Page 1

Service Manual

Master Gas

Production Griddles

models

CG-24, CG-36,

CG-48, CG-60, CG-72

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A

LICENSED PLUMBER OR GAS FITTER. APPROVAL

NUMBER: G-1-07-05-28

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting

your local gas supplier.

Garland Commercial Ranges, Ltd.

1177 Kamato Road

Mississauga, Ontario L4W 1X4 Canada

P: 905 624 0260 F: 905 624 5669

www.Garland-Group.com

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) © 2013 Garland Commercial Ranges, Ltd.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 1

Parts & Service

1 800 427 6668 (Phone, US & Canada)

1 800 361 7745 (Fax, US & Canada)

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of California to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer. Operation of this product could expose you to

carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known to the state of

California to cause birth defects or other reproductive harm.

Keep appliance area free and clear of combustibles.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DIMENSIONS AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

WHAT IS A CHAIN GRIDDLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How Does it work? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Electrical Power, Lighting & Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OPERATION & MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SERVICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Have The Right Tools And Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pilot Flame Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Burner Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Removing the Griddle Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Thermocouple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

How To Replace A Thermocouple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Incandescent Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pilot Ignition Control (Control Module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gas Valve Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CONTROL PANEL SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

SERVICE BULLETIN #95-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Revision History (CG Griddles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 3

Page 4

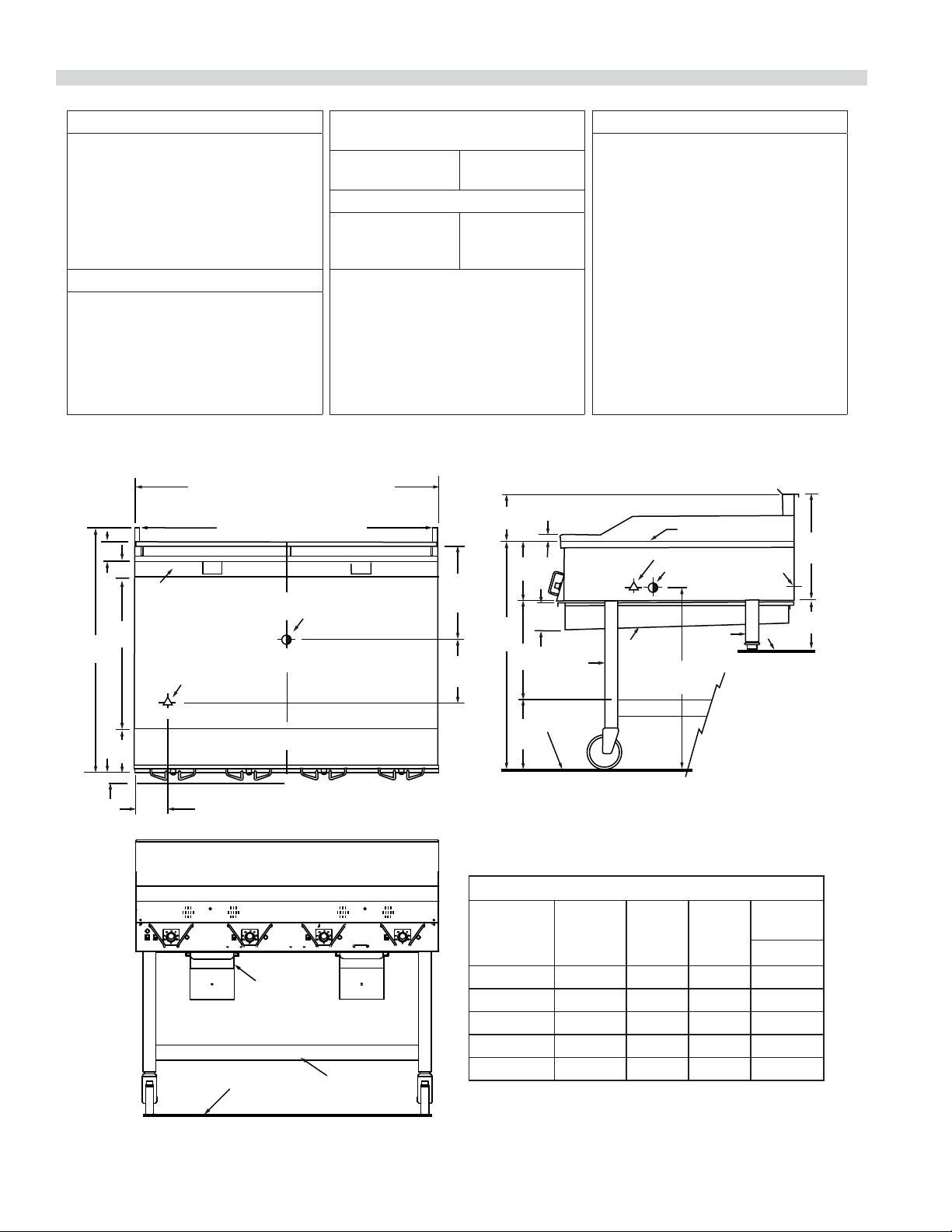

DIMENSIONS AND SPECIFICATIONS

Combustible Wall Clearances

Sides: 6” (152mm)

Back: 6” (152mm)

IMPORTANT:

Unit must be

installed on legs for proper air

circulation.

Ventilation

Commercial cooking equipment

requires an adequate ventilation

system.

Refer to the National Fire

Protection Association’s standard

NFPA96.

Available in 24, 36, 48, 60 & 72 Widths

610, 914, 1219, 1524 & 1829

3" [76mm] Extended Bumper

to Prevent Flue Vent Blockage

Gas Connection Centered

On Unit Width [Left to Right]

38.75

984

2.5

84

3.25

83

24

610

Grease Trough

Electric

Cord/Connection

Manifold Pressure Required

After Built-in Regulator

Natural:

3.5" W.C. (8.75mbar)

Propane:

10" W.C. (25mbar)

Minimum Supply Pressure Required:

Natural:

7" W.C. (17.4mbar)

Propane:

11" W.C. (27.4mbar)

NOTE

Gas Input Ratings shown are for

installations up to 2,000 feet (610mm)

above sea level.

BTU input ratings must be derated for

high altitude installations.

0.625

5.75

20

508

5.5

140

146

35

889

10

254

15

381

16

4.75

121

Optional

Stand

Electrical Requirements

Speci cations:

120 V, Single Phase, 60Hz, 1 A

6’ (1829mm) power supply cord provided.

NOTE: No cord and plug on export units

Direct connection on junction box.

Export Voltages:

NOTE: Export voltages are available on

request.

220-240 V, 50 Hz, 0.4 A, Single Phase.

Rear

Counter

Inches

mm

15.75

400

6

152

DIMENSIONS:

Cooking Surface

Electric Cord/Connection

Gas Connection

Removable

Grease

Drawer

Counter

Leg

27

686

Gas Inlet

1.5

38

152

Finished

Floor

10

6

254

SIDE VIEW

5

127

PLAN VIEW [Model CG-48R]

Dimensions - All Models

INPUT CHART - Natural Or Propane Gas

Shipping

Grease Drawer(s)

2' & 3' Units - One

4', 5' & 6' Units - Two

Model

Number

CG-24R 60,000 17.60 3/4" 335/152

CG-36R 90,000 26.40 3/4" 485/220

BTU/

hour

kW

Gas

Inlet

Weight

lb./kg.

CG-48R 120,000 35.00 3/4" 625/284

CG-60R 150,000 44.00 3/4" 765/348

Finished Floor

Optional Stand

CG-72R 180,000 52.70 1" 995/411

FRONT VIEW [Model CG-48R]

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 4

Page 5

WHAT IS A CHAIN GRIDDLE

Commercial chain restaurants impose strict food procedures

on franchise owners and operators to guarantee the quality

and consistency of the product. Beef burgers, hamburgers,

french fries, onion rings, fried chicken and tortillas for

example, must meet rigid standards of quality involving the

ingredients used, the recipes followed, storage and, not least,

the cooking temperature and time of cooking.

Accuracy of temperature control and the heating stability of

the cooking surface are essential in maintaining consistent

quality in the product. Control and stability are the two

primary features in the new chain griddle. As compared with

previous gas griddles of the same kind, temperature control

of heating zones in the chain griddle is far tighter and more

precise.

Two features provide precision control. One feature is a

burner for every foot of griddle surface. The other is that each

burner is electronically monitored for temperature control.

As a result, at 30,000 BTU using natural gas, there is excellent

energy management and power recovery.

Temperature sensors are embedded in the griddle plate.

Each sensor is close to the plate surface where the load

is. The e ect of this arrangement is to achieve an even

temperature gradient across the plate. Thanks to the

electronic monitoring feature, a much faster response to

changes in surface temperature is achievable in the chain

griddle than in previous units.

The smoother temperature gradient per unit surface area

and accurate temperature control has made the chain

griddle an instant success. This simple explanation of the two

main features of the unit is what makes it so special. Without

fast response and a smooth gradient, the chain griddle

would be just another design among many.

Explaining why the unit is special is one thing and

understanding how it works in another. Service technicians

need to know this to have complete con dence when

servicing the unit. We describe how it works in the next part

of this section.

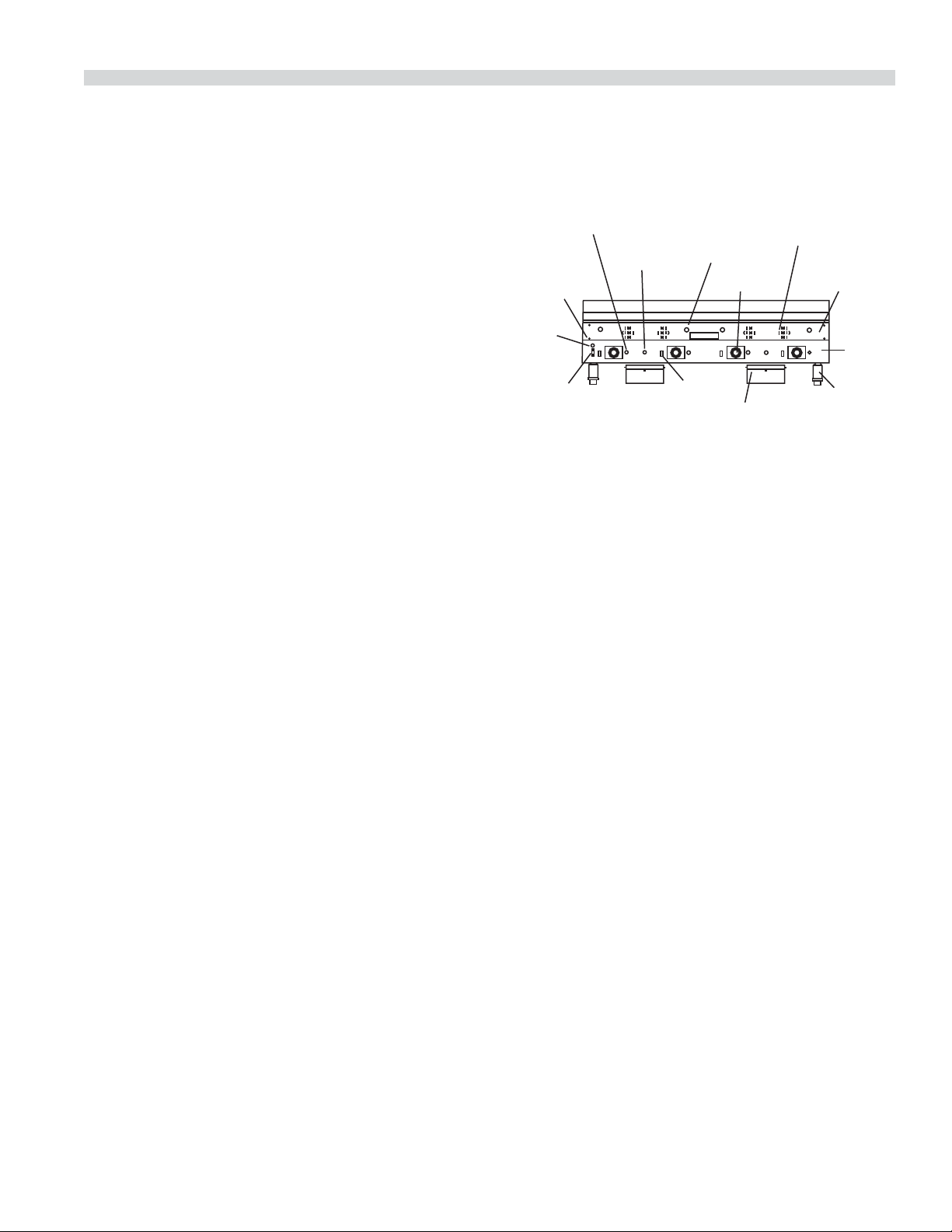

Figure 1 -Front view of counter-top chain griddle

Burner ON amber

indicator light

Securing

fasteners

for removable

top

access panel

Main power

ON

green

indicator

light

Main power

switch

Pilot ON green

indicator light

Zone power

Flame

viewport

thermostat

switch

Air vents

Zone

Grease tray

Removable top

access panel

Hinged

drop-down

bottom half

access

panel

Leg of counter-top

style griddle

How Does it work?

When the main power switch is turned on, the power

indicating lamp is illuminated and power is applied to the

thermostat input of the ignition modules. This will initiate

the pilot ignition sequence. The ignition module supplies a

spark ignition at the pilot burner and will energize the pilot

solenoid valve for a maximum trail period of 50 seconds.

If the pilot ame ignites and is sensed within the 50 second

period, the main burner output of the ignition module will

be energized. The pilot indicating lamp will illuminate. The

main burner solenoid valves are then controlled by the

thermostats. As a thermostat calls for heat, it will energize

its output and the main burner valve along with the burner

indicating lamp will energize. The main burner will cycle with

the thermostat.

There is only one trial for ignition. If the pilot ame is not

sensed during the trail period, the ignition module will lock

out. All ignition module outputs will be de-energized. To reset

the ignition module the main power switch must be turned

o for a period of 30 seconds.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 5

Page 6

WHAT IS A CHAIN GRIDDLE continued

During normal operation, the pilot ame is continually

monitored. The ame current signal must maintain 0.15

microamps minimum. Flame failure response time is 0.8

seconds maximum. If at any time the ignition module does

not detect a pilot ame, it will repeat the ignition process by

allowing a 50 second trial of ignition.

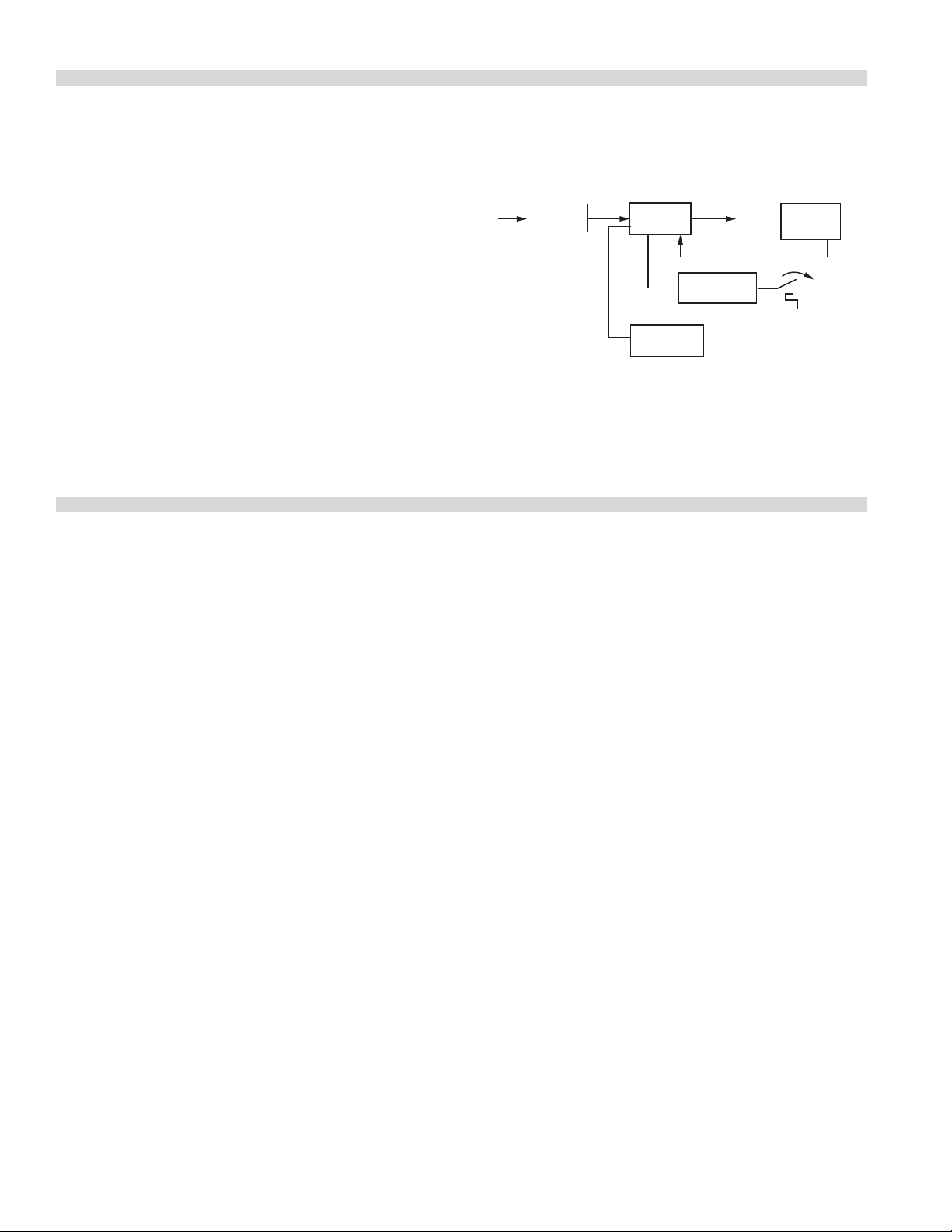

Figure 2 illustrates this sequence of operation.

INSTALLATION

The instructions given for installation form part of the

delivery package. Anyone installing a chain griddle should

follow a strict procedure to make sure installation and

commission are safe, e cient and complies with the

applicable local codes. Here is a check list of things to do in

the order we recommend.

Mechanical

• Uncrate and check for shipping damage both obvious

and hidden. Write a damage report and report

immediately to the carrier.

• Check the serial plate behind the front panel. To do this,

remove the front panel by unscrewing the two screws in

the upper right and left corners. Next unscrew the two

fasteners securing the hinged lower font panel in place.

Note the burner inputs shown on the serial number

plate. It may be necessary to refer to these later. You also

need to be certain of the type of gas to which the unit

is connected. The serial plate also speci es the type of

gas required for the unit. Also, check that the electrical

connections are in good order.

NOTE : The chain griddle is certi ed for installation on a

combustible base with minimum clearance of 6” (152mm)

back and 6” (152mm) sides from combustible walls.

Figure 2 – Sequence of Operation

o/p

Flame

sensor

Power

CAUTION : Check the pipe capacity tables given in the

installation code. When a long supply pipe run is necessary,

you may have to install a supply line lager than 3/4”

• Have a quali ed gas technician check the gas supply to

make sure it will deliver the BTUs of gas the unit requires

to operate with no more than 1/2” water pressure

drop. Also when making this check be certain that all

equipment on the gas line is turned to the ON position.

• If you are installing the unit using a new gas installation,

make sure the supply lines have been cleaned and

purged of piping compound, chips and other debris.

WARNING : Use soap solution if you have to check the gas

lines for leaks.

• Place and install the unit on the legs or caters provided,

and make sure there is a minimum of 4” (102mm) air

space below the unit for adequate air ow to the burners.

CAUTION: Check for obstructions or objects that could

restrict the air ow to the burners.

• Using a spirit level variously across the front, rear and sides

of the unit, level it by adjusting the leveling legs.

Ignition

Pilot valve

Main valve

Spark

Gas Supply

• Every unit is tted with a readily accessible shut-o valve

at the main manifold. Use a minimum of 3/4” NPT pipe to

connect the incoming gas supply.

NOTE : For e cient operation, the griddle plate must be

level.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 6

Page 7

INSTALLATION continued

• Each thermostat controls one zone burner though a

dual solenoid-pressure regulator valve complete with a

pressure test spigot. Check the manifold gas pressure on

each combination valve to make sure it is the same as

that shown on the serial plate. The gas pressure should be

3.5” WC for natural gas and 10.0” for propane gas.

• For access to the pressure test spigots, turn the main

power switch and all zone power switches to the OFF

position and lower the front panel on its hinge. This is a

safety precaution. The test spigots are at the rear of the rear

of the combination regulator valves.

• Connect your manometer to the rst valve for test and

turn the manual shut-o valve to the ON position.

NOTE : The shut o valve is under the unit. When it is ON and

in the open position, the valve position is in line with the

piping. Also, see the electrical procedure below for notes on

the status indictor lights and setting the thermostats.

• Turn the main power switch and the zone power switches

to the ON position.

• Set all the thermostat dials to 350˚F. When all the burners

are operating, check and record the manometer reading,

which should be the same manifold pressure as that

speci ed on the serial plate (3.5” WC for natural gas and

10.0” for propane gas). Adjust the regulator to obtain the

pressure rate speci ed.

• When satis ed with the reading obtained, turn the main

power switch OFF. Remove the manometer test tube and

re-cap the test spigot.

• Repeat this operation on each combination regulator

valve to correctly set it. Then turn each thermostat, zone

and main power switch OFF.

• To check the unit lighting, turn the main power switch of

the unit to the ON position. The green light of the power

switch and the green indictor of the gas pilot of each

section of the griddle should illuminate.

CAUTION : If after two minutes the pilot ignition fails, turn

the main power switch OFF. Wait ve minutes and switch the

main power ON again.

• When the green indicator for each zone is illuminated,

turn the zone power switch for each zone ON. The

thermostats can now be set to the desired temperature.

• The amber light burner indicator cycles with the

operation of the thermostat.

Ventilation

For e cient operation this unit requires a minimum

ventilation air supply of 50frm. The ideal method of

ventilation is a well-designed canopy of hood that exceeds 6”

(152mm) beyond all sides of the unit. Ideally, the bottom of

the hood should be set 6’6” (1981mm) from the oor.

Gas burners and pilot devices need a su cient air supply to

operate e ciently, so do not place large objects anywhere

near them to restrict or in any way limit the air ow.

In most operations, the chain griddle will be used in

conjunction with other kitchen equipment. The need for

the ingress of air to the kitchen area must be su cient to

compensate for the air the ventilation system abstracts.

Unless the air ow is su cient a subnormal, and probable

negative, atmospheric pressure will result, which will

adversely a ect the operation of the equipment and make

work in the kitchen area unpleasant.

Start-Up

Electrical Power, Lighting & Control

WARNING : Do not work on ungrounded equipment. It is

dangerous.

• National and local electrical codes require that all devices

of this type be electrically grounded. Check to make sure

the unit is grounded.

CAUTION : Make sure the electrical connections enclosed by

the panels are in good order and undamaged before closing

and securing the front panels.

NOTE : This griddle is equipped with a 3-pronged plug cord

set to t any 120V AC3-prong, 15 amp-rated, grounded

receptacle.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 7

When the chain griddle is used for the rst time, the griddle

top requires seasoning. To season a griddle surface, follow

this procedure.

1. Wash the griddle surface with a hot, mild detergent or

soap solution, then rinse and dry thoroughly.

2. Set the thermostat to 175˚F for 30 minutes, then apply a

lm of cooking oil to the cooking surface and wipe away

the excess.

3. After (5) ve minutes, wipe the griddle plate clean.

Page 8

INSTALLATION continued

4. Re-set the thermostat to 275°F and apply a second lm of

oil. After (5) ve minutes, wipe o the excess oil.

5. Reset the thermostat to the cooking temperature and

apply a nal lm of oil. After (3) minutes, wipe o the

excess oil. The griddle is now seasoned and ready for use.

OPERATION & MAINTENANCE

During idle periods, reduce the thermostat settings to

conserve energy. A setting of 175°F to 200˚F is enough to

keep the plate warm. Reducing the temperature also reduces

the load on the thermostat.

1. At then end of the operations, turn the power and zone

switches OFF. There is no need to change the thermostat

settings when the unit is not in use.

2. Don’t overheat the griddle. Excessive heat causes grease

to carbonize and makes the surfaces hard to clean.

3. Empty the grease trays often to avoid spillovers.

4. For extended shutdown or major maintenance, turn the

power and zone switches OFF, close the manual shut-o

gas valve, and unplug the electrical power cord.

Cleaning

1. At the end of the cooking operations, wipe and clean the

unit while it is still warm. Use a spatula to remove food

residue and burnt grease.

2. When the plate is cool, wash it with a mild detergent, dry

it, and wipe it with a slightly oiled cloth.

NOTE : We recommend reseasoning the griddle before each

day’s operations begin. Franchise operators who follow

explicit operating procedures should be made aware of this

recommendation.

3. For a more thorough cleaning, use Garland Ranges F69

fryer and griddle cleaner. Polish the plate to a bright nish,

then wash, rinse and thoroughly dry it.

4. Follow the procedure speci ed (see Start-Up) to reseason

the cooking surface.

5. To clean the exterior surface of a chain griddle, clean the

stainless steel with a hot detergent or soap solution.

Remove baked on grease by applying the cleanser in

the direction of the polishing lines of the stainless steel

surface.

CAUTION : Do not rub stainless steel in a circular motion. This

destroys the nished surface of the metal and detracts from

its appearance.

If it is necessary to remove hard and burnt on deposits

from high quality surfaces, use SCOTCH-BRITE or STAINLESS

scouring pads by running with the grain of the nished

steel. Remove heat tint the same way, using if necessary a

non-abrasive powered cleanser with the SCOTCH-BRITE or

STAINLESS pad. On no account use ordinary steel wool, it will

damage the nished surface.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 8

Page 9

SERVICING

Many factors a ect the serviceability of equipment. In the

chain griddle, there are more components to service than in

older models. The new griddle is a compact design. Access

to the temperature control circuitry and ignition units is

easy. Service techniques for the thermocouple will vary

depending on the model type.

They unit is available with a 6” (152mm) leg which means

that under the griddle plate there is only 6” (152mm) of

working room. To replace a thermocouple it is di cult to

lift the griddle plate, rmly secured to the support frame. To

replace a thermocouple requires bottom access because the

plate is securely xed (see Figure 3).

With this introduction to serviceability, and apart from

the features that make the chain griddle superior to more

conventional units, many of the servicing tasks are standard;

the adjustments likewise. The procedures that follow are

a plain guide to servicing, beginning with adjustments to

various components.

Have The Right Tools And Instruments

In addition to a service technician’s normal hand tools, for

servicing this chain griddle we recommend:

1. A manometer or other suitable instrument for measuring

gas pressure

1. To remove the upper front and lower front panels, refer to

the installation procedure given earlier.

2. To reduce the volume of gas feed to the pilot, turn the

small screw in the pilot adjusting valve clockwise.

3. To increase the gas feed to the pilot, turn the same screw

counter-clockwise.

NOTE : Adjust the gas feed to produce a 7/16” (11mm) long

ame to make sure the ame envelopes the top of the ame

sensor.

Burner Air

Make sure a burner is warm before adjusting the air shutters

and follow this procedure.

1. First, loosen the screw along the side of the burner near

the ori ce.

2. A burner ame that gets too much air appears to lift

above the burner as though separated from it. This

means the shutter needs throttling back to a more closed

position.

3. A yellow tip on the ame is a sign that the shutter is

not passing enough air to feed the ame. In this case, it

necessary to open the shutter.

2. A multimeter

3. A digital read-out temperature meter

4 A micro-ammeter

CAUTION : In this chain griddle we use a J-type

thermocouple, which requires a meter with a J-type

connection for checking. Most meters have K-type

connections.

Adjustments

Every griddle is inspected and tested before it leaves the

factory. Adjustments to the unit during installation and

servicing are the responsibility of the eld operator and are

not considered to be defects in material or workmanship.

For this reason, adjustments are not covered under the

equipment warranty.

Pilot Flame Adjustment

A pilot adjustment valve is in the line form each pilot

combination valve and access to it is behind the lower front

panel.

4. When the shutter adjustment is complete, tighten the

screw to lock the shutter setting in the adjusted position.

5. Re-close the upper and lower front panels and replace

the fasteners.

Removing the Griddle Plate

If it is necessary to remove the griddle top, follow this

procedure:

1. Disconnect the power supply.

2. Remove the upper control panel.

3. Open the lower control panel.

4. Disconnect all thermocouple sensors and shield bayonet

adapters. (To reassemble, see the Thermocouple section.)

5. Remove the griddle top retaining bolts (both left and

right).

6. Remove the back ue.

7. The griddle top is now easily removed.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 9

Page 10

SERVICING continued

Thermostat

Make sure the thermostat knob is correctly aligned with

the dial indicator. To align the knob with the graduated dial

correctly, follow this procedure.

1. Turn the knob and shaft fully counter-clockwise. Loosen

the set screw in the knob and align the pointer with the

rst line of the scale at the lower left position.

NOTE : When the knob is fully rotated clockwise, the pointer

should align with the last line of the scale.

2. Set the dial to 350˚F. Wait at least three cycles before

monitoring the temperature.

3. Use a surface temperature probe disc positioned on the

center line with the thermostat knob and centered front

to back on the griddle plate.

The thermostat will overshoot and undershoot as caused

by the lag time in the thermal response of the heat sourceto-plate and plate-to-sensor. The calibration temperature

will be the mid-point between the minimum and maximum

readings. Other than the alignment of the knob pointer,

there is no means to calibrate the thermostat. It has been

precisely calibrated by the manufacturer.

Thermocouple

If the temperature is incorrect check the thermocouple.

The thermocouple in this unit is a Type J, which requires

the use of a J-type temperature meter for checking. For a

complete understanding of the thermocouple used in the

chain griddle see the GCR Service Bulletin #95-5 entitled

“Thermocouples”.

A thermocouple is an accurate temperature measuring

device that consists of two dissimilar conductors joined

together at their ends. It works on a simple principle, which

is that the thermoelectric voltage between the two junctions

is proportional to the temperature di erence between them.

This principle is applied to measure the temperature at one

of the junctions when the other is held at a xed known

temperature. The technology is not new, but its use in GCR

griddles is recent.

The thermocouple probe is embedded in the griddle plate

and accurately registers the surface temperature. It is a

reliable device, but can cause problems when it fails for any

reason. In addition to deterioration from aging, it can fail in

two ways: one from an open-circuit (that is, a break in one of

its wired); the other when it short-circuits.

If a thermocouple open circuits, the thermostat will shut o

and prevent the gas valve from opening, which means the

burner will not function.

If a unit short circuits somewhere behind the junction, it

creates a new junction and because the circuit cannot detect

the existence of a short circuit fault, there is a dramatic

increase in temperature. The thermocouple detects changes

in temperature, but because of the short circuit it may fail to

register the set temperature at the thermostat. This means

the burner may not shut o . At the other extreme, the short

circuit may occur in a place not shielded from the ue gases,

which means the burner may shut o prematurely. These are

the two conditions to look for in a shorted thermocouple.

Deterioration from aging and from welding dissimilar metals

together to for a junction introduces a contaminant that

causes mechanical stress. Over time, ve to ten years, metal

fatigue from aging is certain. As a result, the temperature

curve will vary.

How To Replace A Thermocouple

A heat shield protects the thermocouple from the burner

ames and ue gases. Without the shield, the thermocouple

would register ame heat to the thermostat instead of

sensing the temperature of the griddle plate.

To replace a thermocouple (refer to Figure 3), following this

procedure:

1. Open the front panel to get access to the terminal board.

2. To withdraw the thermocouple, rst remove the heat

shield. It is held in place by two combination Philip

and Robinson-heat size number 10 sheet metal screws.

Remove the heat shield by sliding it down the wire.

3. A bayonet connector secures the thermocouple in place.

Reach inside the hole and push and twist the bayonet

connector a quarter turn.

4. Remove the connection to the terminal board and feed

these wires through the heat shield. The thermocouple is

now removed.

5. Connect the wires of the replacement thermocouple, but

make sure the polarity is correct. Connect the negative

red wires to terminal 7 on the thermostat and the positive

white wire to terminal 8. (See schematic diagram).

6. Thread the thermocouple through the heat shield and

into the plate cavity.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 10

Page 11

SERVICING continued

Figure 3 – Replacing a thermocouple

Adjust to

about 4.5"

before

Bayonet

adapter

7. The bayonet connector is spring loaded. Turn the

connector so that it makes good contact with its seat on

the plate, and adjust the spring so that at least 1” (25mm)

of spring is available to push home. This is, it is loaded 1”

(25mm) from the bayonet adapter.

8. Once this adjustment is made, remove the thermocouple

from its cavity, pry the old heat sink material from the

cavity and apply fresh heat sink compound (Garland

Commercial Ranges part #77024).

9. Re-assemble the unit.

installing

About 1"

before compression

Incandescent Lamps

Griddle plate

Probe heat

shield assembly

• If PL1 doesn’t illuminate when SW1 is closed, replace it.

• Failure of the amber lights (PL3, PL4, etc.) monitoring the

zones cycle with the thermostat is not easy to detect.

When on, an amber zone light is working. If it does not

appear to light as part of the ‘burner on’ cycle, check. If

the thermostat cycles the burner to be on, the PL amber

light should illuminate.

Pilot Ignition Control (Control Module)

The Johnson G770 pilot ignition unit will lock out if the pilot

ame is not sensed before the end of the ignition trial period

and has to be reset.

These lamps, similar in construction if not in shape to

ordinary incandescent light bulbs, sometimes fail because

of metallurgical breakdown of the light lament material.

The green status light (PL1) should illuminate when the main

switch SW1 is closed.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 11

• To reset the ignition control, turn o the thermostat for a

minimum of 30 seconds.

Page 12

SERVICING continued

Gas Valve Regulator

The gas valve regulator (See g 4) used on the griddle is

AGA and CGA approved. The direction of gas ow is at

right angles, right and left viewing the inlet. For setting the

regulator:

• For natural gas, Part #240510 regulator, set at 3.5” W.C. at

22 CFH air each side at 7” W.C. inlet pressure. Regulator

adjustment range is 2.8” to 4.0” WC.

• From propane, part # 245101 regulator, set at 10.0” W.C.

Figure 4 – Gas Valve Regulator

Flow

Inlet

Flow

Pressure

setting screw

Turn counter-clockwise

to increas the pressure

setting

Turn clockwise to

decrease the pressure

Power Switches

Dust caps tted on the main power switch and zone

switches protect them from dust and the corrosive e ect of

cooking fumes. If the dust caps are removed, or not replaced

following servicing, the switches will deteriorate and have

reduced life expectancy. Replace the dust caps following

servicing.

Control Circuit

Figure 4 shows the control schematic for the GC-48 unit,

which has two zones. The ignition and temperature controls

for each zone are identical.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 12

Page 13

CONTROL PANEL SCHEMATIC DIAGRAM

Figure 4 – Control schematic for a Model CG-48

Chain Griddle

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 13

Page 14

SERVICE BULLETIN #95-5

FROM – National Service Department BULLETIN NO. #95-5

TO – National Service Binder Holders DATE – February 24, 1995

Subject: Subject: Thermocouples used in the Chain Griddle

Models CG-36, CG-48, CG-60 & CG-72

This bulletin supplements the chain Griddle Service Manual with a description of the basics of

thermocouple theory and how to use the degree/millivolt tables issued as part of this bulletin.

This bulletin deals with the thermocouple only and how it registers temperature changes.

The type J thermocouple on the new Chain Griddle measures the plate temperature within a

range of accuracy of 2˚F to 4˚F. The J designation refers to the conductors used and, therefore, the

thermoelectric characteristics of the conductors that form the thermocouple. In the Type J unit,

the conductors are iron and the alloy constantan. Constantan is an alloy of copper and nickel.

Thermocouple technology for sensing temperature has been in use for a long time but the Type J

thermocouple is new to Garland Commercial Ranges Limited applications.

To dissimilar metals joined together, as in Figure 1, cause a thermoelectric current to ow in the

circuit formed when the junctions are at di erent temperatures. The current will continue to

ow as along as the junctions (T1 and T2) remain at di erent temperatures. Thermoelectricity

is the direct conversion of heat into electricity and vice versa. The electric motive force (emf)

producing the current is called the “Seebeck Thermal Emf” (Seebeck after the discoverer), and is

proportional to the temperature di erence between the two junctions.

Three laws govern the way thermocouples work: the law of homogeneous circuits, the law of

intermediate metals and the law of successive or intermediate temperatures. The rst law is that

a thermocouple circuit must use di erent metals; the second is that a third metal introduced

will not a ect the couple provided it is maintained at the same temperature along its entire

length; the third provides a means of relating the emf generated to a standardized constant

temperature. Refer to a textbook about thermocouples for a fuller explanation of these laws.

Metal A

I

T

1 junction

V

Metal BMetal B

Figure 1

T

2 junction

T = Temperature

I = Current

V = Voltage (emf)

If the cold junction is at a known or reference temperature it is a simple matter to compare this

with the hot junction at the probe of the thermocouple to obtain an accurate measure of the

hot junction temperature. In practice, the cold junction is eliminated by the use of electrical or

hardware compensating methods.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 14

Page 15

SERVICE BULLETIN #95-5 continued

Tables of millivolt values for degrees Fahrenheit (at reference junction temperature 32˚) and

Centigrade (at reference junction temperature 0˚) have been written and extracts from these

tables form part of this bulletin. These are required if service technicians need to check a

thermocouple without a J calibrated temperature meter.

Check the thermocouple if you nd the temperature variation of the thermostat is more than ±

5˚F from the set point. To check a thermocouple, follow this procedure:

Note: The Type J thermocouple requires the use of a Type J temperature meter.

If a type J meter is not available use a millivolt meter and refer to the tables of

degrees/millvolt values following, to calculate the cold junction compensation.

Remember that the accuracy of you measurements can be no more accurate than your

instruments. Thermocouples generate very small voltages. Many voltmeters cannot read

millivoltages accurately.

Set all control thermostats to the same temperature (350˚F). Allow the griddle plate to saturate

and achieve a steady temperature.

Place a surface temperature probe on the griddle surface about the thermocouple you want to

check. The surface must be cleaned before this procedure. If there is any grease residue on the

probe or griddle plate, it will introduce an error in your reading.

Take the temperature reading of the plate above the controlling thermocouple.

Disconnect the thermocouple from the temperature and, either connect it to a J type calibrated

temperature meter to measure the temperature output directly or, do the following: measure

and record the millivolts generated by the thermocouple. Measure the ambient temperature.

Refer to the table and add the corresponding millvoltage for the ambient temperature to the

value measured from the thermocouple. Find the corresponding temperature in the chart for

millvoltge result.

Example: if the ambient room temperature is 20˚ C add the millvolt value of

20˚C (1.019mV) from the chart to the millvolt reading of the meter and nd the

temperature value in the chart. The temperature should match the reading on

the surface of the plate.

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 15

Page 16

SERVICE BULLETIN #95-5 continued

Type J - Thermocouples (0° to 440°F)

EMF In Millivolts - Reference Junction 0°F

°F012345678910

0 -0.885 -0.868 -0.831 -0.803 -0.776 -0.748 -0.721 -0.694 -0.666 -0.639 -0.611

10 -0.611 -0.583 -0.556 -0.528 -0.501 -0.473 -0.445 -0.418 -0.390 -0.362 -0.334

20 -0.334 -0.307 -0.279 -0.251 -0.223 -0.195 -0.168 -0.140 -0.112 -0.084 -0.058

30 -0.058 -0.028 0.000 0.028 0.056 0.084 0.112 0.140 0.168 0.196 0.224

40 0.224 0.253 0.281 0.309 0.337 0.365 0.394 0.422 0.450 0.478 0.507

50 0.507 0.535 0.563 0.592 0.620 0.648 0.677 0.705 0.734 0.762 0.791

60 0.791 0.891 0.848 0.876 0.905 0.933 0.962 0.990 1.019 1.048 1.076

70 1.076 1.105 1.134 1.262 1.191 1.220 1.248 1.277 1.396 1.335 1.363

80 1.363 1.392 1.421 1.450 1.479 1.507 1.536 1.565 1.594 1.623 1.652

90 1.652 1.681 1.710 1.739 1.768 1.797 1.826 1.855 1.884 1.913 1.942

100 1.942 1.971 2.000 2.029 2.058 2.088 2.117 2.146 2.175 2.204 2.233

110 2.233 2.263 2.292 2.321 2.350 2.380 2.409 2.438 2.467 2.497 2.526

120 2.526 2.555 2.585 2.614 2.644 2.673 2.702 2.732 2.761 2.791 2.820

130 2.820 2.849 2.879 2.908 2.938 2.967 2.997 3.026 3.056 3.085 3.115

140 3.115 3.145 3.174 3.204 3.233 3.263 3.293 3.323 3.352 3.381 3.411

150 3.411 3.441 3.470 3.500 3.530 3.560 3.589 3.619 3.649 3.678 3.708

160 3.708 3.738 3.768 3.798 3.827 3.857 3.887 3.917 3.947 3.976 4.006

170 4.006 4.036 4.066 4.096 4.126 4.156 4.186 4.216 4.245 4.275 4.305

180 4.305 4.335 4.365 4.395 4.425 4.455 4.485 4.515 4.545 4.575 4.605

190 4.605 4.635 4.665 4.695 4.725 4.755 4.786 4.816 4.846 4.876 4.906

200 4.906 4.936 4.966 4.996 5.026 5.057 5.087 5.117 5.147 5.177 5.207

210 5.207 5.238 5.268 5.298 5.328 5.358 5.389 5.419 5.449 5.479 5.509

220 5.509 5.540 5.570 5.600 5.630 5.661 5.691 5.721 5.752 5.782 5.812

230 5.812 5.843 5.873 5.903 5.934 5.964 5.994 6.025 6.055 6.085 6.116

240 6.116 6.146 6.176 6.207 6.237 6.268 6.298 6.328 6.359 6.389 6.420

250 6.420 6.450 6.481 6.511 6.541 6.572 6.602 6.633 6.663 6.694 6.724

260 6.724 6.755 6.785 6.816 6.846 6.877 6.907 6.938 6.968 6.999 7.029

270 7.029 7.060 7.090 7.121 7.151 7.182 7.212 7.243 7.274 7.304 7.335

280 7.335 7.365 7.396 7.426 7.457 7.488 7.518 7.549 7.579 7.610 7.641

290 7.641 7.671 7.702 7.732 7.763 7.794 7.824 7.855 7.885 7.914 7.947

300 7.947 7.977 8.008 8.039 8.069 8.100 8.131 8.161 8.192 8.223 8.253

310 8.253 8.284 8.315 8.345 8.376 8.407 8.437 8.468 8.499 8.530 8.560

320 8.560 8.591 8.622 8.652 8.683 8.714 8.745 8.775 8.806 8.837 8.867

330 8.867 8.898 8.929 8.960 8.990 9.021 9.052 9.083 9.113 9.144 9.175

340 9.175 9.206 9.236 9.267 9.298 9.329 9.359 9.390 9.421 9.452 9.483

350 9.483 9.513 9.544 9.575 9.606 9.636 9.667 9.698 9.729 9.760 9.790

360 9.790 9.821 9.852 9.883 9.914 9.994 9.975 10.006 10.037 10.068 10.098

370 10.098 10.129 10.160 10.191 10.222 10.252 10.283 10.314 10.345 10.376 10.407

380 10.407 10.437 10.468 10.499 10.530 10.561 10.592 10.622 10.653 10.684 10.715

390 10.715 10.746 10.777 10.807 10.838 10.869 10.900 10.931 10.962 10.992 11.023

400 11.023 11.054 11.085 11.116 11.147 11.177 11.208 11.239 11.270 11.301 11.332

410 11.332 11.363 11.292 11.424 11.455 11.486 11.517 11.548 11.578 11.609 11.640

420 11.640 11.671 11.702 11.733 11.764 11.794 11.825 11.856 11.887 11.918 11.949

430 11.949 11.980 12.010 12.041 12.072 12.103 12.134 12.165 12.196 12.226 12.257

440 12.257 12.288 12.319 12.350 12.381 12.411 12.442 12.473 12.504 12.535 12.566

450 12.566 12.597 12.627 12.658 12.689 12.820 12.751 12.782 12.813 12.843 12.875

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 16

Page 17

SERVICE BULLETIN #95-5 continued

Type J - Thermocouples (0° to 240°C)

EMF In Millivolts - Reference Junction 0°C

°C012345678910

0 0.000 0.050 0.101 0.151 0.202 0.253 0.303 0.354 0.405 0.456 0.507

10 0.507 0.550 0.609 0.660 0.711 0.762 0.813 0.865 0.916 0.967 1.019

20 1.019 1.070 1.112 1.174 1.115 1.277 1.329 1.381 1.432 1.484 1.536

30 1.536 1.588 1.640 1.693 1.745 1.797 1.849 1.901 1.954 2.006 2.058

40 2.058 2.111 2.163 2.216 2.260 2.321 2.374 2.426 2.479 2.532 2.585

50 2.585 2.639 2.691 2.743 2.796 2.849 2.902 2.956 3.009 3.062 3.115

60 3.115 3.168 3.221 3.775 3.328 3.381 3.435 3.488 3.542 3.595 3.649

70 3.649 3.702 3.756 3.809 3.863 3.917 3.971 4.024 4.078 4.132 4.186

80 4.186 4.239 4.293 4.347 4.401 4.455 4.509 4.563 4.617 4.671 4.724

90 4.725 4.780 4.834 4.868 4.942 4.996 5.050 5.105 5.159 5.213 5.268

100 5.268 5.322 5.376 5.431 5.485 5.540 5.594 5.649 5.703 5.758 5.813

110 5.812 5.867 5.921 5.976 6.031 6.085 6.140 6.195 6.249 6.304 6.359

120 6.359 6.414 6.468 6.523 6.578 6.633 6.688 6.742 6.797 6.852 6.907

130 6.907 6.962 7.017 7.072 7.127 7.182 7.237 7.292 7.237 7.402 7.457

140 7.457 7.512 7.567 7.622 7.677 7.732 7.787 7.843 7.898 7.953 8.008

150 8.008 8.063 8.118 8.174 8.229 8.284 8.339 8.394 8.450 8.505 8.560

160 8.560 8.616 8.671 8.726 8.788 8.837 8.892 8.947 9.003 9.058 9.113

170 9.113 9.169 9.224 9.279 9.335 9.390 9.446 9.501 9.556 9.612 9.667

180 9.667 9.723 9.778 9.834 9.889 9.944 10.000 10.055 10.111 10.166 10.222

190 10.222 10.277 10.333 10.388 10.444 10.499 10.555 10.610 10.666 10.721 10.777

200 10.777 10.832 10.888 10.943 10.999 11.054 11.110 11.165 11.221 11.276 11.332

210 11.332 11.387 11.443 11.498 11.554 11.609 11.665 11.720 11.776 11.831 11.887

220 11.887 11.943 11.998 12.054 12.109 12.165 12.220 12.276 12.331 12.387 12.442

230 12.442 12.498 12.553 12.609 12.664 12.720 12.776 12.831 12.887 12.942 12.998

240 12.998 13.503 13.109 13.164 13.220 13.275 13.331 13.386 14.442 13.497 13.553

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 17

Page 18

Revision History (CG Griddles)

PAGE# SECTION NOTES DATE

Dimensions and

4

Speci cations

1 Modi ed footer info.

Missing manifold pressure info. Copied from latest Spec Sheet dated 11/13/12.

Revised operating pressure data for LP, 27.4 mbar. Was 24.4 mbar.

MAR 19/13

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13)Page 18

Page 19

G_GC_SM_CHAINGRIDDLE_GCGTRAINING06 (03/19/13) Page 19

Page 20

Master Gas Production Griddles — CG Models Service Manual

Garland Commercial Ranges, Ltd.

1177 Kamato Road

Mississauga, Ontario L4W 1X4 Canada

P: 905 624 0260 F: 905 624 5669

www.Garland-Group.com

Parts & Service

1 800 427 6668 (Phone, US & Canada)

1 800 361 7745 (Fax, US & Canada)

Loading...

Loading...