Page 1

INSTALLATION/OPERATION

INSTRUCTIONS FOR CHAIN

GRIDDLES

THE INSTALLATION AND CONNECTION MUST COMPLY WITH LOCAL CODES, OR IN THE ABSENCE OF LOCAL

CODES, WITH CAN/CGA-B149 INSTALLATION CODE OR WITH THE NATIONAL FUEL GAS CODE, ANSI Z223.1/NFPA

NO. 54 - LATEST EDITION.

ALL BURNER ADJUSTMENTS AND SETTINGS SHALL BE MADE BY A QUALIFIED GAS TECHNICIAN .

POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS.

THIS INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER.

THE APPLIANCE AND ITS INDIVIDUAL SHUT OFF VALVE MUST BE DISCONNECTED FROM THE GAS SUPPLY

PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT SYSTEM AT TEST PRESSURES IN EXCESS OF 1/2

PSIG. (3.45 KPA).

THE APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS INDIVIDUAL

MANUAL SHUT OFF VALVE DURING ANY PRESSURE TESTING OF THE GAS SUPPLY PIPING SYSTEM AT TEST

PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG. (3.45 KPA).

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE VAPOURS AND

LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

WARNING IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

Page 2

INSTALLATION INSTRUCTIONS

SERVICE CLEARANCES

NOT REQUIRED

SERIAL PLATE LOCATION

All burner inputs arc shown on the Serial/Rating Plate of

each unit, located directly behind the front panels. For

access, remove the two screws secur ing the upper front

panel to the body in the upper right and left hand corners,

then slightly raise the panel to lift off. Remove to a safe

location. Next.

GENERAL INFORMATION

1. Damage Check : Check carton or crate for possible

damages incurred in shipping. After carefully

examining, check for "Concealed" damage. Report any

damage immediately to your carrier.

2. The correct type of gas for which the unit was

manufactured is noted on the serial/rating plate,

remove the two screws securing the lower front panel to the

body in the upper right and left hand corners and hinge the

panel downwards. Reverse the procedure to replace both

front panels.

Note: Make sure no electrical connections have been

disturbed.

and this type of gas has to be used.

3. This unit must be installed in accordance with the

following clearances in order to provide proper

operation and servicing of the appliance. Also, it is

recommended that the unit be installed with sufficient

clearances to provide for proper cleaning and

maintenance.

COMBUSTIBLE CLEARANCES 6" (152 mm) 6" (152mm) 6" (152mm)

NON-COMBUSTIBLE CLEARANCES 0" 0" 0"

4. A readily accessible gas shut-off valve is provided on

each unit, attached to the main mani fold under the unit.

Gas supply connection must be made with minimum

3/4 inch NPT pipe. Larger than 3/4 inch (19 mm)

supply pipe may be required when a long run of supply

pipe is necessary. Consult the pipe capacity tables in

the installation code.

5. Have a qualified gas technician check the gas pressure to

make certain that the existing gas facilities (meter,

piping, etc.), will deliver the BTU's of gas required at

the unit, with no more than 1/2 inch (12 mm) water

pressure drop. When checking pressure, be certain that

all the equipment on the same gas line is turned "ON".

LEFT RIGHT

SIDES

6. Make certain that new piping, joints and connections

have been made in a clean manner and have been

purged, so that the piping compound, chips, etc., will

not clog valves and/or controls. Use pipe joint sealant

that is approved for use with liquefied petroleum gas.

7. For models equipped with casters, installation shall be

made with a connection that complies with the

standard for Connectors for Moveable Gas Appliances,

ANSI Z21.69 (Latest Edition)/ CGA 6.16 and a quick disconnect device that complies with the standard for

Quick-Disconnect Devices for Use with Gas Fuel,

ANSI Z21.41 (Latest Edition)/CAN 1-6.9.

BACK

TYPE OF FLOOR OR

BASE

COMBUSTIBLE

2

Page 3

8. Adequate means must be provided to limit movement of

the appliance without depending on the connector and

quick-disconnect device or associated piping. This can

be accomplished by attaching restraining chains/cables

from floor or rear wall to rear of unit.

9. WARNING: Check all gas connections for leaks, using a

soap solution or similar means. Do not check with an

open flame.

10. The unit must be installed on the legs or casters

provided. A minimum 4 inch (101 mm) air space must

be maintained below the unit for required air flow to the

burner systems. Avoid placing any objects under the

unit which could obstruct air flow to the burner

systems.

When the unit is installed in its operating location, level

the unit by adjusting the leveling legs. Use a spirit level

across the front, rear and sides of each unit.

Note: The griddle plate may not rest evenly on the unit

body if the unit is not properly leveled.

11. Each thermostat controls one zone burner through a

combination dual solenoid/pressure regulator valve,

complete with a pressure test spigot. The gas pressure

on each combination valve must be checked when the

unit is installed

to ensure that the gas pressure is the same as specified on

the Serial/Rating plate. For access to the pressure test

spigots, turn the main power switch and all zone power

switches to the "OFF" position as a safety precaution, and

hinge the lower front panel downwards. Pressure test

spigots are located at the rear of each combination valve,

including pilot combination valves. When your manometer is connected to the first combination valve for

test, turn the manual shut off valve, located under the unit,

to the open position (valve handle in line with piping).

Turn the main power switch to "ON" and turn all zone

power switches to "ON". All thermostat dials should be

set to approximately 350°F (182°C). When all burners are

operating, check the reading on the manometer. If not in

accordance with the pressure specified on the

Serial/Rating Plate, adjust the combination valve regula tor

accordingly. When satisfied with the manometer reading,

turn the main power switch to "OFF", remove the

manometer test tube and recap the test spigot. Repeat this

operation on each combination valve until each pressure

regulator is set correctly. Turn each thermostat, zone

power switch and main power switch to "OFF".

NOTE: Make certain no electrical connections have been

disturbed before replacing front panels.

ELECTRICAL CONNECTION

IMPORTANT: This appliance must be electrically

grounded in accordance with local codes, or in the absence

of local codes, with the Canadian Electrical Code C22.1 or

with the National Electrical Code ANSI/NFPA No. 70

(latest edition), whichever is applicable.

WARNING

Electrical Grounding Instructions

This appliance is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug.

A separate 15 amp service must be provided. For 120V

usage, each unit is electrically equipped with a cord set with

a three-prong plug which fits any standard 120 volt, threeprong grounded receptacle.

When the unit is ordered and built for 208/240 volt, the

supply line must be connected to the wiring terminations

located inside the terminal box. For ease in attaching the

supply line, there is a removable cover on the terminal box.

A wiring diagram is attached to the rear panel of each unit.

3

Page 4

VENTILATION

The unit must be installed in a location in which the

facilities for ventilation permit satisfactory combustion of

gas and proper venting. Proper ventilation is imperative for

good operation of the appliance. The ideal method of

ventilating a gas unit is the use of a properly designed

ventilating canopy, which should extend at least 6" (152

mm) beyond all sides of the appliance (except against the

wall, if the canopy is a wall installation). This is usually

part of a mechanical exhaust system .

1. Appliances shall be located so as not to interfere with

proper circulation of air within the

OPERATING INSTRUCTIONS

LIGHTING INSTRUCTIONS

confined space. All gas burners require sufficient air to

operate.

2. Large objects should not be placed in front of the

appliance which might obstruct the air flow through the

front. Do not obstruct the flow of combustion and

ventilation air.

3. Do not permit fans to blow directly at the appliance, and

wherever possible, avoid open windows adjacent to the

appliance sides and back;

also wall type fans which create air cross-currents within

the room.

Wait 5 minutes, then turn the main power switch back to

"ON".

Adequate means must be provided to limit movement of the

appliance without depending on the connector and quick

disconnect device or associate piping. This can be

accomplished by attaching restraining chains/cables from

floor or rear wall to rear of unit.

On units equipped with casters, ensure that front casters are

in the locked position and that the movement restraint is

connected to the appliance.

During an electrical power interruption, turn power switch

to the "OFF" position. This unit cannot be made to operate

without electrical power.

1. First, make certain that all power switches and thermostat

switches are set to "OFF".

2. Connect electrical power cord to 120 volt supply.

3. Turn the gas shut-off valve to the "OPEN" position

(valve handle in line with piping).

4. Turn the main power switch to "ON", power switch green

indicator should illuminate. Wait until gas pilot, green

indicator illuminate.

NOTE: Should pilot ignition fail after a few minutes,

turn the main power switch to "OFF".

5. When the green indicators for their respective zones are

illuminated, turn the zone power switch for each zone

to "ON" and set the thermostats to the desired

temperature settings.

6. The amber burner indicators cycle with the ther mostat

operation.

SHUT DOWN INSTRUCTIONS

1. Turn all zone and power switches to "OFF" (thermostat

dial settings may be left at their set point if preferred)

at the end of daily operations.

2. For extended shut down, turn all zone power switches to

"OFF", turn main power switch to "OFF", close the

manual gas shut-off valve and unplug the electrical

cord set.

NOTE: Do not waste gas or abuse equipment by leaving

thermostats at a high temperature, if not required.

During idling periods, set ther mostats to a low

temperature setting. For example: 175° (79°C) to 200°F

(93°C), to keep griddle warm. Rest thermostats, as

required, for periods of heavy load.

4

Page 5

ADJUSTMENTS

PILOT ADJUSTMENT

NOTE: Each griddle has been factory tested and adjusted

prior to shipment. It may be necessary to further adjust the

unit as part of a proper installa tion. Such adjustments are

the responsibility of the installer. Adjustments are not

considered to be defects in material and workmanship, and

they are not covered under the original equipment warranty.

A pilot adjustment valve is located in the line from each

pilot combination valve. Pilot adjustment is acces sible from

behind the lower front panel. First remove the two screws

securing the upper front panel to the body, in the upper right

and left hand corners, then slightly raise the panel to lift off.

Remove to a safe area. Next, remove the two screws

securing the lower front panel to the body, in the upper right

and left hand corners and hinge the panel downwards.

Turning the small screw in the pilot adjusting valve

clockwise reduces the amount of gas provided to the

pilot(s). Turning the small screw counter-clockwise

increases the gas provided to the pilot(s). The gas should be

adjusted to a 7/16 (11 mm) inch long flame, to ensure that

the flame engulfs the top of the flame sensor.

When the air shutter adjustments are complete on each

burner, re -tighten the air shutter screw so that the correct

setting is locked in place.

NOTE: Make certain no electrical connections have been

disturbed. Replace both panels and secure to body.

THERMOSTAT CALIBRATION

This griddle thermostat is a precision instrument. It is

carefully calibrated at the factory so that the dial setting

matches the actual griddle temperature. Field re -calibration

is seldom necessary and should not be attempted unless

considerable experience with cooking results prove that the

thermostat is not maintaining the set temperature properly.

To check calibration, use a test instrument with a flat

temperature sensing surface, which can be placed on the

griddle plate surface. Place the sensor in the center of the

zone being tested.

1. Turn the griddle "ON" and set the thermostat to 350°F

(176°C). Allow the griddle zone to achieve

temperature and thermostat to cycle at least 3 times.

Take a temperature reading at the time that this

thermostat cycles on for the third time.

MAIN BURNER AIR ADJUSTMENT

Burners should always be warm when an adjustment to air

shutters is made. To adjust air shutters, loosen the small

screw along the side of the burner near the orifice. Lifting

flames on the burner indicates too much air and this air

shutter should be in a more closed position. Yellow tips on

the flames indicate not enough air and the air shutter should

be in a more open position.

2. If, when the thermostat indicates heating (amber

indicator illuminated), the surface tempera ture does not

exceed plus (+) or minus (-) 8°F (13°C) of the

thermostat set point, no re-calibration is necessary.

If the griddle plate surface temperature exceeds +/- 8°F

(13°C), it could indicate a defective thermostat or

sensor. The electronic thermostat is precisely calibrated

at the factory. Any work should be performed by a

qualified service technician.

5

Page 6

MAINTENANCE AND CARE

Periodical inspections by your dealer or qualified service

agency are recommended to check temperatures,

adjustments and ensure moving parts are operative.

Whenever possible, avoid overheating idle equipment, as

this is the primary cause for increased service costs.

Always disconnect the power supply to appliance before

servicing. After servicing, ensure that all connectors are

suitably secured back in place.

SEASONING

Before being used for the first time, all griddle surfaces

must be carefully "broken in" or "seasoned".

1. Remove all factory applied protective materials by

washing with a hot mild detergent or soap solution.

Rinse and dry thoroughly.

2. Set the griddle thermostats to a low tempera ture, 150°F

(65°C)to 175°F (79°C) and allow griddle to operate for

thirty minutes.

3. Apply a thin coat of olive oil or other high grade, salt

free, cooking oil to the surface. Wipe away excess.

4. Allow oil to remain on the griddle surface for 5 minutes,

then wipe off.

5. Reset thermostat to a medium temperature, 275°F

(135°C) to 300°F (149°C), and apply a second thin

coat of oil. Wipe off excess after 5 minutes.

6. Reset thermostat to desire cooking temperature and apply

a final coat of oil. Wipe off excess after 3 minutes. The

griddle is now seasoned and ready for use.

NOTE: Griddle may be re-seasoned at any time by

thoroughly cleaning and following the above procedures.

Griddles should be re-seasoned prior to each day's

operation.

CLEANING

Griddle plates should be cleaned daily while still warm.

Remove carbonized grease and/or food residue with a

spatula.

When necessary, clean griddle surface thoroughly using a

fine griddle brick, or a liquid griddle cleaner (available

from your kitchen equipment dealer).

Polish the griddle surface to a bright finish. Wash griddle

surface, rinse and dry thoroughly. Re -season the griddle as

per the seasoning instructions.

* Avoid overheating the griddle as this may cause sticking

and grease carbonizing, resulting in a hard to clean

surface.

* Do not hit spatula on the griddle plate as this will nick the

surface.

* Empty the grease tray frequently to avoid over filling and

spill overs.

EXTERIOR CLEANING

Normal soil may be removed from stainless steel with a hot

detergent or soap solution. To remove grease that has baked

on, apply cleanser on the metal in the direction of the

polishing lines of the metal. Never rub in a circular

motion.

Soil and burned deposits which do not respond can usually

be removed by rubbing the surface with SCOTCH-BRITE

scouring pads or STAINLESS scouring pads. Do not use

ordinary steel wool.

Heat tint can be removed by a vigorous scouring in the

direction of the polish lines, using SCOTCH-BRITE

scouring pads or STAINLESS scouring pads in

combination with a powdered cleanser.

6

Page 7

SERVICE BULLETIN

Bulletin No:

98017

From: Garland Group Service Department To:

Authorized Service Agencies

SUBJECT: Chain Griddle Panel Cover

Models Effected: CG & CE -36, 48, 60 & 72

A Griddle Panel Cover has been made available to help prevent water and grease from entering the control

compartment and damaging the controls. The panel cover can easily be installed onto existing units.

Date: March 25, 1998

Kit numbers are as follows.

KIT Number Used on Model's

CK171-36 CG & CE36

CK171-48 CG & CE48

CK171-60 CG & CE 60

CK171-72 CG & CE 72

See attached page for mounting instructions.

8

Page 8

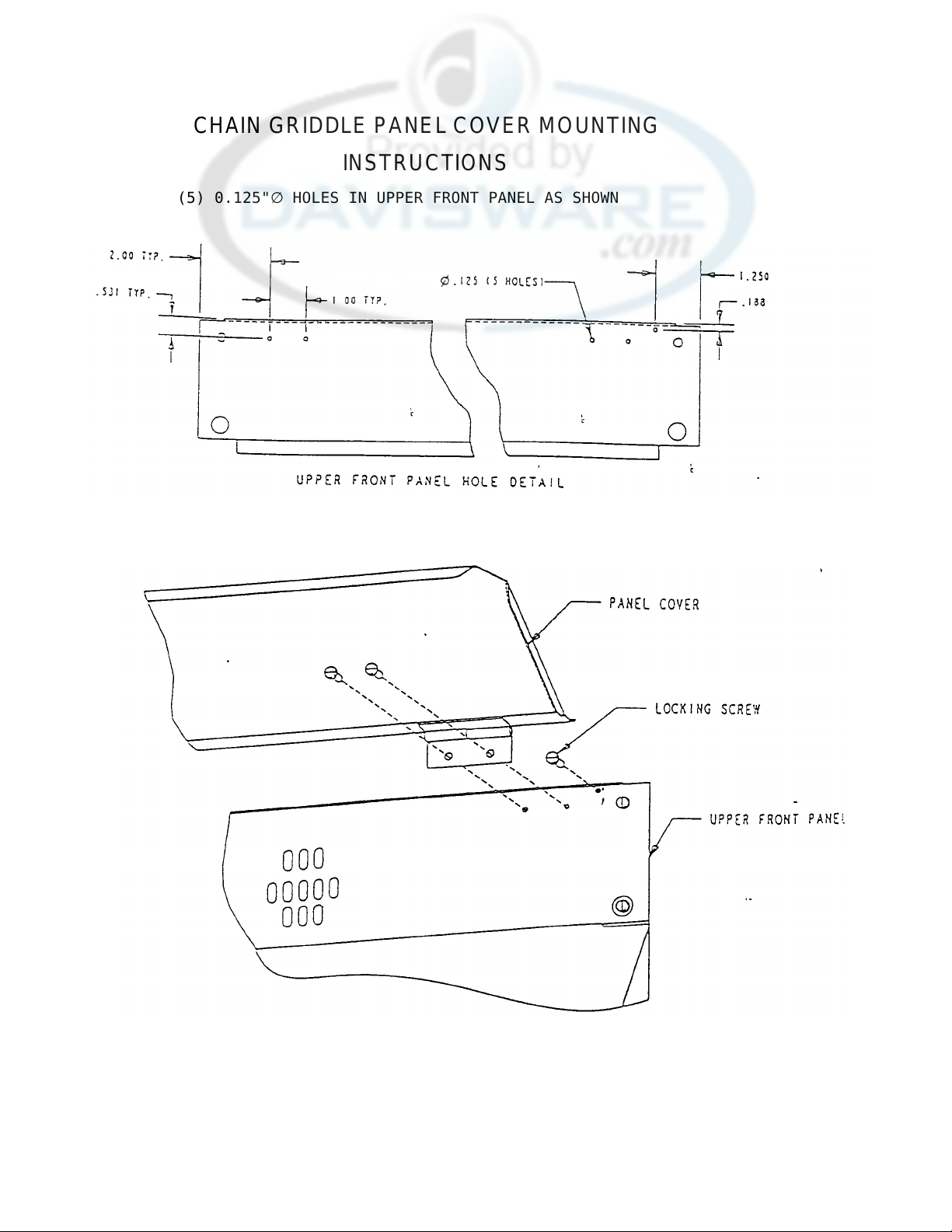

CHAIN GRIDDLE PANEL COVER MOUNTING

INSTRUCTIONS

1. DRILL (5) 0.125"∅ HOLES IN UPPER FRONT PANEL AS SHOWN

2. MOUNT PANEL COVER TO UPPER FRONT PANEL WITH SELF-TAPPING SCREWS (4)

3. INSTALL LOCKING SCREW (1)

9

Page 9

.

Page 10

.

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

GARLAND

MODELS CG -36S. CG-48S, CG-60S. CG-72S

Page 20

GARLAND PARTS IDENTIFICATION

MODEL CG-36S, CG-48S, CG-60S AND CG-72S

GAW-36, GAW-48, GAW-60 AND GAW-72

ITEM PART NO. DESCRIPTION 36S 48S 60S 72S

1 2470299 Griddle Assembly 1

2 2477700 Flue Panel 1

2477703 Flue Panel 1

3 2405201 Burner Assembly - Left 1 2 2 3

4 1466100 Flame Sensor 2 2 3 3

5 2290400 Pilot Assembly - Natural 2 2 3 3

6 2468698 Side Panel - Left 1 1 1 1

7 2409298 Body End Assembly - Left 1 1 1 1

8 2469699 Pull Bar Assembly 1 1 1 1

9 07800-15 32.5" x 8" x 0.5" Insulation 2 2 2 2

10 2408900 Rear Burner Support 3 4 5 6

11 2423700 Bayonet Adapter 3 4 5 6

12 2400699 Probe Shield Assembly 3 4 5 6

13 2423501 J Thermocouple 3 4 5 6

14 2403000 Double Burner Mounting Bkt 1 2 2 3

14(a) 2443000 Single Burner Mounting Bkt 1 1

15 2431900 Orifice Fitting 3 4 5 6

16 M8-38 Orifice Hood - Natural 3 4 5 6

17 2468800 Pan Slide - Right 1 1 1 1

17(a) 2468801 Pan Slide - Left 1 1 1 1

18 2468799 Grease Pan Assembly 2 2 2 2

19 2442100 Front Caster 2 2 2 2

20 G03559-1 Transformer- 120V 1 1

2470298 Griddle Assembly

2470297 Griddle Assembly

2470296 Griddle Assembly

2477701 Flue Panel

2477702 Flue Panel

2405200 Burner Assembly - Right 2 2 3 3

2290401 Pilot Assembly - Propane 2 2 3 3

2468699 Side Panel - Right 1 1 1 1

2409299 Body End Assembly - Right 1 1 1 1

M8-52 Orifice Hood - Propane 3 4 5 6

2442101 Rear Caster 2 2 2 2

2444500 Transformer - 120V

2283700 Transformer - 208V - 240V 1 1

2444501 Transformer - 208V - 240V

1

1

1

1

1 1

1 1

1

21 2399498 Radiation Shield - Left 1 1 1 1

22 2403199 Radiation Shield 1 2 1 3

23 2399399 Radiation Shield - Double

24 2399499 Radiation Shield - Right 1 1 1 1

25 2443299 Radiation Shield 1 1

26 076050-26 3/8" X 3/8" Comp. Elbow 3 6 8 12

27 G01917-1 1/8" N.P.T. Street Elbow 3 3 4 5

28 2439200 Burner Tube 3 4 5 6

29 2405100 Gas Control/Regulator - Natural 3 3 4 5

2405101 Gas Control/Regulator - Propane 3 3 4 5

30 G02352-1 7/16 'cc X 3/8" N.P.T. Comp. Elbow 3 4 6 6

1 1 2

Page 21

GARLAND PARTS IDENTIFICATION

MODEL CG-36S, CG-48S, CG-60S AND CG-72S

GAW-36, GAW-48, GAW-60 AND GAW-72

ITEM PART NO. DESCRIPTION 36R 48R 60S 72S

32 G03674-3 1/8" N.P.T. Pilot Valve 2 2 3 3

33 076029-144 3/8" x 1/8" Reducing Bushing 2 2 3 3

34 2439101 Pilot Tube - Right

35 2043600 Spark Plug Connector 2 2 3 3

36 2152700 Ignition Control 2 2 3 3

37 2446200 Pilot Tube 1 1

38 G01518-1 Shut-Off Valve 1 1 1 1

39 2437100 1" 3/4 Reducing Adapter

40 2439400 Tube-Manifold to Lt Burner Solenoid

41 2450099 Manifold Assembly 1

42 2439300 Tube-Manifold to Lt Burner Solenoid 1 1 1

43 2441900 Tube-Manifold to Ct Burner Solenoid

44 2439500 Tube-Manifold to Rt Burner Solenoid

2442200 Tube-Manifold to Rt Burner Solenoid 1

45 2440200 Tube-Manifold to Rt Pilot Solenoid

46 G01747-3 3/8" Pipe Plug

47 2432000 Electronic Thermostat c/w Overlay Knob 3 4 5 6

48 2469300 Control Panel Cover 1

49 2450900 Wire Harness - Power Connection 1 1 1 1

2411099 Manifold Assembly

2469301 Control Panel Cover

2469302 Control Panel Cover

2469303 Control Panel Cover

2450901 Wire Harness - Control Panel Section 1 1 1 1 1

2450902 Wire Harness - Valve Panel Section 1 1 1 1 2 :

2450903 Wire Harness - Control Panel Section 2

2450904 Wire Harness - Valve Panel Section 2

2450905 Wire Harness - Control Panel Section 3 1

2459906 Wire Harness - Valve Panel Section 3 1

1 1 1

1 2 1

1 1 1

1 1 1

1

2 1

1

1 1 2

1 1 1

1 1

1 1

1

1

1

• 1

50 G04055-2 Green Light 3 3 4 4

51 2423301 Switch 1 1 1 1

52 2423300 Switch 3 4 5 6

53 2423400 Protection Cap 4 5 6 7

54 G04055-1 Amber Light 3 4 5 6

55 2469400 Control Panel 1

56 G02251-1 Test Spigot 4 4 5 6

57 G01738-4 3/4 NPT x 2 1/2" Nipple 1 1 2 2

58 G01474-3 3/4" NPT To 1" NPT 90° Elbow Reducer 1

59 G01474-5 3/4" NPT Elbow

60 G01738-5 3/4" NPT x 6 1/2" Nipple

61 076050-90 Comp. Elbow 7/16" Tube x 1/4 Pipe 3

62 G2840-2 SJT 3/14 15A Cord & Plug Set 120V 1 1 1 1

2469401 Control Panel

2469402 Control Panel

2469403 Control Panel

1

1

1

1

1

Page 22

G

ARLAND

MODELS GAW-36, GAW-48, GAW-60, GAW-72, CG-36R,

CG-48R, CG-60R, CG -72R

Page 23

GARLAND PARTS IDENTIFICATION

MODEL CG-36R, CG-48R, CG-60R AND CG-72R

GAW-36, GAW-48, GAW-60 AND GAW-72

ITEM PART NO. DESCRIPTION 36R 48R 60R 72R

1 2449699 Griddle Assembly 1

2 2449200 Flue Panel 1

2403500 Flue Panel 1

2440700 Flue Panel 1

2449300 Flue Panel 1

3 2405201 Burner Assembly - Left 1 2 2 3

2405200 Burner Assembly - Right 2 2 3 3

4 1466100 Flame Sensor 2 2 3 3

5 2290400 Pilot Assembly - Natural 2 2 3 3

6 2428798 Side Panel - Left 1 1 1 1

7 2409298 Body End Assembly - Left 1 1 1 1

8 2401499 Grease Chute Assembly 1 2 2 2 9 2429900 Grease Chute Seal 1 2 2 2

10 2408900 Rear Burner Support 3 4 5 6

11 2423700 Bayonet Adapter 3 4 5 6

12 2400699 Probe Shield Assembly 3 4 5 6

13 2423501 J Thermocouple 3 4 5 6

14 2403000 Double Burner Mounting Bkt 1 2 2 3

14(a) 2443000 Single Burner Mounting Bkt 1 1

15 2431900 Orifice Fitting 3 4 5 6

16 M8-38 Orifice Hood - Natural 3 4 5 6

17 2429000 Pan Slide 1 2 2 2

18 2430099 Rear Grease Pan 1 2 2 2

19 2442100 Front Caster 2 2 2 2

20 G03559-1 Transformer - 120V 1 1

2428699 Griddle Assembly

2440999 Griddle Assembly

2449799 Griddle Assembly

2290401 Pilot Assembly - Propane 2 2 3 3

2428799 Side Panel - Right 1 1 1 1

2409299 Body End Assembly - Right 1 1 1 1

M8-52 Orifice Hood - Propane 3 4 5 6

2442101 Rear Caster 2 2 2 2

2444500 Transformer - 120V

2283700 Transformer - 208V - 240V 1 1

2444501 Transformer - 208V - 240V

1

1

1 1

1 1

1

21 2399498 Radiation Shield - Left 1 1 1 1

22 2403199 Radiation Shield 1 2 1 3

23 2399399 Radiation Shield - Double 1 1 2

24 2399499 Radiation Shield - Right 1 1 1 1

25 2443299 Radiation Shield 1 1

26 076050-26 3/8" X 3/8" Comp. Elbow 3 6 8 12

27 G01917-1 1/8" N.P.T. Street Elbow 3 3 4 5

28 2439200 Burner Tube 3 4 5 6

29 2405100 Gas Control/Regulator - Natural 3 3 4 5

30 G02352-1 7/16"cc X 3/8" N.P.T .Comp. Elbow 3 4 6 6

31 2439100 Pilot Tube - Left 1 1 1 1

2405101 Gas Control/Regulator - Propane 3 3 4 5

Page 24

GARLAND PARTS IDENTIFICATION

MODEL CG-36R, CG-48R, CG-60R AND CG-72R

GAW-36. GAW-48, GAW-60 AND GAW-72

ITEM PART NO. DESCRIPTION 36R 48R 60R 72R

32 G03674-3 1/8" N.P.T. Pilot Valve 2 2 3 3

33 076029-144 3/8" x 1/8" Reducing Bushing 2 2 3 3

34 2439101 Pilot Tube - Right

35 2043600 Spark Plug Connector 2 2 3 3

36 2152700 Ignition Control 2 2 3 3

37 2446200 Pilot Tube 1 1

38 G01518-1 Shut-Off Valve 1 1 1 1

39 2437100 1" - 3/4" Reducing Adapter 1 1 1 1

40 2439400 Tube-Manifold to Lt Burner Solenoid

41 2450099 Manifold Assembly 1

42 2439300 Tube-Manifold to Lt Burner Solenoid 1 1 1

43 2441900 Tube-Manifold to Ct Burner Solenoid

44 2439500 Tube-Manifold to Rt Burner Solenoid 1

45 2440200 Tube-Manifold to Rt Pilot Solenoid

46 G01747-3 3/8" Pipe Plug

47 2432000 Electronic Thermostatc /w Overlay Knob 3 4 5 6

48 2448800 Control Panel Cover 1

49 2450900 Wire Harness - Power Connection 1 1 1 1

2411099 Manifold Assembly

2442200 Tube-Manifold to Rt Burner Solenoid

2402200 Control Panel Cover

2440500 Control Panel Cover

2448900 Control Panel Cover

2450901 Wire Harness - Control Panel Section 1 1 1 1 1

2450902 Wire Harness - Valve Panel Section 1 1 1 1 2

2450903 Wire Harness - Control Panel Section 2

2450904 Wire Harness - Valve Panel Section 2

2450905 Wire Harness - Control Panel Section 3 1

2459906 Wire Harness - Valve Panel Section 3 1

1 1 1

1 1 1

1 1 1

2 1

1

1 1 2

1 1 1

1 1

1 1

1

1

1

1

1

50 G04055-2 Green Light 3 3 4 4

51 2423301 Switch 1 1 1 1

52 2423300 Switch 3 4 5 6

53 2423400 Protection Cap 4 5 6 7

54 2432100 Handle (Knob Guard) 6 8 10 12

55 G04055-1 Amber Light 3 4 5 6

56 2449099 Control Panel 1

2449199 Control Panel 1

57 G02251-1 Test Spigot 4 4 5 6

58 G01738-4 3/4" NPT x 2 1/2" Nipple 1 1 2 2

59 G01474-3 3/4" NPT to 1" NPT 90° Elbow Reducer 1

60 G01474-5 3/4" NPT Elbow

61 G01738-5 3/4" NPT x 6 1/2" Nipple

62 076050-90 Comp. Elbow 7/16" Tube x 1/4 Pipe 3

63 G2840-2 SJT 3/14 15A Cord & Plug Set 120V 1 1 1 1

2402399 Control Panel

2440699 Control Panel

1

1

1

1

Loading...

Loading...