Garland MSTSR16 Installation Manual

INSTALLATION AND

OPERATION MANUAL

MASTER SENTRY

GAS-OPERATED

SALAMANDER

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # P143 (11/10/08) © 2005 Garland Commercial Industries, Inc.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

Part # P143 (11/10/08)Page 2

TABLE OF CONTENTS

IMPORTANT INFORMATION .............2

DIMENSIONS AND SPECIFICATIONS .....4

Model Designation ...........................4

Sux Denitions .............................4

Table A: Exterior Dimensions . . . . . . . . . . . . . . . . . 5

Table B: Gas Flow Rate Per Model . . . . . . . . . . . . . 5

Table C: Nominal Heat Input (Gross)

Per Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table D: Setting Pressure / Injector Size . . . . . . . 5

Table E: Setting Pressure For “MIN”

Tap Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table F: Pilot Flame Length . . . . . . . . . . . . . . . . . . . 6

Table G: Australian Nominal Gas

Consumption & Injector Size ..................6

INTRODUCTION........................6

Uncrating ....................................6

Product Application ..........................6

Optional Extras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rating Plate ..................................6

INSTALLATION .........................7

General Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Clearances ...................................7

Siting ........................................7

COMMISSIONING ......................8

Burner Adjustments ..........................8

Gas Connection ..............................8

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION............................9

Safety concerns ..............................9

Lighting The Salamander .....................9

Operating Suggestions .......................9

CLEANING AND MAINTENANCE ........10

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operating Controls. . . . . . . . . . . . . . . . . . . . . . . . . .10

SERVICING............................11

Infrared Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gas Taps ....................................11

Safety Equipment Check . . . . . . . . . . . . . . . . . . . . 11

REPLACEMENT OF PARTS..............11

Gas Taps ....................................11

Infrared Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pilot Burner/Thermocouple. . . . . . . . . . . . . . . . . . 11

CONVERSION INSTRUCTIONS ..........12

Ventilation Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Statutory Regulations . . . . . . . . . . . . . . . . . . . . . . . . 7

Part # P143 (11/10/08) Page 3

TROUBLESHOOTING ..................13

SAFETY...............................13

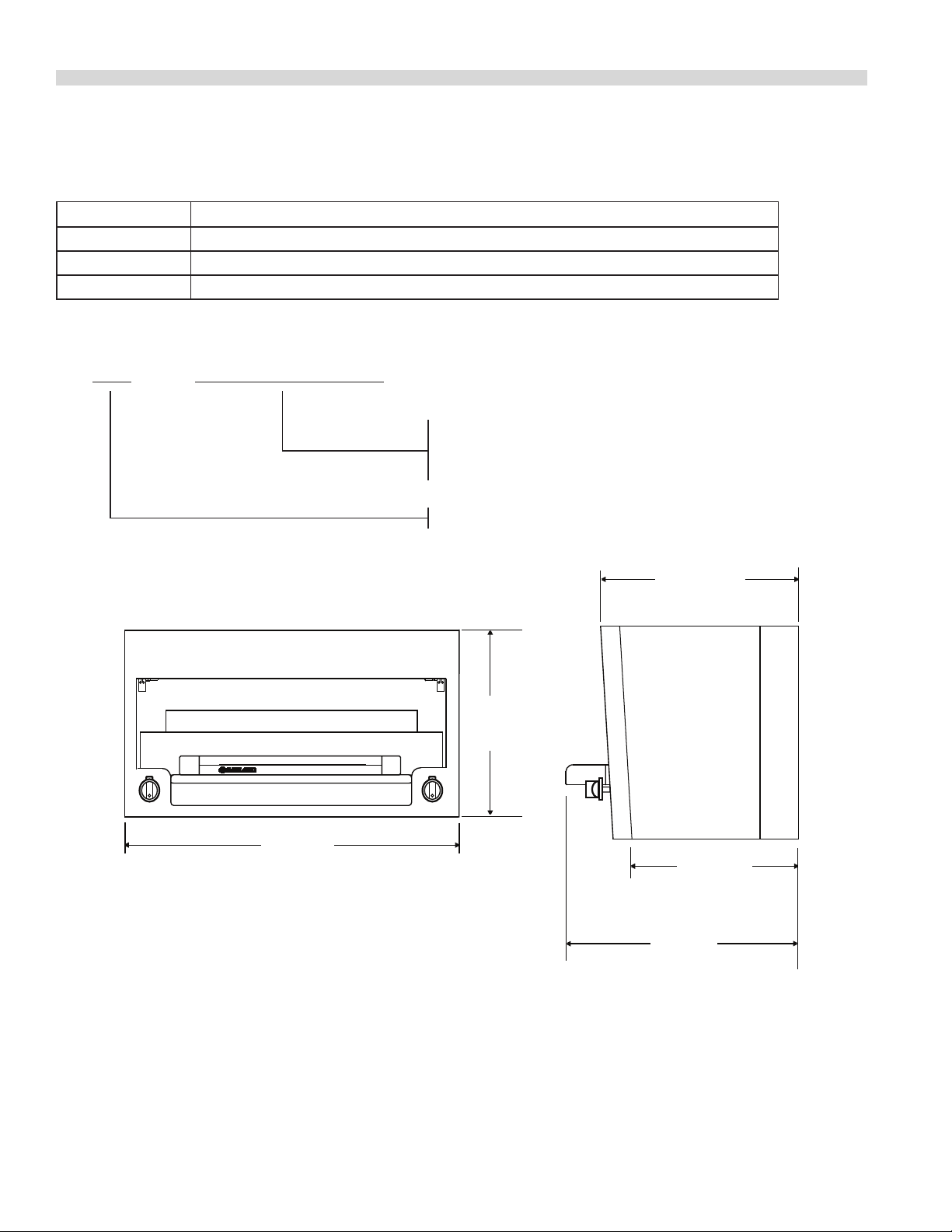

DIMENSIONS AND SPECIFICATIONS

MST SRC, SR16-280, SR16

SRC - Counter Top Version

SR16-280 - Restaurant Range Mount Version

SR16 - Heavy Duty Range Mount Version

Base Model Number

16 5/16"

[414mm]

34"

[864mm]

17 61/64"

[456mm]

16 13/16"

[427mm]

20 1/4"

[514mm]

Model Designation

MODEL DESCRIPTION

MSTSRC 864 mm wide x 414 mm high, infra-red counter mount salamander.

MSTSR16-280 864 mm wide x 1089 mm high, infra-red restaurant range mount salamander.

MSTSR16 864 mm wide x 1089 mm high, infra-red heavy duty range mount salamander.

Sux Denitions

Part # P143 (11/10/08)Page 4

DIMENSIONS AND SPECIFICATIONS Continued

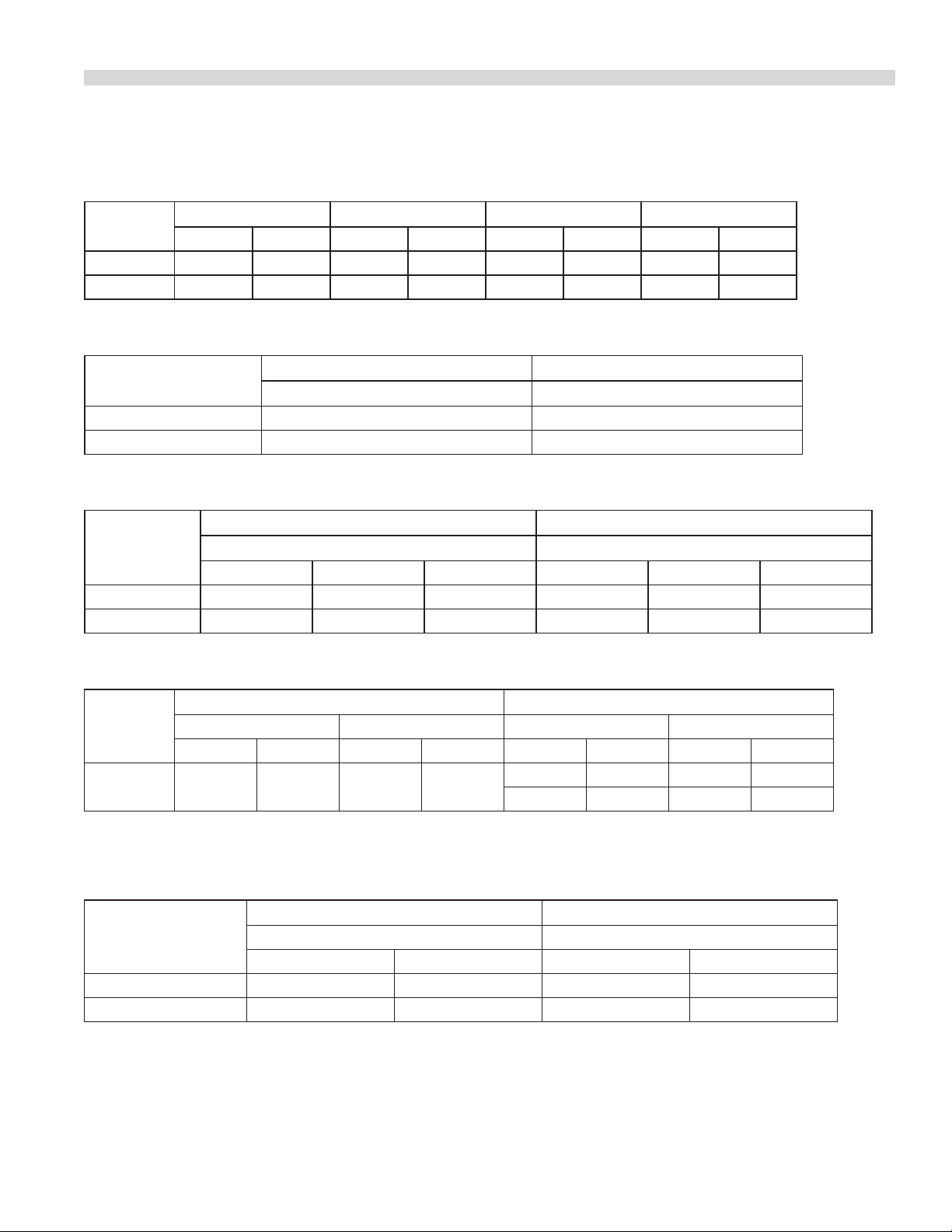

Table A: Exterior Dimensions

MODEL

MSTSRC 414 16.513 864 34 514 20.25 70.3 155

MSTSR16 414 16.513 864 34 514 20.25 95.3 210

HEIGHT WIDTH DEPTH WEIGHT

mm ins mm ins mm ins kg lb

Table B: Gas Flow Rate Per Model

MODEL

MSTSRC 0.88 0.598

MSTSR16 0.88 0.598

NATURAL GAS (m3/h) PROPANE GAS (kg/h)

G20 @ 20mbar G31 @ 37/50 mbar

Table C: Nominal Heat Input (Gross) Per Model

(G20 @ 20 mbar) NATURAL GAS (G31 @ 37/50 mbar) PROPANE

MODEL

MSTSRC 9.23 31,500 33.23 8.35 28,500 30.1

MSTSR16 9.23 31,500 33.23 8.35 28,500 30.1

Nominal Heat Input (Gross) Nominal Heat Input (Gross)

kW BTU/HR MJ/HR kW BTU/HR MJ/HR

Table D: Setting Pressure / Injector Size

MODEL/

SECTION

ALL 20 8 1.6 1.6

NOTE: The pressure must be measured at the pressure test nipple located on the main manifold pipe with all burners lit.

Setting Pressure Injector Size Setting Pressure Injector Size

mbar “W.C. I.D # mm mbar “WC I.D. # mm

37 14.9 1.1 1.1

50 20 61 0.99

Table E: Setting Pressure For “MIN” Tap Position

2ND Family, Group H 3RD Family, Group 3P

(G20 @ 20 mbar) Natural Gas (G31 @ 37/50 mbar) Propane

MODELS

MSTSRC 10.5 4.2 23 9.4

MSTSR16 10.5 4.2 23 9.4

(G20 @ 20 mbar) NAT. GAS (G31 @ 37/50 mbar) PROPANE

mbar “ W.C. mbar “ W.C.

Part # P143 (11/10/08) Page 5

Loading...

Loading...