Page 1

U

:

4

INSTALLATION AND

OPERATION MANUAL

GARLAND 36 E SERIES

HEAVY DUTY ELECTRIC

RANGES AND BROILERS

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis

Swallow e

Telephone

Fax: 081-8

Part # 1009067 Rev13 (12/04/09) © 2004 Garland Commercial Industries, LLC

Part # 1009067 Rev13 (12/04/09) Page 1

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # 1009067 Rev13(12/04/09)Page 2

Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION.............2

DIMENSIONS AND SPECIFICATIONS,

36E SERIES RANGES....................4

DIMENSIONS AND SPECIFICATIONS,

ER36 BROILER .........................5

DIMENSIONS AND SPECIFICATIONS,

ATTACHMENTS ........................6

GENERAL INFORMATION ...............7

Product Information .........................7

Rating Plate ..................................7

Optional extended warranty .................7

INSTALLATION.........................8

Clearances and Setting .......................8

Legs .........................................8

Electrical Connections ........................8

Wiring Diagram ..............................8

Circuit Breakers and Fuses ....................8

Main Line Entrance ...........................9

Terminal Block ...............................9

Sanitary Counter Top Seal ....................9

Assembly of Battery ..........................9

Installation Instructions for Mounting

The ER36 (Salamander) To 36E Series ..........9

Installation Instructions for Mounting

The Double Deck High Shelf 36E Series ......10

Ventilation ..................................10

OPERATION...........................10

Ovens ......................................10

Controls

Preheat

General

Range Base Convection Oven (RC)

Range Base Convection Oven Operation

Problem / Solution

Motor Care

Top Sections ................................12

Cooking Top – Open Type Burners

Boiling Plates

All Purpose Plates

Griddle Plates

Operation of Broiling Section

MAINTENANCE AND CLEANING........15

Painted Finishes ............................15

Stainless Steel ..............................15

Oven Inner Door Liner and Oven Deck

(Porcelain Enamel) ..........................15

Interior Cleaning of Standard Aluminized

Steel Interior Surfaces. .......................15

Cleaning and Care of Top Surface Heating

Burners .....................................16

Cleaning of Griddle, All Purpose Plates and

Boil Plates ..................................16

Broiler Section ..............................16

WIRING DIAGRAMS ...................17

Part # 1009067 Rev13 (12/04/09) Page 3

Page 4

DIMENSIONS AND SPECIFICATIONS, 36E SERIES RANGES

NOMINAL AMPERES PER LINE

THREE PHASE

208V 240V 460V

MODEL

TOTAL

kW

3-PHASE

kW PER PHASE

ALL VOLTAGES

SINGLE PHASE

X-Y Y-Z X-Z 208V 240V 460V X Y Z X Y Z X Y Z

36ER32, 36ER38 21.5 6.5 5 10 103 91 47 69 48 64 61 43 56 31 22 28

36ER32-3 36ER33-88 20.7 6.5 1.2 10 99 88 NA 69 45 60 61 40 53 NA NA NA

36ER33 19.1 6.5 4.2 8.4 92 81 NA 62 45 54 55 40 47 NA NA NA

36ER33-99 18.7 4.2 8 6.5 90 79 NA 45 52 61 40 45 54 NA NA NA

36ER35, 36ER36 18.5 6.5 6 6 89 78 40 53 53 51 46 46 44 24 24 23

36ER39 18.5 6.5 4 8 89 79 40 61 45 50 54 39 45 28 20 23

36ET32, 36ET38 15 5 5 5 72 64 33 42 42 42 37 37 37 19 19 19

36ET/ES32-3, 36ET/ES33-88 14.2 5 4.2 5 68 60 NA 42 39 39 37 34 34 NA NA NA

36ET/ES33 12.6 4.2 4.2 4.2 61 53 NA 35 35 35 31 31 31 NA NA NA

36ET/ES33-99 12.1 4.2 4 4 58 52 NA 35 35 34 31 31 30 NA NA NA

36ET/ES35, 36ET/ES36 12 0 6 6 58 51 26 29 29 51 25 25 44 13 13 23

36ET/ES39 12 4 4 4 58 51 26 34 34 34 30 30 30 15 15 15

36ERC32 20.4 5.4 5 10 98.1 85 NA 65 44 63 56 38 54 NA NA NA

36ERC32-3 19.6 5 4.6 10 94.2 81.7 NA 44 40 61 38 35 53 NA NA NA

36ERC33 18 5 4.6 8.4 86.5 75 NA 56 40 55 49 35 47 NA NA NA

36ERC33-88 19.6 5 4.6 10 94.2 81.7 NA 63 40 61 55 35 53 NA NA NA

36ERC33-99 17.6 8.2 4.4 5 84.6 73.3 NA 56 53 40 48 46 34 NA NA NA

36ERC35 17.4 5 6 6.4 83.7 72.5 NA 52 46 44 45 40 38 NA NA NA

36ERC36 17.4 5.4 6 6 83.6 72.5 NA 48 48 50 42 42 44 NA NA NA

36ERC38 20.4 5 5.4 10 98.1 85 NA 63 44 65 55 38 56 NA NA NA

36ERC39 17.4 5.4 4 8 83.7 72.5 NA 56 40 58 49 34 44 NA NA NA

Note for Model Numbers: ER= Oven Base, ET= Modular TOP, ES=Storage Base, ERC=Convection Oven Base

6"

[152mm]

36"

[914mm]

CLEARANCES

ENTRY TO COMBUSTIBLE WALL

SIDES REAR

1

41-1/4" (1048mm) 36-1/4" (921mm) 3" (76mm) 1/2" (13mm)

1

Rear Clearance for Convection ovens is 2” (51mm)

REAR

ELECTRICAL

6"

[152mm]

24"

[610mm]

6"

[152mm]

1 5"

[381mm]

1 8"

[457mm]

30"

[762mm]

6"

[152mm]

36"

[914mm]

14-1/2"

[368mm]

33-3/4"

[ 857mm]

18"

[ 457mm]

[1600mm]

With "DD

HI SHELF

31-3/8"

[797mm]

With STD

BACKGUARD

63"

"

Part # 1009067 Rev13(12/04/09)Page 4

Page 5

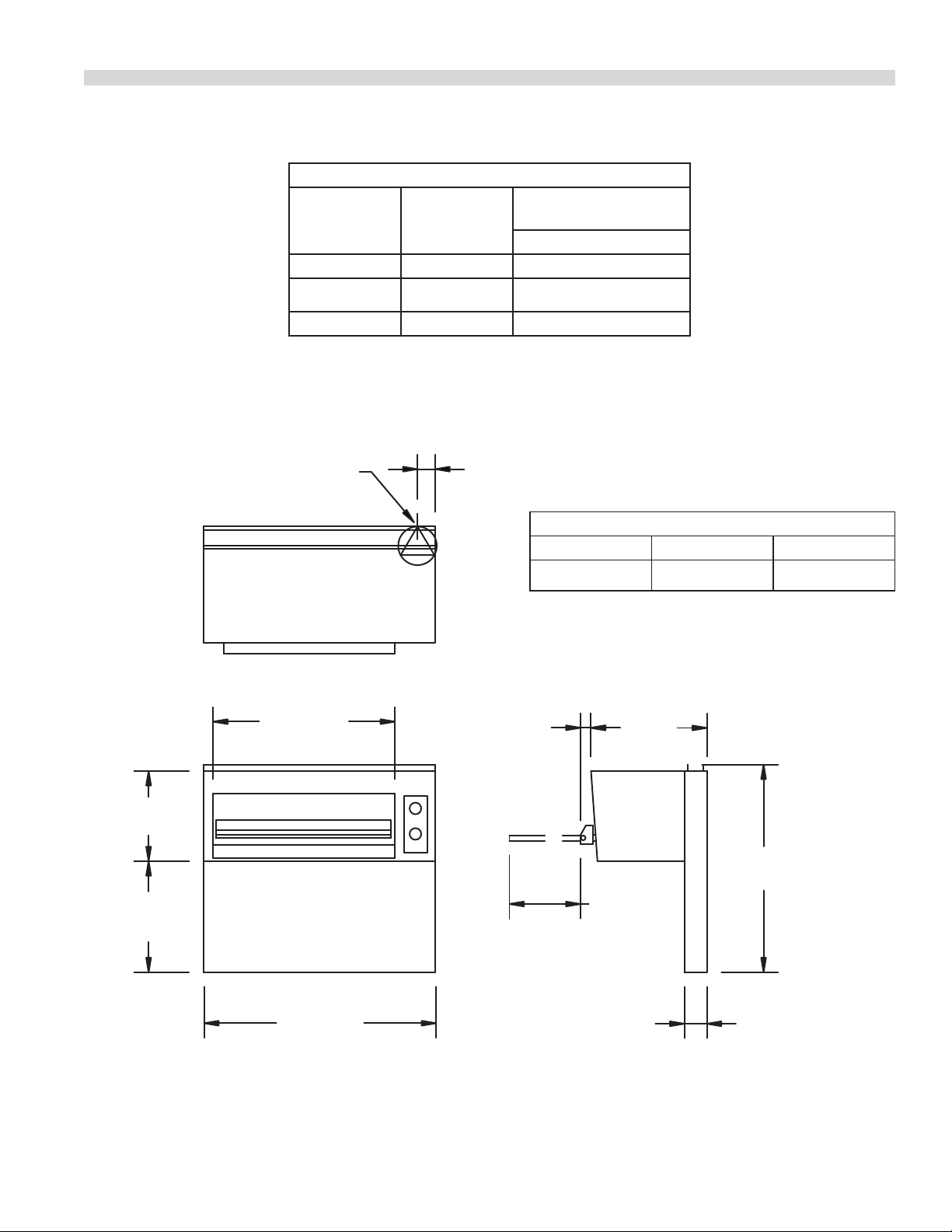

DIMENSIONS AND SPECIFICATIONS, ER36 BROILER

ELECTRICAL LOADING CHART: MODEL ER36

NOMINAL AMPERES

VOLTAGE TOTAL kW

208 7.00 33.7

240 7.00 29.2

460 5.51 12.0

NOTE: When ER36 models are wired independently from the range, they are only available as single phase. Refer to wiring

diagrams for detailed range mount electrical data.

PER LINE

SINGLE PHASE

14"

[356mm]

17-1/4"

[413mm]

REAR

ELECTRICAL

28-1/4"

[718mm]

2-3/4"

[70mm]

1-5/8"

[41mm]

COMBUSTIBLE WALL CLEARANCES

Left Side Right Side Back

6” (152mm) 4-1/2” (114mm) 1/2” (13mm)

18"

[757mm]

32-1/4"

[819mm]

11-1/32"

[280mm]

36"

[914mm]

Part # 1009067 Rev13 (12/04/09) Page 5

3-1/2"

[89mm]

Page 6

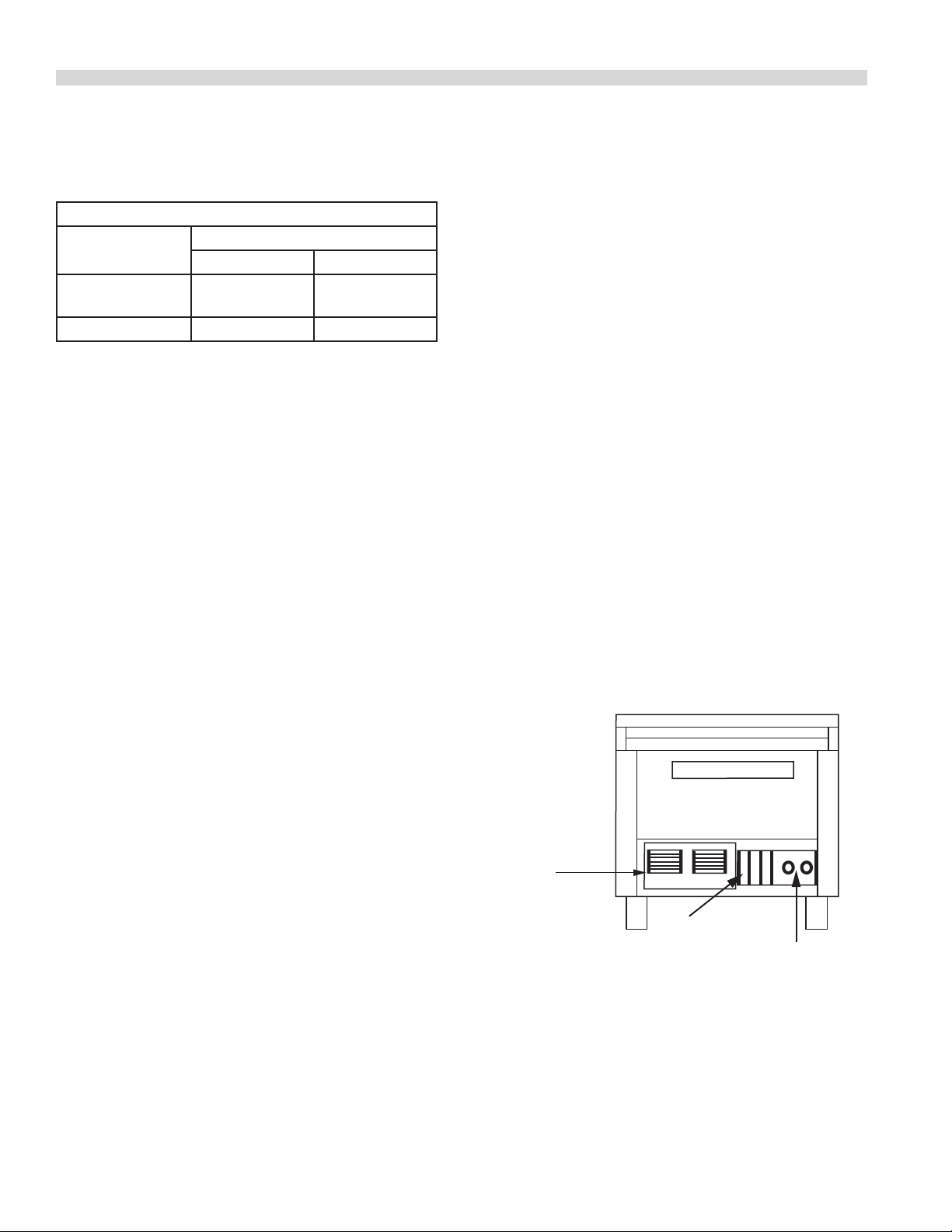

DIMENSIONS AND SPECIFICATIONS, ATTACHMENTS

ELECTRICAL LOADING CHART : MODELS 36ES(ET)16 & 36-ES(ET)15

NOMINAL AMPERES PER LINE

SINGLE PHASE

CLEARANCES

ENTRY

TO COMBUSTIBLE

CRATED UNCRATED SIDES REAR

20-3/4"

(527mm)

18-14"

9464mm)

(76mm)

6"

[152mm]

VOLTAGE TOTAL kW

208 6.00 28.8

240 6.00 25.0

460 6.00 13.0

REAR

ELECTRICAL

INLET

6"

[152mm]

3"

WALL

1/2"

(13mm)

36"

[914mm]

15"

[381mm]

18"

[457mm]

18"

[457mm]

24"

[610mm]

6"

[152mm]

15-9/32"

[388mm]

Garland products are not approved or authorized for home or

residential use, but are intended for commercial applications

only. Garland will not provide service, warranty, maintenance

or support of any kind other than in commercial applications.

18"

[457mm]

63"

[1600mm]

With "DD"

Hi Shelf

Modular Top

12" [305mm]

30"

[762mm]

6"

[152mm]

31-3/8"

[797mm]

With STD.

Backguard

33-3/4"

[857mm]

Part # 1009067 Rev13(12/04/09)Page 6

Page 7

GENERAL INFORMATION

Product Information

36 Series Ranges are designed to battery with other 36 Series

equipment.

Construction

Heavy duty modular construction minimizes the use of hard

to clean screws and bolts on exterior of range. Cleaning is

made easier and more complete.

Circuit Breakers

Supplied standard except for open elements. Fuses are used

for open elements.

Grease Troughs

Front and rear, catch excess grease and spillage. Drain into

grease pans located under range top.

Service

Service and maintenance is done completely from the front.

Oven Base

Giant capacity oven is 26 1/2” (667 mm) wide x 29” (736 mm)

deep x 12 1/2” (318 mm) high. Heavy duty thermostat with

pilot light provides temperature control between 200°F

(93°C) and 500°F (290°C). Top element 3 k.W. and bottom

element 3.5 k.W. each controlled by three heat switch for

exibility of heat. One heavy duty rack is standard. Additional

racks are available at extra cost. Exclusive heat ow oven

design eliminates hot spots and gives consistently even oven

temperatures. Aluminum clad steel oven interior reects heat

back to product and ensures long life. Oven door and oven

deck nished in porcelain. Oven door is heavy duty typed

designed to bear in excess of 250 lbs, (113Kg) load. Spring

adjustment is accessible from front of range.

Storage Base

A storage base with stainless steel doors is available.

Modular Top

For mounting on a custom made stand.

Venting

All ranges are supplied with standard 3” (76 mm) high

stainless steel vent riser. Double Deck High Shelf available

in sizes from 18” (476 mm) to 72” (1829 mm) wide. Standard

nish is stainless steel front with brushed chrome splash wall

and aluminum clad back. Optional nish is stainless steel

shelves, sides and back. A satisfactory power ventilator such

as Vent Master properly adapted to the range may be used.

Rating Plate

When corresponding with the factory refer to the particular

unit by the correct model number (including prex and sux

letters and numbers) and the serial or code number. The

rating plate axed to the unit contains this information.

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

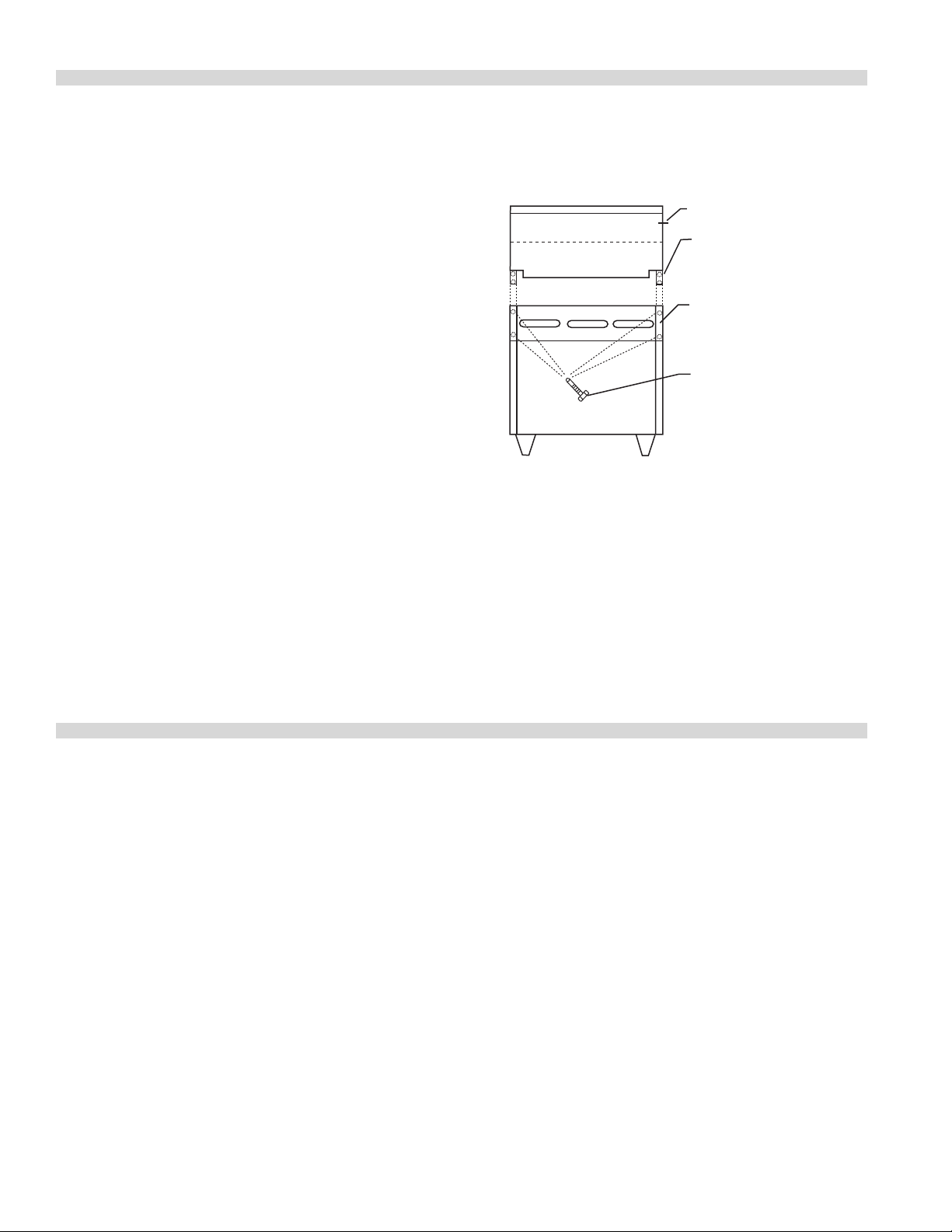

Unit rating plate is located behind the lower front panel.

Optional extended warranty

Garland,

With a tradition of superior equipment quality and

performance, oers you, our valued customer, an additional

one year limited warranty beyond our standard one year

coverage.

This additional coverage for parts and labor may be

purchased on a new equipment order or up to 60 days after

the equipment purchase. Please contact your Equipment

Dealer or Maintenance & Repair Center (list enclosed) to take

advantage of this exception oer.

Thank you for using Garland products. It is our pleasure to

serve you.

Part # 1009067 Rev13 (12/04/09) Page 7

Page 8

INSTALLATION

Clearances and Setting

CLEARANCES

MODEL TYPE

Range and Range

Attachments

Broiler with Range 6” (152mm) 1/2” (13mm)

* Rear clearance for convection oven base models is

2” (51mm).

Proper placement of the range will ensure operator

convenience and satisfactory performance. Adequate

clearance must be provided for servicing, ventilation and

proper operation. The range must be kept free and clear of

combustible material.

TO COMBUSTIBLE WALL

SIDES REAR*

3" (76mm) 1/2" (13mm)

Legs

All units are shipped with N.S.F. approved legs. These legs

must be installed to provide a minimum clearance of 6”

between the oor and bottom of the unit in order to meet

National Sanitation Foundation requirements.

1. Locate unit in its nal position.

2. Raise the rear and block it. Insert the bullet foot into the

leg cone. Tap with mallet until the bullet foot seats up to

the collar. Unit may now be leveled by adjusting hex head

portion of the bullet foot. Repeat for all four legs.

1. Switch panel size.

2. Overload protection.

3. Wire type.

4. Wire size.

5. Temperature limitations of the wires.

6. Method of connection (Cable, Conduit, etc.)

Wiring Diagram

IMPORTANT: Input voltage and phasing must match the

units voltage and phasing.

A wiring diagram is attached to the main back of each unit.

Visually check all electrical connections. Energize electric

service to units. The range is wired standard for three phase

connections. If it is necessary to change to single phase,

please refer to wiring diagrams. Service and unit voltage

must agree. Unit rating plate is located behind the lower

front panel.

Circuit Breakers and Fuses

Heavy duty circuit breakers and fuses are provided to assure

you many years of safe trouble-free operation. They are

located behind the lower front panel.

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

The Garland 36E series complies with the standards CSA

C222 no. 109-latest edition, the UL197-latest edition and the

NSF #4-latest edition. The installation & connection of this

appliance must comply with the current codes. In Canadathe Canadian Electrical Code Part 1 and in the USA-The

national Electrical Code.

Terminal Bock

Located behind

Panel.

Garland

Circuit

Breakers

Part # 1009067 Rev13(12/04/09)Page 8

Fuses

Page 9

INSTALLATION continued

Main Line Entrance

Two (2) alternate entrance location are provided as follows:

1. Through bottom of range. Center line of bottom entrance

hole is 8 3/4” from left and 5” from front base. If conduit

is used, allow an 8 1/2” extension for units installed with

legs adjusted to 6” height, a 5” extension when legs are

adjusted to a minimum height, a 3” extension when legs

are not used.

2. Through back of range. Center line of back entrance is 11”

from left side and 2” up from base of range.

Terminal Block

The terminal block, as well as grounding lug, is mounted

in fuse compartment behind lower from panel. To remove

panel, loosen screws and lift up and out using louver as

handle. All units are equipped with circuit breakers and

provided with a panel in front of terminal block.

Sanitary Counter Top Seal

When a broiler or “T” Section (Top Section) is installed

without legs on a counter top it must be sealed completely

around base with a silicone sealant in compliance with N.S.F.

Standards.

Assembly of Battery

3. Securely fasten Salamander support brackets at the rear

to burner box sides with 1/4 - 20 x 3/4 slot truss head

machine screws, hex nuts and lock washers.

4. Remove lower front panel from Salamander.

5. Place Salamander on the rear of the Range Lining up

holes in Salamander support brackets with holes on

Range.

6. Securely fasten Salamander to Range with

5/16 - 18 x 1 hex head machine screws, hex nuts and

washers. Replace Salamander lower front panel removed

in step 4.

7. Remove Salamander control panel.

8. The two (2) wires coiled on top right section of range

should be run through hole in back of Salamander and

into wiring compartment.

9. Attach two (2) wires to terminal block per encloses wiring

diagram.

10. Replace Salamander control panel removed in step 7.

11. A burner box back panel, which is installed at the back

of the range, is supplied with the salamander. This panel

covers the exposed back of the burner box where the

mounting brackets are attached. Use the metal machine

screws to secure this panel to the back of the range.

All units should be placed in their respective battery

positions. Remove packing material. The protective covering

on stainless steel should also be removed. Level each unit to

the oven rack by adjusting legs. Where legs are not used, unit

must be leveled by using shims. Use a spirit level and level

unit four (4) ways; across front and back and front to back

along left and right sides. The two (2) 5/16” hex head bolts

and nuts labeled “Remove and use for Banking” should be

removed and used for joining unit together through ends of

main front top and main back top.

Installation Instructions for Mounting

The ER36 (Salamander) To 36E Series

1. Back of Range must be easily accessible.

2. Install Salamander support brackets to range by slipping

Salamander support brackets into the opening in the

burner box sides so bottom ange of Salamander

support bracket ts over 10-24 stud in range. Securely

fasten with 10-24 hex nut and lock washers.

Salamander

Bracket

Burner

Back

Salamander

Support

Salamander

Bracket

Burner Box

Side

Part # 1009067 Rev13 (12/04/09) Page 9

Page 10

INSTALLATION continued

Installation Instructions for Mounting

The Double Deck High Shelf 36E Series

1. Back of range must be easily accessible.

2. Remove the at head bolt “A” from each side of high shelf

only when place next to a high shelf, Salamander.

3. Place backguard, high shelf on the rear of the Range

slipping the support brackets into the opening in the

burner box side.

4. Securely fasten support brackets to the burner box sides

with (4) 1/4 - 20 x 3/4 slot truss head machine screws

or (4) #10B x 1/2 Phillips sheet metal screws. Hardware

package will be supplied.

5. Remove lower front panel of the high shelf.

6. Replace at head bolts removed in step 2 so that each high

shelf is bolted to adjacent high shelf at “A”.

Bolt "A"

Upright

Burner Box

Side

1/4 - 20 x 3/4

Slot Truss Head

Machine Screws or

#10B x 1/2 Phillips

Sheet Metal Screws

4 Req.

Ventilation

7. Replace lower front panel of high shelf.

OPERATION

Ovens

Controls

On standard units, the controls for the lower oven section

are located on the right end of the switch pane. Each oven

is equipped with top and bottom heating units. Two (2)

three heat, heavy duty reversible switches allow for separate

operation of each heating unit. An oven thermostat and

indicator lamp are also provided for each oven. Regardless

of Switch Settings of Upper and Lower heating Units, the

Thermostat Has Complete Control of the Temperature of the

Oven.

An adequate ventilation system is recommended for all

commercial electrical cooking appliances. For further

information please refer to “Vapor Removal From cooking

Equipment” National Fire Protection Association Standards.

Preheat

Turn top heating unit (Switch at left of thermostat dial) to

“High”. Turn bottom heating unit (Switch at right of the

thermostat dial) to “High.” Set oven thermostat dial to desired

temperature. Pilot lamp will now come “ON,” indicating

oven has not reached desired temperature. When desired

temperature is reached, pilot lamp will go “OFF”. At this time,

top heating switch may be turned “OFF” or set as desired.

Bottom heating unit may be left at “High” or set as desired.

Part # 1009067 Rev13(12/04/09)Page 10

Page 11

OPERATION continued

During preheat period, keep oven door closed. With oven

operating on rated voltage, it will require approximately 18

to 20 minutes to reach 450°F from a cold start.

Personal preferences of dierent operators dictate time and

temperature requirements for various cooking operations.

For this reason, no times or temperatures are suggested here.

If in doubt, consult a good cookbook on volume cooking.

General

Baking or roasting may be done in the oven on the oven rack

provided with each oven. Best baking or roasting results will

be obtained with only one rack of product at a time. Multirack loading will greatly change bake/roast characteristics

and “done” times. Do not bake or roast directly on the oven

bottom. In choosing pans, be sure pan size will allow space

between back, sides and oven door to allow for proper heat

circulation. Personal preferences of dierent chefs and food

service operators dictate temperature and time requirements

for various oven cooking operations. For this reason, no

cooking times or temperatures are suggested here. If in

doubt, consult a good cookbook on volume food service.

Range Base Convection Oven (RC)

As a guide, set oven temperature 25° to 50° lower than called

for in recipes directions using standard or conventional

ovens. Cooking time may be less depending upon the

product you are preparing. 2% to 5% is a general rule.

Product should be watched the rst time it is prepared.

Cooking time and oven temperature will vary depending

upon such factors as size of load, temperature of product,

and mixture of recipe, particularly moisture. When you

have established satisfactory time and temperature for our

products, record them on a chart and keep as a reference

guide.

Preheat oven thoroughly before use. To reach 350°F takes

approximately 20 minutes. For optimum results oven should

be preheated for 30 minutes to allow for thorough heat

saturation. The load should be centered on the oven racks

to allow for proper heat circulation around the sides. Load

size – the oven will hold three (3) 18” x 26” sheet pans, six

(6) 12” x 20” x 2.5” steam table pans or one (1) 17.75” x 25.75”

roast pan. Never place pans directly on the oven bottom.

Always use the lowest rack position which will allow the

air to circulate within the oven cavity. Load and unload

food as quickly as possible to prevent an excessive drop

in temperature. Avoid using warped pans since level pans

bake more evenly. Do not use a deep pan for shallow cakes,

cookies, etc, as circulation across the surface is essential for

even cooking and browning. To prevent excessive shrinkage,

roast meats at a low temperature (250° to 325°F)

When rethermalizing frozen products preheat the oven 50°

higher than cooking temperature to compensate for heat

loss during and after loading. Thermostat must be returned

to cooking temperature after loading.

Range Base Convection Oven Operation

Activate the power switch to the cook position. Set the fan

speed switch to the desired fan speed. Set oven thermostat

to the desired oven temperature. Allow 20 to 30 minutes to

preheat.

When nished using the oven it should be cooled below

150° before shutting down. Turn the power switch to “cool

Down” and open the oven door. Allow fan to operate for

approximately 30 minutes. To shut down the oven turn the

thermostat and the power switch to the o position.

CAUTION: Motor must operate during cooking cycle. Failure

to do so will shorten motor life!

We recommend, at the end of a bake or roast period, when

the oven will be idle for any period of time to set the oven

thermostat to the lowest temperature setting and allow the

oven to operate. By doing this, the oven motor will keep

itself cool by operating and you will save preheat time for

next ovens’ use. If this procedure is not desirable than we

recommend that the oven be cooled down below 150°F

between baking or roasting periods.

Part # 1009067 Rev13 (12/04/09) Page 11

Page 12

OPERATION continued

Problem / Solution

Heavy Duty Range Convection Oven

Problem Solution

Cakes are dark on the sides

and not done in the center

Cakes edges are too brown Reduce number of pans or

Cakes have light outer color Raise temperature

Cake settles slightly in the

center

Cake ripples Overloading pans or batter

Cakes are too coarse Lower oven Temperature

Pies have uneven color pans Reduce number of pies per

Cupcakes crack on top Lower oven temperature

Meats are browned and not

done in center

Meats are well done and

browned

Meats develop hard crust Reduce temperature or

Rolls have uneven color Reduce number of size

Lower oven temperature

lower oven temperature

Bake longer or raise oven

temperature slightly.

Do not open doors too

often or for long periods

is too thin

rack or eliminate use of

bake pans

Lower temperature and

roast longer.

Reduce time. Limit amount

of moisture

place pan of water in oven.

pans.

Top Sections

Cooking Top – Open Type Burners

High speed tubular heating units are each provided with a

three heat switch. Each high speed tubular heating unit is

rated a 2.1 k.w. designed to give speed and exibility where

sauce pans are used. It should be pointed out that these are

NOT designed or intended for use in heavy (stock pot) duty

service. Use of large stock pots will severely damage surface

elements. It is recommended that only utensils of 8” to 10”

diameter (with a capacity no greater than 1 U.S. gallon), be

used.

Surface heating units should not be left on high heat if not

covered by a cooking utensil. Turn switch to “O” or “Low”

when units are idling. Failure to do this will shorten the life of

the surface heating elements.

NEVER USE LARGE STOCK POTS ON SURFACE HEATING

ELEMENTS!

Top View

of 36ER33

Six

Heating

Units

Motor Care

The motor on your Garland range base convection is

maintenance free since it is constructed with self-lubricating

sealed ball bearing. It is designed to provide durable service

when treated with ordinary care. Be sure to follow the cool

down procedure as mentioned in the above paragraphs or

to lower the oven temperature during idle periods. Failure

to follow the prescribe procedure may not void warranties,

but, may cause your oven motor to fail when you need it the

most.

Switch

Panel

Part # 1009067 Rev13(12/04/09)Page 12

Page 13

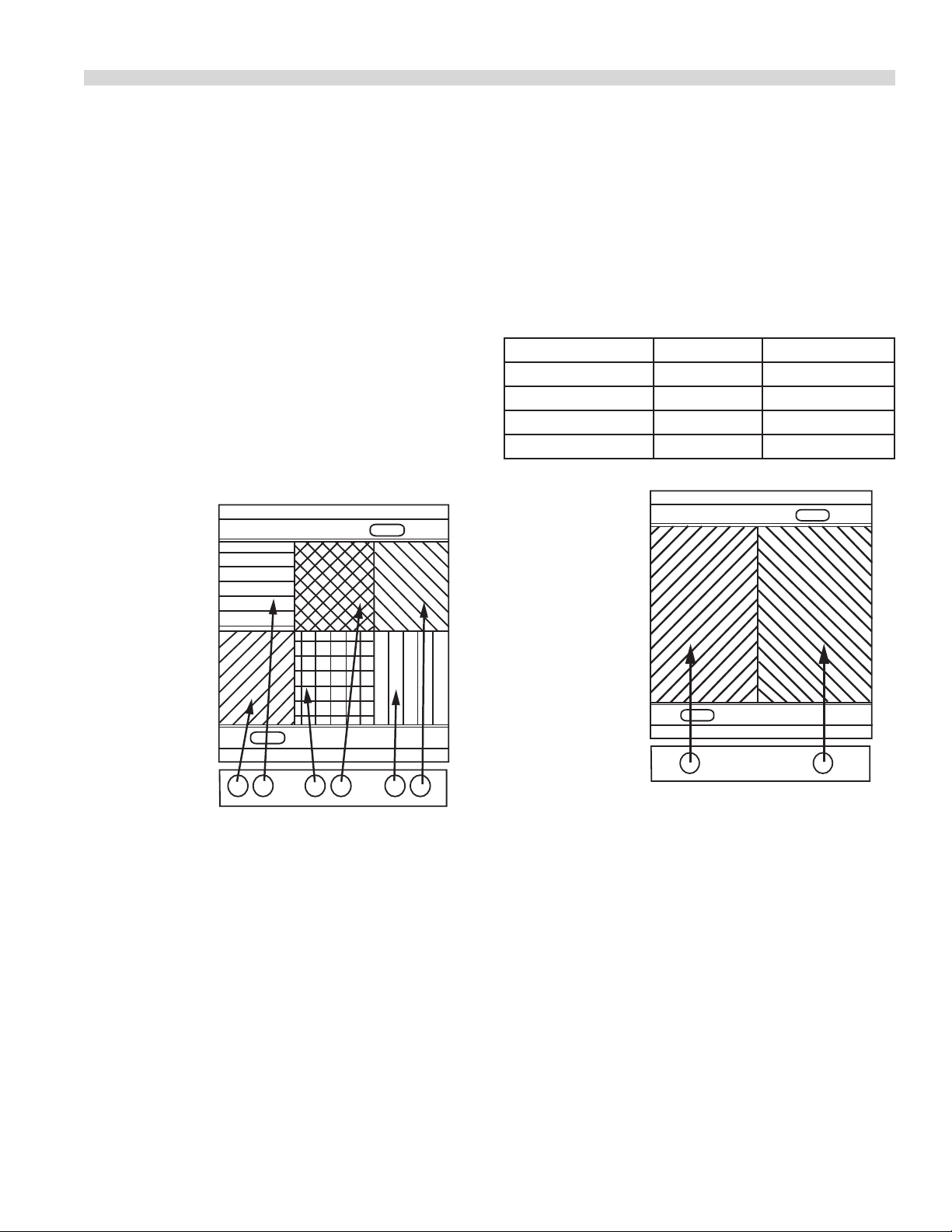

OPERATION continued

Boiling Plates

Remove all factory applied protective material (gelled

mineral oil) by washing with a hot, mild detergent or soap

solution, then dry thoroughly. Before using follow seasoning

procedure in the Griddle Plate Section. All Boiling Plates are

provided with separate front and back heating units. Each

heating unit is operated by a three heat (High-Med-Low-O),

heavy duty reversible switch. Switches are grounded in sets

of two (2) for each 12” of plate. In each group, the switch at

the left operates the front section, the switch at the right

operates the back position.

General Boiling plates are recommended for all stock pot

cooking, These plates are the most exible boiling plates

available. The 36” (914 mm) x 24” (610 mm) steel top, has six

heat zones. Total top input of 12.0 k.W.

Top View

of 36ER39

Six

Heat

Zones

All Purpose Plates

Remove all factory applied protective material (gelled

mineral oil) by washing with a hot, mild detergent or soap

solution, then dry thoroughly. Before using follow seasoning

procedure in the Griddle Plate Section. Each All Purpose Plate

is thermostatically controlled from 250°F to 700°F. thermostat

dials are marked from 1 to 10. Approximate temperatures

settings are as follows.

MODE DIAL SETTING TEMPERATURE

Simmer 1-2 250°F to 300°F

Fry 2-5 300°F to 450°

Boil 5-8 450° to 600°F

Pan Fry & Fast boil 8-10 600°F to 700°

TOP View

of 36ER36

Two

Heat

Zones

Switch

Switch

Panel

Panel

Part # 1009067 Rev13 (12/04/09) Page 13

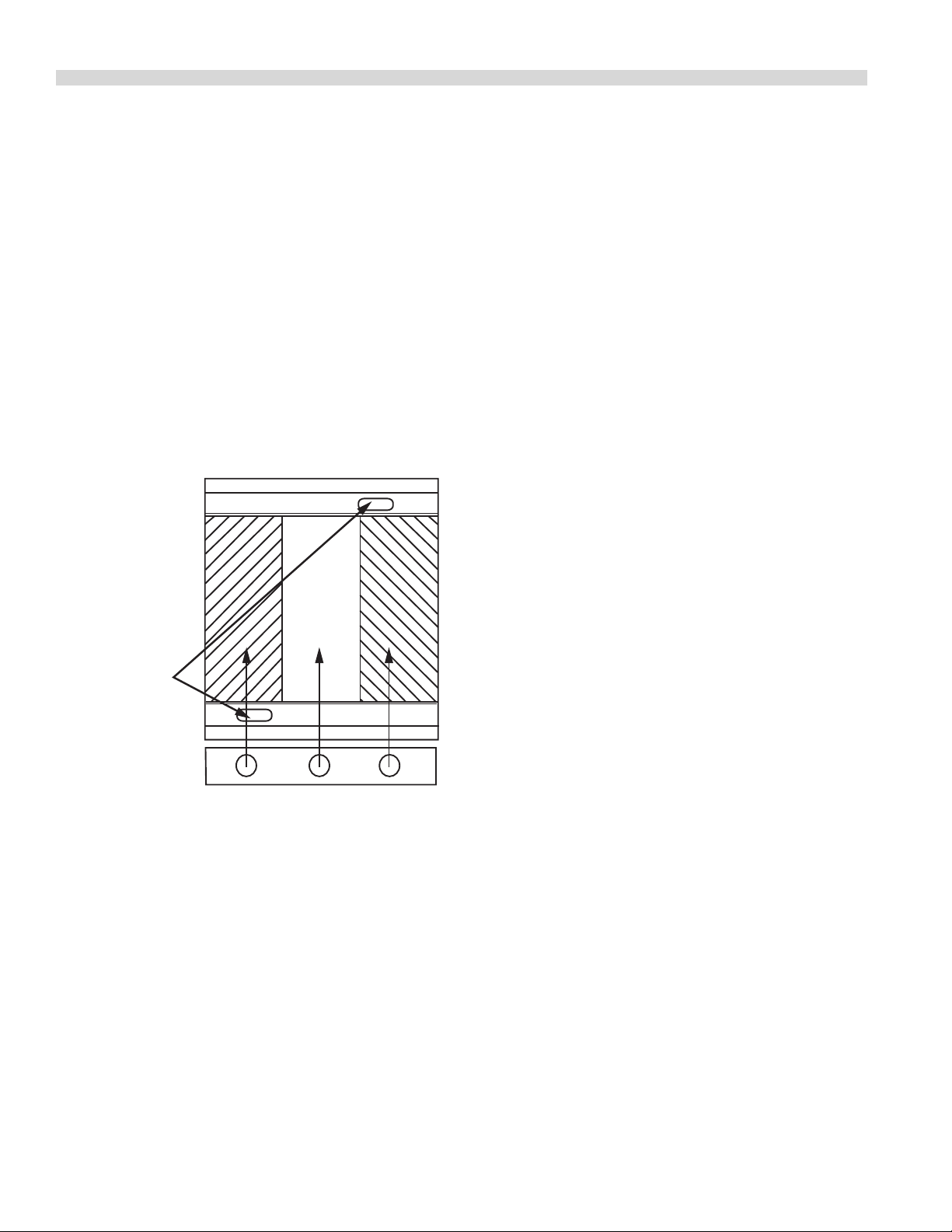

Page 14

OPERATION Continued

Griddle Plates

All steel griddle plates are controlled by thermostats

permitting separate temperatures to be maintained at

any time. Heavy Griddle work recommended for quantity

cooking where even temperature and fast recovery is

required. Top plate has welded 2 1/2” (64 mm) high side

splash guards. Griddle Top: One 36” (914 mm) x 24” (610

mm) polished steel plate, has three heat zones each

thermostatically controlled from 150°F (38°C) to 450°F

(232°C) with indicator lamp. Total top input of 15.0 k.W.

preheats to 350°F (180°C) in eight minutes.

Remove all factory applied protective material (gelled

mineral oil) by washing with a hot, mild detergent or soap

solution, then dry thoroughly.

Top View

of 36ER38

Three

Heat

Zones

Grease

Drains

Switch

Panel

Seasoning

Before being used for the rst time, all griddles must be

“Seasoned.” The following method is recommended:

• Apply a thin coat of cooking oil to the griddle surface,

about one ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

• Turn on all thermostats, set at 150°F setting. Some

discoloration will occur when heat is applied to steel.

• Heat the griddle slowly for 15 to 20 minutes. Then wipe

away oil. Repeat the procedure 2 to 3 times until the

griddle has a slick, mirror like nish. Do this until you have

reached the desired cooking temperature.

Important: Do not attain 450°F during “break-in” period.

Note: Steel griddle surface will tone (blue discoloration) from

heat. This toning will not diminish function or operation and

is not a defect.

The griddle will not require reseasoning if it is used properly.

If the griddle is over heated and product begins to stick to

the surface it may be necessary to repeat the seasoning

process again. If the griddle is cleaned with soap and water it

will be necessary to reseason the griddle surface again.

Operation of Broiling Section

Heavy Duty Electric Broilers are available in single or double

deck model mounted on an oven or storage base. It is also

available as a single deck or double deck modular section.

Broiling Compartments has broiler rack in each section

riding in a spring counter-balanced raising and lowering

mechanism, adjustable to 15 positions. The rack may be

raised to with 1/2” of the heating elements. The 24” by 225/8” broil rack, with attached drip shield, rolls in and out

easily on six roller bearings. A lock stop prevents the rack

from accidentally being pulled out of the tracks, yet the

rack and drip shield may be readily removed for cleaning.

The large porcelain enameled grease pan is removed for

cleaning. Bae spoilers within the pane prevent spillage

during removal.

Heating Elements: Two inconel sheathed heating element

packages are provided; one service the rear half of the

broiling compartment, the other the front half. The element

package for the front half of the broiling compartment is

controlled by a three position heat heavy duty reversible

switch mounted at the bottom of the panel. Each switch

adjusts from full OFF to HIGH, MEDIUM and LOW modes.

Each broiler section is provided with a pilot indicator lamp

mounted in the control panel. When the lamp is lit, it signals

that energy is being applied to the elements. Each element

package has a maximum rating of 6 k.W. providing a 12 k.W.

maximum total for each section

Part # 1009067 Rev13(12/04/09)Page 14

Page 15

MAINTENANCE AND CLEANING

We suggest maintenance and repairs to be performed by an

Garland Authorized Service Agent. The listing provided with

your range is titled “Maintenance and Repair Centers”.

CAUTION: Remember! Water and electricity do not mix, do

not use excessive water, heavily soaked sponges or rags to

clean switch panels or areas near electrical connections!

NOTE: RUST can form on raw steel and cast iron parts. Be

sure parts are dried thoroughly after cleaning. In warm, moist

environments, raw parts may require protection. Wipe down

with light coating of oil, rust inhibitor, or polish as applicable.

Painted Finishes

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

The oven should be permitted to cool down before cleaning

exterior surfaces.

Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a light weight non metallic scouring pad. Dry

thoroughly with a clean cloth.

Stainless Steel

For routine cleaning just wash with a hot water and

detergent solution.

Stainless steel should be cleaned using a mild detergent, a

soft cloth and hot water. If necessary to use a nonmetallic

scouring pad, always rub in the direction of the grain in the

metal to prevent scratching. Use a water based stainless

cleaner (Drakett Twinkle), if you want a high shine. Wash just

a small area at a time or the water will evaporate leaving the

chemicals behind causing streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with a soft clean cloth

before it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

To prevent ngerprints there are several stainless steel

polishes on the market that leave an oily or waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste.

Use only stainless steel, wood or plastic tools if necessary

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers of knives as particles of the iron may

become imbedded and rust. STEEL WOOL SHOULD NEVER BE

USED.

Either a typical bleach solution or hot water can be used to

sanitize stainless steel with out harm.

Oven Inner Door Liner and Oven Deck

(Porcelain Enamel)

The porcelain Oven Inner door Liner and Oven Deck can

be cleaned with oven cleaners such as “Easy-O”, or “Dow

Cleaner”. Follow product manufacture’s instructions for

proper use. CAUTION: Do not get any oven cleaner on any

painted surface, the oven cleaner will remove the paint!

CAUTION: Do not get any oven cleaner on Aluminized Steel

Inner Surfaces, it will cause the surface to turn a deep blue

color and may mar the aluminized surface.

Interior Cleaning of Standard Aluminized

Steel Interior Surfaces.

The oven sides and top linings are formed of heavy gauge

steel with an aluminum fused into its surface to provide

for the reectance of heat back to the food being prepared

and to virtually eliminate the possibility of rust formation.

Establish a regular cleaning schedule or wipe o on the same

day when spillovers occur.

1. Cool down oven.

2. Remove oven racks.

3. Lift rack guides on either side of oven o of holders, pull

the top away from the cavity wall, when it’s cleared the

clips push down and remove. Racks and guides may

be run through dishwasher while oven cavity is being

cleaned.

4. Use a concentrated detergent on a plastic pad to remove

burned on soil. Do Not Use Steel Wool, Oven Cleaner Or

Abrasive Powders. These will remove the aluminum. Rinse

with warm water on a soft cloth. Be sure to remove all

traces of detergent. Any discoloration which may remain

after the soil build-up has been removed will not aect

the performance of the oven.

5. To reinstall reverse procedure. Place the bottom of the

rack guide against the cavity wall. Keeping the top pulled

away from the wall lift up. Push the top of the rack guide

against the wall and push down locking it into place.

Part # 1009067 Rev13 (12/04/09) Page 15

Page 16

MAINTENANCE AND CLEANING continued

Cleaning and Care of

Top Surface Heating Burners

Surface units may be raised to permit removal of spillover

bowls under the surface burners. Spillover bowls may be

cleaned, wiped dry and replaced. Drip trays under the front

control panel may also be removed, washed, rinsed, wiped

dry and replaced. Cooking top may be wiped with a damp

cloth using a mild detergent and wary water. You may also

follow pervious instructions for “cleaning Stainless Steel

Exterior.”

Cleaning of Griddle, All Purpose Plates and

Boil Plates

To produce evenly cooked, perfectly browned griddle

products, keep griddle free from carbonized grease.

Carbonized grease on the surface hinders the transfer of

heat from the griddle surface to food product. This results

in uneven browning and loss of cooking eciency, and

worst of all, carbonized grease tends to cling to the griddle

foods, giving them a highly unsatisfactory and unappetizing

appearance. To keep the griddle clean and operating at peak

performance, follow these simple instructions.

A. After Each Use clean griddle thoroughly with a grill

scraper or spatula. Wipe o any excess debris left from

cooking process.

B. Once A Day clean griddle surface with a grill brick and

grill pad. Remove grease container and clean thoroughly,

in same manor as any ordinary cooking utensil.

C. Once A Week clean griddle surface thoroughly. If

necessary, use a grill stone or grill pad over the griddle

surface. Rub with grain of the metal while still warm. A

detergent may be use on the plate surface to help clean

it, but care must be taken to be sure it is thoroughly

removed. After removal of detergent, the surface of the

plate should be covered with a thin lm of oil to prevent

rusting. To remove discolorations, use a non-abrasive

cleaner. Before re-using the griddle must be reseasoned.

Keep griddle drain tube to grease container clear at all

times on those models without side grease container.

CAUTION: This griddle plate is steel, but the surface is

relatively soft and can be scored or dented by careless use

of spatula. Be careful not to dent, scratch, or gouge the plate

surface. This will cause food to stick in those areas. Also, note

since this is a steel griddle if a light coating of oil is not always

present rust will develop on unexposed areas.

Broiler Section

Broil rack, rack carriage and drip pan may be removed for

cleaning.

Lift broil rack out of carriage. Pull rack carriage forward to

rack stops and raise. Carriage may now be pulled out of

tracks. Raise and pull grease pan forward and out. Entire

interior of broiler may now be cleaned. After washing and

drying, reassemble parts by reversing previous steps.

After cleaning Boil Plates, All Purpose Plates, Griddles,

Tubular Heating Units, Ovens and Broilers, wash front and

back grease troughs and drip trays with hot, mild detergent

or soap solution and dry thoroughly.

Part # 1009067 Rev13(12/04/09)Page 16

Page 17

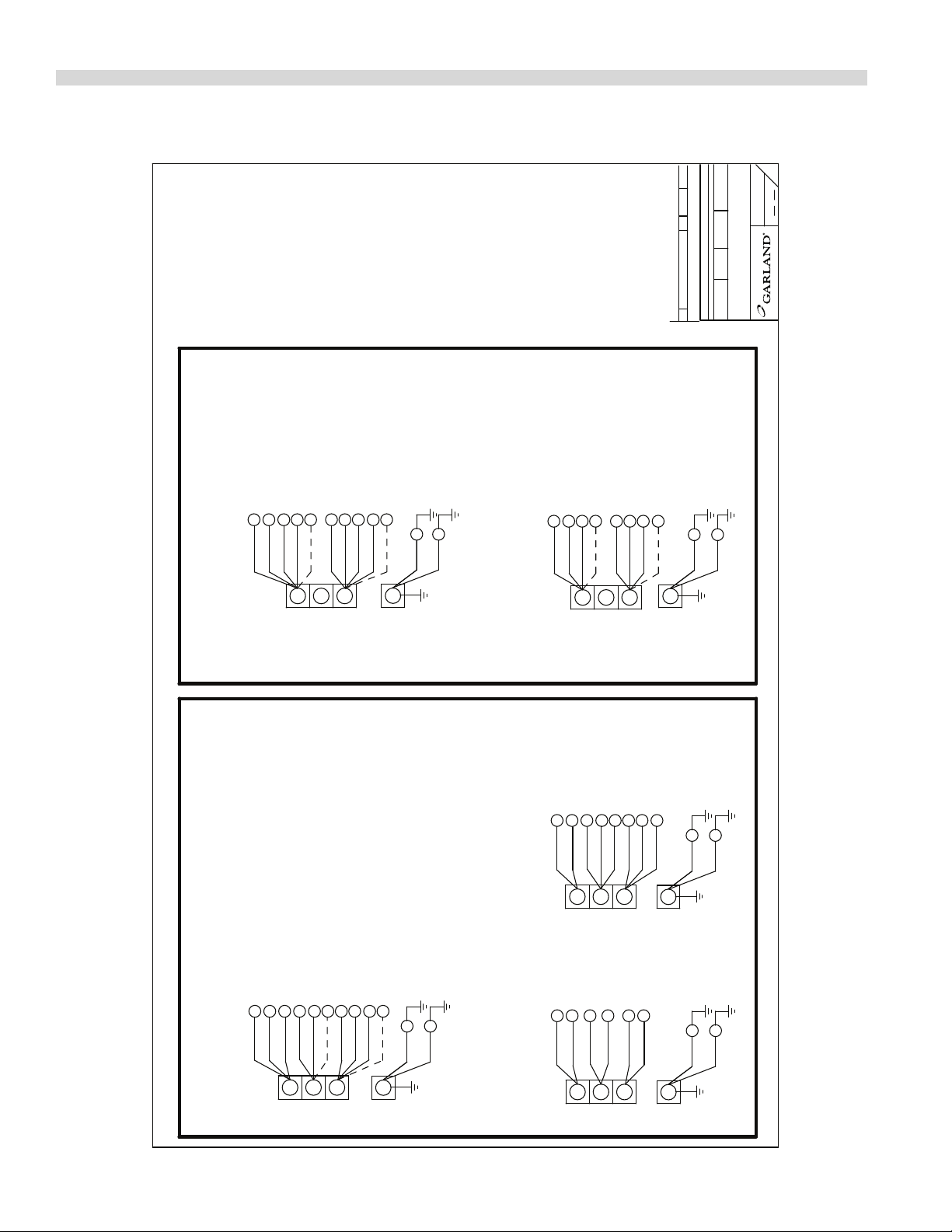

WIRING DIAGRAMS

1500W

OUTER

1500W

OUTER

UPPER OVEN ELEMENTS LOWER OVEN ELEMENTS

G4

5000W

36E SERIES

4514760

36ER-ET-ES 208V/240V

TITLE:

1

31

SHT OF

2000W

1500W

INNER

INNER

4321

18

P3 P1 P2

17

14

16

212019 22 23 24

200-550F

THERMOSTAT

4321

15

P3 P1 P2

13

12

11

40A

98

REV.#

DATE

DR.DESCRIPTION

REVISIONS

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

:

DR.

40A

G5

G3

G1

G2

TB

CENTER

RIGHT

LEFT

4

12

3

6

5

40A

40A

RIGHT

CENTER

LEFT

21

4

6

3

5

OPEN TOP GRIDDLE-ALL PURPOSE TOP OVEN

4KW BOIL TOP

1125W

1125W

6

4

THERMOSTAT

RIGHT

CENTER

LEFT

12

5

3

4

o6

o5

o4

12

2COM

P2

123

P3 P1

o7

o8

4

P2

o3o2o1

2

4

6

CENTER

RIGHT

LEFT

30A 30A

1

3

5

RIGHT

LEFT

CENTER

TO TERMINAL BLOCK

(See page 2 for terminal block connection)

30A

12

34

COM

1

o9

o9

875W

H4

875W

H1

123

P3 P1

LEFT

CENTER

RIGHT

4

6

12

3

H6

43

P2

2

P1

H5

1

P3

H3

H2

324

P1 P2

1

P3

o7

o8

5

ER 7kW

30A

SALAMANDER

56

S2

40A

40A

S1

MODEL:

36ER32; 36ER32-3; 36ER33;

36ER33-88;36ER33-99;36ER38;36ER39

36ES32; 36ES32-3; 36ES33; 36ES33-88;

36ES33-99;36ES38;36ES39;36ES17

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39;36ET17

S3 S4

Part # 1009067 Rev13 (12/04/09) Page 17

Page 18

WIRING DIAGRAMS continued

OVEN

TOP LEFT

TOP CENTER

TOP RIGHT

SALAMANDER

1

3

5

8

SINGLE PHASE CONNECTION

36ER32; 36ER32-3; 36ER33; 36ER33-88;

36ER33-99;36ER38;36ER39

S1

X

Y

REV.#

:

DATE

SEPT 22,2002NANB

DATE

DR.DESCRIPTION

:

SCALE

REVISIONS

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

DR.

REV

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

SALAMANDER

TOP LEFT

TOP CENTER

TOP RIGHT

OVEN

9

2

4

6

S2

E1

E2

Z

G

36ES32; 36ES32-3; 36ES33; 36ES33-88;

36ES33-99;36ES38;36ES39

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39

TOP LEF T

1

TOP CENTER

TOP RIGHT

3

5

X

SALAMANDER

S1

Y

TOP LEF T

2

TOP CENTER

TOP RIGHT

6

4

Z

SALAMANDER

S2

G

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

E1

E2

36E SERIES

36ER-ET-ES 208V/240V

TITLE:

1

32

SHT OF

4514760

TOP CENTER

OVEN

3 PHASE CONNECTION

36ER32; 36ER32-3; 36ER33; 36ER33-88;

TOP LEFT

1

3

8

36ER33-99;36ER38;36ER39

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

TOP CENTER

TOP RIGHT

TOP LEF T

TOP RIGHT

SALAMANDER

TOP LEF T

TOP CENTER

SALAMANDER

1

3

S1

TOP LEFT

1

X

TOP CENTER

X

36ES32; 36ES32-3; 36ES33; 36ES33-88;

TOP LEFT

295

Z

TOP CENTER

TOP RIGHT

4

6

SALAMANDER

S2

E1

G

E2

SALAMANDER

OVEN

TOP RIGHT

S1

X

Y

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

36ES32; 36ES32-3; 36ES33; 36ES33-88;

WITH SALAMANDER

36ES33-99;36ES38;36ES39

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39

NO SALAMANDER

36ES33-99;36ES38;36ES39;36ES17

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39;36ET17

TOP LEFT

Y

TOP RIGHT

532

Y

S2

225

Z

TOP CENTER

TOP RIGHT

4

6

Z

4

E1

E2

G

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

E1

E2

G

Part # 1009067 Rev13(12/04/09)Page 18

Page 19

WIRING DIAGRAMS continued

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 15 5 5 5 72.1 41.6 41.6 41.6

36 ES 32

240 15 5 5 5 62.5 36.1 36.1 36.1

208 22 7 5 10 105.8 50.2 71.1 63.6

240 22 7 5 10 91.7 43.5 61.7 55.1

36 ET 32

36 ES 32 SAL

36 ET 32 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 14.2 5 5 4.2 68.3 41.6 38.4 38.4

36 ES 32-3

240 14.2 5 5 4.2 59.2 36.1 33.2 33.2

208 21.2 7 5 9.2 101.9 50.2 67.7 60.0

240 21.2 7 5 9.2 88.3 43.5 58.6 52.0

36 ET 32-3

36 ES 32-3 SAL

36 ET 32-3 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 12.6 4.2 4.2 4.2 60.6 35.0 35.0 35.0

240 12.6 4.2 4.2 4.2 52.5 30.3 30.3 30.3

208 19.6 7 4.2 8.4 94.2 47.1 64.2 53.4

36 ES 33

36 ET 33

36 ES 33 SAL

240 19.6 7 4.2 8.4 81.7 40.8 55.6 46.3

36 ET 33 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 14.2 5 5 4.2 68.3 41.6 38.4 38.4

240 14.2 5 5 4.2 59.2 36.1 33.2 33.2

36 ES 33-88

36 ET 33-88

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 20.4 7 4.2 9.2 98.1 47.1 67.7 57.1

240 20.4 7 4.2 9.2 85.0 40.8 58.6 49.5

208 12.2 4 4 4.2 58.7 33.3 34.1 34.1

MODEL VOLTAGE TOTAL KW

36 ET 33-88 SAL

36 ES 33-99

36 ES 33-88 SAL

LOADING PER PHASE AMPERAGE

208 19.2 7 4 8.2 92.3 46.4 63.4 51.8

240 19.2 7 4 8.2 80.0 40.2 54.9 44.9

240 12.2 4 4 4.2 50.8 28.9 29.6 29.6

36 ET 33-99

36 ES 33-99 SAL

36 ET 33-99 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

MODEL VOLTAGE TOTAL KW

208 15 5 5 5 72.1 41.6 41.6 41.6

240 15 5 5 5 62.5 36.1 36.1 36.1

208 22 7 5 10 105.8 50.2 71.1 63.6

36 ES 38

36 ET 38

36 ES 38 SAL

240 22 7 5 10 91.7 43.5 61.7 55.1

36 ET 38 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 12 4 4 4 57.7 33.3 33.3 33.3

36 ES 39

240 12 4 4 4 50.0 28.9 28.9 28.9

208 19 7 4 8 91.3 46.4 62.5 50.9

240 19 7 4 8 40.2 79.2 54.2 44.1

36 ET 39

36 ES 39 SAL

36 ES 39 SAL

REV.#

DATE

DR.DESCRIPTION

REVISIONS

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

36E SERIES

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

36ER-ET-ES 208V/240V

:

TITLE:

DR.

1

33

SHT OF

4514760

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 21.5 6.5 10 5 103.4 69.2 48.0 63.6

240 21.5 6.5 10 5 89.6 60.0 41.6 55.1

36 ER 32

LOADING PER PHASE AMPERAGE

208 28.5 6.5 10 12 137.0 69.2 78.2 91.7

240 28.5 6.5 10 12 118.8 60.0 67.7 79.5

36 ER 32 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

MODEL VOLTAGE TOTAL KW

208 20.7 6.5 10 4.2 99.5 69.2 44.9 60.7

240 20.7 6.5 10 4.2 86.3 60.0 38.9 52.6

208 27.7 6.5 10 11.2 133.2 69.2 74.6 88.3

36 ER 32-3

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

240 27.7 6.5 10 11.2 115.4 60.0 64.6 76.5

MODEL VOLTAGE TOTAL KW

36 ER 32-3 SAL

208 19.1 6.5 8.4 4.2 91.8 62.2 44.9 53.4

240 19.1 6.5 8.4 4.2 79.6 53.9 38.9 56.3

36 ER 33

LOADING PER PHASE AMPERAGE

208 26.1 6.5 8.4 11.2 125.5 62.2 74.6 81.9

240 26.1 6.5 8.4 11.2 108.8 53.9 64.6 71.0

36 ER 33 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

MODEL VOLTAGE TOTAL KW

208 20.7 6.5 10 4.2 99.5 69.2 44.9 60.7

240 20.7 6.5 10 4.2 86.3 60.0 38.9 52.6

208 27.7 6.5 10 11.2 133.2 69.2 74.6 88.3

36 ER 33-88

36 ER 32 SAL

240 27.7 6.5 10 11.2 115.4 60.0 64.6 76.5

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 18.7 6.5 8 4.2 89.9 60.5 44.9 51.6

36 ER 33-99

240 18.7 6.5 8 4.2 77.9 52.4 38.9 44.7

208 25.7 6.5 8 11.2 123.6 60.5 74.6 80.3

240 25.7 6.5 8 11.2 107.1 52.4 64.6 69.6

36 ER 33-99 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 21.5 6.5 10 5 103.4 69.2 48.0 63.6

240 21.5 6.5 10 5 89.6 60.0 41.6 55.1

36 ER 38

208 28.5 6.5 10 12 137.0 69.2 78.2 91.7

240 28.5 6.5 10 12 118.8 60.0 67.7 79.5

36 ER 38 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 18.5 6.5 8 4 88.9 60.5 44.1 50.9

240 18.5 6.5 8 4 77.1 52.4 38.2 44.1

36 ER 39

208 25.5 6.5 8 11 122.6 60.5 73.7 79.4

240 25.5 6.5 8 11 106.3 52.4 63.8 68.8

36 ER 39 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 10 5 5 0 48.1 41.6 24.0 24.0

36 ES 17

240 10 5 5 0 41.7 36.1 20.8 20.8

36 ET 17

Part # 1009067 Rev13 (12/04/09) Page 19

Page 20

WIRING DIAGRAMS continued

LOWER OVEN ELEMENTS

OVEN

UPPER OVEN ELEMENTS

1500W

1500W

OUTER

OUTER

2000W

1500W

INNER

INNER

REV.#

:

43

12

18

P2

P1P3

17

14

16

21

200-550F

THERMOSTAT

4321

15

2019 22 23 24

P3 P1 P2

13

12

11

40A40A40A40A

98

DATE

DR.DESCRIPTION

REVISIONS

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

:

DR.

1

36E SERIES

31

SHT OF

4514761

36ER 208V/240V 18"SECTION

TITLE:

A7

RIGHT

LEFT

2

A6

TB

4

1

3

LEFT

RIGHT

2

43

1

1400W

1600W

1600W

1400W

ALL PURPOSE TOP

A1 A2

A5

A4

A3

THERMOSTAT

TO TERMINAL BLOCK

(See page 2 for terminal block connection)

B6

43

P2

1400W

1600W

B4

BOIL TOP

1400W

1600W

2

P1

B5

1

P3

B3

B2

B7

B8

4

P2

3

2

P1

1

P3

B1

ER 7kW

SALAMANDER

RIGHT

LEFT

12

34

40A 40A 40A40A

LEFT

RIGHT

2

43

1

S2

S1

S3 S4

MODEL:

36ER35 36ER36

36ET35 36ET36

36ES35 36ES36

36ET15 36ET16

36ES15 36ES16

Part # 1009067 Rev13(12/04/09)Page 20

Page 21

WIRING DIAGRAMS continued

36ET15 36ET16

36ES15 36ES16

REV.#

:

DATE

SEPT 22,2002NANB

DATE

DR.DESCRIPTION

:

SCALE

REVISIONS

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

DR.

REV

TO CONTROL PANEL

TOP

TOP

1

2

Z

X

Y

TO CIRCUIT BREAKER PANEL

E1

E2

G

1

36ESERIES

32

SHT OF

4514761

36ER 208V/240V 18"SECTION

TITLE:

SALAMANDER

TOP RIGHT

TOP LEFT

OVEN

1

8

36ER35 36ER36

SINGLE PHASE CONNECTION

TOP LEF T

OVEN

1

8

36ER35 36ER36

OVEN

9

3

S1

X

Y

SALAMANDER

TOP RIGHT

OVEN

9

3

S1

X

Y

3 PHASE CONNECTION

TOP LEFT

2

Z

Z

SALAMANDER

TOP RIGHT

4

TOP LEF T

2

S2

TOP RIGHT

4

TO CONTROL PANEL

E1

G

SALAMANDER

TO CONTROL PANEL

S2

E1

G

TO CIRCUIT BREAKER PANEL

E2

36ET35 36ET36

TO CIRCUIT BREAKER PANEL

E2

36ET35 36ET36

TOP RIGHT

TOP LEF T

1

3

36ES35 36ES36

SALAMANDER

TOP LEF T

1

S1

36ES35 36ES36

SALAMANDER

S1

X

X

Y

TOP RIGHT

3

TOP RIGHT

TOP LEF T

2

4

Z

SALAMANDER

TOP LEF T

2

S2

Z

Y

SALAMANDER

S2

TOP RIGHT

4

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

E1

E2

G

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

E1

E2

G

Part # 1009067 Rev13 (12/04/09) Page 21

Page 22

WIRING DIAGRAMS continued

REV.#

DATE

DR.DESCRIPTION

REVISIONS

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

1

36E SERIES

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

:

DR.

33

SHT OF

4514761

36ER 208V/240V 18"SECTION

TITLE:

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 18.5 6.5 6 6 88.9 52.1 52.1 50.0

240 18.5 6.5 6 6 77.1 45.1 45.1 43.3

36 ER 35

LOADING PER PHASE AMPERAGE

208 25.5 6.5 6 13 122.6 52.1 82.7 80.9

240 25.5 6.5 6 13 106.3 45.1 71.7 70.1

36 ER 35 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

MODEL VOLTAGE TOTAL KW

208 18.5 6.5 6 6 88.9 52.1 52.1 50.0

240 18.5 6.5 6 6 77.1 45.1 45.1 43.3

36 ER 36

LOADING PER PHASE AMPERAGE

208 25.5 6.5 6 13 122.6 52.1 82.7 80.9

240 25.5 6.5 6 13 106.3 45.1 71.7 70.1

36 ER 36 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

MODEL VOLTAGE TOTAL KW

208 12 0 6 6 57.7 28.8 28.8 50.0

240 12 0 6 6 50.0 25.0 25.0 43.3

36 ES 35

36 ET 35

LOADING PER PHASE AMPERAGE

208 19 7 6 6 91.3 54.2 54.2 50.0

240 19 7 6 6 79.2 47.0 47.0 43.3

MODEL VOLTAGE TOTAL KW

36 ES 35 SAL

36 ET 35 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

208 12 0 6 6 57.7 28.8 28.8 50.0

36 ES 36

240 12 0 6 6 50.0 25.0 25.0 43.3

208 19 7 6 6 91.3 54.2 54.2 50.0

240 19 7 6 6 79.2 47.0 47.0 43.3

36 ET 36

36 ES 36 SAL

36 ET 36 SAL

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

X-Y X-Z Y-Z 1 Phase X Y Z

208 6 0 6 0 28.8 28.8 0.0 28.8

240 6 0 6 0 25.0 25.0 0.0 25.0

36ES16

36ET16

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

MODEL VOLTAGE TOTAL KW

208 6 0 6 0 28.8 28.8 0.0 28.8

240 6 0 6 0 25.0 25.0 0.0 25.0

36ES15

36ET15

Part # 1009067 Rev13(12/04/09)Page 22

Page 23

WIRING DIAGRAMS continued

PCO4414

WAS 14

23

22

WAS 16

2500W

M~

OUTER ELEMENT

21

YELLOW BLACK

WAS 15

WHITE (LOW SPEED)

YELLOW (HIGH SPEED)

15 16

2500W

INNER ELEMENT

High low switch

HIGH

LOW

19

1

WAS 13 WAS 12

20

150°-550°F

OVEN THERMOSTAT

Cook cool switch

14

Door switch

13

12

1

WAS 12

40A40A30A

18 17 11 19

COM NO NC

98

REV.#

DATE

NOV 25/09

V.C.

DR.DESCRIPTION

REVISIONS

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

WIRE NUMBERS CHANGED

SEE NOTES

1

REV

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

:

DR.

20A 20A

24 25

CENTER

RIGHT

LEFT

43

1 2

5 6

5000W

G4

G5

G1

TB

CENTER

LEFT

G3

G2

RIGHT

2

4

6

3

5

1

36E SERIES

21

SHT OF

4514762

36ERC 208V/240V 12"SECTION

TITLE:

TERMINAL SPECIFICATIONS,

SEE 4525159,

FOR WIRE LENGTHS &

OPEN TOP GRIDDLE - ALL PURPOSE TOP RC OVEN

BOIL TOP

12

COM

1125W

1125W

21

4

6

THERMOSTAT

CENTER

RIGHT

LEFT

1

3

5

4

o6

o5

o4

2COM

P2

123

P3 P1

o7

o8

4

P2

o3o2o1

30A 30A

30A 40A 40A

123

H5

H2

P3 P1

43

P2

2

P1

1

P3

324

P1 P2

1

P3

4

6

CENTER

RIGHT

LEFT

1 2

5

3

40A

S3 S4

40A

o7

o8

ER 7kW

SALAMANDER

S3 S4

1

H6

875W

H4

H3

875W

H1

43

TO TERMINAL BLOCK

CENTER

RIGHT

LEFT

1 2

5 6

CENTER

RIGHT

LEFT

(See page 2 for terminal block connection)

43

1 2

5 6

S2

S1

36ERC32 36ERC32-3 36ERC33 36ERC33-88

36ERC33-88 36ERC38 36ERC39

MODEL:

Part # 1009067 Rev13 (12/04/09) Page 23

Page 24

WIRING DIAGRAMS continued

TOP CENTER

TOP LEFT

OVEN

8

3 PHASE CONNECTION

36ERC32 36ERC32-3 36ERC33 36ERC33-88

36ERC33-88 36ERC38 36ERC39

OVEN

RC MOTOR

1

9

3

24

X

TOP RIGHT

RC MOTOR

5

25

Y

SALAMANDER

S1

Z

TOP LEFT

2

TOP RIGHT

TOP CENTER

6

4

SALAMANDER

S2

G

E1

TO CONTROL PANEL

E2

TO CIRCUIT BREAKER PANEL

OVEN

8

1

SINGLE PHASE CONNECTION

36ERC32 36ERC32-3 36ERC33 36ERC33-88

36ERC33-88 36ERC38 36ERC39

SALAMANDER

5

3

S1

24

X

RC MOTOR

TOP CENTER

TOP RIGHT

TOP LEFT

36ERC 208V/240V 12"SECTION

TITLE:

TO CIRCUIT BREAKER PANEL

E2

1

36E SERIES

22

SHT OF

4514762

PCO4414

REV.#

:

DATE

SEPT 22,2002NANB

DATE

NOV 25/09

V.C.

DR.DESCRIPTION

:

SCALE

REVISIONS

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

WIRE NUMBERS CHANGED

SEE NOTES

:

1

DR.

REV

SALAMANDER

RC MOTOR

TOP LEFT

TOP RIGHT

TOP CENTER

OVEN

9

2

4

6

Z

Y

TO CONTROL PANEL

S2

25

E1

G

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 20.4 5.4 10 5 98.1 65.1 43.3 63.6

240 20.4 5.4 10 5 85.0 56.4 37.5 55.1

MODEL VOLTAGE TOTAL KW

36 ERC 32

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 27.4 5.4 10 12 131.7 65.1 74.2 91.7

240 27.4 5.4 10 12 114.2 56.4 64.3 79.5

MODEL VOLTAGE TOTAL KW

36 ERC 32 SAL

208 19.6 5.4 10 4.2 94.2 65.1 40.1 60.7

240 19.6 5.4 10 4.2 81.7 56.4 34.7 52.6

208 26.6 5.4 10 11.2 127.9 65.1 70.5 88.3

240 26.6 5.4 10 11.2 110.8 56.4 61.1 76.5

36 ERC 32-3

36 ERC 32-3 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 18 5.4 8.4 4.2 86.5 57.9 40.1 53.4

240 18 5.4 8.4 4.2 75.0 50.2 34.7 46.3

MODEL VOLTAGE TOTAL KW

36 ERC 33

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 25 5.4 8.4 11.2 120.2 57.9 70.5 81.9

240 25 5.4 8.4 11.2 104.2 50.2 61.1 71.0

MODEL VOLTAGE TOTAL KW

36 ERC 33 SAL

208 19.6 5.4 10 4.2 94.2 65.1 40.1 60.7

240 19.6 5.4 10 4.2 81.7 56.4 34.7 52.6

208 26.6 5.4 10 11.2 127.9 65.1 70.5 88.3

240 26.6 5.4 10 11.2 110.8 56.4 61.1 76.5

36 ERC 33-88

36 ERC 33-88 SAL

’

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 17.6 5.4 8 4.2 84.6 56.1 40.1 51.6

240 17.6 5.4 8 4.2 73.3 48.7 34.7 44.7

MODEL VOLTAGE TOTAL KW

36 ERC 33-99

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 24.6 5.4 8 11.2 118.3 56.1 70.5 80.3

240 24.6 5.4 8 11.2 102.5 48.7 61.1 69.6

208 20.4 5.4 10 5 98.1 65.1 43.3 63.6

MODEL VOLTAGE TOTAL KW

36 ERC 38

36 ERC 33-99 SAL

240 20.4 5.4 10 5 85.0 56.4 37.5 55.1

208 27.4 5.4 10 12 131.7 65.1 74.2 91.7

240 27.4 5.4 10 12 114.2 56.4 64.3 79.5

36 ERC 38 SAL

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 17.4 5.4 8 4 83.7 56.1 39.3 50.9

240 17.4 5.4 8 4 72.5 48.7 34.0 44.1

MODEL VOLTAGE TOTAL KW

36 ERC 39

208 24.4 5.4 8 11 117.3 56.1 69.6 79.4

240 24.4 5.4 8 11 101.7 48.7 60.3 68.8

36 ERC 39 SAL

Part # 1009067 Rev13(12/04/09)Page 24

Page 25

WIRING DIAGRAMS continued

PCO4414

REV.#

WAS 24

23

22

2500W

OUTER ELEMENT

M~

WHITE (LOW SPEED)

YELLOW (HIGH SPEED)

21

YELLOW BLACK

15 16

2500W

INNER ELEMENT

High low switch

HIGH

LOW

19

WAS 23

1

20

1911

40A40A

150°-550°F

OVEN THERMOSTAT

Cook cool switch

14

Door switch

13

NO NCCOM

12

WAS 11

1

WAS 18

1

20A

18 17

98

DATE

NOV 25/09

V.C.

DR.DESCRIPTION

REVISIONS

WIRE NUMBERS CHANGED

SEE NOTES

1

REV

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

DR.

20A

1

36E SERIES

21

SHT OF

4514763

36ERC 208V/240V 18" SECTION

TITLE:

TERMINAL SPECIFICATIONS,

SEE 4525159,

FOR WIRE LENGTHS &

89

A6

LEFT

RIGHT

2

G5

TB

4

1

3

40A40A

RIGHT

LEFT

2

4

1

3

ALL PURPOSE TOP RC OVEN

BOIL TOP

1600W

1600W

1600W

1400W

B4

B1

A1 A2

SALAMANDER

1600W

1400W

1400W

ER 7kW

1400W

A5

A4

A3

THERMOSTAT

TO TERMINAL BLOCK

(See page 2 for terminal block connection)

B6

43

P2

2

P1

B5

1

P3

B3

B2

B7

43

P2

2

P1

1

P3

LEFT

RIGHT

2

4

1

3

40A 40A40A

RIGHT

LEFT

2

4

1

3

B8

S2

40A

S1

36ERC35;36ERC36

MODEL:

S3 S4

Part # 1009067 Rev13 (12/04/09) Page 25

Page 26

WIRING DIAGRAMS continued

OVEN

8

TOP LEFT

1

TOP RIGHT

RC MOTOR

3

24

SALAMANDER

S1

OVEN

9

TOP LEFT

2

TOP RIGHT

4

PCO4414

REV.#

:

DATE

SEPT 22,2002NANB

DATE

NOV 25/09

V.C.

DR.DESCRIPTION

:

SCALE

REVISIONS

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

WIRE NUMBERS CHANGED

SEE NOTES

:

1

DR.

REV

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

SALAMANDER

RC MOTOR

S2

25

E1

E2

36E SERIES

36ERC 208V/240V 18" SECTION

TITLE:

1

22

SHT OF

4514763

SINGLE PHASE CONNECTION3 PHASE CONNECTION

36ERC35;36ERC36

TOP LEFT

OVEN

RC MOTOR

1

8

24

36ERC35;36ERC36

X

OVEN

9

X

Y

TOP RIGHT

RC MOTOR

3

25

Y

Z

SALAMANDER

S1

Z

TOP LEFT

2

TOP RIGHT

SALAMANDER

4

S2

G

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

208 17.4 5.4 6 6 83.7 47.5 47.5 50.0

240 17.4 5.4 6 6 72.5 41.2 41.2 43.3

208 24.4 5.4 6 13 117.3 47.5 78.8 80.9

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

E1

E2

MODEL VOLTAGE TOTAL KW

36 ERC 35

G

X-Y X-Z Y-Z 1 Phase X Y Z

LOADING PER PHASE AMPERAGE

240 24.4 5.4 6 13 101.7 41.2 68.3 70.1

36 ERC 35 SAL

208 17.4 5.4 6 6 83.7 47.5 47.5 50.0

MODEL VOLTAGE TOTAL KW

36 ERC 36

240 17.4 5.4 6 6 72.5 41.2 41.2 43.3

208 24.4 5.4 6 13 117.3 47.5 78.8 80.9

240 24.4 5.4 6 13 101.7 41.2 68.3 70.1

36 ERC 36 SAL

Part # 1009067 Rev13(12/04/09)Page 26

Page 27

WIRING DIAGRAMS continued

OVEN

OUTER

1500W

1500W

OUTER

UPPER OVEN ELEMENTS LOWER OVEN ELEMENTS

G4

5000W

REV.#

DATE

DR.DESCRIPTION

REVISIONS

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

REV

36ER SERIES

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

36ER-ET-ES EXPORT

:

TITLE:

DR.

31

SHT OF

4514764

2000W

1500W

G5

INNER

INNER

4321

18

17

P3 P1 P2

9

16

232122 26 25 27

65-290C

THERMOSTAT

4321

15

P3 P1 P2

7

12

11

789

TB

LEFT

CENTER

G3

RIGHT

6

G1

G2

CENTER

RIGHT

LEFT

5

34

30A 40A

1

3

5

GRIDDLE - ALL PURPOSE TOP

40-230C

THERMOSTAT

LEFT

RIGHT

CENTER

43

TO TERMINAL BLOCK

CENTER

RIGHT

12 21

56

4

o6

o5

o4

OPEN TOP

12

COM

2COM

1

H6

H6

P2

123

P3 P1

o7

o8

4

P2

o3o2o1

123

P3 P1

2

6

4

LEFT

RIGHT

CENTER

1

5

3

30A

30A40A

LEFT

1

3

5

CENTER

RIGHT

LEFT

1

3

5

(See page 2 for terminal block connection)

H6

43

P2

875W

1125W

H4

BOIL TOP

875W

1125W

2

P1

H5

1

P3

H3

H2

324

P1 P2

1

P3

o7

o8

H1

S3 S2

ER 7kW

SALAMANDER

S1

MODELS:

36ER32; 36ER32-3; 36ER33;

36ER33-88;36ER33-99;36ER38;36ER39

36ES32; 36ES32-3; 36ES33;

36ES33-88;36ES33-99;36ES38;36ES39;36ES17

36ET32; 36ET32-3; 36ET33;

36ET33-88;36ET33-99;36ET38;36ET39;36ET17

Part # 1009067 Rev13 (12/04/09) Page 27

Page 28

WIRING DIAGRAMS continued

TOP LEFT

1

TOP CENTER

TOP RIGHT

3

REV.#

DATE

DR.DESCRIPTION

REVISIONS

REV

TOP CENTER

TOP LEFT

TOP RIGHT

5

2

4

TO CONTROL PANEL

6

E1

36ER SERIES

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

36ER 220V/380V 240V/415V

:

TITLE:

DR.

32

SHT OF

4514764

OVEN

SALAMANDER

TOP RIGHT

TOP CENTER

TOP LEFT

OVEN

1

3

8

3 PHASE

L1

36ER32; 36ER32-3; 36ER33;

36ER33-88;36ER33-99;36ER38;36ER39

9

5

S1

N

L2

L3

L2

SALAMANDER

TOP RIGHT

5

S1

N

L3

TO CONTROL PANEL

SALAMANDER

TOP LEFT

TOP RIGHT

TOP CENTER

2

4

6

S2

E1

E

N

L3

36ES32; 36ES32-3; 36ES33;

36ES33-88;36ES33-99;36ES38;36ES39;36ES17

36ET32; 36ET32-3; 36ET33;

36ET33-88;36ET33-99;36ET38;36ET39;36ET17

SALAMANDER

TOP RIGHT

TOP CENTER

TOP LEFT

OVEN

2

7

TO CONTROL PANEL

4

6

S2

E1

E

36ES32; 36ES32-3; 36ES33;

36ES33-88;36ES33-99;36ES38;36ES39

36ET32; 36ET32-3; 36ET33;

36ET33-88;36ET33-99;36ET38;36ET39

WITH SALAMANDER

L1

NO SALAMANDER

3 PHASE

TOP LEFT

TOP CENTER

1

3

L1

L2

3 PHASE

E

Part # 1009067 Rev13(12/04/09)Page 28

Page 29

WIRING DIAGRAMS continued

REV.#

DATE

DR.DESCRIPTION

REVISIONS

REV

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

:

DATE

SEPT 22,2002NANB

:

SCALE

:

ALL DIMENSIONS ARE IN INCHES

CHK. BY

36ER-ET-ES EXPORT

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

TITLE:

DR.

36ER SERIES

33

SHT OF

4514764

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

415V 3N~ 14.20 5.00 5.00 4.20 59.2 20.8 20.8 17.5

400V 3N~ 13.04 4.59 4.59 3.86 56.7 20.0 20.0 16.8

380V 3N~ 11.93 4.20 4.20 3.53 54.2 19.1 19.1 16.0

415V 3N~ 21.20 4.20 10.0 7.00 88.3 17.5 41.7 29.2

400V 3N~ 19.47 3.86 9.18 6.43 84.7 16.8 39.9 28.0

380V 3N~ 17.81 3.53 8.40 5.88 81.0 16.0 38.2 26.7

415V 3N~ 14.20 5.00 5.00 4.20 59.2 20.8 20.8 17.5

400V 3N~ 13.04 4.59 4.59 3.86 56.7 20.0 20.0 16.8

380V 3N~ 11.93 4.20 4.20 3.53 54.2 19.1 19.1 16.0

415V 3N~ 21.20 4.20 10.00 7.00 88.3 17.5 41.7 29.2

400V 3N~ 19.47 3.86 9.18 6.43 84.7 16.8 39.9 28.0

36 ET 33-99

415V 3N~ 18.70 6.5 8.0 4.2 77.9 27.1 33.3 17.5

400V 3N~ 17.17 6.0 7.3 3.9 74.7 26.0 31.9 16.8

36 ES 33-99

36 ES 33-99 SAL

36 ET 33-99 SAL

380V 3N~ 15.71 5.5 6.7 3.5 71.4 24.8 30.6 16.0

415V 3N~ 25.70 6.5 8.0 11.2 107.1 27.1 33.3 46.7

400V 3N~ 23.60 6.0 7.3 10.3 102.6 26.0 31.9 44.7

380V 3N~ 17.81 3.53 8.40 5.88 81.0 16.0 38.2 26.7

380V 3N~ 21.60 5.5 8.4 10.1 98.2 24.8 38.2 45.8

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

415V 3N~ 15.00 5.00 5.00 5.00 62.5 20.8 20.8 20.8

415V 3N~ 21.50 6.5 10.0 5.0 89.6 27.1 41.7 20.8

400V 3N~ 13.78 4.59 4.59 4.59 59.9 20.0 20.0 20.0

36 ET 38

400V 3N~ 19.75 6.0 9.2 4.6 85.9 26.0 39.9 20.0

380V 3N~ 12.60 4.20 4.20 4.20 57.3 19.1 19.1 19.1

415V 3N~ 22.00 5.00 10.00 7.00 91.7 20.8 41.7 29.2

36 ES 38

36 ET 38 SAL

380V 3N~ 18.07 5.5 8.4 4.2 82.1 24.8 38.2 19.1

415V 3N~ 28.50 6.5 10.0 12.0 118.8 27.1 41.7 50.0

400V 3N~ 20.20 4.59 9.18 6.43 87.8 20.0 39.9 28.0

380V 3N~ 18.49 4.20 8.40 5.88 84.0 19.1 38.2 26.7

36 ES 38 SAL

LOADING PER PHASE AMPERAGE

400V 3N~ 26.17 6.0 9.2 11.0 113.8 26.0 39.9 47.9

380V 3N~ 23.95 5.5 8.4 10.1 108.9 24.8 38.2 45.8

MODEL VOLTAGE TOTAL KW

L1-N L2-N L3-N 1 Phase L1 L2 L3

415V 3N~ 12.0 4.00 4.00 4.00 50.0 16.7 16.7 16.7

36 ET 39

415V 3N~ 18.50 6.5 8.0 4.0 77.1 27.1 33.3 16.7

400V 3N~ 11.02 3.67 3.67 3.67 47.9 16.0 16.0 16.0

380V 3N~ 10.08 3.36 3.36 3.36 45.8 15.3 15.3 15.3

36 ES 39

400V 3N~ 16.99 6.0 7.3 3.7 73.9 26.0 31.9 16.0

380V 3N~ 15.55 5.5 6.7 3.4 70.7 24.8 30.6 15.3

415V 3N~ 19.00 4.00 8.00 7.00 79.2 16.7 33.3 29.2

400V 3N~ 17.45 3.67 7.35 6.43 75.9 16.0 31.9 28.0

380V 3N~ 15.97 3.36 6.72 5.88 72.6 15.3 30.6 26.7

36 ES 39 SAL

36 ET 39 SAL

415V 3N~ 25.50 6.5 8.0 11.0 106.3 27.1 33.3 45.8

400V 3N~ 23.42 6.0 7.3 10.1 101.8 26.0 31.9 43.9

380V 3N~ 21.43 5.5 6.7 9.2 97.4 24.8 30.6 42.0

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3

415V 3N~ 10.00 5.00 5.00 0.00 41.7 20.8 20.8 0.0

400V 3N~ 9.18 4.59 4.59 0.00 39.9 20.0 20.0 0.0

380V 3N~ 8.40 4.20 4.20 0.00 38.2 19.1 19.1 0.0

415V 3N~ 15.00 5.00 5.00 5.00 62.5 20.8 20.8 20.8

400V 3N~ 13.78 4.59 4.59 4.59 59.9 20.0 20.0 20.0

380V 3N~ 12.60 4.20 4.20 4.20 57.3 19.1 19.1 19.1

415V 3N~ 22.00 5.00 10.00 7.00 91.7 20.8 41.7 29.2

400V 3N~ 20.20 4.59 9.18 6.43 87.8 20.0 39.9 28.0

380V 3N~ 18.49 4.20 8.40 5.88 84.0 19.1 38.2 26.7

415V 3N~ 14.20 5.00 5.00 4.20 59.2 20.8 20.8 17.5

400V 3N~ 13.04 4.59 4.59 3.86 56.7 20.0 20.0 16.8

380V 3N~ 11.93 4.20 4.20 3.53 54.2 19.1 19.1 16.0

415V 3N~ 21.20 4.20 10.00 7.00 88.3 17.5 41.7 29.2

400V 3N~ 19.47 3.86 9.18 6.43 84.7 16.8 39.9 28.0

380V 3N~ 17.81 3.53 8.40 5.88 81.0 16.0 38.2 26.7

415V 3N~ 12.60 4.20 4.20 4.20 52.5 17.5 17.5 17.5

400V 3N~ 11.57 3.86 3.86 3.86 50.3 16.8 16.8 16.8

380V 3N~ 10.59 3.53 3.53 3.53 48.1 16.0 16.0 16.0

415V 3N~ 19.60 4.20 8.40 7.00 81.7 17.5 35.0 29.2

400V 3N~ 18.00 3.86 7.71 6.43 78.3 16.8 33.5 28.0

380V 3N~ 16.47 3.53 7.06 5.88 74.9 16.0 32.1 26.7

36 ES 32 SAL

36 ET 32 SAL

415V 3N~ 28.50 6.5 10.0 12.0 118.8 27.1 41.7 50.0

400V 3N~ 26.17 6.0 9.2 11.0 113.8 26.0 39.9 47.9

380V 3N~ 23.95 5.5 8.4 10.1 108.9 24.8 38.2 45.8

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

L1-N L2-N L3-N 1 Phase L1 L2 L3