Page 1

INSTALLATION,

OPERATING & SERVICE

MANUAL

MASTER SERIES HEAVY DUTY

RANGES, FRYERS & BROILERS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

Part # 4519069 (07/24/09) © 2004 Garland Commercial Industries, Inc.

Part # 4519069 (07/24/09) Page 1

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis UK LTD.

Swalloweld Way, Hayes, Middlesex UB3 1DQ ENGLAND

Telephone: 081-561-0433

Fax: 081-848-0041

Page 2

TABLE OF CONTENTS

TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

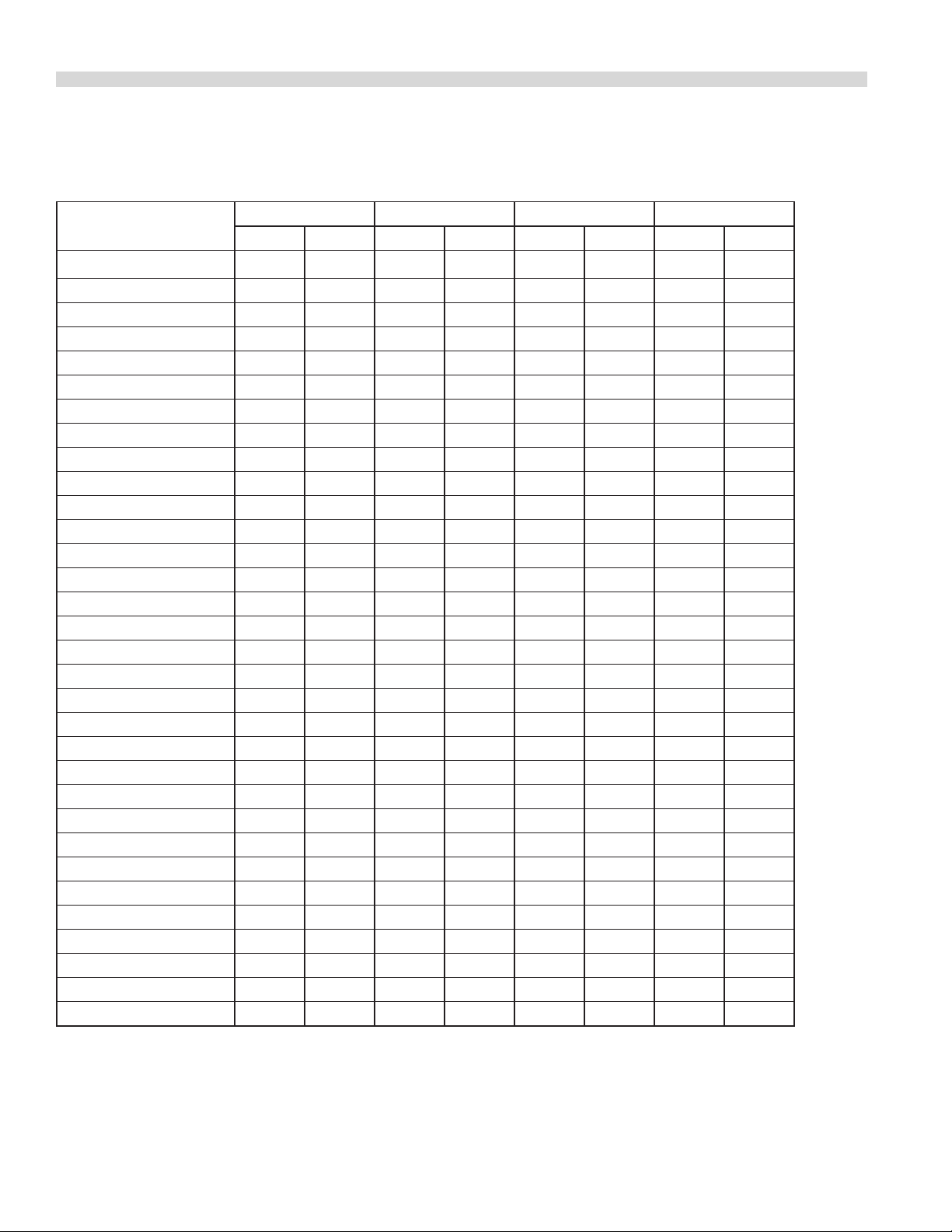

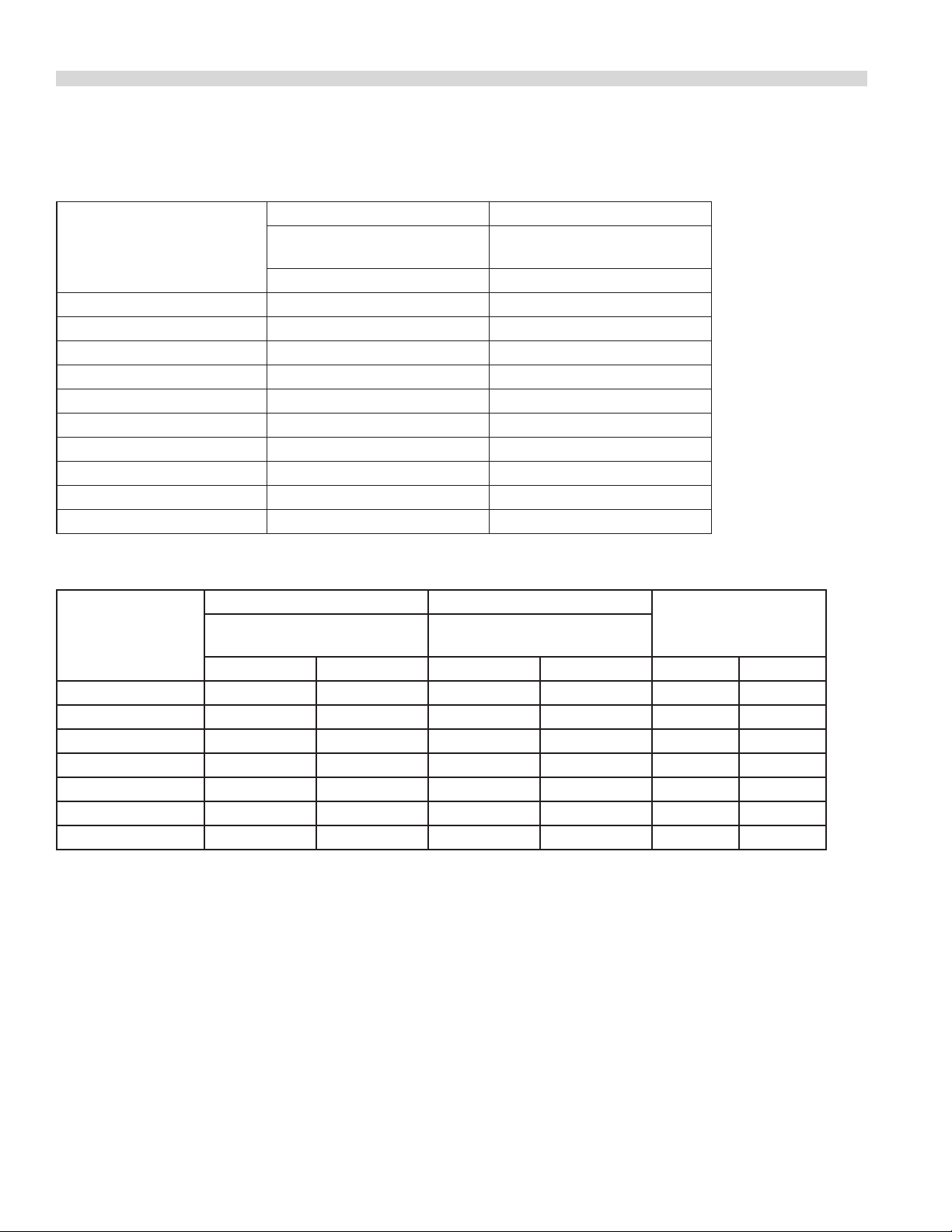

Table B: Model Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table C: Exterior Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table D: Gas Flow Rate (Net) Per Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table E: Heat Input (Gross) Per Burner / Burner Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table F: Pressure Setting / Injector Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table G: Pressure Setting For Low Tap Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table H: Aeration Shutter Setting / Pilot Flame Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Table I: Australia Only Nominal Gas Consumption & Injector Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table J: Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

STATUTORY REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Uncrating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rating Plate Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Optional Extras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Electrical Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Testing & Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pressure Settings (All Models Except Fryers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pressure Settings - Fryers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Burner Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Thermostat Bypass Adjustment - Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Oven Thermostat Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Open Type Hot Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Solid Top/Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Front Fired Solid Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Broiler Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Open Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Solid Hot Plate/Griddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Front Fired Hot Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Broiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Open Top Burners (MST Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hot Top And Spectro-top Sections (MST Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Standard Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

RC Convection Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Char-Broiler (MST Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAINTENANCE AND CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Seasoning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cast Iron Top Grates And Ring Grates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Part # 4519069 (07/24/09)Page 2

Page 3

TABLE OF CONTENTS continued

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Raw Steel Finishes:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Painted Finishes:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stainless Steel Finishes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Oven Interiors (Porcelain Enamel): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Griddles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Open Top Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cast Iron Top Grates And Ring Grates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cast Iron Even Heat Hot Tops And Spectro-Heat Tops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Top and Oven Orices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Pilot Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Burner Gas/Air Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CONVECTION OVEN (RC) – OPERATING TIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cleaning/Servicing Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Open-type Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Front Fired Solid Top Burners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Solid Hot Plate/Griddle Burners: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Oven Burners – Models With Sux R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Oven Burners – Models With Sux RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Broiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pilot Burner Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Hot Plate/Solid Top/Griddle/Broiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Thermostat Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

REPLACEMENT OF PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Gas Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Oven Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pilot/Thermocouple/Spark Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Hot Plate (MST Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Griddle/Solid Top/Front-Fired Hot Top/Broiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Spark Ignition Module Models With Sux E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Push Button Spark Switch Models With Sux E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

RC Oven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CONVERSION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

TROUBLE SHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Open Type Hot Plate, Solid Hot Top, Griddles And Broilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Standard And Convection Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Standard Oven Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Convection Base Oven Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Fryers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Part # 4519069 (07/24/09) Page 3

Page 4

TECHNICAL SPECIFICATIONS

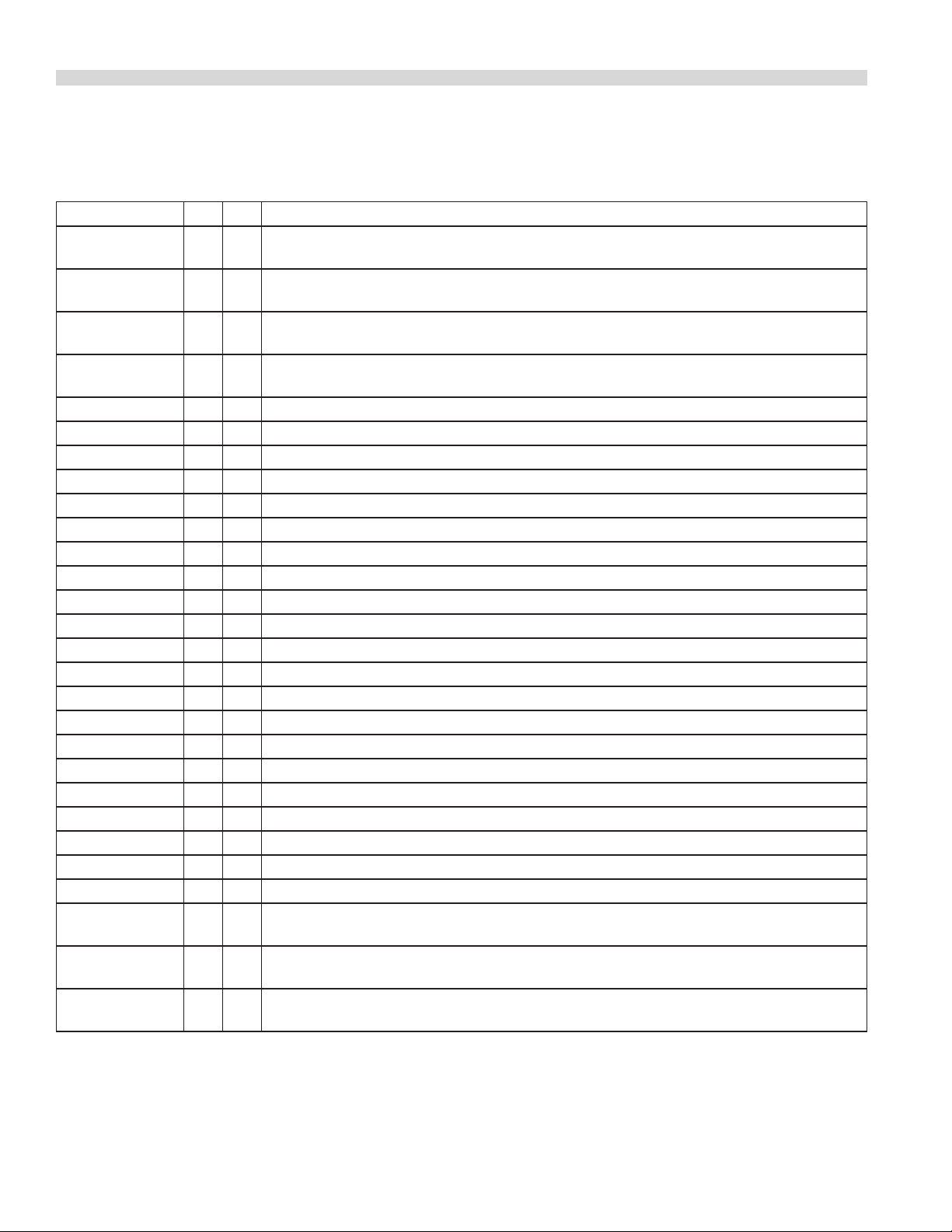

Table B: Model Designations

MODEL MM Ins DESCRIPTION

MST42R(E) 864 34

MST42RC(E) 864 34

MST42S(E) 864 34

MST42T(E) 864 34

MST43R(E) 864 34 Range with oven and six open top burners

MST43RC(E) 864 34 Range with convection oven and six open top burners

MST43S(E) 864 34 Range with storage base and six open top burners

MST43T(E) 864 34 Modular top with six open top burners

MST44R(E) 864 34 Range with oven and four open top burners

MST44RC(E) 864 34 Range with convection oven and four open top burners

MST44S(E) 864 34 Range with storage base and four open top burners

MST44T(E) 864 34 Modular top with four open top burners

MST45R(E) 864 34 Range with oven and two 330 mm wide front red solid hot plate sections

MST45RC(E) 864 34 Range with convection oven and two 330 mm wide front red solid hot plate sections

MST45S(E) 864 34 Range with storage base and two 330 mm wide front red solid hot plate sections

MST45T(E) 864 34 Modular top with two 330 mm wide front red solid hot plate sections

MST46R(E) 864 34 Range with oven and two 330 mm wide even heat solid top sections

MST46RC(E) 864 34 Range with convection over and two 330 mm wide even heat solid top sections

MST46S(E) 864 34 Range with storage base and two 330 mm wide even heat solid top sections

MST46T(E) 864 34 Modular top with two 330 mm wide even heat solid top sections

MST47R(E) 864 34 Range with oven and 864 mm wide tap controlled griddle

MST47RC(E) 864 34 Range with convection oven and 864 mm wide tap controlled griddle

MST47S(E) 864 34 Range with storage base and 864 mm wide tap controlled griddle

MST47T(E) 864 34 Modular top and 864 mm wide tap controlled griddle

MST54R(E) 864 34 Range with oven, two open top burners & a 330 mm wide front red solid top section

MST54RC(E) 864 34

MST54S(E) 864 34

MST54T(E) 864 34

Range with oven, two open top burners & a 432 mm wide solid hot plate or

optional griddle

Range with convection oven, two open top burners & a 432 mm wide solid hot plate or

option griddle

Range with storage compartment, two open top burners & a 432 mm wide

solid hot plate optional griddle

Modular top with two open top burners & a 432 mm wide solid hot plate or

optional griddle.

Range with convection oven, two open top burners & a 330 mm wide

front red solid top section

Range with a storage base, two open top burners & a 330 mm wide front

red solid top section

Modular top with two open top burners & a 330 mm wide

front red solid top section

Part # 4519069 (07/24/09)Page 4

Page 5

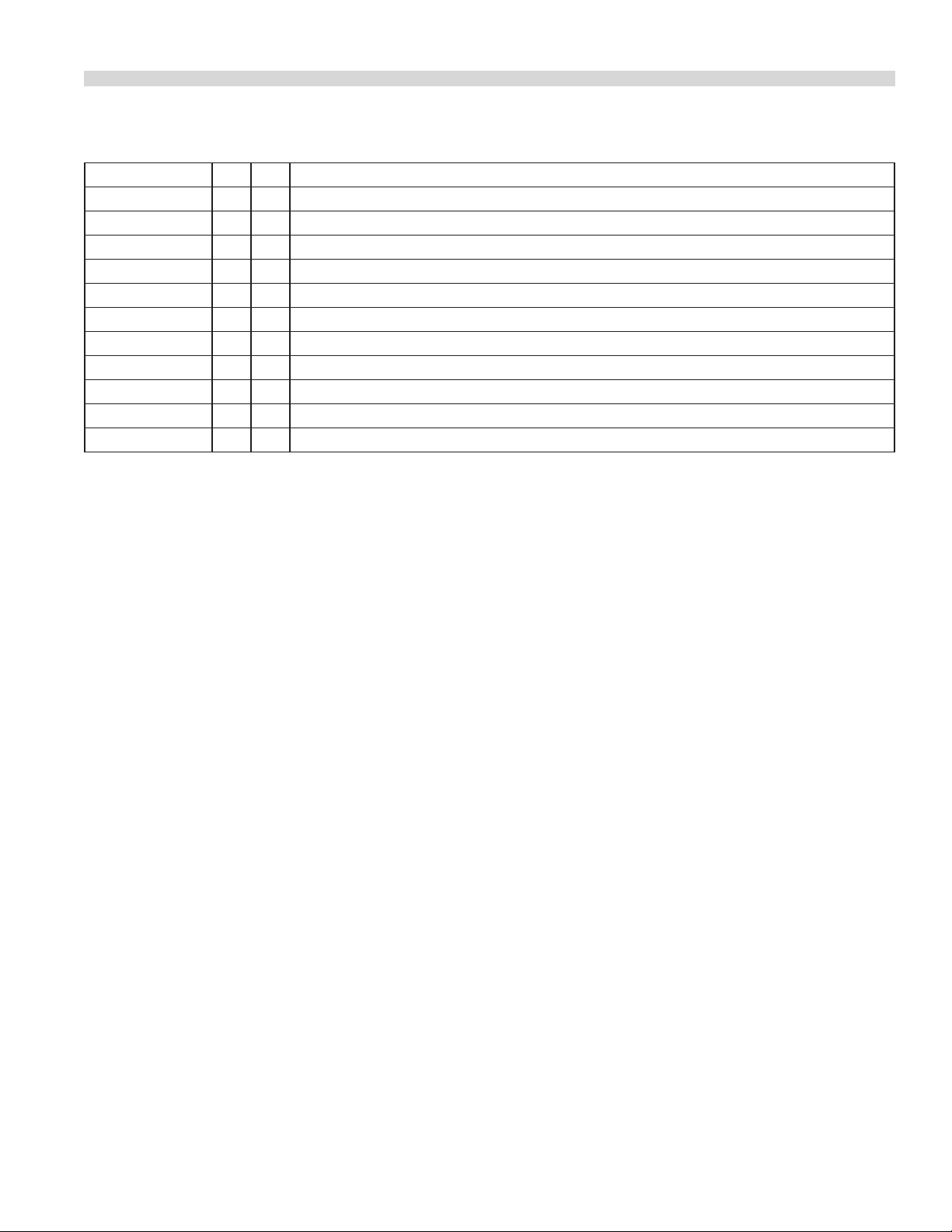

TECHNICAL SPECIFICATIONS continued

MODEL MM Ins DESCRIPTION

MST4S(E) 432 17 Range with storage base and two open top burners

MST4T(E) 432 17 Modular top with two open top burners

MST6S(E) 432 17 Range with 330 mm wide solid hot plate

MST6T(E) 432 17 Modular top with 330 mm wide solid hot plate

MST7S(E) 432 17 Range with 330 mm wide tap controlled griddle

MST7T(E) 432 17 Modular top with 330 mm wide tap controlled griddle

MST17B(E) 432 17 Char broiler

MST24BT(E) 610 24 Char broiler

MST34BT(E) 864 34 Char broiler

MST35 432 17 Deep fat fryer

MST70 610 24 Deep fat fryer

PREFIX DEFINITIONS: SUFFIX DEFINITIONS:

MST Master Sentry c/w total ame failure E Electric spark pilot ignition

B Broiler

T Modular top section

S Storage cabinet under top section

RC Range with convection oven

R Range with standard oven

Part # 4519069 (07/24/09) Page 5

Page 6

TECHNICAL SPECIFICATIONS continued

Table C: Exterior Dimensions

MODELS

MST42R(E) & RC(E) 952.5 37.5 863.6 34 965.2 38 235.9 520

MST42S(E) 952.5 37.5 863.6 34 965.2 38 222.3 490

MST42T(E) 317.5 12.5 863.6 34 965.2 38 99.8 220

MST43R(E) & RC(E) 882.6 34.75 863.6 34 965.2 38 213.2 470

MST43S(E) 882.6 34.75 863.6 34 965.2 38 158.8 350

MST43T(E) 247.6 9.75 863.6 34 965.2 38 99.8 220

MST44R(E) & RC(E) 882.6 34.75 863.6 34 965.2 38 231.4 510

MST44S(E) 882.6 34.75 863.6 34 965.2 38 176.9 390

MST44T(E) 247.6 9.75 863.6 34 965.2 38 108.9 240

MST45R(E) & RC(E) 869.9 34.25 863.6 34 965.2 38 254.1 560

MST45S(E) 369.9 34.25 863.6 34 965.2 38 199.6 440

MST45T(E) 234.9 9.25 863.6 34 965.2 38 136.1 300

MST46R(E) & RC(E) 869.9 34.25 863.6 34 965.2 38 240.5 530

MST46S(E) 869.9 34.25 863.6 34 965.2 38 186 410

MST46T(E) 234.9 9.25 863.6 34 965.2 38 115.7 255

MST47R(E) & RC(E) 952.5 37.5 863.6 34 965.2 38 242.7 535

MST47S(E) 952.5 37.5 863.6 34 965.2 38 188.2 415

MST47T(E) 317.5 12.5 863.6 34 965.2 38 117.9 260

MST54R(E) & RC(E) 882.6 34.75 863.6 34 965.2 38 235.9 520

MST54S(E) 882.6 34.75 863.6 34 965.2 38 181.5 400

MST54T(E) 247.6 9.75 863.6 34 965.2 38 122.5 270

MST4S(E) 882.6 34.75 431.8 17 965.2 38 95.3 210

MST4T(E) 317.5 12.5 431.8 17 965.2 38 59 130

MST6S(E) 882.6 34.75 431.8 17 965.2 38 99.8 220

MST6T(E) 234.9 9.25 431.8 17 965.2 38 54.5 120

MST7S(E) 952.5 37.5 431.8 17 965.2 38 113.5 250

MST7T(E) 317.5 12.5 431.8 17 965.2 38 61.3 135

MST17B 1092.2 43 431.8 17 965.2 38 100 220

MST24B 1092.2 43 609.6 24 965.2 38 149.7 330

MST34B 1092.2 43 863.6 34 965.2 38 231.4 510

MST35F 793.7 31.25 431.8 17 965.2 38 86.2 190

MST70F 793.7 31.25 609.6 24 965.2 38 120.2 265

HEIGHT WIDTH DEPTH WEIGHT

mm ins. mm ins. mm ins. kg lb

NOTE: Height dimensions are specied with 4 inch (101.6mm) legs. Add 2 inches (50.8mm) for 6 inch legs.

Part # 4519069 (07/24/09)Page 6

Page 7

TECHNICAL SPECIFICATIONS continued

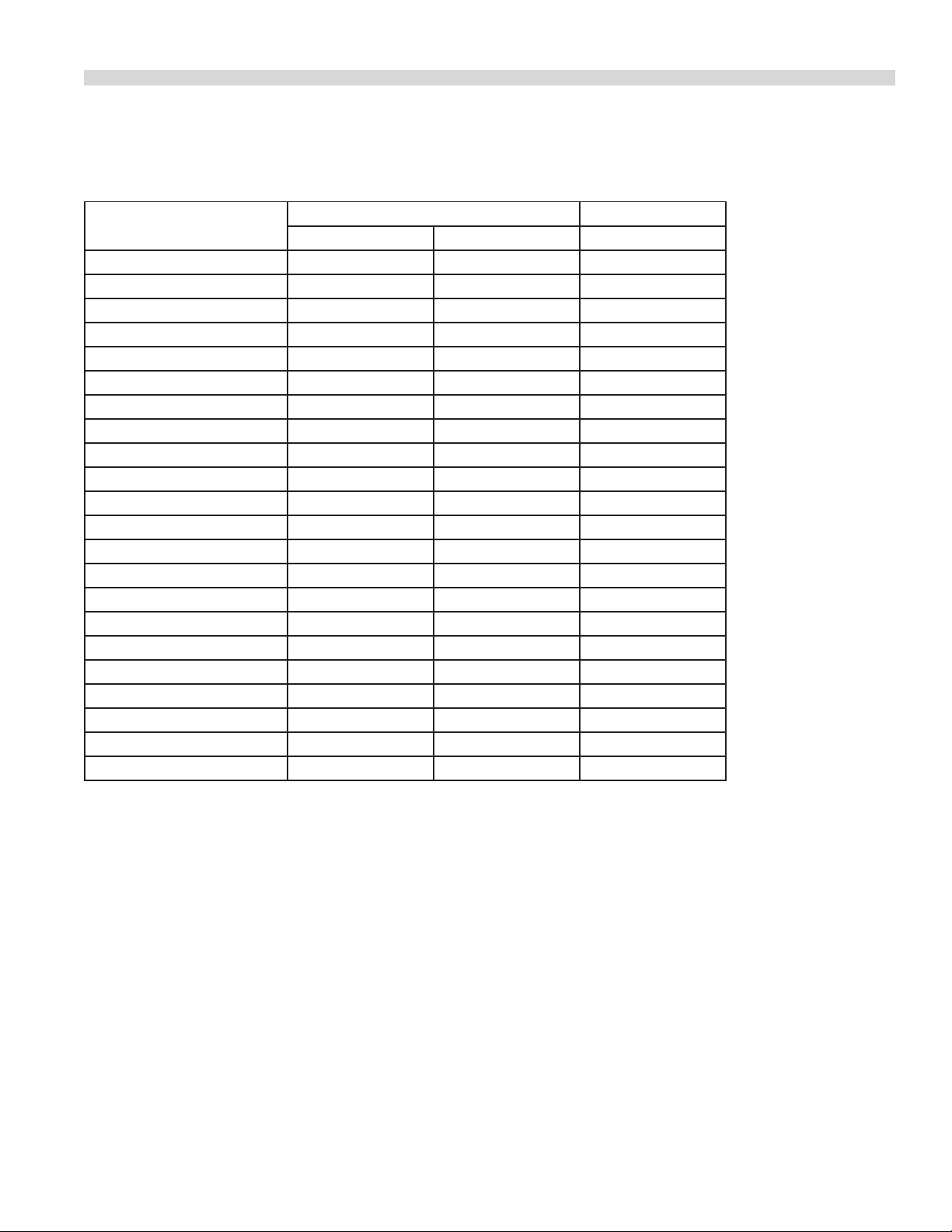

Table D: Gas Flow Rate (Net) Per Model

MODEL

MST42R(E) & RC(E) 2.99 3.47 2.24

MST42S(E) & T(E) 1.87 2.18 1.4

MST43R(E) & RC(E) 5.14 5.97 3.35

MST43S(E) & T(E) 4.02 4.68 2.51

MST44R(E) & RC(E) 4.47 5.19 3.35

MST44S(E) & T(E) 3.35 3.9 2.51

MST45R(E) & RC(E) 3.35 3.9 2.51

MST45S(E) & T(E) 2.24 2.6 1.68

MST46R(E) & RC(E) 3.38 3.93 2.54

MST46S(E) & T(E) 2.26 2.63 1.70

MST47R(E) & RC(E) 3.63 4.22 2.72

MST47S(E) & T(E) 2.51 2.92 1.89

MST54R(E) & RC(E) 3.21 3.73 2.41

MST54S(E) & T(E) 2.09 2.43 1.57

MST4S(E) & T(E) 1.12 1.30 0.84

MST6S(E) & T(E) 0.76 0.88 0.57

MST7S(E) & T(E) 0.76 0.88 0.57

MST17B(E) 1.26 1.46 0.94

MST24B(E) 1.67 1.95 1.26

MST34B(E) 2.51 2.92 1.89

MST35F 3.07 3.57 2.31

MST70F 3.49 4.06 2.62

2nd Family (m3/h) NET 3rd Family (kg/h)

G20 @ 20mbar G25 @ 25mbar G31 @ 37/50mbar

Part # 4519069 (07/24/09) Page 7

Page 8

TECHNICAL SPECIFICATIONS continued

Table E: Heat Input (Gross) Per Burner / Burner Group

2nd Family, Groups H,L & E 3rd Family, Group 3P

MODELS / SECTION

MST40(E) Oven 11.72 42.2 11.72 42.20

MST40RC(E) Oven 11.72 42.2 10.3 36.90

MST42(E) Open Top 5.86 21.1 5.86 21.10

MST42(E) Solid Top/Griddle 7.91 28.48 7.91 28.48

MST43(E) Open Top 7.03 25.32 5.86 21.10

MST44(E) Open Top 8.79 31.65 8.79 31.65

MST45(E) Solid Top 11.72 42.2 11.72 42.20

MST46(E) Solid Top 7.91 28.48 7.91 28.48

MST47(E) Griddle 8.79 31.65 8.79 31.65

MST54(E) Solid Top 10.25 36.92 10.25 36.92

MST54(E) Open Top 5.86 21.1 5.86 21.10

MST4(E) Open Top 5.86 21.1 5.86 21.10

MST6(E) Solid Top 7.91 28.48 7.91 28.48

MST7(E) Griddle 7.91 28.48 7.91 28.48

MST17B(E) Broiler 8.79/4.39 31.65/ 15.82 8.79/4.39 31.65/ 15.82

MST24B(E) Broiler 8.79 31.65 8.79 31.65

MST34B(E) Broiler 8.79 31.65 8.79 31.65

MST35F Fryer 32.23 116.04 32.23 116.04

MST70F Fryer 36.63 131.86 36.63 131.86

(G20/G25 @ 20/25 mbar) Nat Gas (G31 @ 37/50 mbar) Propane

Per burner / section Per burner / section

kW MJ/HR kW MJ/HR

Part # 4519069 (07/24/09)Page 8

Page 9

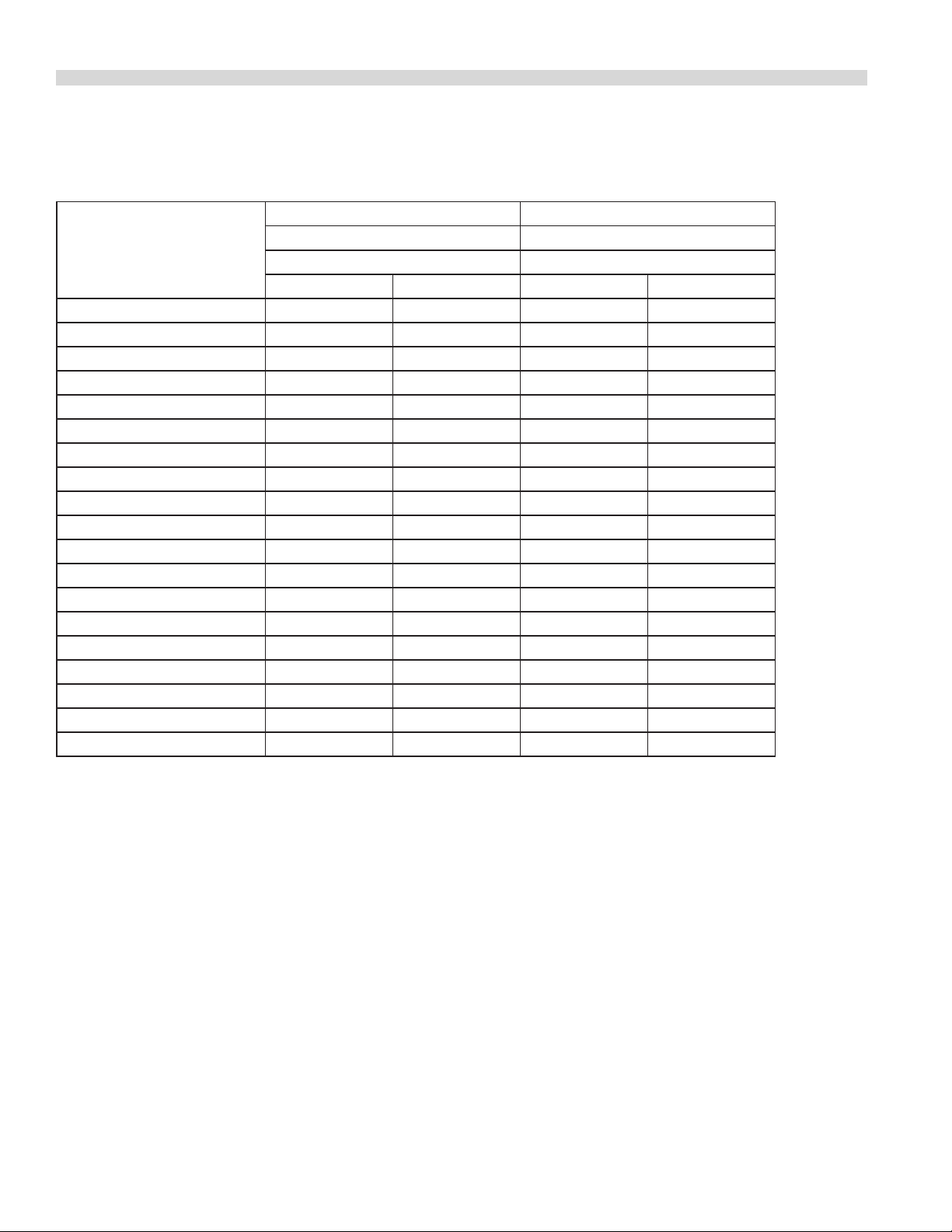

TECHNICAL SPECIFICATIONS continued

Table F: Pressure Setting / Injector Size

2nd Family, Groups H, L & E 3rd Family, Group 3P

Setting Pressure

MODEL/SECTION

MST42(R,RC,S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST43(R,RC,S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST44(R,RC,S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST45(R,RC,S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST46(R,RC,S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST47(R,RC,S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST54(R,RC,S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST4(S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST6(S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

MST7(S & T)(E) 20 8.0 25 10 – – 37/50 14.8/20 – – – –

G20 @ 20

mbar

mbar “WC mbar “WC DMS mm mbar “WC DMS mm DMS mm

G25 & 25

mbar

Injector Size

Setting Pressure Injector Size

G31 @ 37/50

mbar

37 mbar 50 mbar

MST40(E) Oven – – – – 31 2.65 – – 50 1.78 53 1.5

MST40RC(E) Oven – – – – 31 2.65 – – 50 1.6 53 1.5

MST42(E) Open Top – – – – – – – – – – – –

MST42(E)

Solid Top/Griddle

MST43(E) Open Top – – – – 1.9 1.9 – – 1.3 1.3 1.2 1.2

MST44(E) Open Top – – – – – – – – – – – –

MST45(E) Solid Top – – – – 1.4 1.4 – – 63 0.95 66 0.85

MST46(E) Solid Top – – – – 45 2.08 – – 1.4 1.4 1.25 1.2

MST47(E) Griddle – – – – 44 2.18 – – 53 1.51 1.35 1.3

MST54(E) Solid Top – – – – – – – – – – – –

MST54(E) Open Top – – – – – – – – – – – –

MST17B(E) Broiler 20 8.0 25 10 1.5 1.5 37/50 14.8/20 60 1.02 63 0.95

MST24B(E) Broiler 20 8.0 25 10 1.5 1.5 37/50 14.8/20 60 1.02 63 0.95

MST34B(E) Broiler 20 8.0 25 10 1.5 1.5 37/50 14.8/20 60 1.02 63 0.95

MST35F Fryer 10.5 4.2 N/A N/A 1.7 1.7 22.4 9.0 1.0 1.0 1.0 1.0

MST70F Fryer 10.5 4.2 N/A N/A 1.2 1.2 22.4 9.0 0.82 0.82 0.82 0.82

– – – – 45 2.08 – – 1.4 1.4 1.2 1.2

Part # 4519069 (07/24/09) Page 9

Page 10

TECHNICAL SPECIFICATIONS continued

Table G: Pressure Setting For Low Tap Position

2nd Family, Groups H, L & E 3rd Family, Group 3P

MODELS/SECTION

MST40(E) Oven 1.2 1.2

MST42(E) Hot ToP 2.0 3.0

MST42(E) Griddle 2.0 3.0

MST45(E) Hot Top 3.7 11.0

MST46(E) Hot Top 2.0 3.0

MST47(E) Griddle 2.0 3.0

MST54(E) Hot Top – –

MST6(E) Hot Top 2.0 3.0

MST7(E) Griddle 2.0 3.0

MST(17,24,34)(E) Broiler 2.0 7.0

G20/G25 @ 20/25 mbar

Natural Gas

mbar mbar

G31 @ 37/50 mbar

Propane

Table H: Aeration Shutter Setting / Pilot Flame Length

2nd Family, Groups H, L & E 3rd Family, Group 3P

SECTION

Oven 41.3 1.625 42.9 1.688 12.7 0.5

Open Burner 22.0 0.875 25.4 1.0 12.7 0.5

Griddle 25.4 1.0 26.9 1.062 12.7 0.5

Hot Top 25.4 1.0 19 0.75 12.7 0.5

Front Fired Hot Top 26.9 1.062 25.4 1.0 12.7 0.5

Broiler 25.4 1.0 25.4 1.0 12.7 0.5

Fryer N/A N/A N/A N/A 12.7 0.5

G20/G25 @ 20/25 mbar

Natural Gas

mm Ins. mm Ins. mm Ins.

G31 @ 37/50 mbar

Propane

Pilot Flame Length

Part # 4519069 (07/24/09)Page 10

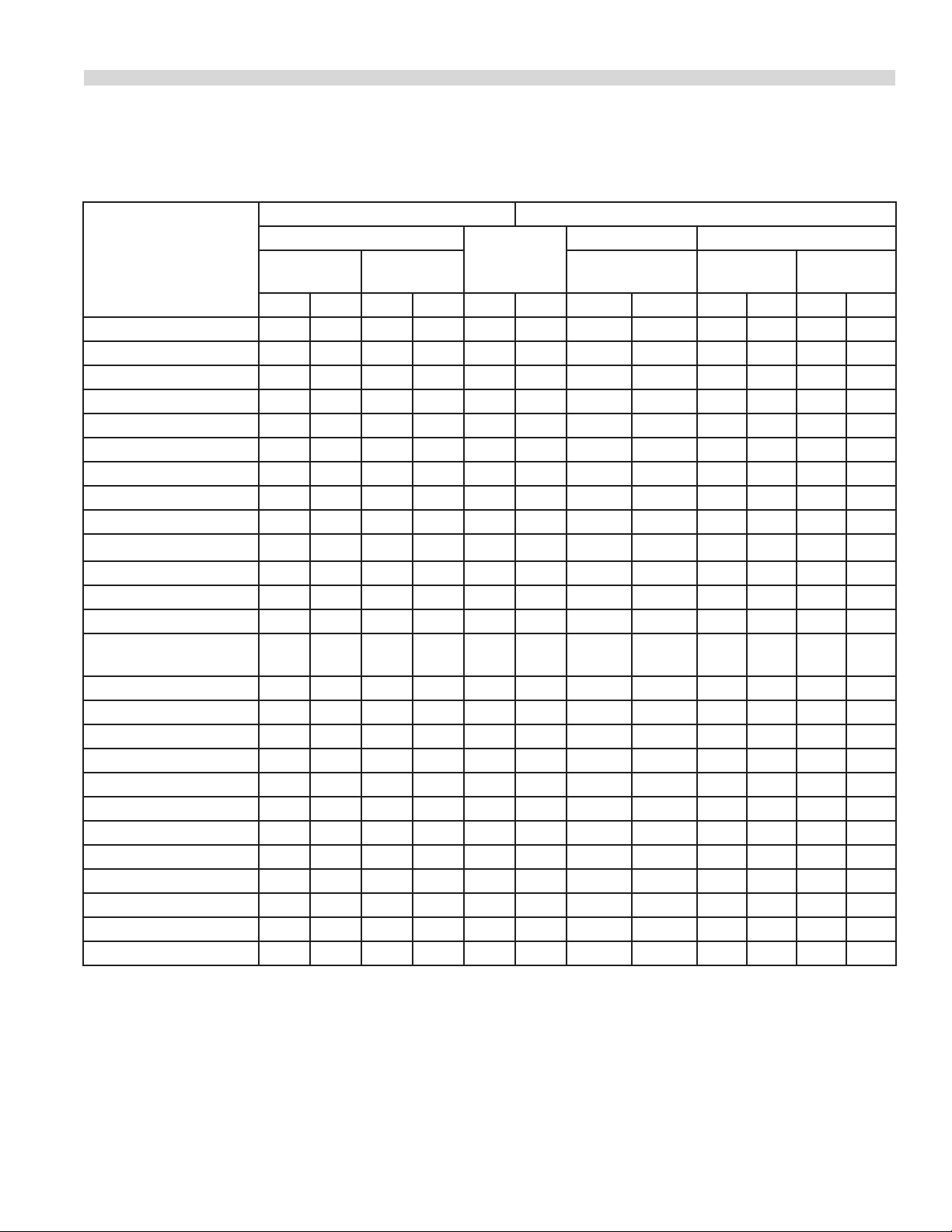

Page 11

TECHNICAL SPECIFICATIONS continued

Table I: Australia Only Nominal Gas Consumption & Injector Sizes

NATURAL GAS PROPANE GAS

MODEL/SECTION

Standard Oven 3.25 42.20 1.0 1.70 36.90 2.49

Convection Oven 3.20 36.90 1 1.70 36.90 2.49

MST43 Open Top 2.35 25.30 1 1.40 21.10 2.49

MST4, 44 Open Top 2.64 36.90 1 1.78 36.90 2.49

MST5, 45 Front Fired Hot Top 1.70 12.30 1 1.07 12.30 2.49

MST6, 46 Even Heat Hot Top 2.85 28.50 1 1.51 28.50 2.49

MST7, 47 Griddle 3.05 31.65 1 1.70 31.65 2.49

MST17,24,30,34B 1.90 33 1 1.15 33 2.49

Table J: Clearances

CLEARANCE FROM COMBUSTIBLE CONSTRUCTION

Model

MST43(R,RC,S,E) 280 11 152 6 Combustible

MST43T 280 11 152 6 Non-Combustible

MST45,5(R,RC,S,E) 150 6 152 6 Combustible

MST45,5(T,E) 150 6 152 6 Non-Combustible

MST42,44,46,47,54,4,6,7(R,RC,S,E) 356 14 152 6 Combustible

MST42,44,46,47,54,4,6,7(T,E) 356 14 152 6 Non-Combustible

MST17,24,34B – – – – Combustible

MST35,70F 152 6 152 6 Combustible

INJ.DIA

mm.

mm Ins. mm Ins.

MJ/H

Sides Rear Base

Gas Pressure

(kPa)

INJ.DIA

mm

MJ/H

Gas Pressure

(kPa)

CLEARANCE FROM NON-COMBUSTIBLE CONSTRUCTION

MODEL

All Models 0 0 0 0 Non-Combustible

Part # 4519069 (07/24/09) Page 11

Sides Rear Base

mm Ins. mm Ins.

Page 12

STATUTORY REGULATIONS

The installation of this appliance must be carried out by

a competent person and in accordance with the relevant

regulations, standards, codes of practice and the related

publications of the Country of destination.

INTRODUCTION

It is required by law that all gas appliances are installed by

competent persons in accordance with the LOCAL GAS

SAFETY REGULATIONS. Failure to install appliances correctly

can lead to prosecution. It is in your own interests and that of

safety to insure that there is compliance with the law.

We suggest installation, maintenance and repairs should be

performed by your local authorized service agency listed in

your information manual pamphlet.

The following instructions should be read carefully as the

manufacturer cannot be held responsible for any damage

to property, persons or animals caused by incorrect

installation or operation of the appliance.

Uncrating

Check crate for possible damage sustained during transit.

Carefully remove the unit from the crate and again check for

damage. Any damage to the appliance must be reported to

the carrier immediately.

AUSTRALIA SPECIFIC CLAUSE This appliance must be

installed in accordance with the manufacturers instructions,

local gas tting regulations and requirements of

AS 5601 / AG 601 installation code. All burner adjustments

and settings should be made by a qualied gas technician.

Rating Plate Location

Every cooking unit has a rating plate. All burner input ratings

are shown on the serial plate of each unit model the location

of the plate is indicated in Table A

Table A.

MODEL

WITH SUFFIX

R & RC Behind the lower kick panel

S & B

T On the front panel

Knowing the equipment model is essential if spare parts

are required or for discussing equipment problems with

Garland’s technical support sta. Table B lists the various

models of heavy duty Ranges, Broilers & Fryers in Garland’s

gas operated Master series.

In the storage cabinet on the left

LOCATION

hand side panel

In the event you have any questions concerning the

installation, use, care or service of the product, write or call

our Product Service Department.

This product has been certied as commercial cooking

equipment and must be installed by professional personnel

as specied.

Part # 4519069 (07/24/09)Page 12

Page 13

INTRODUCTION continued

Safety

If you smell gas

1. Turn o the appliance at the gas inlet cock and open all

doors and windows.

2. Do not operate any electrical switches and extinguish all

naked ames.

3. Contact the local gas authority immediately.

WARNING: do not store ammable materials in or near this

appliance.

Do not store or use gasoline or other ammable vapors and

liquids in the vicinity of this or any other appliance.

INSTALLATION

Do not spray aerosols in the vicinity of this appliance while it

is in operation.

Optional Extras

• Potrack

• Spreaderplate

• Commonfrontrail&backguard

• Endunit

• Casters

1. Carefully remove unit from carton. The wires or ties

retaining the burners and other packing material must be

removed from the unit. Any protective material covering

stainless steel parts must also be removed.

2. All equipment is shipped from the factory with legs

tted, unless otherwise specied. Where the range is to

be mounted on a dais or cove base, it is shipped without

legs. Legs must be tted to the oven where it is installed

on a combustible oor.

3. The back splash or optional pot rack is packed separately.

4. The type of gas and supply pressure that the equipment

was set up for at the factory is noted the data plate and

on the packaging. This type of gas supply must be used.

5. Do not remove permanently axed labels, warning or

data plates from the appliance, for this may void the

manufacturer’s warranty.

Gas Supply

The gas pipe connection is made at the left hand side or

right hand side of the equipment. The size of the pipe work

supplying the appliance must not be less than the inlet

connection, which is 1 1/4” NPT.

NOTE: a 3/4” NPT single unit optional connection must be

specied.

An isolating valve is recommended to be close to the

appliance to allow shutdown during an emergency or

routine servicing. After installation, be certain to check the

complete pipe work for leakage.

Electrical Supply

If 240V, the supply must be connected to the terminal block

termination located at the rear of the range for models with

suxes R, RC, or the front for models with suxes S or T.

For ease in attaching the supply line, there is a removable

cover. A qualied electrician should make the connection to

the mains in accordance with the applicable local codes

Part # 4519069 (07/24/09) Page 13

Page 14

COMMISSIONING

Testing & Adjustments

Fittings and pipe connections: Check all pipe ttings and

connections to the appliance for leaks. Use only approved

gas leak detectors or soap solutions to check tting and pipe

connections. DO NOT USE A FLAME.

1. Turn all valves and thermostats to the OFF position.

2. Turn on the main gas supply valve and light the top

section pilots.

3. Leak test the valves and ttings as described above, seal

any leaks found and re-check to make sure the leak is

sealed.

4. Light the oven pilot.

5. If the range is provided with an oven shut-o valve

separate from the thermostat, turn this valve ON and set

the thermostat at 250°C. Gas will now ow to the oven

burner.

6. Leak test all valves and ttings, seal leaks and re-test.

7. Shut OFF all range valves and set the thermostat dials to

the OFF position.

Pressure Settings (All Models Except Fryers)

1. Make sure all gas taps are in the OFF position and turn on

the main gas supply.

2. Light all pilots in accordance with the User’s Instructions.

Burner Adjustments

• Checkthattheairshutterissettotherequiredopening.

Refer to Table H

Figure 1 – Air Shutter

Fixing Screw

Required Length

of Opening

Injector Location

Thermostat Bypass Adjustment - Oven

Figure 2 – Oven Thermostat

Indicator Mark

0

5

4

0

0

4

0

5

3

0

0

3

0

5

2

By-pass Flame

Adjuster

Calibration

Lock Screws

5

0

0

5

5

0

1

5

0

3

0

0

Dial

Stop

Calibration

Plate

3. Connect a U-gauge manometer to the pressure test point

on the main manifold and turn all gas controls to the ON

or position.

4. Conrm that the pressure is the same as stated on the

rating plate.

Pressure Settings - Fryers

1. Connect a U-Gauge manometer to the pressure test point

at the end of the burner manifold and check that the

pressure setting is the same as stated on the rating plate.

2. If necessary, adjust the pressure using a screw driver to

turn the adjusting screw on the gas control. Turn the

control clockwise to increase pressure and counter.

With reference to Figure 2, the Robertshaw FDO snapthrottle thermostat requires a bypass adjustment. To adjust

the bypass, follow this procedure.

1. Turn the oven temperature control dial to 200°F (93°C)

then allow the oven to heat for 3 minutes.

2. Turn the oven control dial to the OFF position, then

slowly turn the oven temperature control dial counterclockwise until an audible click is heard.

3. Making sure not to disturb the oven temperature control

dial, turn the bypass ame adjusting screw and adjust the

bypass ame to the LOWEST POSSIBLE STABLE FLAME

COVERING THE ENTIRE PORTED AREA OF THE BURNER.

Turn the adjusting screw counter-clockwise to increase or

clockwise to decrease the size of the bypass ame.

Part # 4519069 (07/24/09)Page 14

Page 15

COMMISSIONING continued

Oven Thermostat Calibration

To check the calibration, follow this procedure:

A. Place the thermocouple of the test instrument or a

mercury thermometer in the center of the oven.

B. Turn the oven control dial to 400°F (202°C) to allow the

oven temperature to stabilize. Allow the oven to cycle

twice before taking a test reading.

C. Check the temperature reading when the control cuts

down to bypass. If the temperature does not read within

15°F (5°C) of the dial setting recalibrate as follows.

D. Remove the control dial, making sure not to disturb the

setting.

E. Hold the calibration plate and loosen the two calibration

lock screws until the plate can be rotated independently

of the control.

F. Turn the calibration plate until the temperature indicated

on the plate corresponds with the reading of a test

instrument. Hold the plate and tighten the screws rmly.

G. Repeat the temperature reading check when the control

cuts down to bypass to make sure the correct adjustment

has been made.

Open Type Hot Plate

Minimum ame setting:

To obtain the minimum ame setting:

1 Set the gas valve to the MIN position.

2. Turn the set screw clockwise to reduce the ame and

clockwise to increase it (see Figure 3).

3. The ame should be at the lowest stable ame across the

burner.

Figure 3 – Minimum Flame Setting

Pilot

Adjuster

Low Flame

Adjuster

Test Point

For MST models only

Front Fired Solid Top

Air shtter setting

Figure 4 – Minimum ame setting

A/S setting:

1. Check that the air shutters are set at the required opening

(see Figure 1).

2. Adjust the setting as necessary.

Solid Top/Griddle

A/S setting:

• Checktomakesurethattheairshutterissettogivethe

required opening. Adjust as necessary (see Figure 1).

Refer to Table H

Aeration Shutter

Opening

To obtain the minimum ame setting:

1. Set the gas valve to the MIN position.

2. Using a screwdriver, turn the adjuster on the valve body

clockwise to reduce ame and counter-clockwise to

increase it.

3. Adjust to achieve the minimum stable ame on the

ported area of the burner.

Part # 4519069 (07/24/09) Page 15

Page 16

COMMISSIONING continued

Figure 5 – Minimum Flame Setting

Gas Inlet

Pilot Adjuster Screw

For MST models only

Pilot Gas

Outlet

Min. Flame

Adjusting Screw

Gas Outlet

Broiler Burner

To obtain the minimum ame setting:

1. Set the gas tap to the low ON position.

2. Using a screwdriver, turn the adjuster on the tap body

clockwise to reduce pressure and counter-clockwise to

increase it.

3. Adjust to achieve the minimum stable ame on burner.

The correct briquette arrangement is shown in Figure 6

following.

Figure 6 – Briquette Pattern

Open Burners

1. Light the pilot light in accordance with the User’s

Instructions.

2. Check that the length of the ame is correctly at 7-12mm

and adjust as necessary.

Figure 7 – Minimum Flame Setting

Pilot

Adjuster

Low Flame

Adjuster

Test Point

For the MST models only

Oven

1. Open the lower kick panel.

2. Remove the oven base plate (on R models).

3. Light the pilot light in accordance with the User’s

Instructions.

4. Check that the length of the pilot light is 12mm.

Steel bars

7 Rows

Top view (less main top)

Arrangement

of briquettes

as illustrated

Front

Figure 8 – Minimum Flame Setting

Pilot Adjuster

For pilot light only

Part # 4519069 (07/24/09)Page 16

Page 17

COMMISSIONING continued

Solid Hot Plate/Griddle

1. Light the pilot light in accordance with the User’s

Instructions.

2. Check that the length of the ame is 12mm and adjust as

necessary (see Figure 7).

Front Fired Hot Top

1. Light the pilot light in accordance with the User’s

Instructions.

2. Check that the length of the ame is 12mm and adjust as

necessary (see Figure 5).

Broiler

1. Light the pilot light in accordance with the User’s

Instructions.

2. Check that the length of the ame is 12mm and adjust as

necessary (see Figure 7).

Fryer

1 Light the pilot light in accordance with the User’s

Instructions.

2. Check that the length of the ame is 12mm and adjust as

necessary.

When all the settings have been checked:

1. Remove the U-gauge manometer, replace the pressure

test point screw, the valve panel, oven base plate and the

lower kick panel.

2. Tell the user the location of the gas isolation cock for use

in an emergency.

3. Instruct the owner or user of the equipment in the

ecient and safe operation of the appliance.

OPERATION

This section deals with equipment operating instructions.

To nd the operating instructions for a particular piece of

equipment, consult the Table of contents.

Open Top Burners (MST Models)

1 Push in the gas valve and turn it counter-clockwise to the

ignition position.

2. Holding the valve fully in, light the pilot burner.

3. When the pilot burner is lit, continue holding the valve

fully in for 20 seconds, then release it. If the pilot goes out,

wait for ve minutes, then repeat the start procedure.

4. When the pilot is established, push the valve in again and

turn it counter-clockwise to the desired ame setting.

5. To shut o the burner, turn the dial to the ‘0’ position and

the safety device will disengage within 60 seconds.

Hot Top And Spectro-top Sections

(MST Models)

1 Push in the valve and turn it counter-clockwise to the

IGNITION position.

2. Holding the valve fully in, light the pilot burner.

3. When the pilot burner is lit, continue holding the valve

fully in for 20 seconds, then release it. If the pilot goes out,

wait for ve minutes, then repeat the start procedure.

4. When the pilot is established, push the valve in again and

turn it counter-clockwise to the desired ame setting.

5. To shut o the burner, turn the dial to the ‘0’ position and

the safety device will disengage within 60 seconds.

Part # 4519069 (07/24/09) Page 17

Page 18

OPERATION continued

Standard Ovens

1. Push in the main/pilot gas valve and turn it counterclockwise to the IGNITION position.

2. Lower the front kick panel.

3. Holding the oven gas valve fully in, press the red piezo

igniter button several times.

4. When the pilot burner is lit, continue holding down the

oven gas valve for 20 seconds, then release it. If the pilot

goes out, wait for ve minutes and try again.

5. When the pilot light is established, push the gas valve

in again and turn it counter-clockwise to the full

ON position, then set the thermostat to the desired

temperature.

Shut Down:

1. Turn all valves to the OFF position and the safety device

will disengage within 60 seconds.

2. If the unit is to be shut down for an extended time, close

the in-line gas valve.

RC Convection Ovens

Power failure: In the event of an electrical power failure, do

not operate this oven. It is gas operated, but has electrical

features, motor and door switches. A wiring diagram is

attached to the rear of the appliance.

Start Up:

1. Turn the power switch to the COOK position.

2. Turn the gas oven valve to ON.

3. Turn the thermostat to the designed setting.

Cool Down:

1. Turn the thermostat and oven valve OFF.

2. Return the power switch to OFF.

3. Turn the oven valve OFF.

Motor Care:

The motor on a convection oven is equipped with sealed,

self-lubricating ball bearings and is maintenance free. It will

give durable service when treated with ordinary care. Here

are some operating notes.

1. When the motor is operating, it is cooled internally by

air entering the rear of the motor case, provided proper

clearance has been allowed. Ensure that rear of range has

minimum 25 mm clearance around perimeter.

2. Because the blower wheel is in the oven cavity it is at the

same temperature as the oven. If the motor is stopped

while the oven is hot, heat from the blower wheel is

conducted by the shaft to the motor armature. This can

dramatically shorten motor life.

3. It is recommended that, at the end of the bake or roasting

period when the oven may be idle or ready for shutdown the oven door be left open. Use the COOL-DOWN

position on the fan switch, which keeps the fan operating

for at least 20 minutes.

CAUTION: Never turn the fan OFF when the oven is HOT.

Char-Broiler (MST Models)

1. Raise or remove the cooking grates. Every group of two

burners has one pilot centrally located between them.

2. Push in the gas valve and turn it counter-clockwise to the

Ignition position.

3. Holding the oven gas valve fully in, depress the red piezo

igniter button behind the lower drop-down panel.

4. When the igniter is lit, continue holding down the oven

gas valve for 20 seconds, then release it. If the pilot goes

out, wait for ve minutes and try again.

2. Open the oven door.

3. Turn the power switch to the COOK DOWN position.

Shut Down:

1. Turn the thermostat OFF.

5. When the pilot light is established, push the gas valve

in again and turn it counter-clockwise to the full

ON position, then set the thermostat to the desired

temperature.

Part # 4519069 (07/24/09)Page 18

Page 19

OPERATION continued

Shut Down:

1. Turn all valves to the OFF position by rotating the knob

clockwise 6 mm (1/4”) turn.

2 If the unit is to be shut down for an extended time, close

the in-line gas valve.

NOTE: Sux E models are equipped with an electric spark

ignition module for pilot burner ignition. Pushing the spark

button will ignite all pilot burners simultaneously.

Assembly Of Char-Broiler:

The broiler is supplied with 5/8” (16 mm) diameter steel

rods to support the briquettes. The rods are installed in the

grooves in the support bracket atop the main burners. If it

is necessary to disassemble or replace damaged briquettes,

follow the arrangement shown in Figure 9.

Figure 9– Briquette Pattern

Steel bars

Top view (less main top)

7 Rows

Arrangement

of briquettes

as illustrated

Front

MAINTENANCE AND CLEANING

Proper maintenance, cleaning and care of cooking

equipment is an important part of any program and will keep

it in good operating condition. These notes provide a code

of good practice for users to maintain a regular cleaning

schedule

Seasoning

Griddles

1. Remove any factory applied protective material by

washing with hot water and a mild detergent or soap

solution.

2. Apply a thin coat of cooking oil to the griddle surface in

the proportion of about one ounce per square foot of

surface area. Spread this over the entire surface with a

cloth to create a thin lm. Wipe o any excess oil with a

cloth.

3. Light the burners and set them at the lowest setting.

Some discoloring will occur when heat is applied to the

steel.

4. Heat the griddle slowly for 15 to 20 minutes. Then wipe

away the oil. Repeat this procedure three times or until

the griddle has a slick, mirror-like nish. Continue doing

this until the desired cooking temperature is reached.

CAUTION

Do not go to HIGH (on valve control) or 230°C (on thermostat

control) during the seasoning period. If it is seasoned

properly, the griddle will not require re-seasoning. If,

however, the griddle is overheated and product begins

to stick to the surface, it may be necessary to repeat the

seasoning process.

Part # 4519069 (07/24/09) Page 19

Page 20

MAINTENANCE AND CLEANING continued

Cast Iron Top Grates And Ring Grates

1 Move the grates from the range and wash them in warm

water with mild soap. Then dry them with a clean cloth.

2. Immediately after drying, season the grates lightly with a

non-toxic oil (a light vegetable oil, liquid or spray).

WARNING: Do not season top grates while they are still on

the range top. A ash re may result.

3. After seasoning, replace the top grates on the range and

operate all the range top sections on LOW.

4. Allow the sections to operate for 20 minutes before using

pots and pans on them.

CAUTION: To grates required seasoning whenever they

have been cleaned. Failure to season them after cleaning will

cause rusting.

Cleaning

Raw Steel Finishes:

Some parts of cooking ranges use steel with untreated

surface nish (i.e., hot tops, griddles, springs, doors etc.).

These parts can react with moisture and rust or corrode. This

is normal and not considered a factory defect.

2. Use a paste of water and mild scouring powder if

necessary, but always with the grain, not against it.

Stainless steel is polished in one direction, so clean in

the same direction as the grain to preserve the nish.

Thoroughly rinse and dry with a soft cloth.

3. To avoid the appearance of ngerprints, several stainless

steel polishes are commercially available that leave an

oily or waxy lm. Do not use them on surfaces that will be

in contact with food.

4. Stainless steel may discolor if overheated. These stains

may be removed by vigorous rubbing with a scouring

powder paste or Scotchbrite pad.

CAUTION: Use only stainless steel, wooden or plastic tools

only if it is necessary to scrape o heavy deposits of food and

oil. On no account use ordinary steel scrapers or knives for

this purpose as iron particles may become imbedded in the

stainless steel and lead to corrosion. Never use steel wool on

stainless steel surfaces. It destroys the nish. Hot water or a

mild solution of bleach will sanitize stainless steel without ill

eect.

Oven Interiors (Porcelain Enamel):

WARNING: Before cleaning the inside surface of a range,

unplug the power supply.

• Wipeawayspillsimmediately.

Painted Finishes:

1. Wipe away spills immediately.

2. Allow equipment to cool before cleaning exterior

surfaces. Wipe exposed, cleanable surfaces with a

mild detergent and hot water when the surfaces have

cooled, not before. Remove stubborn residue spots with

a lightweight non-metallic scouring pad and dry the

surface thoroughly with a clean cloth.

Stainless Steel Finishes:

1. For routine cleaning, use hot water and a mild detergent.

Wash a small area at a time. Tackling a large area allows

water to evaporate, leaving chemicals that lead to

streaking. Rinse the washed area with a clean sponge

dipped in a sanitizer, and wipe it dry with a soft cloth

before it can dry by evaporation.

1. Before cleaning an oven interior, remove the racks and

guides. Clean the oven racks and guides with a mild soap

and warm water solution, or pass them through a dish

washer.

2. Clean the porcelain enamel surface daily, using a soap

solution. At least once a week clean the oven thoroughly

with a detergent or any commercial oven cleaner

recommended for use with porcelain enamel, but only

when the oven is cold.

Griddles

CAUTION: Do not use water on griddle tops while they are

hot. Do not try to cool a griddle with ice. This will warp the

plate and may cause it to crack.

To maintain evenly cooked, perfectly browned griddle

products, keep the griddle free from carbonized grease.

Carbonized grease hinders the transfer of heat from the

griddle surface to the food product. This results in uneven

browning and loss of cooking eciency. Carbonized

grease also clings to griddle foods, giving them a highly

unsatisfactory and unappetizing appearance. To keep a

griddle clean and maintain it at peak operating performance,

follow this procedure.

Part # 4519069 (07/24/09)Page 20

Page 21

MAINTENANCE AND CLEANING continued

1. After each use, clean the surface thoroughly with a grill

scraper or spatula. Wipe o debris left over from the

cooking process.

2. Daily: Clean the surface with a grill brick or pad. Remove,

empty and clean the grease container thoroughly.

3. Weekly: Clean the surface well with a grill brick or pad.

Rub with the grain of the metal while it is still warm. A

detergent may be used on the plate surface to help clean

it, but make sure it is removed. After cleaning, cover the

surface with a thin lm of oil to prevent rusting.

4. Use a non-abrasive cleaner to remove discoloration.

Before using the griddle again it must be re-seasoned. On

models without a side grease container, keep the griddle

drain tube to the grease container clear.

CAUTION: The griddle plate is steel, but the surface is

relatively soft and can be easily scored and dented by the

careless use of a spatula. Dents, scratches and gouges in the

surface will cause food to stick.

Open Top Burners

1. Periodically, remove burners and clean them with soap

and hot water.

2. Soak the burner in a bucket of hot soapy water and brush

o any burnt-on grease or debris. Make sure the burner is

thoroughly dry before re-installing it on the range.

3. If the burner ports are blocked or plugged with grease,

clear them with a wire brush or pointed instrument.

Cast Iron Top Grates And Ring Grates

1. Clean with hot water and a mild detergent. Use a wire

brush to remove baked-on food particles.

2. Lightly coat with vegetable oil to help prevent rusting.

CAUTION: To grates required seasoning whenever they

have been cleaned. Failure to season them after cleaning will

cause rusting.

Cast Iron Even Heat Hot Tops And

Spectro-Heat Tops

CAUTION: Do not use water on tops while they are hot, or

use ice to cool them.

1. While the surface is still slightly warm, wipe it with a clean

burlap cloth. Scrape o the burnt-on spillage.

2. Remove the plate and wash it with soap and hot water.

Dry it and apply a thin coating of oil to inhibit rusting.

Excessive use of water could damage the surface and the

controls below.

NOTE: The surface of Cast Iron Hot Tops and Spectro-Heat

Tops will tone (a blue-brown discoloration) from heat. This

does not diminish the cooking operation and is not a defect

Adjustments

Top and Oven Orices

Top and oven orices are xed and cannot be adjusted. A

proper rate is attained if the gas supply pressure is correct.

Use the 1/8” NPT manifold pressure tap to check the pressure.

A well-adjusted air shutter will provide for a distinct blue

ame over the entire port area of the burners when they are

operating at full rate.

Pilot Adjustment

Individual pilot adjustment valves are mounted on the range

top manifold.

1. Adjust the open burner pilot so that the tip of the ame

reaches the middle of a ash tube opening. This ame

may show a slight yellow tip, particularly when used on

propane gas.

2. The pilot burner for the griddle or top burner should

proved rapid ignition of the burner, but should not

impinge on any part of the burner. When correctly

adjusted, it should not lift o the burner nor show a

yellow tip.

Burner Gas/Air Adjustments

Ideal ames vary depending on the type of burner

considered., although a sharp blue blame at full rate is

typical.

To adjust burners, proceed as follows:

1. On the burner (star, Griddle, knuckle, broiler, oven burners)

locate the air shutter. This found at the inlet to the burner

venturi.

2. Loosen the lock-nut so that the air shutter turns freely.

3. If required, re-install the burner, turn on the gas ow and

ignite the burner.

Part # 4519069 (07/24/09) Page 21

Page 22

MAINTENANCE AND CLEANING continued

4. Rotate the air shutter to obtain the following:

a. Open (star) burner – 12 mm stable, sharp inner blue

cones.

b. Hot tops, griddles – 8 mm stable, sharp inner blue

cones.

c. Knuckle burners – 8 mm stable, blue ame.

d. Charbroiler burners – 12 mm stable, blue ame.

5. If the burner ames are sharp and lift o the burner ports,

reduce the primary air by closing the air shutter.

6. If the burner ames are lazy and yellow in appearance,

increase primary air by opening the shutter.

7. If poor burner performance persists, check for proper gas

pressure.

CONVECTION OVEN (RC) – OPERATING TIPS

The following notes are a guide for the use of convection

ovens.

1. Set oven temperatures 5°C to 10°C lower than recipes

specify for the use of standard ovens. The cooking time

may also be less, depending on the product, but two

to ve per cent less cooking time is a general rule. This

needs to be checked for rst time.

2. Cooking time and oven temperate will vary depending

on the size of the load, the temperature of the product,

mixture of the recipe and, in particular, the moisture

content of the product.

8. Never place pans directly on to the oven bottom. Always

use the lowest rack position which allows the air to

circulate within the over cavity.

9. Load and unload food as quickly as possible to prevent

an excessive drop in temperature.

10. Avoid the use of warped pans because level pans bake

more evenly.

11. Do not use a deep pan for shallow cakes, cookies, etc., as

circulation across the surface is essential for even cooking

and browning.

3. When a satisfactory cooking time and temperature for a

particular product is established, make a record for future

use.

4. Preheat the oven before use. To reach 175°C takes about

15 minutes. For the best results, pre-heat the oven for 30

minutes to allow for thorough heat saturation.

6. Set the product in the center of the oven for the best heat

circulation.

7. A convection oven will hold three 450mm x 660mm sheet

pans, six 305mm x 500mm x 63mm steam table pans or

one 530mm x 450mm x 175mm roast pan with cover.

12. To prevent excessive shrinkage, roast meats at a low

temperature: 120°C to 160°C.

13. When re-thermalizing frozen products, pre-heat the

oven 10°C higher than the cooking temperature to

compensate for heat loss during and after loading.

NOTE: The thermostat must be returned to the cooking

temperature after loading.

14. To conserve energy, turn the oven o and allow it to cool

down when not in use.

Part # 4519069 (07/24/09)Page 22

Page 23

SERVICING

Regular maintenance and servicing by competent and

qualied personnel is recommended for the continued safe

and ecient operation of cooking equipment.

WARNING: Before working on any appliance, SHUT OFF the

gas supply at the main shut-o valve and electrical supply

at the main disconnect. On completion of any servicing

work, test for gas leaks before returning the equipment into

service.

Cleaning/Servicing Burners

Open-type Burners

1 Lift and remove the pan supports and hot plate top

section.

2. Lift the front burner to disengage the locating peg and

slide it backwards o the orice.

3. Remove the rear burner in the same manner.

4. Clean the burners in hot soapy water with a sti

scrubbing brush.

5. Rinse the burners and shake them well to removed the

water.

6. Make sure the gas ports are free of debris. Clear ports of

debris if necessary.

7. Reassemble the units in reverse order.

Front Fired Solid Top Burners

1. Remove the key plates from the top of the range.

Solid Hot Plate/Griddle Burners

1 Lift o the griddle or solid plates as applicable.

2. Lift the rear of the burner and slide it backwards o the

orice.

3. Clean the burners in hot soapy water with a sti

scrubbing brush.

4. Rinse the burners and shake them well to remove the

water.

5. Make sure the ports are free of debris. Clear ports of

debris if necessary.

6 Reassemble the burners in reverse order.

Oven Burners – Models With Sux R

1. Remove the oven base plate.

2. Remove the two screws that secure the front air shield in

place and lift out.

3. Slide the burner towards the rear, o the orice tting,

and remove from oven.

4. Clean the burner in hot soapy water with a sti scrubbing

brush.

5. Rinse the burner and shake them well to remove the

water.

6. Make sure the ports are free of debris. Clear ports of

debris if necessary.

2. Lift the burner to disengage the locating peg and slide it

backwards o the orice.

3. Clean the burners in hot soapy water with a sti

scrubbing brush.

4. Rinse the burners and shake them well to remove the

water.

5. Make sure the ports are free of debris. Clear ports of

debris if necessary.

6. Reassemble the burners in reverse order.

Part # 4519069 (07/24/09) Page 23

7. Reassemble the unit in reverse order.

Oven Burners – Models With Sux RC

1. Open the lower kick panel.

2. Remove the left hand oven door spring.

CAUTION: The oven door may need additional support to

remain closed.

3. Remove the left hand front radiation shield.

4. Remove the two screws that secure the front air shield in

place and lift it out.

Page 24

SERVICING continued

5. Slide the burner to the rear and o the orice. Then slide

it to the left and remove it from the combustion chamber.

6. Clean the burner in hot soapy water with a sti scrubbing

brush.

7. Rinse the burner and shake it well to remove the water.

8. Make sure the ports are free of debris. Clear ports of

debris if necessary.

9. Reassemble the unit in reverse order.

Broiler

1. Remove the top plates.

2. Remove the briquettes.

3. Remove the front pilot drip shield and the briquette

support rods.

4. Lift the rear of the burner and slide it to the rear and o

the orice.

5. Clean the burners in hot soapy water with a sti

scrubbing brush.

Oven

1. Open the drop-down lower kick panel.

2. On all models but RC units, remove the oven base plate.

(To deal with RC models, follow the procedure specied

for the burner cleaning instructions.

3. Remove the two screws securing the front air shield and

remove it from the oven.

4. Disconnect the pilot gas supply pipe.

5. Remove the pilot burner from the pilot burner.

6. Clean the pilot burner by blowing through it or washing

it in water.

CAUTION: Do not use wire to clear the pilot burner. It might

damage the unit.

7. Reassemble the unit in reverse order.

Fryer

1. Open the compartment door and disconnect the pilot

gas supply pipe from the combination gas valve.

6. Rinse the burners and shake them well to remove the

water.

7. Make sure the ports are free of debris. Clear ports of

debris if necessary.

8. Reassemble the unit in reverse order.

Pilot Burner Cleaning

Hot Plate/Solid Top/Griddle/Broiler

1. Remove the main burners. Refer to the appropriate

section on burner cleaning.

2. Disconnect the pilot gas supply pipe from the pilot

burner.

3. Remove the pilot burner.

4. Clean the pilot burner by blowing through it or washing it.

CAUTION: Do not use wire to clear the pilot burner. It might

damage the unit.

5. Reassemble the pilot burner in reverse order.

2. Remove the screws that fasten the pilot to the mounting

bracket and remove the pilot burner.

3 Remove the pilot burner from the pilot burner.

4. Clean the burner by blowing through it or washing it in

water.

CAUTION: Do not use wire to clear the pilot burner. It might

damage the unit.

5. Reassemble the unit in reverse order.

Thermostat Calibration

Oven

CAUTION: Remember to check the bypass every time

the oven is recalibrated (refer to the entry on Thermostat

bypass).

Recalibration of the oven thermostat is seldom necessary

and should not be attempted unless the cooking results

denitely prove that the thermostat is not maintaining

the temperatures to which the dial is set. Use a reliable

temperature indicator when checking the oven temperature.

To calibrate an oven thermostat, follow this procedure.

Part # 4519069 (07/24/09)Page 24

Page 25

SERVICING continued

1. Place the thermocouple of the test instrument in the

center of the oven.

2. Light the oven, set the thermostat to 400°F (204°C) and

wait 15 minutes for the oven temperature to stabilize.

3. Check the temperature at 5 minute intervals until three

successive readings are within ±5°F (±3°C) of each other.

4. If the temperature is not within ±20°F (±8°C) of the

thermostat dial setting, refer to Figure 10 to recalibrate

using this procedure.

Figure 10 – Oven thermostat

Indicator Mark

0

5

4

0

0

4

0

5

3

0

0

3

0

5

2

By-pass Flame

Adjuster

Calibration

Lock Screws

5

0

0

5

5

0

1

5

0

3

0

0

Dial

Stop

Calibration

Plate

6. Remove the thermostat dial, making sure not to disturb

the setting.

7. Hold the calibration plate and loosen the two calibration

locking screws.

8. Turn the calibration plate counter – clockwise to increase

the oven temperature or clockwise to decrease it.

NOTE: One division of the calibration plate is equal to 25°F

(14°C).

9. Hold the plate and tighten the screws.

10. Replace the thermostat dial.

11. Recheck the calibration as specied in this procedure to

conrm that the correct adjustment has been made.

Fryer

The same observation made about oven thermostats applies

to fryers. That is, recalibration of the thermostat is seldom

necessary. If experience with the cooking results proves that

the temperature at which the dial is set is incorrect, follow

this procedure to re-calibrate the thermostat. Use a reliable

thermometer only or, preferably, a pyrometer.

1. Suspend the thermometer or thermocouple in the

middle of the fry tank about 2” (76mm) below top level of

oil.

2. Allow the burner to cycle four times.

3. When the burner cycles OFF after the fourth cycle,

compare the reading of the thermometer or

thermocouple with the thermostat setting.

4 If the two readings are not within ±5°F (±3°C) of one

another, loosen the two set screws in the thermostat

knob and set the pointer of the thermostat to agree with

the reading of the test thermometer or thermocouple.

5. Tighten the set screws on the thermostat knob after

resetting the pointer.

Part # 4519069 (07/24/09) Page 25

Page 26

REPLACEMENT OF PARTS

For replacement parts, users and service personnel are

referred to Garland’s Master Series Heavy-duty Ranges and

Attachments parts list. This section of the service manual

deals only with the replacement of parts on heavy duty

cooking equipment.

WARNING: Before servicing any cooking appliance be

certain to SHUT OFF the gas supply at the shut-o valve and

the electrical supply at the main disconnect. On completion

of any servicing work, test for gas leaks before returning the

equipment into service. Regarding electrical work, always

shut o the electrical supply at the mains and secure the

breaker of panel with a lock before doing electrical work. Do

not service electrical equipment until the power is securely

locked o.

Gas Taps

1. Remove the knob of each gas valve and thermostat on

the unit.

2. Remove the two securing screws on the valve panel and

remove it.

3. Disconnect the thermocouple connection at the gas

valve (MST units only).

7. Disconnect the oven gas supply pipe from the outlet of

the thermostat.

8. Release the thermostat sensor retraining clips from the

oven lining and the sensor from the clips.

9. Withdraw the thermostat sensor from the oven

compartment.

10. Fit the replacement thermostat and reassemble the unit

in reverse order.

Pilot/Thermocouple/

Spark Electrode

Hot Plate (MST Only)

1. Remove the burners using the procedure given in the

previous section on burner cleaning.

2. Remove the screws securing the valve panel and remove

the panel.

3. Disconnect the thermocouple connection at the gas

valve.

4. Disconnect the pilot tube connection at the gas valve.

4. Disconnect the pressure tting at the main manifold to

the inlet of the gas valve and remove it.

5. Fit a replacement gas valve.

6. Reassemble the unit in reverse order.

Oven Thermostat

1. Remove the knob of each gas valve and thermostat on

the range.

2. Removed the two securing screws on the valve panel and

remove it.

3 Disconnect the thermocouple connection at the oven gas

valve outlet.

4. Open the lower front panel and remove the right hand

corner column from the range.

5. Remove the two thermostat mounting screws and pull

the thermostat and tubing forward to gain access to

the rear of the thermostat where the inlet and outlet

connections are to be found.

6. Disconnect the pipe work between the oven gas valve

and the thermostat.

5. Remove the screws that secure the pilot burner mounting

bracket and remove the pilot burner, thermocouple or

spark electrode as the case may be.

6. Replace the faulty component and reassemble in reverse

order.

Griddle/Solid Top/Front-Fired Hot Top/Broiler

1. Remove the burners using the procedure given in the

previous section on burner cleaning.

2. Remove the screws securing the fascia panel and remove

the panel.

3. Disconnect the thermocouple connection at the gas

valve.

4 Disconnect the pilot tube connection at the gas valve or

thermostat (MST only).

5. Remove the screws that secure the pilot mounting

bracket to the insert box and remove the pilot.

6. Replace the faulty component and reassemble the unit in

reverse order.

Part # 4519069 (07/24/09)Page 26

Page 27

REPLACEMENT OF PARTS continued

Oven

1. Remove the screws securing the valve panel and remove

the panel.

2. Disconnect the thermocouple connection at the gas

valve.

3. Disconnect the pilot tube connection at the gas valve or

thermostat.

4. Open the lower kick panel.

5. Remove the screws securing the left hand corner column

(or channel and grease bucket on griddle models) and

remove the column.

6. Remove the oven base plate. (For RC models, refer to the

previous section under burner cleaning.)

7. Disconnect the pilot gas supply pipe at the pilot burner.

8. Remove the screws that secure the pilot mounting

bracket to the oven burner support.

9. Remove the pilot assembly.

3. Disconnect the wires from the valves on the ignition

module.

4. Remove the screws that secure the module.

5. Replace with a new module and reassemble the unit in

reverse order.

Push Button Spark Switch Models

With Sux E

1. Open the lower kick panel. (Remove the valve panel on

broilers).

2. Remove the right hand corner column. On broilers,

remove the spark switch enclosure cover behind the front

fascia panel.

3. Disconnect the wires from the taps on the switch.

4. Depress the tabs on the body of the switch and push the

switch through the column opening. (On broilers, it is the

mounting cover.)

5. Fit a replacement switch and reassemble the unit in

reverse order.

10. Replace the faulty component and reassemble the unit in

reverse order.

CAUTION: Don’t not over-tighten the connection between

the thermocouple and the ame safety device. It is sucient

for it to be nger tight plus a quarter of a turn.

Spark Ignition Module Models

With Sux E:

1 Open the lower kick panel (cabinet door on broilers) and

storage base panels.

2. Remove the right hand corner column. On broilers and

storage units, remove the spark module enclosure cover

at the lower right hand front of the storage cabinet.

RC Oven

Power Switch

1. Remove the front valve panel.

2. Remove the right corner column.

3. Disconnect the wires from the taps on the switch.

4. Depress the tabs on the body of the switch and push the

switch through the column opening.

5. Fit a replacement switch and reassemble in reverse order,

ensuring wires are attached correctly.

Part # 4519069 (07/24/09) Page 27

Page 28

CONVERSION INSTRUCTIONS

Servicing must be carried out by a competent person in

accordance with the law.

WARNING: Turn o the gas supply to the appliance at the

service cock before commencing any servicing work.

IMPORTANT: Test for gas soundness on completion of any