer le brûleur et le nettoyer et régler à

signe qu’il y a de la graisse ou des saletés dans la gorge

d’être uniformément bleue, c’est habituellement un

7. Si une amme jaune apparaît autour des bords au lieu

obturateurs d’air si nécessaire.

6. Remonter et véri er la amme. Régler à nouveau les

de la graisse sur les brûleurs. Sécher soigneusement.

appropriée. Laver avec du savon et de l’eau chaude s’il y a

être nettoyé avec un l métallique ou un foret de taille

petite brosse à venturi. Chaque ori ce du brûleur devra

être sorti et brossé à l’intérieur et à l’extérieur avec une

5. S’il semble que des trous sont bouchés, le brûleur devra

électrique (le cas échéant) de la source électrique avant de

REMARQUE : Débrancher le cordon d’alimentation

Intérieur Du Four (Fini En Émail Vitri é)

UTILISER DE LAINE D’ACIER.

risquent de s’incruster dans les surfaces et rouiller. NE JAMAIS

ni de couteaux en acier ordinaire, car des particules de fer

tenaces de graisses ou d’huiles. Ne pas utiliser de grattoirs

bois ou en plastique pour gratter si nécessaire les résidus

Utiliser uniquement des outils en acier inoxydable, en

avec de la crème à base de poudre à récurer.

taches peuvent être éliminées en frottant vigoureusement

L’acier inoxydable peut se décolorer s’il est trop chau é. Ces

ENTRETIEN ET NETTOYAGE Suite

Page 23

Part # 4500195 (02/20/08)Page 14

pouvant être en contact avec les aliments.

la surface. Ne pas utiliser de tels produits sur les surfaces

dans le commerce qui laissent un lm huileux ou cireux sur

extérieures, il existe de nombreux produits disponibles

Pour supprimer les empreintes digitales sur les surfaces

comme indiqué précédemment.

ce sens pour préserver l’apparence d’origine. Rincer ensuite

inoxydable sont polies dans un sens. Frotter en respectant

travailler à contre sens. Toutes les surfaces en acier

douce) si nécessaire, mais en prenant soin de ne jamais

Utiliser une pâte (mélange d’eau et de poudre à récurer

que la zone nettoyée ne sèche.

solution désinfectante et sécher avec un torchon doux avant

Rincer la surface lavée avec une éponge trempée dans une

traces de détergent.

la fois, sinon l’eau s’évaporera et laissera sur la surface des

solution d’eau et de détergent. Laver une petite surface à

Pour le nettoyage de routine, laver simplement avec une

Et Finis Intérieurs Standard Des Fours

Surfaces Extérieures En Acier Inoxydable

inoxydable à base d’eau si l’on veut obtenir un ni brillant.

le métal. Utiliser un produit de nettoyage pour acier

toujours dans le sens du grain a n d’éviter de rayer

d’utiliser un tampon à récurer non métallique, frotter

doux, un chi on et de l’eau chaude. S’il est nécessaire

2. L’acier inoxydable devra être nettoyé avec un détergent

chi on propre.

léger non métallique. Sécher soigneusement avec un

incrustés peuvent être retirés avec un tampon à récurer

avec un détergent doux et de l’eau chaude. Les résidus

1. Essuyer les surfaces exposées lavables une fois refroidies

surfaces extérieures.

On devra laisser le four refroidir avant de nettoyer les

devra être essuyé immédiatement.

Établir un calendrier de nettoyage régulier. Tout déversement

Finis Peints

dans le ventilateur doit être retiré dès que le four est refroidi.

s’envole dans le four. Tout aliment ou autre objet se bloquant

bien la replier autour des bords pour éviter que la feuille ne

utilisé. Si l’on couvre les plats avec une feuille d’aluminium,

Pour conserver l’énergie, arrêter le four lorsqu’il n’est pas

chargement.

Remettre le thermostat à la température de cuisson après le

la perte de chaleur pendant et après le chargement.

de plus que la température de cuisson a n de compenser

Pour les produits congelés, préchau er le four à 50 ºF (10 ºC)

ENTRETIEN ET NETTOYAGE

325 ºF (121 à 163 ºC).

trop important, rôtir les viandes à faible température : 250 à

essentielle pour un brunissage régulier. Pour éviter un retrait

donné que la circulation de l’air au-dessus de ces aliments est

pour les gâteaux peu épais, les petits gâteaux, etc. étant

d’utiliser des plats déformés. Ne pas utiliser un plat profond

température excessive. Pour une cuisson régulière, éviter

rapidement que possible pour empêcher toute chute de

l’intérieur du four. Charger et décharger les aliments aussi

de grille la plus basse permettant à l’air chaud de circuler à

directement sur le fond du four. Toujours utiliser la position

po x 25,75 po (451 mm x 654 mm). Ne jamais placer les plats

x 2,5 (305 mm x 508 mm x 64 mm) ou une rôtissoire de 17,75

x 660 mm), six récipients de table à vapeur de 12 po x 20 po

contenir trois plaques à pâtisserie de 18 po x 26 po (457 mm

bonne circulation de la chaleur sur les côtés. Le four peut

Centrer la charge sur les grilles du four pour permettre une

INFORMATIONS SUR LES APPLICATIONS DES PRODUIT Suite

Page 24

parfaitement chaud.

le four préchau er pendant 30 minutes ou plus a n qu’il soit

ºF (177 ºC). On obtient les meilleurs résultats lorsqu’on laisse

minutes pour que le four atteigne une température de 350

Bien préchau er le four avant de charger. Il faudra environ 15

cuisson pour s’y référer ultérieurement.

devront être notés avec leurs temps et température de

de cuisson nécessaires. Les produits préparés avec succès

les facteurs majeurs in uençant les temps et températures

produit entrant dans le four et son humidité constituent

première fois. L’importance de la charge, la température du

soigneusement n’importe quel produit préparé pour la

une réduction du temps de cuisson de 2 à 5 %. Observer

être réduit en fonction du produit. En général, compter

pour les fours standard. Le temps de cuisson peut également

de 25 à 50 ºF (-4 à 10 ºC) à celle spéci ée dans les recettes

Généralement, on devra utiliser une température inférieure

Fours À Convection

aussi propre et aussi brillante que possible.

la meilleure cuisson possible, maintenir la surface du gril

produira. Cela n’a ectera pas les performances. Pour obtenir

une certaine décoloration de la plaque en acier du gril se

empêcher tout débordement. Au bout d’un certain temps,

à graisse pendant les heures d’utilisation intensive pour

(163 à 177 ºC). Véri er et vidanger fréquemment le tiroir

la plus fréquemment utilisée pour les grils est de 325 à 350 ºF

entaillera également la surface. La gamme de températures

Éviter de heurter la plaque du gril avec une spatule car cela

d’un résidu collant, rendant le gril plus di cile à nettoyer.

les aliments sur un gril car cela produira l’accumulation

la surface, faisant coller les aliments ensuite. Ne jamais saler

ou de plat sur la surface d’un gril car cela rayera ou entaillera

les pommes de terre rissolées, etc. Ne pas placer de marmite

la surface, par exemple les hamburgers, les œufs, les crêpes,

Les grils sont conçus pour cuire directement les aliments sur

Part # 4500195 (02/20/08) Page 13

par le métal.

préchau eront en 10 à 15 minutes grâce à la chaleur retenue

a n de conserver l’énergie. Si nécessaire, les autres sections

section de plaque de cuisson et arrêter les autres sections

les périodes d’inactivité, grouper les marmites sur une

chau ée et le transfert de chaleur sera minimal. Pendant

cuisson parce que seuls les pieds toucheront à la surface

utiliser de plats à rôtir avec des pieds sur une plaque de

donnera des cycles de cuisson irréguliers. On ne devra pas

de façon régulière ni e cace, ce qui gaspillera l’énergie et

déformées ou entaillées ne transféreront pas la chaleur

contact maximal avec la surface de la plaque. Les marmites

Les marmites doivent avoir un fond plat pour obtenir un

n’importe quelle position.

lisse de façon à pouvoir déplacer les marmites facilement à

sont chau ées de façon régulière et o rent une surface

parfaitement le métal de chaleur. Les plaques de cuisson

cuisson de 12 po (305 mm) est de 30 minutes. Cela saturera

Le temps de préchau age recommandé pour une plaque de

plaque de cuisson est de 12 po (305 mm).

ouvert. Le diamètre maximal de la marmite à utiliser sur la

position particulière comme c’est le cas sur un brûleur

être placées n’importe où sur la plaque plutôt qu’à une

soupes, les sauces ou les bouillons. Les marmites peuvent

besoin de faire des cuissons longues en marmite pour les

Les plaques de cuisson sont recommandées lorsque l’on a

Plaques De Cuisson

donné que la chaleur est instantanée.

n’est pas avantageux de laisser brûler une amme étant

lorsqu’ils ne sont pas utilisés pour économiser l’énergie. Il

de 11 po (279 mm). Les brûleurs ouverts devront être fermés

maximal d’une marmite à utiliser sur un brûleur ouvert est

possible pour réduire les pertes de chaleur. Le diamètre

Le plat devra couvrir une surface de grille aussi grande que

cuissons courtes sont les plus e caces sur un brûleur ouvert.

aliments, la friture dans une poêle et les petites marmites. Les

Les brûleurs ouverts sont surtout utilisés pour sauter les

Grils

Brûleurs Ouverts

INFORMATIONS SUR LES APPLICATIONS DES PRODUIT Suite

Page 25

Part # 4500195 (02/20/08)Page 12

réduire la consommation d’énergie.

devront être couverts dans la mesure du possible pour

nourriture plutôt que de petites quantités. Les pots et plats

Le plus e cace est de chau er de grandes quantités de

régulière est souhaitable.

une plaque de cuisson dans le cas où une cuisson lente et

cuisson peut être appliquée.

en acier inoxydable ou en bre. Une légère couche d’huile de

pas considéré comme un défaut. Nettoyer avec un tampon

l’humidité en formant de la rouille. Cela est normal et n’est

crochets de porte, etc. peuvent réagir au contact de

sont en acier brut. Les plaques de cuisson, grils, ressorts,

NOTA : Beaucoup de pièces de la cuisinière commerciale

sont fréquemment utilisés dans ce but.

d’eau salée risquent de piquer les pots en aluminium s’ils

remue avec une cuiller ou un fouet métallique. Les poissons

décolorées si l’on utilise de l’aluminium, en particulier si l’on

peu colorées, telles que la sauce Alfredo, risquent d’être

l’aluminium pour éviter toute réaction chimique. Les sauces

être cuites dans de l’acier inoxydable plutôt que dans de

Les sauces très acides, telles que la sauce tomate, devront

La préparation de soupes, bouillons ou sauces se fait sur

des brûleurs ouverts convenant mieux à ses besoins.

principalement comme solution de rechange, utilisera plutôt

faisant la cuisine sur commande, ou utilisant la cuisinière

di érents de brûleurs, en fonction du menu. Un restaurant

di érents. Il peut être équipé de deux ou même trois types

souplesse et préparer de nombreux types d’aliments

Le dessus de cuisinière est conçu pour donner plus de

maisons de repos où les exigences sont plus faciles.

les cuisines d’église, les casernes de pompier et les petites

applications moins exigeantes telles que les cafés, les écoles,

de sa polyvalence. Elle est plus fréquemment utilisée dans les

La cuisinière est l’appareil le plus utilisé de la cuisine à cause

Généralités

chaud (HOT).

ne doit jamais être mis en position “OFF” si le four est

minutes au minimum. L’interrupteur du ventilateur (FAN)

De cette façon le ventilateur fonctionne pendant 20

et de placer l’interrupteur en position de refroidissement.

avant son arrêt dé nitif, de laisser la porte du four ouverte

lorsque le four reste au ralenti pendant un moment ou

C. Nous recommandons, à la n des périodes de cuisson

raccourcir la durée de vie du moteur.

long de l’axe du moteur dans son bobinage, ce qui peut

la chaleur du ventilateur de la sou erie est conduite le

four. Si le moteur est arrêté alors que le four est chaud,

la cavité du four, il est à la même température que le

B. Étant donné le ventilateur de la sou erie se trouve dans

INFORMATIONS SUR LES APPLICATIONS DES PRODUIT

n’est pas encombrée.

partie arrière du carter, à condition que cette arrivée d’air

refroidissement interne grâce à l’arrivée d’air dans la

A. Lorsque le moteur fonctionne, il assure lui-même son

suggestions sur la façon d’entretenir le moteur :

des années s’il est entretenu normalement. Voici quelques

autolubri ants étanches. Il est conçu pour servir pendant

entretien, puisqu’il est construit avec des roulement à billes

Le moteur de votre cuisinière à convection est sans

FONCTIONNEMENT Suite

Page 26

3. Actionner l’interrupteur en position de refroidissement.

2. Ouvrir la porte.

“OFF”.

1. Mettre le thermostat et le robinet du four en position

Refroidissement:

3. Tourner le thermostat au réglage souhaité.

2. Ouvrir le robinet du four.

cuisson.

1. Placer l’interrupteur d’alimentation en position de

Démarrage :

secondes.

le bouton de réenclenchement pendant environ 60

et répéter les étapes 1 et 2 en maintenant enfoncé

le bouton de réenclenchement, attendre 5 minutes

3 Si la veilleuse ne reste pas allumée après avoir relâché

l’allumeur est situé près du robinet du sécurité.)

jusqu’à ce que la veilleuse du four s’allume. (Le bouton de

2. Pousser à plusieurs reprises sur le bouton de l’allumeur

Part # 4500195 (02/20/08) Page 11

cette procédure au bout de 5 minutes.

bouton. Si la veilleuse ne reste pas allumée, recommencer

réenclenchement pendant 60 secondes. Relâcher le

la veilleuse du four. Maintenir enfoncé le bouton de

l’avant du four (sous la porte du four) tout en allumant

réenclenchement (rouge) situé à la partie inférieure à

2. Appuyer et maintenir enfoncé le bouton de

1. Retirer les plaques de fond du four.

Allumage

Four Standard

brûleur, attendre 5 minutes et essayer de nouveau.

secondes après l’ouverture du robinet, fermer le robinet du

Dans le cas où l’allumage ne se ferait dans un délai de 5

l’allumage de tous les brûleurs dont le robinet est ouvert.

coupée. Il est de la responsabilité de l’utilisateur de véri er

sont pas allumées. L’alimentation en gaz ne sera pas

supérieure même si les veilleuses de cette section ne

ATTENTION : Le gaz alimentera les brûleurs de la section

avoir une amme bleue stable de 5/16 po.

2. Ouvrir complètement les robinets. Le brûleur devrait

1. Allumer les veilleuses situées dans la section rôtissoire

Rôtissoire/Grils Surélevés

près du robinet de sécurité du four (Voir avant).

enfoncé le bouton de réenclenchement (ROUGE) situé

1 Abaisser le panneau inférieur sous la porte; maintenir

Allumage :

Fours À Convection (RC)

3. Follow procedure under “Lighting”above.

3 Suivre la procédure sous “Allumage” à gauche.

2 Attendre 5 minutes.

1. Fermer tous les robinets de gaz.

Réallumage

gaz.

temps prolongée, fermer le robinet d’alimentation en

2 Si la cuisinière doit être arrêtée pendant une période de

» ou au réglage le plus bas.

1. Tourner tous les robinets et thermostats en position « OFF

Arrêt

4. Abaisser le gril en place.

5/8 po.(13-16 mm)

brûleurs devraient avoir une amme bleue stable de 1/2 à

3. Ouvrir complètement les robinets des brûleurs. Les

chaque brûleur.

2. Allumer les veilleuses situées sur le côté avant droit de

1. Soulever l’avant du gril et le bloquer de façon sécuritaire.

Voir le paragraphe Apprêtage des grils avant toute utilisation.

Grils Commandées Par Robinet

tube capillaire dans le compartiment des brûleurs.

particulièrement attention à ne pas laisser une partie du

5. Abaisser avec précautions le gril en place, en faisant

avoir une amme bleue et stable de 5/16 po (8 mm).

4. Régler le thermostat au maximum. Le brûleur devrait

dessous du gril.

insérés dans leurs supports individuels, qui sont situés en

3 Les bulbes thermostatiques doivent être complètement

FONCTIONNEMENT Suite

Page 27

Part # 4500195 (02/20/08)Page 10

chaque brûleur.

2. Allumer les veilleuses situées du côté avant droit de

1. Soulever l’avant du gril et le bloquer de façon sécuritaire.

Voir le paragraphe Apprêtage des grils avant toute utilisation.

Grils Commandés Par Thermostat

4. Remettre en place les sections à plaque de cuisson

bleue et avoir une hauteur d’environ 1/4 de pouce (6 mm).

3. Ouvrir le robinet du brûleur. La amme doit être nette et

assurer un allumage rapide du brûleur.

2 Allumer les veilleuses. La veilleuse doit être réglée pour

avant gauche du brûleur.

Chaque brûleur est doté d’une veilleuse situé sur le côté

1. Soulever ou retirer les sections à plaque de cuisson.

Sections À Plaque De Cuisson

service d’usine autorisée.

1.S’il continue de ne pas s’allumer, consulter une agence de

5 secondes, fermer son robinet et recommencer à l’étape

ATTENTION : Si le brûleur ne s’allume pas dans un délai de

prolongée, fermer le robinet de gaz en ligne.

2. Si l’appareil doit être arrêté pour une période de temps

1. Placer tous les robinets en position « OFF ».

Arrêt:

annulaire.

devrait toucher la partie inférieure d’un placé sur la grille

devrait être stable, d’une hauteur de 1/2 po et bleue et

2 Tourner complètement le robinet. La amme du brûleur

1. Allumer les veilleuses.

Allumage:

Brûleurs Supérieurs Ouverts

d’e ectuer un nouvel apprêtage.

est nettoyée avec de l’eau et du savon, il sera nécessaire

recommencer le processus d’apprêtage. Si la plaque à frire

commencent à coller à la surface, il peut être nécessaire de

utilisé correctement. S’il est surchau é et que les aliments

Le gril n’aura pas besoin d’un nouvel apprêtage s’il est

pas un défaut.

ne réduira en rien les fonctions ou l’utilisation et ne constitue

(décoloration bleue) à cause de la chaleur. Cette décoloration

NOTA : La surface en acier de la plaque à frire se décolorera

thermostat) pendant le processus d’apprêtage.

la commande à robinet) ou 450°F (sur la commande à

IMPORTANT : Ne pas utiliser le réglage maximal (sur

FONCTIONNEMENT

température de cuisson souhaitée.

un miroir. Continuer jusqu’à ce que l’on atteigne la

à trois fois, jusqu’à obtention d’un ni luisant comme

puis essuyer l’huile. Recommencer la procédure deux

4. Chau er la plaque lentement pendant 15 à 20 minutes,

de l’acier.

certaine décoloration se produira pendant le chau age

3. Allumer tous les brûleurs et les régler au plus bas. Une

chi on.

créer un lm n. Essuyer tout excès d’huile avec un

surface. Étaler sur toute la surface avec un chi on pour

surface du gril, environ une once par pied carré de

2. Appliquer une ne couche d’huile de cuisson sur la

solution savonneuse.

lavant avec de l’eau chaude et un détergent doux ou une

1. Retirer le revêtement de protection appliqué en usine en

Apprêtage Des Grils

ESSAIS ET RÉGLAGES Suite

Page 28

Part # 4500195 (02/20/08) Page 9

brûleur, attendre 5 minutes et essayer de nouveau.

secondes après l’ouverture du robinet, fermer le robinet du

Dans le cas où l’allumage ne se ferait dans un délai de 5

l’allumage de tous les brûleurs dont le robinet est ouvert.

coupée. Il est de la responsabilité de l’utilisateur de véri er

sont pas allumées. L’alimentation en gaz ne sera pas

supérieure même si les veilleuses de cette section ne

ATTENTION : Le gaz alimentera les brûleurs de la section

de l’installation et réglés si nécessaire.

les brûleurs et les veilleuses doivent être véri és au moment

Tous les appareils sont testés et réglés en usine. Cependant,

thermostats à “OFF” ou à la position la plus basse.

7. Fermer tous les robinets et régler les cadrans des

nouvelle véri cation.

section. Corriger les fuites éventuelles et faire une

robinets et raccord comme décrit au début de la présente

500oF (260oC). Véri er la présence de fuites sur tous les

6. Dans tous les cas, régler maintenant le thermostat à

doté de son propre robinet marche/arrêt.

thermostat du four a une position “OFF”, le thermostat est

séparé du thermostat, ouvrir ce robinet Si le cadran du

5 Si la cuisinière est équipée d’un robinet d’arrêt du four

4. Allumer la veilleuse du four.

fuites si nécessaire et véri er de nouveau.

comme décrit dans la procédure ci-dessus. Réparer les

3. Véri er la présence de fuites aux robinets et raccords,

toutes les veilleuses de la section haute.

2. Ouvrir le robinet principal d’alimentation en gaz. Allumer

position “OFF”.

1. Véri er que tous les robinets et thermostats sont en

réutiliser ensuite.

de xation) doivent être soigneusement rangées pour les

supérieures. Toutes les pièces retirées (y compris les moyens

correctement les grils, les plaques de cuisson et grilles

nécessaire de retirer ou au moins de soulever et de supporter

panneau(x) inférieur(s) avant et les grilles du four. Il peut être

est nécessaire de retirer le(s) panneau(x) des robinets, le(s)

accéder à toutes les canalisations de gaz et aux raccords il

connexions de tuyaux. NE PAS UTILISER DE FLAMME ! Pour

produits équivalents, appliqués sur et autour des raccords et

détecteurs de fuites approuvés, de l’eau savonneuse ou des

testés pour détecter les fuites éventuelles. Utiliser des

Tous les raccords et connexions de tuyaux doivent être

ESSAIS ET RÉGLAGES

empêcher la circulation d’air à l’avant.

placer d’objets encombrants devant l’appareil, a n de ne pas

su samment d’air pour fonctionner et on ne devra pas

Tous les brûleurs à gaz et les veilleuses ont besoin de

doit être égale à la quantité d’air évacué.

pénètre dans la pièce. La quantité d’air entrant dans la pièce

correctement, il est nécessaire que de l’air de remplacement

pièce. Pour qu’une ventilation d’aspiration fonctionne

Une forte ventilation d’aspiration créera un vide dans la

pieds six pouces (1981 mm) au-dessus du sol.

(152 mm), au-delà des cotés des appareils et se trouver à six

correctement conçue qui devra se prolonger de six pouces

un équipement à ammes nues est d’utiliser une hotte

fonctionnement optimal. La méthode idéale pour ventiler

Une ventilation correcte est essentielle pour un

destination.

consulter le(s) code(s) applicable(s) dans le pays de

générales. Pour des recommandations plus détaillées,

Les remarques suivantes constituent des indications

Air De Ventilation

conformément aux codes locaux.

IMPORTANT – Cet appareil doit être relié à la terre

(Modèles avec su xe “RC”)

Connexion Électrique

PROLONGÉE. PURGER AVANT DE REBRANCHER LE GAZ”.

D’OUVRIR L’ALIMENTATION. APRÈS UN PÉRIODE D’ARRÊT

AMONT DOIVENT ÊTRE MIS EN POSITION D’ARRÊT AVANT

“TOUS LES ROBINETS DE BRÛLEURS ET DE VEILLEUSES EN

INSTALLATION Suite

Page 29

Part # 4500195 (02/20/08)Page 8

automatique :

d’installation du robinet d’isolement ou du système

L’avertissement suivant DOIT être a ché à l’endroit

d’accès près de la sortie.

robinet d’isolement doit être installé à un endroit facile

Lorsque cela est impossible, un système automatique de

d’une sortie dans un endroit facile d’accès.

ce robinet sera installé soit à l’extérieur de la cuisine ou près

cuisine en cas d’urgence. Chaque fois que cela est possible,

l’arrivée de gaz dans la cuisine pour permettre d’isoler la

Un robinet à commande manuelle doit être installé sur

l’appareil.

de déconnexion doit être installé entre le robinet de gaz et

ou de nettoyage. Un raccord union ou tout autre moyen

pouvoir isoler l’appareil lors de toute intervention d’entretien

d’un robinet de gaz manuel en amont de l’appareil pour

Tous les appareils xes (non mobiles) DOIVENT être équipés

fonctionnement.

être alimenté avec la pression de gaz nécessaire à son

et de la canalisation pour s’assurer que l’appareil peut

compagnie de gaz locale de véri er la taille du compteur

B. S’il s’agit d’une nouvelle installation, demander à la

propane.

ceux estampillés “PRO” doivent l’être uniquement au

“NAT” doit uniquement être connectés au gaz naturel,