Page 1

INSTALLATION AND

OPERATION MANUAL

MASTER SERIES

HEAVY DUTY GAS FRYERS

MODELS M/MST35 & M/MST70

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 1382677 (01/08) © 2005 Garland Commercial Industries, Inc.

Part # 1382677 (01/08) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swallow eld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of california to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

california to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

NOTE: Before leaving the factory, the fryer was tested with oil in the frypot; therefore, it is necessary to clean the frypot

before adding frying compound. Rinse the frypot with clean water, then put some fryer cleaner on a damp cloth, full

strength, and wipe the entire frypot clean. Rinse it thoroughly and wipe dry. The fryer is now ready foruse. If the fryer

does not have a stainlesssteel frypot and is not to beused immediately after cleaning,coat the entire frypot surface

with shortening or cooking oil to prevent rusting.

Part # 1382677 (01/08)Page 2

Page 3

Part # 1382677 (01/08) Page 3

TABLE OF CONTENTS

ImportantInformation .................2

Dimensions And Specications,

ModelM/MST35 .......................4

Dimensions And Specications,

ModelM/MST70 .......................5

Installation ............................6

Rating Plate..................................6

Pre-Installation Instructions..................6

Clearances ..................................7

Gas Connections and Piping Sizing...........7

Frypot.......................................7

Casters......................................7

Legs.........................................7

Ventilation and Air Supply....................8

Assembly Of Battery.........................8

Assembly Instructions M-Series

Low Prole Backguard .......................9

OPERATION ..........................10

Using the Fryer for the First Time............10

Lighting Instructions........................11

Stand By....................................11

Complete Shut Down.......................11

Safety Concerns ............................11

Optimum Operation Tips....................11

Suggestions for Quality Fried Food ..........12

CLEANINGANDMAINTENANCE........13

Routine Care................................13

Cleaning....................................13

Painted Finishes.........................13

Stainless Steel ........................... 13

Draining and Filtering Of Fryer Compound. . .13

Maintenance ...............................14

Preventive Maintenance................. 14

TroubleShootingAndAdjustments....15

Assembly Instructions M-Series Backguard....9

Radiation Shield ............................10

Adjustments................................15

Trouble Shooting ...........................15

Thermostat Calibration .....................16

Page 4

DIMENSIONS AND SPECIFICATIONS, MODEL M/MST35

3-1/2"

[89mm]

37-7/8"

[962mm]

33-3/8"

[848mm]

34-3/8"

[873mm]

13-1/8"

[333mm]

CLEARANCES

INSTALLATION ENTRY

Sides Rear Crated Uncrated

6"

(152mm)6"(152mm)

31-1/2"

[800mm]

29-1/4"

(746mm)

17-1/4"

(618mm)

46-3/4"

[1187mm]

With "BG"

BACKGUARD

SHIPPING

WEIGHT

220lb.

(100kg)

40-1/4"

30-1/4"

[768mm]

6"

[152mm]

17"

[432mm]

TOTAL INPUT

33-7/8"

[860mm]

OPERATING

PRESSURE

1-1/4" N.P.T.

[32mm]

GAS INLET

34"

[864mm]

ORIFICE

[1022mm]

With "LPBG"

BACKGUARD

Natural Propane NAT PRO NAT PRO

110,000 BTU/Hr

(32.23kW/Hr)

85,000 BTU/Hr

(24.91kW/Hr)

4.0" WC

(10mbar)

9.0" WC

(22mbar)

#51 1.05MM 1-1/4” N.P.T

Gas input ratings shown here are for installations up to 2,000 feet (610mm) above sea level.

Input must be derated for high altitude installations.

FRYING CAPACITY (per hour)

FRENCH FRIES FISH BREADED CHICKEN

Raw to Done Blanched to Done 3oz. (84g), Battered Raw to Done

60lb. (27kg) 80lb. (36kg) 60lb. (27kg) 28lb. (13kg)

63-3/4"

[1619mm]

With "DDBG"

BACKGUARD

MANIFOLD

PIPE SIZE

Part # 1382677 (01/08)Page 4

Page 5

Part # 1382677 (01/08) Page 5

DIMENSIONS AND SPECIFICATIONS, MODEL M/MST70

3-1/2"

37-7/8"

962mm]

[89mm]

34-3/8"

[873mm]

19-5/8"

[498mm]

Input-BTU (Natural Gas) 125,000 (36.62 kW)

Gas input ratings shown here are for installations up to 2,000

feet (610mm) above sea level Input must be derated for high

altitude installations.

Gas manifold pipe size: 1-1/4” N.P.T.

DIMENSIONS & SPECIFICATIONS

Width 24"(612mm)

Depth 38" (965mm

Height (w/ NSF Legs) 36-3/8" (924mm)

Height (w/o NSF Legs) 30-3/8" (772mm)

Shipping WT:(LB/KG) 225(120.5)

33-3/8"

848mm]

31-1/2"

[800mm]

46-3/4"

[1187mm]

W/ "BG"

BACKGUARD

30-3/8"

772mm]

33-7/8"

[860mm]

1-1/4" N.P.T.

[32mm]

GAS INLET

40-1/4"

[1022mm]

W/"LPBG"

BACKGUARD

63-3/4"

[1619mm]

W/"DDBG"

BACKGUARD

6"

152mm]

24"

[610mm]

INSTILLATION NOTES

Combustible Wall Clearances 1 Entry Clearances

Sides: 6" (152mm

Back: 6" (152mm)

NOTE: Installation clearance reductions are applicable only where local codes permits. NOTE: Data applies only to North America.

Crated: 29-1/4" (997mm)

Uncrated: 17-1/4" (438mm)

Natural: 6" WC (15mbar)

Propane: 10" WC (25mbar)

34"

[864mm]

Manifold Operating

Pressure

NAT

#56

Orice

PRO

#66

PRODUCTION CHART: Frying Capacities (per hour)

French Fries Fish Breaded Chicken

Raw to Finish

70 lb (32 kg)

Blanced to Finish

95 lb (43 kg)

3 oz Battered

100 lb (45 kg)

Raw to Done

28 lb (13 kg)

Page 6

INSTALLATION

The importance of proper installation of commercial

gas cooking equipment cannot be over stressed. Proper

performance of the equipment is dependent, in great part,

on the compliance of the installation with the manufacturer’s

specications. In addition, compliance with the National

Fuel Gas code ANSI Z 223.1-1988/NFPA and/or Local code is

required to assure safe and ecient operation.

Appliances shall be installed in a location in which the

facilities for ventilation permit satisfactory combustion of gas

and proper venting. Appliances shall be located so as not to

interfere with proper circulation of air within the conned

space. When buildings are so tight that normal inltration

does not provide the necessary air, outside air shall be

introduced.

Rating Plate

When corresponding with the factory or your local

authorized factory service center regarding service problems

or replacement parts, be sure to refer to the particular unit

by the correct model number (including the prex and sux

letters and numbers) and the warranty serial number. The

rating plate axed to the unit contains this information.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product must be installed by professional personnel as

specied. Garland/U.S. Range products are not approved or

authorized for home or residential use, but are intended for

commercial applications only. Garland / U.S. Range will not

provide service, warranty, maintenance or support of any

kind other than in commercial applications.

B. If it is a new installation have the gas authorities check

meter size and piping to assure that the unit is supplied

with sucient amount of gas pressure required to

operate the UNIT.

C. If it is additional or replacement equipment have gas

authorities check pressure to make certain that existing

meter and piping will supply fuel to the unit with not

more than ½” water column pressure drop.

NOTE: When checking gas pressure be sure that all other

equipment on the same gas line is on.

A pressure regulator is supplied as standard equipment with

GARLAND Heavy Duty Gas Fryers and Restaurant Gas Series

Fryers. The pressure regulator is “built-in” to the fryer, (the

regulator is part of the combination safety valve). Installation

must conform with the National Fuel Gas code ANSI Z223.11988 or latest edition NFPA No. 54-Latest Edition and

National Electrical code ANSI/NFPA 70-1990 or latest edition

and/or local code to assure safe and ecient operation.

NOTE: The appliance and its individual shut-o valve (not

supplied by manufacturer) must be disconnected from the

gas supply piping system during any pressure testing of that

system at pressures in excess of 1/2 PSIG

(3.45 KPa). The appliance must be isolated from the gas

supply piping system by closing its individual manual shuto (not supplied by manufacturer) during any testing of the

gas supply piping system at test pressures equal to or less

than 1/2 PSIG (3.45KPa).

NOTE: In Canada, the installation shall be in accordance

with CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE

or CAN/CGA-B149.2 PROPANE GAS INSTALLATION CODE and

local codes where applicable.

NOTE: Adequate clearance must be provided for servicing

and proper operation.

Pre-Installation Instructions

Before assembly and connection check gas supply.

A. The type of gas for which the unit is equipped is stamped

on the data plate located on inner door panel. Connect

a unit stamped “NAT” only to natural gas; connect those

stamped “PRO” only to propane gas.

NOTE: This appliance is not recommended for residential

installation.

Part # 1382677 (01/08)Page 6

Page 7

Part # 1382677 (01/08) Page 7

INSTALLATION Continued

Clearances

From Combustible material 6” (152mm) sides and rear. A

clearance of 0.0” to non combustible construction as sides

& rear is acceptable. The fryer is suitable for installation on

combustible oor.

Gas Connections and Piping Sizing

The size of the gas line is very important. If the line is too

small, the gas pressure at the burner manifold will be low.

This will cause slow recovery, delayed ignition, and pilot

outage. Refer to the Gas Line Sizing Chart in the nation Fuel

Codebook.

Before connecting new pipe to your GARLAND Fryer, the

pipe must be thoroughly blown out to depose of all foreign

particles. If these foreign particles get into the burner and

controls they will cause improper and sometimes dangerous

operation.

When using thread compound, use it sparingly and one on

male threads. Use compound that is impervious to the action

of Propane gases. Do not put any on the rst two threads.

This will prevent fouling the controls and clogging the pilot

and main burner orices.

Make sure that installer checks all plumbing with a soap

solution for leaks. DO NOT USE A FLAME, MATCHES,

CANDLES, or other ignition source in checking for leaks.

Frypot

Before leaving the factory, the fryer was tested, and the

thermostat was calibrated, with oil in the frypot; therefore,

it is necessary to clean the frypot before adding frying

compound. Rinse the frypot with clean water, then put some

fryer cleaner on a damp cloth, full strength, and wipe the

entire frypot clean. Rinse it thoroughly and wipe dry. The

fryer is now ready for use. If the fryer doe not have a stainless

steel frypot and is not to be used immediately after cleaning,

coat the entire frypot surface with shortening or cooking oil

to prevent rust.

Casters

A. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69/CSA 6.16, Addenda Z21.69B2006/CSA 6.16B-2006 (or latest edition), and a quickdisconnect device that complies with the Standard for

Quick Disconnects for Use with Gas Fuel, ANSI Z21.41/

CSA 6.9, Addenda Z21.41A-2005/CSA 6.16A-2005 (or

latest edition).

B. The front casters of the unit are equipped with brakes

to limit the movement of the fryer without depending

on the connector and any quick disconnect device or its

associated piping to limit the appliance movement.

C. Please be aware, required restraint is attached to a

bracket on the fryer (connection point is located on the

left rear caster of the fryer), and if disconnection of the

restraint is necessary, be sure to reconnect the restraint

after the fryer has been returned to its originally installed

position.

NOTE: When installed, the fryer must be restrained to

prevent tipping in order to avoid the splashing of hot liquid.

The means of restraint may be the manner of installation,

such as connection to a battery of appliances. Or installing

the fryer in an alcove, or by separate means, such as

adequate ties.

Legs

Raise front of the unit and block. Do not lay unit on its back..

Position leg insert into leg retainer opening and tap up until

it seats at collar ange. Repeat at rear of unit making sure all

four legs are adjusted to same height. Legs can be adjusted

to overcome an uneven oor.

CAUTION: These types of GARLAND Fryers cannot be

installed on a masonry base or without proper clearance

from oor. Primary air is supplied to the ‘jet – type” burner

from the front and mainly from the bottom of the fryer. If

installed on a masonry base or directly on oor without

the use of the factory supplied 6” (152mm) legs or casters,

improper combustion will occur.

Page 8

INSTALLATION Continued

Ventilation and Air Supply

One of the most important considerations is ventilation.

The fryer must be installed so that products of combustions

are removed eciently, but so that the kitchen ventilation

system does not produce drafts that interfere with proper

burner operation. The fryer ue opening must NOT be placed

close to the intake of the exhaust fan.

The fryer must never have its ue extended in a chimney

fashion. This changes the combustion characteristics of the

fryer. This will cause the fryer to be slow to recover, frequently

cause delayed ignition, and sometimes cause pilot outage.

The ideal method of ventilating a fryer is the use of a

properly designed canopy which should extend six inches

(6”) (152mm)beyond all sides of the appliance and six feet

(6’) six inches (6”) (1981mm) from the oor.

Many operators do not realize that the nest ventilation

system will break down when it is not maintained properly.

The duct system, the hood, and the lter bank must be

cleaned on a regular basis and kept free of grease.

Adequate distances must be maintained from the ue outlet

of the fryer to the lower edge of the lter bank. Filters should

never be installed in the horizontal position. They should be

installed at an angle of 45 degrees, and a drip tray should be

located beneath the lowest edge of the lter. NFPA Standard

No.96 states that “A Minimum distance of 18” (457mm)

should be maintained between the ue outlet and the lower

edge of the grease lter.” We recommend that the MINIMUM

DISTANCE BE 24” (610mm) FROM THE FLUE OUTLET TO

THE BOTTOM EDGE OF THE FILTER WHEN THE APPLIANCE

CONSUMES MORE THAN 120,000 B.T.U. PER HOUR.

A strong exhaust fan will create a vacuum in the room, for an

exhaust system vent to work properly, replacement air must

enter the room in which the vent is located.

All gas burners and pilots need sucient air to operate and

large objects should not be placed in front of this fryer which

would obstruct the air ow through the front. A minimum of

24” (610mm) should be provided at the front of the unit for

servicing and proper operation. Air for combustion enters

the unit below the cabinet at the base. Do not place anything

around the base or under the fryer.

Assembly Of Battery

All heavy duty batteries equipment is aligned and tted at

the factory, from left to right and must be installed in this

order. There is a diagram provided with every heavy duty

battery. All 35M/MST Fryers and 70M/MST Fryers may be

installed to battery with other GARLAND 40 Series Ranges,

sharing common manifold connections.

A. All such units should be placed in their respective battery

position. Detach valve panels to prevent damage,

remove them from the area where the battery is being

assembled.

B. Level each unit (if a range, to the oven rack) by adjusting

the six inch (6”/152mm) legs, or where legs are not used,

adjust level with shims. Readjust legs, if required.

C. Connect units together by mating the unions at each

end of the manifold. (Adjoining units must have

matching unions, unless the union parts are of the

same specications, a leak proof connection cannot be

assured.) Hand tighten unions at this point.

D. The units should be fastened at the rear by inserting 5/16”

bolts through the holes provided at the rear of the burner

box sides. Install washer and nut and hand tighten. Be

sure of proper unit alignment in the battery before nal

tightening of these bolts or unions. Improper tightening

will cause “fanning” or “bowing” of batteried units.

The nal tightening of the union should be accomplished

by using a suitable spanner wrench. If such a wrench

is not available, the GARLAND union collar has special

ridges, and a cold chisel can be driven against these

ridges to properly seat and seal the union.

E. The manifold of this unit or the manifold of which is

a part of must be equipped with a certied pressure

regulator suitable for battery application and adjustable

for an outlet pressure at the manifold as specied on the

rating place

Part # 1382677 (01/08)Page 8

Page 9

Part # 1382677 (01/08) Page 9

INSTALLATION Continued

1

"X"

"X"

2

5

8

4

3

6

7

Assembly Instructions

M-Series Low Prole Backguard

1. Remove ue cap #6 by removing six (6) [#10] sheet metal

screws.

2. Remove front panel #5 by lifting upward.

3. With back panel #4 still attached to the left #2 and right

#3 uprights, drop uprights into the rectangular cutouts at

the rear of the range #1.

4. Fasten uprights #2 and #3 to the range #1 with four (4)

5/16” -18 bolts and at washers #7 and #8.

5. If unit is in a battery lineup, fasten adjacent units together

at hole marked “X” with 1/4” -20 bolts, nuts, and washers.

6. Install front panel #5 previously remove.

7. Install ue cap #6 previously removed.

6

9

4

3

7

Assembly Instructions M-Series Backguard

1. Remove front panel #5 by lifting upward.

2. With back panel #4 still attached to the left #2 and right

#3 uprights, drop uprights into the rectangular cutouts at

the rear of the range.

3. Fasten uprights #2 and #3 to the range #1 with four (4)

5/16” -18 bolts and at washers #6 and #7.

4. If unit is in a battery line up, fasten adjacent units

together at hole marked “X” with 1/4” -20 bolts and

washers.

5. Install front panel #5 previously removed. Attach front

panel #5 to range #1 with sheet metal screws.

8

~

2

"X"

"X"

~

1

5

Page 10

INSTALLATION Continued

FLUE RISER

BACK ALUMINIZED

SIDES AND FRONT

HEAT SHIELD

FIGURE 2

METHOD OF ATTACHING RADIATION SHIELD TO

BACKGUARD OR HIGH SHELF

FIGURE 1

Radiation Shield

This radiation shield must be in place when fryer is installed

in other than re resistive locations.

IMPORTANT: The ue riser must be installed within the back

guard. This rectangular riser ts over the collar of the ue

collector box inside the fryer. Place the ue riser upright

through opening in the back top and slide over collar. (See

Figure 2.).

RADIATION SHIELD

REMOVE EXISTING

#10 SHEET METAL

SCREWS (2 REQ'D)

FROM HIGH SHELF OR

BACKGUARD TO INSTALL

RADIATION SHIELD

OPERATION

Using the Fryer for the First Time

Before lighting the pilot, ll the frypot with frying compound.

Then light the pilot according to the instructions inside

the fryer compartment on the inner panel. If you are using

a cooking oil, you may now turn the main burner on by

turning the knob on the automatic gas valve. If you use a

hydrogenated (solid) frying compound, it is wise to melt it in

a stock pot on the range before putting it in the fryer. If this

is not done, pack the frypot with the compound and turn the

main burner on for a few seconds and turn it o for a few. See

the lighting and shut-down instructions for “How to turn on

the main burner once the pilot is lighted.”

Intervals of about three seconds on and ten seconds o are

about right. Keep doing this until the shortening is melted.

If any smoke is seen during this process, you are heating

too fast and scorching the shortening, thus cutting down

its useful life and possible damaging the frypot. Shortening

level must cover the thermostat bulbs when fryer is in

operation.

After turning the main burner on, set the thermostat at 325°

to check calibration of the thermostat. Let the burner cycle

at least four times and suspend a deep fat fryer thermometer

in the middle of the frypot about 3” deep. When the burner

just comes on after the fourth cycle, the reading on the

thermostat should agree with the thermostat setting. If not,

calibrate the thermostat according to the instructions in the

Cleaning and Maintenance Section of this manual.

Part # 1382677 (01/08)Page 10

Page 11

Part # 1382677 (01/08) Page 11

OPERATION Continued

Lighting Instructions

For specic models see “Lighting Instructions” on the inside

of fryer compartment.

(Frypot must be lled before lighting).

1. Turn thermostat knob to the frying temperature. The

thermostat knob is located inside the compartment in

the front of the frypot.

2. Open the fryer door and turn the combination safety

valve knob to the PILOT position.

3. Push the knob in, light the pilot and continue to hold knob

in for about sixty seconds after the ame has been lit.

4. Turn valve knob counter-clockwise to ON.

5. Main burners will now light and will be controlled

automatically by the thermostat

OFF

P

I

L

O

T

NO

AUTOMATIC VALVE KNOB

PILOT POSITION

T

O

L

I

P

OFF

AUTOMATIC VALVE KNOB

ON POSITION

NO

Stand By

1. Turn fryer gas valve knob to “PILOT” position.

2. Put frypot cover in place.

Complete Shut Down

Turn gas valve knob clockwise to pilot position, DEPRESS

knob, slightly clockwise, release knob and continue turning

clockwise to OFF.

Safety Concerns

WARNING: The operator should be aware of the

HAZARDOUS NATURE, inadvertent splashing and spilling

etc., and RESULTANT CONSEQUENCES, personal burns,

res, slipping on spilled liquid etc., when moving the fryer

with liquid in the vessel. If the fryer is to be moved, it is

recommended that the liquid in the vessel be cooled to

room temperature and removed from the vessel.

To assure you of maximum protection and performance

your GARLAND Fryer is equipped with the best and most

reliable controls and safety devices available. The operation

thermostat will regulate frying compound temperatures to

close tolerances in a range between 250° and 375°.

If for any reason the pilot should be extinguished the

combination safety valve will close o the gas ow to the

main burners and pilot burner. As an additional safety feature

this valve prevents gas from owing to the main burners

when the pilot is being ignited.

On all units, due to the high rate of heating, and high limit

control device is provided as standard equipment. If for

any reason the frying compound temperature exceed the

maximum dial temperature the entire fryer will turn OFF at

450°F. If this should occur, have qualied service technician

check the system. FOR NO REASON SHOULD THIS HIGH LIMIT

DEVICE BE BY-PASSED!

Optimum Operation Tips

NO

AUTOMATIC VALVE KNOB

OFF POSITION

NOTE: Fryer cannot be shut o at the thermostat.

Thermostat used only to control temperatures.

OFF

P

I

L

O

T

One of the most important considerations in the protable

use of a fryer is the choice of the frying compound used. A

better frying compound will actually cost you less, because

it lasts longer than the lower grades and produce fried foods

with superior taste and appearance. There are numerous

high-grade products available and you are strongly urged to

use them.

Page 12

OPERATION Continued

For maximum frying compound life, good operators nd

they do best by frying at the lowest temperature that will

give a high-quality product. Thus, with a super-fast fryer,

such as your GARLAND, you do not have to fry potatoes at

375°F or 400°F, your fry at 325°F. A little experimenting will

determine just the right temperatures for your menu items.

The worst enemies of frying compound are light, heat,

air and salt. Thus, its life can materially be lengthened by

keeping the fryer covered when not in use, frying at the

lowest temperatures, and by reducing the temperatures

during stand-by periods.

A common habit which is harmful to frying compounds is

that of salting foods in baskets over frypot. Also, if food is

fried ahead and stored over the frypot to keep hot, as is often

done, it will rapidly lose its crispness and will taste greasy.

A common error in frying is to overload the baskets

under the mistaken impression that this will increase the

production of the fryer. For any given fryer, and any given

food product being fried there is a certain load which will

produce the maximum amount of food per hour. For best

results, we recommend the baskets be lled between ½ and

⁄ full. If the baskets are loaded beyond this, the total hourly

production rate will decrease.

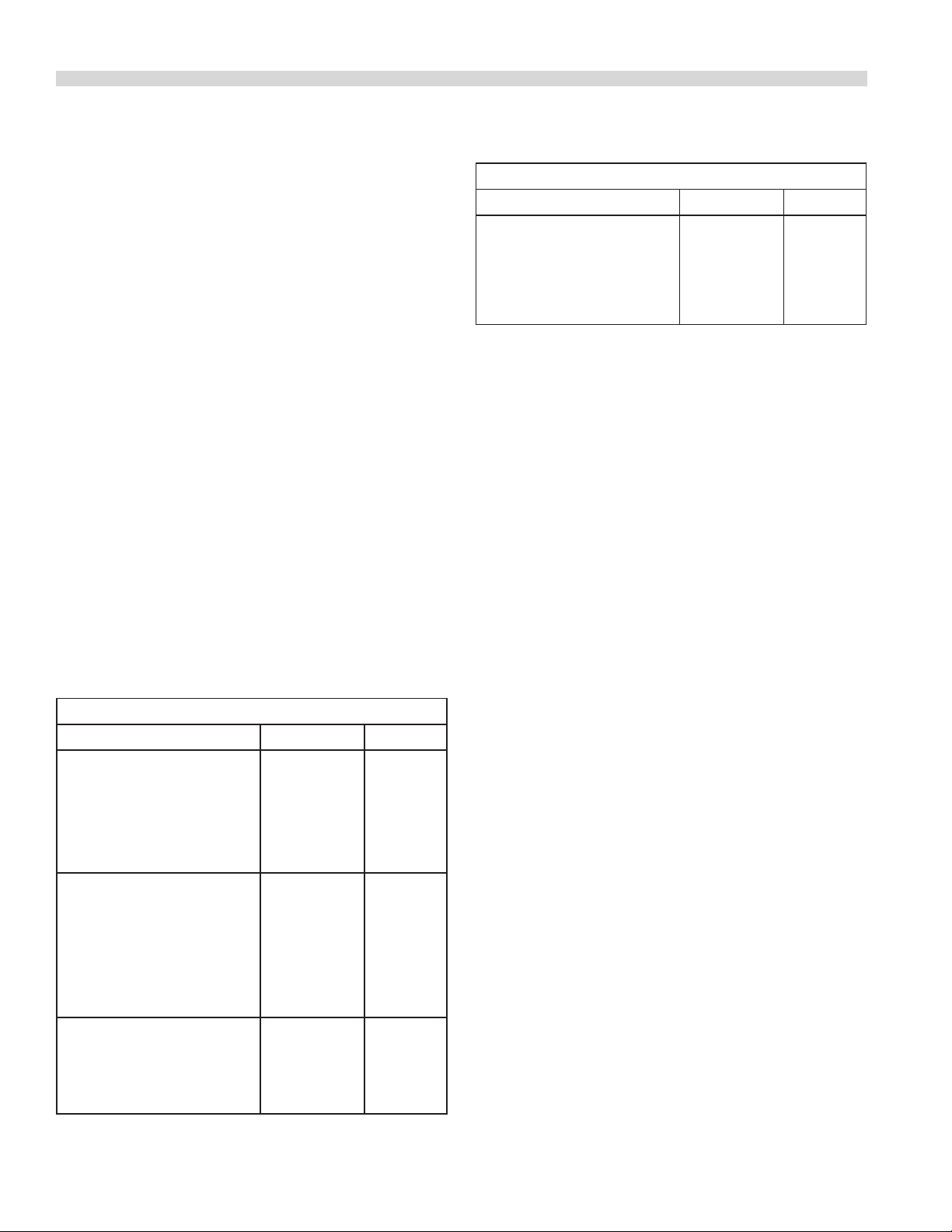

To give you a staring point, the following chart suggests the

temperatures at which most operators fry certain foods:

FRYING CHART

Product

Fritters

Fruit 350 3-5 Min

Vegetables (asparagus,

cauliower, corn,

eggplant, tomato)

Temperature Time

350 5-8 Min

Suggestions for Quality Fried Food

• Fresh, uncontaminated frying compound product better

fried products.

• Taste the frying compound once a day. Your patrons do,

when they eat the product.

• Filter the frying compound daily. Merely straining the

shortening is inadequate. You may choose the GARLAND

Filter Quick ltering system. This system is designed to

match-up to your GARLAND Fryer. Or, you may choose to

use a lter and lter cone.

• Drain or dry foods before frying. Excess moisture and

water breaks down frying compound.

• Do not salt or otherwise season food over the fryer.

This practice contaminates the frying compound and

accelerates it deterioration.

FRYING CHART

Product

French Fried Potatoes

Raw-to-done 350 5-7 Min

Blanching 325 4 Min

Browning

French Fried Onion Rings 360 2-3 Min

Seafood

Shrimp 360 2-3 Min

Oysters 350 1-4 Min

Scallops 250 3-5 Min

Fillets 350 3-4 Min

Clams 350-360 1-3 Min

Chicken

Small Pieces 350 6-10 Min

Large Pieces 350-360 8-11 Min

Cutlets, Chops (1” thick)

Temperature Time

350 2 Min

325 5-7 Min

• Do not shake breaded items over the fryer.

• Keep the frypot covered when not in use. This will

prevent air from oxidizing the frying compound and will

keep impurities out.

• Do not overheat the frying compound. Follow the

temperature recommended in tested recipes. The

company which provides your frying compound can

provide tested recipes and techniques for use with their

shorting.

• Watch for signs of compound breakdown. An unusual

darkening of the compound or smoking are the rst signs

of breakdown. Foaming, objectionable change in avour

of the product and gumming also indicate a breakdown

of the frying compound.

• Set the thermostat at 200°F or below, when not frying.

• Darkened frying compound and incorrect batter or

breading can cause a fried product to appear to be done.

Use tested recipe or obtain batter or breading specially

prepared for today’s frying techniques.

Part # 1382677 (01/08)Page 12

Page 13

Part # 1382677 (01/08) Page 13

CLEANING AND MAINTENANCE

Routine Care

NEVER operate the burner with an empty frypot. It only takes

a few minutes to completely ruin a frypot this way, and the

frypot warranty is void if this is done.

The frying compound should be ltered at least once a day. If

a heavy volume of breaded food is fried, it may be necessary

to lter two or more times a day. This will increase the life

of the frying compound and produce better-tasting food.

GARLAND lter cones are ideal for this and are inexpensive

and readily obtainable from your dealer or parts distributor.

The fryer should be cleaned daily, and this operation can

be combined with ltering the frying compound. After the

fryer is drained, wipe the inside with cloth saturated in a

commercial fryer/griddle cleaner, then rinse thoroughly.

Wipe dry and put the ltered compound back in the

frypot. The frypot should be boiled out once a week with a

commercial fryer/griddle cleaner according to direction on

the bottle. Each day wipe down the controls and all inside

the door with a damp cloth. Remove the basket hanger and

clean at least once a week. This way your fryer will stay clean

and new looking much longer. Be sure that the grease cover

for the automatic gas valve is kept in place.

Cleaning

Painted Finishes

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

The fryer should be permitted to cool down before cleaning

exterior surfaces.

1. Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a light weight non metallic scouring pad.

Dry thoroughly with a clean cloth.

2. Stainless steel should be cleaned using a mild detergent,

a soft cloth and hot water. If necessary to use a

nonmetallic scouring pad, always rub in the direction of

the grain in the metal to prevent scratching. Use a water

based stainless cleaner (commercially available), if you

want a high shine.

Stainless Steel

For routine cleaning just wash with a hot water and

detergent solution. Wash just a small area at a time or the

water will evaporate leaving chemicals behind causing

streaking. Rinse the washed area with a clean sponge dipped

in a sanitizing solution and wipe dry with a soft clean cloth

before it can dry. Use a paste (of water and a mild scouring

powder) if you have to, but never rub against the grain.

All stainless steel has been polished in one direction. Rub

with the polish lines to preserve the original nish. Then

thoroughly rinse as before. To prevent ngerprints there

are several stainless steel polishes on the market that leave

an oily or waxy lm. Do not use on surfaces that will be in

contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste. Use only stainless steel, wood or plastic tools

it necessary to scrape o heavy deposits of grease and oil.

Do not use ordinary steel scrapers or knives as particles of

iron may become imbedded and rust. STEEL WOOL SHOULD

NEVER BE USED. Either a typical bleach solution or hot water

can be use to sanitize stainless steel with harm.

Draining and Filtering Of Fryer Compound

The draining and ltering of fryer compound must be

accomplished with care to avoid the possibility of a burn

resulting from careless handling.

Filtering: Turn fryer o. If you are using a lter other than the

GARLAND Filter Quick, consult the ltering manufactures’

operation instructions for recommended ltering procedure.

Instructions for use of the lter Quick are included in the

Owners Manual shipped with your lter Quick unit.

The following is a recommended procedure to drain and

lter your compound when no lter machine is available:

1. Screw the drain pipe provided with your fryer into the

drain valve. Assure that you have rmly attached the

drain pipe and that the curved end portion is pointing

“do wn .”

Page 14

CLEANING AND MAINTENANCE Continued

2. Position the stock pot or other container under the

drain pipe. The stock pot or other container must be of

sucient design to withstand the heat generated by the

hot compound and must also be able to hold liquids. It is

recommended that where no lter machine is available,

the lter cone holder and lter cones be used. Be sure the

lter cone holder is resting securely on the stock pot or

other container.

3. Open the drain valve slowly to avoid splattering.

However, since splattering may occur anyway, extreme

caution should always be employed.

4. If the valve becomes clogged with food particles you

may wish to use a poker-like tool. The tool must be used

from the inside of the frypot only and caution should be

employed that the tool is gripped by the user as far as

possible from the hot fryer compound in the frypot. Do

not hammer on the drain valve as damage to the ball

inside the valve will cause it to leak. NEVER use this tool

or any other tool to unclog the valve from the front of the

valve. If the clog comes loose, hot compound could pour

out rapidly so beware of splattering in this event.

5. We recommend that the drained compound be allowed

to cool to 100ºF or lower before transporting the stock

pot or other container, removing the drain pipe, or

removing the lter cone holder and lter cone.

Maintenance

Your GARLAND equipment is ruggedly constructed and is

designed, with normal care, to give you long and lasting

service. It is, of course, desirable to keep your equipment

in the best possible condition. As the equipment is used,

whether in light or heavy duty service, it should be cleaned

often and a regular cleaning schedule should be established

on a daily, week and/or monthly basis, depending upon

severity of use.

Preventive Maintenance

In order to keep the unit operation at top eciency, it is

advisable to perform preventive maintenance regularly. The

frequency of this maintenance will depend on how hard the

unit is used, and you should discuss this with your nearest

GARLAND authorized Service Agent.

Preventive maintenance should cover at least the following:

1. Check pilot ame for correct length.

2. Check main burner ames for good ignition and proper

burner adjustment.

3. Check thermostat calibration.

4. Check thermopile output.

5. This fryer needs no lubrication.

Part # 1382677 (01/08)Page 14

Page 15

Part # 1382677 (01/08) Page 15

TROUBLE SHOOTING AND ADJUSTMENTS

Adjustments

The burner used on your GARLAND Fryer is a patented

design which does not require primary air, so no primary air

adjustment is possible. When the proper gas is being used,

at the proper pressure, and the ceramic targets are adjusted

properly, combustion will begin about even with the bottom

of the ceramic. The sound that is characteristic is a low roar,

similar to a blowtorch.

The correct type of gas and BTU content for which the fryer

was equipped at the factory is noted on the nameplate, and

this gas must be used.

NEVER THROTTLE DOWN THE INCOMING GAS IN AN EFFORT

TO MAKE THE FLAME BURN DIRECTLY ON THE ORIFICE.

Trouble Shooting

Possible Causes Remedy

Thermostat does not call for heat

1

(does not open gas valve at all).

a. Lead wires damaged. a. Repair or replace wires on thermostat.

b. Set too low. b. Raise setting.

c. Out of calibration c. Re-calibrate

d. Thermostat defective d. Replace

A piece of mechanical equipment which is used as hard as

a deep fat fryer is going to require service as the fryer gets

older; therefore, the following chart outlines problems that

are most likely to occur and what to do to correct them.

There are several possible sources of trouble in connection

with the operating thermostat. Usually the trouble will be

noticed by either the thermostat not causing the gas valve to

open, or by causing it to open at the wrong temperature. If

it opens the gas valve at the wrong temperature, it is said to

be out of calibration. If all the other parts of the appliance are

operation as they should, the following chart will help locate

the source of trouble and correct it.

1 See Below:

2. Thermostat does not control set point 2 See Below:

a. Out of calibration. a. Re-calibrate

b. Contaminated or burned contacts b. Replace thermostat

c. Knob of thermostat loose on shaft c. Calibrate thermostat and tighten set screws.

Page 16

TROUBLE SHOOTING AND ADJUSTMENTS Continued

Thermostat Calibration

To calibrate the Fenwal Thermostat, ll the frypot to the FULL

mark with frying compound and turn the burner on. Insert a

thermometer in the center of the frypot with the bulb about

two inches below the surface. Allow the burner to cycle

about four times, the thermometer reading should be within

5° of the thermostat knob setting. If this does not agree with

the pointer of the thermostat knob:

1. Loosen the two set screws on the thermostat knob

2. Set the pointer at the temperature indicated on the

thermometer.

3. Tighten the set screws rmly.

4. Be sure the black surface of the knob is spaced away

from the dial plate at least the thickness of a dime.

HI-LIMIT

THERMOSTAT

NOTE: DO NOT TURN ADJUSTING SHAFT MORE THAN TWO

TURNS IN EITHER DIRECTION OR PERMANENT DAMAGE CAN

RESULT. THIS ACTION MAY VOID THE STANDARD WARRANTY.

The Fenwal Thermostat is an electric switch with contacts

that open on a temperature rise. It will respond to

temperature changes of approximately 1º when the fryer is

idling with no food being fried.

Turning the adjusting shaft counter-clockwise increases the

temperature at which time the contacts will open. Some of

the most common problems occur in connection with the

pilot generator. These usually show as poor ignition of the

main burner or frequent pilot outage.

Below is a diagram of how the Fenwal thermostat and HiLimit controls are wired to the safety system.

OPERATING

THERMOSTAT

BLK BLK WHT WHT

OPTIONAL ON OFF SWITCH

PILOT

GENERATOR

Part # 1382677 (01/08)Page 16

Page 17

Page 18

Page 19

Pièce nº 1382677 (01/08)Page 18

Page 20

Pièce nº 1382677 (01/08) Page 17

DE VEILLEUSE

GÉNÉRATEUR

BLANC

INTERRUPTEUR MARCHE/ARRÊT EN OPTION

BLANC

BLANC

NOIR NOIR

EN FONCTION

THERMOSTAT

HAUTE LIMITE

THERMOSTAT

DÉPANNAGE ET RÉGLAGES suite

Page 21

Pièce nº 1382677 (01/08)Page 16

sûreté.

et les Contrôles de Hautes Limites sont reliés au système de

Sous, un diagramme illustre comment le Thermostat Fenwal

veilleuse irrégulière.

mauvais allumage du brûleur principal ou une amme de

veilleuse. Ceux-ci sont normalement remarqués par un

surviennent sont en rapport avec le générateur de la

s’ouvriront. Certains des problèmes les plus courants qui

augmente la température et à ce moment-là, les contacts

Tourner la tige d’ajustement dans le sens anti-horaire

nourriture n’est à frire.

de 1° lorsque la friteuse fonctionne au ralenti et qu’aucune

de chaleur. Il réagira à des changements de température

des contacts qui ouvrent lorsqu’il y a une augmentation

Le thermostat Fenwal est un commutateur électrique avec

PRATIQUE PEUT ANNULER LA GARANTIE STANDARD.

DU DOMMAGE PERMANENT PEUT EN RÉSULTER. CETTE

DE DEUX FOIS DANS UN SENS OU DANS L’AUTRE SINON

NOTE: NE PAS FAIRE PIVOTER LA TIGE D’AJUSTEMENT PLUS

plaque du bouton.

sous au moins entre la surface noire du bouton et la

4. S’assurer qu’il y a un espace de l’épaisseur d’un dix

3. serrer les vis fermement.

indiquée sur le thermomètre,

2. régler l’indicateur du thermostat à la température

1. Dévisser les quatre vis sur le bouton du thermostat,

pas à l’indicateur du bouton du thermostat:

réglage du bouton du thermostat. Si la lecture ne correspond

la lecture sur le thermomètre devrait être à moins de 5° du

la surface. Laisser le brûleur e ectuer environ quatre cycles,

de la friteuse, et placer le bulbe à environ deux pouces sous

allumer le brûleur. Introduire un thermomètre dans le centre

la marque « FULL » (plein) avec du composé à friture et

Pour calibrer le Thermostat Fenwal, remplir la friteuse jusqu’à

Directives Pour Le Calibrage Du Thermostat

c. Le bouton du thermostat est lâche. c. Calibrer le thermostat et serrer les vis.

b. Contacts contaminés ou brûlés. b. Remplacer le thermostat.

a. Hors-calibrage. a. Calibrer à nouveau.

2. Le thermostat ne contrôle pas le point de réglage. 2 Voir Ci-bas :

1 Voir Ci-bas :

d. Thermostat défectueux. d. Remplacer

c. Hors-calibrage. c. Calibrer à nouveau.

b. Réglé trop bas. b. Relever le réglage.

a. Fil conducteur est endommagé. a. Réparer ou remplacer les ls du thermostat

(n’ouvre pas la soupape à gaz du tout)

1

Le thermostat ne fait aucune demande de chaleur

Causes Possibles Solutions

DÉPANNAGE ET RÉGLAGES suite

Page 22

Pièce nº 1382677 (01/08) Page 15

problème et à le corriger.

il se doit, le tableau suivant aidera à localiser la source du

toutes les autres pièces de l’appareil fonctionnent comme

mauvaise température; ceci indique un hors-calibrage. Si

ou lorsque l’ouverture de la soupape à gaz se fait à une

lorsque le thermostat ne peut faire ouvrir la soupape à gaz,

avec le thermostat. Normalement le problème sera remarqué

Plusieurs sources de problèmes sont possibles en rapport

remédier.

problèmes probables qui surviendront et que faire pour y

mesure qu’elle vieillira; donc, le tableau suivant indique les

friteuse aura besoin d’un entretien de service au fur et à

Un appareil mécanique utilisé aussi intensément qu’une

Dépannage

FAIRE BRÛLER LA FLAMME DIRECTEMENT SUR L’ORIFICE.

NE JAMAIS RÉDUIRE LE DÉBIT DE GAZ DANS UN EFFORT DE

signalétique, et ce gaz seulement doit être utilisé.

friteuse est fabriqué à l’usine est indiqué sur la plaque

Le type de gaz requis et le contenu BTU pour lequel la

un faible rugissement semblable à un chalumeau.

la base de la céramique. Le son qui est caractéristique est à

correctement ajustées, la combustion débutera au niveau de

à la pression requise, et que les cibles en céramiques sont

ajustement possible. Lorsque le type de gaz requis est utilisé,

brevetée, ne demande pas d’air primaire donc aucun

Le brûleur de votre Friteuse GARLAND, de conception

Réglages

DÉPANNAGE ET RÉGLAGES

5. Cette friteuse ne demande aucune lubri cation.

4. Véri er le rendement de l’élément thermoélectrique.

3. Véri er le calibrage du thermostat.

l’ajustement du brûleur.

2. Véri er l’allumage des ammes du brûleur principal et

1. Véri er la hauteur de la amme de la veilleuse.

Un entretien préventif devrait couvrir les points suivants:

votre Agent Autorisé de Service local GARLAND.

l’utilisation de l’appareil et vous devriez demander conseil à

régulièrement. La fréquence de cet entretien dépendra de

il est judicieux d’e ectuer un entretien préventif

A n de maintenir l’e cacité de l’appareil à son maximum,

Entretien Préventif

l’utilisation.

journalière, semestrielle et/ou mensuelle, selon la sévérité de

de nettoyage régulier devrait être établie, sur une base

ou intensément, il doit être nettoyé souvent et un horaire

mesure que cet appareil est utilisé, que ce soit légèrement

de garder votre appareil en parfaite condition. Au fur et à

si entretenu normalement. Il est désirable, bien entendu,

conçu pour vous donner un rendement de longue durée

Votre appareil GARLAND est de construction solide et est

Entretien

d’enlever le support et le ltre en forme de cône.

ou l’autre contenant, d’enlever le tuyau de drainage, ou

drainé à 100°F ou moins avant de transporter la marmite,

5. Nous recommandons de laisser refroidir le composé

ENTRETIEN ET NETTOYAGE suite

Page 23

Pièce nº 1382677 (01/08)Page 14

détériorer

pour nettoyer hygiéniquement l’acier inoxydable sans le

conscient de la possibilité d’éclaboussures.

le composé chaud peut couler rapidement alors soyez

soupape par l’avant de celle-ci. Si le bouchon se défait,

JAMAIS utiliser cet outil, ou un autre, pour déboucher la

à la bille à l’intérieur de la soupape causera une fuite. NE

frapper sur la soupape de drainage puisque du dommage

loin que possible du composé à friture chaud. Ne pas

que l’utilisateur retienne l’outil de manière à se tenir aussi

seulement et des précautions devraient être prises a n

tisonnier. L’outil doit être utilisé à l’intérieur de la friteuse

nourriture, vous pouvez utiliser un outil semblable à un

4. Si la soupape se bouche à cause des particules de

devraient toujours être prises.

peut quand même survenir, d’extrêmes précautions

l’éclaboussement. Cependant, puisqu’un éclaboussement

3. Ouvrir la soupape de drainage lentement pour éviter

contenant.

appuyé de façon sécuritaire sur la marmite ou l’autre

en forme de cône. S’assurer que le support à ltre soit

n’est pas disponible, d’utiliser un support et un ltre

liquides. On recommande, lorsqu’une machine à ltrer

à friture chaud et doit aussi être capable de contenir les

capable de supporter la chaleur générée par le composé

de drainage. La marmite, ou l’autre contenant, doit être

2. Placer une marmite ou un autre contenant sous le tuyau

est pointée vers le bas.

drainage soit xé solidement et que l’extrémité courbée

dans la soupape de drainage. S’assurer que le tuyau de

1. Visser le tuyau de drainage fourni avec votre friteuse

disponible :

ltrer votre composé lorsqu’une machine à ltrer n’est pas

La méthode suivante est recommandée pour drainer et

avec chaque appareil « Filter Quick ».

Quick » sont incluses dans le Manuel de l’Utilisateur inclus

recommandée. Les directives pour l’utilisation du « Filter

les directives du manufacturier pour la méthode de ltrage

le « Filter Quick » GARLAND ( ltre rapide Garland), consultez

Filtrage : Arrêter la friteuse. Si vous utilisez un ltre, autre que

brûlures.

accomplis soigneusement a n d’éviter la possibilité de

Le drainage et le ltrage du composé à friture doivent être

solution de blanchiment ou d’eau chaude peut être utilisée

LAINE D’ACIER NE DEVRAIT JAMAIS ÊTRE UTILISÉE. Une

des parcelles de fer peuvent s’encastrer et rouiller. De la

pas utiliser de grattoirs de métal ou de couteaux puisque

plastique pour enlever les dépôts de graisse ou d’huile. Ne

utiliser seulement de la laine d’acier, un outil de bois ou de

vigoureusement avec une pâte à récurer. Si nécessaire,

taches peuvent normalement être enlevées en frottant

L’acier inoxydable peut se décolorer si surchau é. Ces

contact direct avec la nourriture.

huile ou cire. Ne pas les utiliser sur les surfaces qui sont en

qui préviennent les marques de doigts, et ne laissent aucune

le marché plusieurs marques de polis pour l’acier inoxydable

Ensuite, bien rincer comme auparavant. Vous trouverez sur

le même sens que les lignes pour préserver son fmi original.

inoxydable a été poli dans une seule direction. Frotter dans

le devez mais toujours frotter dans le sens du grain. L’acier

pâte (mélange d’eau et de poudre à récurer douce) si vous

doux et propre avant que la surface ne sèche. Utiliser une

dans une solution hygiénique et essuyer avec un linge

Rincer la surface lavée avec une éponge propre trempée

à la fois sinon l’eau en s’évaporant laissera des bariolages.

chaude et du détergent. Laver seulement une petite surface

Pour un nettoyage de routine, simplement laver avec de l’eau

Acier Inoxydable

désirée.

(disponible en magasin), si une surface brillante est

égratignures. Utiliser un abrasif à base d’eau pour acier

toujours frotter dans le sens du grain pour prévenir les

d’utiliser un tampon à récurer non-métallique,

de l’eau chaude et du savon doux. S’il est nécessaire

2. L’acier inoxydable doit être lavé avec un chi on délicat,

non métallique. Assécher à fond avec un linge propre.

peuvent être frottées avec un tampon à récurer léger et

de l’eau chaude et un savon doux. Les taches rebelles

1. Lorsque la friteuse est refroidie, essuyer les surfaces avec

extérieures.

Laisser refroidir la friteuse avant de nettoyer les surfaces

devraient être essuyées immédiatement.

Établir un horaire de nettoyage régulier. Les éclaboussures

Les Surfaces Enduites De Peinture

Directives De Drainage Et De Filtrage

Nettoyage

ENTRETIEN ET NETTOYAGE suite

Page 24

Pièce nº 1382677 (01/08) Page 13

place.

couvercle de la soupape à gaz automatique est laissé en

et d’apparence neuve plus longtemps. S’assurer que le

par semaine. De cette manière, votre friteuse restera propre

Enlever le support de paniers et le laver au moins une fois

contrôles et l’intérieur de la porte avec un linge humide.

les directives sur la bouteille. Chaque jour, essuyer les

nettoyeur commercial pour friteuses/plaques à frire, selon

être amenée à ébullition une fois par semaine, avec un

remettre le composé dans la friteuse. La friteuse devrait

à frire, ensuite rincer minutieusement. Assécher et

linge et un nettoyeur commercial pour friteuses/plaques

Après avoir vidé la friteuse, essuyer l’intérieur avec un

peut être combiné avec le ltrage du composé à friture.

La friteuse devrait être nettoyée tous les jours, et ce travail

chez votre détaillant ou distributeur de pièces.

de cônes sont l’idéal et non dispendieux; ils sont disponibles

nourriture de meilleur goût. Les ltres GARLAND en forme

Ceci prolonge la vie du composé à friture et produit une

peut être nécessaire de ltrer deux fois ou plus chaque jour.

moins. Si un lourd volume de nourriture panée est frit, il

Le composé à friture devrait être ltré une fois par jour au

ruinée et la garantie de la friteuse est annulée dans ce cas-ci.

vide. En quelques minutes seulement, la friteuse peut être

NE JAMAIS faire fonctionner le brûleur lorsque la friteuse est

Entretien Général

ENTRETIEN ET NETTOYAGE

préparées pour les techniques de friture d’aujourd’hui.

acheter de la chapelure ou de la pâte spécialement

sont cuits. Utiliser une recette déjà expérimentée ou

la pâte inexactes peuvent laisser croire que les produits

• Un composé à friture brunissant et de la chapelure ou de

n’est pas utilisée.

• Régler le thermostat à 200°F ou moins, lorsque la friteuse

aussi une dégradation du composé à friture.

dans le goût des produits et l’encrassement indiquent

de la fumée. De l’écume ou un changement désagréable

brunissement inhabituel ou lorsque le composé émet

composé. Les premiers signes de dégradation sont: un

• Surveiller les signes de dégradation de votre

techniques pour l’utilisation de leur graisse.

à friture peut vous fournir des recettes testées et des

températures recommandées. Le fournisseur de composé

• Ne pas surchau er le composé à friture. Suivre les

gardera les saletés à l’extérieur.

Ceci préviendra l’air d’oxyder le composé à friture et

• Laisser la friteuse couverte lorsqu’elle n’est pas utilisée.

friteuse.

• Ne pas secouer les aliments panés au-dessus de la

composé à friture et accélère sa détérioration.

la friteuse. Cette pratique contribue à contaminer le

• Ne pas saler ou assaisonner la nourriture au-dessus de

composé à friture.

L’excès d’humidité et d’eau provoquent la dégradation du

• Drainer ou essuyer la nourriture avant de la faire frire.

ltre en forme de cône.

égaler votre Friteuse Garland, ou vous pouvez choisir un

Filtration Rapide GARLAND; ce système est conçu pour

est inadéquat. Vous pouvez choisir le système de

• Filtrer le composé à friture tous les jours. Etirer la graisse

le font, lorsqu’ils mangent le produit.

• Goûter au composé à friture une fois par jour. Vos clients

meilleurs aliments frits.

• Un composé à friture frais, non contaminé, produits de

D’aliments Frits

Suggestions Pour Une Qualité

FONCTIONNEMENT suite

Page 25

Pièce nº 1382677 (01/08)Page 12

aubergines, tomates)

350 5-8 Min

325 5-7 Min

350 2 Min

Température Temps

Produit

TABLEAU DE FRITURE

choux- eurs, maïs,

Légumes (asperges,

Fruits 350 3-5 Min

Beignets

(1” épais)

Escalopes, Côtelettes

Gros Morceaux 350-360 8-11 Min

Petits Morceaux 350 6-10 Min

Poulet

Palourdes 350-360 1-3 Min

Filets 350 3-4 Min

Pétoncles 250 3-5 Min

Huîtres 350 1-4 Min

Crevettes 360 2-3 Min

Fruits de Mer

Oignons Frits 360 2-3 Min

Brunir

Blanchir 325 4 Min

Cru à bien-cuit 350 5-7 Min

Patates Frites

chaleur, l’air et le sel. Par conséquent, pour prolonger la

Les pires ennemis du composé à friture sont l’éclairage, la

déterminera les températures requises pour vos menus.

terre à 375°F ou 400°F, mais à 325°F. E ectuer des essais

friteuse GARLAND, vous ne devez pas frire vos pommes de

conséquent, avec une friteuse ultra-rapide, telle que la

résultats en cuisant les fritures à basse température. Par

utilisateurs avisés trouvent qu’ils obtiennent les meilleurs

Pour une période d’utilisation maximale du composé, les

vous recommande fortement de les utiliser.

Plusieurs produits de haute qualité sont disponibles et on

des aliments de meilleur goût et d’apparence supérieure.

que les composés moins dispendieux et qu’ils produisent

coûteront moins chers parce qu’ils durent plus longtemps

pro table. Les composés à friture de meilleure qualité vous

importantes pour que l’utilisation de la friteuse soit

Le choix du composé à friture est l’une des considérations

Bouts Fonctionnants D’Optimum

NE DOIT, POUR AUCUNE RAISON QUE CE SOIT, ÊTRE ANNULÉ.

technicien de service quali é. CE DISPOSITIF HAUTE LIMITE

Si ceci se produit faire véri er le système complet par un

maximale du cadran, la friteuse en entier s’arrête à 450°.

température du composé à friture dépasse la température

contrôle de haute limite. Si pour une raison ou une autre, la

sont munis, en équipement standard, d’un dispositif de

A cause du haut niveau de chaleur, tous les appareils

aliments :

suggère des températures qui sont utilisées pour certains

Pour vous donner un point de départ, le tableau suivant

que ceci, le taux de production horaire diminuera.

(1/2) et les deux-tiers (2/3). Si les paniers sont remplis plus

nous recommandons de remplir les paniers entre la moitié

quantité de nourriture à l’heure. Pour de meilleurs résultats,

quelle nourriture à frire, on obtient seulement une certaine

de la friteuse. Pour n’importe quelle friteuse et n’importe

sous l’impression erronée qu’on augmentera la productivité

Une erreur commune en friture est de surcharger les paniers

croustillante et goûtera le gras.

le voit souvent, la nourriture perdra rapidement sa qualité

au-dessus de la friteuse pour la garder chaude, comme on

friteuse. Aussi, si la nourriture est frite à l’avance et placée

celle de saler les aliments dans le panier au-dessus de la

Une habitude commune nocive au composé à friture est

températures pendant les périodes d’attentes.

pas utilisée, frire à des températures basses, et réduire les

vie de la friteuse on doit la garder couverte lorsqu’elle n’est

pendant l’allumage de la veilleuse.

empêche le gaz de circuler jusqû aux brûleurs principaux

Comme caractéristique supplémentaire, cette soupape

gaz vers les brûleurs principaux et le brûleur de la veilleuse.

la soupape de sûreté combinée arrêtera la circulation de

Si pour une raison ou une autre la veilleuse devait s’éteindre,

les températures du composé à friture entre 250° et 375°.

disponibles. Le thermostat de grande précision, contrôlera

meilleurs et des plus ables contrôles et dispositifs de sûreté

protection maximale, votre Friteuse GARLAND est munie des

Pour vous assurer d’un bon fonctionnement et d’une

température de la pièce et de l’enlever du récipient.

il est recommandé de refroidir le liquide du récipient à la

à l’intérieur du récipient. Si la friteuse doit être déplacée,

renversé etc., si la friteuse est déplacée lorsqu’il y a du liquide

brûlures corporelles, incendies, glissades sur du liquide

et DES CONSÉQUENCES pouvant en résulter, telles que

DES RISQUES d’éclaboussures et de débordements etc.,

AVERTISSEMENT : L’utilisateur devrait connaître la NATURE

Problèmes De Sécurité

FONCTIONNEMENT suite

Page 26

Pièce nº 1382677 (01/08) Page 11

dans le sens horaire jusqu’à la position « OFF » (arrêt).

le sens horaire, relâcher le bouton et continuer à tourner

la position veilleuse. Appuyer légèrement sur le bouton dans

Tourner le bouton de la soupape à gaz dans le sens horaire à

automatiquement par le thermostat.

5. Les brûleurs principaux s’allumeront et seront contrôlés

NO

P

O

L

I

L

I

OFF

T

P

OFF

Arrêt Complet

2. Mettre le couvercle de la friteuse en place.

position « PILOT » (veilleuse).

1. Tourner le bouton de la soupape à gaz de la friteuse à la

Friteuse Mise En Attente (stand-by)

thermostat contrôle seulement les températures.

NOTE : La friteuse ne peut être arrêtée par le thermostat. Le

DU BOUTON DE ROBINET AUTOMATIQUE

POSITION OFF

T

O

NO

à la position « ON » (en marche).

4. Tourner le bouton de la soupape dans le sens anti-horaire

secondes après que la amme soit allumée.

d’appuyer sur le bouton pendant environ soixante

3. Appuyer sur le bouton, allumer la veilleuse et continuer

(veilleuse).

la soupape de sûreté combinée à la position « PILOT »

2. Ouvrir la porte de la friteuse et tourner le bouton de

compartiment à l’avant de la friteuse.

friture. Le bouton du thermostat est situé à l’intérieur du

1. Tourner le bouton du thermostat à la température pour

(La friteuse doit être remplie avant son allumage).

l’intérieur du compartiment de la friteuse.

Pour les modèles spéci ques, voir « Directives d’Allumage» à

Directives D’allumage

DU BOUTON DE ROBINET AUTOMATIQUE

POSITION ON

OFF

P

I

L

O

T

DU BOUTON DE ROBINET AUTOMATIQUE

POSITION PILOT

NO

à la Section Entretien de ce manuel.

thermostat. Sinon, calibrer le thermostat selon les directives

sur le thermomètre devrait être identique au réglage du

le brûleur s’allume, après son quatrième cycle, la lecture

milieu de la friteuse, à environ 3 Po de profondeur. Lorsque

suspendre un thermomètre pour friteuse profonde dans le

le thermostat e ectuer un minimum de quatre cycles et

à 325° pour véri er le calibrage du thermostat. Laisser

Après avoir allumé le brûleur principal, régler le thermostat

lorsque la friteuse fonctionne.

Le niveau de graisse doit couvrir les bulbes de thermostats

d’utilisation de la graisse et peut endommager la friteuse.

est trop rapide et que la graisse brûle, donc réduit le temps

cours de ce processus, ceci indique que le réchau ement

que le composé soit fondu. Si de la fumée se produit au

secondes d’arrêt sont convenables. Continuer jusqu’à ce

Des périodes d’environ trois secondes en marche et dix

FONCTIONNEMENT suite

Page 27

Pièce nº 1382677 (01/08)Page 10

sage de le faire fondre dans une marmite, sur la cuisinière,

vous utilisez un composé à friture hydrogéné (solide), il est

en pivotant le bouton de la soupape à gaz automatique. Si

allumée ».

Comment allumer le brûleur principal lorsque la veilleuse est

quelques secondes. Voir les directives d’allumage et d’arrêt: «

pendant quelques secondes et l’arrêter pendant aussi

composé à friture et mettre le brûleur principal en marche

le composé préalablement, remplir la friteuse avec le

avant de l’introduire dans la friteuse. Si on ne fait pas fondre

cuisson, vous pouvez maintenant allumer le brûleur principal

compartiment de la friteuse. Si vous utilisez de l’huile à

les directives indiquées sur le panneau intérieur du

un composé à friture. Ensuite, allumer la veilleuse selon

Avant d’allumer la veilleuse, remplir le bac à l’huile avec

Première Utilisation De La Friteuse

FONCTIONNEMENT

FIGURE 2

le dessus arrière et le glisser sur le collet. (Voir le Dessin 2.)

friteuse. Placer le conduit d’évent vertical dans l’ouverture sur

VERTICAL

CONDUIT D'ÉVENT

ARRIÈRE ALUMINÉE

CÔTÉS DE DEVANT

ÉCRAN DE CHALEUR

sur le collet de la boite du collecteur d’évent à l’intérieur de la

l’intérieur du protecteur arrière. Ce conduit vertical s’ajuste

IMPORTANT : Le conduit d’évent vertical doit être installé à

feu.

installée dans un emplacement qui n’est pas à l’épreuve du

Cet écran de chaleur doit être en place lorsque la friteuse est

Écran De Chaleur

FIGURE 1

L’ÉCRAN DE CHALEUR.

ARRIÈRE POUR INSTALLER

OU DU PROTECTEUR

DE LA TABLETTE SUPÉRIEURE

EXISTANTES (#10) (2 REQUISES)

ENLEVER LES VIS À MÉTAL

ÉCRAN DE CHALEUR

ARRIÈRE OU À LA TABLETTE SUPÉRIEURE

MÉTHODE DE FIXATION DE L'ÉCRAN DE CHALEUR AU PROTECTEUR

INSTALLATION suite

Page 28

Pièce nº 1382677 (01/08) Page 9

1

1

"X"

"X"

5

7

6

3

2

8

8

7

4

3

5

~

~

6

"X"

"X"

2

4

9

7. Installer le capuchon d’évent #5 enlevé précédemment.

6. Installer le panneau avant #5 enlevé précédemment.

vis à métal.

Relier le panneau avant #5 à la cuisinière #1 à l’aide des

5 Installer le panneau avant #5 enlevé précédemment.

boulons 1/4Po-20, écrous et rondelles.

adjacents ensemble par le trou indiqué « X » à l’aide des

5. Si l’appareil fait partie d’un groupe, xer les appareils

boulons 1/4Po-20, écrous et rondelles.

adjacents ensemble par le trou indiqué « X » à l’aide des

4. Si l’appareil fait partie d’un groupe, xer les appareils

(4) boulons 5/16Po-18 et les rondelles plates #7 et #8.

4. Fixer les montants #2 et #3 à la cuisinière #1 avec quatre

(4) boulons 5/16Po-18 et les rondelles plates #6 et #7.

3. Fixer les montants #2 et #3 à la cuisinière #1 avec quatre

à l’arrière de la cuisinière.

et au droit #3, descendre les montants dans les découpés

2. Avec le panneau arrière #4 relié aux montants gauche #2

verticalement.

1. Enlever le panneau avant #5 en le soulevant

Arrière Pour Série M

Directives D’assemblage Protecteur

à l’arrière de la cuisinière #1.

et au droit #3, descendre les montants dans les découpés

3. Avec le panneau arrière #4 relié aux montants gauche #2

verticalement.

2. Enlever le panneau avant #5 en le soulevant

métal [#10].

1. Enlever le capuchon d’évent #6 en enlevant six (6) vis à

Arrière À Pro l Bas Pour Série M

Directives D’assemblage Protecteur

INSTALLATION suite

Page 29

Pièce nº 1382677 (01/08)Page 8

que spéci ée sur la plaque signalétique.

et réglable pour une pression de sortie au collecteur telle

homologué approprié pour une installation en groupe

fait partie, doit être muni d’un régulateur de pression

d’asseoir et de sceller le raccord.

un ciseau à froid peut être passé le long de ces arêtes a n

le collet de raccord Garland est muni d’arêtes spéciaux et

d’une clé anglaise. Si une clé anglaise n’est pas disponible,

serrage incorrect fera « courber » les appareils.

de serrer dé nitivement ces raccords ou ces boulons. Un

manuellement. Véri er l’alignement de l’appareil avant

boite de brûleur. Installer la rondelle et l’écrou et serrer

boulons 5/16 Po dans les trous à l’arrière des côtés de la

Serrer les raccords manuellement pour l’instant.

caractéristiques, un raccord étanche ne peut être assuré).

moins que les pièces de raccordement aient les mêmes

contigus doivent être munis des raccords jumeaux; à

raccords à chaque extrémité du collecteur. (Les appareils

niveau à l’aide de cales (shims). Ajuster les pattes si requis.

ou lorsque les pattes ne sont pas utilisées, ajuster le

four) en ajustant les pattes de six pouces (6po/152mm)

un endroit éloigné de l’installation.

soupape pour prévenir les dommages et les garder dans

position respective du groupe. Détacher les panneaux de

E. Le collecteur de cet appareil ou le collecteur auquel il

Le serrage nal du raccord devrait être exécuté à l’aide

D. Les appareils devraient être xés à l’arrière en insérant les

C. Raccorder les appareils ensemble en jumelant les

B. Niveler chaque appareil (si une cuisinière, par la grille du

A. Tous ces appareils devraient être placés dans leur

situé.

l’air de remplacement doit entrer dans la pièce où l’évent est

pièce. Pour qu’un système d’évent fonctionne correctement,

Un bon ventilateur d’échappement créera le vide dans la

L’APPAREIL CONSOMME PLUS DE 120,000 BTU À L’HEURE”.

SORTIE D’ÉVENT ET LE CÔTÉ INFÉRIEUR DU FILTRE LORSQUE

: UNE DISTANCE MINIMALE DE 24po (610mm) ENTRE LA

le côté inférieur du ltre à graisse ». Nous recommandons

(457mm) devrait être maintenue entre la sortie d’évent et

No. 96 stipulent que : « Une distance minimale de 18Po

être placé sous le côté le plus bas du ltre. Les Normes NFPA

angle de 45 degrés, et un plateau d’égouttement devrait

position horizontale. Ils devraient être installés dans un

des ltres. Les ltres ne devraient jamais être installés en

sortie d’évent de la friteuse et le côté inférieur de l’ensemble

Les distances adéquates doivent être maintenues entre la

sans aucune graisse.

des ltres doivent être nettoyés sur une base régulière et

correctement. Le système de conduits, la hotte et l’ensemble

système d’évacuation se détériorera s’il n’est pas entretenu

Beaucoup d’utilisateurs ne réalisent pas que le meilleur

6Po) (1981mm) du plancher.

tous les côtés de l’appareil et à six pieds et six pouces (6Pi

laquelle devrait dépasser de six pouces (6Po) (152mm) sur

friteuse est l’utilisation d’une hotte conçue adéquatement

La méthode idéale pour éliminer les gaz d’évent d’une

retardé et quelques fois une amme de veilleuse irrégulière.

une récupération lente de l’appareil, souvent un allumage

combustion de la friteuse et cause des e ets négatifs comme

d’une « cheminée ». Ceci change les caractéristiques de

La friteuse ne doit jamais avoir un évent allongé à la manière

40, et partager les raccords d’un collecteur commun.

installées en groupe avec d’autres cuisinières Garland, Série

Toutes les Friteuses 35M ainsi que 70M peuvent être

fourni avec chaque groupe d’appareils haute performance.

et doivent être installés dans cet ordre. Un diagramme est

et ajustés à l’usine, en partant de la gauche vers la droite

Tous les appareils haute performance regroupés sont alignés

Assemblage Du Groupe D’appareils

objets près de la base ou sous la friteuse.

L’air de combustion pénètre par la base. Ne pas placer des

prévu pour un bon fonctionnement et le service d’entretien.

minimal de 24Po (152mm) à l’avant de l’appareil devrait être

empêcherait la circulation d’air par l’avant. Un espace

doivent pas être placés à l’avant de cette friteuse ce qui

su samment d’air pour fonctionner et de gros objets ne

Tous les brûleurs au gaz et les veilleuses ont besoins de

près de l’entrée du ventilateur.

brûleur. L’ouverture d’évent de la friteuse NE doit pas être

de courants d’air qui entravent le bon fonctionnement du

le système de ventilation de la cuisine ne doit pas produire

l’évacuation e cace des produits de la combustion mais

lors de l’installation. L’installation de la friteuse doit assurer

L’évacuation est l’une des plus importantes considérations

Évacuation Et Alimentation D’air

une mauvaise combustion se produira.

des roulettes de 6 Po (152mm) fournies par le manufacturier,

directement sur un plancher, sans l’utilisation des pattes ou

friteuse. Si l’appareil est installé sur une base en béton ou

brûleur jet par l’avant et principalement par la base de la

dégagement requis du plancher. L’air primaire est fourni au

être installés sur une base en béton ou sans avoir le

PRUDENCE :Ces genres de Friteuses GARLAND ne peuvent

INSTALLATION suite

Page 30

inégal.

Les pattes peuvent être ajustées pour corriger un plancher

que les quatre pattes soient ajustées à la même hauteur.

en place. Répéter pour l’arrière de l’appareil en s’assurant

et frapper légèrement sur la patte jusqu’à ce qu’elle soit

l’appareil sur son côté arrière. Placer la patte dans l’ouverture

Relever l’avant de l’appareil et l’immobiliser. Ne pas placer

Pattes

séparés tels que des attaches adéquates.

ou installer la friteuse dans une alcôve, ou par des moyens

de l’installer, tel qu’un raccordement à un groupe d’appareils

Les moyens de restriction peuvent résider dans la manière

de basculer a n d’éviter l’éclaboussement du liquide chaud.

NOTE: Après son installation, la friteuse doit être empêchée

friteuse ait été replacée à son emplacement original.

est nécessaire, s’assurer de la rebrancher après que la

de la friteuse), et si le débranchement de cette restriction

(point de raccord est situé sur la roulette arrière gauche

C. La restriction requise est xée à un taquet sur la friteuse

ou de sa tuyauterie associée.

du raccord et de tout dispositif de débranchement rapide

de limiter tout mouvement de la friteuse sans dépendre

B. Les roulettes avant de l’appareil sont munies de freins a n

6.16A-2005 (ou la dernière édition).

Fuel, ANSI Z21.4 1/CSA 6.9, Addenda Z21.4 1A-2005/CSA

la norme Standard for Quick Disconnects for Use with Gas

(ou la dernière édition) et un raccord rapide conforme à

Z21.69/CSA 6.16, Addenda Z21.69B-2006/CSA 6.16B-2006

norme Connectors for Movable Gas Appliances, ANSI

A. L’installation sera faite avec un raccord conforme à la

Roulettes

ou de l’huile à cuisson a n de prévenir la rouille.

le nettoyage, enduire entièrement le bac avec de la graisse

en acier inoxydable et n’est pas utilisé immédiatement après

à être utilisée. Si la friteuse n’est pas munie d’un bac à l’huile

complètement et l’assécher. La friteuse est maintenant prête

un linge humide et un nettoyeur pour friteuses. Le rincer