Garland 4523368 Instructions Manual

Part #

Description

Quantity

1415703

Baso Safety Valve

1

4522554

7/16” x 10” Flex Tube

2

4522558

Pre-bent 3/16” Tubing

1

076050-89

3/16” Union

1

M231

1/4IN X 3/16IN CC COMP Nut

2

M126

1/4IN TO 3/16IN SLEEVE - Ferrule

2

1095499

7/16cc – 3/8 NPT Straight Connector

2

4522557

Valve Bracket

1

F60

#10 x 5/8 Sheet Metal Screw

4

M123

7/16IN C.C. COMPRESSION - Nut (for Flex Tube end)

2

M122

7/16IN C.C. BALL SLEEVE - Ferrule (for Flex Tube end)

2

F312

LOCK NUT-10-24 K-LOCK - Nut (for Baso Valve)

1

F587

BOLT # 10-24 x 2-1/4 SL - Bolt (for Baso Valve)

1

4522556

Redesigned Kick Panel

1

4522201

Welded Bracket Oven Burner

1

F32

#10-24 x ½ Pan HD Type F Screw (For Pilot Bracket)

1

070239-10

RC Pilot Natural Gas

1

078239-11

RC Pilot Propane

1

M124

¼” Tubing Ferrule

1

M125

¼” Comp. Nut

1

1415000

Robertshaw Thermocouple

1

4521446

¼” x 12” Flex Tube

1

4523367

MANUAL-HIGH HEAT KIT-RC

1

G7227-1

Lighting Instructions

1

M121

Rivet

2

H280-series Valve Overheat / Relocation Kit Instructions: RC Ovens

Instructions for Applying Kit #4523368

This kit is for a convection RC, 36” oven only. For a Standard 36” oven, use Kit #4522559

Installation Prerequisites:

RC Oven, Piezoelectric Ignition

U-Burner with no welded bracket

Tools Needed:

Wrenches

Small Hacksaw (for extension installation if required)

Screwdrivers (Robertson, Flat), long and short

Riveter

Electrical Tape

Parts:

03/09/09 P/N 4523367 Page 1

Instructions:

1) Remove Kick Plate

Unscrew and set aside

This kick plate will not be reinstalled. A replacement is provided in the kit.

2) Remove Safety Valve

The following steps will apply for a Baso Valve:

1) Unscrew 11/16” compression nut on oven orifice fitting.

2) Unscrew 11/16” compression nut on 11/16” elbow on Valve Main Burner Gas Inlet.

Elbow itself should still be connected to Main Gas Inlet but detached from valve.

3) Unscrew 7/16” compression nut on Pilot Gas Inlet.

4) Unscrew 7/16” compression nut on Pilot Gas Outlet.

5) Unscrew 3/8” thermocouple nut.

6) Unscrew #10 sheet metal screw holding valve bracket onto lower front frame.

7) Remove valve.

03/09/09 P/N 4523367 Page 2

Baso Safety Valve: Prior to removal

3) Unscrew Igniter Bracket

Unscrew the two screws holding down the igniter bracket to the orifice bracket.

Left: Before removal, location of screws shown by arrows

Right: After removal

4) Remove Door Springs

Once the springs are removed, the oven door will be free to fall. Use a strong tape to

keep the oven door closed for safety purposes.

For the door hinge with no microswitch:

Insert a long screwdriver underneath the bell crank assembly such that the tip

extends behind the air shield. See the following pictures for details.

Insertion of screwdriver underneath bell crank assembly and air shield

03/09/09 P/N 4523367 Page 3

Pry upward with the screwdriver. While holding this position, unhook the oven door

hinge link.

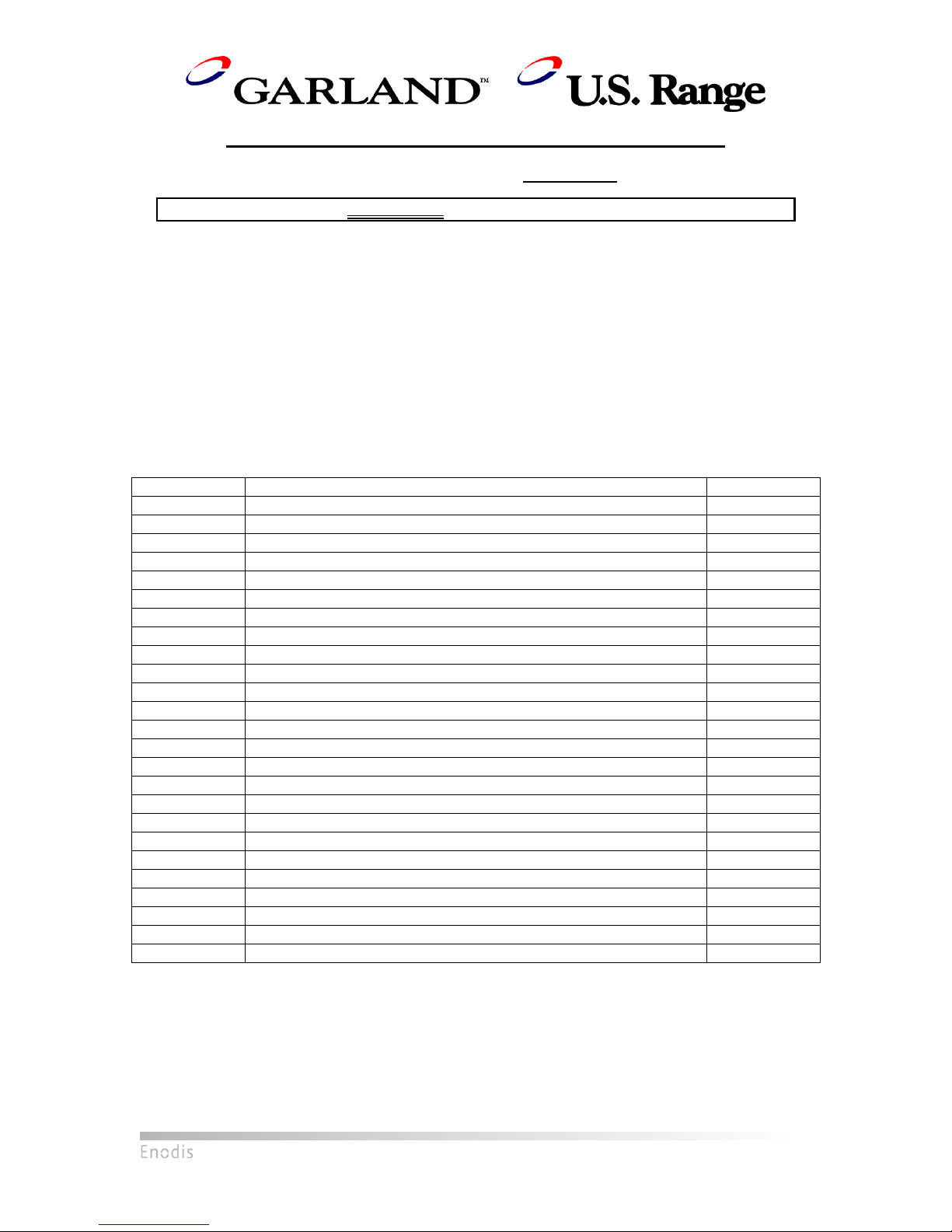

Unhooked oven door hinge link

Use flat head screwdriver to pry spring from bell crank assembly. Remove spring.

Prying spring from bell crank assembly

03/09/09 P/N 4523367 Page 4

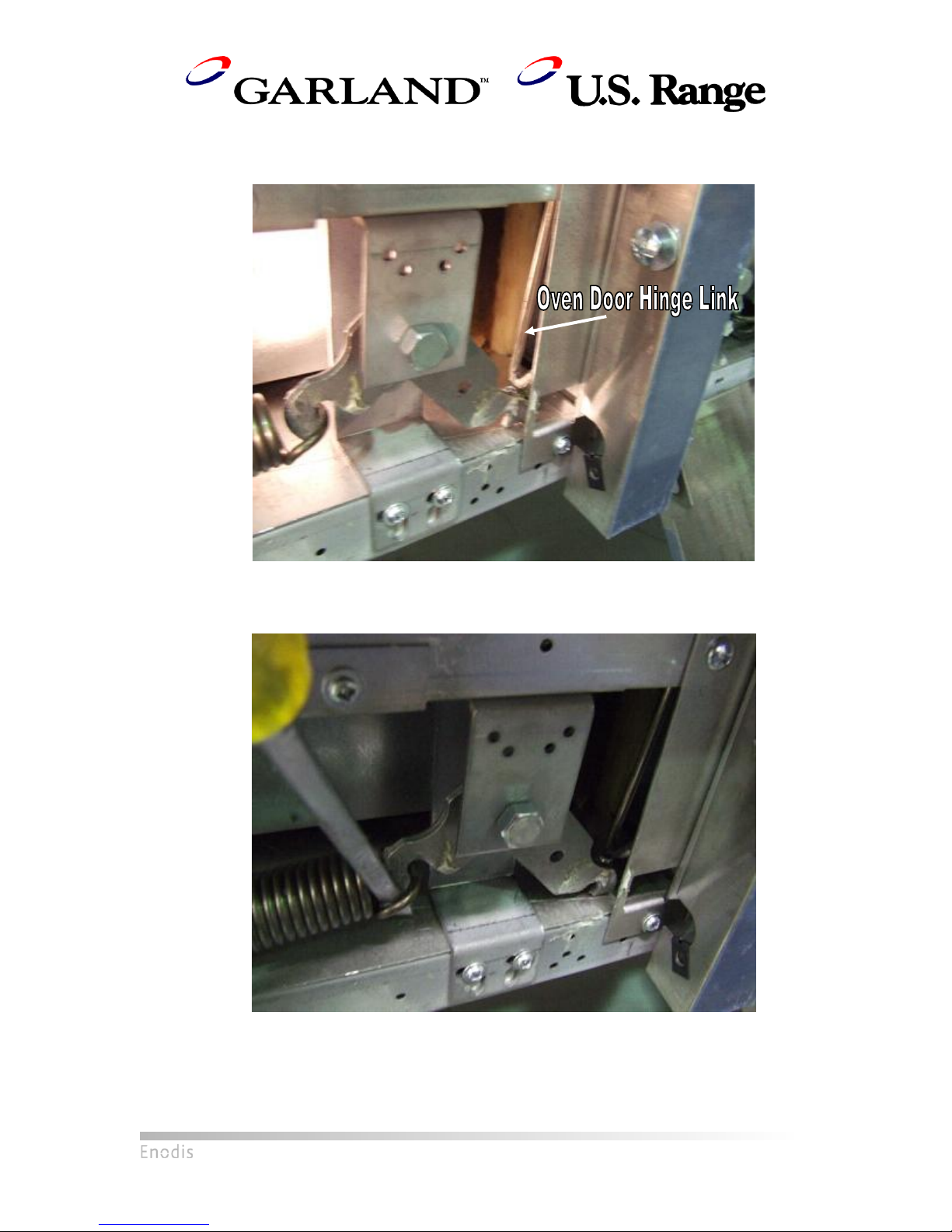

For the door hinge with a microswitch:

Unscrew the microswitch bracket from the oven frame. It is important that the

microswitch be removed prior to removing the spring to prevent damage to the

microswitch when the springs are reinstalled later.

Microswitch bracket held to oven frame by two screws indicated by the arrows

Follow the same steps as before, using the screwdriver to pry the bell crank

assembly upwards to unhook the oven door hinge link, then pry the spring loose from

the bell crank assembly.

03/09/09 P/N 4523367 Page 5

5) Remove Orifice Bracket

After removing the igniter bracket, the orifice bracket will be held in place by a single

screw directly above the orifice.

Note that with the removal of the igniter bracket, the orifice bracket is held down by a single screw

as shown by the arrow

03/09/09 P/N 4523367 Page 6

Screw this nut

onto the fitting

to secure the

fitting onto the

tube

3/16” Ferrule

6) Install Extension Fitting (if applicable)

If pilot gas tube going into the valve already has an extension piece (short piece of

tubing plus 3/16” brass fitting), unscrew the shorter piece of tubing and proceed to

Step 13. Otherwise, follow these steps to install the proper fitting.

This step must be performed if a TS-11 valve was just removed.

If a Baso valve was uninstalled, cut off 2.5” of the free end of the incoming pilot gas tube

to remove the original ferrule and nut and a section of the tubing. If a TS-11 valve was

uninstalled, cut off just enough tubing to remove the ferrule.

Refer to the Assembly Drawing included in this manual:

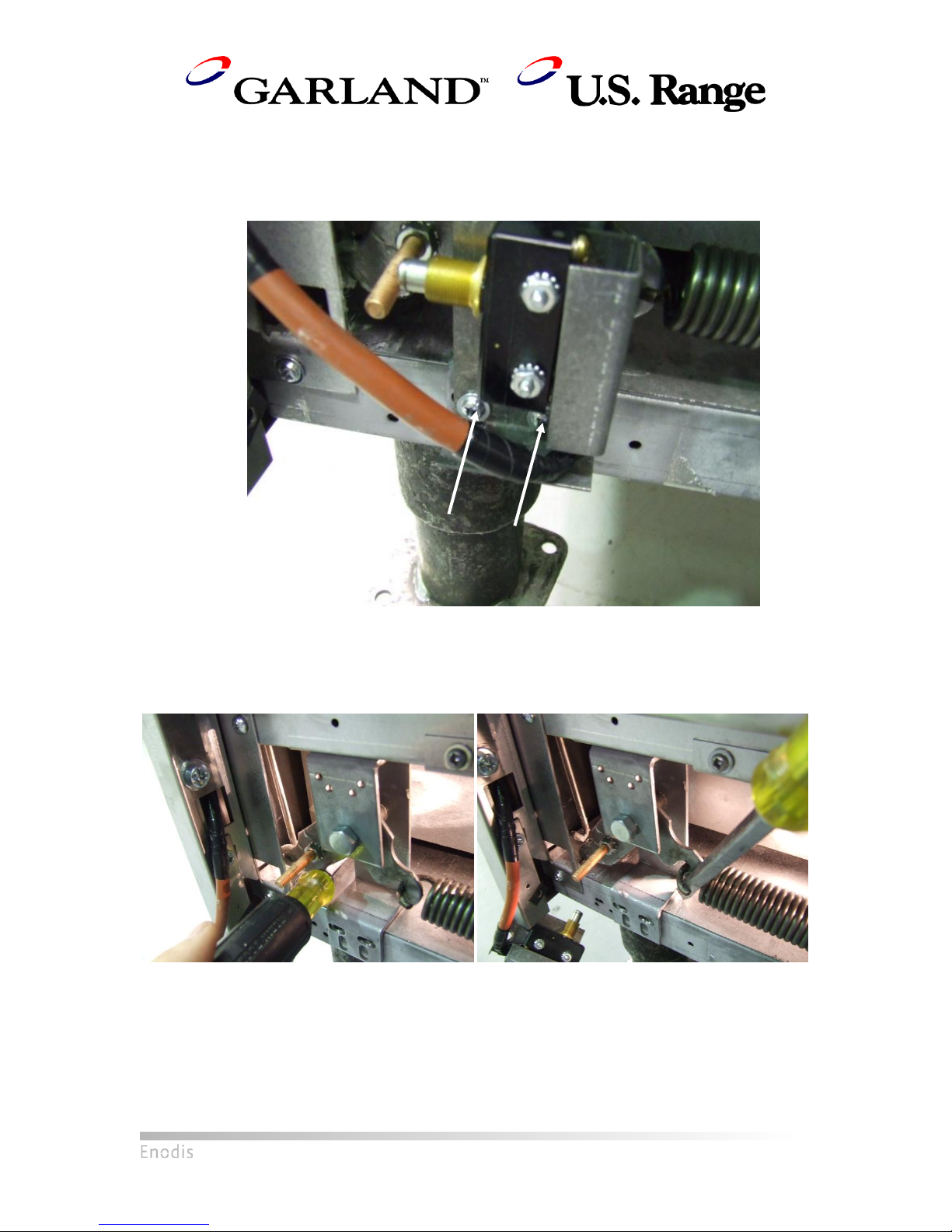

i) Unscrew one end of the 3/16” fitting (Part 4, Assembly Drawing) to release the

nut and ferrule. Slide the nut and the ferrule onto the free end of the incoming

pilot gas tube.

ii) Insert the remaining portion of the fitting onto the end of the pilot gas tube. Screw

on the nut to firmly attach the fitting to the tube. See pictures below for details.

iii) Ensure all connections are leak-proof. Do not over-tighten.

Left: Measure 2.5” from tip of pilot tube and cut

Right: Pilot tube after cutting

Extension fitting installed, with nut released to show location of ferrule

03/09/09 P/N 4523367 Page 7

Loading...

Loading...