Page 1

MODEL NUMBERS

MWG-9501

MWGH-9501

MWGF-9501

MWGL-9501

MWGR-9501

OPERATIONS MANUAL

INTERNATIONAL

NOTE: This manual pertains to all grill models listed above. The reader/operator must interpret its contents to applicable

needs. However, if there is any question of interpretation of any literature pertaining to Garland grills, please contact our

Customer Service Department at one of the phone numbers listed above.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING

THIS EQUIPMENT.

®

MANUFACTURED EXCLUSIVELY FOR

McDonald’s

BY

GARLAND COMMERCIAL INDUSTRIES, INC.

185 EAST SOUTH STREET

FREELAND, PENNSYLVANIA 18224

TOLL FREE: (800) 446-8367

PHONE: (570) 636-1000

FAX: (570) 636-9874

Come visit us on the web at

www.garland-group.com

E-mail: clamshell@garland-group.com

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE

- KEEP APPLIANCE AREA FREE AND CLEAR OF COMBUSTIBLES!

- PLEASE READ ALL SECTIONS OF THIS MANUAL AND RETAIN FOR FUTURE REFERENCE

- THIS PRODUCT HAS BEEN CERTIFIED AS COMMERCIAL COOKING EQUIPMENT AND MUST BE INSTALLED BY

PROFESSIONAL PERSONNEL AS SPECIFIED.

- ALL BURNER ADJUSTMENTS AND SETTINGS MUST BE MADE BY A QUALIFIED GAS TECHNICIAN

CAUTION: THIS EQUIPMENT MUST ONLY BE OPERATED UNDER AN APPROVED HOOD SYSTEM.

THIS EQUIPMENT MUST BE INSTALLED AND COMMISSIONED BY A PROFESSIONAL FACTORY TRAINED

TECHNICIAN.

GAS

®

GRILLS

MODEL NUMBERS

MWG-9501

MWGH-9501

MWGF-9501

MWGL-9501

MWGR-9501

MANUFACTURED EXCLUSIVELY FOR

McDonald's

BY

GARLAND COMMERCIAL INDUSTRIES, INC.

185 EAST SOUTH STREET

FREELAND, PENNSYLVANIA 18224

TOLL FREE: (800) 446-8367

PHONE: (570) 636-1000

FAX: (570) 636-9874

Come visit us on the web at

www.garland-group.com

E-mail: clamshell@garland-group.com

Rev 1 P/N 1881061 IN(091304)

Page 2

Page 3

Table of Contents

WARRANTY ........................................................................................................................................................................................................................ 5

INTRODUCTION ............................................................................................................................................................................................................. 5

SAFETY .................................................................................................................................................................................................................................. 5

SHIPPING DAMAGE CLAIM PROCEDURE .................................................................................................................................................. 6

LIGHTING INSTRUCTIONS .................................................................................................................................................................................... 6

SHUT DOWN INSTRUCTIONS ...............................................................................................................................................................................7

CLEANING AND MAINTENANCE ....................................................................................................................................................................... 7

FULL SIZE GAS CLAMSHELL MWG-9501 ................................................................................................................................................9

SPECIFICATIONS .......................................................................................................................................................................................................... 10

RELEASE MATERIAL INSTALLATION .......................................................................................................................................................... 11

RELEASE MATERIAL INSTALLATION (OPTIONAL) ........................................................................................................................... 12

2-SPEED FAN INTERFACE INFORMATION ................................................................................................................................................ 14

UNIT INSTALLATION ................................................................................................................................................................................................. 14

CLAMSHELL GRILL CONTROLS ...................................................................................................................................................................... 18

CONTROLES DE LA PARRILLA DE DOBLE COCCIÓN ..................................................................................................................... 18

DESCRIPTION OF GRILL CONTROLS ........................................................................................................................................................... 19

NORMAL OPERATING MODES ........................................................................................................................................................................... 20

PROGRAM LOGIC CHART .....................................................................................................................................................................................23

SYSTEM SETUP .................................................................................................................................................................................................. 24

MENU ITEMS ....................................................................................................................................................................................................... 26

National Code Requirements .................................................................................................................................................................. 15

Electrical Instructions .............................................................................................................................................................................15

Mennekes 7 pin Socket / Plug ................................................................................................................................................................. 15

Gas Connections, and pipe sizing ..........................................................................................................................................................17

Ventilation and Clearance ......................................................................................................................................................................17

Changing to a different type of gas ........................................................................................................................................................ 17

General Overview ................................................................................................................................................................................... 19

The Master Power (Pushbutton (ON / OFF) ..........................................................................................................................................19

Indicator Lights .......................................................................................................................................................................................19

Ignition Status Indicator Light - Center LED ........................................................................................................................................19

Up Arrow Button - Two Functions ..........................................................................................................................................................19

Right Arrow Button - Two Functions ......................................................................................................................................................19

Program Mode Button - Two Functions ................................................................................................................................................. 19

Menu Button - Two Functions ................................................................................................................................................................20

Temperature / Function Button - Two Functions ....................................................................................................................................20

Preheat Mode (Eprom 6.20 and higher) ................................................................................................................................................. 20

To Cook in Clam Grill Mode: ................................................................................................................................................................. 20

Standby Button - Black ........................................................................................................................................................................... 20

Cancel / Raise Button - Green ................................................................................................................................................................20

To Cook in Flat Grill Mode: ................................................................................................................................................................... 20

Standby Mode: ........................................................................................................................................................................................21

EXIT the Standby Mode: ......................................................................................................................................................................... 21

Standby Alarm (Version 6.20 and higher) .............................................................................................................................................. 21

To Display the Current Temperature ......................................................................................................................................................21

To View Settings for a Menu Item: .......................................................................................................................................................... 21

To Reset Factory Defaults ......................................................................................................................................................................21

To Clean the Grill: .................................................................................................................................................................................. 22

Breakfast to Lunch Transition (Transition Cooking) .............................................................................................................................. 22

Multi-Stage Cooking ............................................................................................................................................................................... 22

To Display Temperatures in F or C ........................................................................................................................................................24

To Change the Speaker Volume (High / Low) ........................................................................................................................................24

To Change the Gap Calibration .............................................................................................................................................................24

To Enable / Disable Start Delay ............................................................................................................................................................. 24

To Change Start Delay Timer ................................................................................................................................................................. 25

To Change the Standby Alert Feature - EPROM Chip Ver. 6.20 and higher .........................................................................................25

To Enable / Disable Multi-Stage Cooking - EPROM Chip Ver. 7.XX and higher .................................................................................25

To Add or Delete a Menu Item ...............................................................................................................................................................26

To Change the Remove Time ..................................................................................................................................................................26

To Change the Remove Time Alarm (Auto/Manual) ............................................................................................................................... 26

To Change the Sear Time ........................................................................................................................................................................27

To Change the Sear Time Alarm (Auto/Manual) ....................................................................................................................................27

To Change the Toast Buns Time .............................................................................................................................................................. 27

To Change the Toast Buns Alarm (Auto/Manul) ....................................................................................................................................27

To Change Turn Time ..............................................................................................................................................................................28

To Change Turn In Alarm (Auto / Manual) ............................................................................................................................................28

Page 4

TABLE OF CONTENTS

To Change the grill surface set temperature .......................................................................................................................................... 28

To Change the upper platen set temperature .......................................................................................................................................... 29

To Enable High Limit Test - GRILL SURFACE (Chip V. 3.52 and 4.0* ONLY) ....................................................................................29

To Enable High Limit Test - PLATEN (Chip V. 3.52 and 4.0* ONLY) ..................................................................................................29

TO ADD / PROGRAM NEW MENU ITEMS .................................................................................................................................................... 30

PROBE CALIBRATION .............................................................................................................................................................................................. 32

OPTIONAL ACCESSORIES ......................................................................................................................................................................................34

TROUBLESHOOTING ................................................................................................................................................................................................. 35

POSSIBLE ERROR MESSAGES ..................................................................................................................................................................... 35

IN STORE TROUBLESHOOTING GUIDE ..................................................................................................................................................36

CONTROLLER MENU ITEMS ............................................................................................................................................................................... 37

CONTROLLER MENU ITEMS (EPROM CHIP VER. 7.XX) ................................................................................................................ 39

TEMPERATURE CONVERSION (F / C) ...........................................................................................................................................................41

MANUAL CORRECTIONS AND MODIFICATIONS .................................................................................................................................43

To Add / Program an [Option Menu - CLAM] .......................................................................................................................................30

To Add / Program an [OPTION MENU - FLAT] ................................................................................................................................... 31

“Probe Open” ......................................................................................................................................................................................... 35

“Clam did not go down” ........................................................................................................................................................................35

“Upper Platen Stuck” ............................................................................................................................................................................. 35

“Eprom Corrupt” ................................................................................................................................................................................... 35

“Ignition Failure” ..................................................................................................................................................................................35

“High Limit” ........................................................................................................................................................................................... 35

“Motor Overcurrent” ............................................................................................................................................................................. 35

“Faulty Element / Shorted Probe” ......................................................................................................................................................... 35

Page 5

WARRANTY

INTRODUCTION

This warranty covers defects in material and workmanship

under normal use providing that:

a) the equipment has not been accidentally or

intentionally damaged, altered or misused.

b) the equipment is properly installed, adjusted,

operated and maintained in accordance with national and

local codes and in accordance with the installation instructions

provided with this product.

c) the warranty serial number affixed to the appliance

by us has not been defaced, obliterated or removed.

d) an acceptable report for any claim under this

warranty is supplied to us.

The equipment warranty coverage remains in force for one

(1) year (parts and labor) from the date the equipment is

put into operation and two (2) years (parts only) for the

microprocessor controller, motor speed controller and upper

platen (aluminum casting and shroud).

The Garland Group agrees to repair or replace, at it’s

option, any part that proves to be defective in material or

workmanship at no charge for the part or normal labor.

We assume no responsibility for installation, adjustments,

diagnosis, or normal maintenance such as: lubrication of

springs or valves. We exclude failures caused by erratic

voltage or gas supplies. We assume no responsibility for

travel costs beyond 100 miles round trip, travel other

than overland, and overtime costs of repair. We exclude

broken glass, paint and porcelain finish, surface rust, gasket

material, ceramic material, light bulbs and fuses from normal

coverage. We exclude damage or dysfunction caused by fire,

flood, and like “Acts of God” that are beyond the control of

The Garland Group.

The Garland Group’s liability on a claim of warranty shall

not exceed the price of the material and/or service, which

caused the claim. This warranty is limited and is in lieu of all

other warranties, expressed or implied. The Garland Group,

our employees, or our agents shall not be held liable for any

claims of personal injury or consequential damage or loss.

This warranty gives you specific legal rights, and you may

have other rights which vary from state to state.

The Garland clamshell grill, manufactured exclusively for

McDonald's, provides a method for efficient two-sided

cooking, while accommodating a variety of products. The

unit will also serve as a flat grill, and meets all of McDonald's

standards for safety, efficiency, and cleanliness.

SAFETY

Always follow these safety precautions when operating the

clamshell grill.

THIS GRILL MUST be operated by persons who have been

given adequate training.

CAUTION: THIS EQUIPMENT MUST ONLY BE

OPERATED UNDER AN APPROVED HOOD SYSTEM.

DO NOT OPERATE THE GRILL UNLESS IT HAS

BEEN COMMISSIONED (START-UP) BY A FACTORY

AUTHORIZED SERVICE CENTER.

DO NOT operate the grill without reading this

operation manual.

DO NOT operate the clamshell grill unless it has

been properly installed and grounded.

DO NOT operate the clamshell grill unless all service

and access panels are in place and fastened properly.

The Garland clamshell grill is a semi-automatic cooking

appliance. The upper platen is lowered automatically,

following the manual; two-handed initiation of the cooking

cycle, and the upper platen is raised automatically upon

completion of the cooking cycle.

When two sided cooking, the area between the upper platen

and the griddle plate should be regarded as a “danger zone”.

During two sided cooking the operator must not be within

this danger zone. When used as a flat grill, then this area is

no longer a danger zone, the platens do not move.

For whatever reason, be it cleaning, maintenance, normal

operation, any exposed person must use extreme caution if

within this danger zone.

In two side cooking the upper platen remains in the lowered

position by nature of it’s own weight. It is not locked down.

It can be raised by lifting of the handle on the front of the

platen, which pivots the platen about its rear mounting

point.

The clamshell grill may during its operation emit airborne

noise equivalent to a continuous A weighted sound pressure

level of 73dB(A).

5

Page 6

The clamshell grill must only be used for single and two

sided cooking of foodstuffs in a McDonald’s store and must

not be used for any other purpose.

on the floor.

NOTE: The anchor assembly remains fastened to the back

wall of the grill bay.

WARNING: To avoid serious personal injury:

DO NOT attempt to repair or replace any part of the

clamshell grill unless all main power supplies to the grill

have been disconnected.

USE EXTREME CAUTION in setting up, operating and

cleaning the clamshell grill to avoid coming in contact with

hot grill surfaces or hot grease. Suitable protective clothing

should be worn to prevent the risk of burns.

WARNING: This appliance must not be cleaned with a

water jet. DO NOT apply ice to a HOT grill surface.

NOTE: All warning labels and markings on the grill, which

call attention to further dangers and necessary precautions.

HAZARD COMMUNICATION STANDARD, (HCS) The procedures in this manual include the use of chemical

products. These chemical products will be printed in bold

face, followed by the abbreviation (HCS) in the text portion

of the procedure. See the Hazard Communication Standard,

(HCS) manual for the appropriate Material Safety Data

Sheet(s), (MSDS).

WARNING: After turning the master power switch to

the START position, the grill will go through an initialization

process. If the upper platens are in the lowered position they

will return to their raised upper position. This movement

takes approximately 8 seconds.

After service or cleaning is complete, return the grill to its

position in the bay and reattach the anchors by placing the

retainer on the caster post and turning the knob clockwise to

tighten.

NOTE: For safety reasons, the grill must be secured in the

grill bay in this manner before operation can resume.

SHIPPING DAMAGE CLAIM PROCEDURE

Please note that the Garland equipment was carefully

inspected and packed by skilled personnel before leaving

the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the

equipment.

What to do if the equipment arrives damaged:

1. File a claim immediately regardless of the extent of

damage.

2. Be sure to note, "visible loss or damage," on the freight

bill or express receipt and have the person making the

delivery sign it.

3. Concealed loss or damage: if damage is unnoticed until

the equipment is unpacked, notify the freight company

immediately, (within 15 days), and file a concealed

damage claim.

MAINTENANCE - the platen support arms carriage block

bearing bushes, the platen adjuster nuts, the platen support

(shoulder) bolt and the cam follower should be checked

annually for wear. Should there be any noticeable play in the

bearing bushes and any visible wear on the platen adjuster

nuts, platen support bolts or cam follower, then they must

be replaced.

MAINTENANCE - the audible alarm that sounds on platen

lowering, platen raising and 5 seconds before the completion

of the cooking cycle is to advise the operator that the platen

is about to move. The function of this device may be tested

by pushing the left hand CANCEL button. If no sound is

heard, ensure that the alarm volume is not set to low in

SYSTEM SETUP. If there is still no sound then a service

engineer should be called out to rectify the fault.

SERVICE AND CLEANING - The grill is secured in the

grill bay by the installer using two anchors that lock onto

the front casters. If the grill is to be moved out of the bay

for cleaning or service, remove the anchor from each caster

by turning the knob counterclockwise to loosen the retainer.

When the retainer is free of the caster, lay the assembly aside

LIGHTING INSTRUCTIONS

1. Ensure that the flexible gas hose is connected to the grill

and the power cords are plugged into the receptacles.

2. Turn the main power switch ON and allow the controls to

go through the power-up self-check. Once the control(s)

panel displays the word “OFF”, the unit is ready to begin

the heating process.

3. By selecting any of the menu items (pressing the menu

button) the controls will automatically initiate the

heating cycle appropriate for the menu item selected.

The burner(s) should light and heat until the temperature

specified by the menu item has been obtained.

4. If ignition of the burner does not occur on the first trial,

the second from the bottom indicator light will flash

amber. If the burner(s) does not light within four trials

for ignition, the control(s) will display a flashing warning

“IGNITION FAILURE”, the flashing amber light will

turn to solid red and an audible alarm will sound. If this

occurs, turn the main power switch off, wait 5 minutes,

then repeat steps 2 and 3.

6

Page 7

SHUT DOWN INSTRUCTIONS

1. To shut down unit at any time, switch the main power

switch to off (non-lit) position.

Caution: Do not scrape or otherwise scratch the

upper platens. The use of metal scrapers, abrasive pads,

or wire brushes will permanently damage the surface of the

upper platens.

2. For extended shut down periods, switch main power

switch to off position, disconnect unit from gas supply

line and unplug electrical connections.

CLEANING AND MAINTENANCE

Tools: McD Hi-Temp Grill Cleaner (HCS), McD All

Purpose Super Concentrate (HCS), McD's NOSCRATCH( Pad and Pad Holder, a suitable container,

High-Temperature Pot Brush and Grill Cloth, Stainless

Steel Pan Filled With Lukewarm Water, Protective

Gloves, (to protect hands from heat), Grill Squeegee and

Grill Scraper.

Warning: The upper platen surface and edges are

very hot! To prevent burn injuries, use extreme caution

when wiping down release sheets and platen edges.

Important: Frequently throughout the day, (at least 4

times per hour), thoroughly wipe down the release sheets

and platen edges with a damp grill cloth.

1. PRESS the "MENU" button until "CLEAN MODE" is

displayed, (the control will maintain the proper cleaning

temperature). Repeat with the other control. "READY

TO CLEAN" will be displayed and an audible alarm will

sound when the grill is at the proper cleaning temperature.

PRESS the "MENU" button to display "OFF." The

"OFF" position on the controllers allows the operator to

raise and lower the upper platens, (for clamshell grills),

to alternate positions for proper cleaning of the platen

edges.

2. Empty and replace the grease troughs. Grease troughs

should be emptied and replaced consistent with store

security policy.

3. Put on the protective gloves and wipe down the exposed

surface of the release sheet with a damp grill cloth.

4. Remove the release sheet locking clips and bars. Clean

the release sheets following the instructions provided by

your local cleaning chemical supplier.

5. Scrape only the lower grill surface with the grill scraper,

and squeegee any residue into the grease troughs with the

grill squeegee.

6. Open one packet of McD Hi-Temp Grill Cleaner, (HCS),

and empty the contents into a suitable container. (One

packet cleans a 3ft. grill).

7. Firmly attach the McD NO-SCRATCH( Pad to the pad

holder.

8. Dip the NO-SCRATCH( Pad into the grill cleaner.

9. Spread a light coating of grill cleaner over the entire

platen surface, BACK, FRONT AND SIDE EDGES

of both upper platens. DO NOT SCRUB WHILE

APPLYING THE PRODUCT.

10. After applying the grill cleaner, lightly scrub the platen

surfaces, BACK, FRONT AND SIDE EDGES with the

NO-SCRATCH( Pad until all the soil has been liquefied

by the grill cleaner. For stubborn soils, apply additional

grill cleaner and lightly scrub. DO NOT RINSE THE

PLATENS AT THIS TIME.

11. Starting at the back of the lower grill, spread a light

coating of grill cleaner over the entire surface. DO NOT

SCRUB WHILE APPLYING THE PRODUCT.

12. After applying the grill cleaner, lightly scrub the grill

surface with the NO-SCRATCH( Pad until all the soil

has been liquefied

13. For Clamshell Grills, rinse the upper platens with a

dripping wet grill cloth. RINSE PLATEN EDGE

THOROUGHLY, THEN WIPE DOWN BACK EDGE

OF PLATEN.

14. Carefully pour small quantities of lukewarm water onto

the grill while brushing the surface, backsplash, and

bullnose with a LONGLIFE( pot brush or equivalent

high-temperature brush. Continue until the water no

longer boils away and the grill remains wet. Squeegee

dry.

Caution: Ice, cold water, or large quantities of water

must never be applied to the grill plate or upper platen.

Severe damage to the grill will occur!

15. Clean the release sheets as follows:

16. Place the sheets on the lower grill. Scrub both sides of

the sheets with the same McD NO-SCRATCH( Pad used

on the grill.

Page 8

Note: It is generally not necessary to apply additional

product to the NO-SCRATCH( Pad. If the pad is not wet

enough, rewet with a small amount of water, if no cleaner is

left.

a. Rinse both sides of the sheets with a wet grill cloth.

b. Rinse the lower grill by flooding the surface twice with

lukewarm water. Squeegee after each rinse.

17. Wipe the lower grill surface, backsplash, bullnose, and

hood with a clean, damp grill cloth.

AFTER CLEANING - Apply a thin coat of fresh shortening

to the lower grill surface only. Wipe down the surrounding

areas. Empty, wash, rinse, and replace the grease troughs.

Note: Repeat this procedure to clean additional grills.

Reverse NO-SCRATCH( Pad, and use clean side.

CLEANING AFTER EACH RUN OF PRODUCT:

Using grill scraper, scrape grease on lower grill plate from

front to back only. Do not scrape across the rear of the lower

grill plate with grill scraper. Use wiper squeegee to clean

release material sheet on upper platen in a downward motion.

Hold handle at a slight upward angle with wiper end facing

downward. Do not press hard against the release material

sheet to prevent scratching or tearing.

Push the grease at the rear of the lower grill plate into the

grease cans using the wiper squeegee only. Do not use the

grill scraper for this step.

Warning: Grill Temperatures will cause severe skin

burns.

Use the grill cloth to clean back splash and bullnose areas as

needed during operation.

Note: To increase life of release material sheet, wipe

down with folded grill cloth four (4) times every hour.

8

Page 9

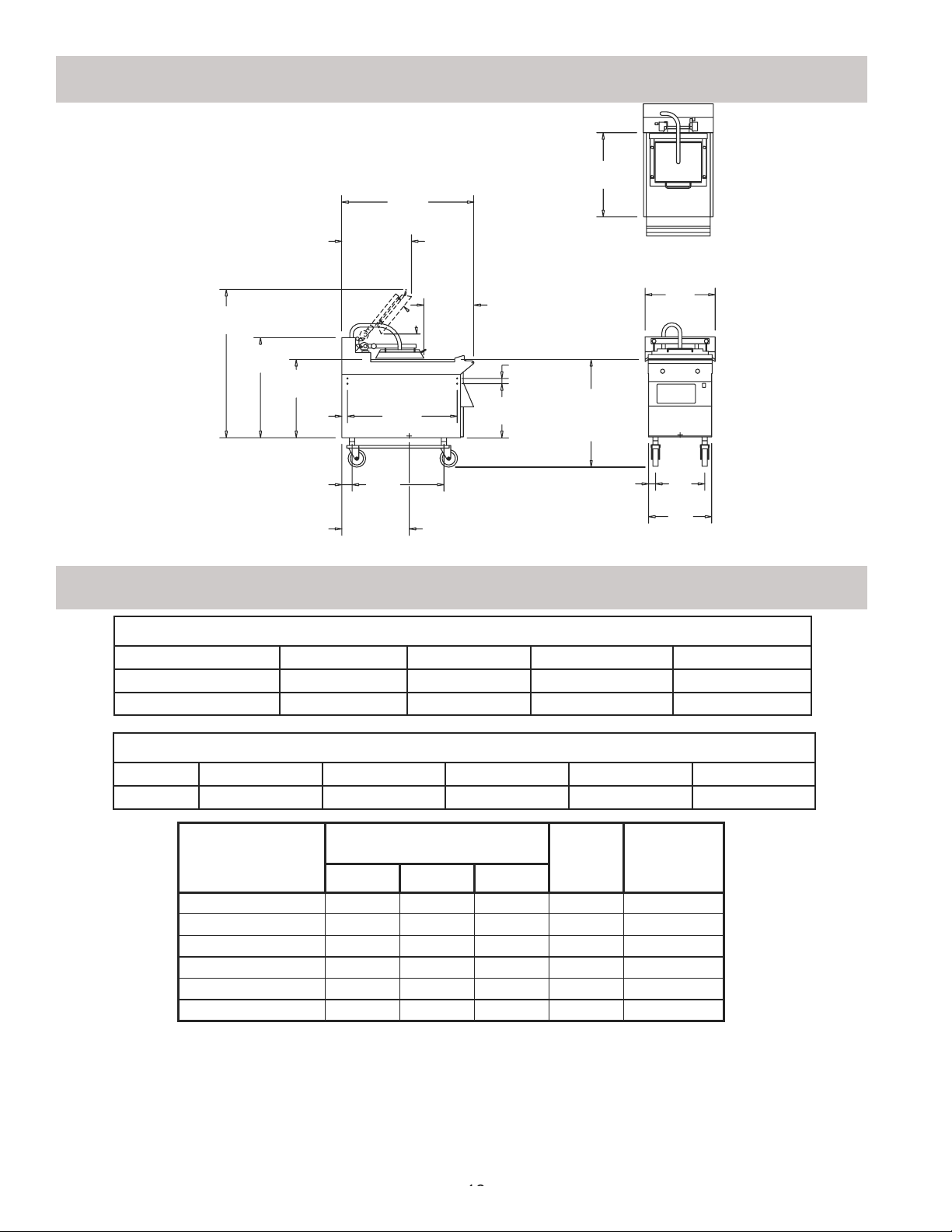

42-11/32

[1076mm]

28-9/16

[725mm]

20-21/64

[516mm]

BOTTOM CABLE ENTRANCE

[41mm]

4-1/16 [103mm]

VENT FAN

INTERFACE

3/4 DIA

[19mm]

11/32

[9mm]

2-59/64

[74mm]

7-1/2 [190mm]

SPECIFICATIONS

37-3/4

[959mm]

19-29/32

[505mm]

14-5/16

[363mm]

51°

1-5/8

31-21/64

[796mm]

26-1/4

[667mm]

25-1/2 [648mm]

3/4" N.P.T. BOTTOM GAS INLET

15-27/64

[392mm]

1-1/2 [38mm]

22-5/16

[567mm]

2-1/2 x 4-3/8

[65mm] x [111mm]

24

[610mm]

30-3/4 [781mm]

TO

33 [838mm]

COOKING HEIGHT

1-63/64 [50mm]

FLUE OPENING

38

[965mm]

32-3/64

[814mm]

36

[914mm]

1-3/4

[44mm]

FULL SIZE GAS CLAMSHELL MWG-9501

Gas Input Specifications

GAS TYPE Heat Input / kW Setting Pressure Manifold Pressure Flow Rate

Natural 18.46 20/25 mbar 8.75 mbar 1.96 m3/h

Propane 18.88 30/37/50 mbar 25 mbar 1.46 kg/h

MINIMUM CLEARANCES FOR SERVICING

TOP FRONT LEFT SIDE RIGHT SIDE REAR

(mm) * 600 150 150 150

KW LOAD

9.8

10

11. 2

NOMINAL AMPERES PER LINE

Volts Model

L1 L2 L3

14.0 14.0 14.0 415 (-G)

24.5 24.5 24.5 230 (-O)

27.2 27.2 27.2 120/208 (-I)

13.8 13.8 13.8 400 (-H)

13.2 15.3 13.2 220/380 (-H-A)

15.0 15.0 15.0 380 (-I)

25.7 25.7 25.7 220 (-J), (-K), (-M)

14.84 14.84 14.84 380 (-N)

16.8 16.8 16.8 220/380 (-P), (-Q)

31 31 31 208 (-R)

29.5 29.5 29.5 220 (-S)

29.7 29.7 29.7 208 (-T)

9

Page 10

SPECIFICATIONS

[610mm]

24

20

[508mm]

[392mm]

15-27/64

[567mm]

22-5/16

[725mm]

28-9/16

[796mm]

31-21/64

26-1/4

[667mm]

[74mm]

2-59/64

[41mm]

1-5/8

14-5/16

[363mm]

37-3/4

[959mm]

1-1/2 [38mm]

30-3/4 [781mm]

33 [838mm]

COOKING HEIGHT

TO

1-63/64 [50mm]

14-3/64

[357mm]

18

[457mm]

19-1/4 [489mm]

BOTTOM CABLE ENTRANCE

51°

19-29/32

[505mm]

42-11/32

[1076mm]

SPECIFICATIONS

BOTTOM CABLE ENTRANCE

19-1/4 [489mm]

1-1/2 [38mm]

30-3/4 [781mm]

33 [838mm]

COOKING HEIGHT

1-63/64 [50mm]

HALF SIZE GAS CLAMSHELL MWGH-9501

Gas Input Specifications

GAS TYPE Heat Input / kW Setting Pressure Manifold Pressure Flow Rate

Natural 9.23 20/25 mbar 8.75 mbar .98 m3/h

Propane 9.44 30/37/50 mbar 25 mbar .73 kg/h

MINIMUM CLEARANCES FOR SERVICING

TOP FRONT LEFT SIDE RIGHT SIDE REAR

(mm) * 600 150 150 150

KW LOAD

4.9 14 14 14 230 (-O)

5.6 8.5 8.5 8.5 380 (-G)

5.6 8.5 8.5 8.5 220/380 (-H-A)

5.6 8.5 8.5 8.5 380 (-N)

5.6 15.5 15.5 15.5 208 (-D)

5.6 8.5 8.5 8.5 220/380 (-ME-A)

NOMINAL AMPERES PER LINE

L1 L2 L3

10

1010

Volts Model

Page 11

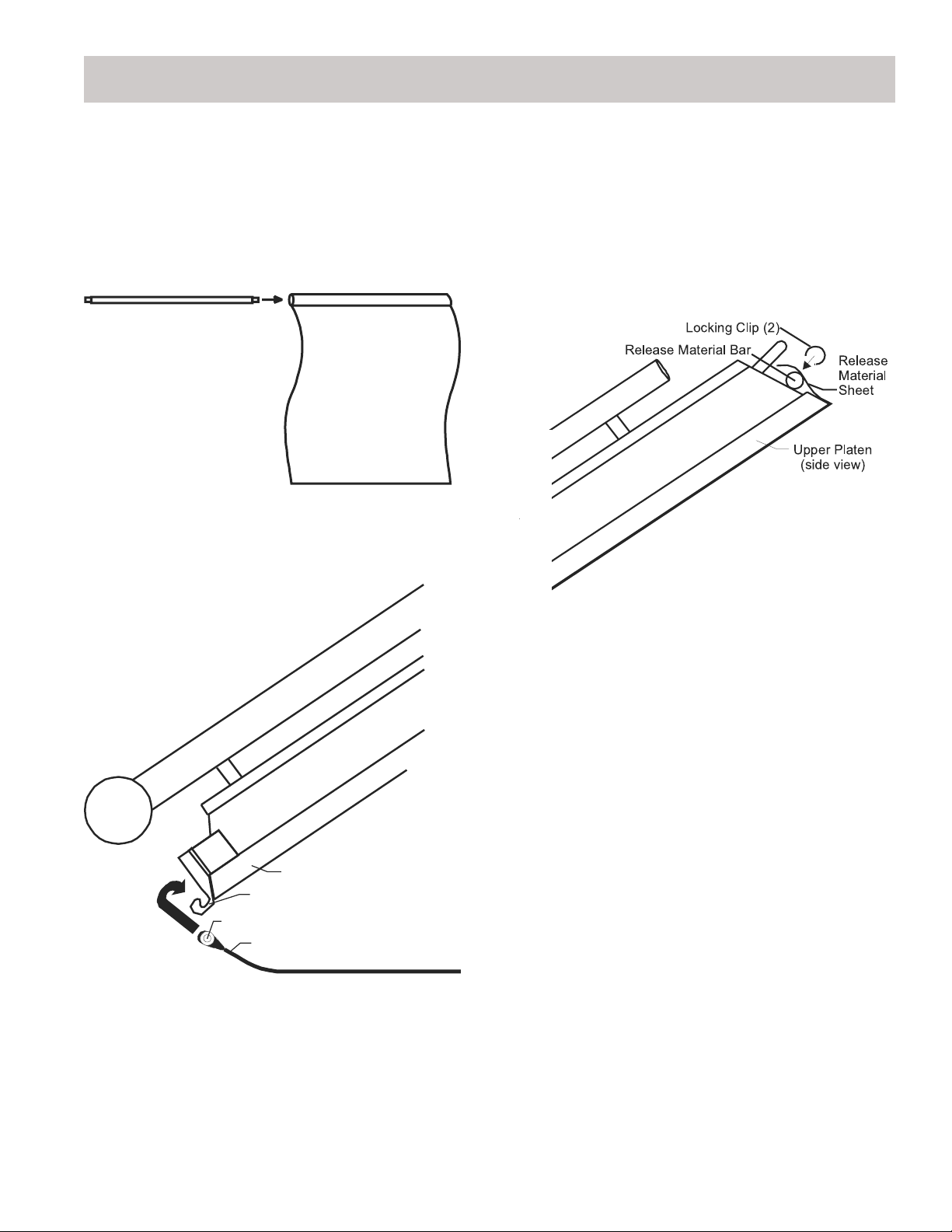

RELEASE MATERIAL INSTALLATION

The following procedures are the procedures for installing the teflon sheets on to the upper platen

on the Garland Clamshell grill. The components shown below are included with your grill when

purchansed.

1. Slide release material rod through hemmed end of the

release material sheet.

2. Hook release material rod on brackets located at the rear

of the upper platen

4. Place locking clips over release material sheet and press

into place over release material bar

5. Check alignment and tightness of release material against

upper platen.

Upper Platen (Side View)

Release Material Hook

Release Material Rod

Release Material Sheet

3. Holding the bottom of the realease material sheet in place,

gently pull the sheet toward the front of the platen.

NOTE: Make sure release material fits smoothly over upper

platen.

NOTE: Installing release material sheets too tight may cause

premature failure of the sheet.

Installing only 1 clip on over the release material bar

may cause the release material sheet to be too loose.

Ensure that 2 clips are installed on the tefl on bar at

all times.

Relase material sheets should be replaced when:

• Product sticks to release material

• Carbon build-up causes problems in taste or

appearance.

• A tear in the release material sheet’s cooking area.

• Relase material coating is worn off sheet.

NOTE: Rotate the release sheets on daily basis

11

Page 12

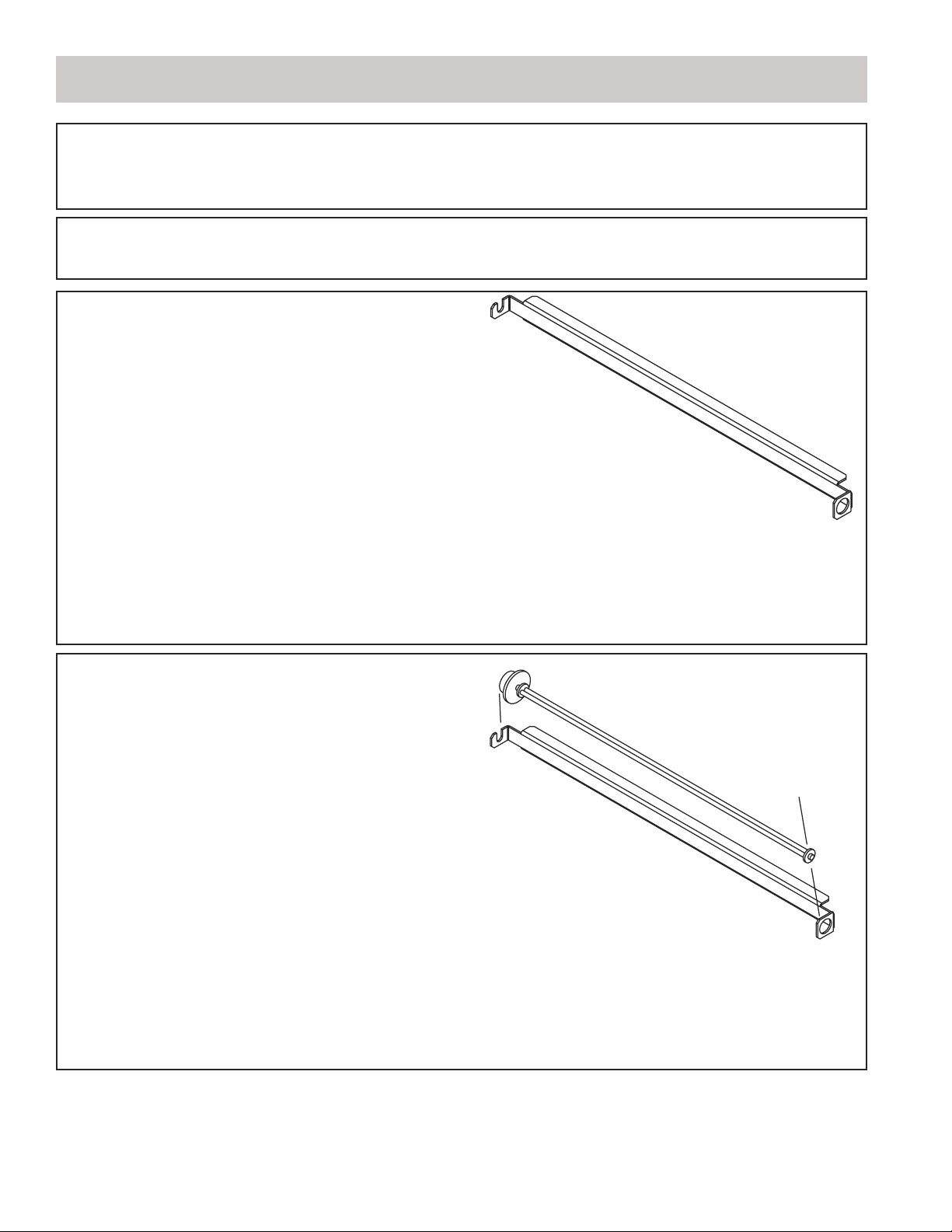

RELEASE MATERIAL INSTALLATION (OPTIONAL)

NOTE: TEFLON ROLLUP BAR ASSEMBLY’S ARE SEPARATE FOR LEFT AND FOR RIGHT.

NOTE THE “L” OR “R” STAMPED ON THE BRACKET ASSEMBLY FOR CORRECT

POSITIONING.

WARNING: UPPER PLATEN TEMPERATURES ARE VERY HOT. PLATEN SHOULD BE

COOL WHILE INSTALLING

1. If attached, remove Teflon sheet clips located on

the front of the platen.

2. Insure Teflon bar that is bolted to the upper

platen is free and clear of carbon buildup, and clean as

necessary.

3. Install Teflon rollup bar bracket by placing new

rollup over existing Teflon bar, with the set screws facing

DOWN (See Figure 1).

4. Tighten set screws using 1/8” allen wrench.

5. Install teflon roller bar in rollup bracket. (See

Figure 2)

Figure 1 - Teflon Rollup bar bracket

Insert this end first

Figure 2 - Inserting teflon roller bar into bracket

12

Page 13

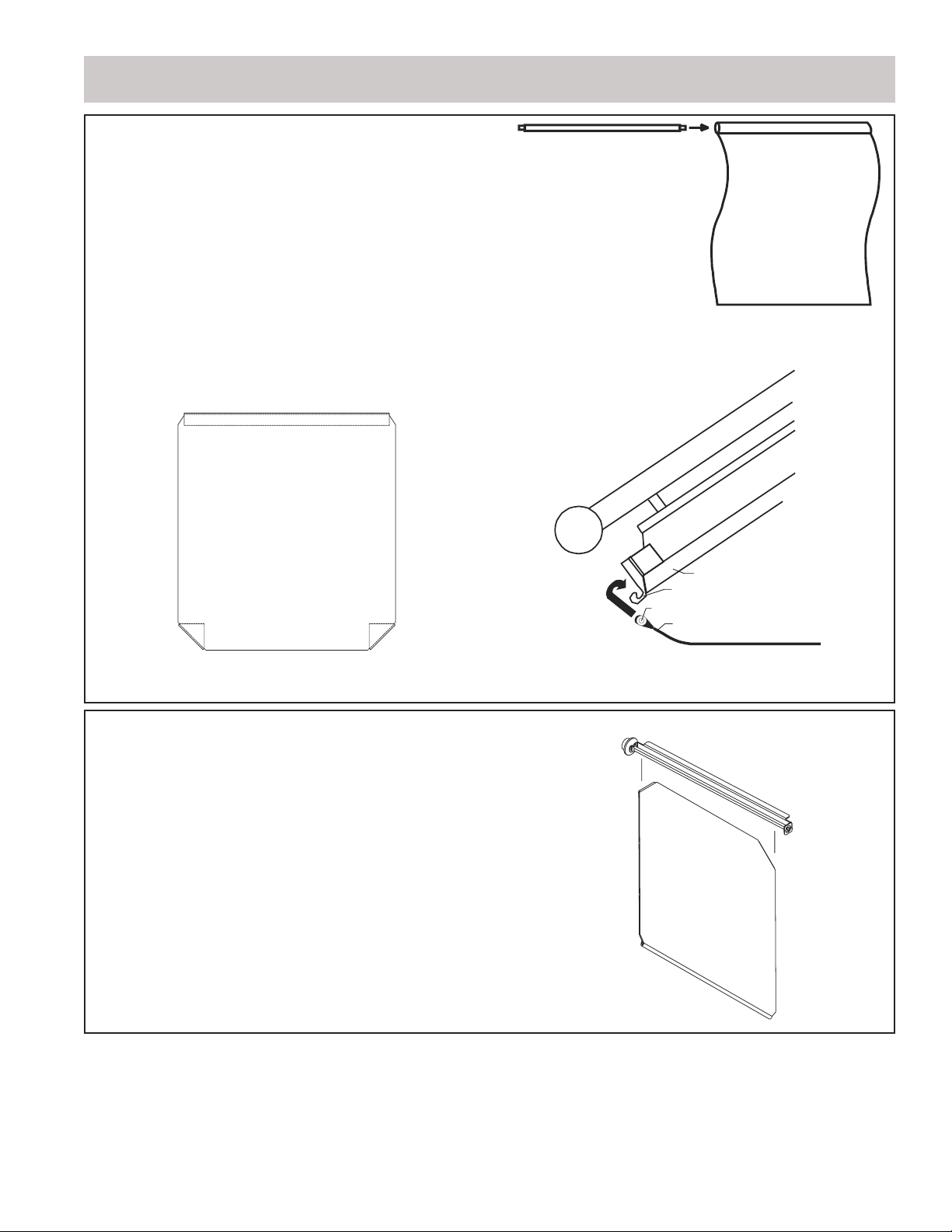

RELEASE MATERIAL INSTALLATION (OPTIONAL)

6. Install existing rod through opening on teflon

sheet as previously done with existing rod and sheet.

7. Clip existing teflon bar in rear of platen as

previously done with existing rod and sheet.

8. Fold corner edges of front of teflon sheet

approximately 1 inch on top and side, and insert folded

sheet through opening in Teflon rollup.

9. Once inserted, pull through and hold Teflon sheet

in center, and turn the tightening knob clockwise (for right

platen) and counter-clockwise (for left platen).

10. Once tight, turn locking knob in opposite direction

of tightening knob.

Upper Platen (Side View)

Release Material Hook

Release Material Rod

Release Material Sheet

13

Page 14

2-SPEED FAN INTERFACE INFORMATION

This unit is equipped with a 2-speed fan interface (Grills

manufactured post grill serial number 0010CL0036).

McDonalds stores built post May 2000 are equipped with

the capability of a 2-speed interface. In the event that a store

is a capable 2-speed fan store, and the grill is not a 2-speed

fan unit, a separate 2-speed installation kit is available upon

request at a set billable price to the store.

Units equipped with a 2-speed fan interface still require

the 5-wire interlock cord, in addition to a separate 3-wire

extension cord supplied from the hood exhaust system.

2-speed installation instructions are available upon request.

2-speed activation will occur at the following times:

LOW SPEED (all active AFTER (1) ONE MINUTE)

UNIT INSTALLATION

IMPORTANT: RATING PLATE FOR THIS EQUIPMENT

IS LOCATED IN TWO PLACES. ONE IS LOCATED

INSIDE BACK PANEL ON LEFT SIDE, SECOND

RATING PLATE LOCATED UNDER FRONT CONTROL

PANEL ON CENTER.

This equipment must be installed by a competent factory

trained, certified, licensed and / or authorized service or

installation person.

WARNING. This appliance must be earthed.

Prior to installation, the four castors and two locking

channels, supplied loose with the grill, must be securely

located on the underside of the base. The castors fitted with

a brake must be located at the front of the grill. The castors

are located through the locking channel with the folded

edges facing down, such that when all castors are located,

they cannot rotate.

This appliance should be connected to a potential equalization

system. To facilitate this a labeled equipotential bonding

point is fitted to the rear of the grill.

It is recommended that this grill is connected to a residual

current (earth leakage) device with a tripping current not

exceeding 30mA. The leakage current of this grill will not

exceed 5mA.

This grill is supplied with a seven pin socket, as specified

by the McDonald’s Corporation, for installation in new

grill stations. This socket is supplied fitted to the grill at the

factory. This socket allows for disconnection from the supply

with all pole separation of at least 3mm.

1. All platens (equipped and are active 2-speed fan grills)

go into the standby mode. (For standby mode see page

23).

2. All platens (equipped and are active 2-speed fan grills)

are in the OFF mode.

3. All platens (equipped and are active 2-speed fan grills)

are idle (in the up position).

4. When grill is initially turned on for initial heat up in the

morning.

HIGH SPEED (Active immediately)

1. A cook cycle on at least 1 platen (equipped and are active

2-speed fan grills) is initiated.

2. When grill is initialized using the main ON/OFF Master

Power switch for 1 minute.

3. CLEAN MODE.

For connection to existing older grill stations, please refer

to your Kitchen Equipment Supplier for a conversion kit

that allows connection to two power supply cords and one

interlock cord. This kit must be connected according to the

instructions and wiring diagram supplied with it and the

warning labels supplied with the kit must be applied to the

grill.

CAUTION: Prior to installation, check the electrical supply

to ensure input voltage and phase match the equipment

voltage rating and phase. See data plate located rear left side

of grill and lower front panel.

Grill is to be located directly under ventilation system and fit

securely with grill locks attached.

Once installed in the grill station underneath the ventilation

system, the raised position of the upper platens must be

adjusted to allow at least 40mm (1.6”) of clearance between

the handle on the front of the upper platen and the lower lip

of the ventilation system hood. The raised position of each

platen is adjusted by raising or lowering the upper of the two

microswitches (limit switches) in the rear of the grill. The

lower microswitch position must not be adjusted.

Grill plate must be level front to back, side to side and

diagonally. This leveling must be done with the unit under

the hood and in it’s normal operational position to prevent

warping of the grill plate.

NOTE: Once the platen elevation is adjusted, set the

mechanical over-run bolts in the rear of the unit to prevent

accidental over-run in the event of failure of the upper

microswitch.

14

Page 15

UNIT INSTALLATION

Installation shall be made with the gas connector that has

been specified by The McDonald’s Corporation and is

supplied loose with the grill. The quick disconnect fitting and

gas shut off valve must be installed in the direction indicated

on their outer body.

National Code Requirements

The type of gas for which the grill is equipped is stamped on

the data plate on the inside rear of the unit and on the lower

front panel. Connect a grill stamped for Natural Gas (High

(H) or Low (L) Calorific Value) only to Natural Gas; connect

those stamped for Propane Gas only to Propane Gas. When

installing gas grills, the installation must comply with the

latest edition of the National Gas Installation Requirements.

When installing any type of gas-fired commercial kitchen

equipment, the requirements of the National Fire Protection

Association must be followed implicitly.

Electrical Instructions

All electrically operated appliances must be electrically

earthed in accordance with local codes; or in the absence

of local codes, with the latest edition of National Wiring

Regulations. A wiring diagram is located on the rear panel of

the grill. See rating plate in rear of grill, or lower front panel

for proper voltages.

WARNING: Installer Note - The grill is designed for

connection to a special interlock system. Check receptacle

wiring diagram before connecting. Diagram located in this

manual and on the rear of the grill.

J

1

N

N

2

1

3

6

7

4

5

The Menneks 7-pin Socket is used in International Units,

Mennekes 7 pin Socket / Plug

J2

Int IntLimLimCom 115 115 115

-CE, -H, -ME, -FR, and -K.

As shown in the diagram to the left, the Mennekes socket/

plug is used to bring both single, and three phase power to

the unit.

Lim Lim Com 115 115 115 Int Int

N

N

15

Page 16

UNIT INSTALLATION

Gas Connections, and pipe sizing

The size of the gas line is very important. If the line is too

small, the gas pressure at the burner manifold will be low.

This will cause slow recovery and delayed ignition. The

incoming gas pressure line should be a minimum of 1-1/2”.

All grills require a 3/4” connection.

Before connecting new pipe the pipe must be blown out to

dispose of any foreign particles. These particles will cause

improper operation.

When using thread compound, use small amounts on male

threads only. Use a compound that is not effected by the

chemical action of LP gases. Avoid applying compound to

the first two threads to prevent clogging of the burner orifices

and control valve.

Have the installer check all gas plumbing with a soap

solution for leaks. DO NOT USE matches, candles or other

ignition sources in checking for leaks.

The grill must be disconnected from the gas supply system

when pressure testing of that system at pressures in excess

of 150mbar.

Test all piping and connections for gas leaks. A rich soap

solution should be used for this purpose. Never use a

flame.

Ventilation and Clearance

One of the most important considerations of efficient grill

operation is proper ventilation and air supply. Insure the

grill is installed so the products of combustion are removed

efficiently and the ventilation system does not produce drafts

that interfere with proper burner operation.

Proper operation of exhaust fans (proper speed, rotation and

adjustment) is essential. In addition to the exhaust system the

make-up air system (HVAC) for the kitchen is the air supply

for the combustion air for the burners. Proper incoming air

is essential for all gas operated equipment. Poor incoming

make-up will cause inefficient burner operation, delayed

ignition and possible burner failure. Insure air balancing is

performed on the system as required by the PMS card.

Any ventilation system will break down if improperly

maintained. The duct system, the hood, and the filters must

be cleaned on a regular basis and kept grease free.

Check the data plate to determine the proper type of gas

before connecting the quick disconnect or piping from the

building gas supply.

An incoming gas pressure test nipple is provided on the

incoming gas manifold for pressure checks.

Minimum incoming gas pressure for Natural Gas is 15 mbar.

Maximum incoming gas pressure for Natural Gas is 34.5

mbar.

Minimum incoming gas pressure for LP Gas is 27.5 mbar.

Maximum incoming gas pressure for LP Gas is 34.5 mbar

Burner operating gas pressure can be checked at the outlet

side of the gas valve at the pressure test point.

Burner manifold pressure for Natural Gas must be 8.75 mbar.

Burner pressure for LP Gas must be 25 mbar.

To adjust the burner pressure, remove the sealing screw

from the pressure test nipple, connect a manometer, remove

the sealing cap on the gas valve regulator, turn on the grill,

adjust the screw in the regulator to give the correct pressure,

turn off the grill, refit the regulator sealing cap, remove the

manometer, replace the seal screw in the test nipple and test

for gas leaks.

Gas pressures should be checked by the local Gas Company

or an authorized service agency only.

The room containing the grill is required to have a permanent

air vent. The minimum effective area of the vent shall be 4.5

cm² per kW. Air vents shall be of such a size to compensate

for the effects of any extract fan in the premises.

Changing to a different type of gas

Changing from one gas category to another must only be

done by a Qualified Gas Engineer.

To change from category II to III or vice versa, the gas valve,

enrichment tube igniter and orifice must be changed to that

supplied by the Authorized Service Agency for the gas you

are changing to. On completion of changing these three

components, you should test all joints for leaks, verify that

the manifold pressure is adjusted to the value given in the

specification pages in this manual, and repeat the burner air

adjustment procedure. This is to be found on the following

page in this manual. When the burner is correctly adjusted,

the alternate rating plate decal must be placed over the

existing rating plates to reflect the new category for which

the grill is set.

To change from one gas type to another within the same

category (High to Low Calorific Value Natural Gas or vice

versa), change the orifice to that supplied by the Authorized

Service Agency.

Page 17

INITIAL SETUP OF GRILL

Burner Air Adjustment

1. Visually inspect the color of the burner tile. After the

burner has been running for several minutes, the tile

surface should be glowing DULL ORANGE, with very

little or no blue haze visible above the tile surface. (Note:

Just after the burner ignites, it will have some blue haze

above the tile surface. This will remain until the tile has

heated up and is glowing dull orange). If the burner does

not become dull orange, then the burner air supply needs

to be adjusted.

2. Loosen the lock nut holding the air adjustment in place.

Slowly turn the air adjustment out (counterclockwise).

The burner tile surface should begin to brighten.

3. If it brightens, then continue turning the screw

counterclockwise until the burn tile surface brightens

and then begins to have a blue haze to it again. Stop

turning the adjuster. Begin turning the adjuster in while

COUNTING THE NUMBER OF TURNS until the tile

again has a blue haze. Stop tuning. Divide the number

of turns turned in by half and unscrew (counterclockwise)

the adjuster that number of turns. The adjustment is now

complete. Tighten down the lock nut.

Ignitor Adjustment

The Igniter location is factory set and does not normally

require adjustment. Adjustment should only be conducted if

the Micro-Amp (μA) reading taken by placing a Micro-Amp

(μA) meter in line between the ignition module and the flame

sense wire reads below 0.22 Microamps (μA). The normal

reading is around 0.80 (μA) to 1.5 (μA). If the reading is

low, the igniter can be a moved up or down to achieve the

Page 18

PROG

CLAMSHELL GRILL CONTROLS

START (ON)

STOP (OFF)

MASTER

POWER

"CANCEL/RAISE

BUTTON

"READY"

INDICATOR

LIGHTS

"UP ARROW"

BUTTON

(WHEN PUSHED SIMULTANEOUSLY-CLAMMODELS

UPPER

REAR

IGNITION

FRONT

"RIGHT ARROW"

BUTTON

"COOKING TIME COUNTDOWN

(WHEN PUSHED

FLAT GRILL COOKING

"LOWER PLATEN"

MENU FUNCTION

PROG

MENU

SELECT

"MENU"

BUTTON

"PROGRAMMODE"

"TEMPERATURE"/

"PROGRAM

BUTTON

"STANDBY"

BUTTON

DISPLAY

TEMP

FUNCTION”

BUTTON

ENCENDER (ON)

APAGAR (OFF)

INTERRUPTOR

GENERAL

BOTÓN “FLECHA ARRIBA"

CONTROLES DE LA PARRILLA DE DOBLE COCCIÓN

"CANCELAR/SUBIR PLANCHA"

BOTÓNDE

INDICADORES

DE LISTO

(READY)

"INICIAR TIEMPO DE COCCIÓN"

(CUANDO SE OPRIMEN SIMULTÁNEAMENTE)

(MODELOS PLANOS SOLAMENTE)

BOTONES DE "BAJAR PLANCHA"

(CUANDO SE OPRIMEN SIMULTÁNEAMENTE -

MODELOS DE DOBLE COCCIÓN)

SUPERIOR

SECCI TRASERAÓN

IGNICIÓN

FRENTE

MENÚ FUNCIÓN

PROG

SELECC.

MENÚ

TEMP

BOTÓNDE

"ESPERA"

PANTALLA

BOTÓN “FLECHA DERECHA"

BOTÓNDE“MENÚ"

MODALIDAD DE

PROGRAMACIÓN

18

“TEMPERATURA/FUNCIÓN"

BOTÓNDE

Page 19

DESCRIPTION OF GRILL CONTROLS

General Overview

The grill control will allow for 2 functions, both described in

the following sections.

The “Normal Operating Mode”, also known as the Cook

Mode is the mode in which is used during normal cooking.

In the normal operating mode, the operator can start a cook

cycle, cancel a cook cycle, view actual temperatures, view

settings for the currently selected menu item, scroll to

another menu item (Both forward and backward), and enter

the “Programming Mode”.

The “Programming Mode” is the mode in which the grill

operator, manager, or service technician can change various

programmed features to specific menu items, or change

features that would apply to the entire grill.

The Master Power (Pushbutton (ON / OFF)

Controls power to the grill and must be turned “ON” to start

the operation. The controller displays will be active

when the switch is “ON”.

Indicator Lights

There are four, (4), indicator lights, indicating the temperature

status of each zone on the grill, one, (1), on the upper platen,

(top light), and three, (3), on the lower, (lower section of

lights, top to bottom; rear, center, front, respectively - see

diagram on previous page). Each light can display three,

(3), different colors, indicating temperature status for the

corresponding zone.

Red: The zone(s) is too hot (more than 79ºF/43ºC over

the set temperature) or heat zone(s) failure.

Amber: The zone(s) is calling for heat.

Ignition Status Indicator Light - Center LED

The center light in the lower section indicates burner ignition

status in the following ways:

Green: status OK.

Amber: Flashing indicates that ignition retrial has

occurred at least once, (4 tries maximum). Once activated

the flashing amber light will continue to flash, until ignition

is achieved, (in four tries or less, total), at which time the

light will remain amber, but stop flashing.

Red: Indicates that ignition was not accomplished after

4 tries, and that the ignition system has been shut down,

requiring a manual reset, (power-down).

Up Arrow Button - Two Functions

1) In the cook mode, when depressed, it will display the

Remove time, Top Temperature, Bottom temperature and

Gap setting for the menu item displayed. Each item will

be displayed in the order as stated above. After 5 seconds

the display will return to the product menu item.

2) In the program mode, it will change the value of the

current cursor digit, (see “RIGHT ARROW” button).

Right Arrow Button - Two Functions

1) In the program mode various displayed parameters will

be shown in numerical values. Each number, when

displayed, will have a flashing digit...the cursor digit.

The “RIGHT ARROW” button will move the cursor to

the next digit. Using the “RIGHT ARROW” button in

conjunction with the “UP ARROW” button described

above, any parameter value displayed in the program

mode may be altered.

Green: The zone(s) is at or above the set temperature

(maximum of 79ºF/43ºC).

Display:

The controller display will contain information relevant to

each operation in both cook and program modes.

2) In the cook mode it will scroll backward through the

menu items.

Program Mode Button - Two Functions

1) The primary function is to access Programming and

Calibration of the grill. Push and hold for five (5)

seconds. Display will show type and version number.

There are two programming features,

“MENU ITEMS” and “SYSTEM SETUP”.

2) The second function is when used with “TEMP” button.

To display all temperature zones at the same time, press

the “TEMP” button one time and the ‘PROG” button

five (5) times. This will display all four (4) temperature

zones.

Page 20

DESCRIPTION OF GRILL CONTROLS

Menu Button - Two Functions

1) In the cook mode this button will allow you to change

menu items.

2) In the programming mode, the button is used to advance

to the next program item.

Temperature / Function Button - Two Functions

1) In the Cook mode, each time the button is pressed the

current temperature for one zone will be displayed. The

displayed temperature begins at the upper platen and

works sequentially to the front each time you press the

button. After five (5) seconds the display will return to

the menu item selected.

2) In the Program mode, this button becomes the Function

button allowing you to scroll through the functions in the

“MENU ITEMS” section of programming.

NORMAL OPERATING MODES

NOTE - TO STOP THE GRILL AT ANY TIME, TURN THE MASTER

POWER SWITCH OFF

Standby Button - Black

When both “STANDBY” and “CANCEL/RAISE” buttons

are pressed simultaneously, the upper platen will lower to the

griddle surface. Press the “STANDBY” button again within

five (5) seconds from the start of the cook cycle, to place

the controller in its “standby” state. The display will flash

“STANDBY” along with the menu item currently selected.

For energy conservation and periods of non-use this will

maintain grill temperatures.

Cancel / Raise Button - Green

From the “STANDBY” mode, pushing this button will

cancel “Standby” and raise platen. During the cooking cycle,

pressing this button will cancel the cooking timer and return

the grill to the “IDLE” mode.

NOTE: If the platen is in motion, pressing the “CANCEL/

RAISE” button will stop the platen in motion and return

the platen to the “IDLE” mode (Eprom version 3.52 and

greater).

Preheat Mode (Eprom 6.20 and higher)

The first menu item selected after pressing the “MENU

SELECT” button is “PREHEAT”. Preheat mode is not

actually a menu item, as it does not have a remove time.

Preheat mode has been designed to alarm the operator when

the grill is “READY TO COOK”.

The upper platen set temperature is 425º F (218ºC) and a

lower grill surface set temperature of 350ºF (177ºC). When

the grill reaches these set temperatures, the operator can then

select a menu item with equal set temperatures, and the grill

will be ready to cook.

To Cook in Clam Grill Mode:

1. SELECT a clam grill menu by pressing the “MENU

SELECT” button, until you attain the required Clam

menu item. The display may read either “TOO COOL” or

“TOO HOT,” (alternating with the “MENU ITEM”), until

the grill attains the set temperature range for that menu,

then the “MENU ITEM,” (only), will be displayed.

the GREEN (“CANCEL/RAISE”) and the BLACK

(“STANDBY”) buttons at the same time. An audible alert

will sound and the platen will lower to the preset gap and

the timing will automatically start.

3. When the cook cycle times down to five, (5), seconds

remaining, a pre-time-out alarm will sound to alert the

grill operator.

4. When the cooking time has been completed, the upper

platen will raise and the display will flash “REMOVE”

with an audible alert, then remove product per the

prescribed method.

5. To cancel a cooking cycle, press the GREEN (“CANCEL/

RAISE”) button. The upper platen will rise. The display

will flash “CANCEL” with an audible alert.

NOTE: If the alarm cancel is set to AUTO, the audible alert

will sound five (5) seconds before timing is finished.

-ORIf the alarm cancel is set to MANUAL, the audible alert will

sound as the timing is finished.

NOTE: If the display reads either “TOO COOL” or “TOO

HOT” the upper platen will not lower and initiate a cooking

sequence.

2. After laying product in the prescribed method, press

To Cook in Flat Grill Mode:

1. SELECT a flat menu by pressing the “MENU SELECT”

button, until you attain the required menu item. The

display may read either “TOO COOL” or “TOO HOT”

(alternating with the “MENU ITEM”) until the grill

Page 21

NORMAL OPERATING MODES

attains the set temperature for that menu.

2. After laying product in the prescribed method, press

the GREEN, (“CANCEL/RAISE”), and the BLACK,

(“STANDBY”), buttons at the same time, starting the

cooking time countdown.

NOTE: If the display reads either “TOO COOL” or “TOO

HOT” the controller will not initiate a cooking sequence.

3. PERFORM the required functions displayed, i.e.; sear,

turn, to cancel the audible alerts, press the BLACK

(“STANDBY”) button.

CAUTION: Pressing the GREEN (“CANCEL/RAISE”)

button will cancel the cooking cycle, and pressing any

other button on the controller will cancel the alarm.

4. When the cooking time has been completed, the display

will flash “REMOVE” with an audible alert. Remove

product per the prescribed method.

The alarm is INACTIVE if the “Standby Alarm” feature

under SYSTEM SETUP is enabled to “NO”.

To Display the Current Temperature

1. PRESS the "TEMP" button and repeat for each zone

to be displayed.

1st press - CENTER UPPER PLATEN

2nd press - REAR LOWER ZONE

3rd press - FRONT LOWER ZONE

NOTE: The temperatures may be displayed at any time,

including during a cooking cycle.

To display all temperature zones at the same time, press the

“TEMP” button one, (1), time, then the “PROG” button

five (5) times.

NOTE: If a required flat grill menu cannot be found, go

to the programming mode (see programming, “MENU

ITEMS”.

Standby Mode:

1. SELECT a clam grill menu by pressing the "MENU

SELECT" button, until you attain the required menu

item.

NOTE: If the display reads either "TOO COOL" or "TOO

HOT" the upper platen will not go into "STANDBY".

2. PRESS the GREEN ("CANCEL/RAISE") and the

BLACK ("STANDBY") buttons at the same time. As soon

as the upper platen moves down, release both buttons and

press the BLACK ("STANDBY") button again, (within 5

seconds), from the start of a cook cycle,the display will

read "STANDBY MODE" alternating with the "MENU

ITEM".

EXIT the Standby Mode:

1. PRESS the GREEN (“CANCEL/RAISE”) button.

The upper platen will raise and the display will read

“CANCEL” with an audible alarm.

To View Settings for a Menu Item:

1. With the required menu displayed, PRESS the “UP

ARROW “ button ( ↑).

2. PRESSING the “UP ARROW” button ( ↑ ) repeatedly will

cycle through and display that menu’s function time(s),

set temperature(s) and the gap setting (if applicable).

NOTE: The display will return to the menu (menu name)

after five (5) seconds if the “UP ARROW” button ( ↑ ) has

not been pressed.

To Reset Factory Defaults

NOTE: All settings on all menus will revert to factory

defaults. It is recommended that all current settings be

recorded on paper prior to reloading the factory default

settings.

1. PRESS and HOLD the “PROG” button for five, (5),

seconds. (Display will flash GC450 and the program

version number.

2. PRESS and HOLD the “UP ARROW” button ( ↑ ) for

twenty, (10), seconds, “RELOAD DEFAULTS “ will be

displayed.

Standby Alarm (Version 6.20 and higher)

An audible alarm called the “Standby Alarm” has been added

to version 6.20 EPROM chip. This alarm, when enabled to

“YES” (See Programming - System Setup) will sound if the

grill has been idle for 300 seconds (5 minutes) signaling the

operator to put the grill into the Standby Mode.

3. PRESS the “RIGHT ARROW” button (→) to reload.

(Display will read “RELOADING DEFAULTS”).

4. PRESS the “RIGHT ARROW” (→) to return to the

normal OPERATING MODE.

NOTE: Pressing any other button will cancel the RELOAD

DEFAULTS request.

Page 22

NORMAL OPERATING MODES

To Clean the Grill:

1. PRESS the “MENU” button to obtain the menu “CLEAN

MODE.” (The controls will maintain the proper cleaning

temperature).

2. “READY TO CLEAN” will be displayed when the grill

is at the proper cleaning temperature and an audible

alarm will sound. Press the “MENU” button to display

“OFF.” The “OFF” position on the controllers allows the

operator to raise and lower the upper platens to alternate

positions for proper cleaning of the side and rear edges of

the platens.

3. When cleaning is completed, you may turn the “MASTER

POWER” (rocker) switch off.

NOTE: Be sure to check upper platen safety pin is disengaged

(pulled out) prior to pushing grill back under grill.

Breakfast to Lunch Transition (Transition

Cooking)

Approximately 30 minutes before changing to the lunch

menu, perform the following:

1. PRESS the "TEMP" button (to display the upper platen

temperature).

2. Press the "UP ARROW" ( ↑ ) button.

3. The upper platen indicator will light (AMBER) and

maintain the normal operating (set) temperature.

Multi-Stage Cooking

If you have version 7.30 EPROM chip software, your

controller is equipped with the new Multi-stage cooking

feature.

With Multi-Stage cooking, the product being cooked is

cooked using multiple gap settings for a selected period of

time.

For example, during 4:1 cooking, the platen would normally

gap at a gap setting of .416 (Four-hundred and sixteen

thousands) for the entire length of the cook cycle.

With multi stage cooking, the platen may gap at the

beginning of the cook cycle for .416 for only 20 seconds. At

the interval of 21 seconds, the gap may change to .400 for

another 25 seconds.

At the 46 second interval (in the remove time), the platen

may regap at .420.

NOTE: the above mentioned example is IS NOT the

McDonalds multi gap formula for 4:1 cooking.

All of the “CLAM” menu items programmed in this 7.30

eprom chip have options to cook using the multi-stage gap

feature.

Currently, 10:1 - CLAM, and 4:1 - CLAM are the only menu

items with a factory default program with multiple gaps.

Please see table to right showing additional stages for these

products.

PRODUCT FUNCTION TIME GAP

(MULTI ACTIVE)

REMOVE IN 37 .265

10:1 - CLAM

4:1

STAGE #1 5 .245

STAGE #2 0 0

STAGE #3 0 0

REMOVE IN 107 .425

STAGE #1 10 .400

STAGE #2 0 0

STAGE #3 0 0

TOAST

BUNS TIME

0

0

TOP

TEMP

425ºF

218ºC

425ºF

277ºC

BOTTOM

TEMP

350ºF

177ºC

350ºF

177ºC

THE TABLE ABOVE REPRESENTS THE 2 MENU ITEMS THAT HAVE A FACTORY DEFAULT

SETTING FOR MULTI STAGE COOKING.

*** ONLY AVAILABLE IN 7.XX ***

FOR INFORMATION REGARDING ALL MENU ITEMS, AND THEIR DETAILED LISTING OF

FUNCTIONS, SEE “CONTROLLER MENU ITEMS”

Page 23

PROGRAM LOGIC CHART

The diagram below is a graphical representation of the control’s menu structure in the program modes. The following pages

detail the various programming procedures. After you become more familiar with these procedures, this diagram will serve as a

quick reference to the program functions and the key sequences needed to access them.

1X

PROG

MENU

MENU

SELECT

PROG

VERSION X.XX

MENU ITEMS

SELECT MENU ITEM

PRESS & HOLD

(5 Seconds)

SYSTEM SETUP

MENU

MENU

SELECT

SELECT SETTING

2X

PROG

CLAM MENU

ITEMS

FUNCTION

TEMP

SEAR IN...

SEAR IN ALARM

(AUTO / MANUAL)

TURN IN...

TURN IN ALARM

(AUTO / MANUAL)

STIR IN...

STIR IN ALARM

(AUTO / MANUAL)

REMOVE IN...

REMOVE IN ALARM

(AUTO / MANUAL)

TOAST BUNS IN...

TOAST BUNS IN ALARM

(AUTO / MANUAL)

SET TEMPERATURE (UPPER PLATEN)

SET TEMPERATURE (GRILL SURFACE)

FLAT MENU ITEMS ONLY

23

1X

2X

3X

4X

5X

6X

DISPLAY TEMP

(Fahrenheit/Celcius)

ALARM VOLUME

STANDBY ALERT

PROBE CALIBRATION

GAP VERIFICATION

MULTI GAP (YES / NO)

FUNCTION

TEMP

TOP TEMP.

BACK TEMP.

MIDDLE TEMP.

FRONT TEMP.

Page 24

PROGRAMMING

SYSTEM SETUP

To Display Temperatures in F or C

1. PRESS and HOLD the “PROG” button for five, (5),

seconds. (Display will flash GC450 and the program

version number).

2. PRESS the “PROG” button twice to display “SYSTEM

SETUP”.

3. PRESS the “MENU” button to display “DISPLAY

TEMP. IN : ºF/ºC”.

4. PRESS the “UP ARROW” button ( ↑ ) to change ºF or

ºC.

5. PRESS the “PROG” button to display “SYSTEM

SETUP”.

6. PRESS the “RIGHT ARROW” button (→) to return to

the normal OPERATING MODE.

To Change the Speaker Volume (High / Low)

1. PRESS and HOLD the “PROG” button for five, (5),

seconds. (Display will flash GC450 and the program

version number).

2. PRESS the “PROG” button twice to display “SYSTEM

SETUP”.

To Change the Gap Calibration

1. PRESS and HOLD the "PROG" button for five, (5),

seconds. (Display will flash GC450 and the program

version number).

2. PRESS the "PROG" button twice to display "SYSTEM

SETUP".

3. PRESS and HOLD the "UP ARROW" ( ↑ ) button for

ten, (10), seconds, "GAP CALIBRATION" will be

displayed.

4. PRESS the "UP ARROW" button ( ↑ ) again, the "+"

(PLUS) button to increase the value OR the "RIGHT

ARROW" button (→), "-" (MINUS) to decrease the

value.

5. PRESS the "PROG" button to display "SYSTEM

SETUP".

6. PRESS the "RIGHT ARROW" button (→), to return

to the normal OPERATING MODE.

To Enable / Disable Start Delay

1. PRESS and HOLD the “PROG” button for five, (5),

seconds. (Display will flash GC450 and the program

version number).

3. PRESS the “MENU” button to display “ALARM

VOLUME”.

4. PRESS the “UP ARROW” button ( ↑ ) to change

(HIGH/LOW).

5. PRESS the “PROG” button to display “SYSTEM

SETUP”.

6. PRESS the “RIGHT ARROW” button (→) to return

to the normal OPERATING MODE.

2. PRESS the “PROG” button twice to display “SYSTEM

SETUP”.

3. PRESS and HOLD the “UP ARROW”( ↑ ) button for

ten, (10), seconds, “GAP CALIBRATION” will be

displayed.

4. PRESS the “MENU” button. The hold feature will

display “OFF”.

5. HOLD the “RIGHT ARROW” (→) for ten, (10),

seconds, the “OFF WILL FLASH”.

6. PRESS the “UP ARROW” ( ↑ ) to change the safety

(ON/OFF).

7. PRESS the “PROG” button to display “SYSTEM

SETUP”.

8. PRESS the “RIGHT ARROW” button (→) to return to

the normal OPERATING MODE.

24

Page 25

PROGRAMMING

SYSTEM SETUP

To Change Start Delay Timer

1. PRESS and HOLD the “PROG” button for five, (5),

seconds. (Display will flash GC450 and the program

version number).

2. PRESS the “PROG” button twice to display “SYSTEM

SETUP”.

3. PRESS and HOLD the “UP ARROW”( ↑ ) button for

ten, (10), seconds, “GAP CALIBRATION” will be

displayed.

4. PRESS the “MENU” button. The hold feature will

display “OFF”.

5. HOLD the “RIGHT ARROW” (→) for ten, (10),

seconds, the “(ON / OFF) WILL FLASH”.

6. PRESS the “UP ARROW” (↑) to change the safety

(ON/OFF).

7. PRESS the “FUNCTION” button to display “DELAY

TIME:”

8. PRESS the “UP ARROW” (↑) to change the delay time

seconds in increments of .5 seconds.

9. PRESS the “PROG” button to display “SYSTEM

SETUP”.

To Change the Standby Alert Feature - EPROM

Chip Ver. 6.20 and higher

1. PRESS and HOLD the “PROG” button for five, (5),

seconds. (Display will flash GC450 and the program

version number).

2. PRESS the “PROG” button twice to display “SYSTEM

SETUP”.

3. PRESS the “MENU” button until “STANDBY ALERT

(YES/NO)”.

4. PRESS the “UP ARROW” button (↑) to change (YES/

NO).

5. PRESS the “PROG” button to display “SYSTEM

SETUP”.

6. PRESS the “RIGHT ARROW” button (→) to return to

the normal OPERATING MODE.

To Enable / Disable Multi-Stage Cooking - EPROM

Chip Ver. 7.XX and higher

1. PRESS and HOLD the “PROG” button for five, (5),

seconds. (Display will flash GC450 and the program

version number).

10. PRESS the “RIGHT ARROW” button (→) to return to

the normal OPERATING MODE.

NOTE: To Determine your version EPROM chip. PRESS and HOLD the PROG button for approximately 5 seconds. The

controller will flash “GC450 - V. X.XX”. Eprom Chips are available by calling your local factory authrorized service center.

2. PRESS the “PROG” button twice to display “SYSTEM

SETUP”.