Page 1

INSTALLATION AND

OPERATION MANUAL

GARLAND ELECTRIC

TEPPAN YAKI GRIDDLE

E22-36 SERIES

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Part # 4517056 Rev 3 (08/24/11) © 2004 Garland Commercial Industries, Inc.

Page 2

Part # 4517056 Rev 3 (08/24/11)Page 2

Page 3

TABLE OF CONTENTS

SPECIFICATION AND INSTALLATION OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . 4

Flanged Griddle Installation – Table Cut Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Supply: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Electrical Supply Connection: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Siting: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ventilation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Installation Procedure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Commissioning: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

MAINTENANCE & CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electromechanical Bulb and Capillary Thermostat: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Models Manufactured Prior To September 2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electronic Thermostat Models With Spade Type Temperature Control Sensors: . . . . .8

Models Manufactured Since October 2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Miscellaneous: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part # 4517056 Rev 3 (08/24/11) Page 3

Page 4

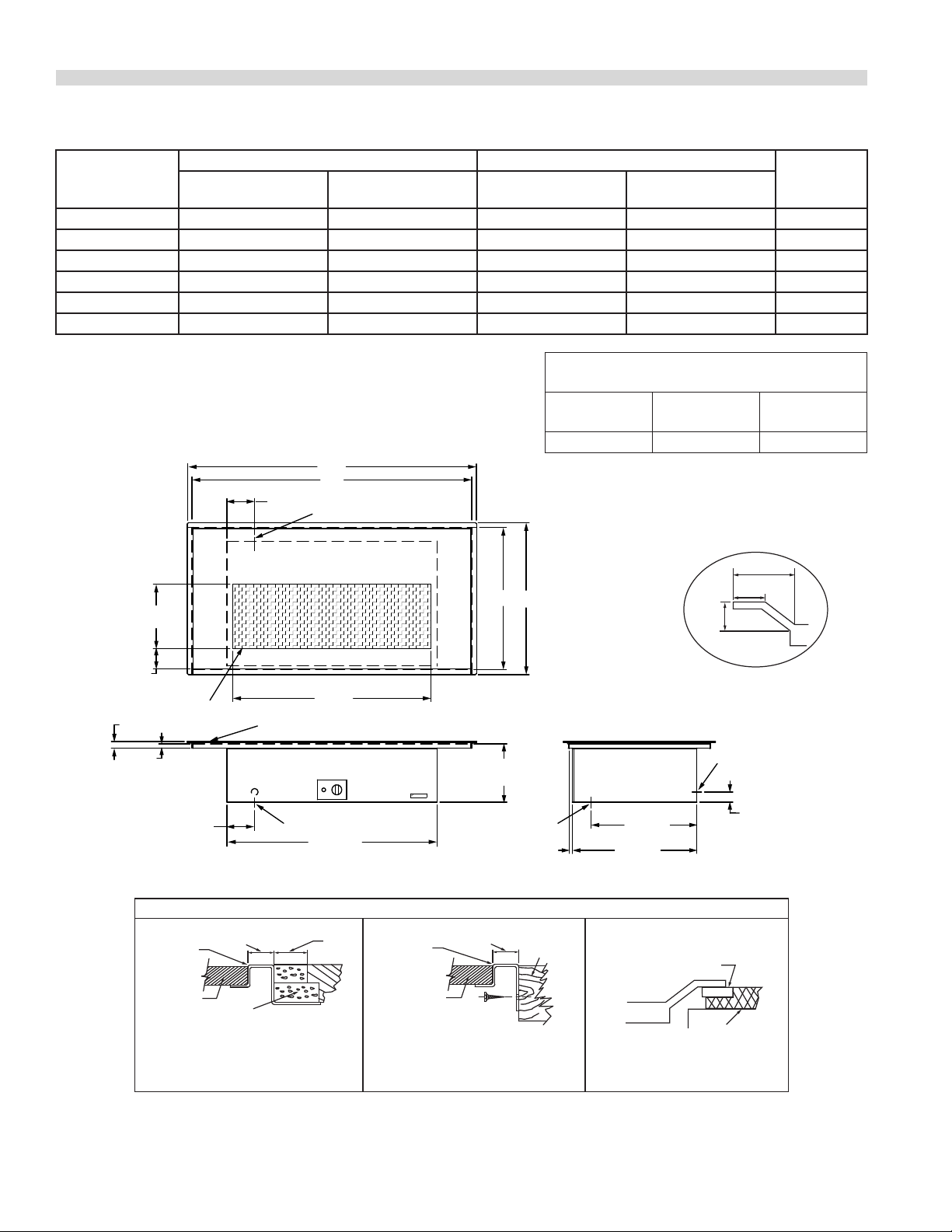

SPECIFICATION AND INSTALLATION OPTIONS

Griddle Size With Flange Griddle Size Less Flange Shipping

Model

Width (A) Depth (B) Width (C) Depth (D)

E22-36-36GMX 37-5/8" (957mm) 26-9/16" (675mm) 35-13/16" (910mm) 24-1/4" (616mm) 330/150

E22-36-45GMX 46-15/16" (1192mm) 28-1/4" (718mm) 45-1/8" (1146mm) 26-15/16" (685mm) 340/154

E22-36-48GMX 49-5/8" (1260mm) 26-9/16" (675mm) 47-13/16" (1215mm) 24-1/4" (616mm) 350/159

E22-36-56GMX 58-3/16" (1478mm) 28-1/4" (718mm) 56-3/8" (1432mm) 26-15/16" (685mm) 385/175

E22-36-60GMX 61-5/8" (1565mm) 26-9/16" (675mm) 59-13/16" (1520mm) 24-1/4" (616mm) 385/175

E22-36-72GMX 73-5/8" (1870mm) 26-9/16" (675mm) 71-13/16" (1824mm) 24-1/4" (616mm) 400/182

Wt

lb/kg

The E22-36-36GMX is for installation in non-combustible locations only.

All others should be installed with the adjacent minimum clearances from

combustible material.

A

C

11"

[279mm]

3 1/2"

[89mm]

HOT SPOT AREA

1 9/16"

[29mm]

3/4"

[19mm]

4 3/4"

[121mm]

4 3/4"

[121mm]

STEEL PLATE

REAR CABLE

ENTRANCE

34"

[864mm]

BOTTOM CABLE

ENTRANCE

36"

[914mm]

FRONT VIEW

D

10"

GARLAND

[254mm]

BOTTOM CABLE

ENTRANCE

Body Side Minimum Installation

Clearances: In/mm

Left & Right

Sides

Rear

1/2 /12-1/2 1/2/121/2 Combustible

1"

[25mm]

.5"

B

1/2"

[13mm]

18 1/4"

[464mm]

21 3/8"

[543mm]

[12mm]

.5"

[12mm]

FLANGE

MEASUREMENTS

REAR CABLE

ENTRANCE

[44mm]

1 3/4"

Type of Floor

Base

SUGGESTED MOUNTINGS (Not to Scale)

1"

[25mm]

METAL

EXPANSION

STRIP

BY OTHERS

GRILL

BY

GARLAND

MARBLE / SIMILAR

NON-COMBUSTIBLE

MATERIAL MUST BE

3" [76mm] SIDES & BACK

TABLE TOP MOUNTING

WITH NON- FLANGE EDGE

36" WIDE MODEL (E22-36-36GMX)

3"

[76 mm]

METAL

EXPANSION

STRIP

BY OTHERS

GRILL

GARLAND

TABLE TOP MOUNTING

NON FLANGED EDGE

45" TO 72" MODELS

MINIMUM CLEARANCE TO

COMBUSTIBLE CONSTRUCTION

1" [25mm] SIDES AND BACK

1"

[25mm]

BY

WOODEN

TABLE

BY OTHERS

EXPANSION STRIP

SUPPLIED BY OTHERS

NON-COMBUSTIBLE

i.e. MARBLE OR SIMILAR

GRILL WITH

FLANGE

TABLE TOP MOUNTING

WITH FLANGED

EDGE OPTION

TABLE TOP

WOOD ect.

Garland products are not approved or Authorized for home or residential use, but are intended for commercial applications only.

Garland will not provide service, warranty, maintenance or support of any kind other than in commercial applications.

Part # 4517056 Rev 3 (08/24/11)Page 4

Page 5

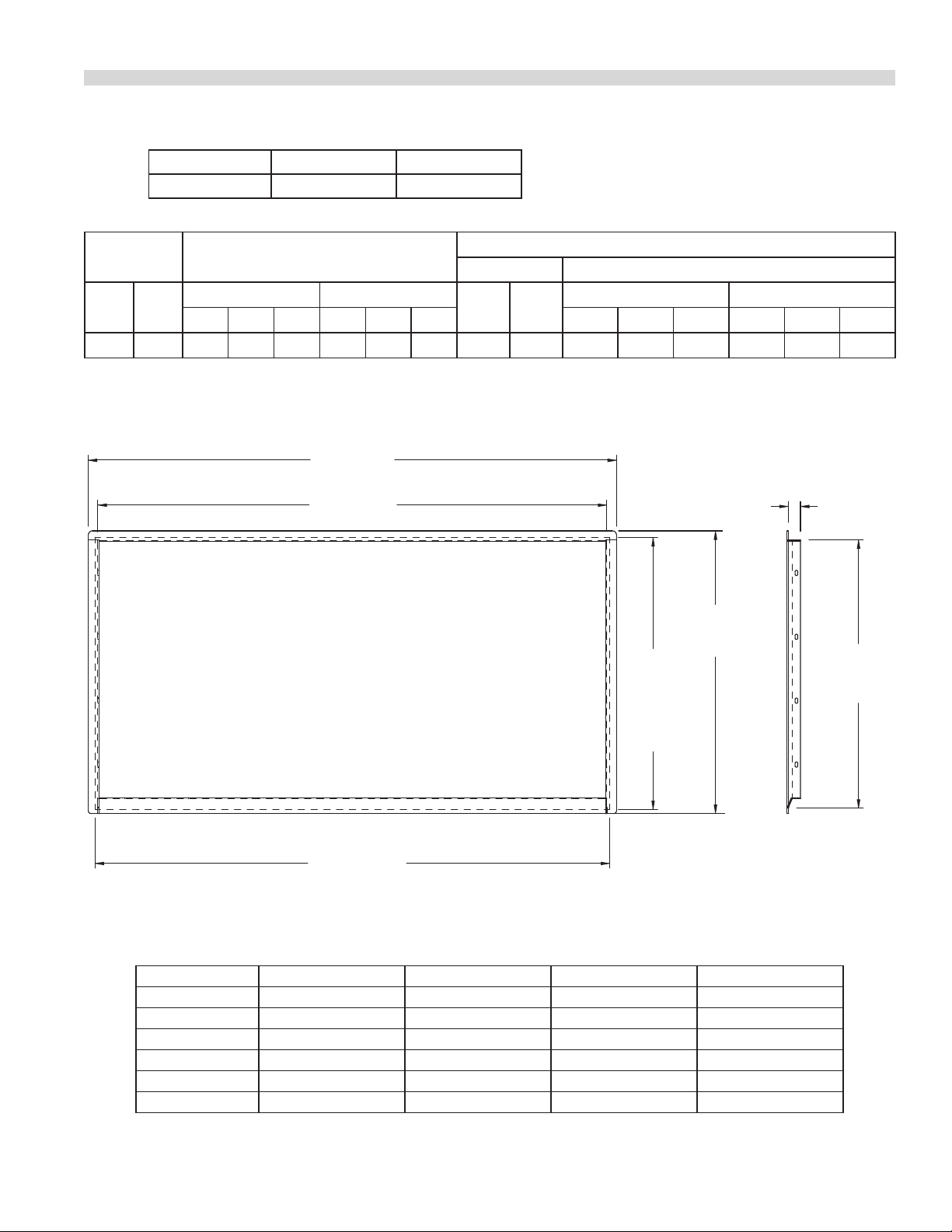

SPECIFICATION AND INSTALLATION OPTIONS continued

Model Shown: E22-36-48GMX

Models E22-36-36GM(X) E22-36-45GM(X) E22-36-48GM(X)

E22-36-56GM(X) E22-36-60GM(X) E22-36-72GM(X)

X sux use electronic thermostats

Total kW

Loading

240V 208V

6.7 6.7 3.35 — 3.35 3.35 — 3.35 27.92 32.21 24.22 13.96 13.96 27.95 16.11 16.11

Flanged Griddle Installation – Table Cut Sizes

kW Loading Per Phase

Single Phase Three Phase

240V 208V

240V 208V

X-Y Y-Z X-Z X-Y Y-Z X-Z X Y Z X Y Z

Nominal Amps Per Phase

240V 208V

A

49-5/8"

[1260mm]

47-13/16"

[1215mm]

1-1/8"

[29mm]

26-9/16"

[675mm]

25-9/16"

[649mm]

B

25-3/16"

[640mm]

Minimum

Table

Cut Out

D

48-3/8"

[1229mm]

Minimum

Table Cut Out

GRILL PLATE

DIMENSIONS ARE

-1/16", +0

C

Recommended table cut out

MODEL A B C D

E22-36-36GMX 37-5/8" (957mm) 26-9/16" (675mm) 36-3/8" (934mm) 25-9/16" (649mm)

E22-36-45GMX 46-15/16" (1192mm) 28-1/4" (718mm) 45-11/16" (1160mm) 27-1/4" (692mm)

E22-36-48GMX 49-5/8" (1260mm) 26-9/16" (675mm) 48-3/8" (1229mm) 25-9/16" (649mm)

E22-36-56GMX 58-3/16" (1478mm) 28-1/4" (718mm) 56-15/16" (1445mm) 27-1/4" (692mm)

E22-36-60GMX 61-5/8" (1565mm) 26-9/16" (675mm) 60-3/8" (1534mm) 25-9/16" (649mm)

E22-36-72GMX 73-5/8" (1870mm) 26-9/16" (675mm) 72-3/8" (1828mm) 25-9/16" (649mm)

Part # 4517056 Rev 3 (08/24/11) Page 5

Page 6

GENERAL INFORMATION

1. Check the crate for possible damage sustained during

transit. Carefully remove the unit from the crate and again

check for damage. Any damage to the appliance must be

reported to the carrier immediately.

2. The type of voltage supply that the equipment was

manufactured for at the factory is noted on the data plate

on the equipment. This type of supply must be used.

SAFETY

• A qualied person must make the installation in

accordance with the authority having jurisdiction and

local codes.

• This unit must only be operated by a qualied person. DO

NOT operate without reading this manual.

• DO NOT operate this appliance unless all service and

access panels are in place and fastened properly.

3. Do not remove permanently axed labels, warning or

data plates form the appliance, this may void approvals

and create a safety hazard.

The Garland E22 series complies with the standards

CSA C22.2 no. 109 – latest edition and UL197 – latest edition.

The installation and connection of this appliance must comply

with current codes. In Canada – the Canadian Electrical Code

Part 1 and in the USA – the National Electrical Code.

• DO NOT clean this appliance unless the power supply is

disconnected.

WARNING: To avoid serious personal injury:

• USE EXTREME CAUTION in setting up, operating and

cleaning these appliances to avoid coming in contact

with hot surfaces. Wear suitable protective clothing or use

proper utensils to prevent the risk of burns.

• DO NOT attempt to repair or replace any part of this

appliance unless all main power supplies have been

disconnected.

NOTE: All warning labels and markings on this appliance,

which call attention to further dangers and necessary

precautions.

Part # 4517056 Rev 3 (08/24/11)Page 6

Page 7

INSTALLATION

Electrical Supply:

Before attempting the electrical connection, the rating plate

should be checked to ensure the equipment’s electrical

characteristics and the supply electrical characteristics agree.

On griddles the supply entrance is located at the rear or

alternatively on the main bottom. The supply terminal block

is accessible from the front. The electrical supply must be

adequate for the voltage, phase and current marked on the

rating plate.

Note: A means of disconnection from the supply having

a contact separation of at least 3 mm in all poles must be

incorporated in the xed wiring.

WARNING: THIS APPLIANCE MUST BE EARTHED.

Electrical Supply Connection:

For supply connection, use wire suitable for 75°C (167°F).

A bottom knockout is provided near the front left side of the

unit, located behind the control panel. To view the knockout,

loosen the four acorn nuts and remove the control panel. The

terminal block is also located in this area.

The rear supply cable entrance is located on the right side

when facing the rear of the unit. The cable is fed towards the

front through the wire way.

Siting:

The base on which the griddle is to be sited must be capable

of adequately supporting the weight of the appliance and

any ancillary equipment. Once in position, check that the

equipment is level, both front and back and side to side.

Adjust if necessary.

Ventilation:

This product is to be installed under a ventilation hood.

Proper operation of exhaust fans (proper speed, rotation and

adjustment) is essential. In addition a make-up air system for

the kitchen to supply fresh air is recommended.

Any ventilation system will break down if improperly

maintained. The duct system, the hood, and the lters must

be cleaned on a regular basis and kept grease free.

General Installation Procedure:

1. Carefully remove the unit from the crate. All packing

material must be removed from the unit.

2. All griddles are shipped from the factory with leveling

feet.

3. Place the griddle in the desired location and level from

side to side and back to front.

4. Adequate clearance must be provided for servicing,

ventilation and proper operation. The product must be

kept free from combustible material.

Commissioning:

1. Ensure all circuit breakers located in the lower

compartment are set to the ON (1) position.

2. Ensure that all controls are in the o position and turn on

the main electrical supply.

3. Operate the grill in accordance with the instructions.

4. Check that the product functions correctly and that the

voltage supply to the unit does not drop by more than 5%

when all sections are operated simultaneously.

When the operation has been checked, hand this instruction

manual to the user or purchaser for retention. Instruct them

in the ecient and safe operation of the appliance.

Part # 4517056 Rev 3 (08/24/11) Page 7

Page 8

MAINTENANCE & CLEANING

Regular servicing by a competent person is recommended to

ensure the continued safe and ecient performance of the

appliance.

WARNING: Turn o the electrical mains before commencing

any servicing work.

1. Use a test instrument with a special disc type

thermocouple or a reliable surface type pyrometer. Note:

a drop of oil on the surface of the disc will provide better

contact with the plate.

2. Set all griddle thermostats to 350°F (177°C). In order to

allow the griddle temperature to stabilize, the thermostats

must be allowed to cycle twice before taking a test

reading.

3. Check the griddle temperature when the thermostat just

cycles o. Place the thermocouple or pyrometer rmly on

the griddle surface, directly above the sensing bulb of the

thermostat. The reading should be between 335°F (168°C)

and 365°F (185°F). If the reading is outside of these limits,

calibrate as follows:

Electromechanical Bulb and Capillary

Thermostat:

Models Manufactured Prior To September 2003

1. Carefully remove the dial, not disturbing the shaft

position.

3. Replace the thermostat dial and repeat steps 1 through 3

to verify that a correct adjustment has been made.

Electronic Thermostat Models With Spade Type

Temperature Control Sensors:

Models Manufactured Since October 2003

1. Electronic thermostat control models are very reliable and

are not calibrated in the eld.

2. If temperature settings are not consistent, an authorized

service technician should be called for inspection.

Miscellaneous:

1. Wire brush the surface of the griddle to removed baked

on material, wash with hot water, dry thoroughly. Lightly

coat the surface with vegetable oil to prevent rusting.

2. Wipe exposed surfaces with a mild detergent and

hot water. Stubborn residue may be removed with a

lightweight non-metallic scouring pad. Stainless steel

areas should be washed with mild detergent, hot water

and a soft cloth. If necessary, use a non-metallic scouring

pad, always rub in the direction of the grain in the metal to

prevent scratching.

NEVER USE STEEL WOOL.

2. Hold shaft steady and with a small at screw driver turn

the calibration screw located inside the shaft clockwise to

decrease temperature and counter-clockwise to increase

the temperature. Note: Each 1/4 turn of the screw will

create a change of approximately 35°F (20°C).

Part # 4517056 Rev 3 (08/24/11)Page 8

Page 9

WIRING DIAGRAMS

Part # 4517056 Rev 3 (08/24/11) Page 9

Page 10

WIRING DIAGRAMS continued

Part # 4517056 Rev 3 (08/24/11)Page 10

Page 11

Part # 4517056 Rev 3 (08/24/11) Page 11

Page 12

Page 13

Page 14

Pièce n°4517056 Rev 3 (08/24/11) Page 11

Page 15

Pièce n°4517056 Rev 3 (08/24/11)Page 10

SCHÉMAS DE CÂBLAGE suite

Page 16

Pièce n°4517056 Rev 3 (08/24/11) Page 9

SCHÉMAS DE CÂBLAGE

Page 17

Pièce n°4517056 Rev 3 (08/24/11)Page 8

tour de la vis modie la température d’environ 35ºF (20°C).

augmenter la température. Remarque : Chaque 1/4 de

dans le sens contraire des aiguilles d’une montre pour

aiguilles d’une montre pour diminuer la température ou

NE JAMAIS UTILISER DE LAINE D’ACIER.

sens du grain du métal pour éviter de rayer.

tampon à récurer non métallique, toujours frotter dans le

doux et de l’eau chaude. S’il est nécessaire d’utiliser un

doivent être nettoyées avec un détergent doux, un chion

léger non métallique. Les surfaces en acier inoxydable

rebelles peuvent être éliminés avec un tampon à récurer

avec de l’eau chaude et un détergent doux. Les résidus

2. . Essuyer les surfaces exposées quand elles sont froides

rouille.

couche d’huile végétale pour empêcher la formation de

chaude et bien sécher. Recouvrir les surfaces d’une ne

éliminer les produits alimentaires cuits, laver à l'eau très

1. Nettoyer la surface du gril à la brosse métallique pour

Divers :

inspection.

un réparateur agréé doit être appelé pour faire une

2. Si les réglages de température ne sont pas constants,

la vis d’étalonnage à l’intérieur de l’axe dans le sens des

2. En immobilisant l’axe, tourner avec un petit tournevis plat

de l’axe.

1. Retirer soigneusement le cadran, sans modier la position

Modèles Fabriqués Avant Septembre 2003

Capillaire Thermostat :

Thermostat À Bulbe Électromécanique Et

ci-après :

résultat est hors de ces limites, étalonner comme indiqué

être compris entre 335°F (168°C) et 365°F (185°F). Si le

au-dessus du bulbe thermostatique. Le résultat devrait

thermocouple ou le pyromètre sur la surface du gril, juste

coupe l’alimentation. Appliquer fermement le

3. Vérier la température du gril juste quand le thermostat

température.

laisser les thermostats cycler deux fois avant de mesurer la

permettre à la température du gril de se stabiliser, il faut

2. Régler tous les thermostats de grils à 350°F (177°C). Pour

sont très ables et ne sont pas étalonnés sur place.

1. Les modèles commandés par thermostat électronique

Modèles Fabriqué Depuis Octobre 2003

Rectangulaires :

Capteurs De Température De Type À Cosses

disque assurera un meilleur contact avec la plaque.

« surface ». Remarque : une goutte d’huile sur la face du

spécial de type à disque ou un pyromètre able de type

1. Utiliser un instrument d’essai avec un thermocouple

commencer les travaux de réparation.

AVERTISSEMENT : Couper l’alimentation électrique avant de

Modèles À Thermostat Électronique Avec

fonctionnement sécuritaire et ecace des appareils.

étapes 1 à 3 pour vérier que le réglage est correct.

3. Remettre en place le cadran du thermostat et répéter les

compétente est recommandé pour assurer un

Un entretien eectué régulièrement par une personne

MAINTENANCE ET NETTOYAGE

Page 18

utilisation ecace et sécuritaire des appareils.

à l'acheteur pour qu'il le conserve et s’en serve pour une

commandes en position d’arrêt. Laisser le présent manuel

Une fois le fonctionnement vérié, tourner toutes les

simultanément.

de plus de 5 % quand toutes les sections sont activées

l'alimentation électrique de chaque appareil ne chute pas

4. Vérier que l’appareil fonctionne correctement et que

3. Activer l’appareil conformément aux instructions.

Pièce n°4517056 Rev 3 (08/24/11) Page 7

nécessaire.

de niveau, entre l'avant et l'arrière et entre les côtés. Ajuster si

auxiliaire. Une fois que l’appareil est en place, vérier qu'il est

supporter le poids de l’appareil et de tout l’équipement

La base sur laquelle le gril doit être posé doit pouvoir

d'arrêt et mettre l'appareil sous tension.

2. S'assurer que toutes les commandes sont en position

compartiment inférieur sont réglés en position ON (1).

1. Vérier que tous les disjoncteurs situés dans le

Mise En Service :

l'écart des matériaux combustibles.

la ventilation et l’utilisation. L’appareil doit être tenu à

4. Un dégagement susant doit être prévu pour l’entretien,

niveau entre les côtés et entre l’arrière et l'avant.

3. Placer le gril à l’emplacement souhaité et le mettre de

mise de niveau.

2. Tous les grils sont expédiés de l’usine avec des pieds de

matériel d’emballage doit être retiré de l’appareil.

1. Retirer avec précaution l’appareil du carton. Tout le

Procédure Générale D’installation :

éliminée.

doivent être nettoyés régulièrement et la graisse doit être

entretenu. Le système de conduits, la hotte et les ltres

Tout système de ventilation tombera en panne s’il est mal

alimenter la cuisine en air frais.

il est recommandé d’avoir un système d’air d’appoint pour

(vitesse, rotation et réglage corrects) est essentiel. En plus,

Un bon fonctionnement des ventilateurs d’extraction

Cet appareil doit être installé sous une hotte de ventilation.

Implantation :

passage de câble.

l’appareil. Le câble doit passer vers l’avant de l’appareil par un

droit lorsque l’on se place en face de la partie arrière de

L’entrée arrière du câble d’alimentation se trouve sur le côté

se trouve également dans cette zone.

quatre écrous borgnes et retirer le panneau avant. Le bornier

de commande. Pour voir l’entrée défonçable, desserrer les

avant gauche de l’appareil se trouvant derrière le panneau

Une entrée défonçable inférieure est prévue près du côté

à une température de 75°C(167°F).

Pour la connexion d’alimentation, utiliser un câble convenant

Branchement De L’alimentation Électrique :

AVERTISSEMENT : CET APPAREIL DOIT ETRE RELIE A LA TERRE.

intégré au câblage xe.

séparation des contacts d’au moins 3 mm (0,12 po) doit être

Remarque : Un moyen de coupure de l’alimentation avec une

phases et l’intensité.

indications de la plaque signalétique pour la tension, les

l’avant. L’alimentation électrique doit correspondre aux

l'appareil. Le bornier d’alimentation est accessible depuis

est située à l’arrière ou encore sur le fond principal de

l’alimentation électrique Sur les grils, l’entrée d’alimentation

électriques de l’appareil correspondent à celles de

signalétique pour s’assurer que les caractéristiques

Avant d’essayer de brancher l’appareil, vérier la plaque

Ventilation :

Alimentation Électrique :

INSTALLATION

Page 19

Pièce n°4517056 Rev 3 (08/24/11)Page 6

dangers et précautions nécessaires.

le présent appareil, qui attirent l’attention sur les autres

NOTER les étiquettes et marques d’avertissement sur

brûlures.

ou utiliser des ustensiles adaptés pour éviter les risques de

chaudes. Porter des vêtements de protection convenables

cet appareil an d’éviter tout contact avec les surfaces

• FAIRE TRÈS ATTENTION pour installer, utiliser et nettoyer

AVERTISSEMENT : Pour éviter les blessures graves

électrique soit débranchée.

• NE PAS nettoyer cet appareil sans que l’alimentation

toutes les alimentations électriques.

quelle partie de cet appareil avant d’avoir débranché

• NE PAS essayer de réparer ou de remplacer n’importe

d’accès ne sont pas en place et xés correctement.

• NE PAS utiliser cet appareil si les panneaux d’entretien et

qualiée. NE PAS l’utiliser sans avoir lu le présent manuel.

• L’appareil ne doit être utilisé que par une personne

locaux.

conformément à l’autorité ayant juridiction et aux codes

• Une personne qualiée doit eectuer l’installation

Sécurité

Electrical Code.

électrique canadien, partie 1 et aux É—U. – le National

être conformes aux codes en vigueur. Au Canada - le Code

L’installation et le branchement de cet appareil doivent

nº 109 – dernière édition et UL 197 – dernière édition.

La série Garland E22 est conforme aux normes CSA C22.2

annuler les agréments et créer un danger.

signalétiques xée de façon permanente car cela peut

3. Ne pas retirer les étiquettes, avertissements ou plaques

d’alimentation.

plaque signalétique et l’emballage On doit utiliser ce type

l’équipement a été fabriqué en usine est indiqué sur la

2. Le type d’alimentation électrique pour lequel

transporteur.

Tout dommage doit être immédiatement signalé au

de la caisse et vérier encore la présence de dommages.

transport. Sortir avec précaution l’appareil du carton ou

1. Vérier si la caisse a été endommagé pendant le

INFORMATIONS GÉNÉRALES

Page 20

[640mm]

25-3/16"

B

SONT -1/16 PO, +0

LES DIMENSIONS

D

Découpe

[649mm]

25-9/16"

[675mm]

26-9/16"

DE LA PLAQUE DU GRIL

De La Table

Minimum

Pièce n°4517056 Rev 3 (08/24/11) Page 5

E22-36-72GMX 73-5/8" (1870mm) 26-9/16" (675mm) 72-3/8" (1828mm) 25-9/16" (649mm)

E22-36-60GMX 61-5/8" (1565mm) 26-9/16" (675mm) 60-3/8" (1534mm) 25-9/16" (649mm)

E22-36-56GMX 58-3/16" (1478mm) 28-1/4" (718mm) 56-15/16" (1445mm) 27-1/4" (692mm)

E22-36-48GMX 49-5/8" (1260mm) 26-9/16" (675mm) 48-3/8" (1229mm) 25-9/16" (649mm)

E22-36-45GMX 46-15/16" (1192mm) 28-1/4" (718mm) 45-11/16" (1160mm) 27-1/4" (692mm)

E22-36-36GMX 37-5/8" (957mm) 26-9/16" (675mm) 36-3/8" (934mm) 25-9/16" (649mm)

MODÈLE A B C D

Découpe De La Table Recommandéet

C

Minimum De La Table

Découpe

[1229mm]

48-3/8"

[29mm]

1-1/8"

[1215mm]

47-13/16"

[1260mm]

49-5/8"

A

Modèle illustré E22-36-48GMX

Installation Du Gril À Brides – Dimensions De La Découpe De La Table

6.7 6.7 3.35 — 3.35 3.35 — 3.35 27.92 32.21 24.22 13.96 13.96 27.95 16.11 16.11

240V 208V

240V 208V

Monophasé Triphasé

Charge Par Phase (kW)

Ampérage Nominal Par Phase

X-Y Y-Z X-Z X-Y Y-Z X-Z X Y Z X Y Z

240V 208V

Le suxe X indique l’utilisation de thermostats électroniques

E22-36-56GM(X) E22-36-60GM(X) E22-36-72GM(X)

240V 208V

Totale kW

Puissance

Modèles E22-36-36GM(X) E22-36-45GM(X) E22-36-48GM(X)

SPÉCIFICATIONS ET OPTIONS D’INSTALLATION suite

Page 21

Pièce n°4517056 Rev 3 (08/24/11)Page 4

quelle sorte pour des applications autres que commerciales.

applications commerciales seulement. Garland n’ore pas de services de réparation, garantie, entretien ou soutien de n’importe

Les produits Garland ne sont pas agréés ni autorisés pour une utilisation personnelle ou résidentielle, mais sont destinés à des

1"

EN BOIS, ETC.

COMPTOIR

[44mm]

1 3/4"

ENTRANCE

REAR CABLE

DE LA BRIDE

[12mm]

.5"

[25mm]

BORD À BRIDEON

AVEC OPTION

MONTAGE ENCASTRÉ

AVEC BRIDE

GRIL

p. ex. MARBRE OU SIMILAIRE

ACHETÉE SUR PLACE

BANDE DE DILATATION

- MATÉRIAU NON COMBUSTIBLE -

SUR PLACE

ACHETÉE

TABLE EN BOIS

1"

[25mm]

CÔTÉS ET ARRIÈRE

COMBUSTIBLES 1 PO [25 mm]

PAR RAPPORT AUX MATÉRIAUX

BORD SANS BRIDE

MONTAGE ENCASTRÉ

MODÈLES 45 À 72 PO – DÉGAGEMENT MINIMUM

PAR GARLAND

GRIL FOURNI

E SUR PLACE

ACHETÉ

MÉTALLIQUE

DE DILATATION

BANDE

MONTAGE ENCASTRÉ

CÔTÉS ET L’ARRIÈRE

DE 3 PO (76 mm) SUR LES

[76 mm]

3"

1"

[25mm]

MODÈLE DE 36 PO DE LARGE (E22-36-36GMX)

AVEC BORD SANS BRIDE

NON COMBUSTIBLE SE PROLONGEANT

MARBRE/SIMILAIRE MATÉRIAU

PAR GARLAND

GRIL FOURNI

SUR PLACE

ACHETÉE

MÉTALLIQUE

DILATATION

BANDE DE

SUGGESTIONS DE MONTAGE (Pas À L’échelle)

[543mm]

21 3/8"

[464mm]

18 1/4"

DIMENSIONS

[12mm]

.5"

[13mm]

1/2"

DU CÂBLEE

ENTRÉE INFÉRIEURE

[254mm]

10"

B

D

*$5/$1'

VUE AVANT

[914mm]

36"

[864mm]

34"

DU CÂBLE

ENTRÉE INFÉRIEURE

PLAQUE D’ACIER

[121mm]

4 3/4"

[19mm]

3/4"

[29mm]

1 9/16"

POINT CHAUD

[89mm]

3 1/2"

[279mm]

11"

Base

Plancher Ou

Type De

lb/kg

expédition

DU CÂBLE

ENTRÉE ARRIÈRE

[121mm]

4 3/4"

C

1/2 /12-1/2 1/2/121/2 Combustible

Arrière

Et Droit

Côtés Gauche

Côtés De La Carrosserie: Po/mm

Dégagement Minimum D’installation Sur Les

A

minimum ci-dessus par rapport aux matériaux combustibles.

incombustibles. Tous les autres modèles doivent être installés avec les jeux

Le modèle E22-36-36GMX doit être installé uniquement dans des endroits

E22-36-72GMX 73-5/8" (1870mm) 26-9/16" (675mm) 71-13/16" (1824mm) 24-1/4" (616mm) 400/182

E22-36-60GMX 61-5/8" (1565mm) 26-9/16" (675mm) 59-13/16" (1520mm) 24-1/4" (616mm) 385/175

E22-36-56GMX 58-3/16" (1478mm) 28-1/4" (718mm) 56-3/8" (1432mm) 26-15/16" (685mm) 385/175

E22-36-48GMX 49-5/8" (1260mm) 26-9/16" (675mm) 47-13/16" (1215mm) 24-1/4" (616mm) 350/159

E22-36-45GMX 46-15/16" (1192mm) 28-1/4" (718mm) 45-1/8" (1146mm) 26-15/16" (685mm) 340/154

E22-36-36GMX 37-5/8" (957mm) 26-9/16" (675mm) 35-13/16" (910mm) 24-1/4" (616mm) 330/150

Largeur (A) Profondeur (B) Largeur (C) Profondeur (D)

Modèle

Dimension Du Gril Avec Bride Dimension Du Gril Sans Bride Pds

SPÉCIFICATIONS ET OPTIONS D’INSTALLATION

Page 22

Pièce n°4517056 Rev 3 (08/24/11) Page 3

SCHÉMAS DE CÂBLAGE..............................................9

Divers : ..........................................................................8

Modèles Fabriqué Depuis Octobre 2003.......................................8

De Type À Cosses Rectangulaires : ................................................8

Modèles À Thermostat Électronique Avec Capteurs De Température

Modèles Fabriqués Avant Septembre 2003 ....................................8

Thermostat À Bulbe Électromécanique Et Capillaire Thermostat : ...................8

MAINTENANCE ET NETTOYAGE ......................................8

Mise En Service : .................................................................7

Procédure Générale D’installation : ...............................................7

Ventilation : ......................................................................7

Implantation : ....................................................................7

Branchement De L’alimentation Électrique : .......................................7

Alimentation Électrique : .........................................................7

INSTALLATION......................................................7

Sécurité ............................................................6

INFORMATIONS GÉNÉRALES .........................................6

Installation Du Gril À Brides – Dimensions De La Découpe De La Table .............5

SPÉCIFICATIONS ET OPTIONS D’INSTALLATION .......................4

TABLE DES MATIÈRES

Page 23

Pièce n°4517056 Rev 3 (08/24/11)Page 2

Page 24

Pièce n°4517056 Rev 3 (08/24/11) © 2004 Garland Commercial Industries, Inc.

Télécopieur : 905-624-5669

Téléphone : 905-624-0260

CANADA

1177 Kamato Road, Mississauga, Ontario L4W 1X4

GARLAND COMMERCIAL RANGES, LTD.

conception et les spécications des pièces) peuvent être remplacés ou modiés sans préavis.

de Garland à : http://www.garland-group.com. Les renseignements contenus dans le présent document (y compris la

ou par des agents d’entretien non autorisés. Pour obtenir la liste des agents de service autorisés, consulter le site web

numéro de série aurait été mutilé, oblitéré ou supprimé ou qui aurait été modié ou réparé avec des pièces non autorisées

codes nationaux et locaux ou aux instructions d’installation fournies avec le produit ou n’importe quel produit dont le

en ce qui concerne n’importe quel produit mal installé, réglé, utilisé ou qui n’aurait pas été entretenu conformément aux

d’entretien autorisé par Garland utilisant des pièces de rechange d’origine Garland. Garland n’aura aucune obligation

L’attention des utilisateurs est attirée sur le fait que l’entretien et les réparations doivent être eectués par un agent

SIGNALÉTIQUE.

ÉLECTRIQUES FIGURANT SUR LA PLAQUE

EST CONFORME AUX CARACTÉRISTIQUES

VÉRIFIER QUE L’ALIMENTATION ÉLECTRIQUE

CODE ANSI / NFPA – ÉDITION EN VIGUEUR.

LOCAUX. AUX É.-U. – LE NATIONAL ELECTRICAL

DE L’ÉLECTRICITÉ, PARTIE 1 ET/OU LES CODES

VIGUEUR: AU CANADA – LE CODE CANADIEN

DEVRONT ÊTRE CONFORMES AUX CODES EN

L’INSTALLATION ET LES CONNEXIONS

L’ÉQUIPEMENT.

AVANT D’INSTALLER OU DE RÉPARER

D’UTILISATION ET D’ENTRETIEN

LES INSTRUCTIONS D’INSTALLATION,

SURES OU LA MORT. LIRE SOIGNEUSEMENT

DES DOMMAGES MATÉRIELS, DES BLES-

ENTRETIEN MAL FAITS PEUVENT CAUSER

MODIFICATIONS, DES RÉPARATIONS OU UN

UNE INSTALLATION, DES RÉGLAGES, DES

AVERTISSEMENT

PROFESSIONNEL TEL QUE SPÉCIFIÉ.

ET DOIT ÊTRE INSTALLÉ PAR DU PERSONNEL

QU’ÉQUIPEMENT PROFESSIONNEL DE CUISSON

CE PRODUIT A ÉTÉ HOMOLOGUÉ EN TANT

ULTÉRIEUREMENT.

MANUEL ET LE CONSERVER POUR S’Y REPORTER

LIRE TOUTES LES SECTIONS DU PRÉSENT

POUR VOTRE SÉCURIT:

SÉRIE E22-36

APPAREIL OU DE TOUT AUTRE APPAREIL

INFLAMMABLES À PROXIMITÉ DE CET

OU D’AUTRES VAPEURS OU LIQUIDES

NE PAS STOCKER NI UTILISER D’ESSENCE

TEPPAN YAKI GARLAND

GRIL ÉLECTRIQUE

D’INSTALLATION

MANUEL D’UTILISATION ET

Loading...

Loading...