Garland MC-E20-2, MC-E20-2S, MC-E20-4, MC-E20-4C, MC-E20-6 Part Manual

...

SERVICE MANUAL

MANUFATURED EXCLUSIVELY FOR

McDonald's

BY

GARLAND COMMERCIAL INDUSTRIES, INC,

FREELAND, PENNSYLVANIA 18224

TOLL FREE: (800) 446-8367

PHONE: (570) 636-1000

FAX: (570) 636-9874

Come visit us on the web at www

.garland-group.com

E-mail: clamshell@gariand-group.com

NOTE:This manual pertains to 2 cell, 4 cell, and 6 cell pizza ovens. The reader/operator must

interpret its contents to applicable needs. However, if there is any question of interpretation of

any literature pertaining to Garland / McDonalds pizza ovens, please contact our Customer

Service Department at one of the phone numbers listed above.

MULTI-PURPOSE GARLAND

OVEN

MC-E20-2

MC-E20-2S

MC-E20-4

MC-E20-4C

MC-E20-6

MC-E20-6C

WARNING:

This product contains chemicals known to the State of California to cause cancer. *Installation and servicing of this product could expose you to airborne particles of glasswool/ceramic fibers. Inhalation of airborne particles of

glasswool/ceramic fibers is known to the State of California to cause cancer.

PLEASE READ ALL SECTIONS OF THIS MANUAL AND RETAIN FOR FUTURE REFERENCE.

CAUTION: THIS EQUIPMENT MUST ONLY BE OPERATED UNDER AN APPROVED HOOD SYSTEM

THIS EQUIPMENT "MUST" BE INSTALLED AND COMMISSIONED BY A PROFESSIONAL

FACTORY TRAINED TECHNICIAN

Part #MCDSVMN Rev. 5

Printed in the U.S.A

(07/00)

SAFETY ............................................................................................3

INTRODUCTION................................................................................3

WARRANTY ......................................................................................3

MC-E20-2

. . . . . . . . . . . . . . . . . . . . . . . . . 5

MC-E20-4

. . . . . . . . . . . . . . . . . . . . . . . . . 6

MC-E20-6. . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION - CANADA ..............................................................8

INSTALLATION - U.S.A.....................................................................8

PARTS IDENTIFICATION AND FUNCTION ....................................9

PARTS IDENTIFICATION AND FUNCTION ....................................10

PARTS IDENTIFICATION AND FUNCTION ....................................11

PARTS IDENTIFICATION AND FUNCTION ....................................12

Timer Switch ....................................................................13

Heat On Indicator ............................................................13

Temperature Switch ........................................................13

Select Switch ....................................................................13

On/Switch

..........................................................................13

HARDWARE ......................................................................................13

Control Switch Operation

................................................13

Before First Use

................................................................13

OPERATION ......................................................................................13

TO PROGRAM THECONTROLLER ................................................14

SET - UP ............................................................................................14

TO CHANGE DUTY CYCLE TOP ....................................................15

TO CHANGE REMOVE TIME ..........................................................15

TO CHANGE THE SET TEMPERATURE ........................................15

TO CHANGE DUTY CYCLE BOTTOM ............................................16

TO RESTORE FACTORY SETTINGS ..............................................16

TO CALIBRATE THECONTROLLER................................................17

TROUBLESHOOTING GUIDE ..........................................................18

CONTROLLER PRODUCT SETTINGS ............................................19

TO REPLACE CELL CONTACTOR ..................................................20

TO REPLACE THECONTROLLER ..................................................20

NON-SCHEDULED MAINTENANCE ................................................20

TO REPLACETHERMOCOUPLE......................................................21

TO REPLACE 24 VOLT TRANSFORMER........................................21

TO REPLACE HI-LIMIT CONTROL ..................................................21

TO REPLACE BLOWER MOTOR ASSY OR BLOWER WHEEL ....22

TO REPLACE MOTOR RESET SWITCH ........................................22

TO REPLACE DOOR ASSEMBLY....................................................23

TO ADJUST OR REPLACE DOOR SPRING, SLEEVE ASSY. OR

DOOR STOP W/CHAINON 4'S & 6'S BUILT PRIOR 4/23/93 ..........23

TO ADJUST OR REPLACE DOOR SPRING, SLEEVE ASSY. OR

DOOR STOP ON 4'S & 6'S BUILT AFTER 4/23/93 ........................23

TO REPLACE THE PROGRAM CHIP ..............................................24

TO REPLACE BUSHING ..................................................................24

Table of Contents

2

The model MC-E20-2, MC-E20-4 and MC-E20-6

are electric, air impingement ovens. The -4 is a four

cell oven and the -6 is a six cell oven. The -4 and 6 cell ovens also inter-lock to ventilation hood system and fire suppression system.

The models MC-E20-4C and MC-E20-6C are electric, air impingement ovens. However, these ovens

are exclusively for use in Canada and offer NO

inter-lock system to ventilation or fire suppression

system.

READ ALL SECTIONS OF THIS MANUAL

We warranty to the original purchaser only, that this

new GARLAND commercial cooking equipment sold

by us is free from all defects in material and factory

workmanship for a period of one year from our date

of shipment.

Further, component parts (excluding controllers and

motors) will continue in warranty (parts value only )

for an additional 24 months beyond the first year of

coverage.

Provided that:

A. The equipment has not been accidentally or

intentionally damaged, altered, abused ]or misused.

B. The equipment is properly installed,

adjusted, operated and maintained.

C. Has the warranty serial number affixed to

the appliance by us that has not been

defaced, obliterated or removed.

D. An acceptable report for any claim under

this warranty is supplied to us.

E. The equipment is not sold or used for

home or residential use.

Any defective part (excluding broken glass, ceramics, or porcelain, and light bulbs) brought to the

attention of the selling dealer or a listed Authorized

GARLAND Service Agency will be repaired or

replaced with out charge within the United States.

Shipment outside the United States will be prepaid

to our closest port.

We assume no liability for diagnosis, normal maintenance such as lubrication, adjustment, or calibration

of controls, nor for the cost of travel in excess of

either two (2) hours of fifty (50) miles to and from the

installation by an Authorized GARLAND Service

Agency.

This warranty is limited and is lieu of all other warranties, expressed or implied, and we neither

assume nor authorize any person to assume for us

any other obligation or liability in connection with our

equipment. We, our employees, or our agents shall

not be held liable for any claims for personal injuries

or consequential damages or loss, however caused.

WARRANTY INTRODUCTION

The GARLAND air impingement oven has many

safety features incorporated. However, the only way

to ensure safe operation is to fully understand the

proper installation, operation and maintenance procedures. The instructions in this manual have been

prepared to aid you in learning the proper procedures.

Where information is of particular importance or is

safety related, the word NOTE, CAUTION or

WARNING are used. Their usage is described

below:

NOTE - The word NOTE is used to highlight especially important information.

CAUTION - The word CAUTION is used to alert you

to a procedure that, if not performed properly, may

damage the equipment.

WARNING - The word WARNING is used to alert

you to a procedure, that if not performed properly,

may cause personal injury.

We suggest installation, maintenance and general

repairs be performed by local Authorized GARLAND Service Agencies shown in your GARLAND

Agency/Distributor list provided with the oven.

SAFETY

3

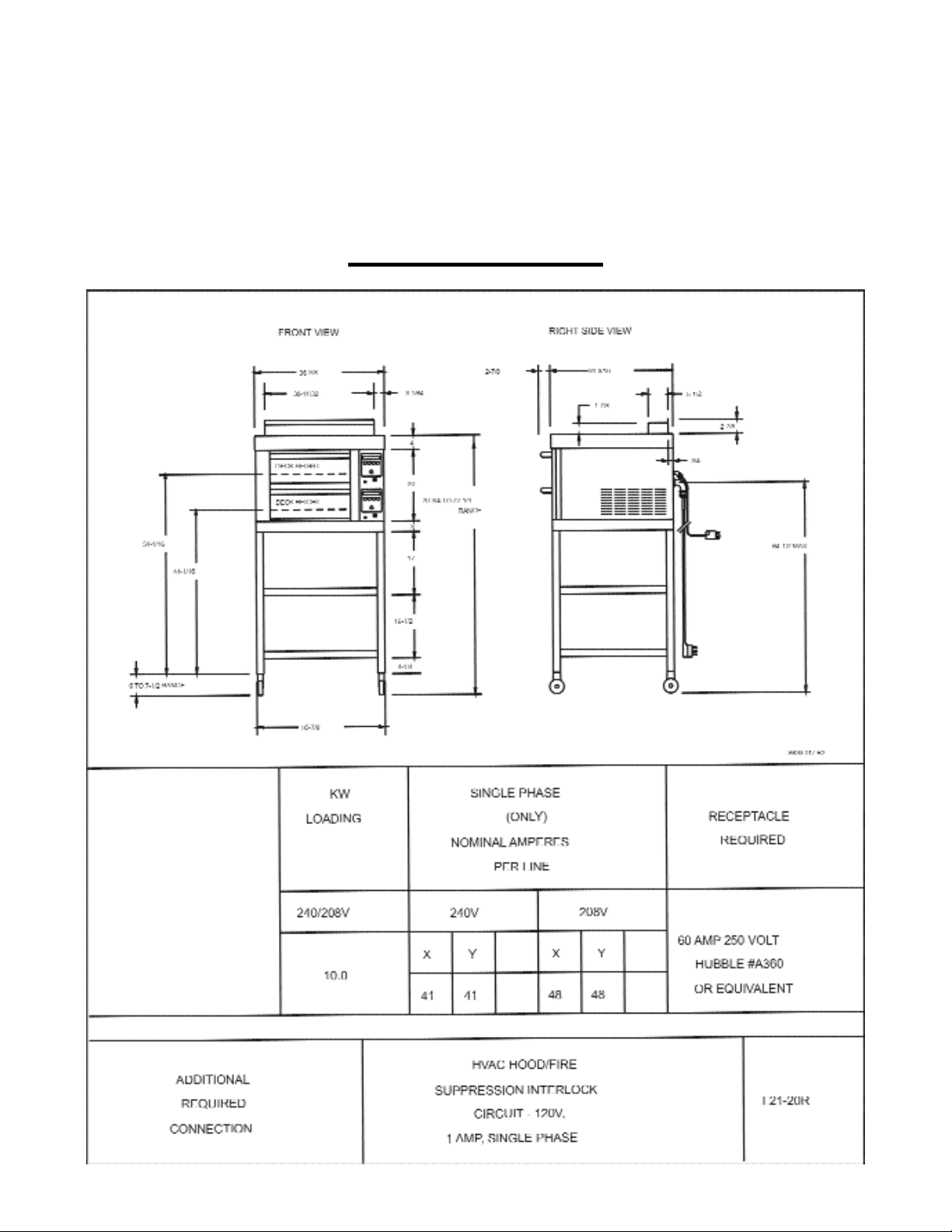

DIMENSIONAL DIAGRAM

MC-E20-2

5

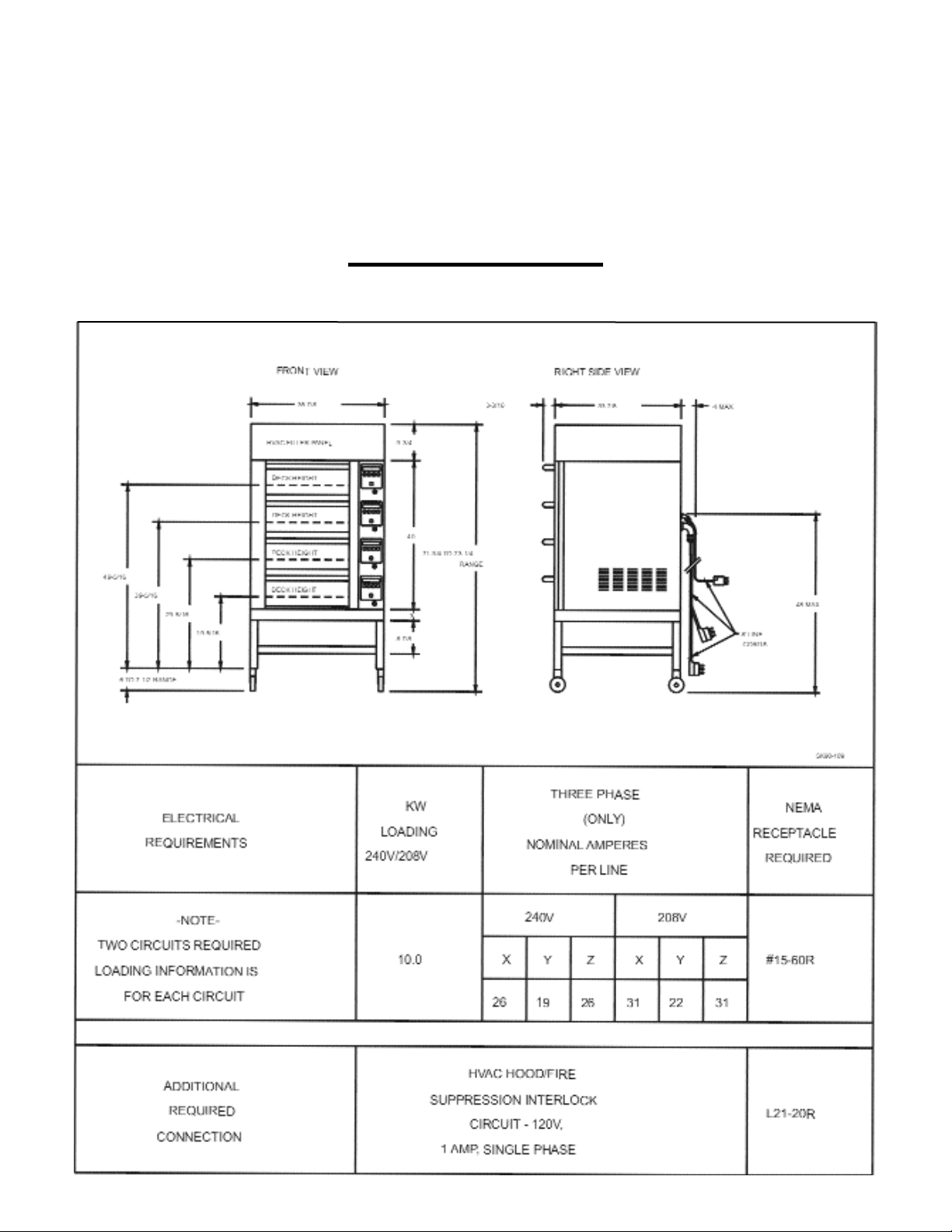

DIMENSIONAL DIAGRAM

MC-E20-4

6

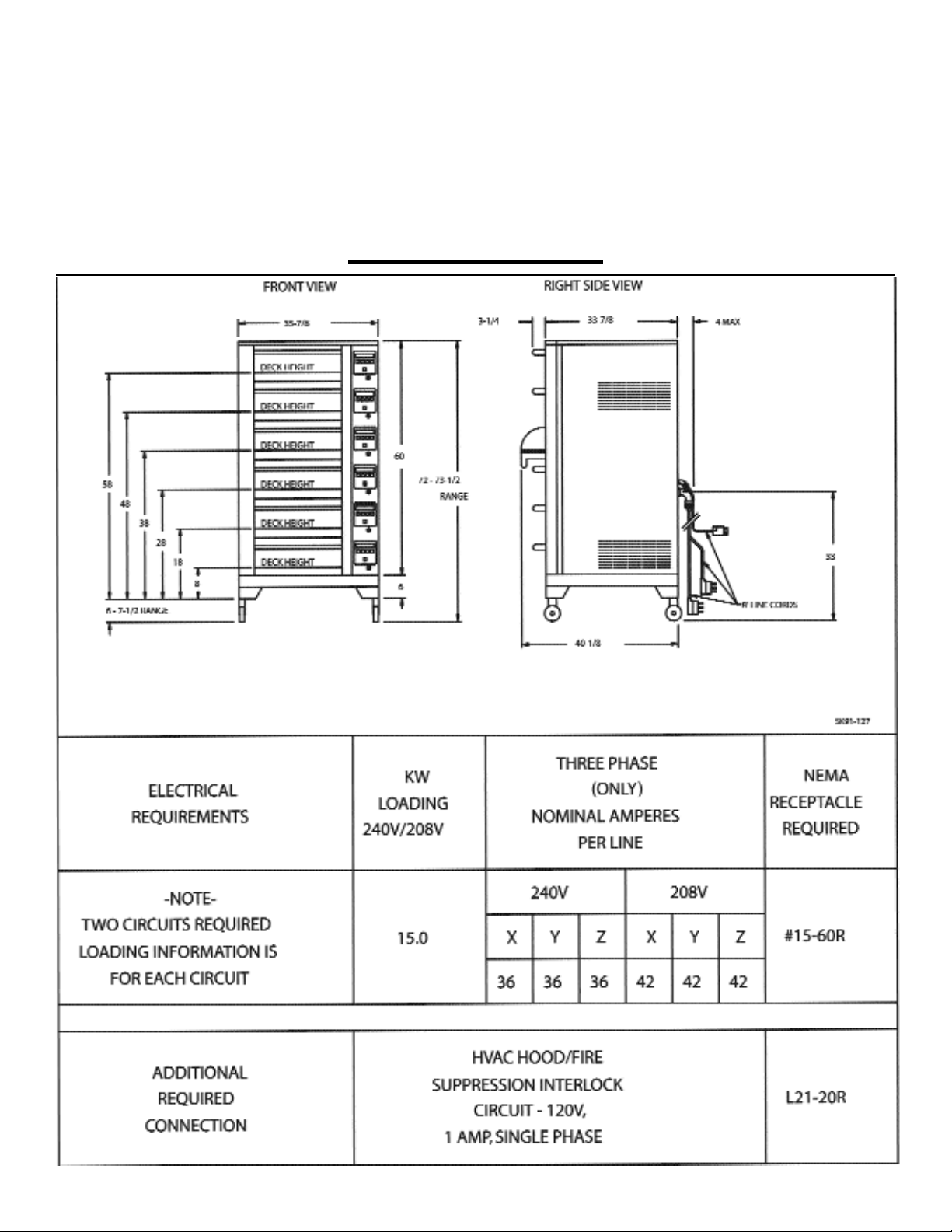

MC-E20-6

DIMENSIONAL DIAGRAM

7

CAUTION - Prior to installation, check the electric

supply to ensure input voltage and phase match the

equipment voltage rating and phase. See data plate

located top front of top cell control section.

NOTE - The -4 and -6 have two (2) Power Supply

Cords and one (1) Interconnect Cord. Each plug

shall be supplied by an individual branch circuit of 60

AMPS. These instructions must be followed to

ensure proper installation of this unit. The power

connections for the oven are two (2) NEMA No. 1560P, 60 AMP, 208/240 Volt, 3 Phase plugs and one

(1) NEMA No. L21- 20P, 20 AMP, 120/208 Volt, 1

Phase plug. The -2 utilizes one, 60 AMP, 250 Volt, 1

Phase plug, (receptacle provided).

Unit is to be located directly under ventilation system.

Unit must maintain a four (4") minimum clearance

from rear wall.

Unit must be level and front casters placed in locked

position.

WARNING - The appliance area must be kept free

and clear of combustibles.

WARNING - All electrical appliances must be electrically grounded in accordance with local codes or

in the absence of local codes, with national electric

code ANSI/NFPA - latest version.

CAUTION - The - 4 and - 6 have more than one (1)

power supply cord. Unplug all cords before moving

or servicing this appliance.

WARNING - INSTALLER NOTE - The -4 and -6

ovens are designed for connection to a special interlock system. Check receptacle wiring diagram below

before connecting.

CAUTION - Prior to installation, check the electric

supply to ensure input voltage and phase match the

equipment voltage rating and phase. See data plate

located top front of top cell control section.

NOTE - A four (4) pole, five (5) wire plug and a four

(4) wire with ground cord must be provided for

power connection on the -4C and -6C. Check the

local Codes and Standard for proper wire size.

Unit must maintain a four (4") minimum clearance

from rear wall.

Unit must be level and front casters placed in locked

position.

WARNING - The appliance area must be kept free

and clear of combustibles.

WARNING - All electrical appliances must be electrically grounded in accordance with local codes.

1

2

3

N

120 VAC

To Motor On Fan

Neutral

INSTALLATION - U.S.A. INSTALLATION - CANADA

8

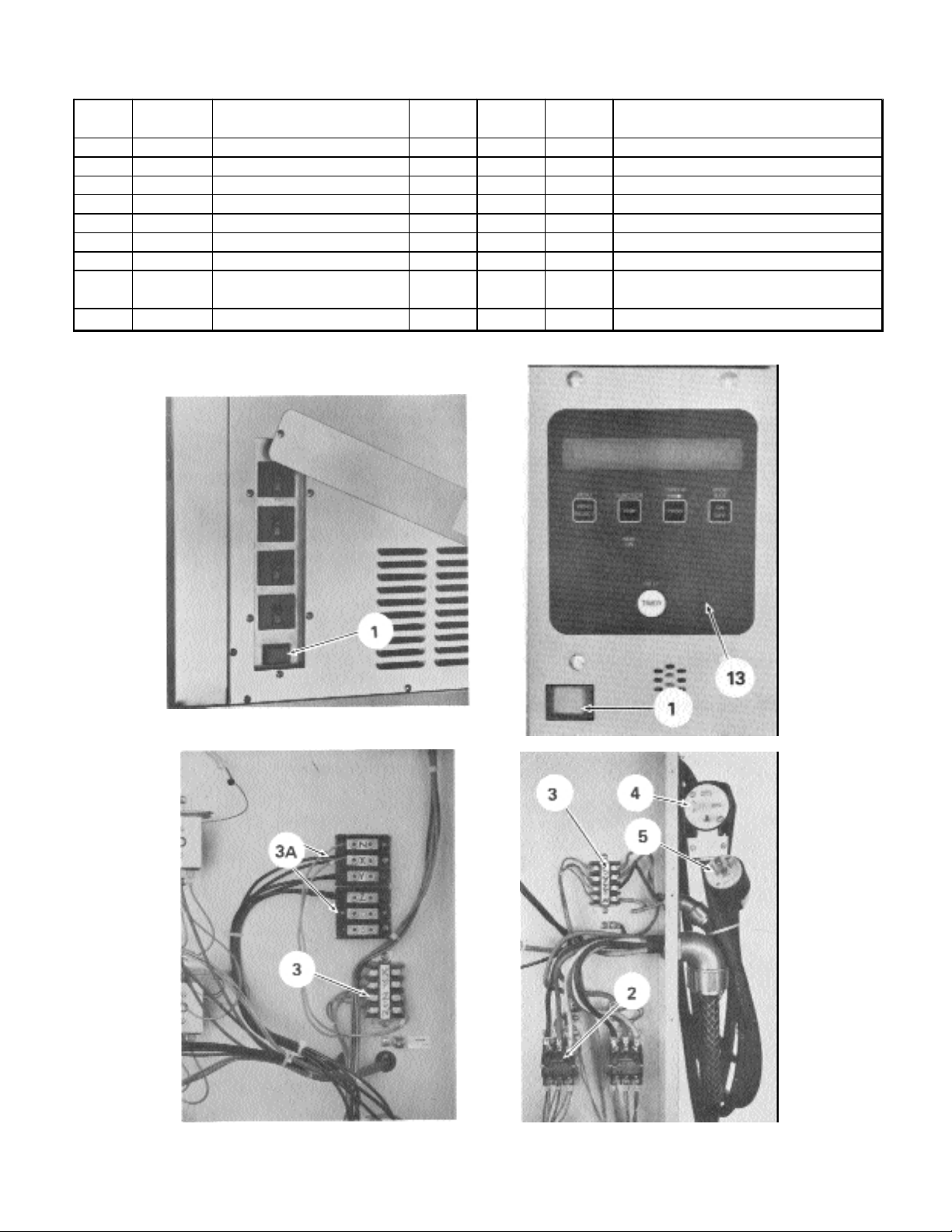

ITEM PART # DESCRIPTION

2 CELL

QTY.

4 CELL

QTY.

6 CELL

QTY.

FUNCTION

1 1639700

Master On/Off Switch 1 1 Turns contactors on/off. Red

1 a 1639701 Master On/Off Switch 1 Turns contactors on/off. Amber

2 1637001

Main Contactor **1 2 2 Connects power to cell fuse.

1637002

Main Contactor 208/240 1 Connects power to cell fuse.

3 1233901

Terminal Block 1 1 1 115V Junction

3A 1193900 Terminal Block 1 2 2 208V Junction

*4 1718501 Power cord set 2 2 Supplies power to contactors

*5 1718502 Interlock cord set **1 1 1

Supplies power to Master Power

ON/OFF switch

*6

11718503

Power cord set 1 Supplies power to unit

*For U.S.A. models only. ** Used on 2 Packs after June 1993.

PARTS IDENTIFICATION AND FUNCTION

9

ITEM PART # DESCRIPTION

2CELL

QTY.

4 CELL

QTY.

6 CELL

QTY.

FUNCTION

8 1637700

Lockin Caster 2 2 2 Support base.

9 1637701

Non-Locking Caster 2 2 2 Support base.

ITEM PART # DESCRIPTION

2CELL

QTY.

4 CELL

QTY.

6 CELL

QTY.

FUNCTION

10 1631796

Bottom Jet Plate w uide 2 4 6. Directs heated air and supports rack.

11 1635000

Rack 2 4 6 Supports product.

12 8005200

1/4Turn Fastener Prior 7/93 8 12 **Secure jet late.

13 1635700

Controller 2 4 6 Controls time and temperature.

1635708

Rebuilt Controller 2 4 6 Control time and temperature.

14 1635900

Motor Rese t Sw itch 4 6 **Resta r t M o to r

15 1130107

Fuse 4 8 12 Reset Motor

16 1130106

Fuse Holder 4 8 12 Holds Fuse.

**Used Prior to June 1993

PARTS IDENTIFICATION AND FUNCTION

10

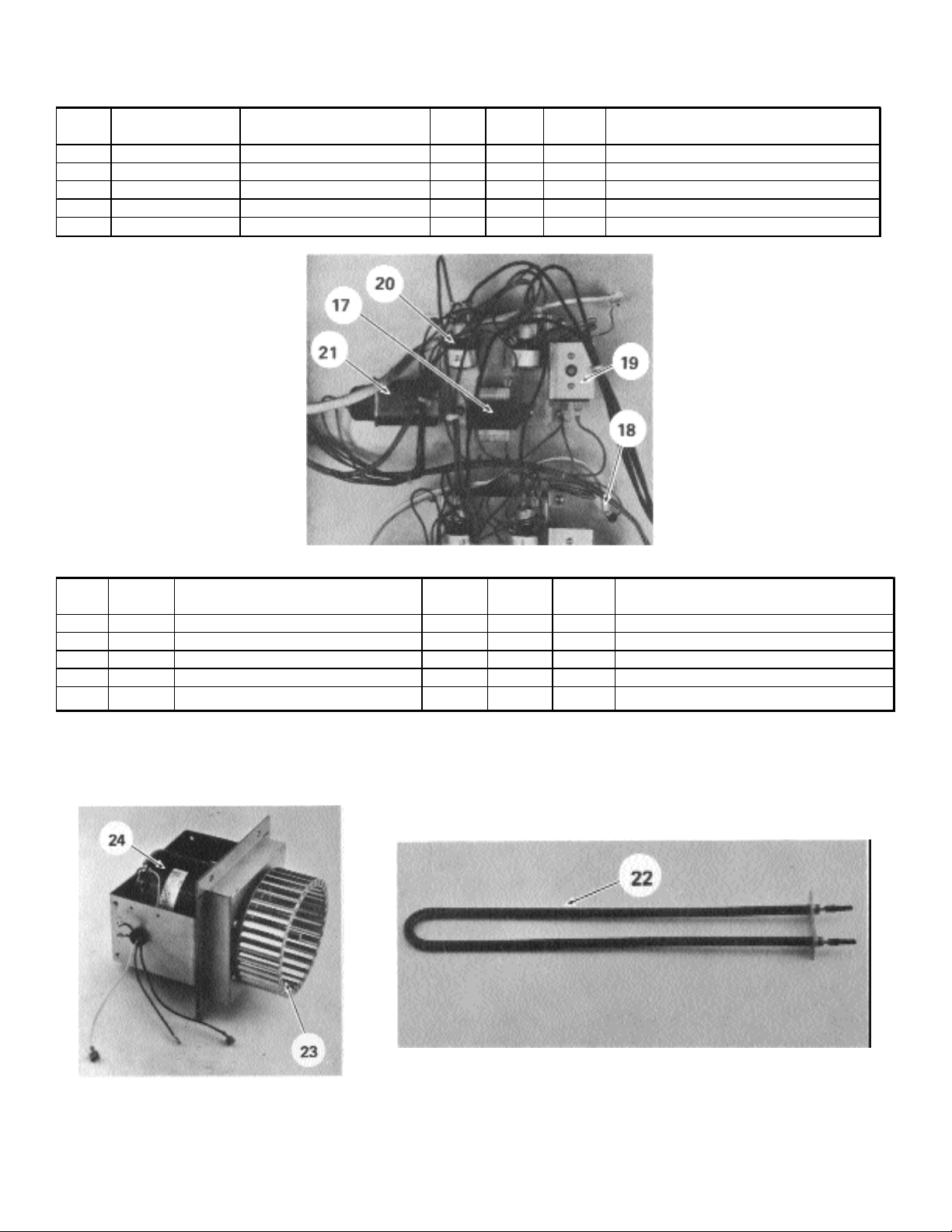

ITEM PART # DESCRIPTION

2CELL

QTY.

4 CELL

QTY.

6 CELL

QTY.

FUNCTION

17 1636000

24VAC Transformer 2 4 6 Provides voltage to 24V control system.

18 1636100

Thermocouple 2 4 6 Monitor oven temperature for control.

19 1682502

Cell Hi-Limit Control 2 4 6 Prevents excessive tem peratures

20 1637000

Cell Contactor 4 8 12 Provides voltage to heat elements

21 1636501

Blower Motor Capacitor (only) 24 6

ITEM PART # DESCRIPTION

2CELL

QTY.

4 CELL

QTY.

6 CELL

QTY.

FUNCTION

22 1616800

208VAC Heater Element 8 16 24 Heat source. Obs /Avail.

1616803

208VAC Heater Element 8 16 24 Heat source. Used after 4/29/94

1616801

40V Heater element 8 16 24 Heat source.

23 1636800

Blower W heel 2 4 6 Directs air to 'et plates.

24 1636599

Blower Motor Assy. 2 4

6

PARTS IDENTIFICATION AND FUNCTION

11

Loading...

Loading...