Garland MWG3W-1 Installation Manual

INSTALLATION AND

OPERATION MANUAL

GARLAND 3 PLATEN

GAS & ELECTRIC

CLAMSHELL GRILLS

WITH PRODUCT RECOGNITION

MODELS:

MWE3W-1

MWE3S-1

MWG3W-1

®

C US

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY, OR

DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL AND

RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND MUST

BE INSTALLED BY PROFESSIONAL PERSONNEL AS

SPECIFIED.

INSTALLATION AND ELECTRICAL CONNECTION MUST

COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL CODE

PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE ANSI /

NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON THE

RATING PLATE.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting your

local gas supplier

Part#: 4530407 Rev 05 (30 Jan 2015)

MANUFACTURED EXCLUSIVELY FOR McDonald’s BY

GARLAND COMMERCIAL RANGES

http://www.garland-group.com

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

IMPORTANT INFORMATION

WARNING:

THIS PRODUCT CONTAINS CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER AND/OR

BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM. INSTALLATION AND SERVICING OF THIS PRODUCT COULD

EXPOSE YOU TO AIRBORNE PARTICLES OF GLASS WOOL/CERAMIC FIBERS. INHALATION OF AIRBORNE PAR

TICLES OF GLASS WOOL/CERAMIC FIBERS IS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER. OPERA

TION OF THIS PRODUCT COULD EXPOSE YOU TO CARBON MONOXIDE IF NOT ADJUSTED PROPERLY. INHALA

TION OF CARBON MONOXIDE IS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE BIRTH DEFECTS OR OTHER

REPRODUCTIVE HARM.

KEEP APPLIANCE AREA FREE AND CLEAR OF COMBUSTIBLES.

Page 2

Part#: 4530407 Rev 05 (30 Jan 2015)

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

CONTENTS

IMPORTANT INFORMATION _______________________ 2

INTRODUCTION _________________________________ 4

WARRANTY ____________________________________ 4

SHIPPING DAMAGE PROCEDURE ___________________ 4

RATING PLATE DESCRIPTION ______________________ 6

MECHANICAL SPECIFICATIONS ____________________ 7

Dimension Models: MWE3W-1, MWG3W-1 . . . . . . . . . . . . . . . . . . . .7

Dimension Models: MWE3S-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ELECTRICAL INPUT SPECIFICATIONS - DELTA _________ 9

ELECTRICAL INPUT SPECIFICATIONS - WYE _________ 11

INSTALLATION & START UP _______________________ 13

Installation Store Responsibilities: . . . . . . . . . . . . . . . . . . . . . . . . . . .13

A start-up DOES NOT include: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

A start-up DOES include: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Items included with the purchase of your new grill from Manufacturer: . .1 3

Items NOT included from the manufacturer and should be

purchased from the Kitchen Equipment Supplier (KES): . . . . . .13

Installation of Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Power Supply Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Mennekes 3 & 5 Pins (Option 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Mennekes 7 Pins (Option 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Terminal Blocks Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Exhaust hood Type & Platen Height. . . . . . . . . . . . . . . . . . . . . . . . . .17

Setting the Proper Combustion Levels. . . . . . . . . . . . . . . . . . . . . . .18

Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Grill StartUp Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

TEMPERATURE PROBE CALIBRATION ______________ 21

INSTALLATION OF WRAP AROUND RELEASE MATERIAL

MOUNTING BRACKETS __________________________ 25

INSTALLATION OF SPLASH SHIELD ________________ 25

INSTALLATION OF RELEASE MATERIAL _____________ 26

INSTALLATION OF VAPOR SHIELD _________________ 27

GRILL ACCESSORIES ____________________________ 27

Splash Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Te on Wraparound Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Vapor Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3Phase 4-Wire (50 & 30 Amps) Cord. . . . . . . . . . . . . . . . . . . . . . . . . .28

Te on Sheet, Rod & Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

CLEANING & MAINTENANCE _____________________ 30

PULL / PUSH GRILL PROCEDURE __________________ 33

DESCRIPTION OF GRILL CONTROL _________________ 34

ERROR MESSAGING _____________________________ 35

OPERATION PROCEDURES _______________________ 35

General Overview: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

To turn the grill on:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

To Select a Menu item: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Menu Item Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

To enter the standby mode: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

To Exit the standby Mode: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Part#: 4530407 Rev 05 (30 Jan 2015)

To display the current temperatures:. . . . . . . . . . . . . . . . . . . . . . . . .37

Breakfast In Manual mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Lunch In Manual mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

To Change The Cook Time for a Menu Item. . . . . . . . . . . . . . . . . . .37

Breakfast In Auto mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Lunch In Auto mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

PRODUCT RECOGNITION ________________________ 38

Transition Cooking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

To Shutdown Grill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

COMMON PRODUCT RECOGNITION ISSUES _________ 39

PATTY PLACEMENT _____________________________ 40

BEEF INTEGRITY ________________________________ 41

PROGRAM LOGIC TREE; PRODUCT MENU ___________ 42

CONTROL PROGRAMMING; PRODUCT MENU _______ 43

Programming Modes; Product Menu . . . . . . . . . . . . . . . . . . . . . . . .43

To change the name of an existing menu item . . . . . . . . . . . . . . .43

To activate / deactivate a menu item in the Normal Operating

mode library, or change its day-part . . . . . . . . . . . . . . . . . . . . . . . . .43

To change the grill surface set point temperature . . . . . . . . . . . .43

To change the grill upper platen set point temperature . . . . . .43

To Change the INSTANT ON TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

To Change the REMOVE IN TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

To Change the MULTI STAGE TIME . . . . . . . . . . . . . . . . . . . . . . . . . . .44

To Change the REMOVE ALARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

To Change the GAP SETTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

To Change the GAP MUL/PR START . . . . . . . . . . . . . . . . . . . . . . . . . .45

To Change the GAP MULTI STAGE (1,2 or3) . . . . . . . . . . . . . . . . . . .45

To Change the MUST REMOVE IN . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

To Change the TOAST BUNS TIME. . . . . . . . . . . . . . . . . . . . . . . . . . . .45

To Change the TOAST BUNS ALARM (Auto / Manual) . . . . . . . . .45

To Change the TOO COOL FLAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

To Change the FLIP TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

To Change the FLIP ALARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

To Change the SEAR TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

To Change the SEAR ALARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

To Add NEW Menu Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

To activate Clean Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

PROGRAM LOGIC TREE; SYSTEM MENU ____________ 48

Programming Modes; System Setup . . . . . . . . . . . . . . . . . . . . . . . .49

To Change the Time Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . .49

To change the Programming Standby Alarm . . . . . . . . . . . . . . . . .49

CONTROL PROGRAMMING; SYSTEM MENU _________ 49

To change the Key Chirp (Yes / No) . . . . . . . . . . . . . . . . . . . . . . . . . .50

To change the Audible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

To Restore Factory Defaults for All Product Menu Items. . . . . . .50

FACTORY DEFAULT SETTING ______________________ 51

Factory Default Setting - Product Menu - World . . . . . . . . . . . . . .51

Factory Default Setting - Product Menu - Canada, Australia & UK 52

Factory Default Setting - Product Menu - Japan & Hong Kong 53

DECLARATION OF CONFORMITY (CE Marked Models) __ 54

INSTALLATION OPERATION MANUAL HISTORY ______ 54

INDEX ________________________________________ 55

Page 3

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

INTRODUCTION

The Garland clamshell grill, manufactured exclusively for McDonald’s, provides a method for e cient two-sided cooking,

while accommodating a variety of products. The unit will also serve as a at grill, and meets all of McDonald’s standards for

safety, e ciency, and cleanliness.

WARRANTY

This warranty covers defects in material and workmanship under normal use providing that:

a. the equipment has not been accidentally or intentionally damaged, altered or misused.

b. the equipment is properly installed, adjusted, operated and maintained in accordance with national and local

codes and in accordance with the installation instructions provided with this product.

c. the warranty serial number a xed to the appliance by us has not been defaced, obliterated or removed.

d. an acceptable report for any claim under this warranty is supplied to us.

The equipment warranty coverage remains in force for two (2) years, (parts and labor), from the date the equipment is

put into operation.

The Garland Group agrees to repair or replace, at it’s option, any part that proves to be defective in material or

workmanship at no charge for the part or normal labor.

We assume no responsibility for installation, adjustments, diagnosis, or normal maintenance such as: lubrication of

springs or valves. We exclude failures caused by erratic voltage or gas supplies.

We assume no responsibility for travel costs beyond 100 miles round trip, travel other than overland, and overtime

costs of repair.

We exclude broken glass, paint and porcelain nish, surface rust, gasket material, ceramic material, light bulbs and

fuses from normal coverage.

We exclude damage or dysfunction caused by re, ood, and like “Acts of God” that are beyond the control of The

Garland Group.

The Garland Group’s liability on a claim of warranty shall not exceed the price of the material and/or service, which

caused the claim.

This warranty is limited and is in lieu of all other warranties, expressed or implied. The Garland Group, our employees,

or our agents shall not be held liable for any claims of personal injury or consequential damage or loss.

This warranty gives you speci c legal rights, and you may have other rights which vary from state to state.

SHIPPING DAMAGE PROCEDURE

Please note that the Garland equipment was carefully inspected and packed by skilled personnel before leaving the

factory. The transportation company assumes full responsibility for safe delivery upon acceptance of the equipment. What

to do if the equipment arrives damaged:

1. File a claim immediately regardless of the extent of damage.

2. Be sure to note, “visible loss or damage,” on the freight bill or express receipt and have the person making the delivery sign it.

3. Concealed loss or damage: if damage is unnoticed until the equipment is unpacked, notify the freight company immediately, (within 15 days), and le a concealed damage claim.

Page 4

Part#: 4530407 Rev 05 (30 Jan 2015)

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

SAFETY

• DISCONNECT ALL POWER SUPPLIES BEFORE OPENING PANELS FOR SERVICING.

• KEEP THE APPLIANCE AREA FREE AND CLEAR FROM COMBUSTIBLES.

• DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATION AIR.

• ALLOW A MINIMUM OF 24 INCHES UNOBSTRUCTED CLEARANCE IN FRONT OF THE UNIT FOR

SERVICING

This appliance is for professional use and shall be used only by quali ed personnel.

WARNING: Accessible parts may become hot during use. Young children should be kept away. This appliance is not intended for

use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.”

CAUTION: THIS EQUIPMENT MUST ONLY BE OPERATED UNDER AN APPROVED HOOD SYSTEM IN ACCORDANCE WITH

LOCAL REGULATIONS IN FORCE.

DO NOT OPERATE THE GRILL UNLESS IT HAS BEEN COMMISSIONED (START-UP) BY A FACTORY AUTHORIZED SERVICE CENTER.

DO NOT operate the grill without reading this operation manual.

DO NOT operate the clamshell grill unless it has been properly installed and grounded.

DO NOT operate the clamshell grill unless all service and access panels are in place and fastened properly.

Means of disconnection, must be incorporated in the xed wiring in accordance with local wiring rules (such as a switch, fuse,

or circuit breaker). External equipotential bonding conductor provided on rear of appliance. Use as applicable, in accordance

with local wiring rules.

The Garland clamshell grill is a semi-automatic cooking appliance. The upper platen is lowered automatically, following the

manual, single-handed or two handed based on the model, initiation of the cooking cycle, and raised automatically upon

completion of the cooking cycle.

WARNING:

When two sided cooking, the area between the upper platen and the griddle plate and the area between upper platen and

ventilation hood should be regarded as a “DANGER ZONE”. During two sided cooking the operator must keep body parts

and tools clear of the danger zone when platens are in motion. When used as a at grill, unexpected movement of platens

can occur during cleaning or servicing. For wh atever reason, be it cleaning, maintenance or normal operation, any exposed

person must use extreme caution if within this danger zone. Temperatures on solid cooking surfaces are intended to operate

above 120C (250F).

In two sided cooking the upper platen remains in the lowered position by nature of it’s own weight. It is not locked down. It can

be raised by lifting of the handle on the front of the platen, which pivots the platen about its rear mounting point.

The clamshell grill must only be used for single and two sided cooking of foodstu s in a McDonald’s store.

SOUND EMISSIONS: Sound pressure levels at the grill operator’s position may exceed 70 dB(A) when audible alarms are active.

Audible volume may be adjusted to below 70 dB(A). See Control Programming Section.

WARNING: To avoid serious personal injury: DO NOT attempt to repair or replace any part of the clamshell grill unless all main

power supplies to the grill have been disconnected.

Part#: 4530407 Rev 05 (30 Jan 2015)

Page 5

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

SAFETY

USE EXTREME CAUTION in setting up, operating and cleaning the clamshell grill to avoid coming in contact with hot grill

surfaces or hot grease. Suitable protective clothing should be worn to prevent the risk of burns.

WARNING: This appliance must not be cleaned with a water jet. DO NOT apply ice to a HOT grill surface.

NOTE: All warning labels and markings on the grill, which call attention to further dangers and necessary precautions.

HAZARD COMMUNICATION STANDARD, (HCS) - The procedures in this manual include the use of chemical products. These

chemical products will be printed in bold face, followed by the abbreviation (HCS) in the text portion of the procedure. See the

Hazard Communication Standard, (HCS) manual for the appropriate Material Safety Data Sheet(s), (MSDS).

WARNING: After turning the master power switch to the START position, the grill will go through an initialization process. If the

upper platens are in the lowered position they will return to their raised upper position.

MAINTENANCE - the platen support arms carriage block bearing bushings, the platen adjuster nuts, the platen support (shoulder)

bolt and the cam follower should be checked annually for wear. Should there be any noticeable play in the bearing bushings

and any visible wear on the platen adjuster nuts, platen support bolts or cam follower, then they must be replaced.

MAINTENANCE - the audible alarm that sounds at the end of a cook cycle is to advise the operator that the platen is about

to move. The function of this device may be tested by pushing the left hand CANCEL button. If no sound is heard, ensure that

the alarm volume is not set too low in SYSTEM SETUP. If there is still no sound then a service engineer should be called out to

rectify the fault.

SERVICE AND CLEANING - The grill may be secured in the grill bay by the installer using two anchors that lock onto the front

casters. If the grill is to be moved out of the bay for cleaning or service, remove the anchor from each caster by turning the knob

counterclockwise to loosen the retainer. When the retainer is free of the caster, lay the assembly aside on the oor.

CLEANING - NEVER clean the grill, interior or exterior, using a high-pressure sprayer, water jet, vapor steam cleaner or any other

liquid sprayer. NEVER use ice to cool the grill for cleaning. USE ONLY approved cleaners by McDonald’s.

NOTE: If anchors are present, the anchor assembly remains fastened to the back wall of the grill bay. After service or cleaning

is complete, return the grill to its position in the bay and reattach the anchors by placing the retainer on the caster post and

turning the knob clockwise to tighten. For safety reasons, the grill must be secured in the grill bay in this manner before operation can resume.

WARNING:

Pinch Hazard keep hands and tools clear when platens are in motion. Unexpected movement of platens can occur during

cleaning or servicing process. Turn Grill O at main switch when cleaning platen.

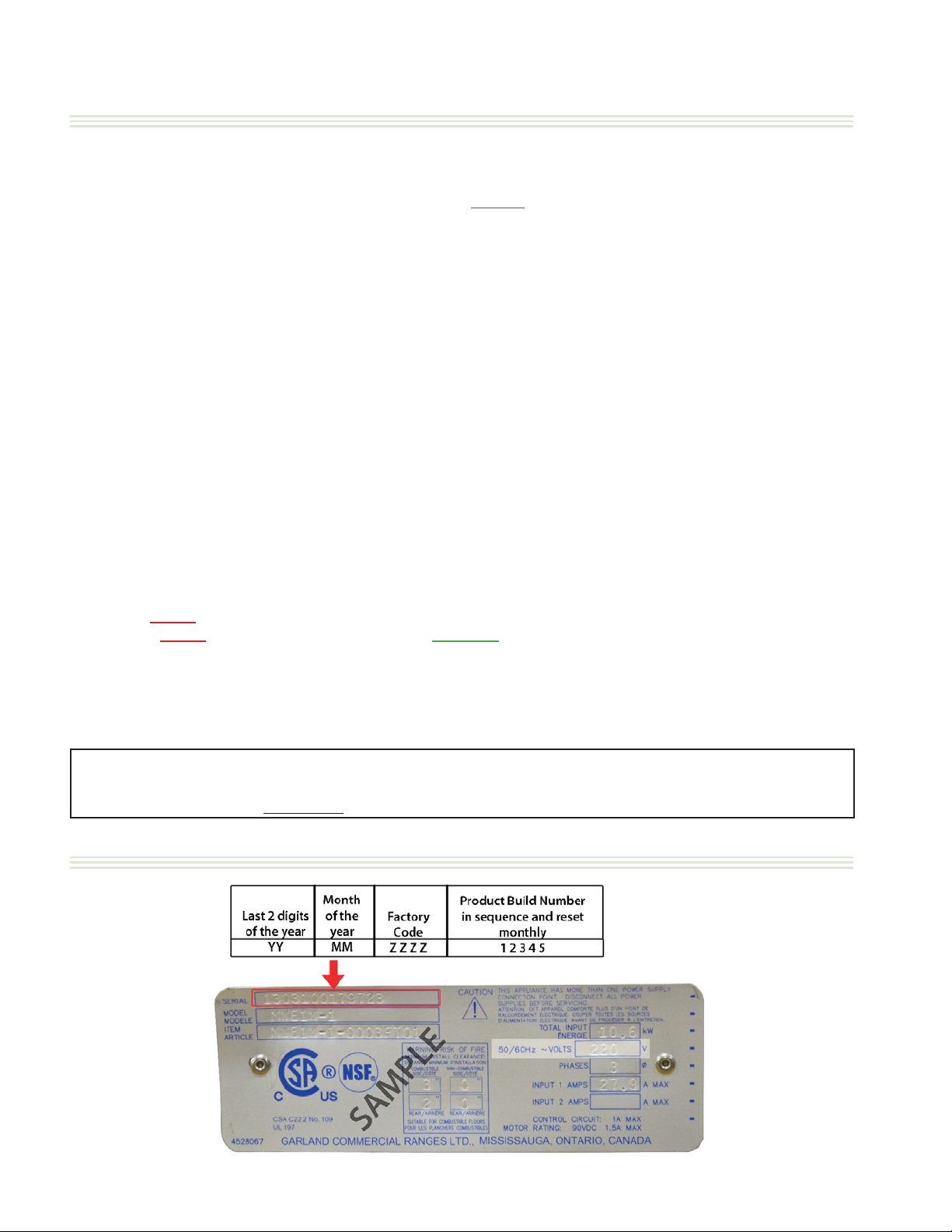

RATING PLATE DESCRIPTION

Page 6

Part#: 4530407 Rev 05 (30 Jan 2015)

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

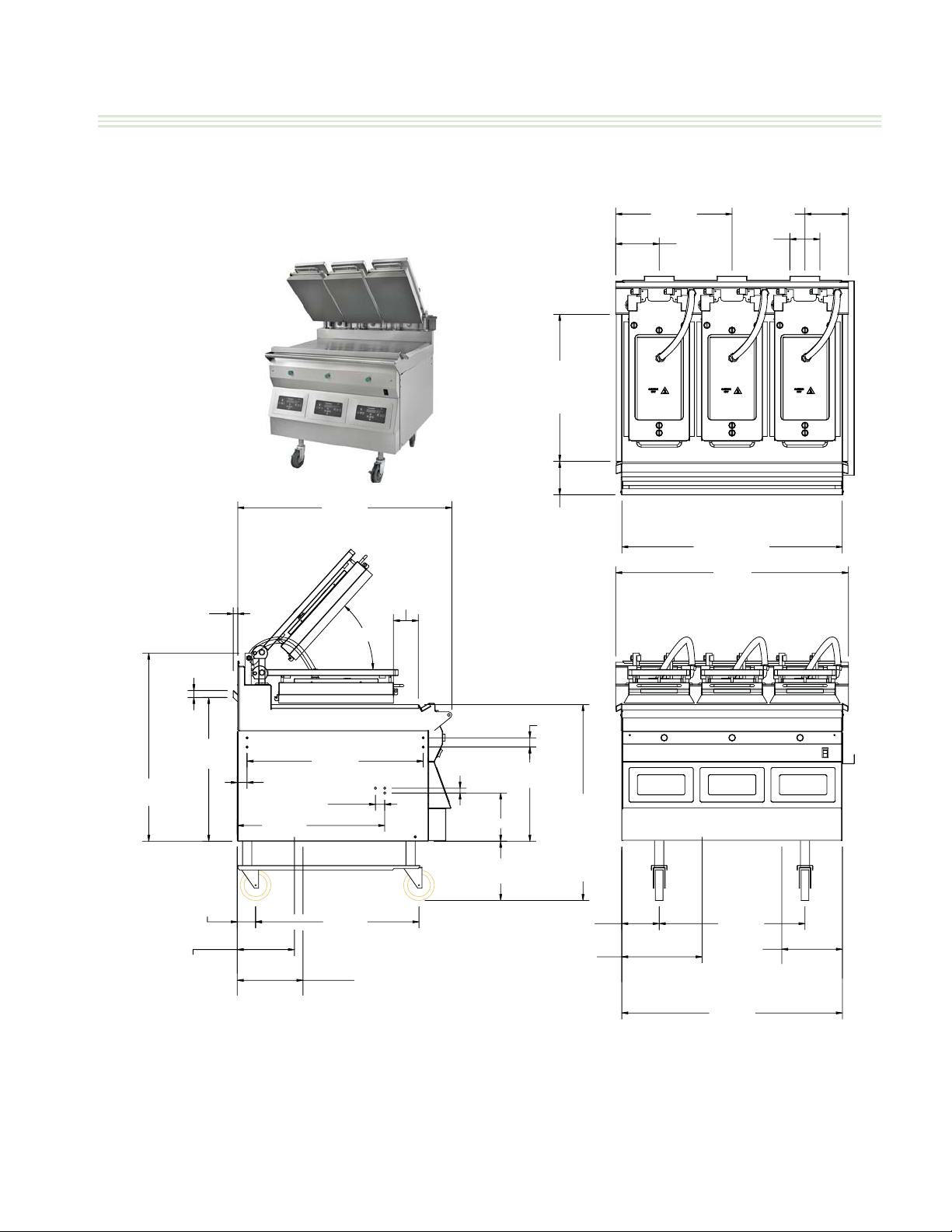

MECHANICAL SPECIFICATIONS

MWG3W ONLY

Dimensions:

Models MWE3W-1, MWG3W-1

34.968

[888mm]

24.000

[610mm]

(PLATE DEPTH)

5.475

[139mm]

19.001

[483mm]

7.111

[181mm]

[914mm]

(PLATE WIDTH)

7.110

[181mm]

4.895

[124mm]

36.000

[19mm]

MWG3W ONLY

1.146

[29mm]

30.714

[780mm]

9.335

[237mm]

BOTTOM CABLE

ENTRANCE

.737

22.835

[850mm]

2.993

[76mm]

1.598

[41mm]

24.084

[612mm]

28.771

[731mm]

1.516

[39mm]

26.679

[678mm]

4.064

[103mm]

"COLD ZONE"

48°

10.730

[273mm]

3/4" NPT GAS INLET

MWG3W ONLY

.787

[20mm]

7.875 [200mm]

9.684

[246mm]

SK07-587 (GAS)

1.500

[38mm]

15.384

[391mm]

[333mm]

BOTTOM CABLE

ENTRANCE

30.750

[781mm]

TO

33.000

[838mm]

(COOKING

HEIGHT)

6.106

[155mm]

13.123

38.000

[965mm]

23.812

[605mm]

9.901

[251mm]

3/4" NPT GAS INLET

MWG3W ONLY

36.027

[915mm]

Part#: 4530407 Rev 05 (30 Jan 2015)

Page 7

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

MECHANICAL SPECIFICATIONS

Dimensions:

Models MWE3S-1

21.65

[550mm]

PLATE DEPTH

5.475

32.60

[828mm]

[139mm]

36.00

[914mm]

PLATE WIDTH

38.00

[965mm]

30.714

[780mm]

2.993

[76mm]

9.335

[237mm]

BOTTOM CABLE

ENTRANCE

1.598

[41mm]

24.084

[612mm]

26.42

[671mm]

1.516

[39mm]

24.33

[618mm]

1.70 [43mm]

“COLD ZONE”

48°

.787

[20mm]

7.875 [200mm]

9.684 [246mm]

1.50

[38mm]

15.384

[391mm]

BOTTOM CABLE

30.75 [781mm]

TO

33.00 [838mm]

COOKING HEIGHT

6.106

[155mm]

ENTRANCE

13.123

[333mm]

23.812

[605mm]

36.027

[915mm]

Page 8

Part#: 4530407 Rev 05 (30 Jan 2015)

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

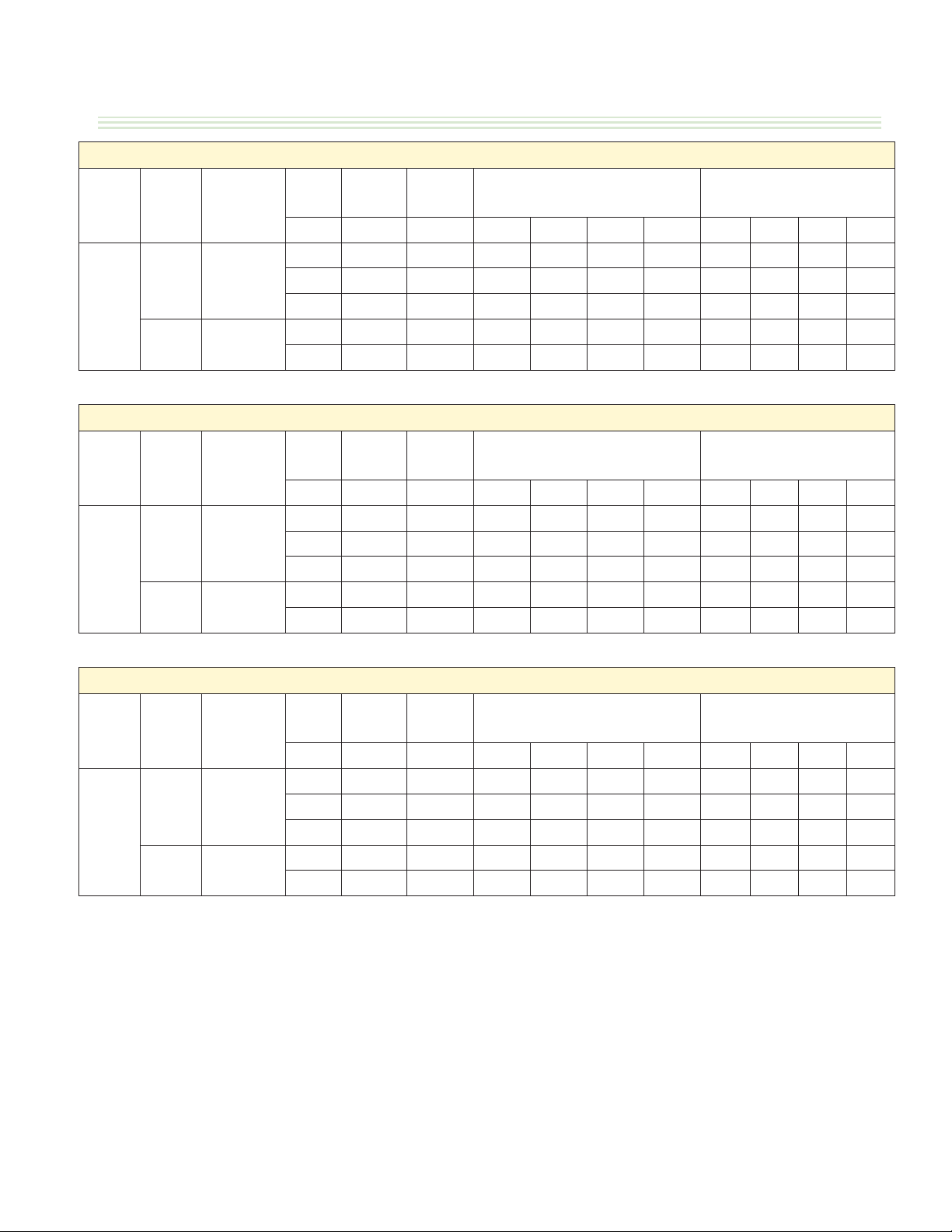

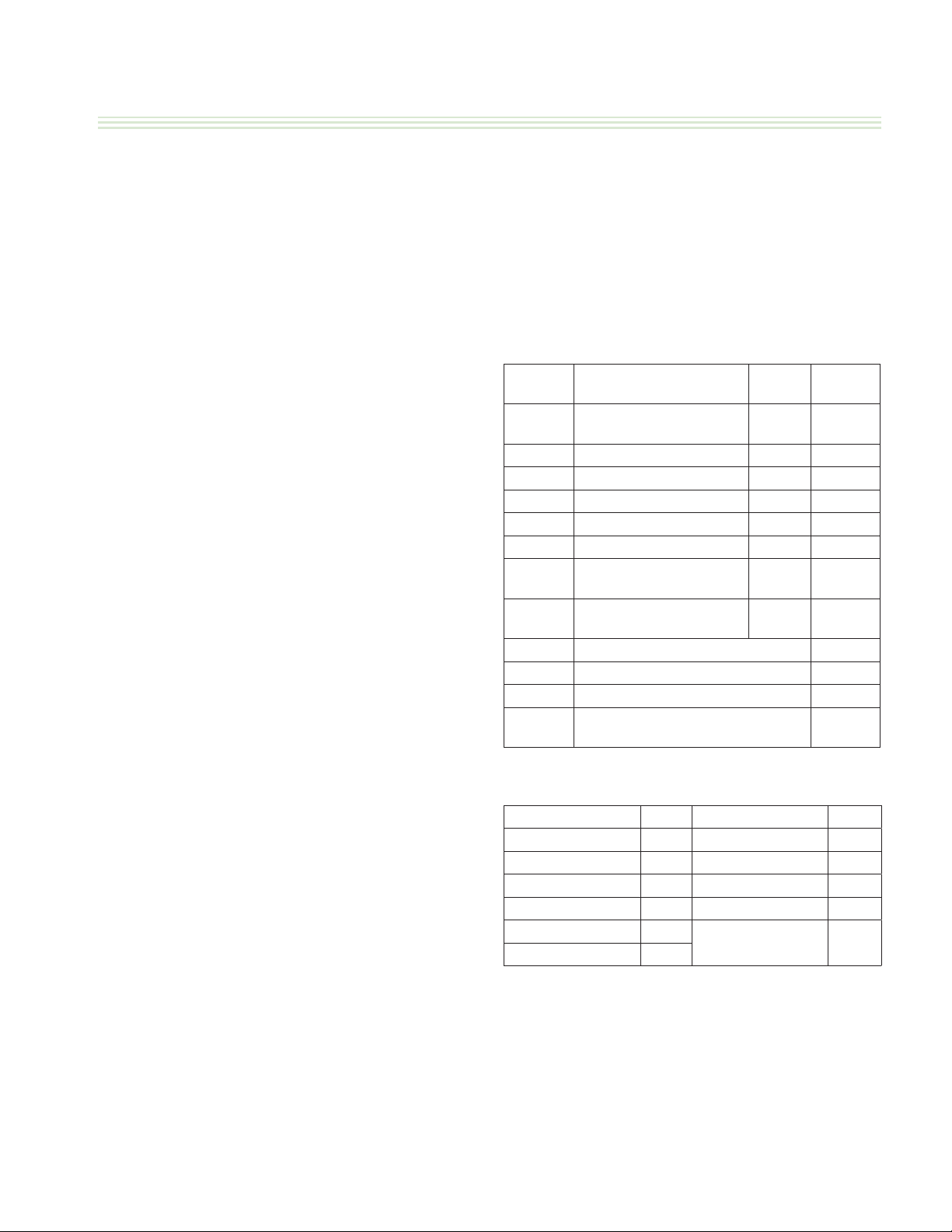

ELECTRICAL INPUT SPECIFICATIONS - DELTA

DELTA - 200 Volts Models

Model Drawing

Electric 4530440

3

Platen

Gas 4530442

Model Drawing

Electric 4530440

3

Platen

Gas 4530442

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 2.3 2.7 2.9 7.9 21.7 22.6 24.3

TB2 78 0.1 0.7

TB3 4.2 5.4 4.6 14.6 43.4 39.9 43.4

TB1 600 3.0 3.0 3.6 9.6 26.0 28.7 28.7

TB2 380 0.4 0.5 3.3

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 2.4 2.8 3.0 8.2 21.5 22.4 24.0

TB2 78 0.1 0.6

TB3 4.8 5.6 4.8 15.1 43.1 39.7 43.1

TB1 600 3.3 3.3 3.9 10.4 27.1 29.6 29.6

TB2 380 0.4 3.2

MCB Total loads Kw Amps/line

DELTA - 208 Volts Models

MCB Total loads Kw Amps/line

Model Drawing

Electric 4530440

3

Platen

Gas 4530442

DELTA - 220 Volts Models

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 2.4 2.8 3.0 8.2 20.4 21.2 22.7

TB2 78 0.1 0.6

TB3 4.8 5.6 4.8 15.1 40.7 37.5 40.7

TB1 600 3.3 3.3 3.9 10.4 25.6 28.0 28.0

TB2 380 0.4 3.0

MCB Total loads Kw Amps/line

Part#: 4530407 Rev 05 (30 Jan 2015)

Page 9

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

ELECTRICAL INPUT SPECIFICATIONS - DELTA

DELTA - 230 Volts Models

Model Drawing

Electric 4530440

3

Platen

Gas 4530442

Model Drawing

Electric 4530440

3

Platen

Gas 4530442

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 2.4 2.8 3.0 8.2 19.5 20.2 21.7

TB2 78 0.1 0.6

TB3 4.8 5.6 4.8 15.1 38.9 35.9 38.9

TB1 600 3.3 3.3 3.9 10.4 24.5 26.8 26.8

TB2 380 0.4 2.9

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 2.4 2.8 3.0 8.2 18.7 19.4 20.8

TB2 78 0.1 0.6

TB3 4.8 5.6 4.8 15.1 37.3 34.4 37.3

TB1 600 3.3 3.3 3.9 10.4 23.5 25.7 25.7

TB2 380 0.4 2.7

MCB Total loads Kw Amps/line

DELTA - 240 Volts Models

MCB Total loads Kw Amps/line

Page 10

Part#: 4530407 Rev 05 (30 Jan 2015)

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

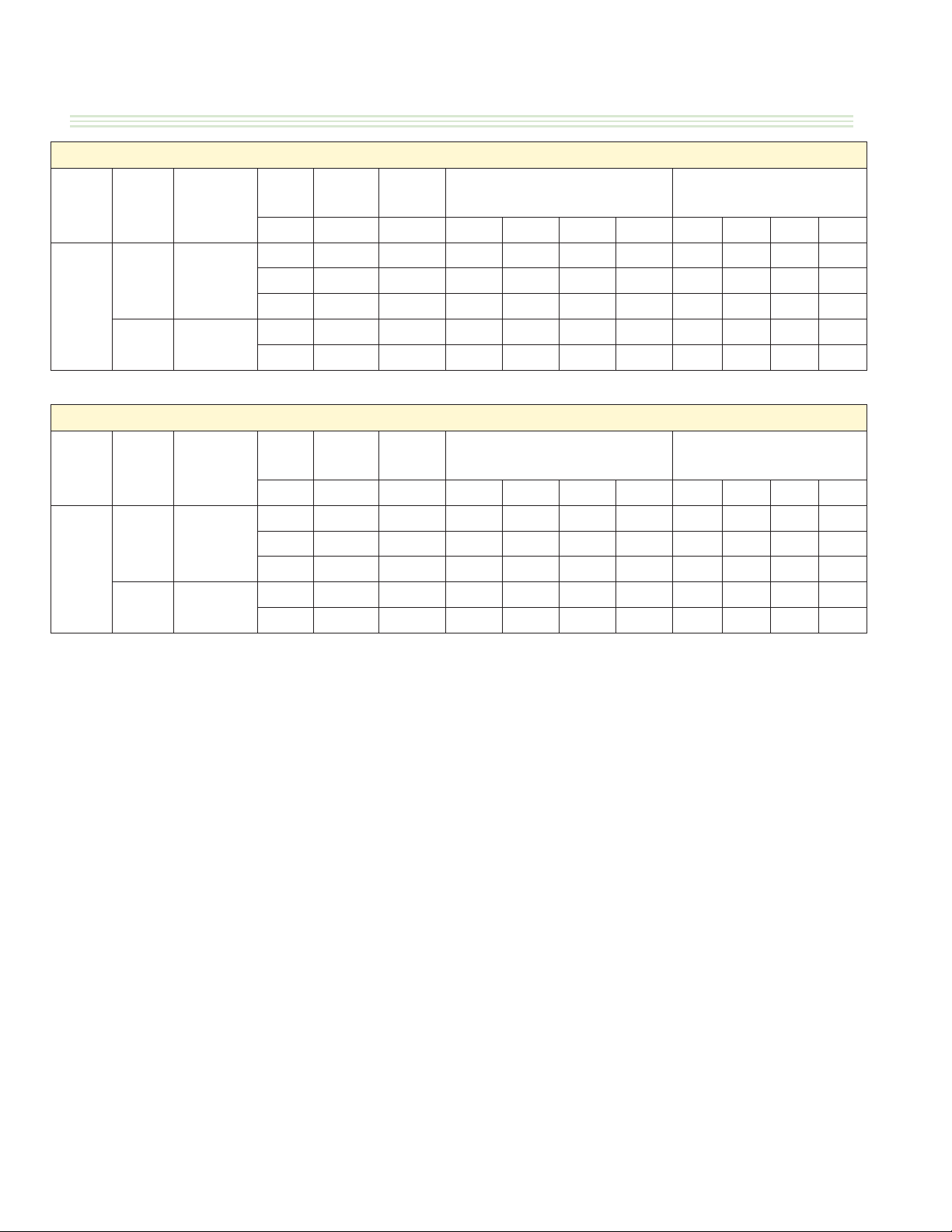

ELECTRICAL INPUT SPECIFICATIONS - WYE

WYE - 380 Volts Models

Model Drawing

Electric

STD

3

Electric

Platen

Model Drawing

3

Platen

H.K.

Gas 4530442

Electric

STD

Electric

H.K.

Gas 4530442

4530442

4530440

4530442

4530440

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 7.8 8.4 7.2 23.3 35.3 38.1 32.6

TB2 78 0.1 0.4

TB1 600 3.0 2.8 2.4 8.2 13.6 12.7 10.9

TB2 78 0.1 0.4

TB3 4.8 5.6 4.8 15.1 21.7 25.4 21.7

TB1 600 3.9 3.3 3.3 10.4 17.5 14.8 14.8

TB2 380.4 0.4 1.7

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 7.8 8.4 7.2 23.3 33.6 36.2 31.0

TB2 78 0.1 0.3

TB1 600 3.0 2.8 2.4 8.2 12.9 12.1 10.3

TB2 78 0.1 0.3

TB3 4.8 5.6 4.8 15.1 20.6 24.1 20.6

TB1 600 3.9 3.3 3.3 10.4 16.7 14.1 14.1

TB2 380.4 0.4 1.6

MCB Total loads Kw Amps/line

WYE - 400 Volts Models

MCB Total loads Kw Amps/line

Model Drawing

Electric

STD

3

Electric

Platen

Part#: 4530407 Rev 05 (30 Jan 2015)

H.K.

Gas 4530442

4530442

4530440

WYE - 415 Volts Models

Con-

trol

I/E L1-L3 L1-L2 L2-L3 L3-L1 All Ctrl L1 L2 L3

TB1 600 7.8 8.4 7.2 23.3 32.3 34.8 29.8

TB2 78 0.1 0.3

TB1 600 3.0 2.8 2.4 8.2 12.5 11.6 9.9

TB2 78 0.1 0.3

TB3 4.8 5.6 4.8 15.1 19.9 23.2 19.9

TB1 600 3.9 3.3 3.3 10.4 16.1 13.6 13.6

TB2 380.4 0.4 1.6

MCB Total loads Kw Amps/line

Page 11

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

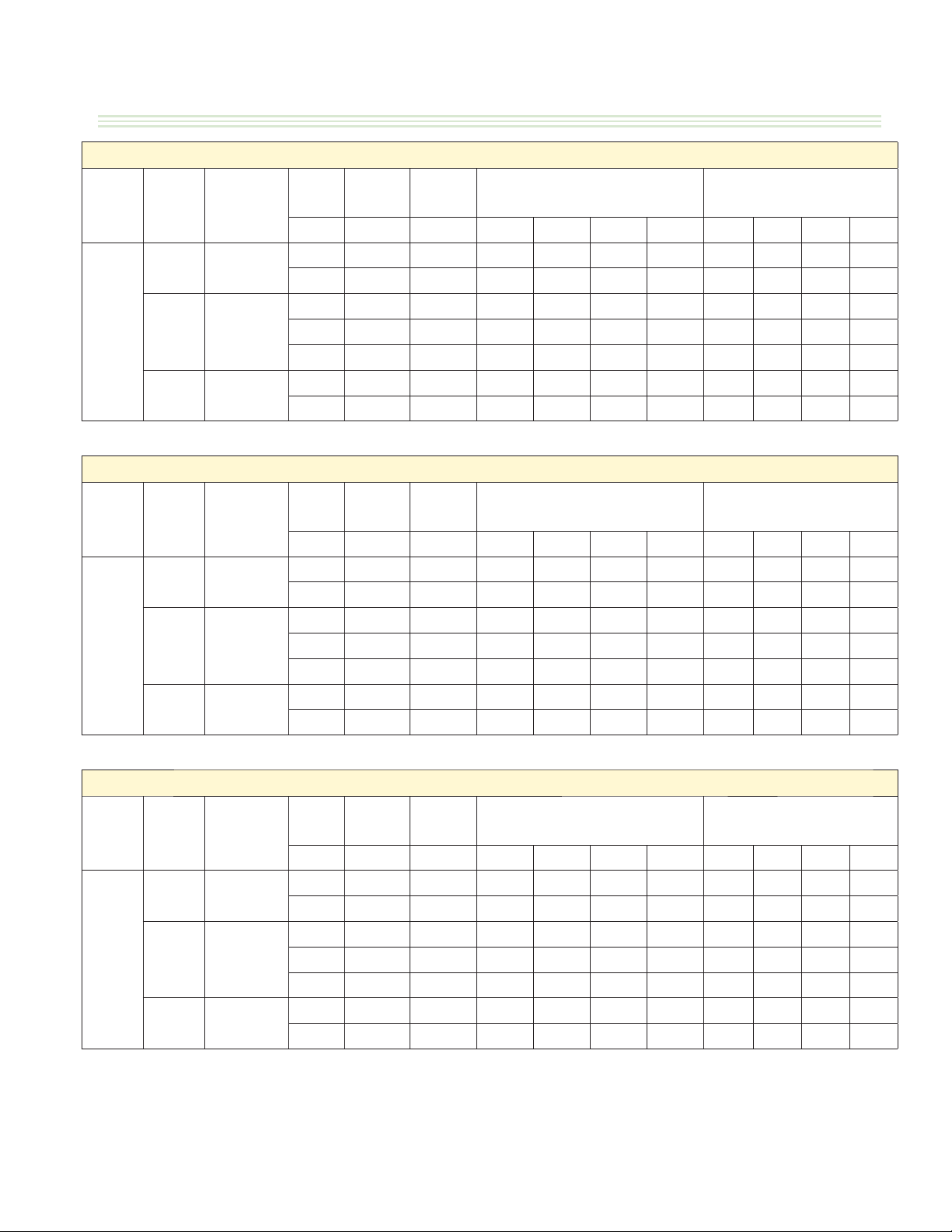

GAS INPUT SPECIFICATIONS

Input Speci cations, GAS Grills, North America: Gas Input

GAS

MAX INPUT

NET PER

BURNER

BTU/H

TOTAL INPUT

RATING

BTU/H

INJECTOR

SIZE

AIR SHUTTER

SETTING

MM

SUPPLY

PRESSURE

IN W.C.

NATURAL GAS 32,000 96,000 #35 10 7 3.5

NATURAL GAS 27,000 81,000 #38 10 7 3.5

PROPANE 32,000 96,000 #43 10 11 3.5

PROPANE 27,000 81,000 #45 10 11 3.5

Input Speci cations, GAS Grills, Japan: Gas Input

MAX INPUT

GAS

NET PER

BURNER

BTU/H

13A 32,000 96,000 #38 10 7 3.5

PROPANE 32,000 96,000 #43 10 11 3.5

LPG* 32,000* 96,000* #45 10* 11 3.5

TOTAL INPUT

RATING

BTU/H

INJECTOR

SIZE

AIR SHUTTER

SETTING

MM

SUPPLY

PRESSURE

IN W.C.

BURNER

MANIFOLD

PRESSURE

IN W.C.

BURNER

MANIFOLD

PRESSURE

IN W.C.

INPUTS BASED ON HEATING VALUES BELOW

13A PROPANE LPG*

1237 BTU/ft

3

2500 BTU/ft

3

2963 BTU/ft3 *

* VARIES DEPENDING ON COMPOSITION OF GAS

Input Speci cations, GAS Grills, CE Approved Model MWG3W-CE: Gas Input

TOTAL

INPUT

RATING

kW

INJECTOR

SIZE

GAS GROUP

MAX INPUT

NET PER

BURNER kW

G20 NG 8.9 26.7 2.79mm (#35) 10.0 20/25 8.7 0.94 m3/h

G25 NG 7.6 22.8 2.79mm (#35) 10.0 20 8.7 0.93 m3/h

G31 LPG 9.6 28.8 2.26mm (#43) 10.0 37/50 8.7 0.94 m3/h

NET HEATING VALUE BY GAS GROUP

G20 G25 G31

34.02 MJ/m3; 0.555 SG 29.25 MJ/m3; 0.613 SG 88.0 MJ/m3 (46.34 MJ/kg); 1.55 SG

GAS CATEGORIES

CATEGORY DESTINATION COUNTRIES SUPPLY PRESSURE (mbar)

I

2H

I

2E

I

2L

I

2ER

I

3P

I

3P

I

3P

AT, CH, CZ, DK, ES, FI, GB, IE, IS, IT, NO, PT, SE 20.0

DE, LU 20.0

NL 25.0

FR 20.0 / 25.0

NL 30.0

BE, CH, CZ, ES, FR, GB, GR, IE, LU 37.0

BE, CH, DE, CZ, ES, FR, NL 50.0

AIR

SHUTTER

SETTING

mm

SUPPLY

PRESSURE

mbar

BURNER

PRESSURE

mbar

VOLUMETRIC

GAS RATE

PER BURNER

Page 12

Part#: 4530407 Rev 05 (30 Jan 2015)

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

INSTALLATION & START UP

Installation Store Responsibilities:

• Ensure grill gets install by a competent, quali ed,

trained personnel.

• Ensure store readiness of utilities, product & personnel.

• Contact your local Garland Factory Authorized Service

Center for a start-up date.

• Participate in the start-up to ensure a successful startup and familiarity with the grill.

• Conduct training with your crew personnel to ensure

maximum utilization of the grill.

Once the installation is complete as per the procedures

below, a factory authorized service company MUST startup the grill according to Garland Commercial Ranges startup standards.

A start-up DOES NOT include:

1. Uncrating the unit

2. Placing the unit in its position under the exhaust hood.

3. Leveling the grill on the oor under the exhaust hood.

4. Attaching the supply cord(s) unless supplied by the

factory.

5. Making adjustments to the ventilation system.

6. Sheet metal work required due to improper exhaust

hood application.

7. Set proper gas and verify with beef integrity check that

two consecutive runs yield the approved beef integrity

results as per McDonalds standards.

8. Conduct brief training of store manager on the

operation of the grill.

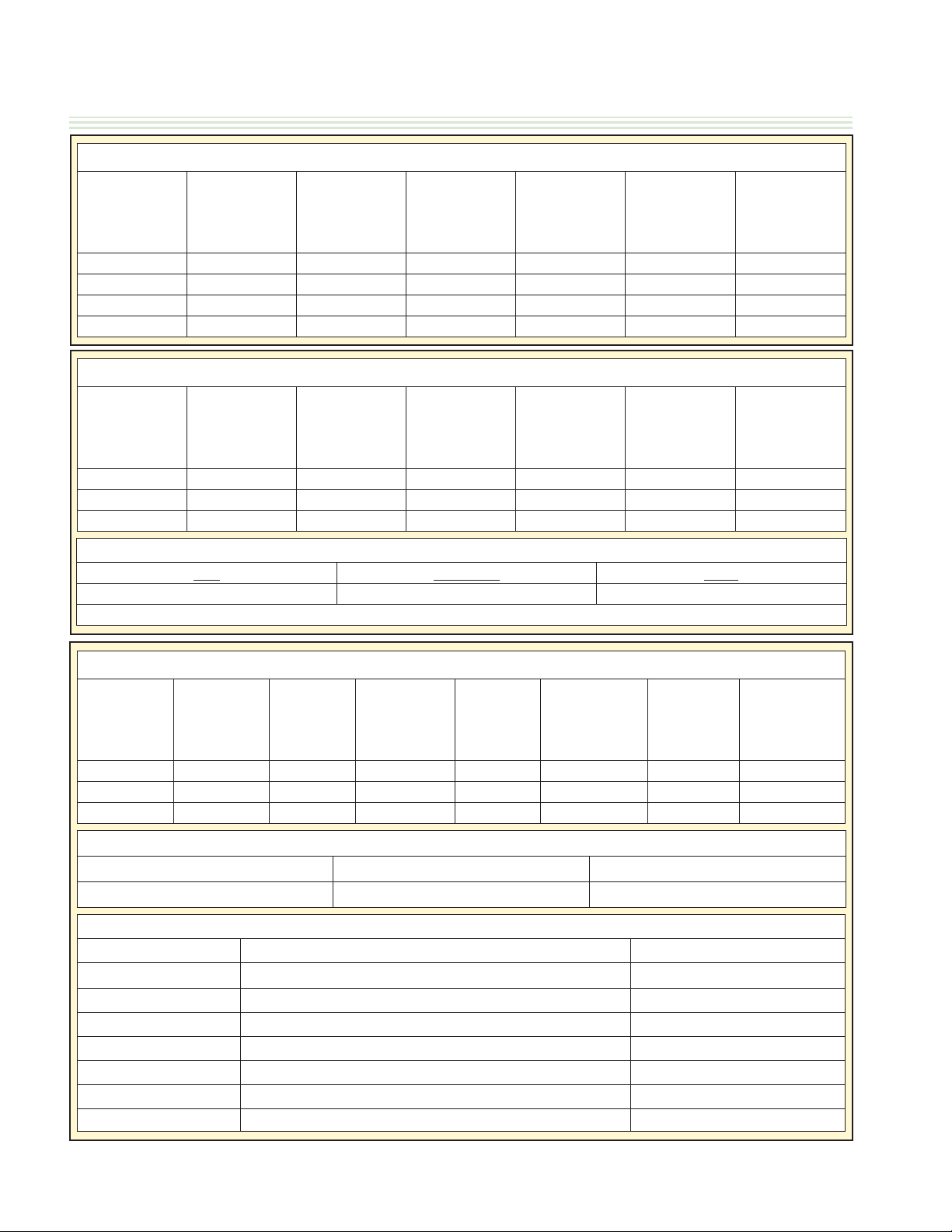

Items included with the purchase of your

new grill from Manufacturer:

1. One (1) World Grill gas & electric included the following

list, except countries mentioned;

Part # Description

4521792

4527643 Te on Release Sheet 9 0

4527294 Te on Sheet Clip 15 3

4521355 Te on Bar, Rear 3 3

4523492 Splash Shield 3 3

4525436 Splash Shield (Japan only) 0 3

4530053

4530054

Part # Description Qty

4517563 5” Front Swivel Caster w/Brake 2

1792003 5” Rear Swivel Caster 2

4523352

Te on Sheet

(Japan not included)

W/A Plate, Vapor Shield

(UK & Japan not included)

Silicone, Front, Vapor

(UK & Japan not included)

Leg Brace Locking Bracket - Standard

(Japan not included)

Wrap

Around

Non-Wrap

Around

06

33

33

1

7. Adjusting the grill to achieve beef integrity that

deviates from the McDonalds standard.

A start-up DOES include:

1. Veri cation of supply voltage and, if applicable gas

supply.

2. Leak test and gas pressure check on gas grills.

3. Electrical safety check.

4. Verify operation of grill by allowing unit to attain set

temperature.

5. Verify operation of platens, if applicable, and timer

functions.

6. Ensure time out alarm is functional and platens raise (if

applicable)

Part#: 4530407 Rev 05 (30 Jan 2015)

2. One (1) World Grill gas model only included the

following;

Description Qty Description Qty

13” Nipple 1 Shut O Valve 1

3/4 Street Elbows 2 Bracket, Pipe Hanger 1

Coupling 1 Screws 4

Pipe & Bracket Assy 1 Label 1

Nipple 1

Hanger Brackets 2

Connection

Instruction

1

Items NOT included from the manufacturer

and should be purchased from the Kitchen

Equipment Supplier (KES):

1. Any electrical cords needed for application.

2. Any ue box needed for application.

3. Any grease traps or grease rails needed for application.

Page 13

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

INSTALLATION & START UP (continued)

THE FOLLOWING INSTALLATION PROCEDURE

CAN BE PERFORMED BY A:

• FACTORY AUTHORIZED SERVICE CENTER

• AN APPROVED QUALIFIED INSTALLATION PERSONNEL

APPROVED BY PURCHASER OF GRILL

• LICENSED INSTALLER CONTRACTED BY KES.

• CONTACT LOCAL GARLAND FACTORY AUTHORIZED

SERVICE CENTER FOR MORE DETAILS.Uncrate unit from

crating material

CAUTION:

PRIOR TO INSTALLATION, CHECK THE ELECTRICAL

SUPPLY TO ENSURE INPUT VOLTAGE AND PHASE

MATCH THE EQUIPMENT VOLTAGE RATING AND

PHASE. MANY LOCAL CODES EXIST, IT IS THE

RESPONSIBILITY OF THE OWNER/INSTALLER TO

COMPLY WITH THESE CODES.

NOTE: ENSURE THAT PLATENS ARE STRAPPED

DOWN SECURELY THROUGH STEP 6 TO PREVENT

PLATENS FROM RAISING. SEVERE DAMAGE MAY

OCCUR.

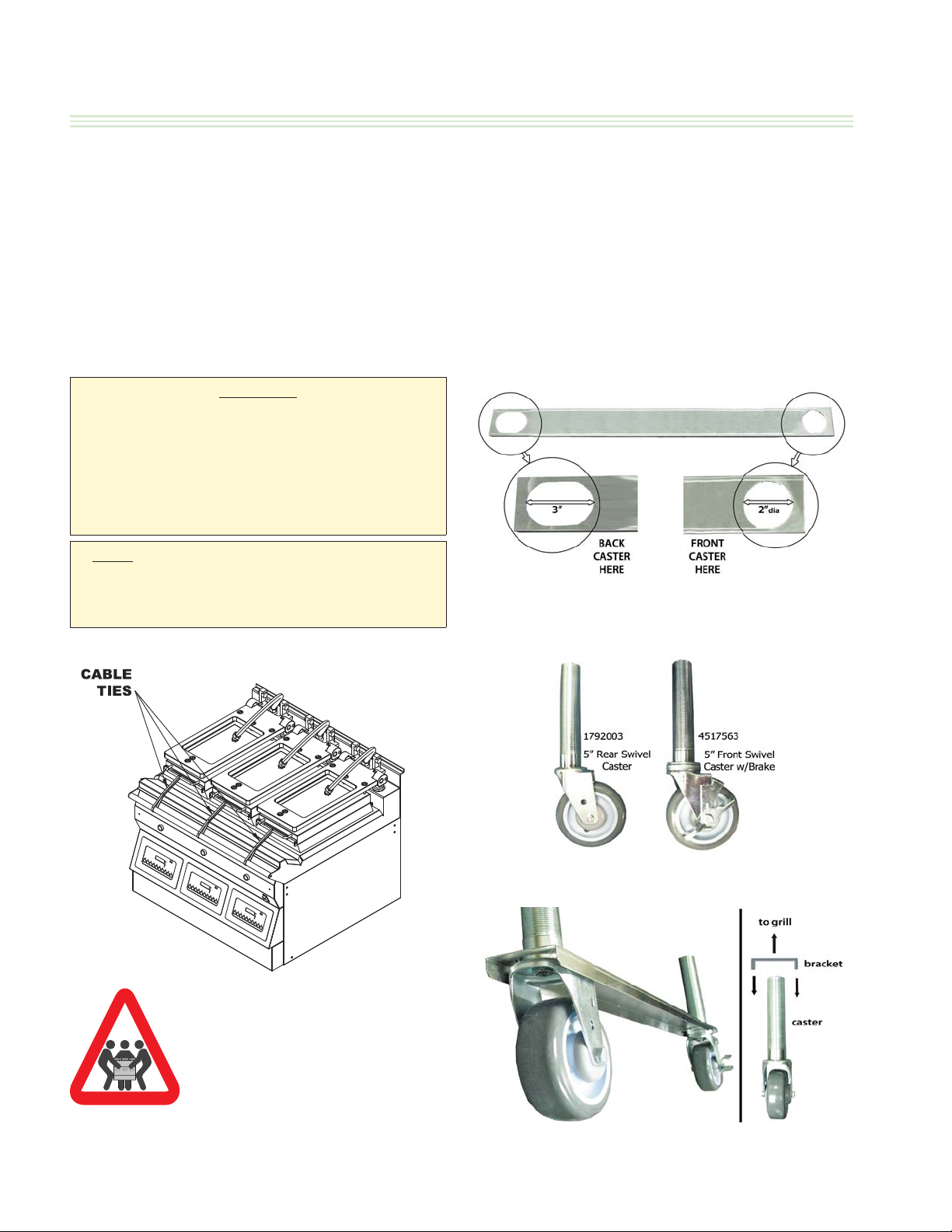

Installation of Casters

1. Put a pair of heavy gloves to protect your hands and

wear a lumbar support for lower back. Safety is the

rst concern when moving a heavy grill since it weigh

approximately 950lbs (431kg) or more.

2. Next procedure will require use of lifting aids and

proper lifting/moving techniques. Slide the grill away

from walls.

3. Check out the leg brace locking bracket included with

your purchased, Ensure you understand the front and

the back as shown below.

4. Check out the caster included with your purchased,

Ensure you understand the front and the rear casters

as shown below.

Page 14

5. Tip unit over on its back. Install casters & channels as

shown diagram below. Bracket notch facing the oor.

WARNING, HEAVY OBJECT!

The following procedure will require use of

lifting aids and proper lifting technique when

removing or replacing. To avoid serious

injuries use assistance when moving or lifting.

Part#: 4530407 Rev 05 (30 Jan 2015)

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

INSTALLATION & START UP (continued)

WARNING:

It is recommended that the rear casters are

screwed in all the way before tipping the unit.

Front

Caster

Rear

Caster

6. Block back caster in place to avoid the unit sliding

forward or backward.

7. Carefully rotate grill back on its casters. Now you may

cut and remove the platen securing straps.

8. Remove back body side and Install power cords per

your country / area’s speci cations.

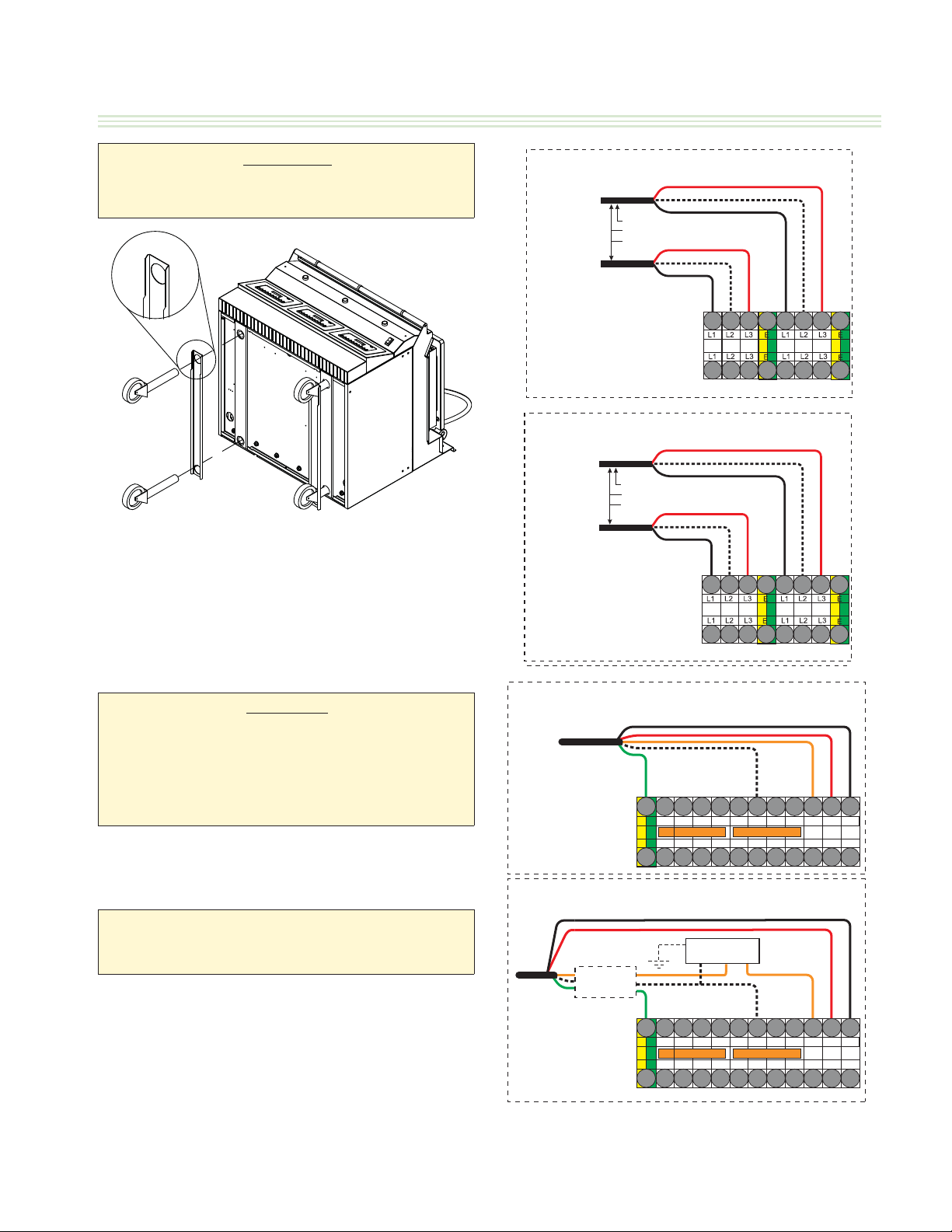

Electrical Cable Hookup

DUAL POWER SUPPLY CONNECTION

USA & some other

MWG3W HAS ONE ELECTRICAL CORD.

MWE3W HAS TWO ELECTRICAL CORDS.

MWE3S HAS TWO ELECTRICAL CORDS.

POWER CORDS & PLUGS

ARE NOT SUPPLIED

BY THE MANUFACTURER

Electrical Cable Hookup

DUAL POWER SUPPLY CONNECTION

USA & some other

MWG3W HAS ONE ELECTRICAL CORD.

MWE3W HAS TWO ELECTRICAL CORDS.

MWE3S HAS TWO ELECTRICAL CORDS.

POWER CORDS & PLUGS

ARE NOT SUPPLIED

BY THE MANUFACTURER

INPUT 1

INPUT 1

INPUT 2

INPUT 2

WARNING:

The appliances must be electrically grounded in

accordance with local codes, or in the absence of

local codes, with the National Electrical Code ANSI/

NFPA 70, or the Canadian Electrical Code CSA C22.1

as applicable.

Power Supply Connection

All electric connections must be made by a quali ed,

properly equipped technician.

NOTE: WIRING DIAGRAM LOCATED INSIDE

LOWER FRONT PANEL.

“DISCONNECT POWER BEFORE OPENING”

Hood-Interlock & Control Power Supply; where applicable

1 x 20AMP NEMA 21-20

POWER CORDS

ARE NOT SUPPLIED

BY THE

MANUFACTURER

EEL1 L1 L1 L1

L1 L1 L1 L1

Hood-Interlock & Control Power Supply; where applicable

JAPAN VERSION ONLY

TRANSFORMER

LINE

FILTER

1 x 20AMP NEMA 21-20

POWER CORDS

ARE NOT SUPPLIED

BY THE

EEL1 L1 L1 L1

L1 L1 L1 L1

MANUFACTURER

WhWht

Wht

Wht Wht Wht

1201000

WhWht

Wht

Wht Wht Wht

tWhtWht

tWhtWht

Ora Red

Ora Red Blk

Ora Red

Ora Red Blk

Blk

Blk

Part#: 4530407 Rev 05 (30 Jan 2015)

Page 15

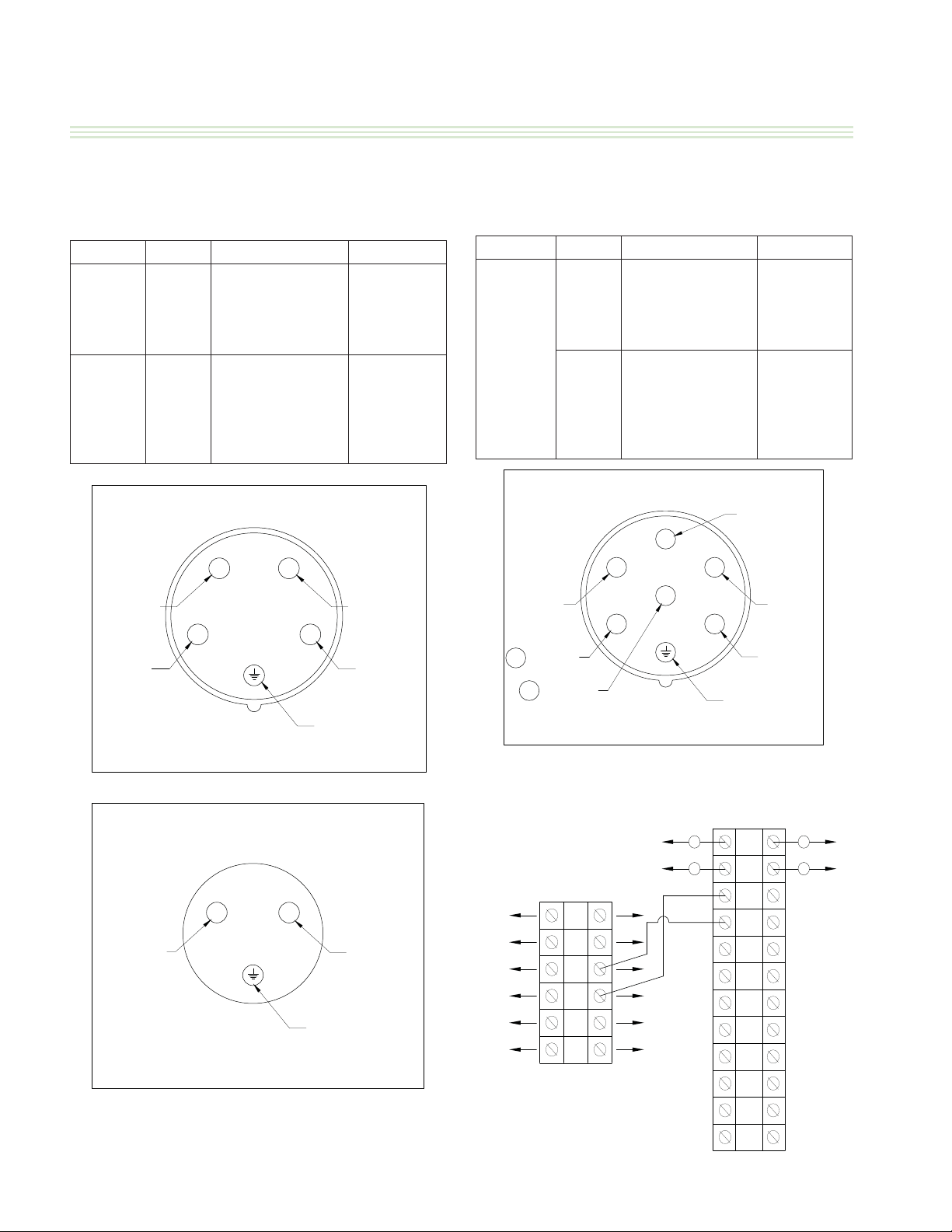

INSTALLATION/OPERATION MANUAL- 3 PLATEN GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION

INSTALLATION & STARTUP (continued)

Important Note:

Mennekes option is available only in some con gurations, check with your supplier for more details.

Mennekes 3 & 5 Pins (Option 1)

Connector Pins Intended Load Connected to

Mennekes

5 Pins

Mennekes

3 Pins

L3-TB1

N-TB1

Grill and Platen

1,2,3,4,

GND

1,2,GND

MENNEKES 5-PIN OPTION

Heaters

~3N 380/400/415

32Amps

50/60Hz

~1N 120-250 VAC,

16A

Control loads (N3,

MCB, Ignition

controller, blower,

gas valve)

3

2

4

1

E-TB1

TB1

L1, L2, L3, N,

GND

TB2

Orange &

White Replace

jumpers J-N

and J-L1

L2-TB1

L1-TB1

Mennekes 7 Pins (Option 2)

Connector Pins Intended Load Connected to

Mennekes

7 Pins

N-TB1

BLK-TB2

4

5

1,2,3,4,

GND

5,6

RED-TB2

Grill and Platen

Heaters

~3N 380/400/415

32Amps

50/60Hz

Swicth, Pilot duty

only

10A 250VAC, 15A

125VAC, 12(6)A

250VAC T85

MENNEKES 7-PIN OPTION

L3-TB1

3

4

2

6

5

3-Y 380/400/415, 50/60HZ

1

E-TB1

TB1

L1, L2, L3, N,

GND

TB2

Black & Red

L2-TB1

L1-TB1

WHT-TB2

Page 16

3-Y 380/400/415, 50/60HZ

MENNEKES 3-PIN OPTION

2

L-N 220/230/240, 50/60HZ

1

E-TB2

ORA-TB2

Terminal Blocks Diagram

TO SWITCH

TB1

E

N

N

TO CONTACTORS

L1

TO MENNEKES

L2

L3

Part#: 4530407 Rev 05 (30 Jan 2015)

J-L1

J-N

TB2

4

BLK

RED

ORA

WHT

WHT

WHT

WHT

4

TO MENNEKES

(7 PINS)

55

L1

L1

L1

L1

E

GARLAND CLAMSHELL GRILLS WITH PRODUCT RECOGNITION INSTALLATION/OPERATION MANUAL- 3 PLATEN

INSTALLATION & START UP (continued)

9. Install Optional Front Gas connection (If available).

12.00

(REF)

ATTACH FLEX GAS LINE TO ELBOW

5.28 (REF)

ATTACH HANGER #4527008 TO BASE IN LOCATION SHOWN

WITH #10-24 SELF TAPPING SCREWS

INSTALL 3/4 NIPPLE THROUGH HANGER AND INTO

EXISTING ELBOW

ROTATE EXISTING ELBOW TO ANGLE SHOWN

3/4-14 NPT

2.00

(REF)

a. Isolate grill from any power source by unplugging

all electrical connections.

b. Rotate existing elbow as shown in the diagram

below.

c. Attach support bracket (PN 4528775)to base

as shown with #10-24 screws and lock washers

supplied.

NOTE: For retro t applications, drill 2x .161 holes and

use self tapping screws provided.

d. Install 3/4” NPT nipple through support bracket and

onto existing elbow. Attach locking ring with 2x

#10-24 screws.

e. Install elbow to orientation show below.

f. Install nipple.

g. Attach ex gas hose to nipple.

12. Install ue box to back of grill.

FLUE BOX IS

NOT SUPPLIED BY

THE MANUFACTURER

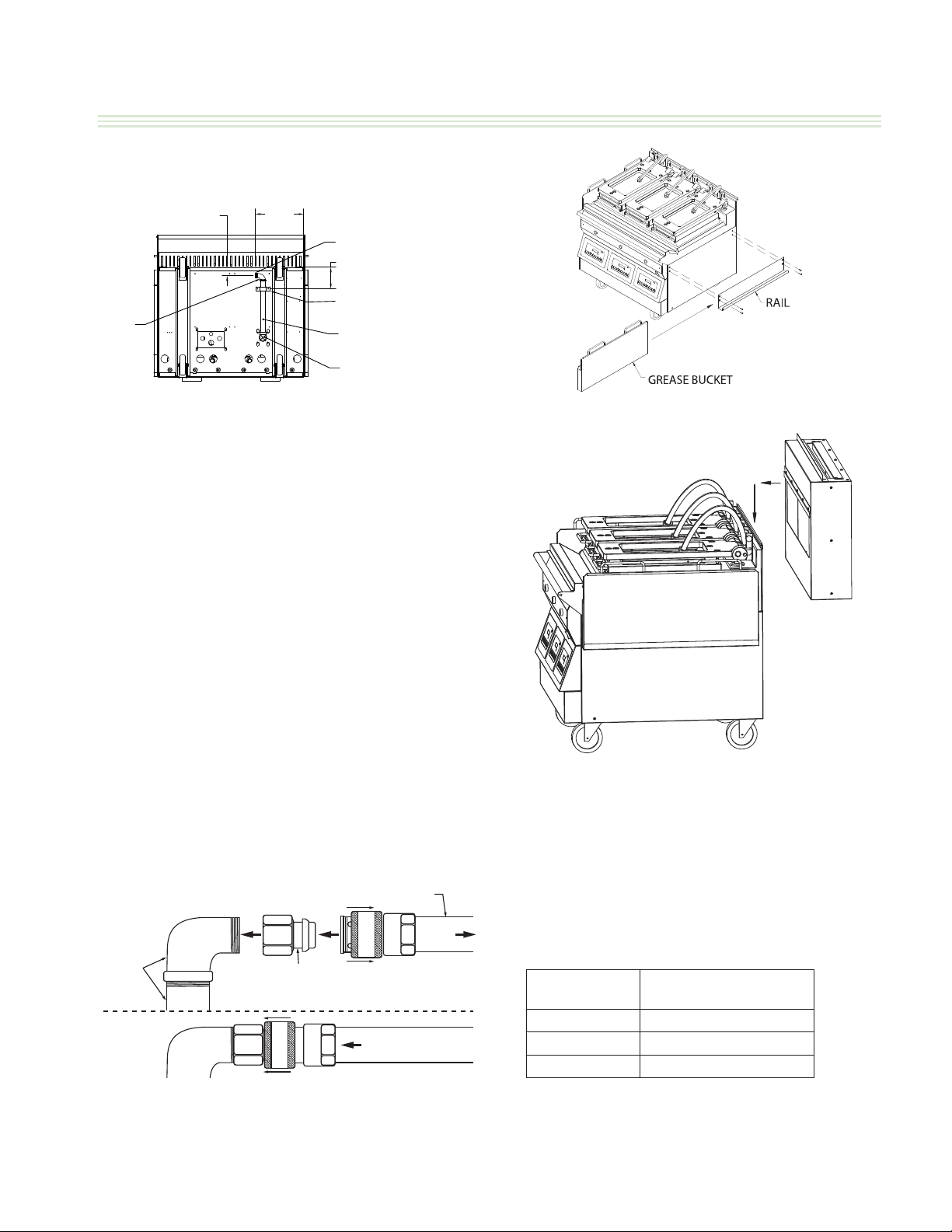

GREASE BUCKETS & RAILS

ARE NOT SUPPLIED

BY THE MANUFACTURER

10. GAS GRILL ONLY, (for electric grills, skip steps 7 & 8):

Install the included quick-disconnect gas hose to the

inlet tting on the underside of the grill by threading

a 3/4” NPT nipple into the elbow, then install the brass

male quick-disconnect coupler included with the hose.

Connect the hose and ensure the sleeve snaps fully

forward against the retaining ring.

FLEXIBLE GAS HOSE

GAS

FLOW

TO GAS

SUPPLY

FACTORY

INSTALLED

GAS INLET

UNDERNEATH GRILL

MALE COUPLER

[INSTALL FIRST]

With the manual shut-o valve closed, install the other

end of the hose to the gas supply.

11. Install grease bucket rails as shown below:

Part#: 4530407 Rev 05 (30 Jan 2015)

13. Roll grill under exhaust hood. Grill must be level front

to back, side to side and diagonally. Adjust casters

accordingly to obtain nal level.

Exhaust hood Type & Platen Height

With the platens in the raised position, measure the

height from the front edge of the platen to the grill

surface. Determine which type of exhaust hood the

store has and check for exhaust hood type/platen

height compatibility according to the table below:

Exhaust hood

TYPE

Universal 18

92 Series 17” (432mm)

GSC 18

CORRECT PLATEN HEIGHT

1

⁄2” (470mm)

1

⁄2” (470mm)

Page 17

Loading...

Loading...